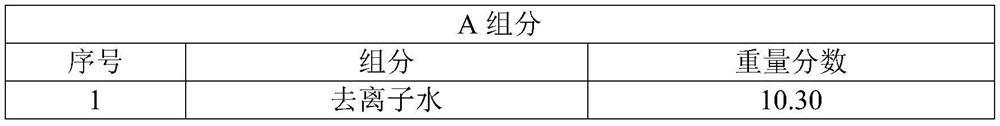

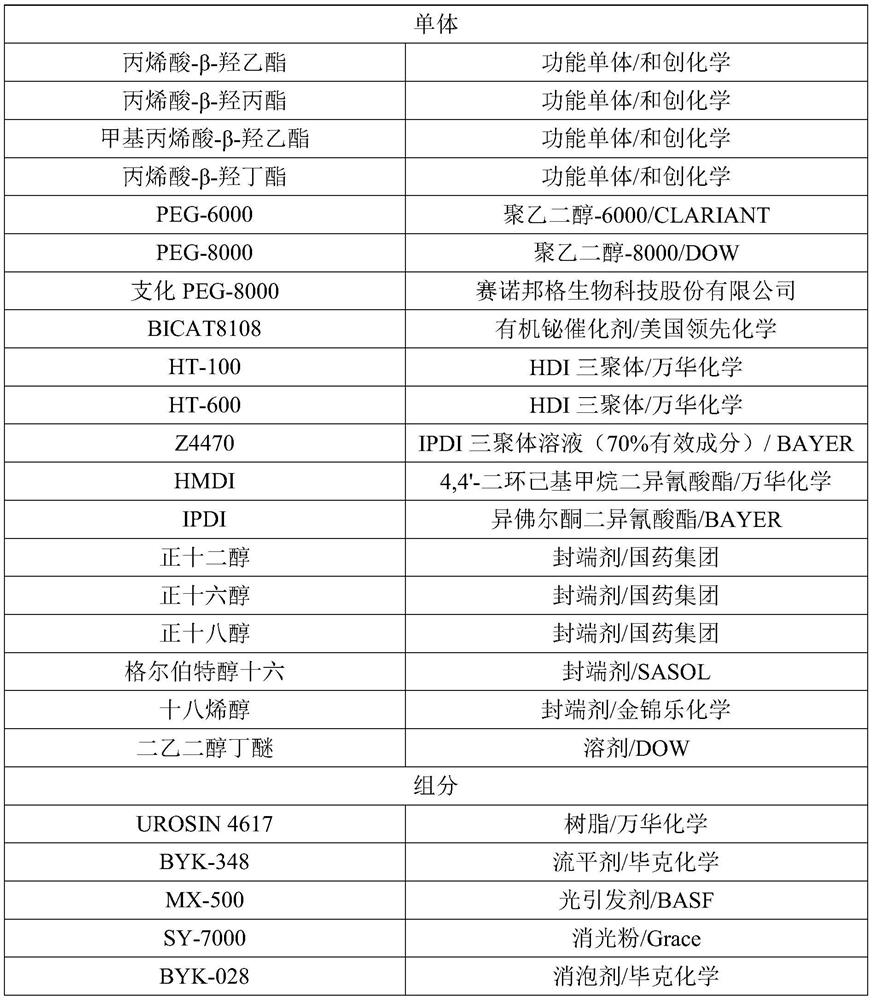

Patents

Literature

51results about How to "High thickening efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

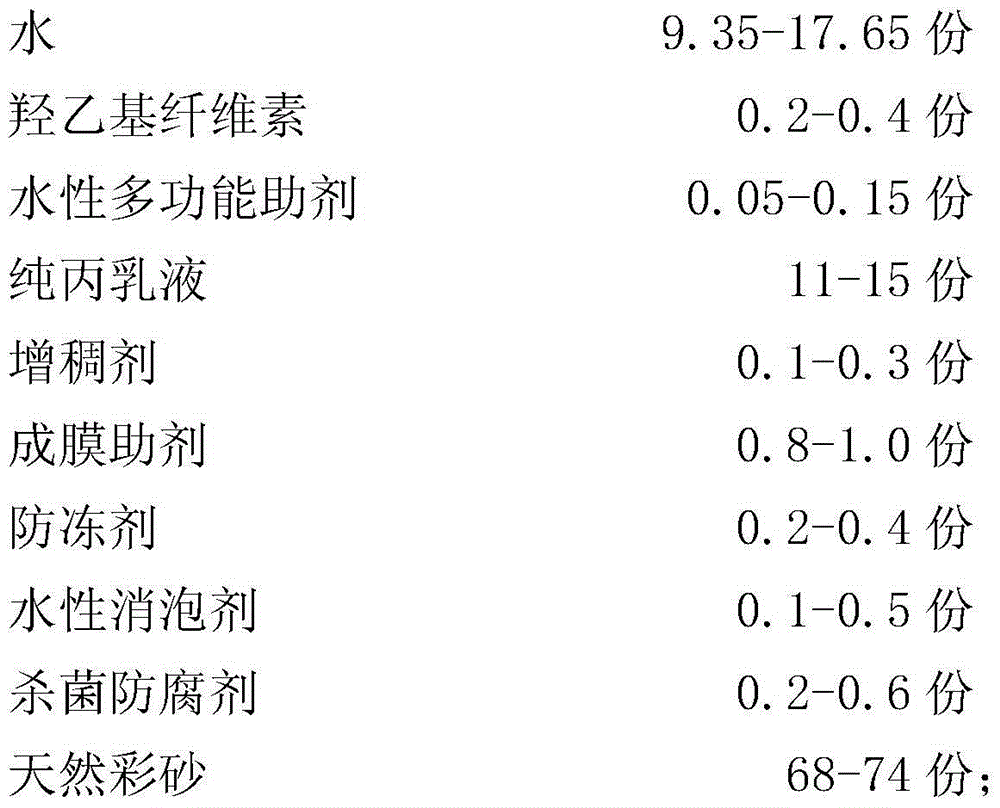

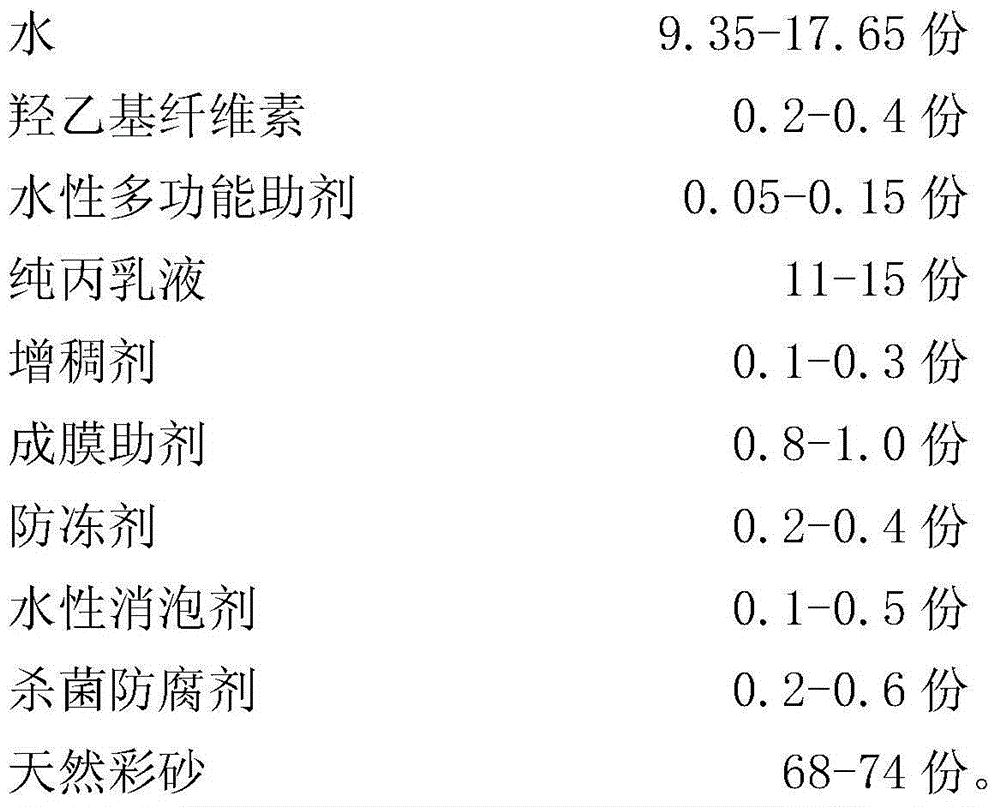

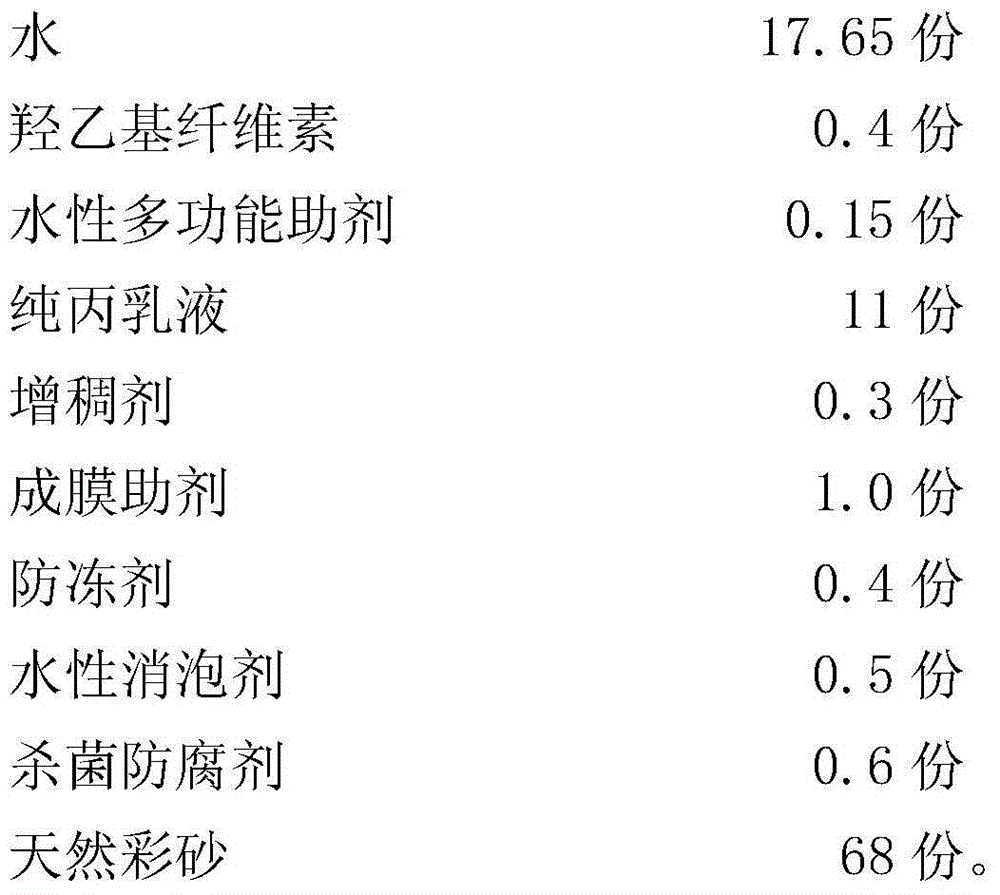

Really stone paint and preparation method thereof

The invention relates to a really stone paint and a preparation method thereof. The really stone paint is prepared from the following components in part by weight: water, hydroxyethyl celluloses, a waterborne multifunctional assistant, polyacrylic emulsion, a thickener, a coalescing agent, an antifreezing agent, a water-based defoamer, a fungicidal preservative and natural colored sand. The really stone paint prepared by the preparation method can realize the effects of good water resistance and good adhesive force under the condition of low temperature and high humidity and under the condition of low temperature and low humidity.

Owner:SKSHU PAINT

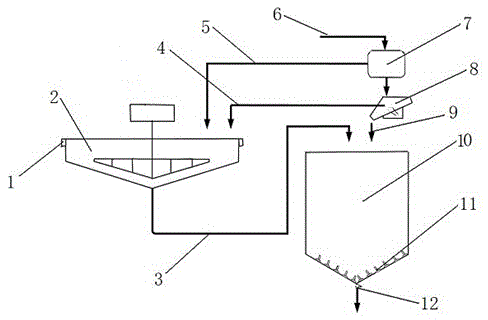

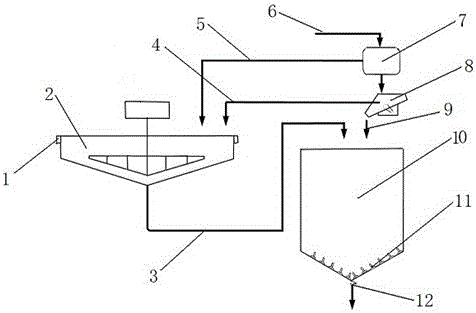

Thickening method and thickening system of whole tailing material slurry paste

InactiveCN104829150AHigh thickening efficiencyAchieve a thickening effectSolid waste managementSedimentation settling tanksCycloneSlurry

The invention discloses a thickening method and a thickening system of whole tailing material slurry paste, wherein the thickening method includes following steps: (1) feeding whole tailing material slurry into a cyclone machine to separate the whole tailing material slurry into crude granular mortar and fine granular mortar, wherein the crude granular mortar, at a bottom flow, is fed into a vibrating sieve while the fine granular mortar, at an over flow, is fed into a thickener; (2) in the vibrating sieve, vibrating the fine granular mortar to sieve the fine granular mortar and feeding the fine granular mortar into the thickener, wherein crude granules are discharged into a sand bin; (3) feeding an over flow in the cyclone machine into the thickener and feeding the bottom flow in the thickener into the sand bin; and (4) in the sand bin, mixing the crude granular mortar and the fine granular mortar to obtain the paste. The thickening system is composed of the cyclone machine, the vibrating sieve, the sand bin and the thickener, wherein a material slurry pipe is connected to input of the cyclone machine. Outputs of the cyclone machine include two groups, one is connected to the vibrating sieve and the other is connected to the thickener. The outputs of the vibrating sieve include two groups, one is connected to the thickener, and the other is connected to the tail sand bin. The output of the thickener is connected to the sand bin. In the invention, the tailing material slurry is separated into crude granular mortar and fine granular mortar and then is thickened, so that thickening concentration can reach 70-82%, which is higher than that of a deep-cone thickener and a sand bin by 2-5%. The tailing utilization rate is higher than 95%.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

Liquid Thickeners for Aqueous Systems

InactiveUS20090209659A1Time stableEasy to useCosmetic preparationsOrganic detergent compounding agentsOrganic solventCarboxylic acid

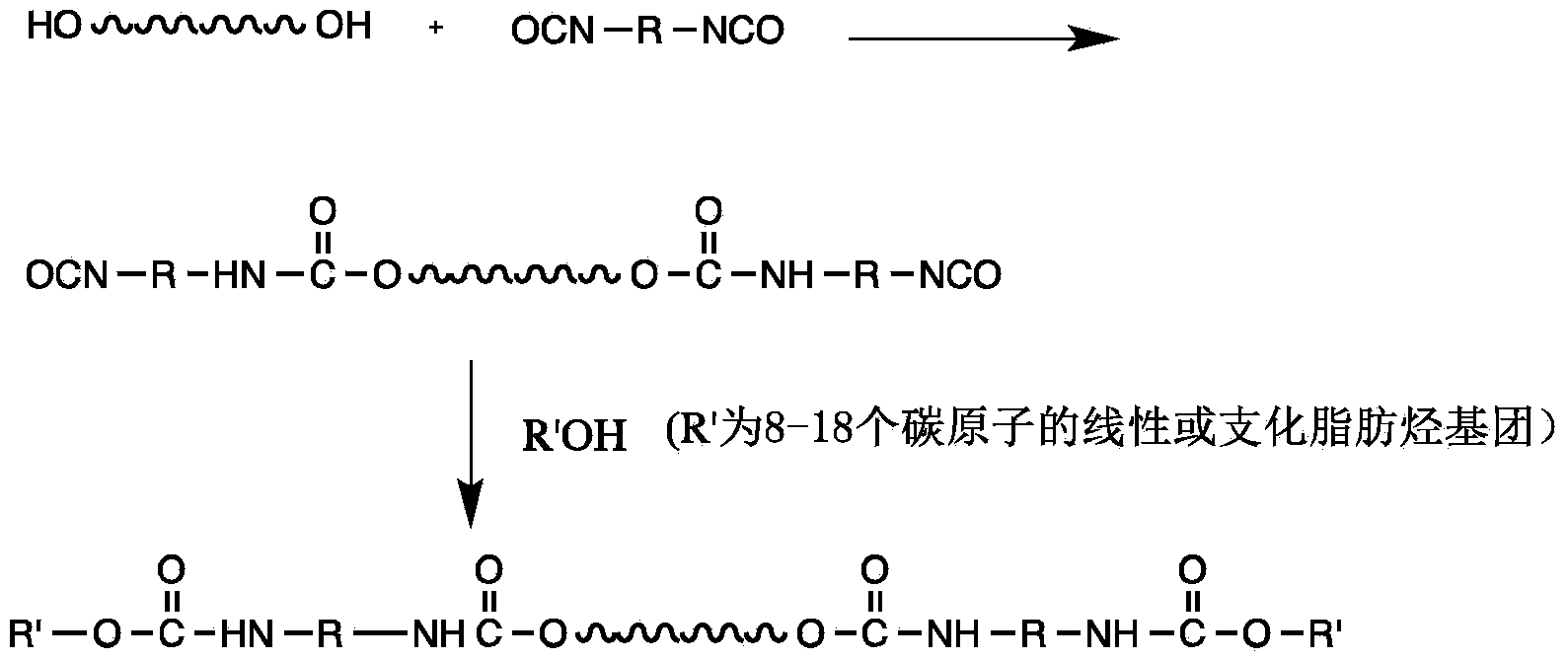

Liquid thickener for aqueous systems containing, as viscosity suppressing agent, from 5 to 40% wt of ethoxylated mono- and / or di-glycerides of carboxylic acids having from 6 to 18 carbon atoms, from 15 to 40% wt of a polyurethane associative thickener, obtained from the reaction of at least one organic polyisocyanate, at least one water soluble polyether diol and at least one hydrophobic capping agent containing from 10 to 24 carbon atoms, from 20 to 80% wt of water, and which is devoid of organic solvents, volatile organic compounds and other viscosity suppressing agents.

Owner:LAMBERTI SPA

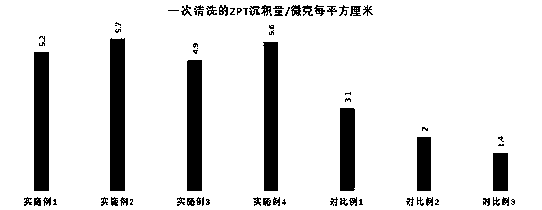

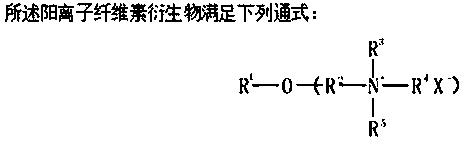

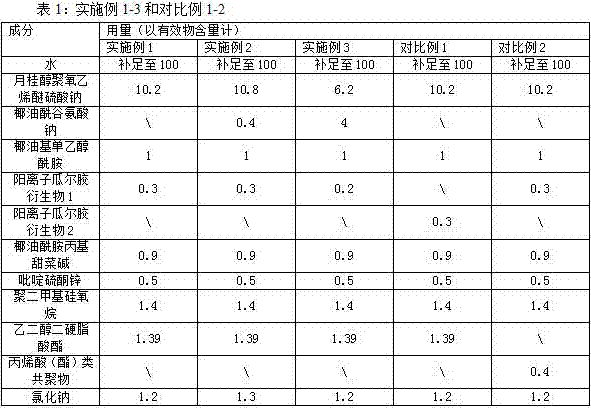

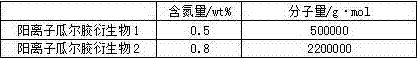

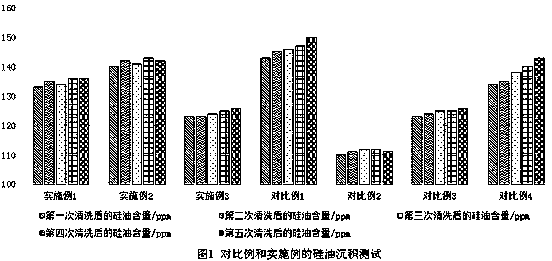

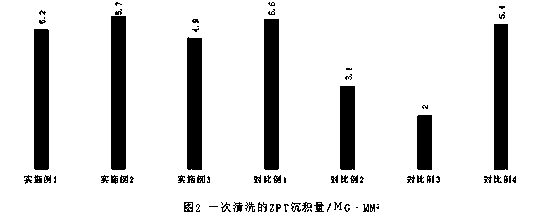

Shampooing cream composition capable of enhancing deposition of anti-dandruff agent

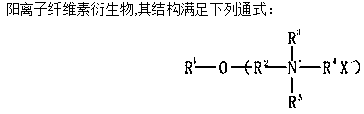

ActiveCN107440935AStrong flocculation strengthHelp to carryCosmetic preparationsHair cosmeticsSodium PyrithioneSuspending Agents

The invention relates to a shampooing composition, and in particular a shampooing cream composition capable of enhancing deposition of an anti-dandruff agent; the composition consists of an anionic surfactant, an ampholytic surfactant, a cationic polysaccharide polymer derivative, zinc pyrithione, a non-volatile conditioning agent, 0.01-10% of a suspending agent and the balance of purified water, wherein the cationic polysaccharide polymer derivative is any one or a compound of the following two derivatives: (i) a cationic cellulose derivative and (ii) a cationic guar gum derivative; the viscosity of a 2% pure water solution of the cationic cellulose derivative is 20000-40000cps and a nitrogen content of the cationic cellulose derivative is 0.8-3.1%; the charge density of the cationic guar gum derivative is 0.5-1.0meq / g and the molecular weight of the cationic guar gum derivative is 400000-1500000g / mol. The shampooing cream composition provided by the invention is good in flocculation phase character and excellent in anti-dandruff agent deposition capacity; and a relatively outstanding anti-dandruff effect is achieved, so that, the shampooing composition, when applied to a user for a long time, can achieve an obvious effect of removing dandruff.

Owner:OPAL COSMETICS HUIZHOU

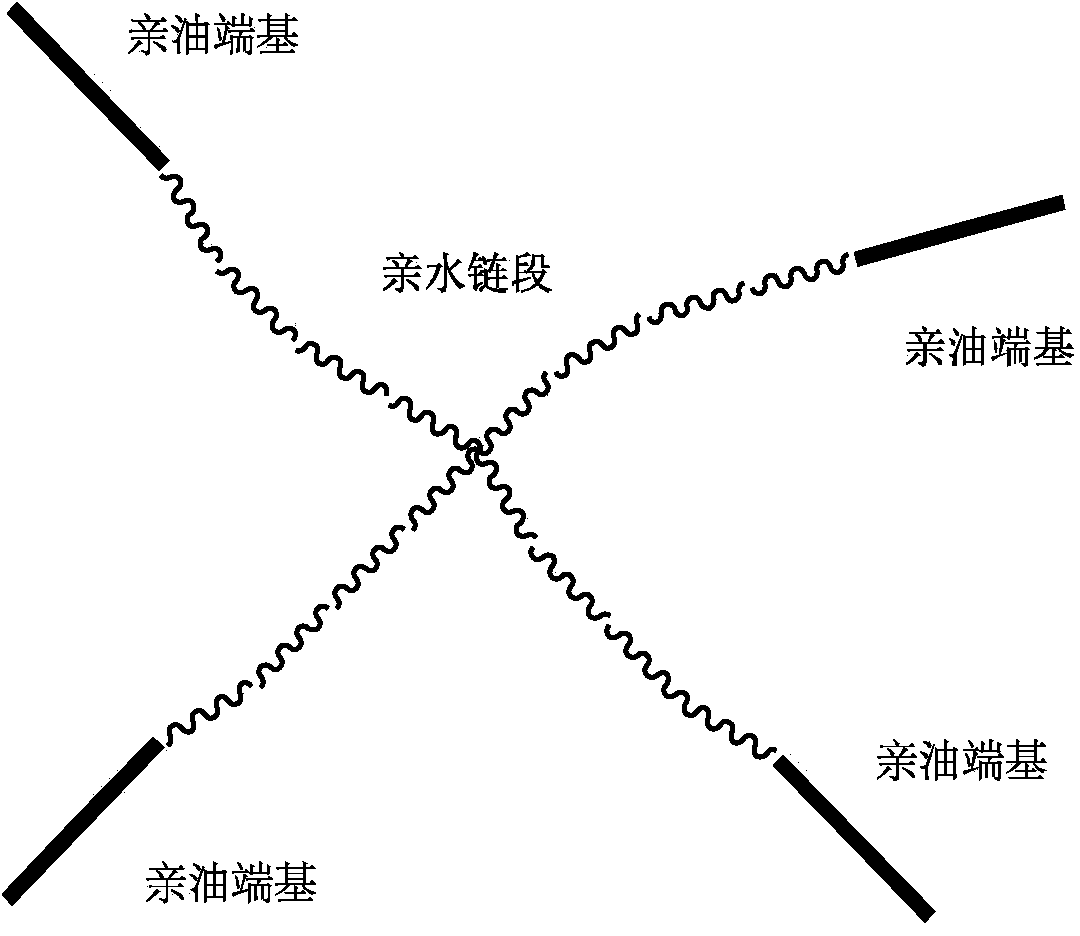

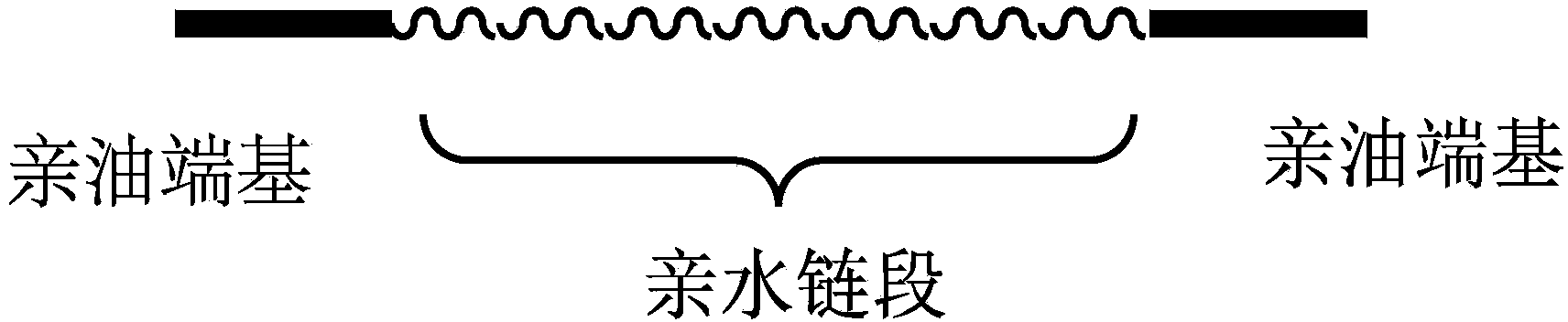

Preparation method of linear and star polyethylene associated thickening agent

InactiveCN104211941AHigh thickening efficiencyReduce temperature sensitivityMacromolecular adhesive additivesCoatingsPolymer scienceHydrophilic polymers

The invention adopts the initiator of polyol and ring opening oxirane for polymerization to synthesize star polyethylene glycol with single-arm molecular weight of 2000-5000; the star polyethylene glycol reacts with alkyl isocyanate to modify an end group of polyethylene glycol into lipophilic alkyl. The lipophilic-hydrophilic polymer with star structure associates in a water system to increase the viscosity of the system. The star polyurethane associated thickening agent synthesized by the invention has very good stability.

Owner:ANHUI UNIVERSITY

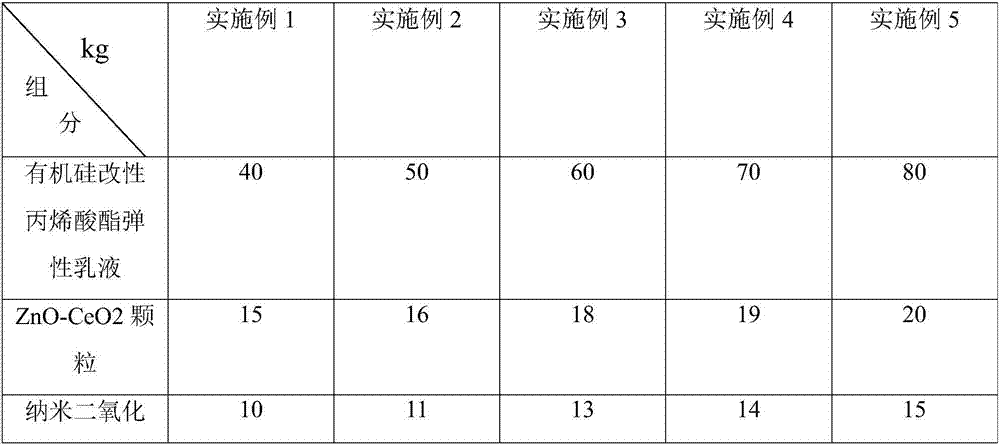

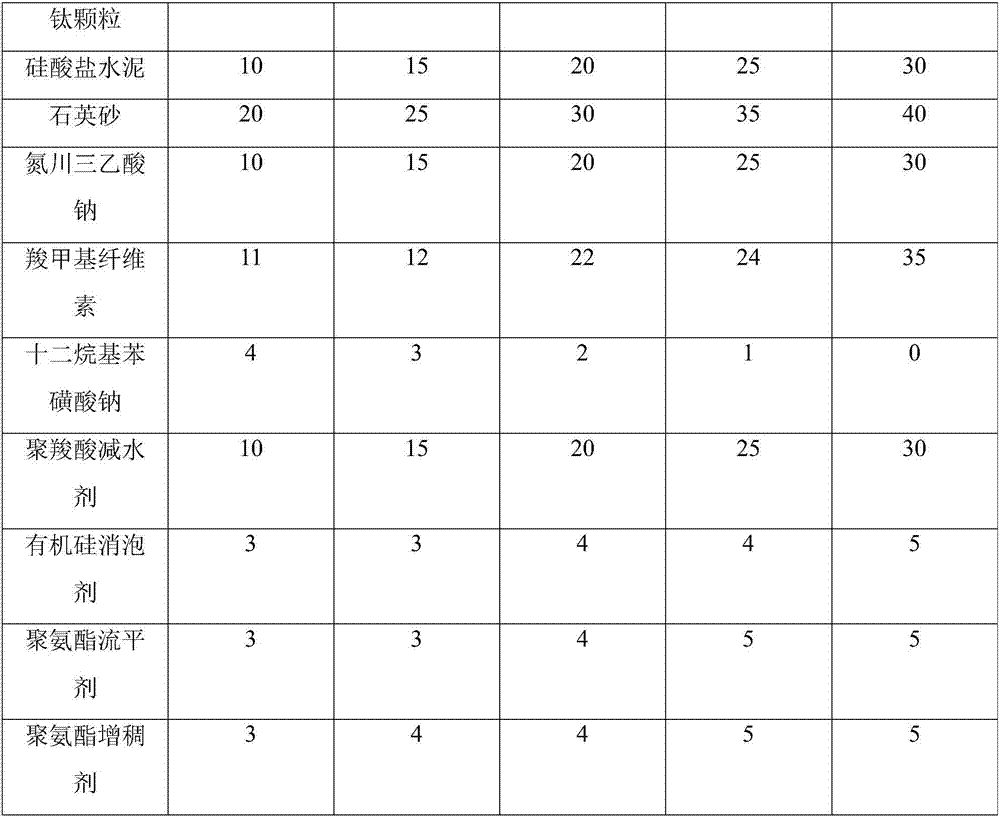

Waterproof crack-resisting coating and preparation method thereof

InactiveCN107987647AHigh elongationResponsiveAntifouling/underwater paintsPaints with biocidesCelluloseCrack resistance

The invention discloses a waterproof crack-resisting coating and a preparation method thereof, and relates to the field of coating materials. The waterproof crack-resisting coating is prepared from the following components in parts by weight: 40 to 80 parts of elastic emulsion, 15 to 20 parts of ZnO-CeO2 particles, 10 to 30 parts of Portland cement, 20 to 40 parts of quartz sand, 10 to 30 parts ofcomplexing agent, 10 to 30 parts of cellulose, 10 to 30 parts of water reducing agent, 3 to 5 parts of defoaming agent, 3 to 5 parts of dispersing agent, 3 to 5 parts of leveling agent and 3 to 5 parts of thickening agent. The waterproof crack-resisting coating provided by the invention has the advantages of excellent waterproof and crack resistance, scrubbing resistance, pulverization resistance, stain resistance, weather fastness, good aging resistance, storage stability, low cost, greenness and environment friendliness.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

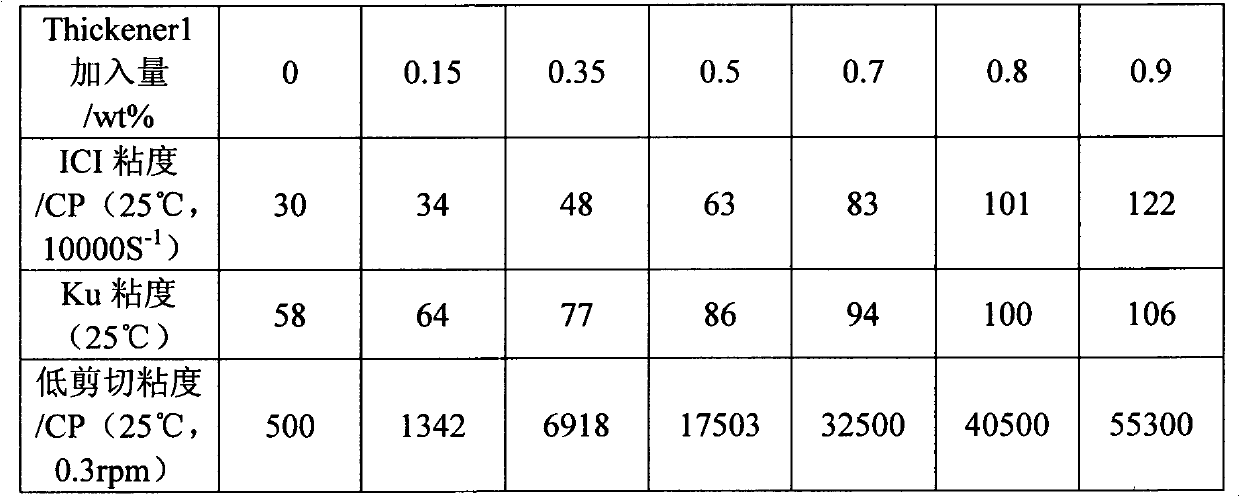

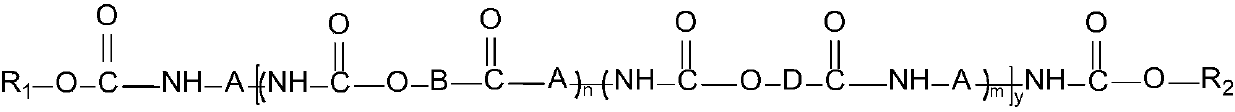

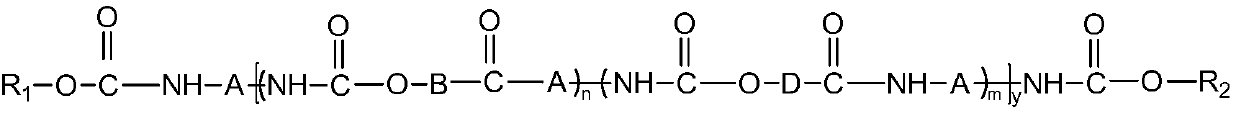

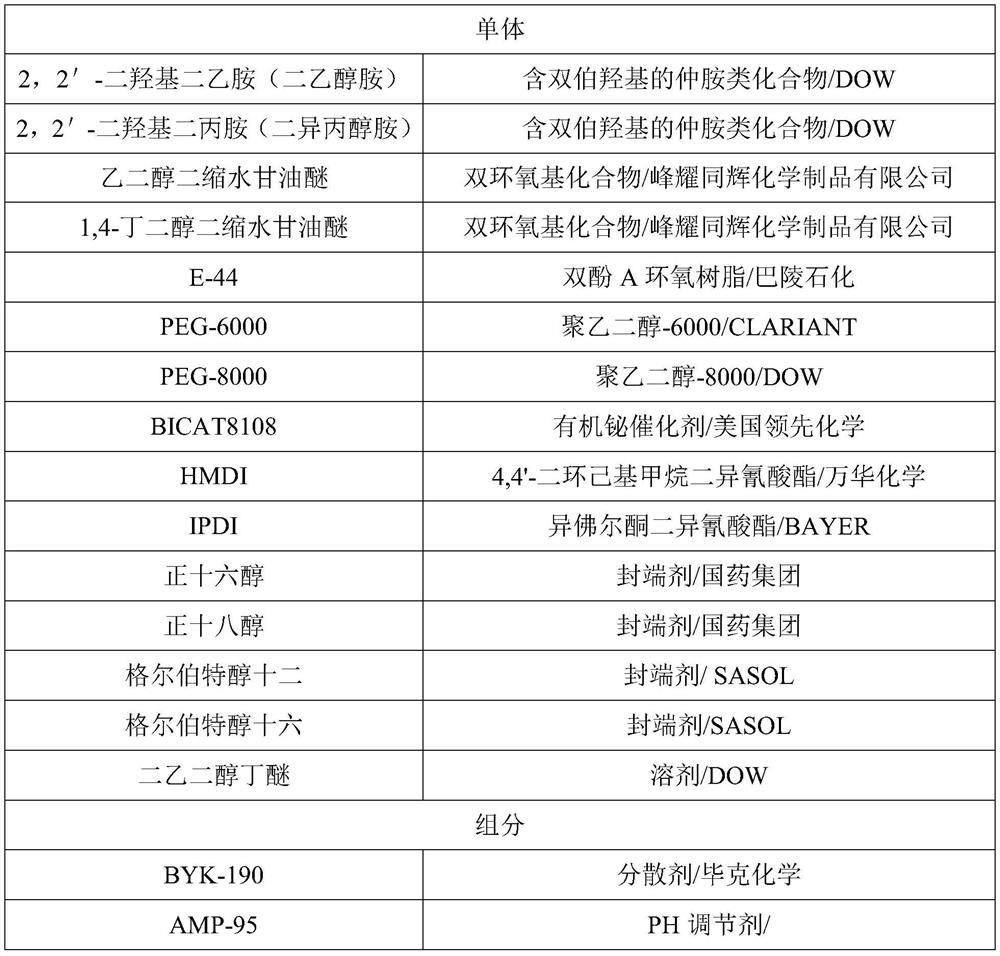

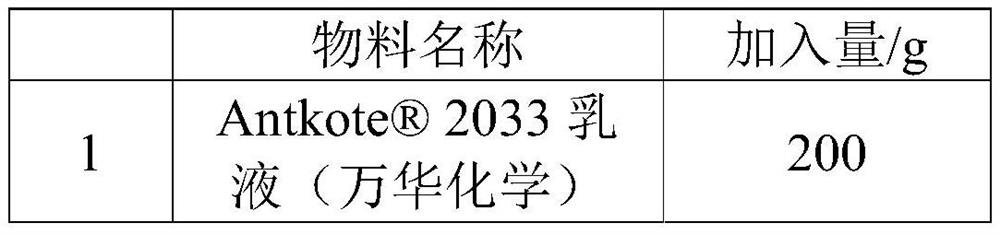

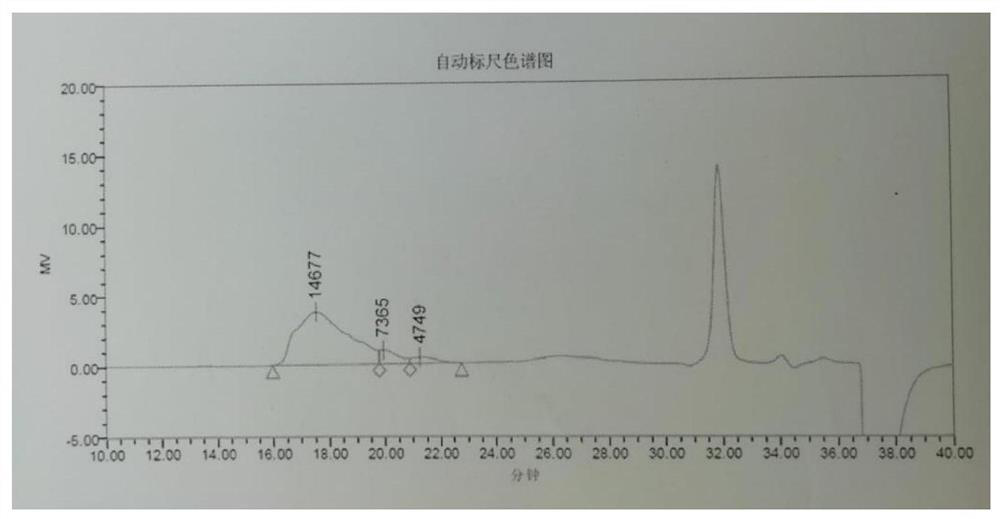

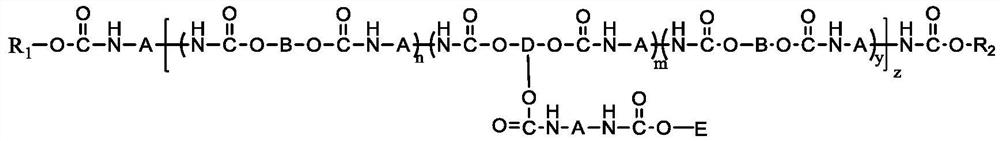

Polyurethane and preparation method and application thereof

Owner:WANHUA CHEM GUANGDONG +2

Polyurethane polymer suitable for viscosity adjustment of waterborne high solvent system and composition containing same

The invention relates to a polyurethane polymer suitable for the viscosity adjustment of a waterborne high solvent system and a composition containing the same. The polyurethane polymer contains a hydrophobic structure with functional groups that can react with isocyanate bonds and one or more hydrophobic end-capping structures with single functionality on the main chains of the polymer. The hydrophobic structure with the functional groups that can react with isocyanate bonds contains 4-70 carbon atoms besides the connecting group carbon atoms, and each hydrophobic end-capping structure with single functionality contains 8-30 carbon atoms besides the connecting group carbon atoms. The hydrophobic structure with the functional groups that can react with isocyanate bonds is introduced into the main chains of the polyurethane polymer, The hydrophobic structure can form a cage-like structure on the main chains of the polyurethane polymer and can effectively interact with the solvent in thesystem, and thus the influence of the solvent on the thickening of the system is reduced, and the thickening efficiency is especially high in the high solvent system.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD +2

Gold brocade coating material

The invention relates the gold brocade coating, belonging to building textured paint field. The raw materials comprises clarity ala emulsion, mica titanium pearl essence, film former lipidol-12, dispersing agent polycarboxylate, defoaming agent NXZ and thickening agent acrylic acid series polycarboxylic acids. The coating has good environmental protection, ageing resistance and water resistance. The gold brocade coating can be used to finish wall.

Owner:北京中化科城技术研究所

High-performance real-stone-like paint and preparation method thereof

InactiveCN108300024AImprove water resistanceImprove stain resistanceAntifouling/underwater paintsPaints with biocidesHigh humidityEmulsion

The invention discloses a high-performance real-stone-like paint and a preparation method thereof. The high-performance real-stone-like paint comprises, by weight, 100 parts of water, 80-120 parts ofa cellulose dispersant, 58-60 parts of white sand, 3-10 parts of natural color sand a, 10-12 parts of natural color sand b, 2-4 parts of a bactericide, 3-20 parts of ethylene glycol, 3-8 parts of an antifoaming agent, 5-17 parts of a film forming aid2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, 150-200 parts of an emulsion, 2-5 parts of a thickener RM-8W and 30-40 parts of silica sol. Accordingto the invention, since the thickener RM-8W is utilized, thickening efficiency is improved, and the water resistance, stain resistance and adhesion performance of the real-stone-like paint are greatly enhanced; at the same time, the 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate film forming aid is employed to control the film formation time of the real-stone-like paint, so the drying time of real-stone-like paint is made controllable; and the natural color sand a with a size of 40-80 meshes and the natural color sand b with a size of 80-120 meshes are matched according to a reasonable ratio, so the water resistance, stain resistance and adhesion performance of the real-stone-like paint are further improved, and the problems of proneness to floating and whitening and poor adhesion duringconstruction at low temperature and high humidity and construction at low temperature and low humidity are overcome, and thus, the comprehensive performance of the real-stone-like paint is greatly optimized.

Owner:JIANGSU GUOJIAO CHEM TECH

Flaky molding compound resin composition, flaky molding compound and preparation method of flaky molding compound

The invention discloses flaky molding compound resin composition, a flaky molding compound and a preparation method of the flaky molding compound. The flaky molding compound resin composition is prepared from substances in parts by weight as follows: 40-60 parts of epoxy resin, 1-20 parts of a thickening agent, 1-5 parts of a thickening accelerant and 1-5 parts of a curing agent. The flaky moldingcompound prepared from the flaky molding compound composition has good mechanical strength, good toughness, low VOC (volatile organic compound) content and good environmental protection performance.

Owner:BYD CO LTD

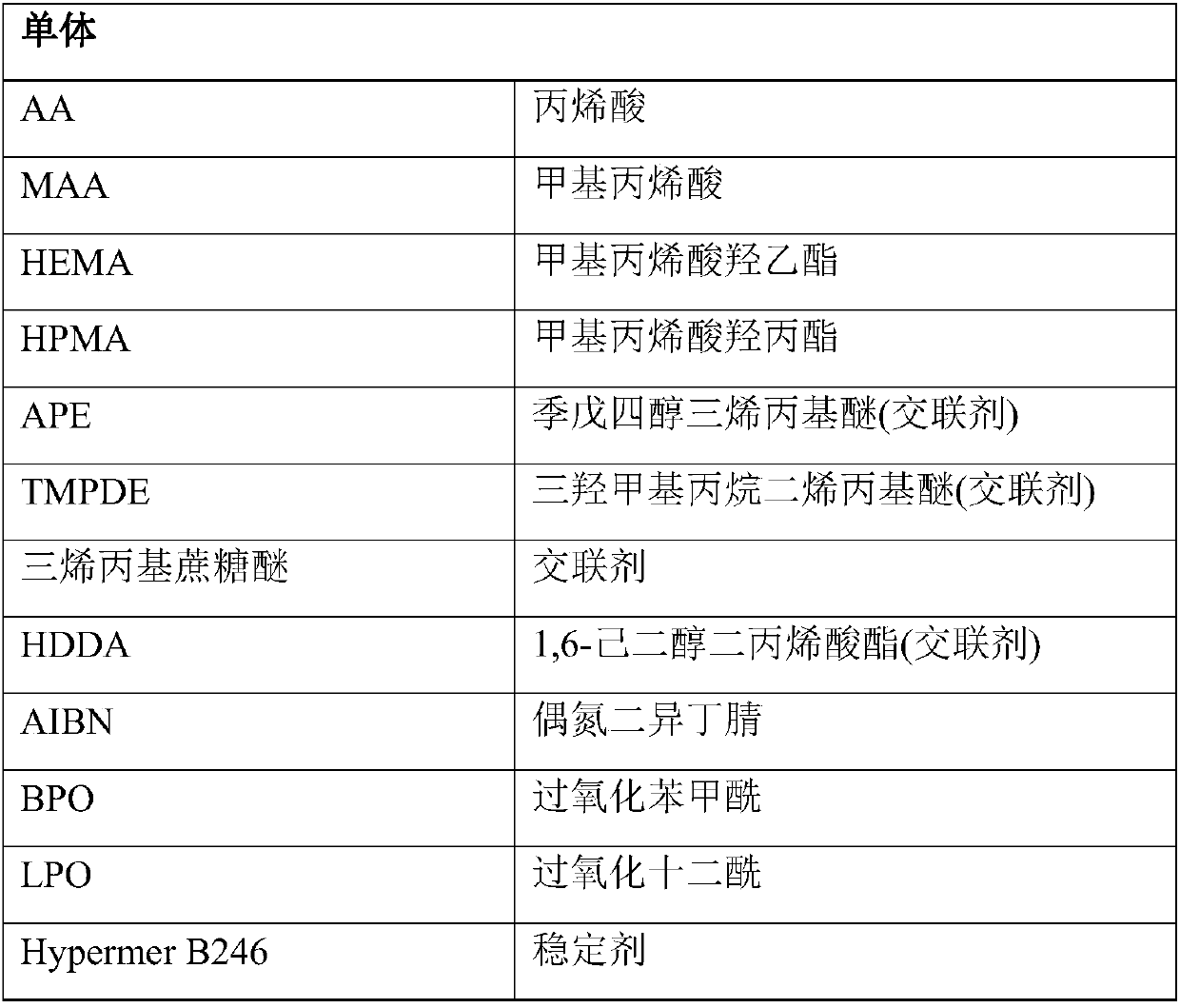

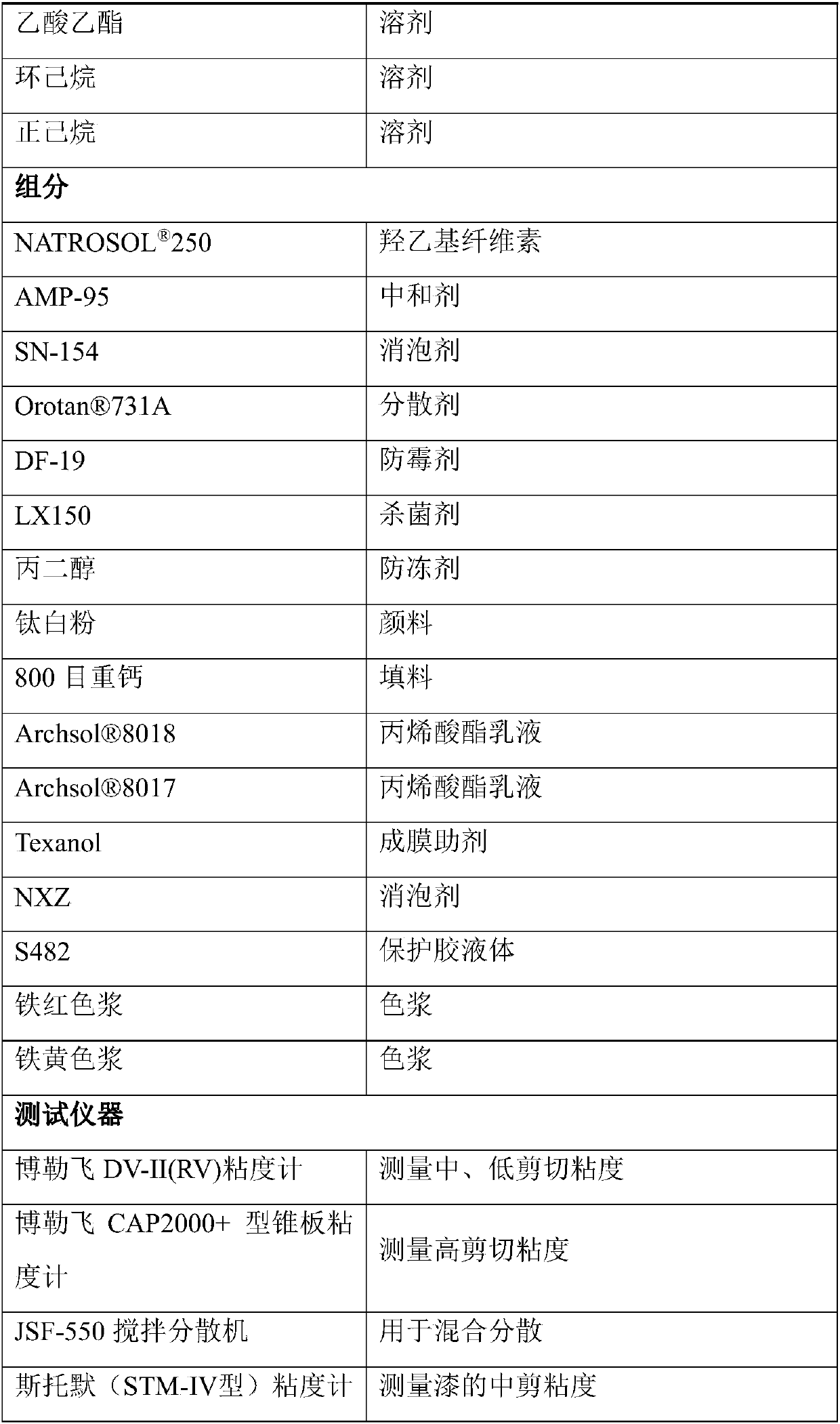

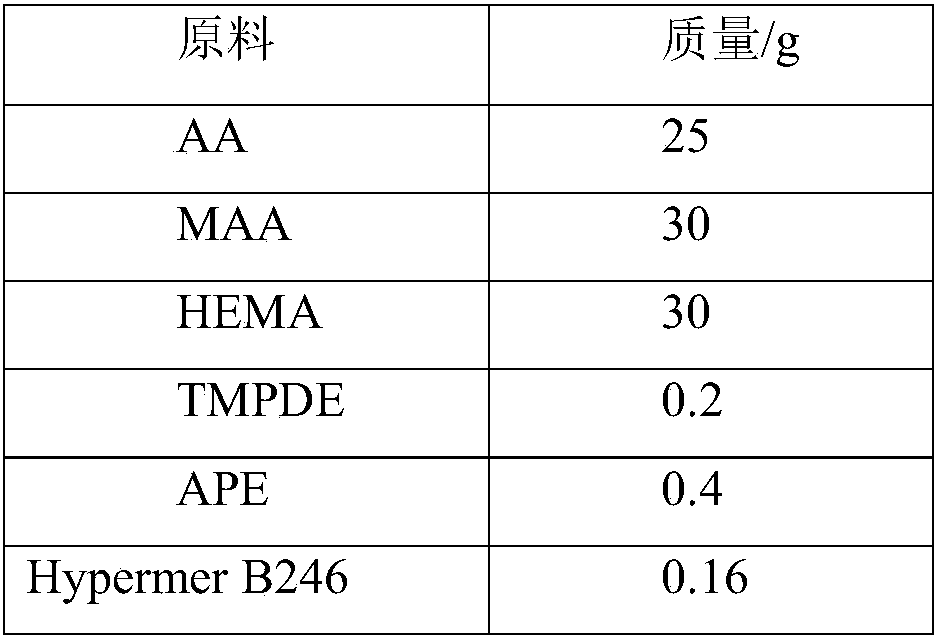

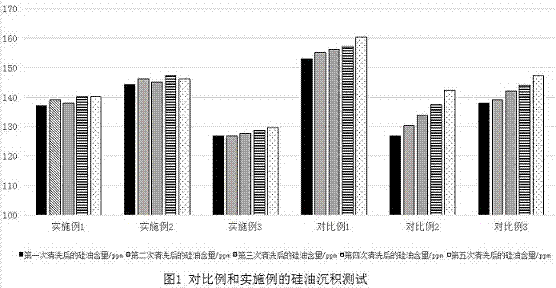

Highly-crosslinked acrylate copolymer as well as preparation method and application thereof as thickening agent

PendingCN109957062AIncrease viscosityHigh molecular weightMulticolor effect coatingsMonomer compositionCarboxylic acid

The invention relates to a highly-crosslinked acrylate copolymer as well as a preparation method and application thereof as a thickening agent. The copolymer is prepared by precipitation polymerization triggered by free radicals of a monomer composition containing the following monomers in a solvent: a) 10-80wt% of first monomer component selected from one or more of olefin monounsaturated monomers containing at least one carboxyl group; b) 89.9-15wt% of second olefin monounsaturated monomer component selected from one or more of C1-C4 hydroxyl alkyl esters of a straight chain or a branched chain of (methyl)acrylic acid; and c)0.01-5wt% of crosslinked component selected from polyalkenyl polyether with at least two polymerizable olefin unsaturated double bonds. The highly-crosslinked acrylate copolymer disclosed by the invention shows excellent performances such as high thickening efficiency as well as good system compatibility and storage stability in a multi-color coating.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD +2

Refreshing shampoo composition with good hair wetting property

InactiveCN107412003AEffective carryCarry helpCosmetic preparationsHair cosmeticsFlocculationSuspending Agents

The invention belongs to the field of daily chemicals and relates to shampoo composition. The refreshing shampoo composition with a good hair wetting property is prepared from raw materials as follows: an anionic surfactant, an ampholytic surfactant, a cationic guar gum derivative with the charge density being about 0.5-1.0 meq / g and the molecular weight being 400,000-1,500,000 g / mol, a nonionic surfactant, salt, a non-volatile conditioner, a suspending agent and the balance of pure water. Through reasonable establishment of a composition system structure and limitation of key parameters of raw materials, the shampoo composition which enables users to have good wet washing feeling and refreshing dry hair feeling is provided, prevents oil return and has reduced silicone oil accumulation; the composition has medium-strength flocculation and reasonable silicone oil deposition and is made of mild components, applicable to various hair, remarkable in effect, low in cost and simple and convenient to use.

Owner:OPAL COSMETICS HUIZHOU

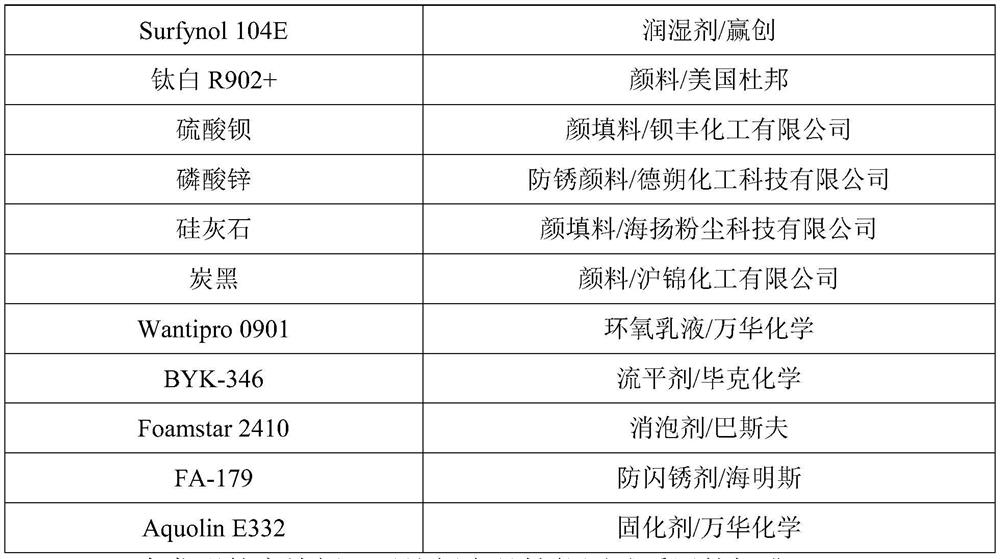

Reaction viscosity adjusting composition suitable for two-component waterborne epoxy system as well as preparation method and application of reaction viscosity adjusting composition

ActiveCN113817126AImprove mechanical propertiesGood chemical resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyPolymer science

The invention discloses a reactive viscosity adjusting composition suitable for a two-component waterborne epoxy system and a preparation method of the reactive viscosity adjusting composition. The viscosity adjusting composition is prepared from the following raw materials: a secondary amine compound containing double primary hydroxyl groups, a diepoxy compound, polyether polyol, diisocyanate, hydrophobic long-chain fatty alcohol, a catalyst, a stabilizer, and an optional alcohol ether solvent and / or water. The viscosity adjusting composition is mainly used for a two-component waterborne epoxy system, not only has an efficient viscosity adjusting effect, but also can be used for improving the physical and mechanical properties and chemical reagent resistance of a paint film as the molecular structure contains an active epoxy group and can participate in a crosslinking curing reaction of the paint film, so that the viscosity adjusting composition has a wide industrial application prospect.

Owner:WANHUA CHEM GRP CO LTD

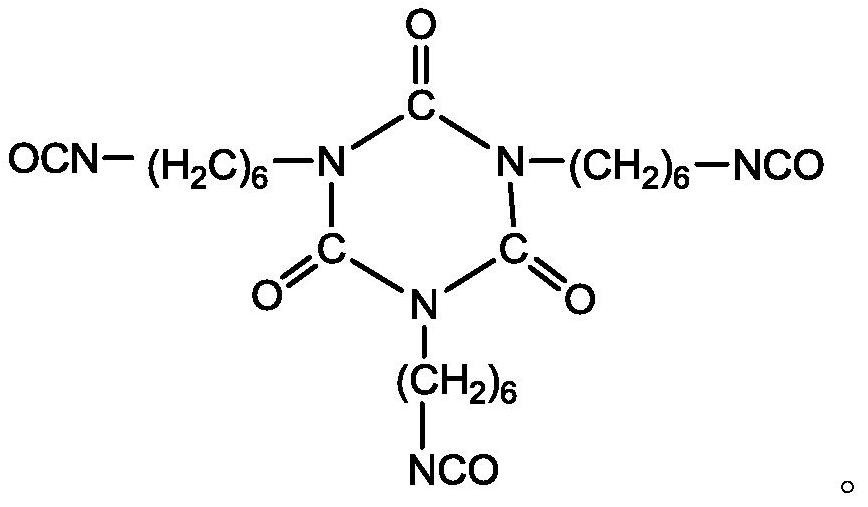

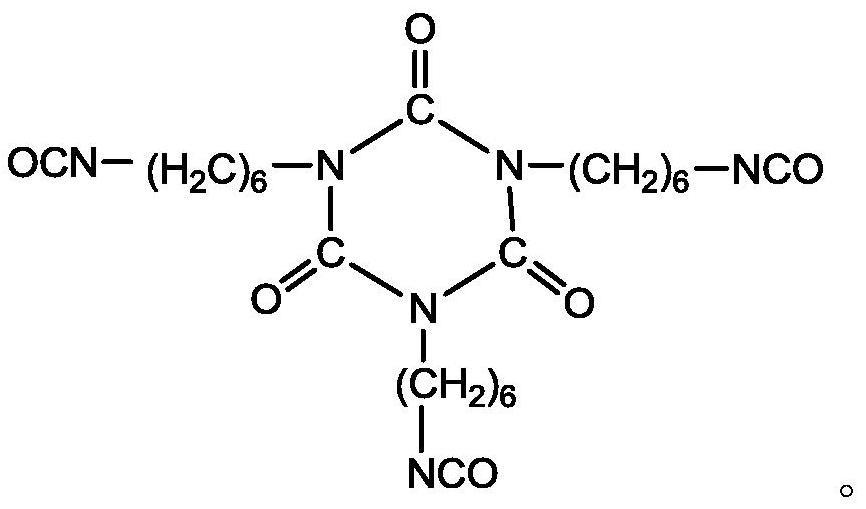

Light-cured polyurethane associated thickener as well as preparation method and application thereof

ActiveCN113061224AGood thickening effectGood physical and mechanical propertiesAnti-corrosive paintsPolymer sciencePtru catalyst

The invention relates to a light-cured polyurethane associated thickener as well as a preparation method and application thereof. The light-cured polyurethane associated thickener is prepared from the following raw materials: an acrylate monomer containing a primary hydroxyl group, an HDI tripolymer, polyether polyol, long-carbon-chain fatty alcohol, diisocyanate, a catalyst and an optional alcohol ether solvent and / or water. The polyurethane thickener is mainly applied to a water-based UV coating, not only has higher thickening efficiency, but also can improve the physical and mechanical properties and chemical reagent resistance of a paint film due to the fact that the molecular structure contains photocurable C = C and HDI tripolymer rigid six-membered rings with relatively high activity, so that the polyurethane thickener has a wide industrial application prospect.

Owner:WANHUA CHEM GRP CO LTD

Graphene diatom ooze paint capable of killing bacterial and removing aldehyde and its preparation method

InactiveCN107629675ASolve the problem of not having the performance of adsorbing pollutants such as formaldehydeHigh glossAntifouling/underwater paintsPaints with biocidesCelluloseSorbent

The invention provides a graphene diatom ooze paint capable of killing bacterial and removing aldehyde and its preparation method to overcome the problem that conventional paints are incapable of absorbing pollutants like aldehyde. The graphene diatom ooze paint capable of killing bacterial and removing aldehyde comprises the following raw materials by weight: 1 to 10 parts of graphene oxide, 30 to 50 parts of natural diatom ooze, 10 to 30 parts of white cement, 20 to 50 parts of an adsorbent, 5 to 10 parts of dispersible adhesive powder, 1 to 5 parts of cellulose, 5 to 20 parts of light calcium carbonate, 0.5 to 1 part of polypropylene fibers, 1 to 2 parts of wood fibers, 1 to 5 parts of nanometer silica, 1 to 10 parts of titanium dioxide, 1 to 5 parts of iron oxide pigment and 1 to 3 parts of sodium hexametaphosphate. The paint prepared in the invention is capable of decomposing formaldehyde; in an enclosed environment, formaldehyde efficiency of the paint is as high as 95% and benzene removal efficiency is 93%; and the paint can effectively remove harmful gas in a room and increase indoor negative ion concentration, and is beneficial for human health.

Owner:环秀(青岛)建材科技有限公司

Anti-dandruff shampoo composition for improving excessive deposition of effective particles

ActiveCN107582432AStrong flocculation strengthEasy to carryCosmetic preparationsHair cosmeticsSelective depositionUltimate tensile strength

The invention belongs to the field of daily chemicals, and relates to a shampoo composition. The anti-dandruff shampoo composition for improving excessive deposition of effective particles comprises an anionic surfactant, an amphoteric surfactant, 0.05-3% of a cationic cellulose derivative, an anti-dandruff agent, a non-volatile conditioning agent, a suspension, and the balance of pure water. Users using the anti-dandruff shampoo composition for improving the excessive deposition of effective particles for a long term do not feel greasiness, stiffing or other discomforts; and the composition realizes selective deposition of floc and no excess accumulation deposition on the premise of achieving a good flocculating intensity and carrying the effective particles through reasonable establishment of the structure of the composition, synergies among all raw materials and restriction of key parameters of the raw materials. The composition has the advantages of mild composition, suitableness for all kinds of hair, remarkable effect, low cost, and simplicity in application.

Owner:OPAL COSMETICS HUIZHOU

Aldehyde removal sterilizing weather-resistant environment-friendly latex paint and preparation method thereof

InactiveCN107216751AImprove stabilityLong-lasting and efficient removal of aldehydesAntifouling/underwater paintsPaints with biocidesPolyvinyl alcoholIndoor air

The invention discloses aldehyde removal sterilizing weather-resistant environment-friendly latex paint which comprises the following raw materials in parts by weight: 2-4 parts of polyvinyl alcohol, 0.2-0.4 part of sodium hexametaphosphate, 0.05-0.15 part of pyrethroid, 30-40 parts of an acrylic copolymerized emulsion, 1-2 parts of propylene glycol, 1-3 parts of hydroxyethyl cellulose, 20-26 parts of filler, 1-2 parts of a compound processing aid, 2-3 parts of a function enhancing additive, 10-14 parts of an aldehyde removal additive and 20-30 parts of deionized water. The latex paint disclosed by the invention is good in film hardness, high in covering force, good in scrub resistance and long in service life, is free of a bulging fall-off phenomenon, and is high in stability, good in water resistance and acid and alkali resistance and excellent in comprehensive performance. In addition, the latex paint also can purify indoor air, prevent mildews and algae and kill mosquitoes lastingly. The raw materials of the latex paint disclosed by the invention are safe and reliable in component, free of environmental pollution, easily available, relatively low in cost, concise in process, easy to operate and realize industrial production, and has relatively high practical value and good application prospect.

Owner:合肥市淑芹美装饰工程有限公司

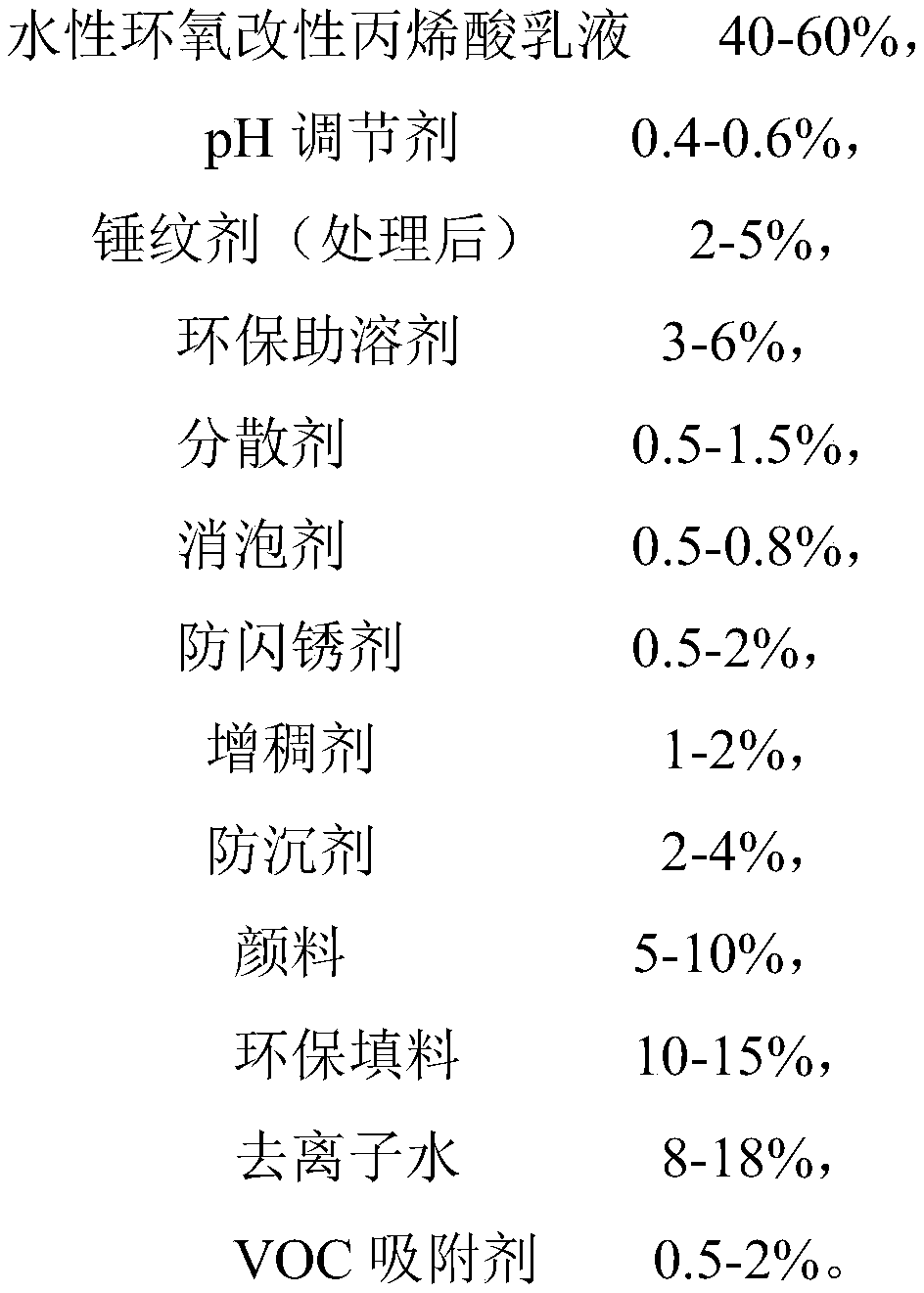

Waterborne single-component ultralow-VOC (volatile organic compounds) quick-drying orange-figured paint and preparation method thereof

InactiveCN109796831AImprove performanceDecorativeAnti-corrosive paintsEpoxy resin coatingsEpoxyEmulsion

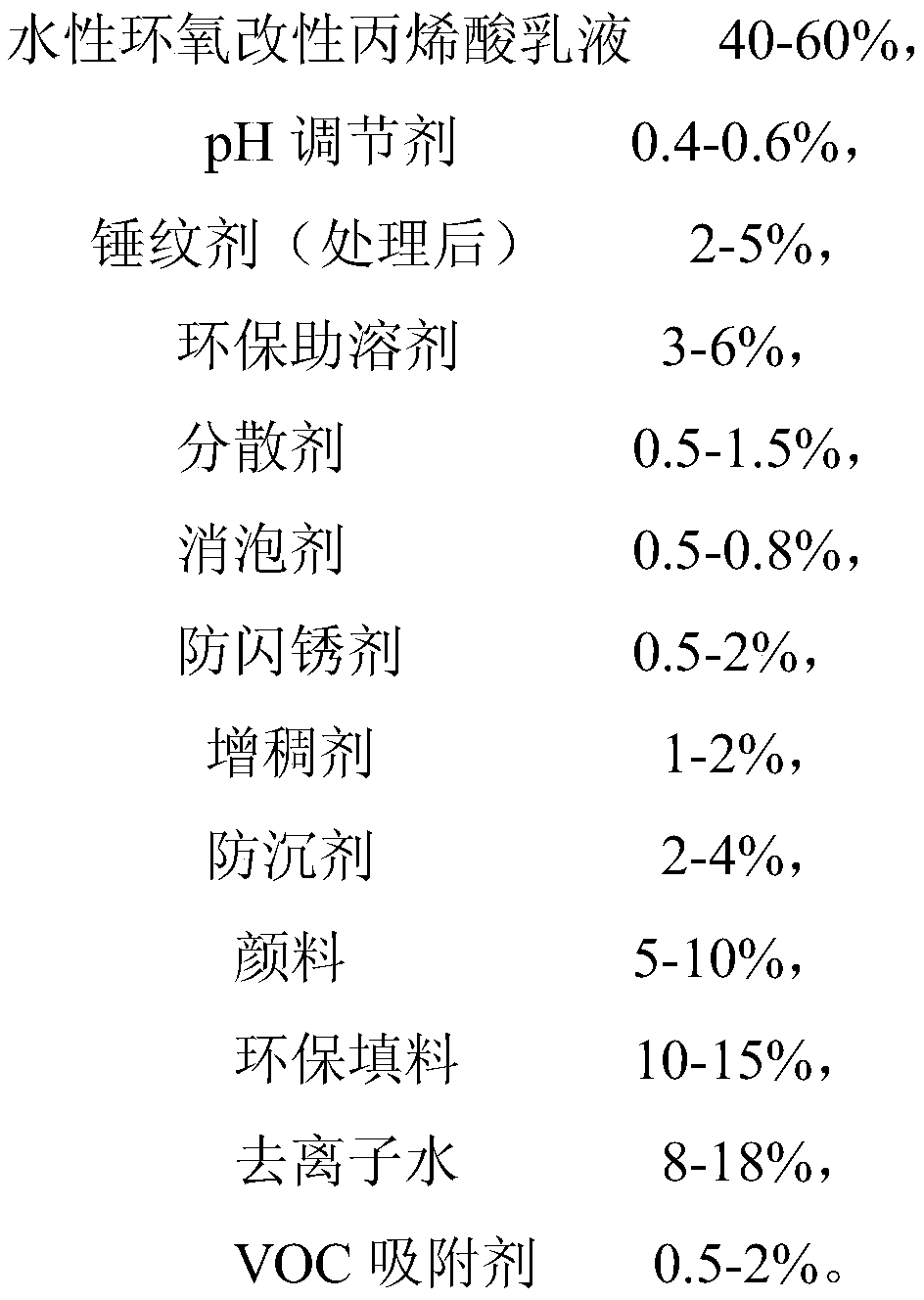

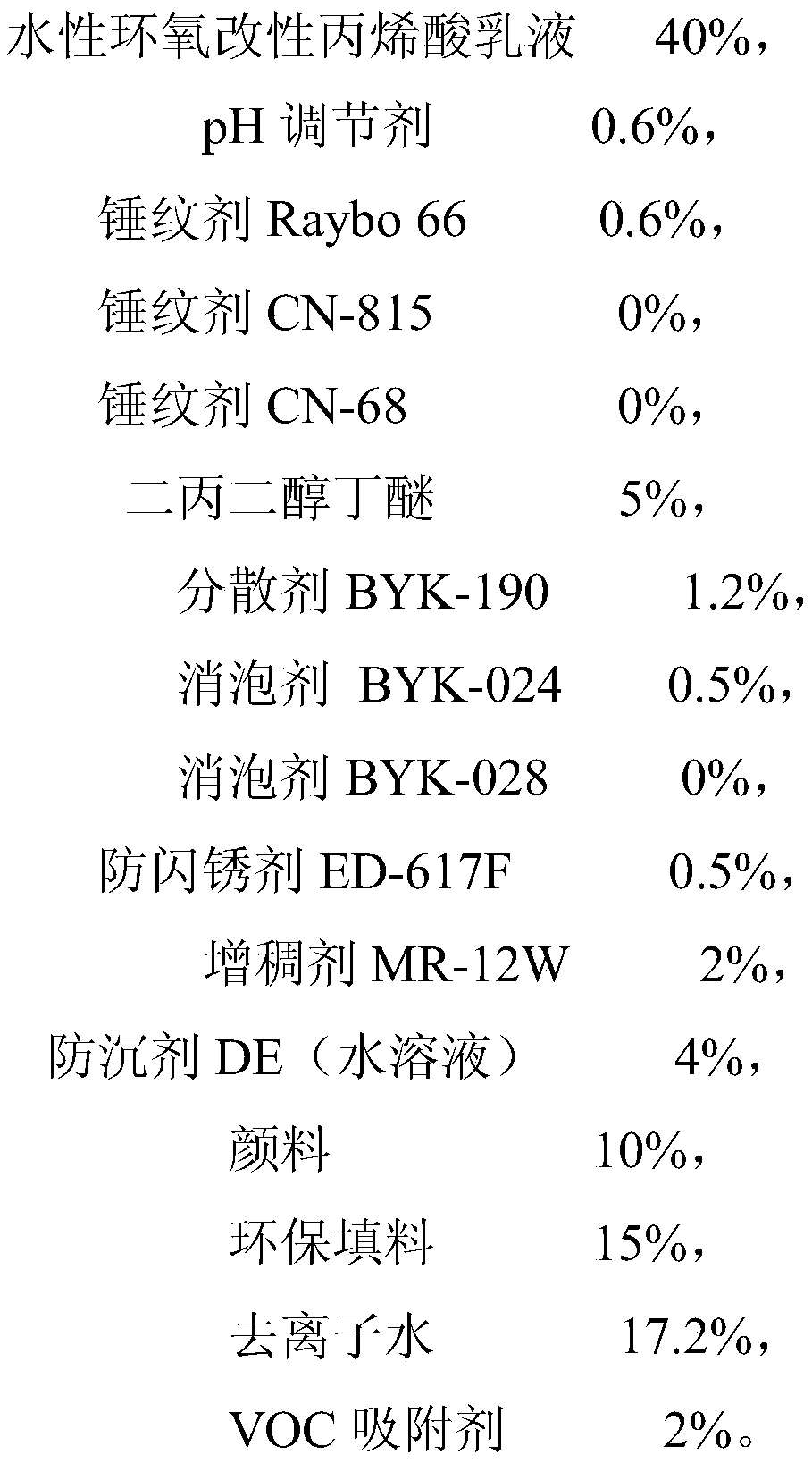

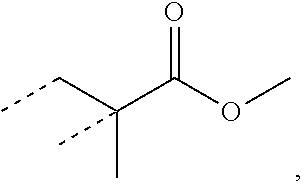

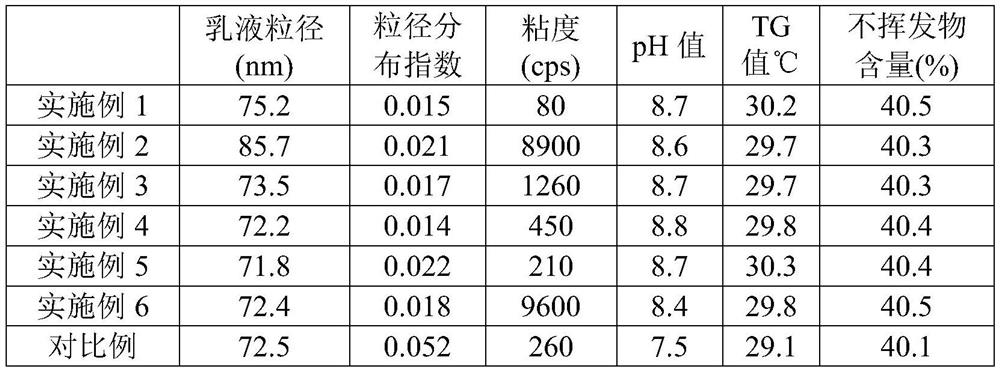

The invention discloses a waterborne single-component ultralow-VOC (volatile organic compounds) quick-drying orange-figured paint and a preparation method thereof. The waterborne single-component ultralow-VOC quick-drying orange-figured paint comprises, by weight, 40-60% of waterborne epoxy-modified acrylic emulsion, 0.4-0.6% of a pH regulator, 2-5% of a hammer agent (treated), 5-10% of an environment-friendly cosolvent, 0.5-1.5% of a dispersant, 0.5-0.8% of a defoamer, 0.5-2% of a flash rust inhibitor, 1-2% of a thickener, 2-4% of an anti-settling agent, 10% of a pigment, 10-15% of an environment-friendly filler, 9-18% of deionized water, and 0.5-2% of a VOC adsorbent.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Aqueous thickener blend composition

ActiveUS20210171787A1High thickening efficiencyGood storage stabilityEmulsion paintsAcid inhibitionOrganic chemistry

An aqueous thickener blend composition comprising an aqueous hydrophobically-modified alkali soluble or alkali swellable thickener composition and an acid-suppressible associative thickener composition, affording high thickening efficiency and providing an aqueous coating composition comprising such aqueous thickener blend composition with good heat-age stability and color float stability.

Owner:ROHM & HAAS CO +1

Preparation method of two-in-one emulsion for multicolor paint

PendingCN112358566AGuaranteed stabilityImprove water resistanceMulticolor effect coatingsPolymer sciencePolyurethane adhesive

The invention relates to the technical field of water-based multicolor paint, in particular to a preparation method of two-in-one emulsion for multicolor paint, which comprises the following raw materials in parts by weight: 500-650 parts of deionized water, 0.1-10 part of reactive emulsifier, 0.5-10 part of anionic emulsifier, 0.1-5 part of acidic monomer, 1-12 parts of amino monomer, 1-50 partsof nitrile monomer and 1-50 parts of hydrophilic functional monomer. The invention relates to a high-temperature-resistant polyurethane adhesive which comprises the following components in parts by weight: 350-450 parts of a main monomer, 0.1-2 part of buffer salt, 0.1-10 part of an initiator, 1-15 parts of a silane coupling agent, 0.1-50 part of a pH regulator, 0.2-10 part of a defoaming agent and 0.5-10 part of a preservative. The two-in-one emulsion for the multicolor coating prepared by the invention can replace two emulsions, namely a dispersion phase emulsion and a continuous phase emulsion, required for preparing the multicolor coating, so that the problem that the compatibility of the two emulsions is unstable due to poor batch stability of the dispersion phase emulsion and the continuous phase emulsion is solved, and the stability of the multicolor coating is further ensured; The wide market prospects are realized.

Owner:HENGSHUI XINGUANG CHEM

Waterborne polyurethane (PU) bottoming resin for artificial leather

The invention discloses a waterborne polyurethane (PU) bottoming resin for artificial leather. The resin consists of the following raw materials in percentage by weight: 50 to 65 percent of waterborne hydroxyl cross-linking agent, 30 to 40 percent of water, 1 to 3 percent of amino-modified silicone oil slip agent, 0.5 to 1 percent of organic silicon flatting agent, 2 to 5 percent of organic silicon deforming agent and 0.5 to 2 percent of waterborne PU thickening agent. According to the waterborne PU bottoming resin for the artificial leather, water is used as a solvent, replaces dimethylformamide, butanone and other toxic solvents, and has non-combustible performance, safety performance, environment-friendly performance and cost-saving performance; the bottoming resin has the advantages of high film-forming property, high adhesion fastness and solvent-resistant, cold-resistant, hydrolysis-resistant and heat-aging-resistant coatings; and a finished product made of the bottoming resin has the advantages of handfeel fullness, good bottoming effect, good genuine leather feeling, fine and smooth texture, high air permeability and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Controlling branch level and viscosity of polyalphaolefins with propene addition

InactiveUS7943807B2Efficient preparationHigh VIHydrocarbons from unsaturated hydrocarbon additionHydrocarbonsAlpha-olefinViscosity

The invention relates to a polyalphaolefin formed from a decene and propene and having a branch level greater than 19% and to a process for forming such polyalphaolefins. The invention also relates to a process for forming a polyalphaolefin from at least two monomers, the two monomers comprising a decene and propene, the process comprising the steps of, inter alia, providing a correlation between the total amount of propene used to form the polyalphaolefin and at least one of branch level or viscosity of the polyalphaolefin to make polyalphaolefins comprising decene and propene with predictable branch levels and viscosities.

Owner:LANXESS SOLUTIONS US INC

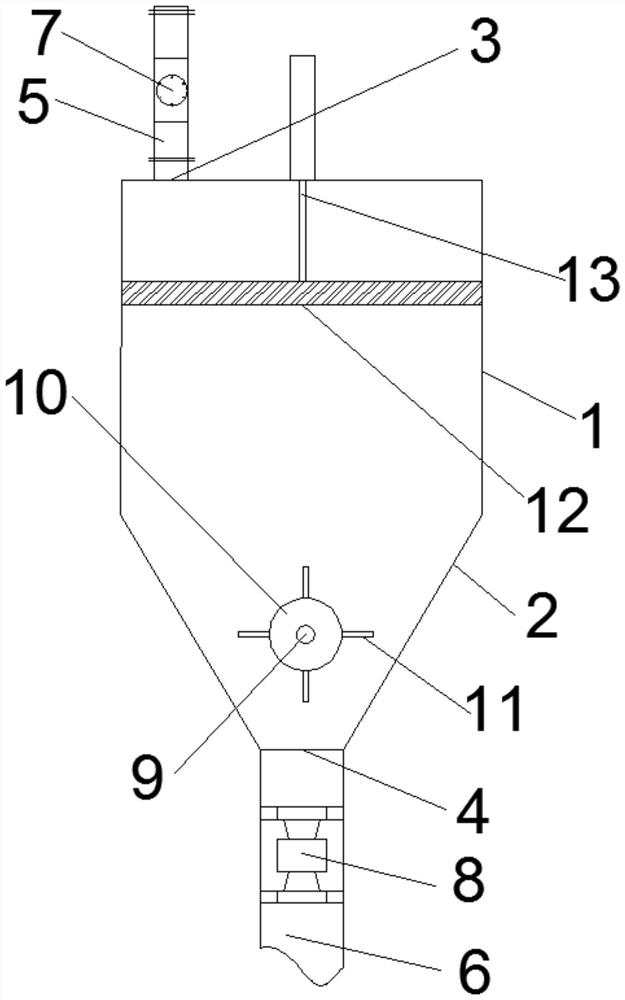

Nitrate slurry thickener

PendingCN112717490AControl feed rateEasy to measure by weightSettling tanks feed/dischargeSedimentation settling tanksEngineeringProcess engineering

The invention discloses a nitre slurry thickener, belongs to the technical field of anhydrous sodium sulphate production equipment, aims to provide a nitre slurry thickener, and solves the problems that an existing nitre slurry thickener is low in automation degree and a discharge port is easy to block. The nitre slurry thickener comprises a barrel body, the barrel body comprises a column body part located on the upper portion and a cone body part located on the lower portion, a feeding port is formed in the top wall of the column body part, a discharging port is formed in the bottom wall of the cone body part, the feeding port communicates with a feeding pipe, the discharging port communicates with a discharging pipe, and an electric control valve is installed on the feeding pipe; an electronic weighing flow meter is installed in the discharging pipe, and an anti-blocking device is installed at the position, located above the discharging port, in the cone part. The invention is suitable for the nitrate slurry thickener.

Owner:四川省洪雅青衣江元明粉有限公司

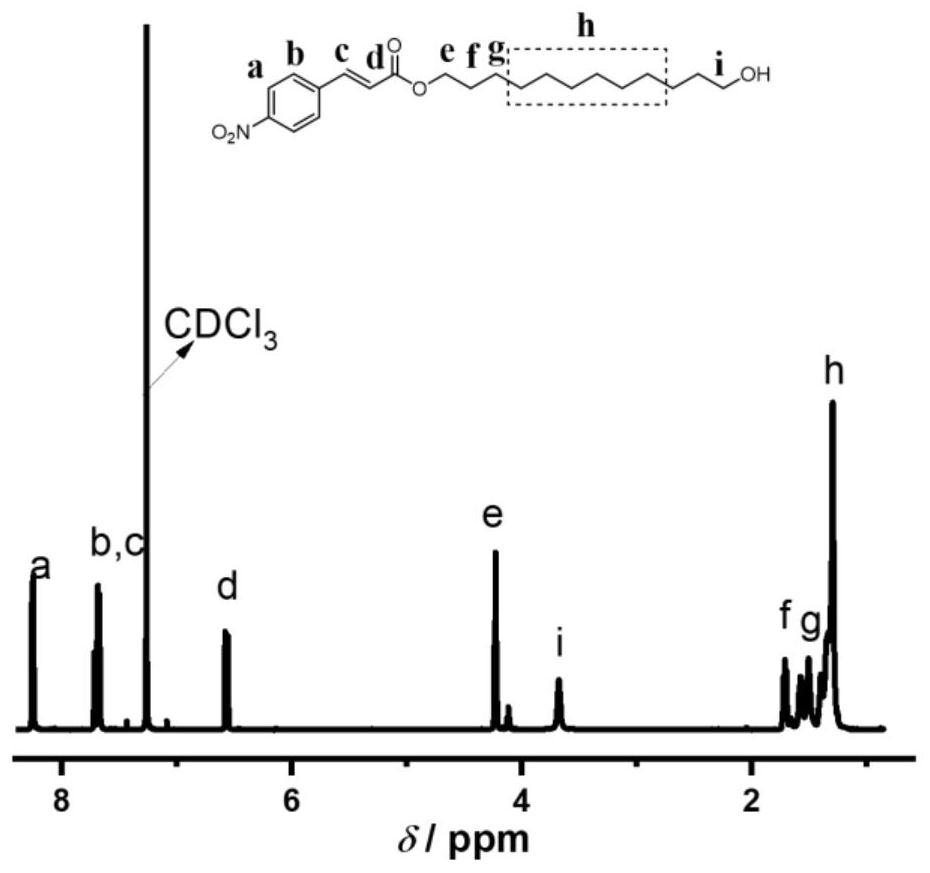

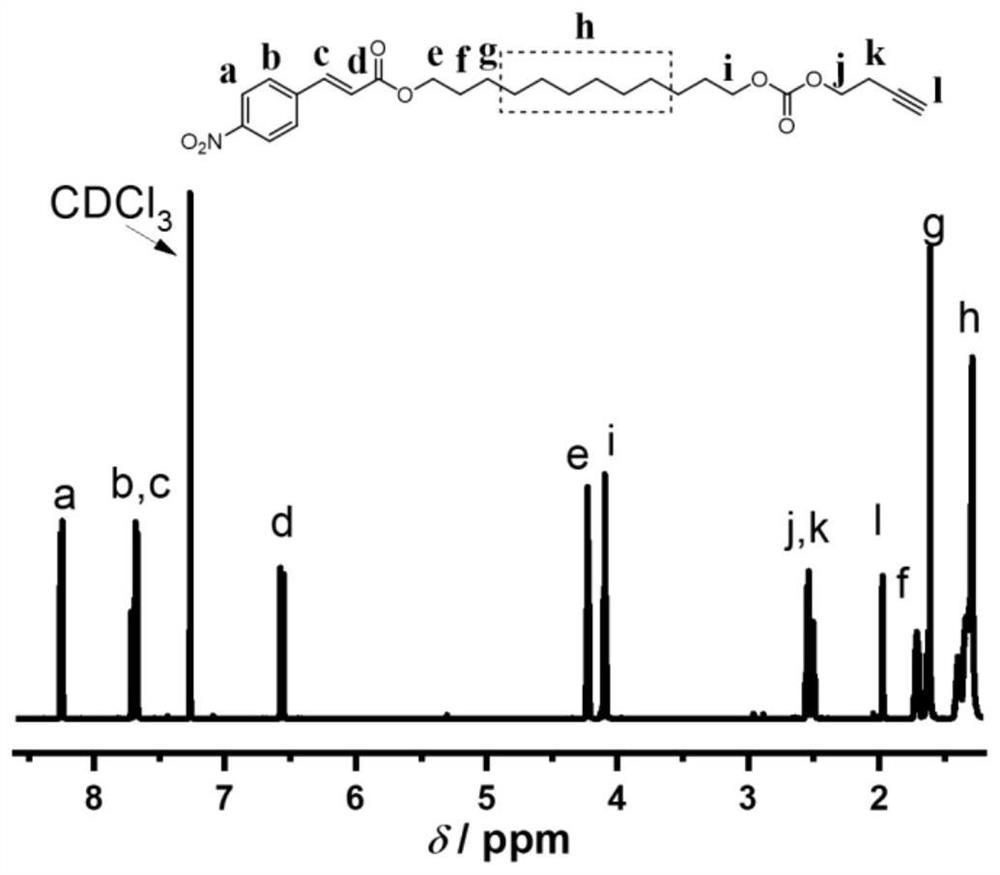

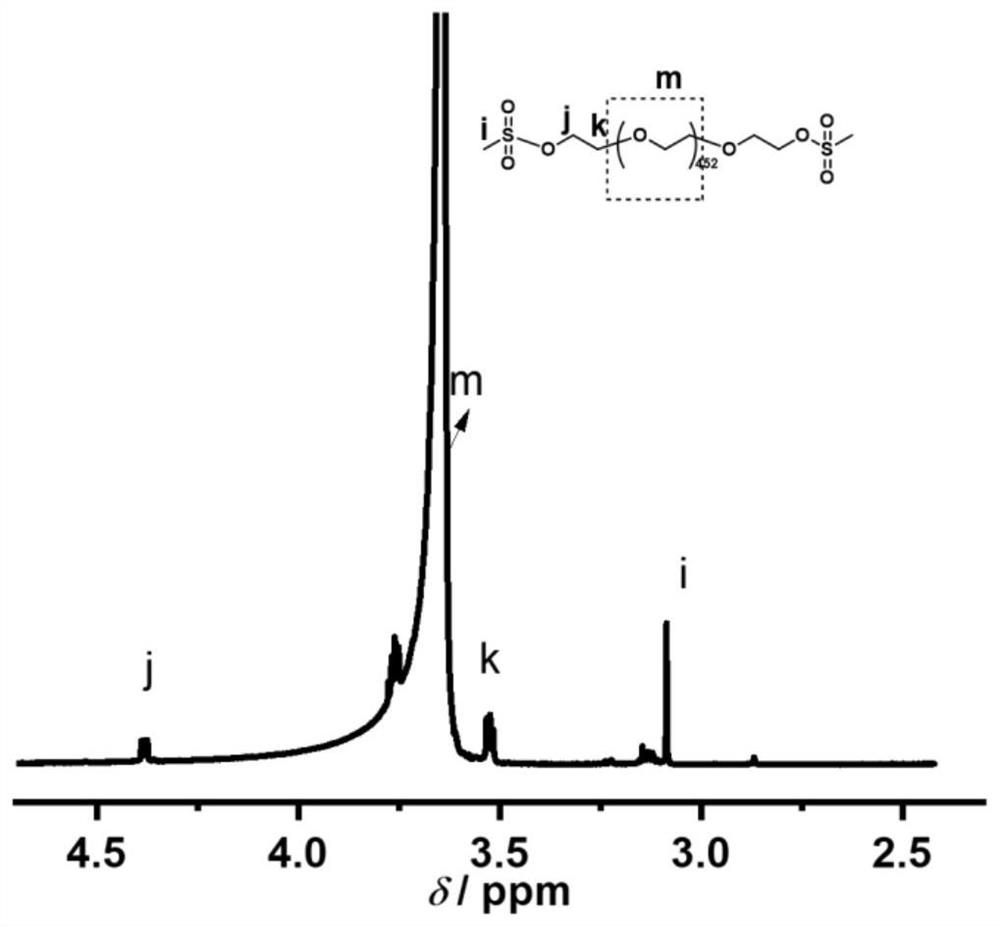

P-nitrocinnamic acid modified rapid-reactivity associated thickener as well as preparation method and application thereof

ActiveCN114752055AHigh thickening efficiencyReduce dosageInksMacromolecular adhesive additivesChemical synthesisPolyethylene glycol

The invention discloses a p-nitrocinnamic acid modified rapid reactive associative thickener as well as a preparation method and application thereof. The preparation method comprises the following steps: starting from p-nitrocinnamic acid, sequentially carrying out nucleophilic substitution reaction on p-nitrocinnamic acid and halogenated fatty alcohol to prepare a p-nitrocinnamic acid substituted fatty alcohol end-capping reagent intermediate, and then carrying out esterification reaction on the p-nitrocinnamic acid substituted fatty alcohol end-capping reagent intermediate and 4-pentynoic acid to prepare a p-nitrocinnamic acid end-capping reagent containing terminal alkynyl; hydroxyl-terminated polyethylene glycol is used as an initial polymer, and an azido-terminated precursor polymer is synthesized through a two-step reaction. A click chemical synthesis strategy is used, and p-nitro cinnamic acid groups are efficiently modified to two ends of a hydrophilic polyethylene glycol main chain to obtain the p-nitro modified reactive associative polymer. An aqueous solution (with the concentration of 3 wt%) of the compound is subjected to a photodimerization reaction under the irradiation of 365nm ultraviolet light, and under a 25.8 mw / cm < 2 > light source, the viscosity of the solution is increased by 614 times after the solution is irradiated for 75s compared with that before the solution is irradiated.

Owner:SOUTH CHINA UNIV OF TECH

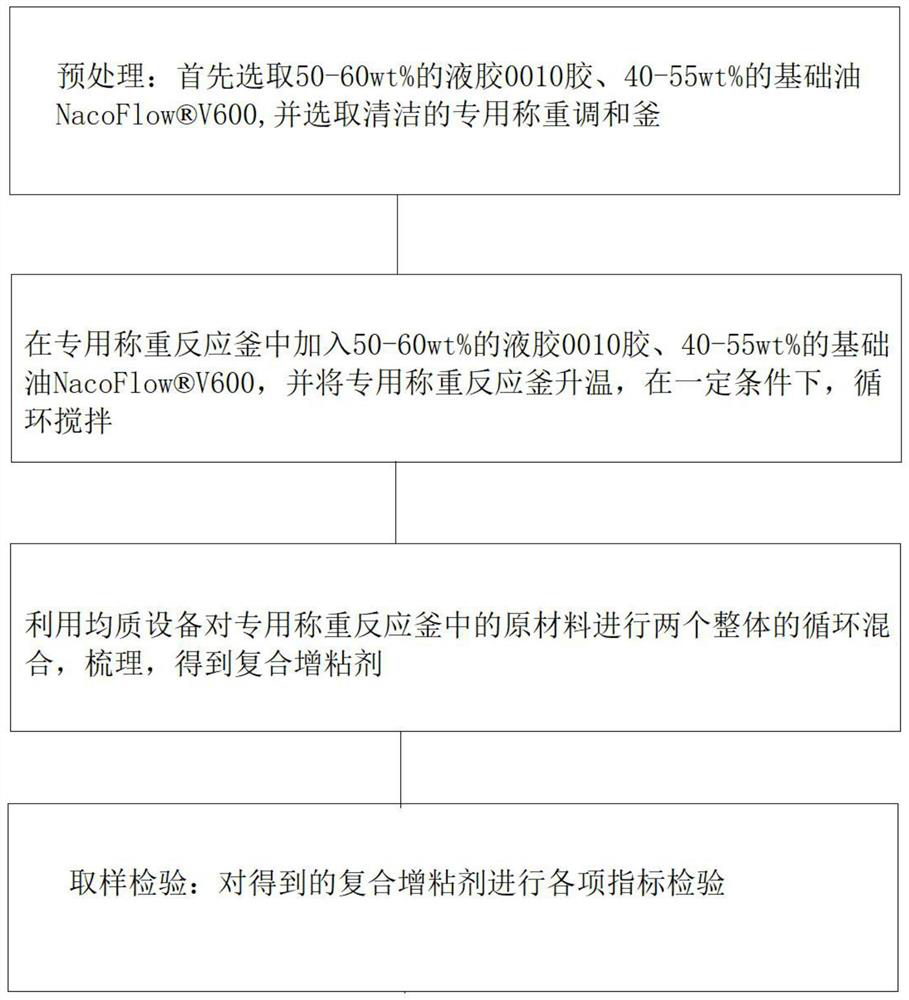

Internal combustion engine oil composite tackifier and preparation method thereof

PendingCN112592751AHigh thickening efficiencyAdd lessAdditivesProcess engineeringEnvironmental geology

The invention provides an internal combustion engine oil composite tackifier and a preparation method thereof. The preparation method comprises the following steps: firstly, selecting 50-60wt% of liquid glue 0010 and 40-55wt% of base oil, and selecting a clean special weighing and blending kettle; adding 50-60 wt% of liquid glue 0010 and 40-55 wt% of base oil into a special weighing reaction kettle, heating the special weighing reaction kettle, and performing circular stirring under a certain condition; carrying out two-whole cyclic mixing and carding on the raw materials in the special weighing reaction kettle by utilizing homogenizing equipment to obtain a composite tackifier; and sampling and inspecting: inspecting various indexes of the obtained composite tackifier. The composite tackifier is especially suitable for blending diesel engine oil with a long mileage of 100,000 km or above, is also especially suitable for product subdivision of gasoline and engine oil according to HTHSdata, has core data SSI of not more than 15, thickening efficiency of 0.8, high thickening efficiency and a small addition amount, reduces a cost, has excellent oxidation resistance, the oil film of an old vehicle can be improved, and the sealing performance of all components is enhanced.

Owner:圣保路石油化工(天津)股份有限公司

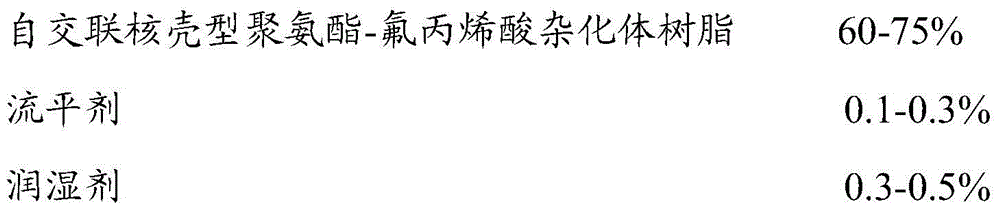

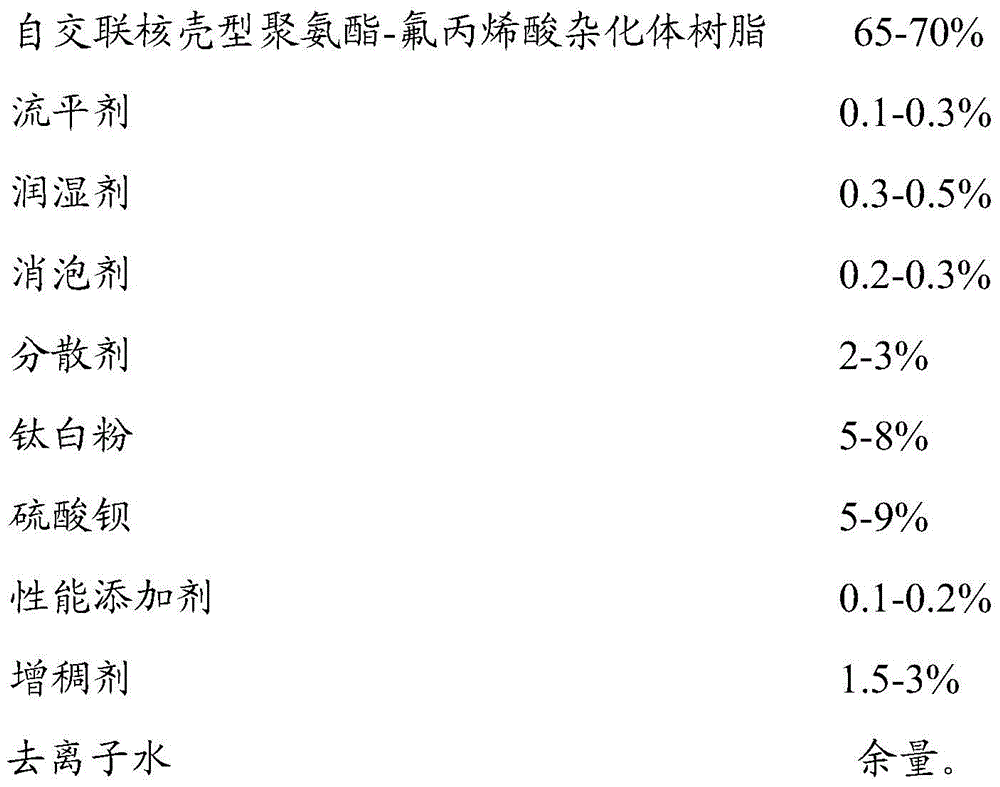

Environmentally friendly high-performance water-based audio paint

InactiveCN104356845BImprove performanceHigh film hardnessCoatingsWater basedEnvironmental resistance

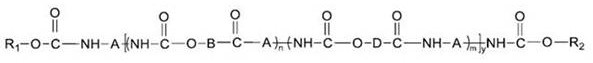

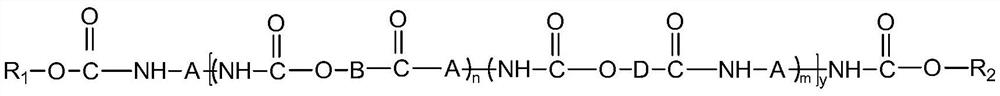

The invention discloses an environment-friendly high-performance water-based paint for sound equipment, which is prepared from the following raw materials in percentage by weight: 60-75% of self-crosslinked core-shell polyurethane-fluorine acrylic acid hybrid resin, 0.1-0.3% of leveling agent, 0.3-0.5% of wetting agent, 0.2-0.3% of defoaming agent, 2-3% of dispersing agent, 5-8% of titanium white, 5-9% of barium sulfate, 0.1-0.2% of performance additive, 1.5-3% of thickener and the balance of deionized water. By compounding the self-crosslinked core-shell polyurethane-fluorine acrylic acid hybrid resin with the thickener, leveling agent, wetting agent and other assistants, the prepared environment-friendly high-performance water-based paint for sound equipment has the comprehensive properties of high hardness, scratch resistance, high fullness, plump and smooth spray points and the like. By using the water as the solvent, the environment-friendly high-performance water-based paint for sound equipment is pollution-free and nontoxic for the environment and human body, is a novel environment-friendly material for coating sound equipment, and can be completely substituted for the existing oil-based paint for sound equipment.

Owner:广州益景春环保材料科技有限公司

A kind of polyurethane polymer suitable for viscosity adjustment of aqueous high solvent system and composition containing the same

ActiveCN109957091BReduce the effect of thickeningHigh thickening efficiencyEndcappingPolymer science

The present invention relates to a polyurethane polymer suitable for viscosity adjustment of an aqueous high solvent system and a composition containing the same. The polyurethane polymer comprises, on the polymer backbone, a hydrophobic structure having a functional group reactive with an isocyanate bond, and one or more monofunctional hydrophobic end-capped structures, the hydrophobic structure having a functional group reactive with an isocyanate bond Comprising 4 carbon atoms to 70 carbon atoms excluding the carbon atoms of the linker, the monofunctional hydrophobic end-capped structure comprises 8 carbon atoms to 30 carbon atoms excluding the carbon atoms of the linker. The present invention introduces a hydrophobic structure of functional groups that can react with isocyanate bonds on the main chain of the polyurethane polymer, and the hydrophobic structure can form a "cage-like" structure on the main chain of the polyurethane polymer, which can effectively interact with the solvent in the system. , reduce the influence of solvent on system thickening, especially in high solvent system, it has high thickening efficiency.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD +2

Polyurethane thickening agent with dispersing function as well as preparation method and application thereof

The invention discloses a polyurethane type thickening agent with a dispersing function and a preparation method thereof, a polymer main chain of the thickening agent simultaneously contains a polyurethane structure and an acrylate structure, and the main chain also contains one or more monofunctional hydrophobic end-capping structures. A synthesized polyacrylate polymer and a synthesized isocyanate group-terminated macromolecular chain segment polymer are used, a polyhydroxy compound is added, and a polymerization reaction is performed. The thickening agent shows higher system matching property and compatibility, meanwhile, the thickening efficiency is relatively high, and the use of a dispersing agent can be reduced.

Owner:WANHUA CHEM GRP CO LTD

A method and system for thickening the whole tailings slurry paste

InactiveCN104829150BHigh thickening efficiencyAchieve a thickening effectSolid waste managementSedimentation settling tanksCyclonePrill

The invention discloses a thickening method and a thickening system of whole tailing material slurry paste, wherein the thickening method includes following steps: (1) feeding whole tailing material slurry into a cyclone machine to separate the whole tailing material slurry into crude granular mortar and fine granular mortar, wherein the crude granular mortar, at a bottom flow, is fed into a vibrating sieve while the fine granular mortar, at an over flow, is fed into a thickener; (2) in the vibrating sieve, vibrating the fine granular mortar to sieve the fine granular mortar and feeding the fine granular mortar into the thickener, wherein crude granules are discharged into a sand bin; (3) feeding an over flow in the cyclone machine into the thickener and feeding the bottom flow in the thickener into the sand bin; and (4) in the sand bin, mixing the crude granular mortar and the fine granular mortar to obtain the paste. The thickening system is composed of the cyclone machine, the vibrating sieve, the sand bin and the thickener, wherein a material slurry pipe is connected to input of the cyclone machine. Outputs of the cyclone machine include two groups, one is connected to the vibrating sieve and the other is connected to the thickener. The outputs of the vibrating sieve include two groups, one is connected to the thickener, and the other is connected to the tail sand bin. The output of the thickener is connected to the sand bin. In the invention, the tailing material slurry is separated into crude granular mortar and fine granular mortar and then is thickened, so that thickening concentration can reach 70-82%, which is higher than that of a deep-cone thickener and a sand bin by 2-5%. The tailing utilization rate is higher than 95%.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com