Automatic steel ladle covering and uncovering device

A ladle cover and uncovering technology, which is applied to metal processing equipment, casting molten material containers, casting equipment, etc., to achieve the effect of strong practicability, less man-hours, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

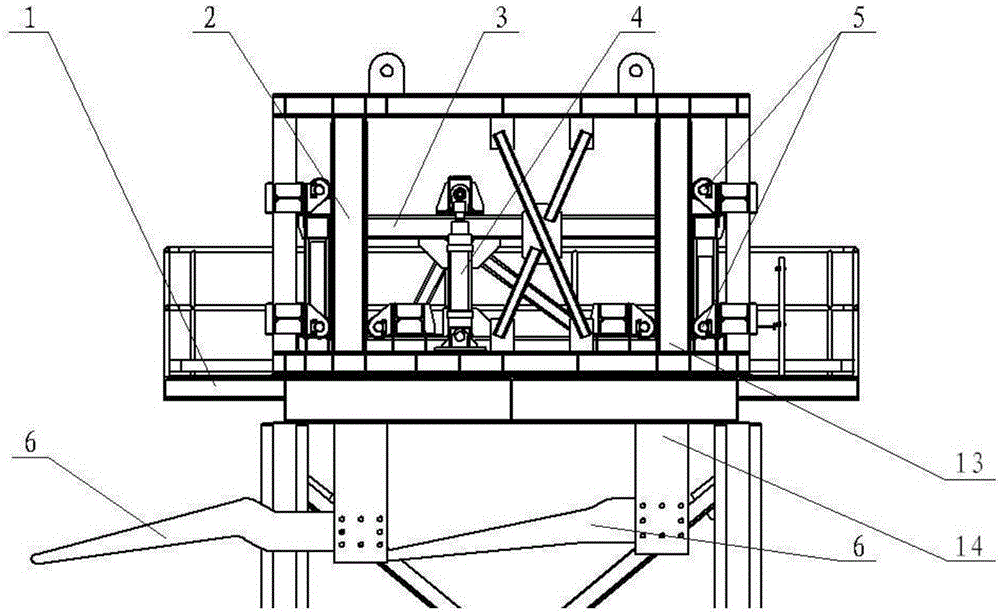

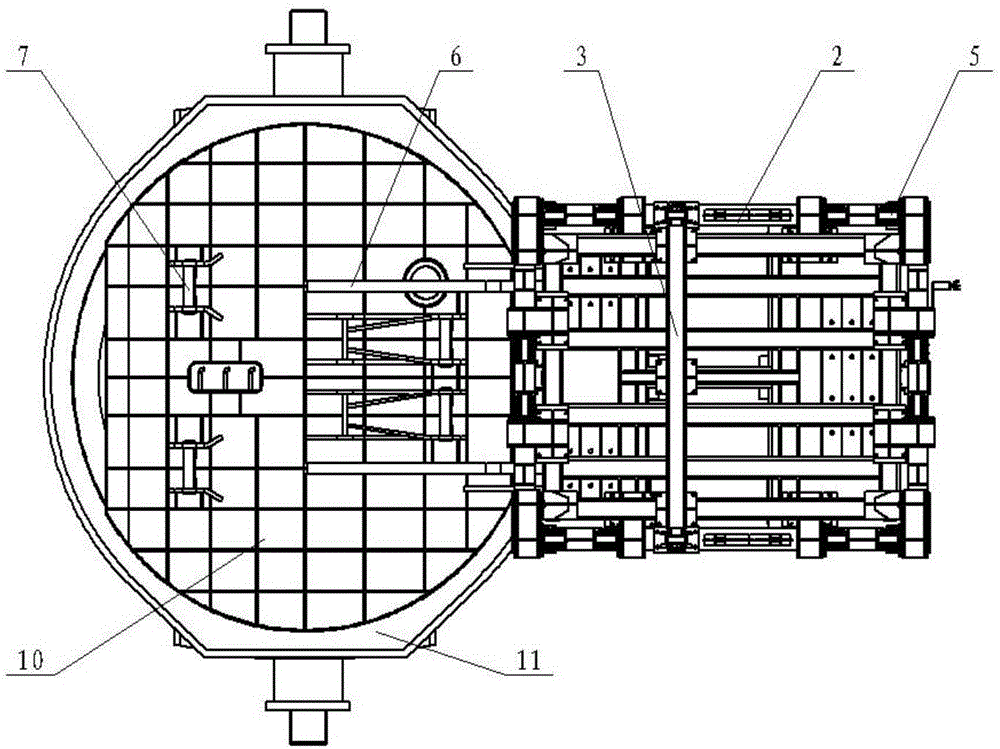

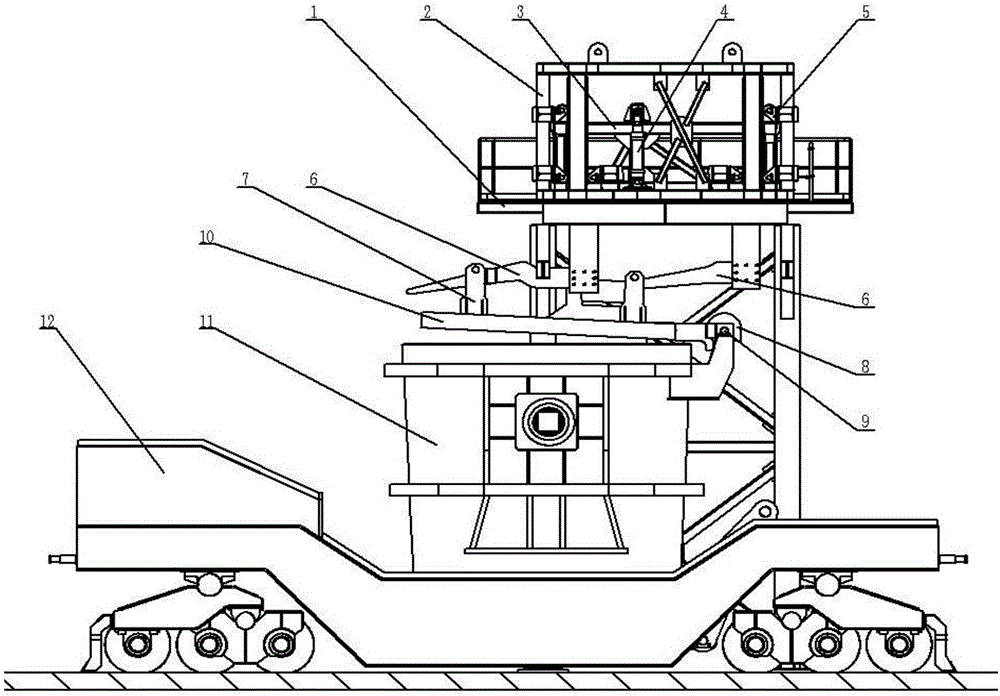

[0022] A ladle automatic cover removal device, comprising a mechanism fixing table 1, a fixed support 2, a lifting support 3, a lifting hydraulic cylinder 4, a guide wheel 5, a slotting gear 6, a ladle cover rotation lifting point 7, a ladle cover limit hook 8, Limiting hook bar 9, ladle cover 10, ladle 11, ladle car 12, guide rail 13, vertical connector 14, limit groove 15. The fixed bracket 2 is installed on the mechanism fixing table 1 through the connecting piece, and the fixed bracket 2 and the lifting bracket 3 are connected relatively through the lifting hydraulic cylinder 4; the lifting bracket 3 is connected with the fixed bracket 2 through the lifting hydraulic cylinder 4; The piston rod of the cylinder 4 is connected with the lifting bracket 3, and the cylinder body of the lifting hydraulic cylinder 4 is connected with the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com