Heat supplying and oxygen enrichment integrated heat pump assembly for aquaculture

A technology for aquaculture and heat pump units, applied in applications, fish farming, refrigerators, etc., can solve problems such as large pipeline losses, and achieve the effects of improving utilization, reducing losses, and reducing heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

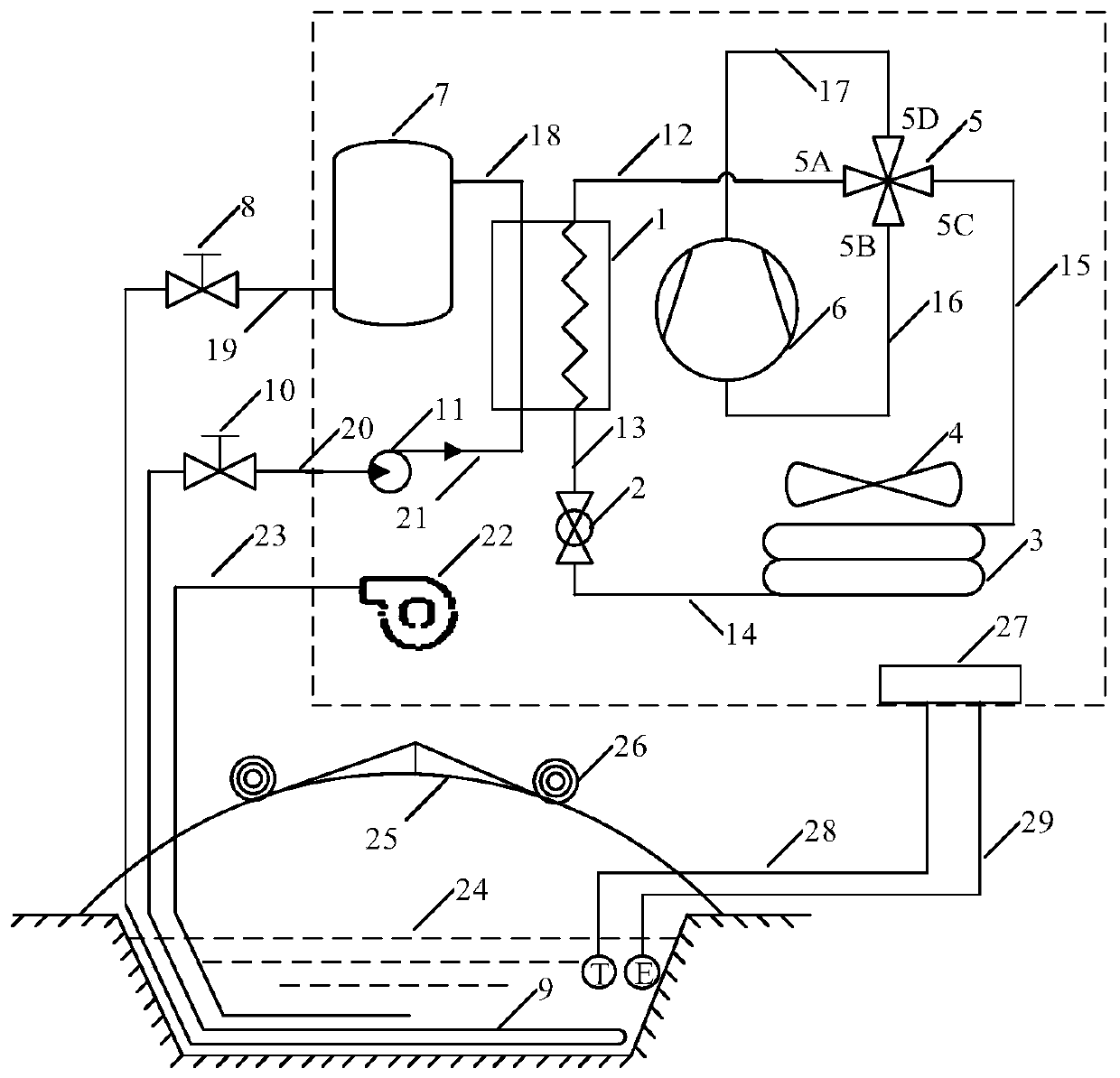

Embodiment 1

[0033] An integrated heat pump unit for heating and oxygenation for aquaculture, the structure and process are as follows figure 1 As shown, the main structure includes water source heat exchanger 1, electronic expansion valve 2, air source heat exchanger 3, axial flow fan 4, four-way reversing valve 5, compressor 6, buffer water tank 7, first stop valve 8, Exchange water pipe 9, second stop valve 10, water pump 11, connecting pipes 12, 13, 14, 15, 16, 17, water pipes 18, 19, 20, 21, blower 22, air pipe 23, pond 24, plastic greenhouse 25, thermal insulation straw mat 26, control box 27, water temperature probe 28, water quality probe 29.

[0034]The connection relationship of each component is: one end of the refrigerant of the water source heat exchanger 1 communicates with an interface 5A of the four-way reversing valve 5 through the connecting pipe 12, and the other end communicates with the end of the electronic expansion valve 2 through the connecting pipe 13, and the ele...

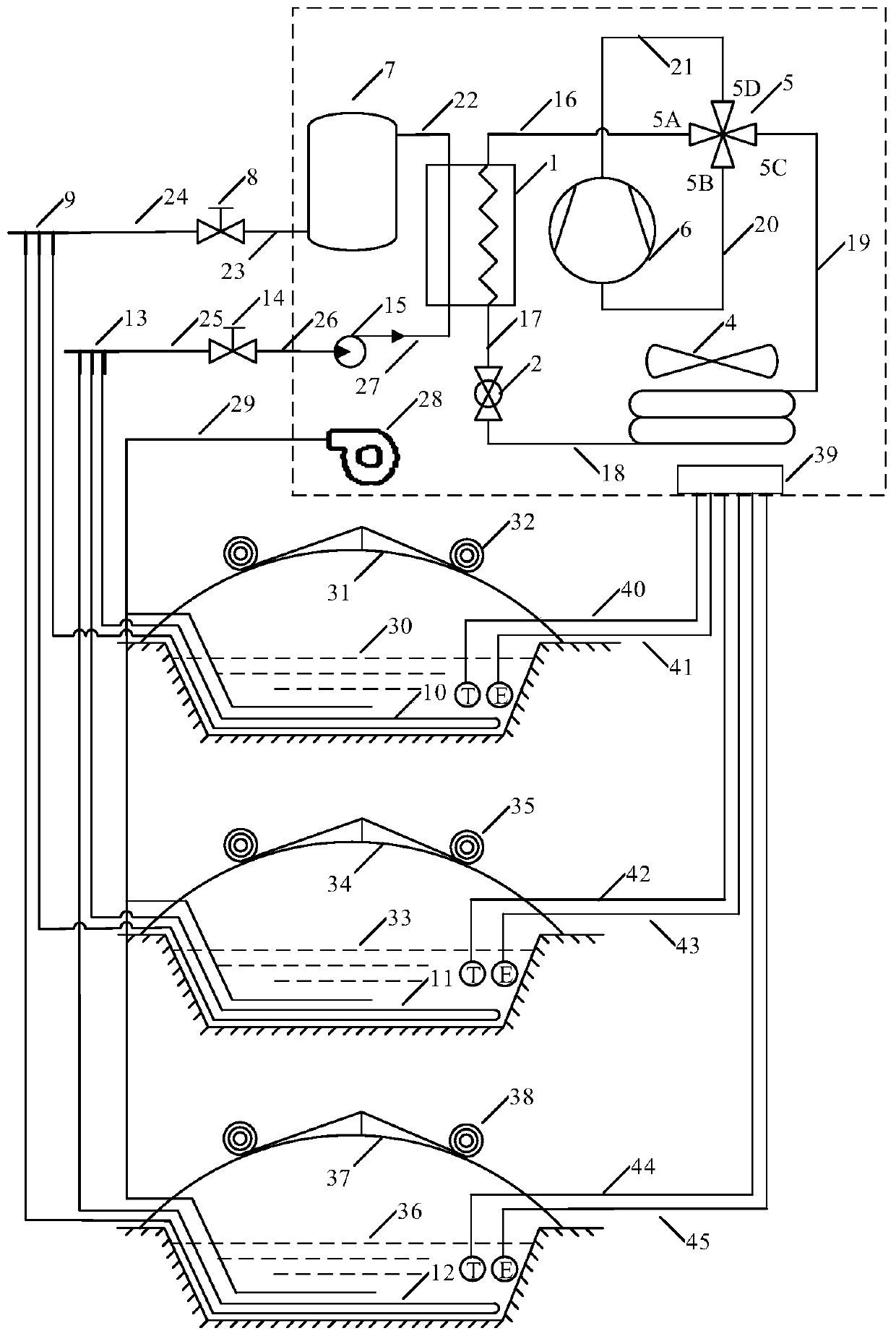

Embodiment 2

[0043] An integrated heat pump for heating and oxygenation for aquaculture with one drive and three units, the structure and process are as follows figure 2 As shown, the main structure includes water source heat exchanger 1, electronic expansion valve 2, air source heat exchanger 3, axial flow fan 4, four-way reversing valve 5, compressor 6, buffer water tank 7, first stop valve 8, First water separator 9, first water exchange pipe 10, second water exchange pipe 11, third water exchange pipe 12, second water separator 13, second stop valve 14, water pump 15, connecting pipes 16, 17, 18, 19, 20, 21, water pipes 22, 23, 24, 25, 26, 27, blower 28, air pipe 29, the first pond 30, the first plastic greenhouse 31, the first straw mat 32, the second pond 33, the second plastic greenhouse 34, the second straw mat 35, the third pond 36, the third plastic greenhouse 37, the third straw mat 38, the control box 39, the first water temperature probe 40, the second water temperature probe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com