P-nitrocinnamic acid modified rapid-reactivity associated thickener as well as preparation method and application thereof

A technology of p-nitrocinnamic acid and associative thickener, which is applied in the field of UV fast-responsive associative thickener and its preparation, can solve the problems of inconspicuous lifting, insufficient distance and photoreactivity, and achieve application Wide range, improved thickening efficiency, and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A preparation method of a fast-reactive associative thickener modified with p-nitrocinnamic acid, comprising the following steps:

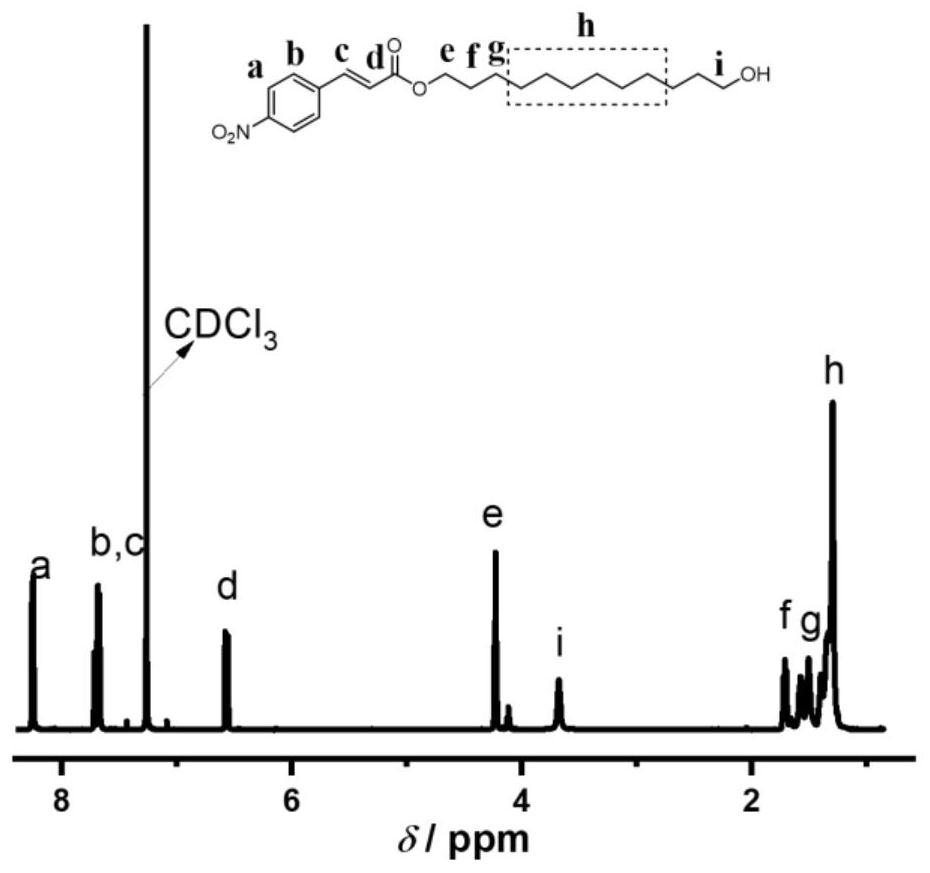

[0044] (1) 0.50g (3.40mmol) of p-nitrocinnamic acid, 1.35g (5.10mmol) of 12-bromo-1-dodecanol, 0.82g (7.65mmol) of anhydrous sodium carbonate were dissolved in 10ml of 2- Butanone was added to a 50ml high vacuum thick-walled reaction flask. After blowing out the air in the bottle with nitrogen, the reaction was performed by heating to 85° C. in an oil bath under a nitrogen atmosphere for 15 hours. The reaction end point was confirmed by thin layer chromatography (TLC), the solvent in the reaction flask was removed under reduced pressure, extracted with dichloromethane and saturated brine, and concentrated. The concentrated liquid was dried to obtain a white paste-like solid, which was n-dodecanol p-nitrocinnamic acid, and the yield was 91%.

[0045] The obtained n-dodecanol p-nitrocinnamate is dissolved in CDCl 3 The 1H NMR spectrum data...

Embodiment 2

[0067] A preparation method of a fast-reactive associative thickener modified with p-nitrocinnamic acid, comprising the following steps:

[0068] (1) 0.50g (3.40mmol) of p-nitrocinnamic acid, 0.93g (5.10mmol) of 6-bromo-1-hexanol, 1.06g (7.65mmol) of anhydrous potassium carbonate were dissolved in 10ml of acetone solvent , added to a 50ml high-vacuum thick-walled reaction flask. After blowing out the air in the bottle with nitrogen, the reaction was performed by heating to 80° C. in an oil bath under a nitrogen atmosphere for 17 hours. The reaction end point was determined by thin layer chromatography, the solvent in the reaction flask was removed under reduced pressure, extracted with dichloromethane and saturated brine, and concentrated. The concentrated liquid was dried to obtain a white paste-like solid, which was n-hexanol p-nitrocinnamic acid, and the yield was 93%.

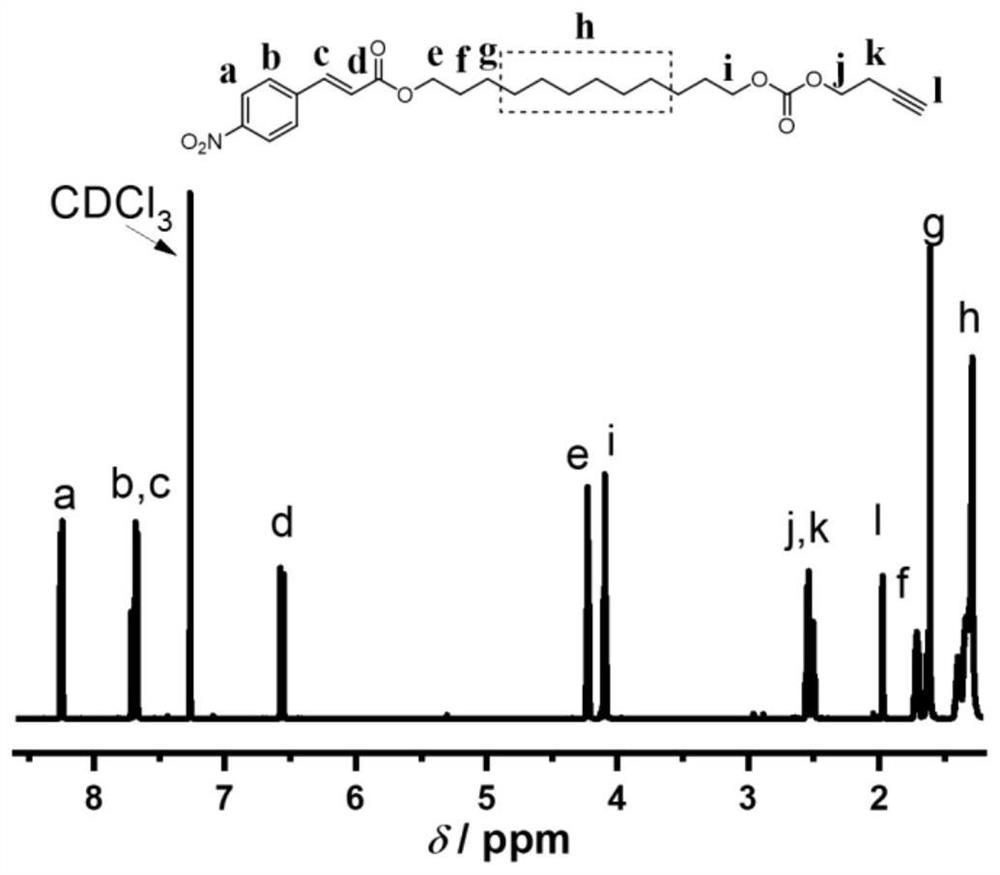

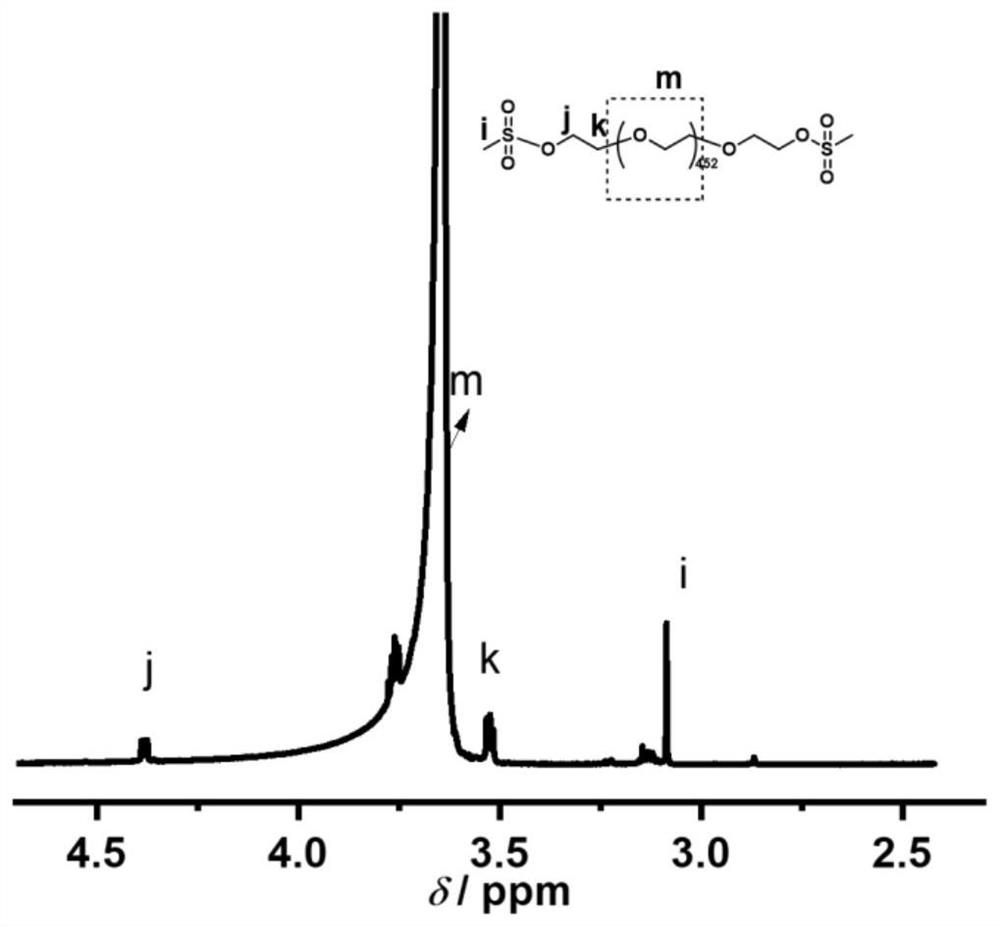

[0069] (2) 7.36g (2.51mmol) of n-hexanol p-nitrocinnamate, 0.36g (3.70mmol) of 4-pentynoic acid, 0.062...

Embodiment 3

[0085] A preparation method of a fast-reactive associative thickener modified with p-nitrocinnamic acid, comprising the following steps:

[0086](1) 0.78g (4.00mmol) of p-nitrocinnamic acid, 1.60g (6.00mmol) of 12-bromo-1-dodecanol, 1.31g (8.5mmol) of anhydrous potassium carbonate were dissolved in 15ml of N, N-dimethylformamide solvent was added to a 50ml high vacuum thick-walled reaction flask. Under an argon atmosphere, the oil bath was heated to 75 °C for 18 h. The reaction end point was determined by thin layer chromatography, the solvent in the reaction flask was removed under reduced pressure, extracted with dichloromethane and saturated brine, and concentrated. The concentrated liquid was dried to obtain a white paste-like solid, which was n-dodecanol p-nitrocinnamic acid, and the yield was 93%.

[0087] (2) 0.90g (2.38mmol) of n-dodecanol p-nitrocinnamic acid, 0.37g (3.80) of 4-pentynoic acid, 0.065g (0.54mmol) of DMAP and 15ml of anhydrous tetrahydrofuran were adde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com