Thermal power plant delivery multi-pipe network heating and cooling system and operation method

A technology for thermal power plants and cooling systems, applied in heating systems, piping systems, hot water central heating systems, etc., can solve the problems of insufficient power supply, slow development of cooling load, and poor operation benefits, etc. Pipeline utilization, improving utilization efficiency, and reducing the effect of low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

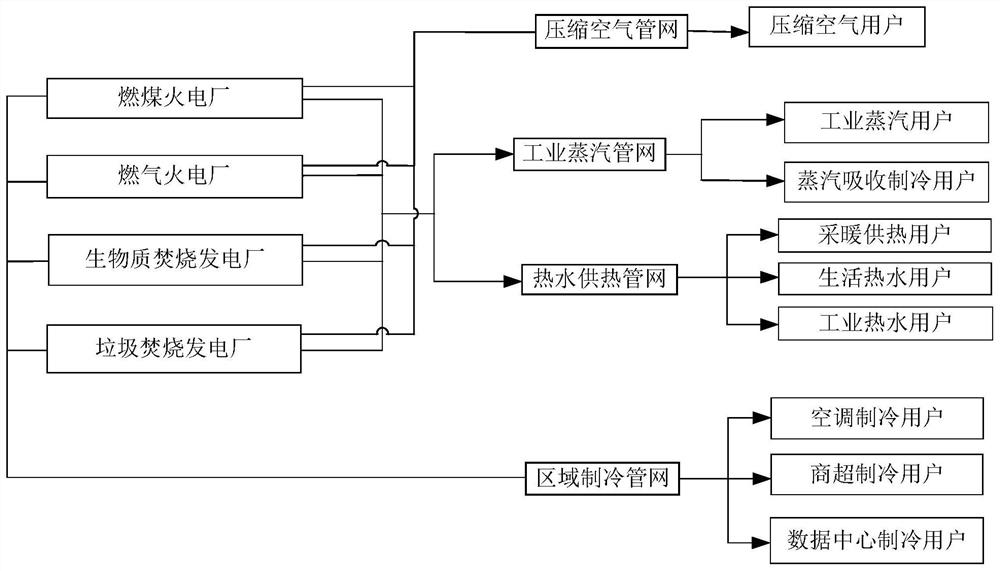

[0038] Please refer to figure 1 , figure 1 An overall schematic diagram of an implementable system provided by the present invention; the power plant provides steam to industrial steam users and steam absorption refrigeration users through industrial steam / compressed air equipment; Provide compressed air.

[0039] The power plant provides hot water to heating users, domestic hot water users and industrial hot water users respectively through the hot water heating pipe network.

[0040] The power plant provides cooling energy to air-conditioning cooling users, supermarket cooling users, and data center cooling users through the regional cooling pipe network.

Embodiment 2

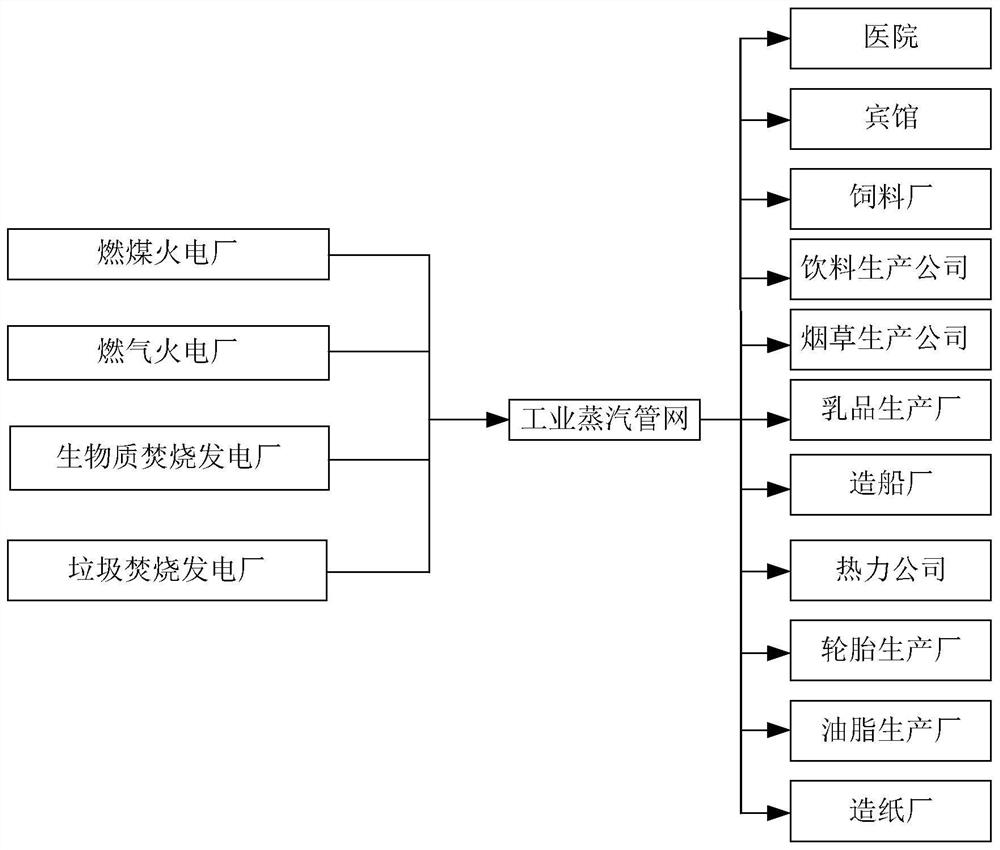

[0042] Set up at least two transmission pipelines with different diameters in the transmission pipeline, and the transmission pipelines with different diameters are arranged in parallel; select the most matching diameter pipeline to transport industrial steam to industrial users; according to the increase of industrial load, gradually transition from small diameter pipelines to Large-diameter pipelines, so as to give full play to the optimal operation level of the project.

[0043] refer to figure 2, industrial steam users include beverage production companies, tobacco production companies, paper mills, shipyards, feed production plants, beer production plants, oil production plants, tire production plants and dairy production plants; industrial steam users also include hospitals and hotels; will be different The use of industrial steam users who require different temperatures and pressures is included in the supply objects, which can better realize the use of steam with temp...

Embodiment 3

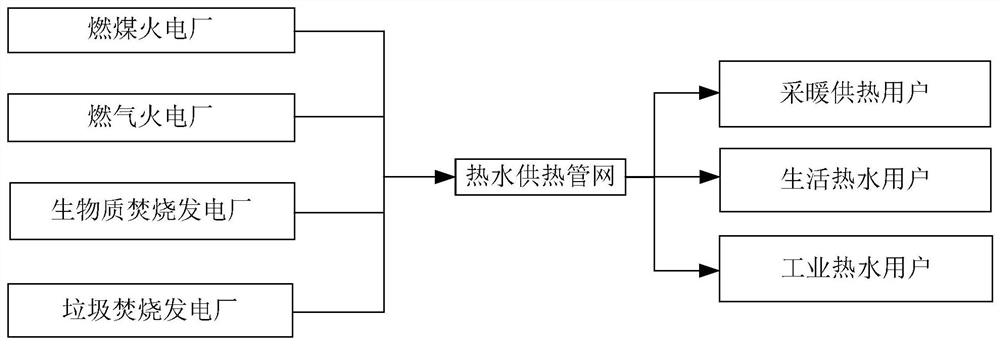

[0047] In the early stage of project implementation, small-diameter pipelines were selected to supply regional heating and hot water to terminal buildings. As the heating area increases, switch to large-diameter pipelines to supply heating areas with larger building areas.

[0048] refer to image 3 , similarly, the present invention regards hot water users with different hot water consumption as heating objects at the same time, so as to realize flexible configuration of hot water supply and full utilization of heat energy.

[0049] In summer, pipelines with appropriate flow calibers are used to supply domestic hot water demand, avoiding the original mode of only winter heating services, and increasing the summer benefits of thermal power plant heating.

[0050] The operation of circulating water in heating networks from small diameter to large diameter pipelines avoids the problems of too few heat users in the initial stage of many new heating projects and the low efficiency...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com