A kind of polyurethane polymer suitable for viscosity adjustment of aqueous high solvent system and composition containing the same

A polyurethane polymer, hydrophobic technology, applied in the field of polyurethane polymer preparation, can solve the problems of low thickening efficiency, inability to thicken viscosity, large addition amount, etc., and achieve the effect of high thickening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

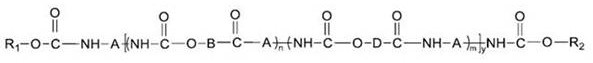

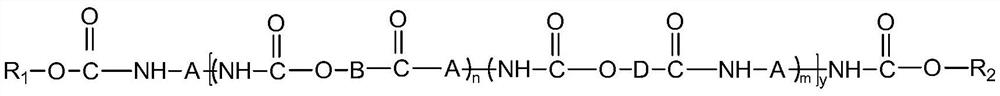

Method used

Image

Examples

Embodiment 1

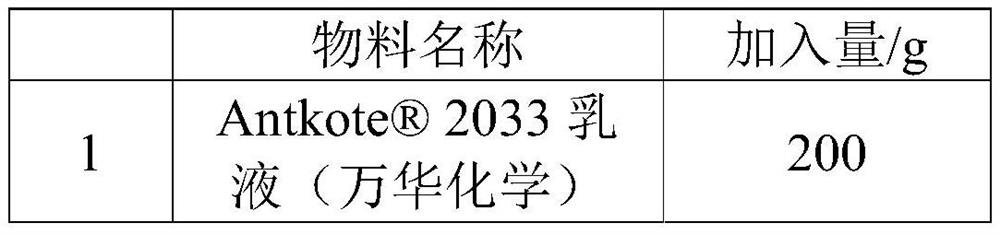

[0066] A kind of viscosity adjusting composition, its synthetic formula is composed such as table 1:

[0067] Table 1

[0068] raw material mass / g PEG6000 100 Di(5-hydroxy-lauric acid) glycol ester 3.56 BICAT8018 0.05 HMDI 13.5 octadecanol 4.55 Diethylene glycol monobutyl ether 81.1 water 202.8

[0069] The steps of the viscosity-adjusting composition synthesized by this formula are as follows:

[0070] 1) 100g of polyethylene glycol 6000 (PEG6000) was added to a 500ml there-necked flask equipped with electromagnetic stirring and a nitrogen inlet, and the negative pressure (pressure less than 100Pa) was dewatered at 110°C for 2 hours;

[0071] 2) Cool down to 80°C, feed nitrogen into the three-necked flask to relieve pressure, add 3.56g of bis(5-hydroxy-lauric acid) ethylene glycol ester to the three-necked flask, and switch to mechanical stirring until stirring is uniform;

[0072] 3) under nitrogen protection, add 0...

Embodiment 2

[0075] A kind of viscosity adjusting composition, its synthetic formula is composed such as table 2:

[0076] Table 2

[0077] raw material mass / g PEG6000 100 Di(5-hydroxy-lauric acid) glycol ester 3.56 BICAT8018 0.05 HDI 8.4 octadecanol 4.55 Diethylene glycol monobutyl ether 77.7 water 194.3

[0078] The synthesis steps of Example 2 are similar to those of Example 1, and will not be repeated here. The viscosity adjusting composition C2 obtained according to this formula is obtained.

Embodiment 3

[0080] A kind of viscosity adjusting composition, its synthetic formula is composed such as table 3:

[0081] table 3

[0082] raw material mass / g PEG6000 100 Di(5-hydroxy-lauric acid) glycol ester 3.56 BICAT8018 0.05 HMDI 13.5 hexacosanol 6.38 Diethylene glycol monobutyl ether 82.3 water 205.8

[0083] The synthesis steps of Example 3 are similar to those of Example 1, and will not be repeated here. The viscosity-adjusting composition C3 is obtained according to this formula.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com