Polyurethane polymer suitable for viscosity adjustment of waterborne high solvent system and composition containing same

A polyurethane polymer and hydrophobic technology, applied in the field of polyurethane polymer preparation, can solve the problems of large addition, inability to thicken viscosity, low thickening efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

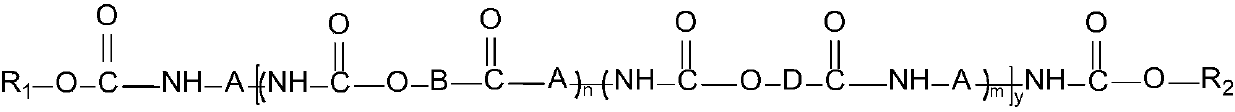

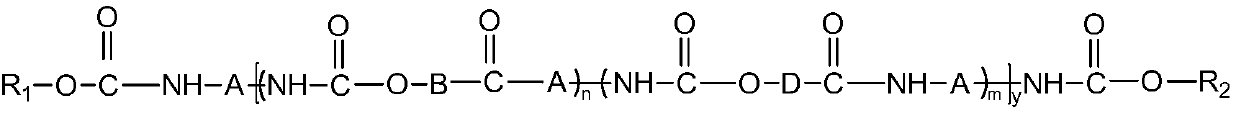

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

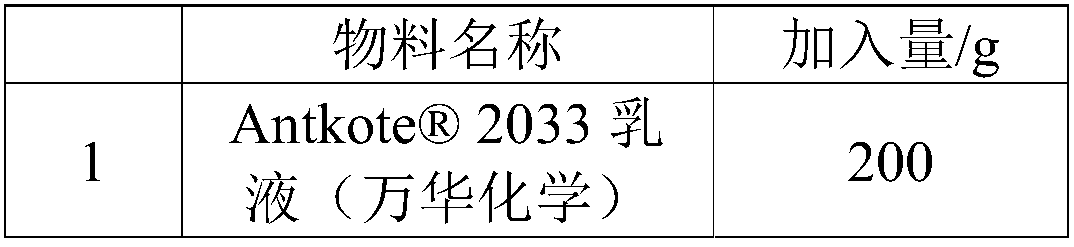

[0066] A kind of viscosity adjusting composition, its synthetic formula is composed as table 1:

[0067] Table 1

[0068] raw material Mass / g PEG6000 100 Ethylene glycol bis(5-hydroxy-laurate) 3.56 BICAT8018 0.05 HMDI 13.5 stearyl alcohol 4.55 Diethylene glycol monobutyl ether 81.1 water 202.8

[0069] Its steps of the viscosity adjusting composition that adopts this prescription synthesis are as follows:

[0070] 1) Add 100g of polyethylene glycol 6000 (PEG6000) into a 500ml three-necked flask equipped with electromagnetic stirring and nitrogen inlet, and remove water at 110°C for 2 hours under negative pressure (pressure less than 100Pa);

[0071] 2) Cool down to 80°C, pass nitrogen gas into the three-necked flask to release the pressure, add 3.56g of bis(5-hydroxy-lauric acid)ethylene glycol ester into the three-necked flask, and use mechanical stirring instead until the stirring is uniform;

[0072] 3) Under nitro...

Embodiment 2

[0075] A kind of viscosity adjusting composition, its synthetic formula is composed as table 2:

[0076] Table 2

[0077] raw material Mass / g PEG6000 100 Ethylene glycol bis(5-hydroxy-laurate) 3.56 BICAT8018 0.05 HDI 8.4 stearyl alcohol 4.55 Diethylene glycol monobutyl ether 77.7 water 194.3

[0078] The synthesis steps of Example 2 are similar to those of Example 1, and will not be repeated here. The viscosity-adjusting composition C2 is obtained according to this formula.

Embodiment 3

[0080] A kind of viscosity adjusting composition, its synthetic formulation is composed as table 3:

[0081] table 3

[0082] raw material Mass / g PEG6000 100 Ethylene glycol bis(5-hydroxy-laurate) 3.56 BICAT8018 0.05 HMDI 13.5 Hexacyl alcohol 6.38 Diethylene glycol monobutyl ether 82.3 water 205.8

[0083] The synthesis steps of Example 3 are similar to those of Example 1, and will not be repeated here. The viscosity-adjusting composition C3 is obtained according to this formula.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com