Installation structure of plant roof grid structure project and construction method thereof

A technology for installing structures and net frames, which is applied to truss structures, building structures, and the processing of building materials. It can solve problems such as difficult management and coordination, factory building collapse, and easy rain leakage, and achieves the goal of improving factory roof water leakage. Defects, low construction difficulty coefficient, and enhanced water-leakage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

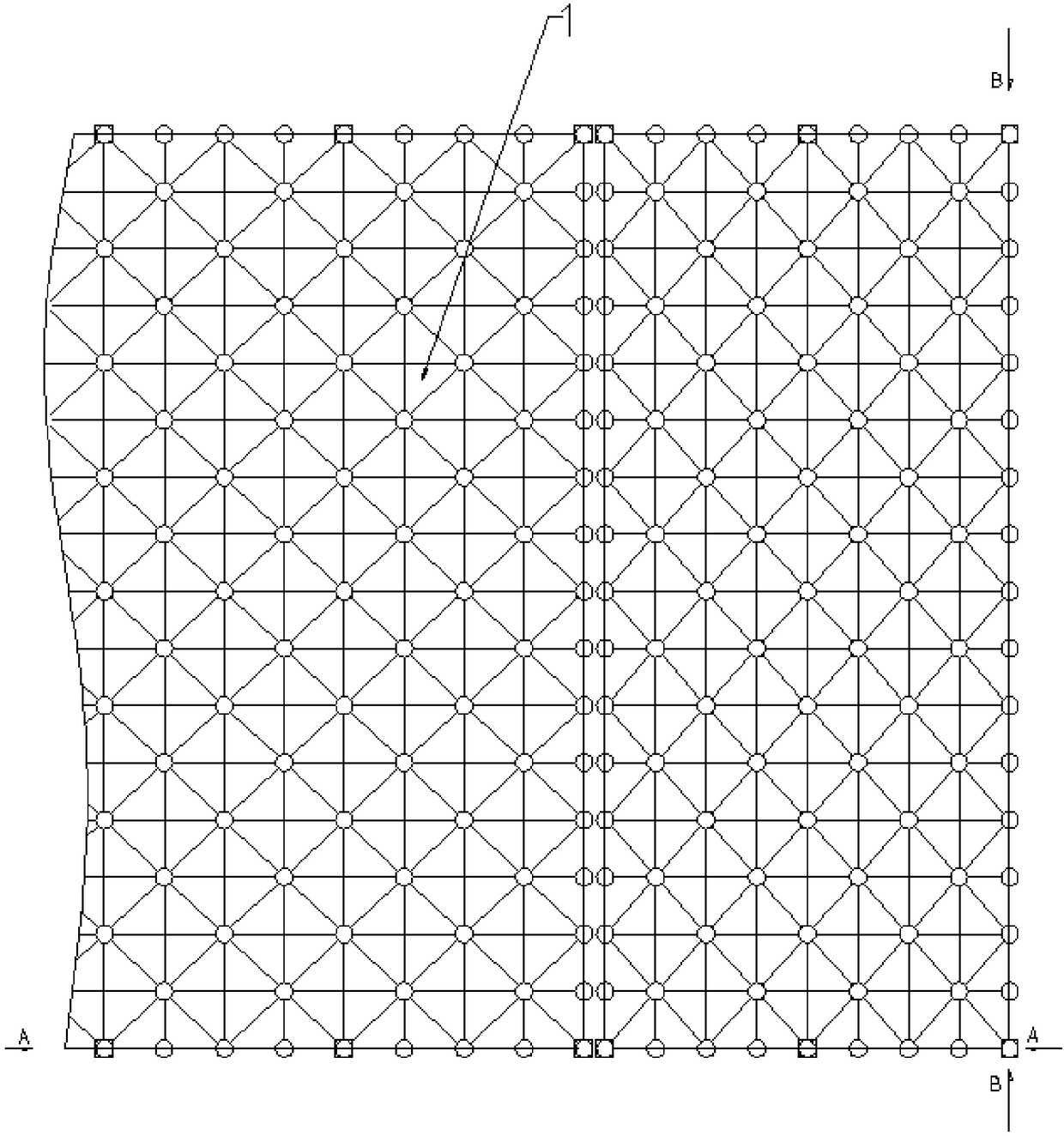

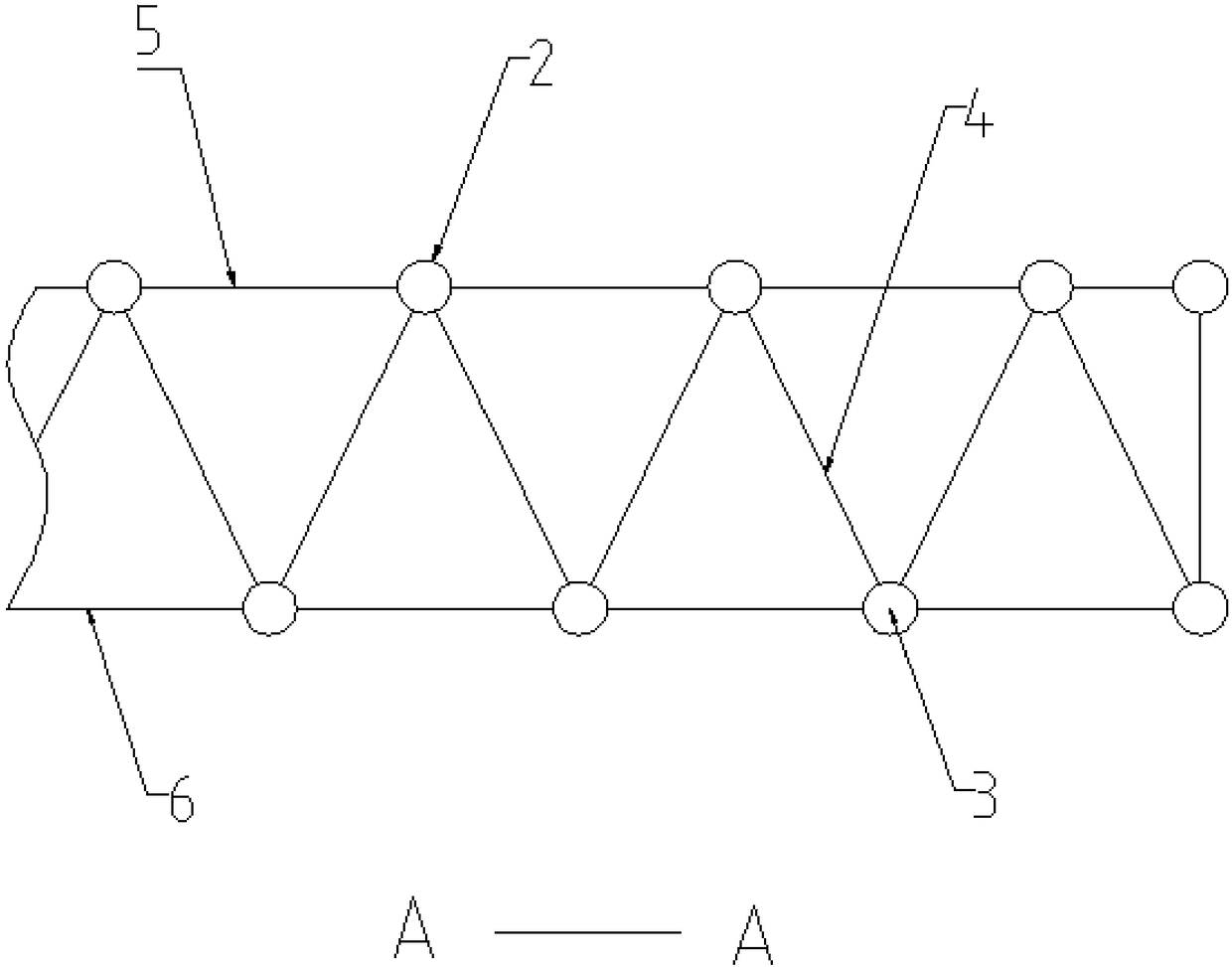

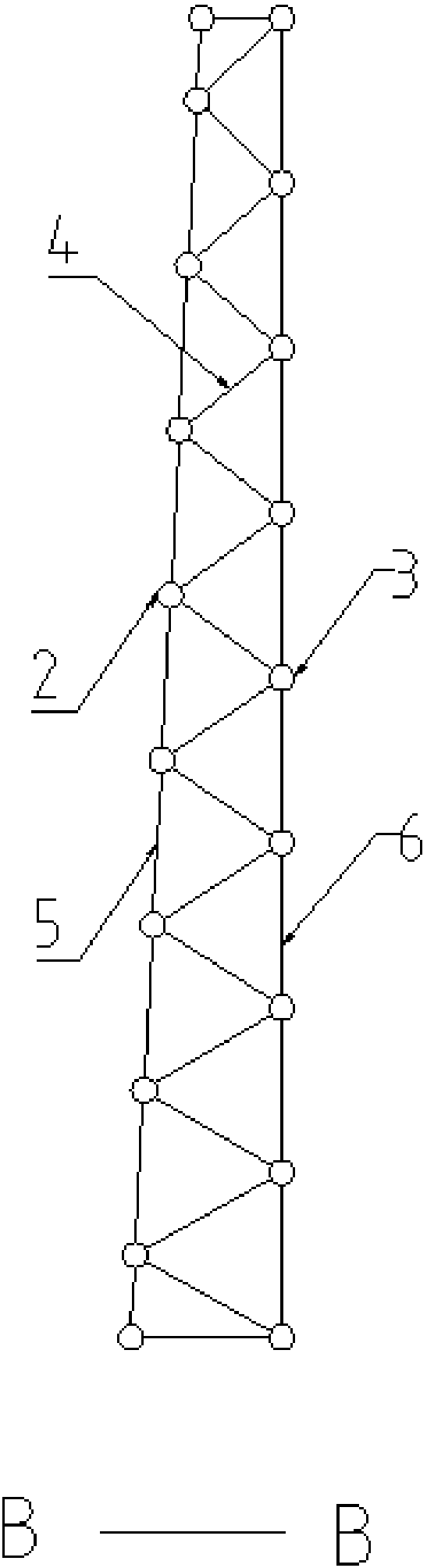

[0062] Such as Figure 1-Figure 15 As shown, the present invention discloses an installation structure for factory roof network frame engineering, which includes a roof frame beam 9, which is a roof structural surface capable of carrying the roof structure of the factory building, and the roof frame beam 9 is provided with a roof panel At least two grids 1 are connected to the lower part of the roof panel layer, and each grid frame 1 is distributed below the roof panel layer along the same straight line. The structure of the entire roof is damaged; the grid 1 includes the upper string layer of the grid frame and the lower string layer of the grid frame, and the upper string layer of the grid frame and the lower string layer of the grid frame are all in a grid frame structure, that is, they are composed of several rectangular grid units , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com