Electrolytic copper foil additive heating insulation system

A technology of heating and heat preservation and electrolytic copper foil, which is applied in electrolysis process, electrolysis components, electroforming, etc., can solve the problems of high failure rate of heating system, failure of additives, burning of heating rods, etc., and achieve low heat source temperature and stable system High performance and increased safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below through examples, and the following examples are explanations of the present invention and the present invention is not limited to the following examples.

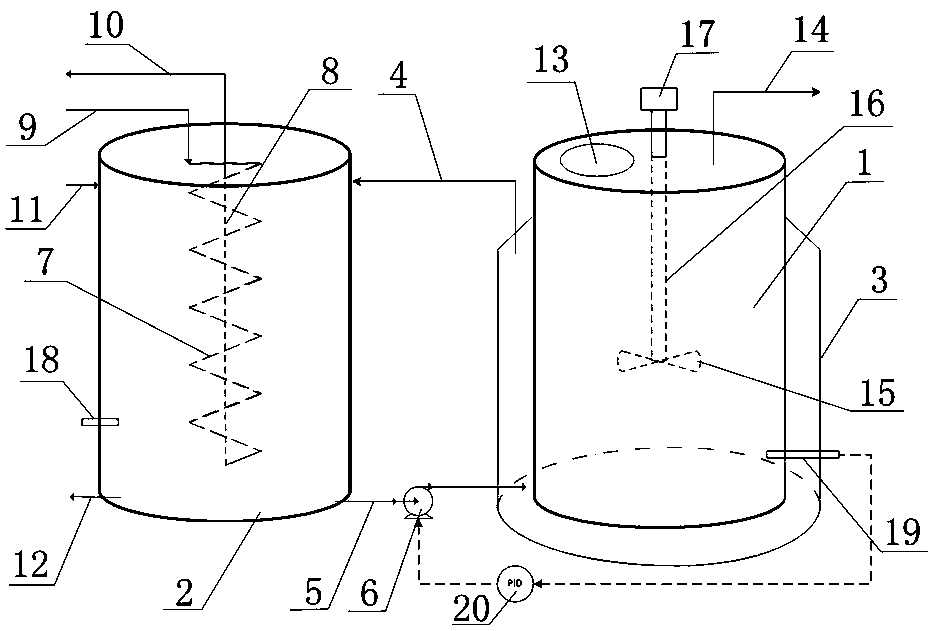

[0018] Such as figure 1 As shown, an electrolytic copper foil additive heating and heat preservation system of the present invention includes an additive tank 1 and a heating tank 2. A heating jacket 3 is arranged on the outside of the additive tank 1. The heating jacket 3 is a cylinder without a cover and the heating jacket 3 The inner diameter is larger than the outer diameter of the additive tank 1, the heating jacket 3 is sleeved on the outside of the additive tank 1 from the lower end of the additive tank 1, the upper end of the heating jacket 3 extends obliquely inward and is sealed and fixed on the outer surface of the additive tank 1, and the inner wall of the heating jacket 3 The gap between the outer wall of the additive tank 1 is a closed hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com