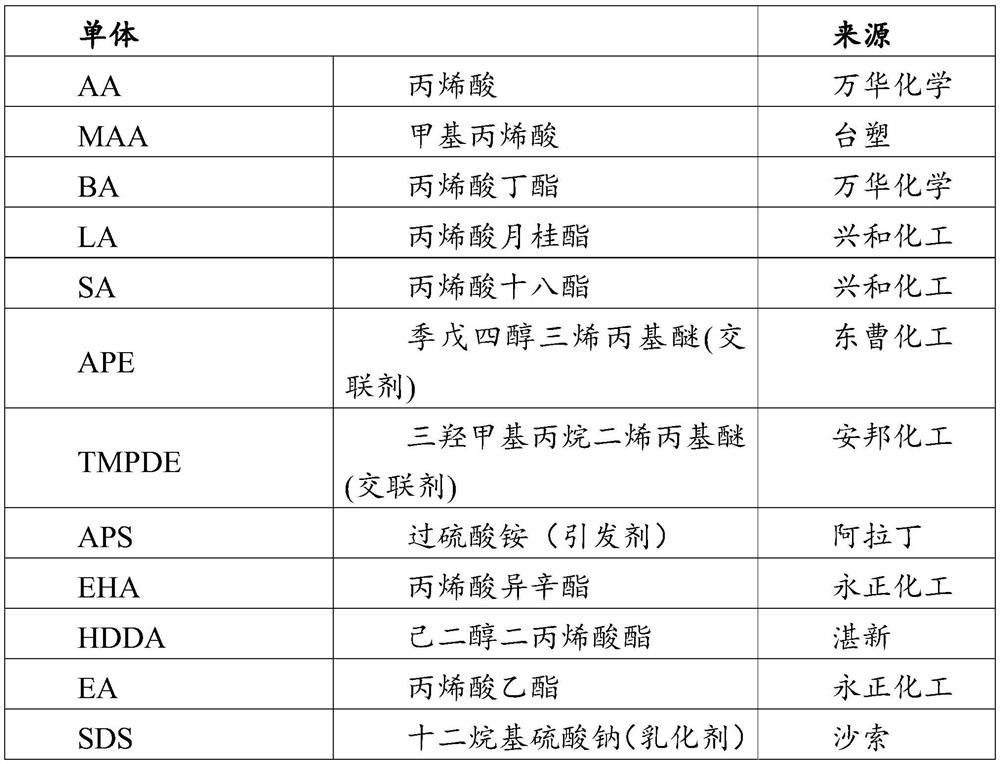

Acrylic ester swellable rheology modifier with core-shell structure and preparation method thereof

A technology of rheology modifier and acrylate, which can be applied in the direction of coating, etc., and can solve the problems of poor water resistance and water whitening resistance of the paint film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

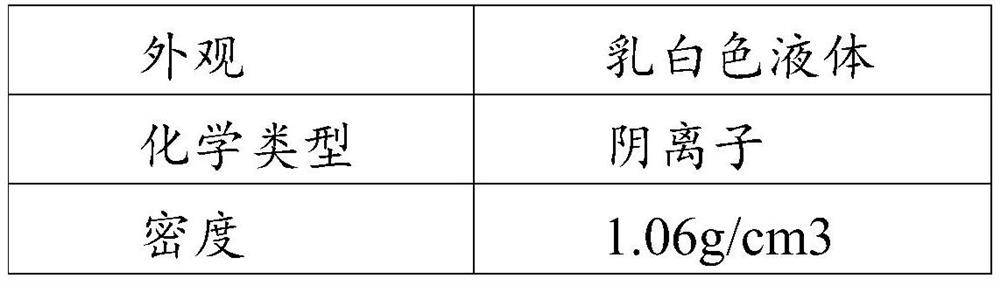

[0069] A kind of acrylate swelling type rheology modifier of core-shell structure, its synthetic formula composition is as table 1:

[0070] Table 1

[0071]

[0072] The steps of the acrylic swelling type rheology modifier of the core-shell structure synthesized by this formula are as follows:

[0073] 1) Add 1g of SDS and 250g of water into a four-necked flask, connect the condenser, start stirring, mix well, and pass nitrogen to remove the oxygen in the reactor;

[0074] 2) The configuration of the core layer monomer: add 4.51g of SDS and 87.9g of water into flask 1, stir to fully dissolve the SDS, then add 151.81g of BA, 1.19g of cross-linking monomer TMPDE and 52g of MAA in sequence, and configure it as pre-emulsion 1;

[0075] 3) Configuration of the transition layer monomer: add 0.6g of SDS and 15g of water into the flask 2, stir to fully dissolve the SDS, then add 21g of BA, 17g of EHA and 7g of MAA in sequence to form a pre-emulsion 2;

[0076] 4) Configuration ...

Embodiment 2

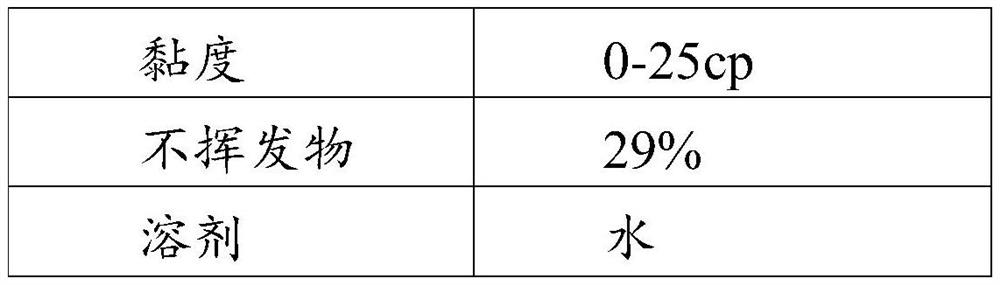

[0084] A kind of acrylate swelling type rheology modifier of core-shell structure, its synthetic formula composition is as table 2:

[0085] Table 2

[0086]

[0087] The synthetic process of embodiment 2 is the same as embodiment 1, repeats it no longer here, the product A2 that obtains according to this formula.

Embodiment 3

[0089] A kind of acrylate swelling type rheology modifier of core-shell structure, its synthetic formula is composed as table 3:

[0090] table 3

[0091]

[0092] The synthetic process of embodiment 3 is the same as embodiment 1, repeats it no longer here, the product A3 that obtains according to this formula.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com