Preparation method of acrylic acid organic silicon soap-free copolymer nano-emulsion

A nano-emulsion and organosilicon technology is applied in the field of preparation of polymer emulsions to achieve the effects of improving water resistance, high bonding strength and reducing water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

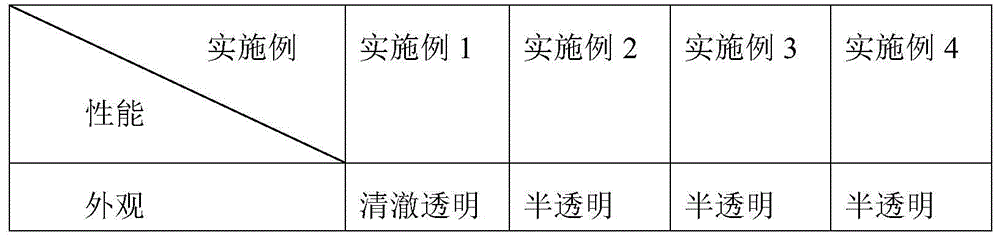

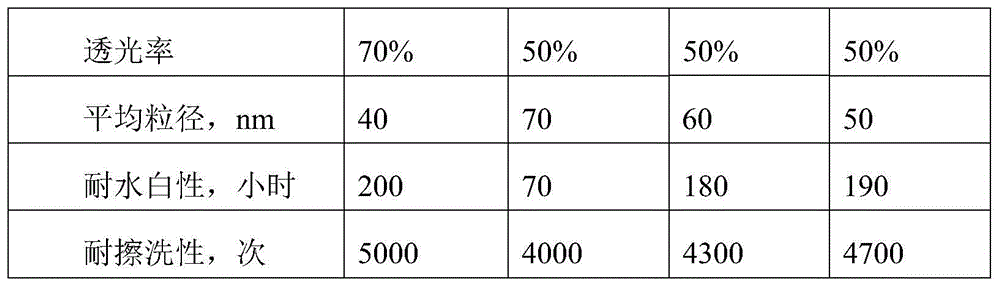

Examples

Embodiment 1

[0032] Add 230kg deionized water, 7.8kg allyl alkyl alcohol ether sulfate SR-1025, 2.2kg acrylamide into the pre-emulsification tank, then add 2.1kg methacrylic acid (AA), 106kg isooctyl acrylate (2- EHA), 124kg methyl methacrylate (MMA), and 1.3kg n-amyl alcohol are dispersed at high speed to prepare pre-emulsion A.

[0033] Add 504.2kg deionized water, 8.2kg allyl alkyl alcohol ether sulfate SR-1025, 1.2kg n-amyl alcohol in the reactor, then heat to 83~85°C, prepare 1.56kg pre-emulsion ( A) and initiator potassium persulfate (KPS) 0.64kg+18.3kg deionized aqueous solution was added to the reactor, the reaction temperature was kept at 85-87°C, and the reaction process was controlled within 10 minutes to prepare the seed emulsion.

[0034] Simultaneously drop the pre-emulsion and initiator solution (potassium persulfate KPS1.47kg+125.9kg deionized aqueous solution) into the reactor, continue to ensure that the temperature of the reactor is 86-88°C, and the dropping time is cont...

Embodiment 2

[0039] Add 230kg deionized water, 7.8kg methacrylamide isopropyl sulfonic acid AMPS-2404, 2.2kg acrylamide into the pre-emulsification tank, then add 2.1kg methacrylic acid (AA), 106kg isooctyl acrylate (2- EHA), 124kg methyl methacrylate (MMA), and 1.3kg n-propanol were dispersed at high speed to obtain pre-emulsion A.

[0040]Add 504.2kg of deionized water, 8.2kg of methacrylamide isopropylsulfonic acid AMPS-2404, 1.2kg of n-propanol into the reaction kettle, then heat to 83-85°C, and prepare 1.56kg of pre-emulsion ( A) and the initiator sodium persulfate 0.64kg+18.3kg deionized aqueous solution were added to the reactor, the reaction temperature was kept at 85-87°C, the reaction process was controlled within 15 minutes, and the seed emulsion was obtained.

[0041] Simultaneously drop the pre-emulsion and initiator solution (sodium persulfate 1.47kg + 125.9kg deionized aqueous solution) into the reactor, keep the temperature of the reactor at 86-88°C, and control the droppin...

Embodiment 3

[0046] Add 230kg deionized water, 7.8kg allyl alkyl sulfosuccinate M-12S, 2.2kg acrylamide into the pre-emulsification tank, then add 2.1kg methacrylic acid (AA), 106kg isooctyl acrylate ( 2-EHA), 124kg methyl methacrylate (MMA), and 1.3kg n-butanol were dispersed at high speed to obtain pre-emulsion A.

[0047] Add 504.2kg of deionized water, 8.2kg of allyl alkyl sulfosuccinate M-12S, and 1.2kg of n-butanol into the reaction kettle, and then heat it to 83-85°C to prepare 1.56kg of pre-emulsified Solution (A) and initiator potassium persulfate (KPS) 0.64kg+18.3kg deionized aqueous solution were added to the reactor, the reaction temperature was kept at 85-87°C, and the reaction process was controlled within 5 minutes to prepare the seed emulsion.

[0048] Simultaneously drop the pre-emulsion and initiator solution (potassium persulfate KPS1.47kg+125.9kg deionized aqueous solution) into the reaction kettle, continue to ensure that the temperature of the reaction kettle is 86-88...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com