Patents

Literature

139 results about "Composition C" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Composition C family is a family of related US-specified plastic explosives consisting primarily of RDX. All can be moulded by hand for use in demolition work and packed by hand into shaped charge devices. Variants have different proportions and plasticisers and include composition C-2, composition C-3, and composition C-4.

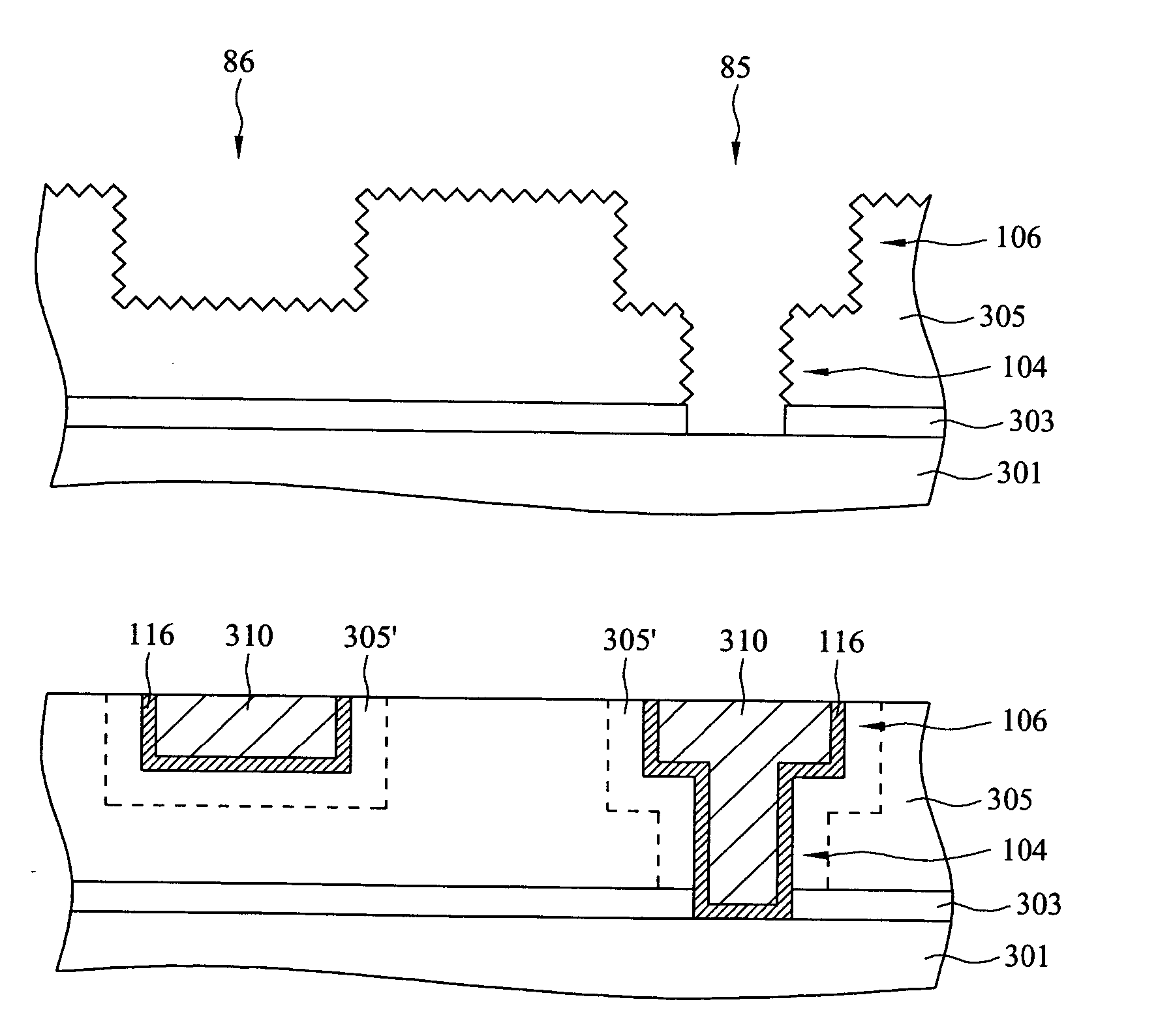

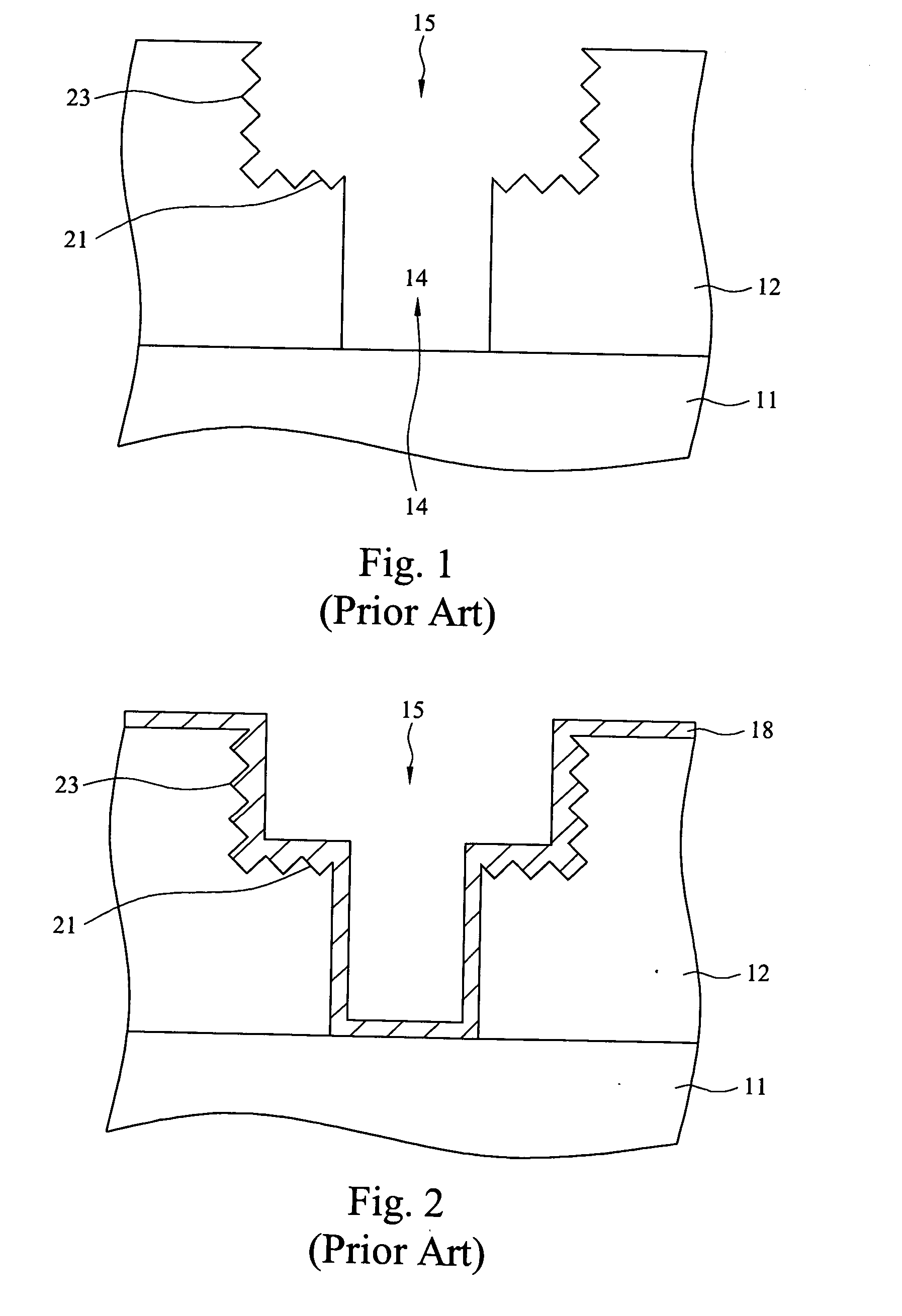

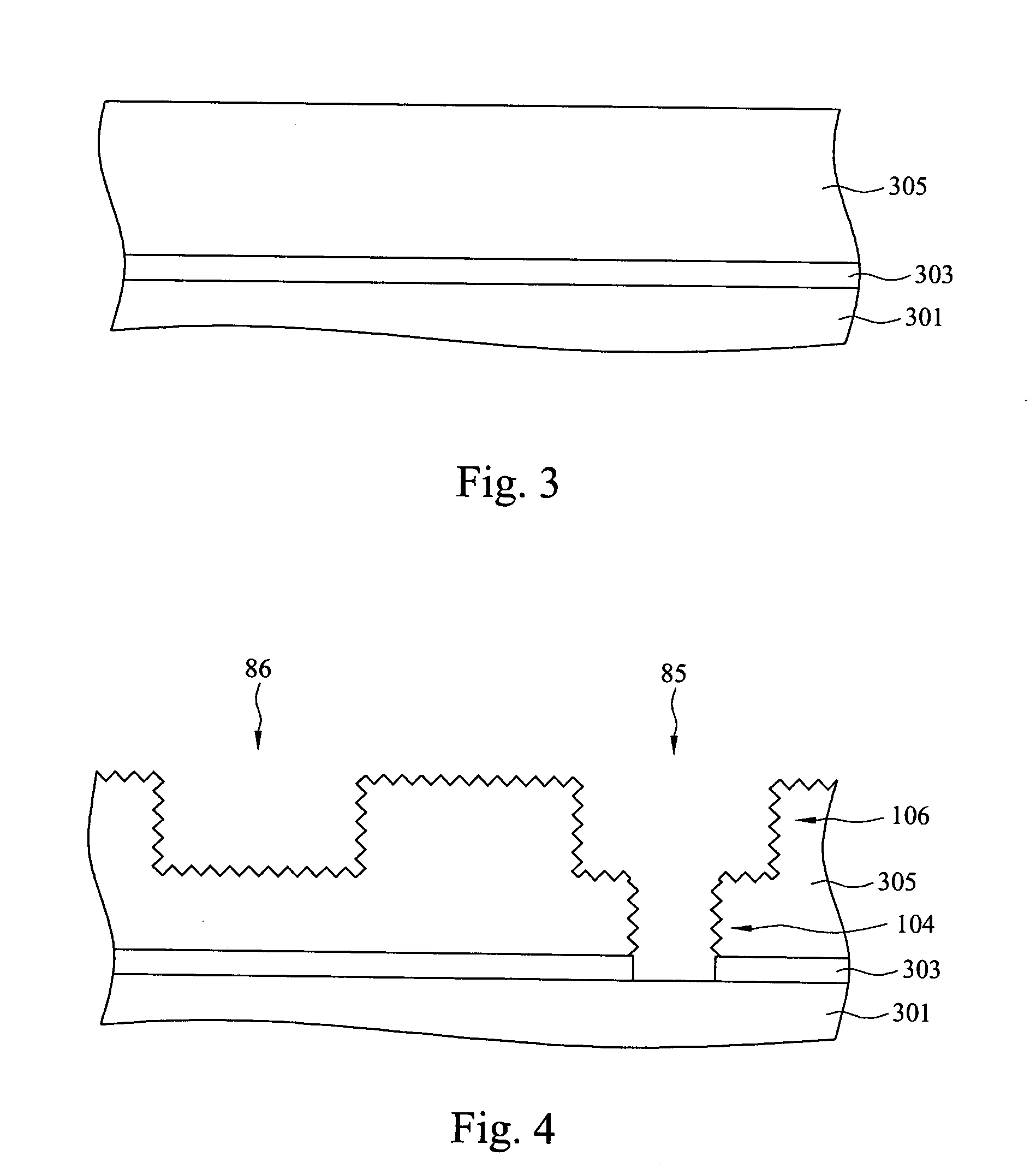

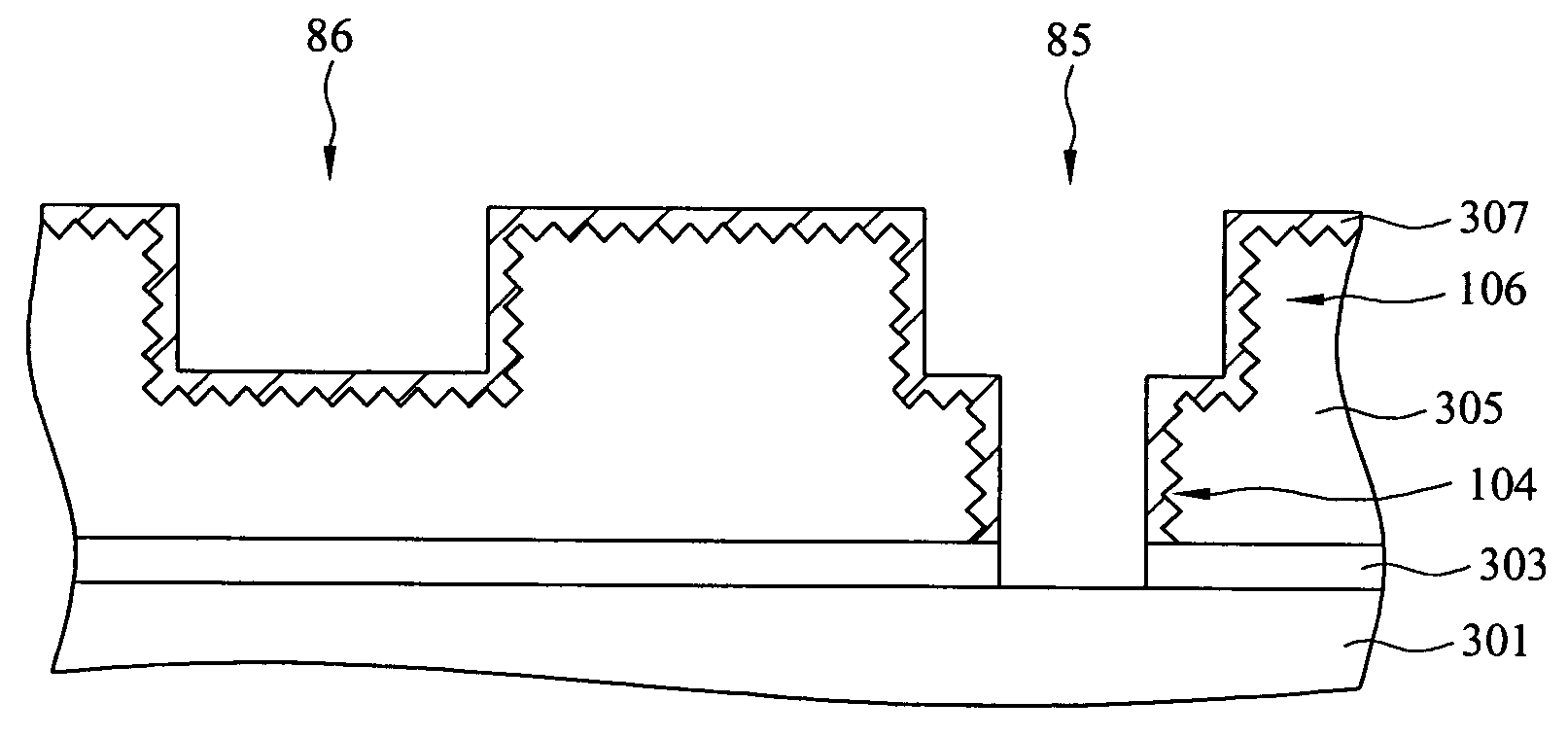

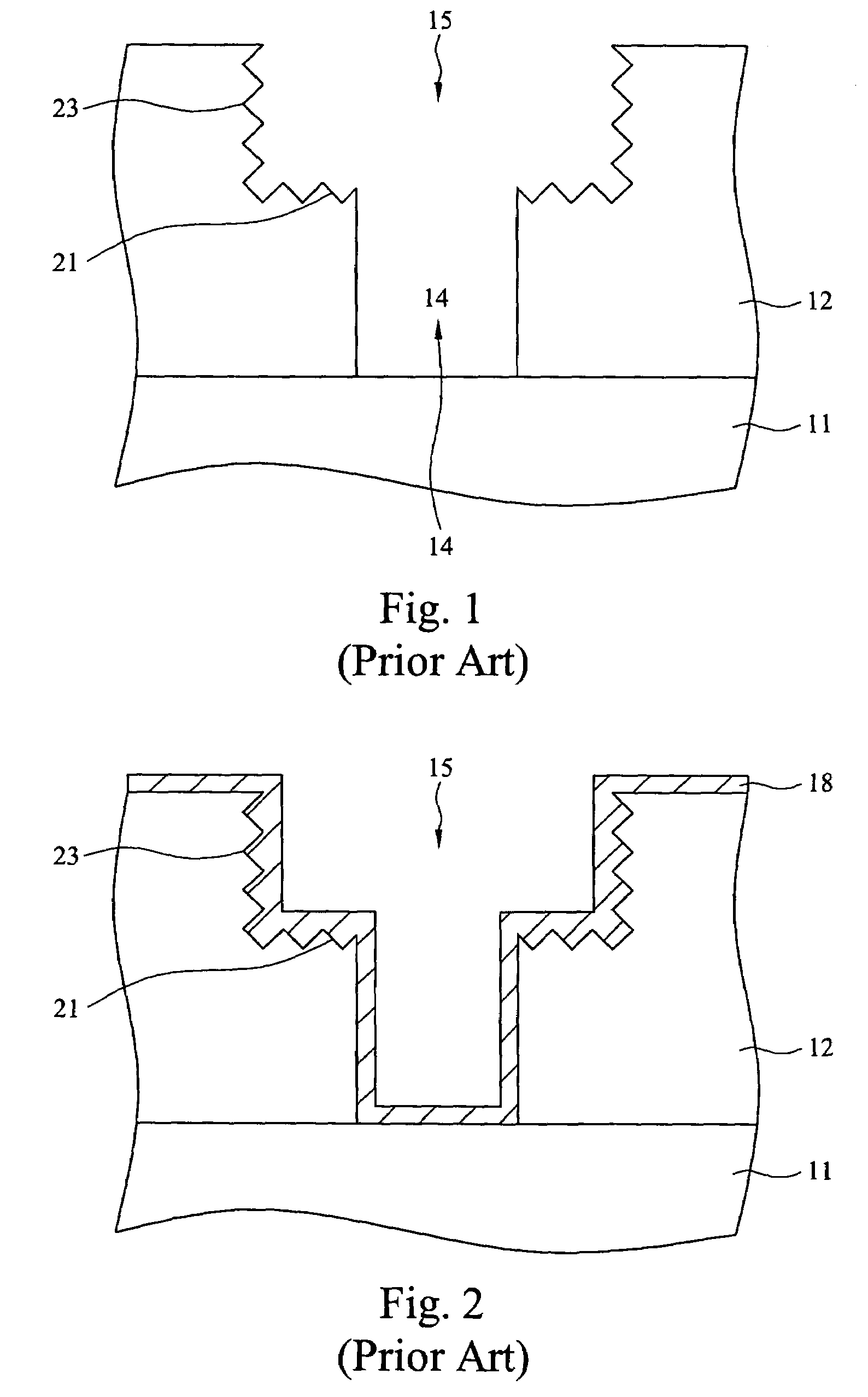

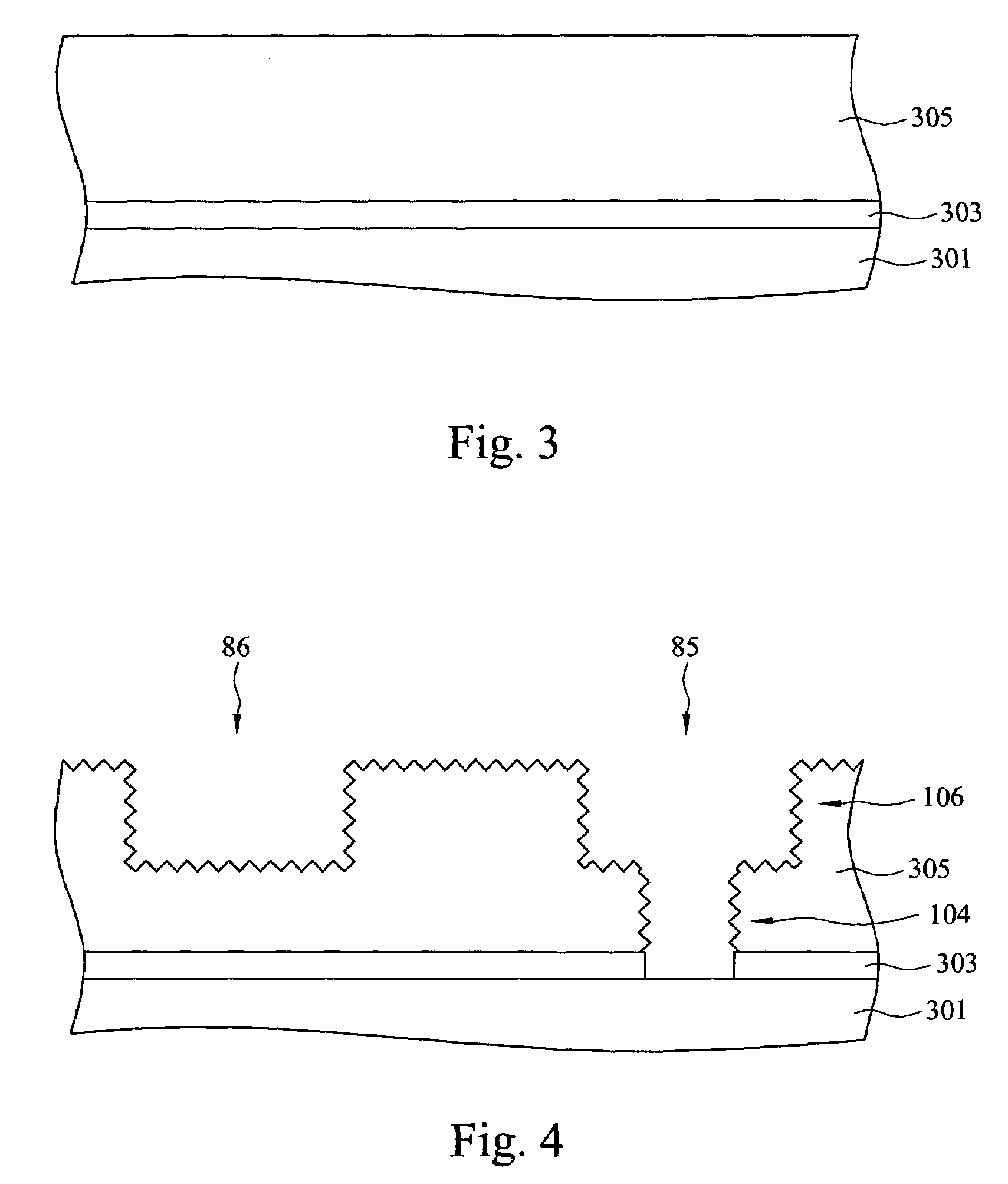

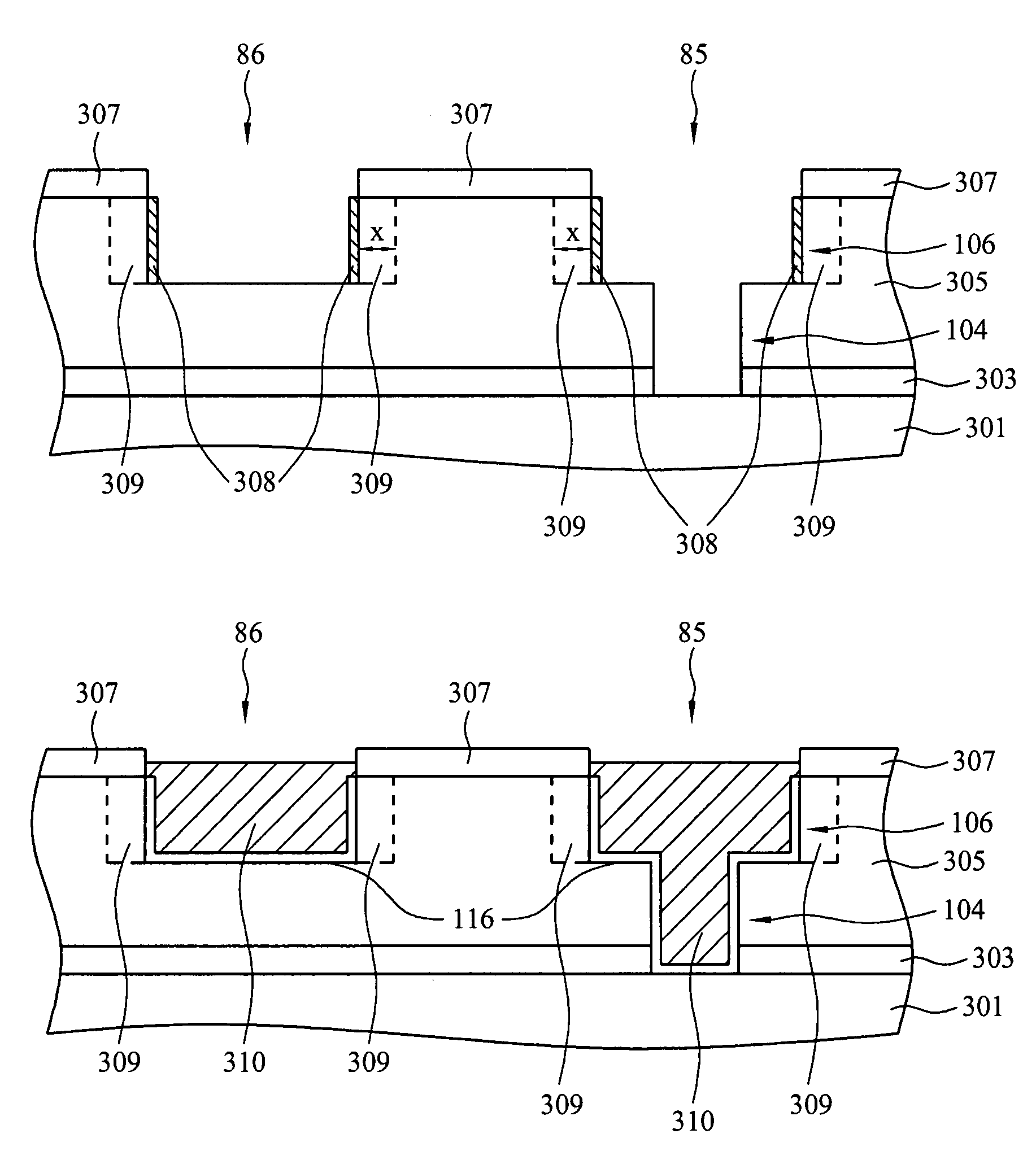

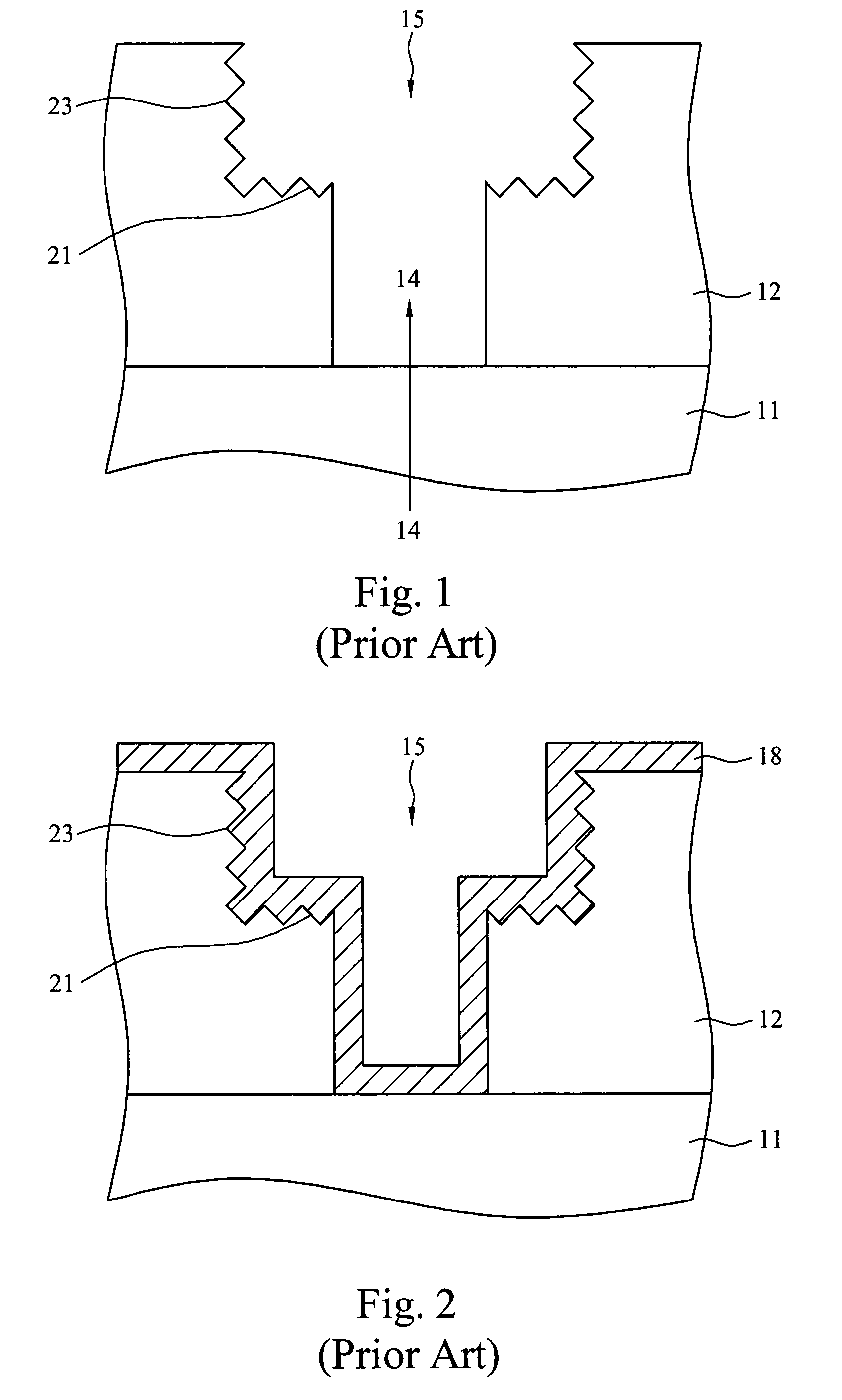

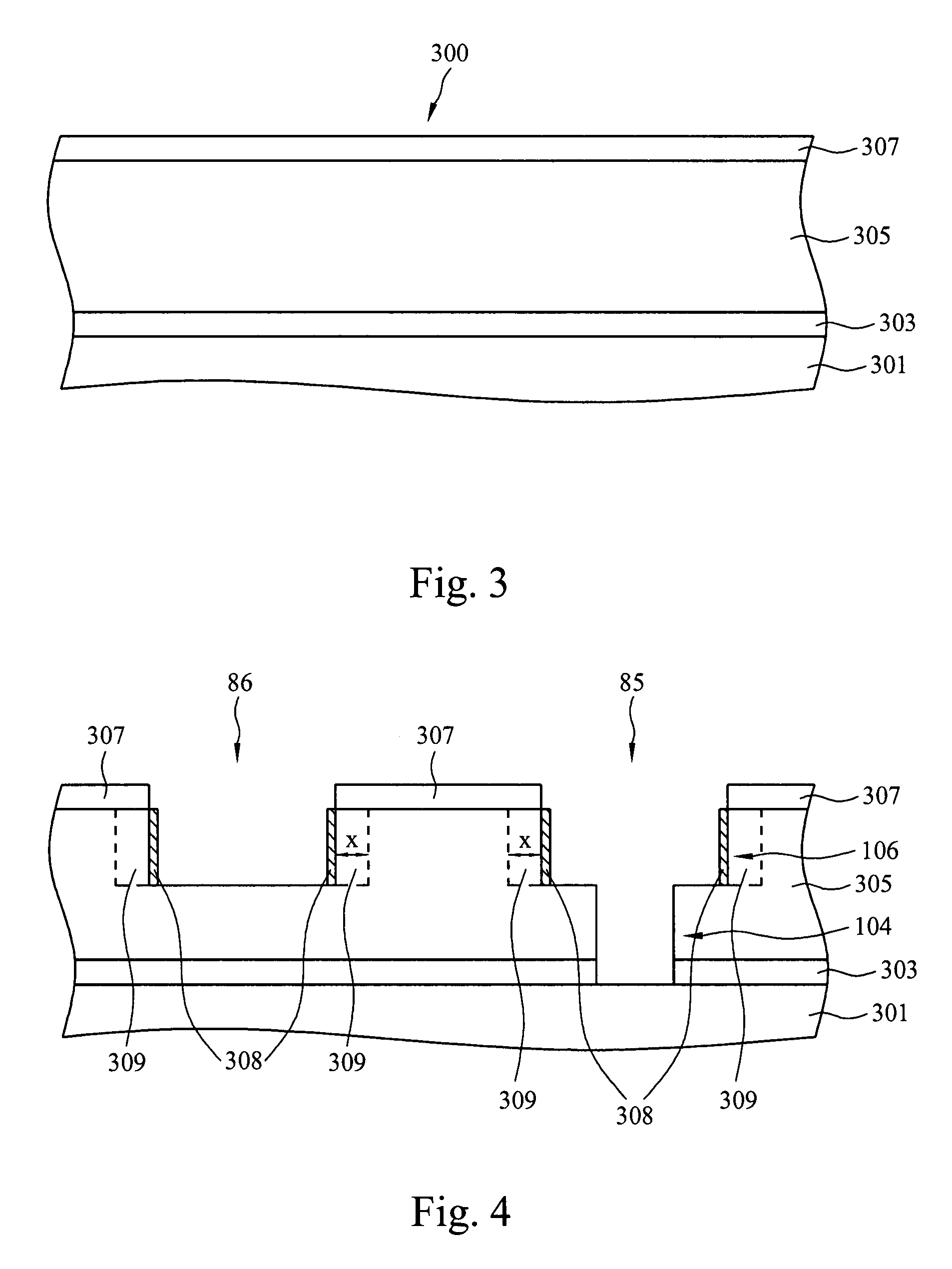

Sealing pores of low-k dielectrics using CxHy

A semiconductor method of manufacturing involving porous and / or carbon containing, low-k dielectrics is provided. The method includes forming a hydrocarbon of the general composition CxHy on the surface of the low-k dielectric. The hydrocarbon layer includes depositing a precursor material, preferably C2H4 or (CH3)2CHC6H6CH3. In accordance with embodiments of this invention, carbon diffuses into the low-k dielectric, thereby reducing carbon depletion damage caused by plasma processing or etching. Surface dielectric pores damaged by plasma processing are also repaired by sealing them with the CXHY layer. Embodiments include semiconductor devices, such as devices having damascene interconnect structures, manufacturing using methods provided.

Owner:TAIWAN SEMICON MFG CO LTD

Sealing pores of low-k dielectrics using CxHy

A semiconductor method of manufacturing involving porous and / or carbon containing, low-k dielectrics is provided. The method includes forming a hydrocarbon of the general composition CxHy on the surface of the low-k dielectric. The hydrocarbon layer includes depositing a precursor material, preferably C2H4 or (CH3)2CHC6H6CH3. In accordance with embodiments of this invention, carbon diffuses into the low-k dielectric, thereby reducing carbon depletion damage caused by plasma processing or etching. Surface dielectric pores damaged by plasma processing are also repaired by sealing them with the CxHy layer. Embodiments include semiconductor devices, such as devices having damascene interconnect structures, manufacturing using methods provided.

Owner:TAIWAN SEMICON MFG CO LTD

Plasticiser compositions

C9 to C11 alkyl benzoates are used as plasticisers for polyvinyl chloride in particular in combination with plasticisers such as di-2-ethyl hexyl phthalate, diisononyl phthalate, di-2-propyl heptyl phthalate, diisodecyl phthalate or di-2-ethyl hexyl terephthalate. The use of the C9 to C11 alkyl benzoates provides low viscosity low volatility plasticisers, which are fast fusing with lower hot bench gelation temperature and which can be used to reduce the staining problems associated with use of di-2-ethyl hexyl phthalate and diisononyl phthalate. The low viscosity of the C9 to C11 alkyl benzoates allows the formulation of solvent free flexible PVC formulations meeting stringent VOC limitations.

Owner:EXXONMOBIL CHEMICAL CO INC

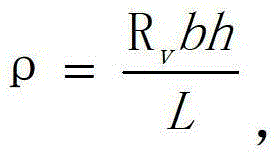

Conductive plastic and preparation method thereof

The invention provides a conductive plastic and a preparation method thereof. The conductive plastic comprises the following blended compositions: a, thermoplastic resin; b, rubber particle with a crosslinking structure; c, a conductive filter; and d, a low-melting-point metal. The gel content of the composition b is 60% by weight or more, and the average particle size of the composition b is 0.02-1 mu m; the composition c is not fused at a thermoplastic-resin processing temperature; the composition d is at least one of a single-composition metal or metal alloy, the melting point of the composition d is 20-480 DEG C and is lower than the thermoplastic-resin processing temperature; and the weight ratio of the composition b to the composition a is 0.1:99.9-30:70. The conductive plastic is low in filling content of the conductive filler and the metal, is relatively low in conductive performance, can be prepared by using a common melt blending method, and can be used to prepare antistatic electromagnetic-wave-interference-resisting electron production equipment and tools with dust-free requirements, and electronic apparatuses, instrument housings and decoration materials of dust-free production workshops.

Owner:CHINA PETROLEUM & CHEM CORP +1

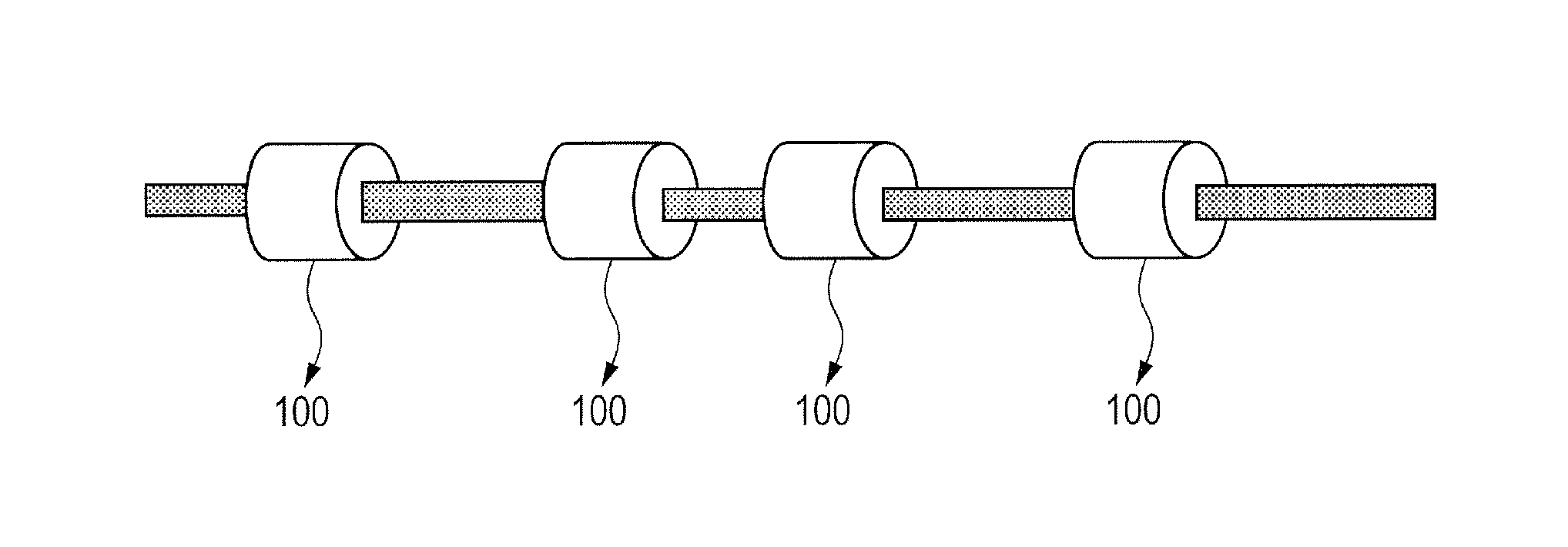

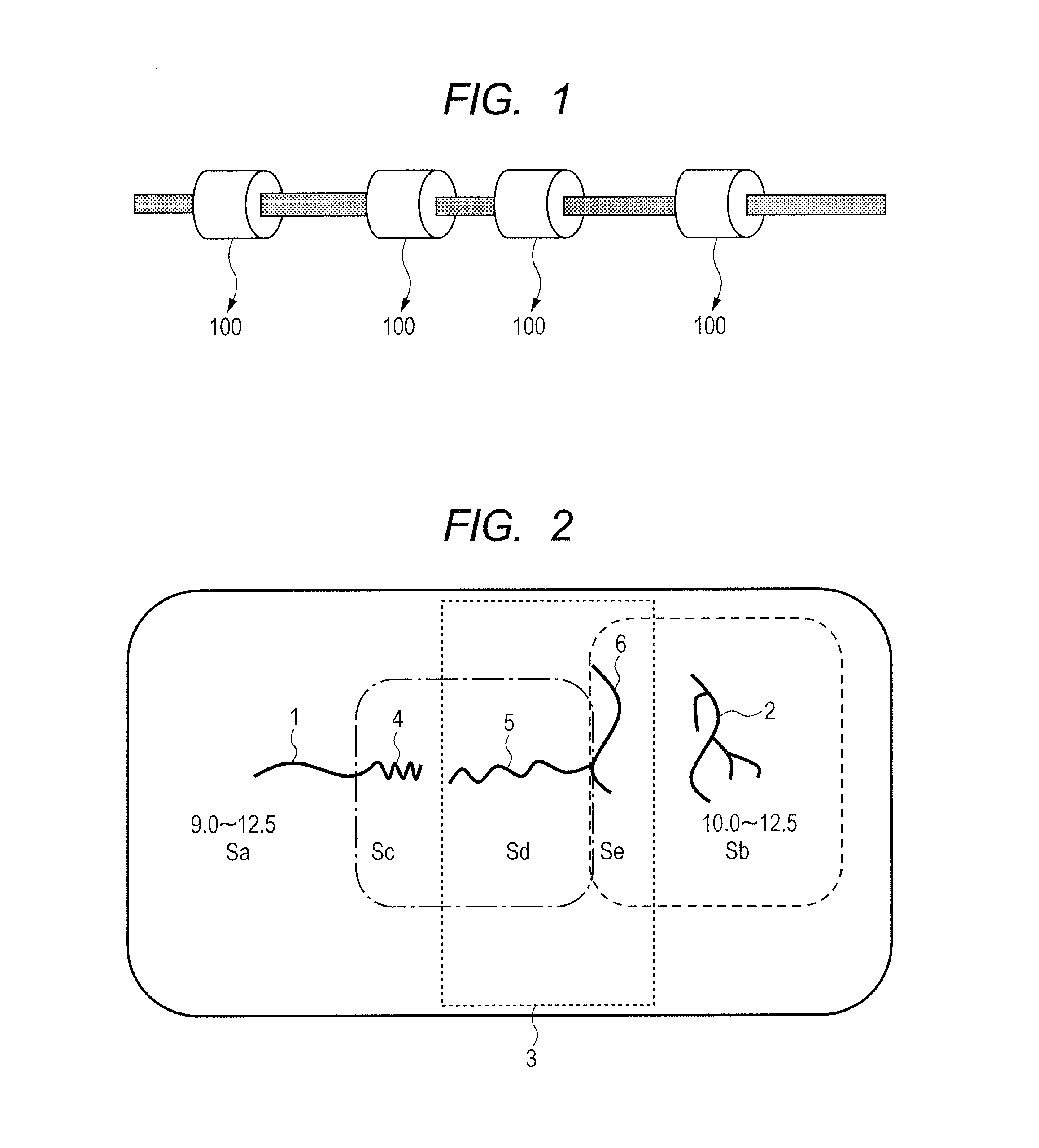

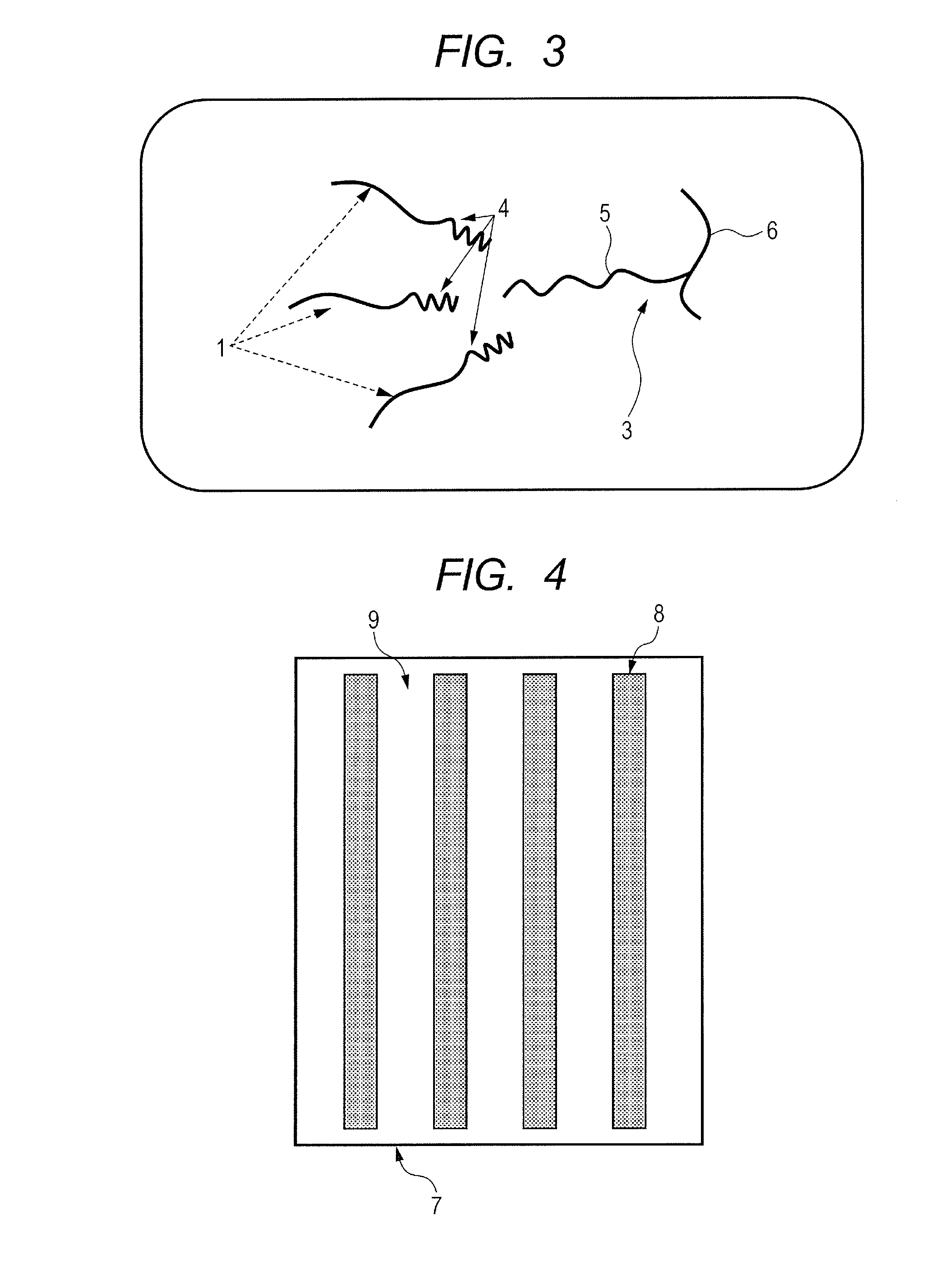

Toner

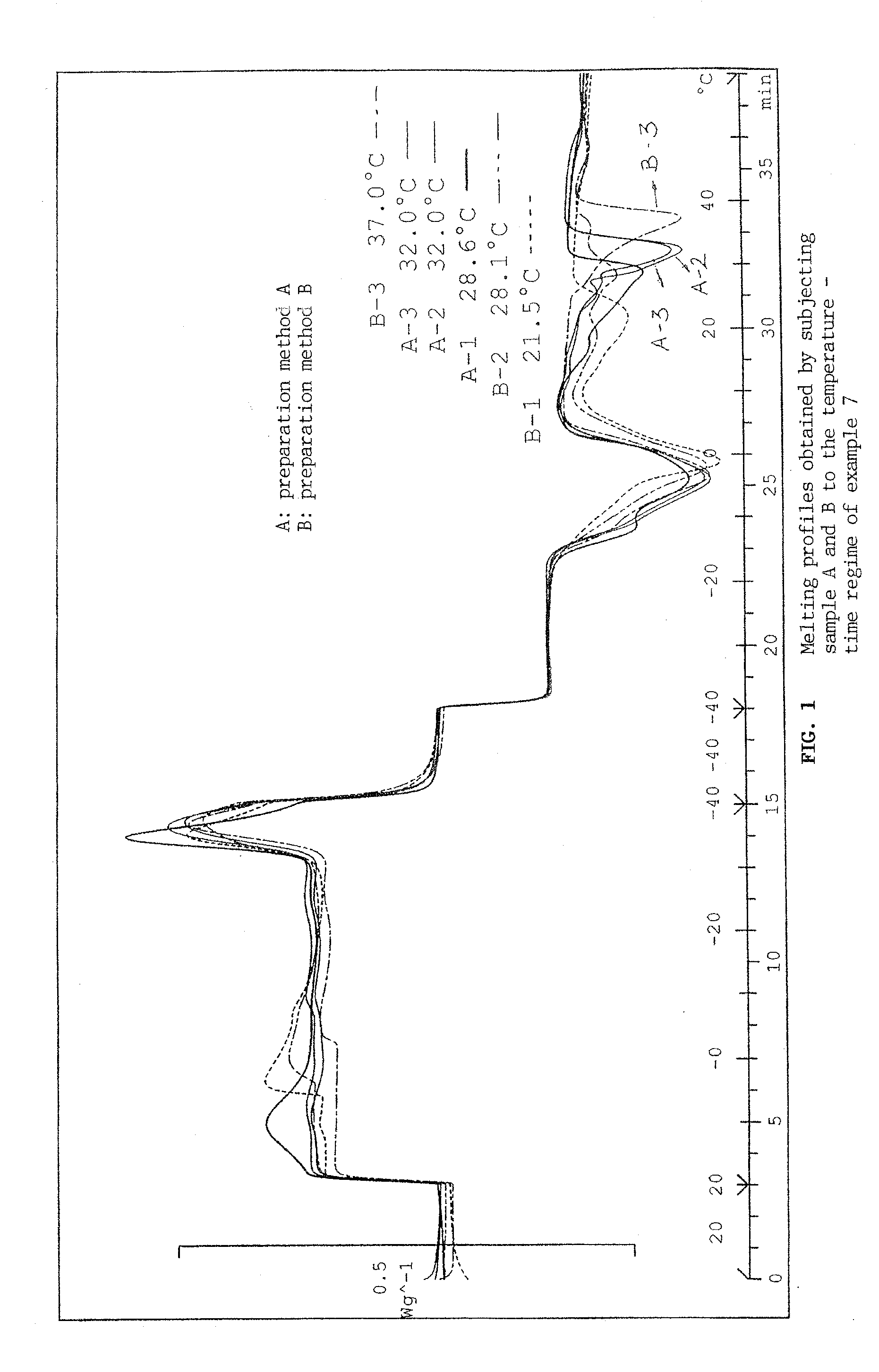

Provided is a toner exhibiting satisfactory fixability even in high-speed fixing process involving a double-sided printing mechanism, keeping stable toner image even after a conveyance step, and doesn't cause curling to a fixing roller even in thin paper. In a toner including toner particles, each of which contains polyester resins A and B, a coloring agent, and a resin composition C, the resin A includes a crystal nucleating agent bonded to a polyester molecular chain including a moiety capable of forming a crystalline structure. The resin B doesn't include a moiety capable of forming a crystalline structure. The composition C is obtained by copolymerizing a vinyl-based resin component with a polyolefin resin component. SP values the resin A, the resin B, the agent, the polyolefin component, and the vinyl-based component satisfy the particular relationships.

Owner:CANON KK

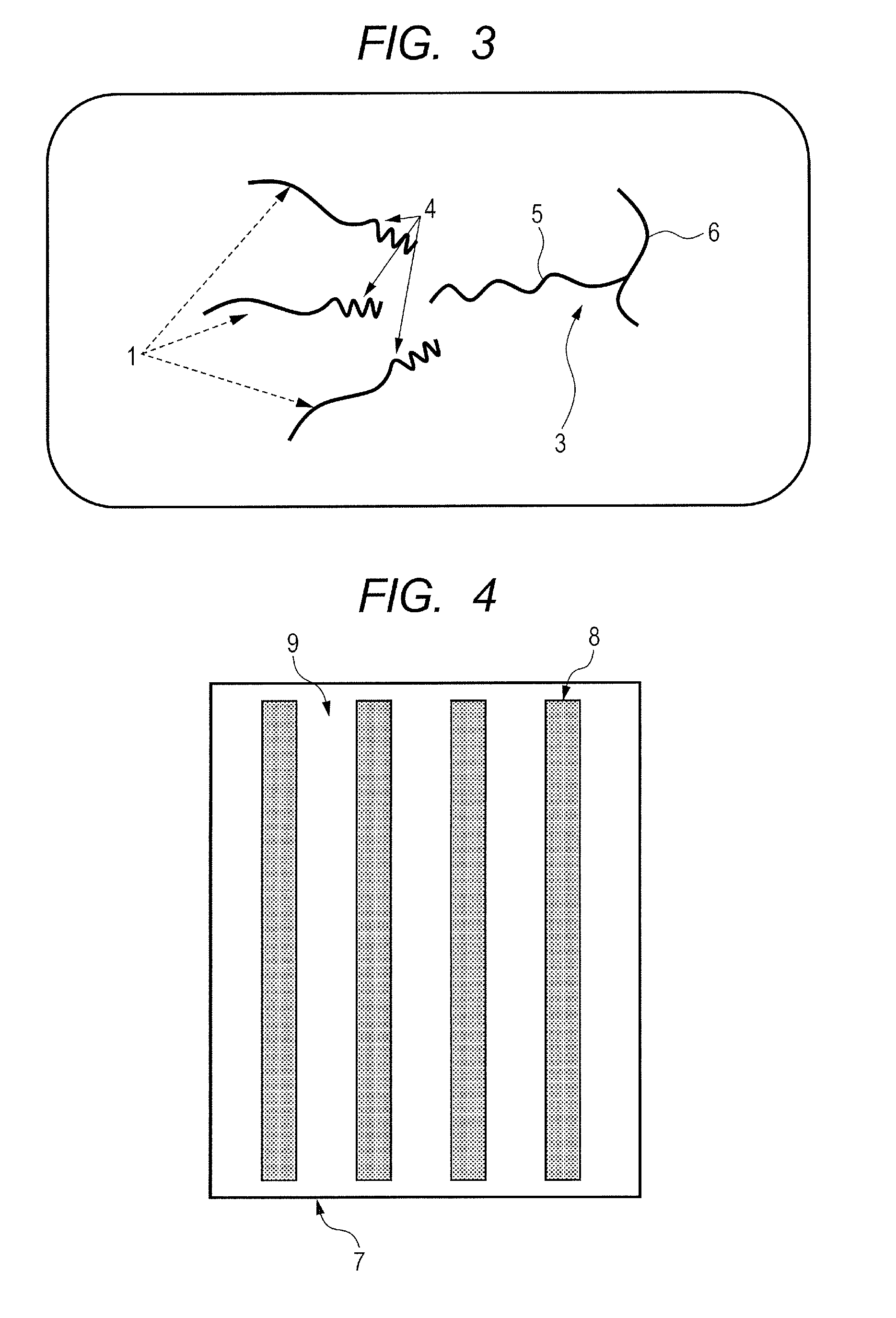

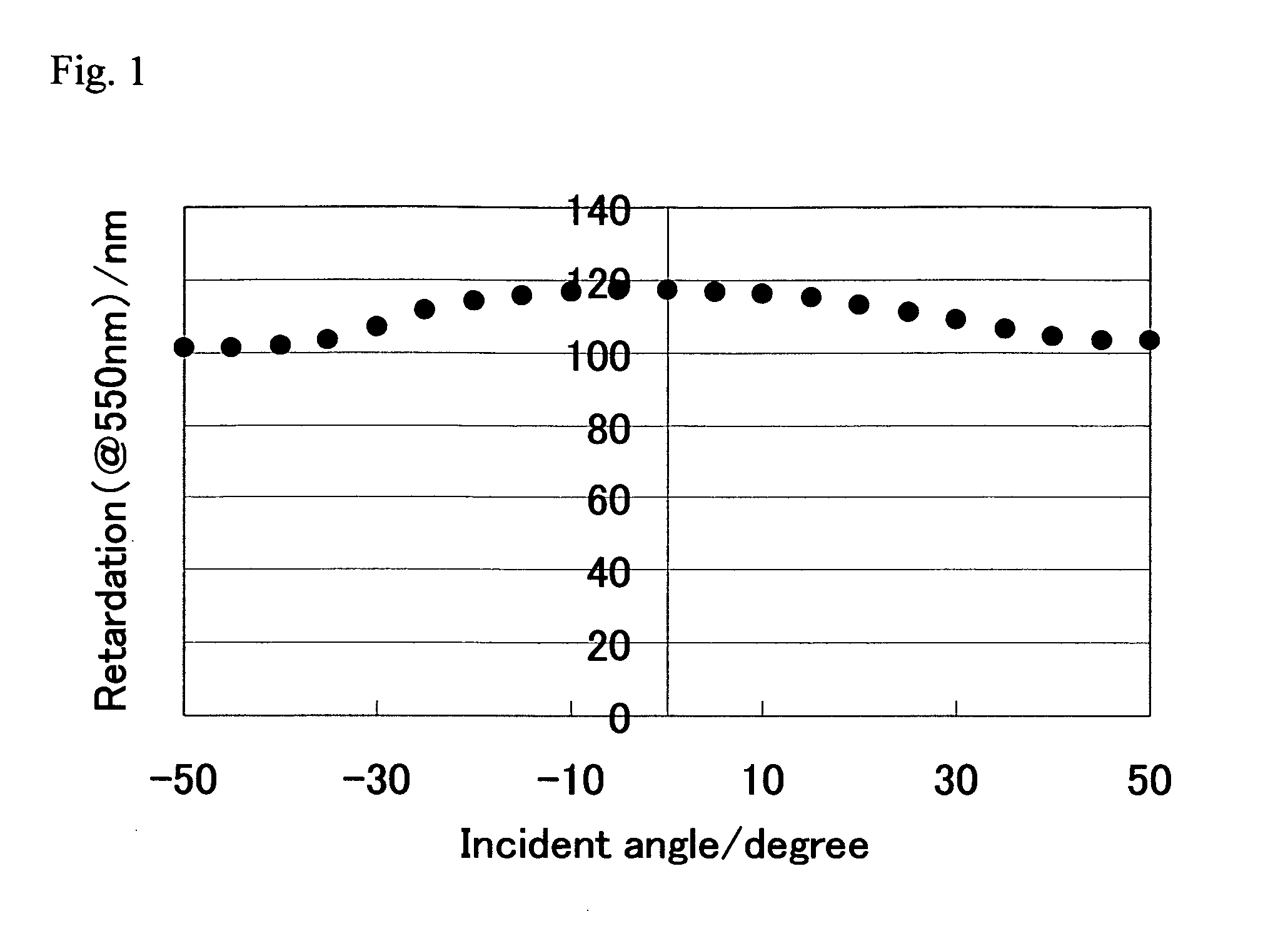

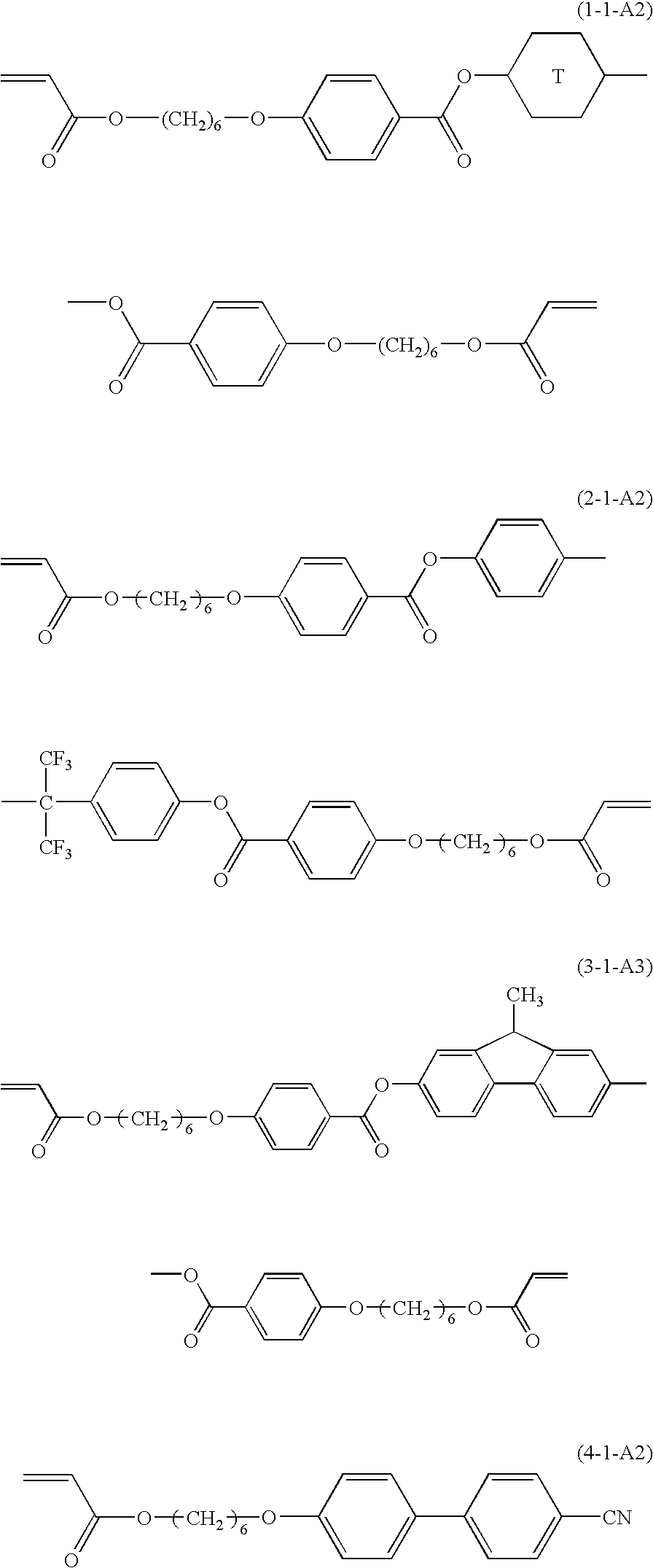

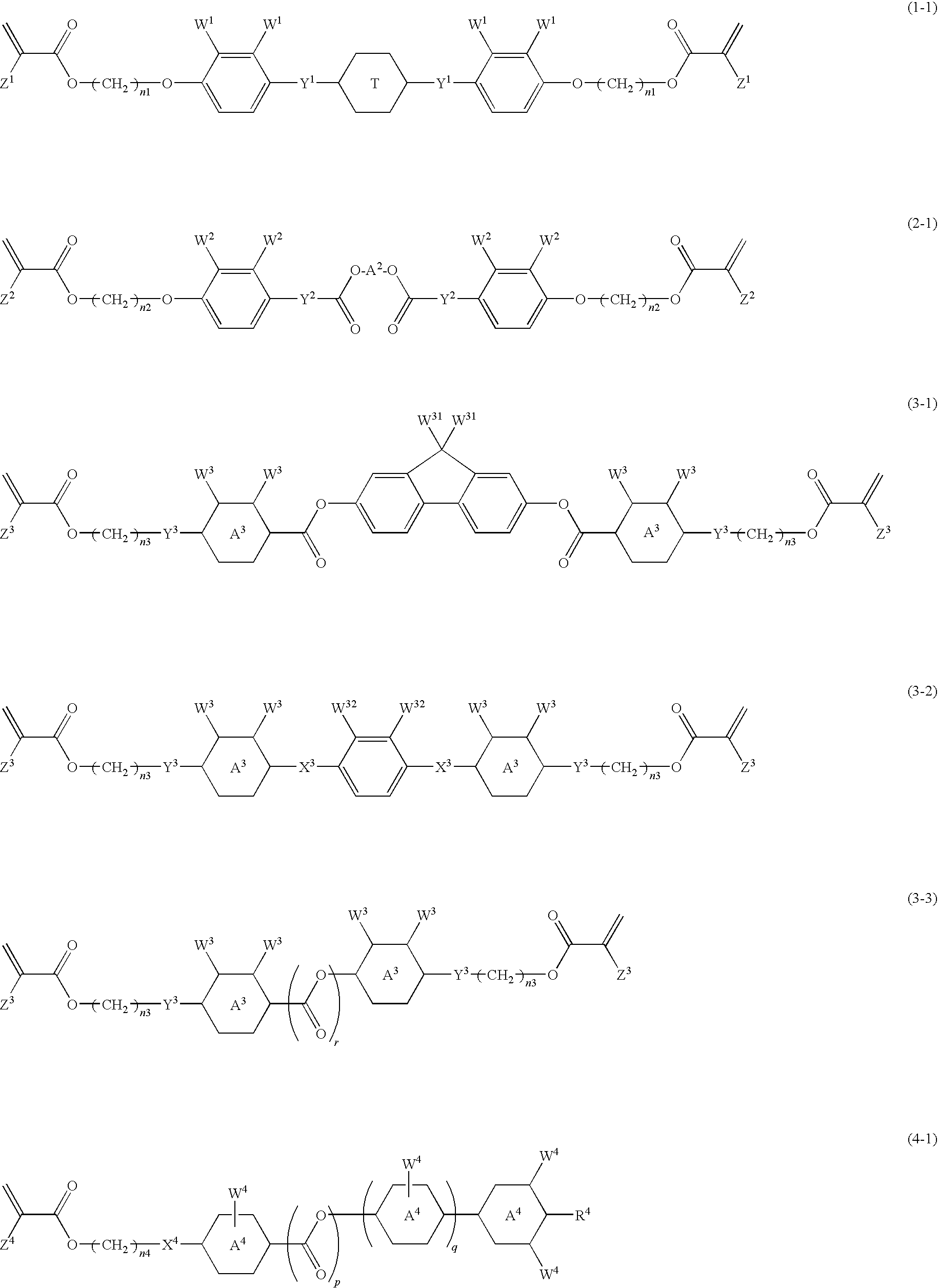

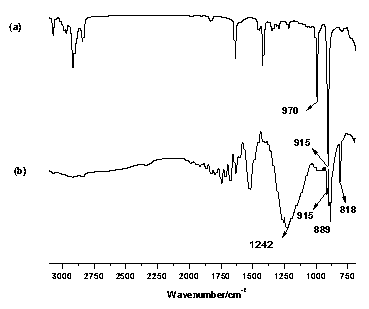

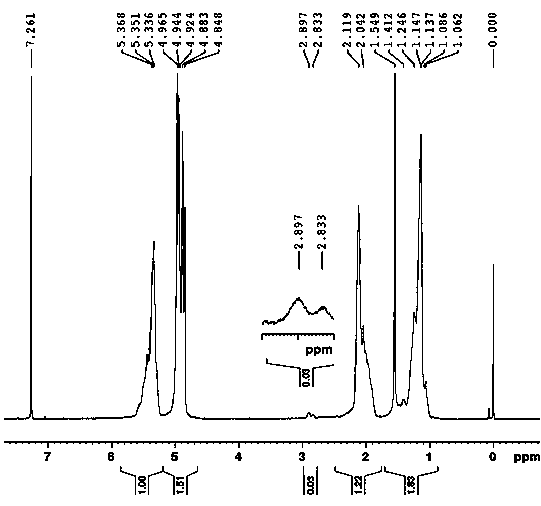

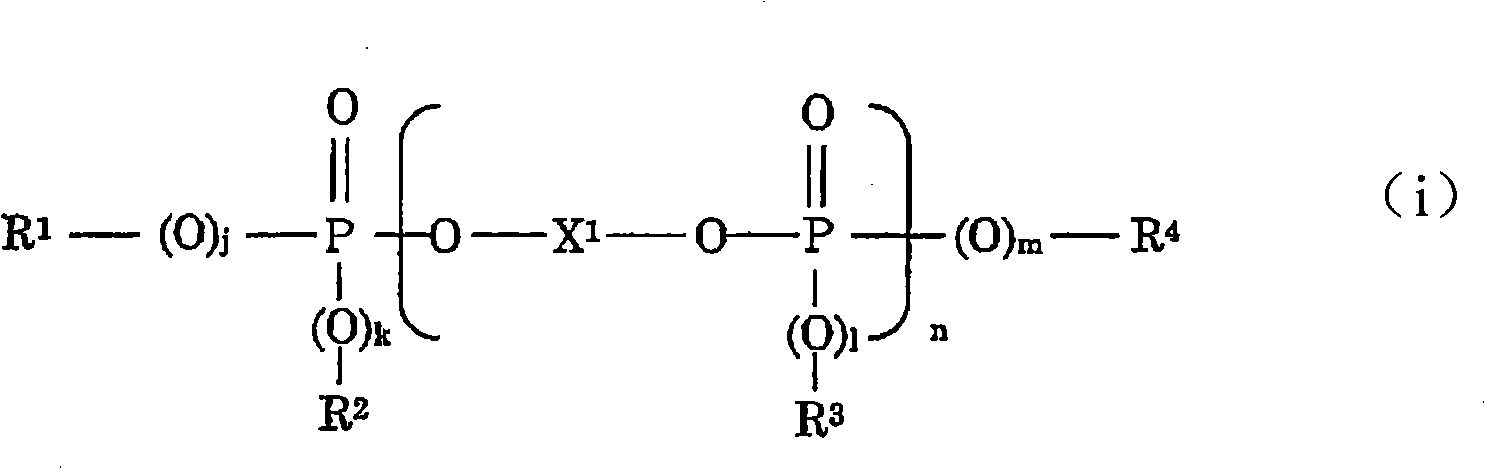

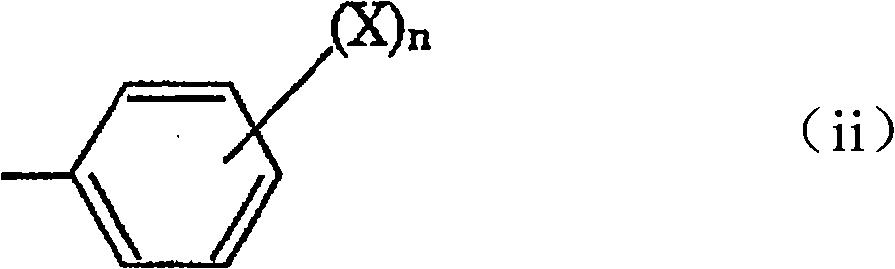

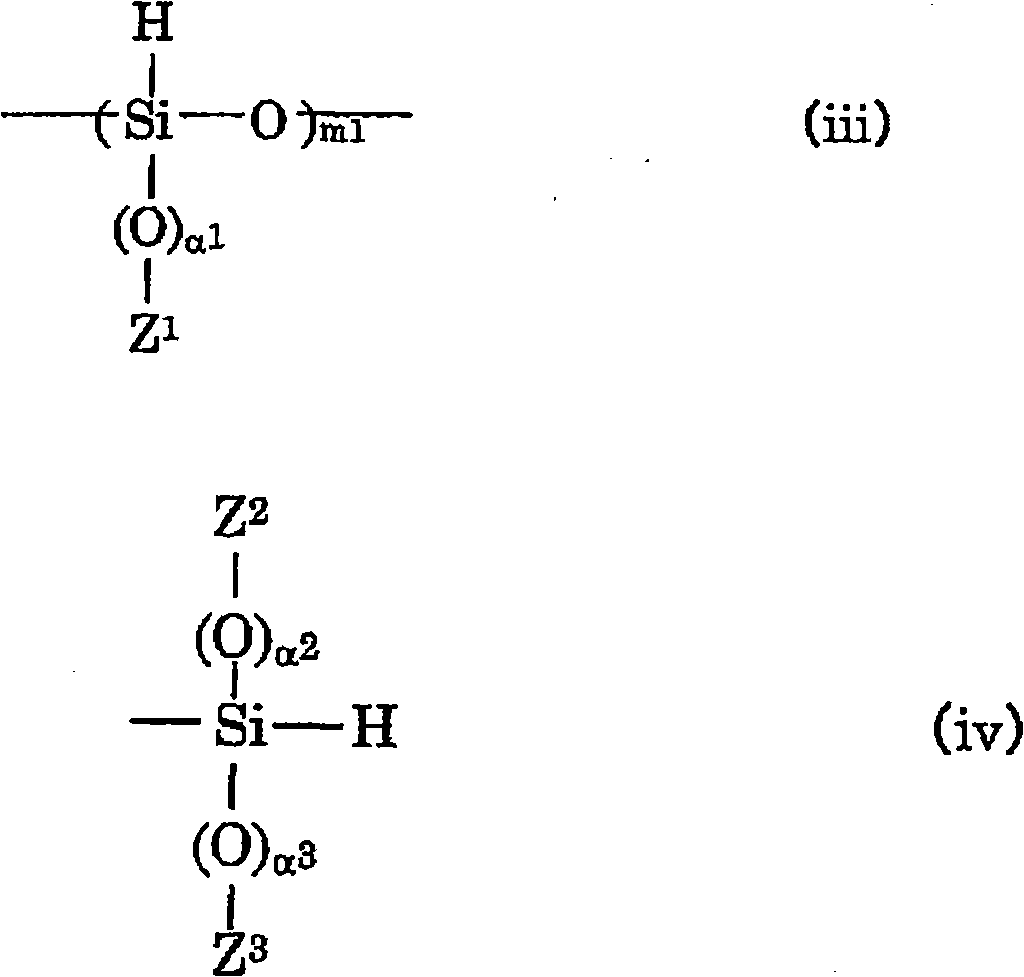

Polymerizable liquid crystal composition and homogeneous-aligned liquid crystal film

ActiveUS20100143612A1Uniform thicknessPrevent productivity being deterioratedLiquid crystal compositionsThin material handlingLiquid-crystal displayOrganic chemistry

A polymerizable liquid crystal composition is provided that can exhibit a uniform homogeneous alignment by coating the composition on a supporting substrate having been subjected to an alignment treatment. The polymerizable liquid crystal composition contains a mixture of polymerizable compounds containing a compound selected from a group of compounds represented by the formula (1-1) as a component A and a compound selected from a group of compounds represented by the formula (2-1) as a component B as essential components, and optionally containing a compound selected from a group of compounds represented by the formulae (3-1) to (3-3) as a component C and / or a compound selected from a group of compounds represented by the formula (4-1) as a component D, and contains at least one nonionic surfactant as a component E. Examples of each of the components are shown below, in which T represents triptycen-1,4-diyl.

Owner:JNC PETROCHEM CORP +1

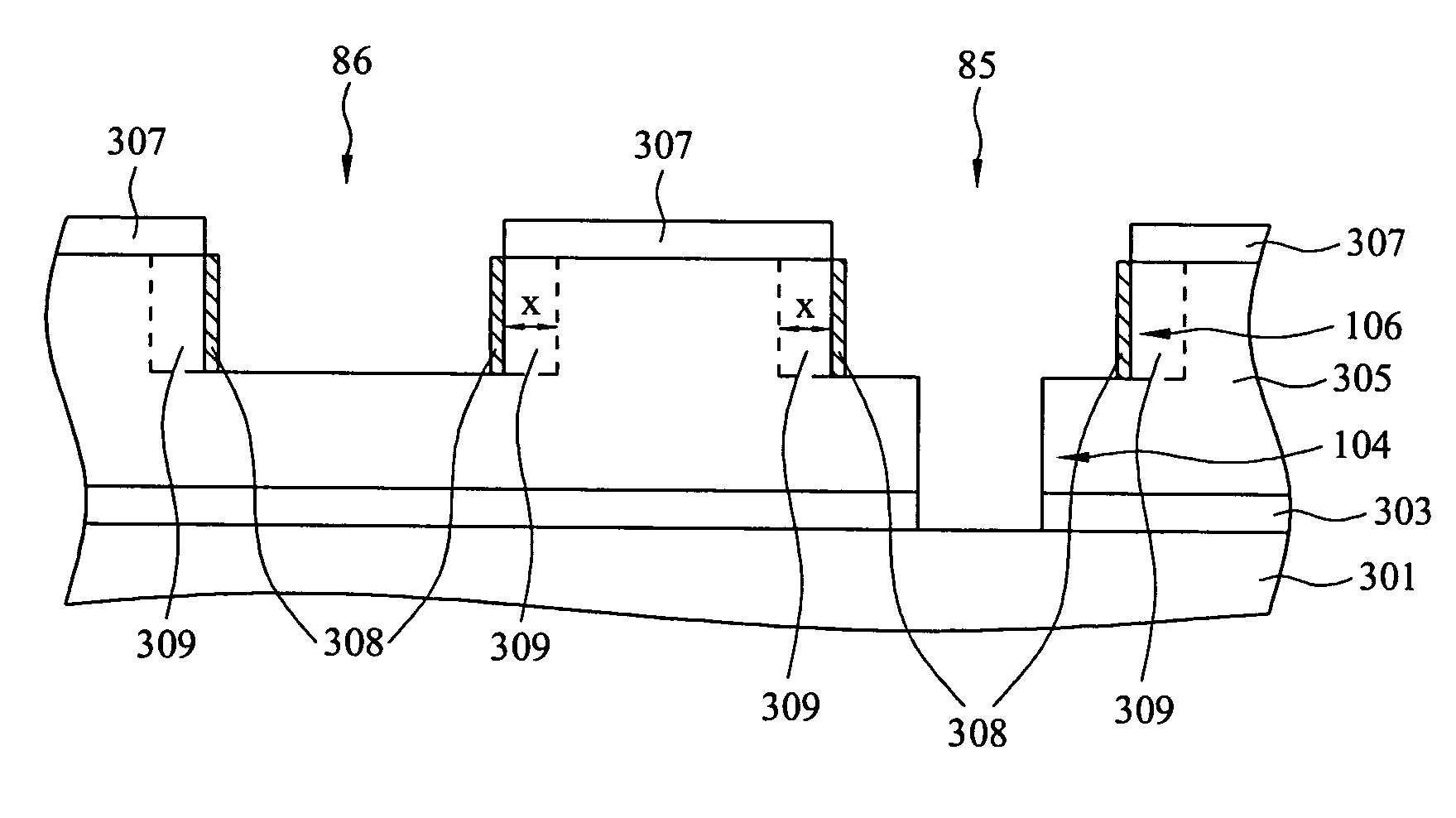

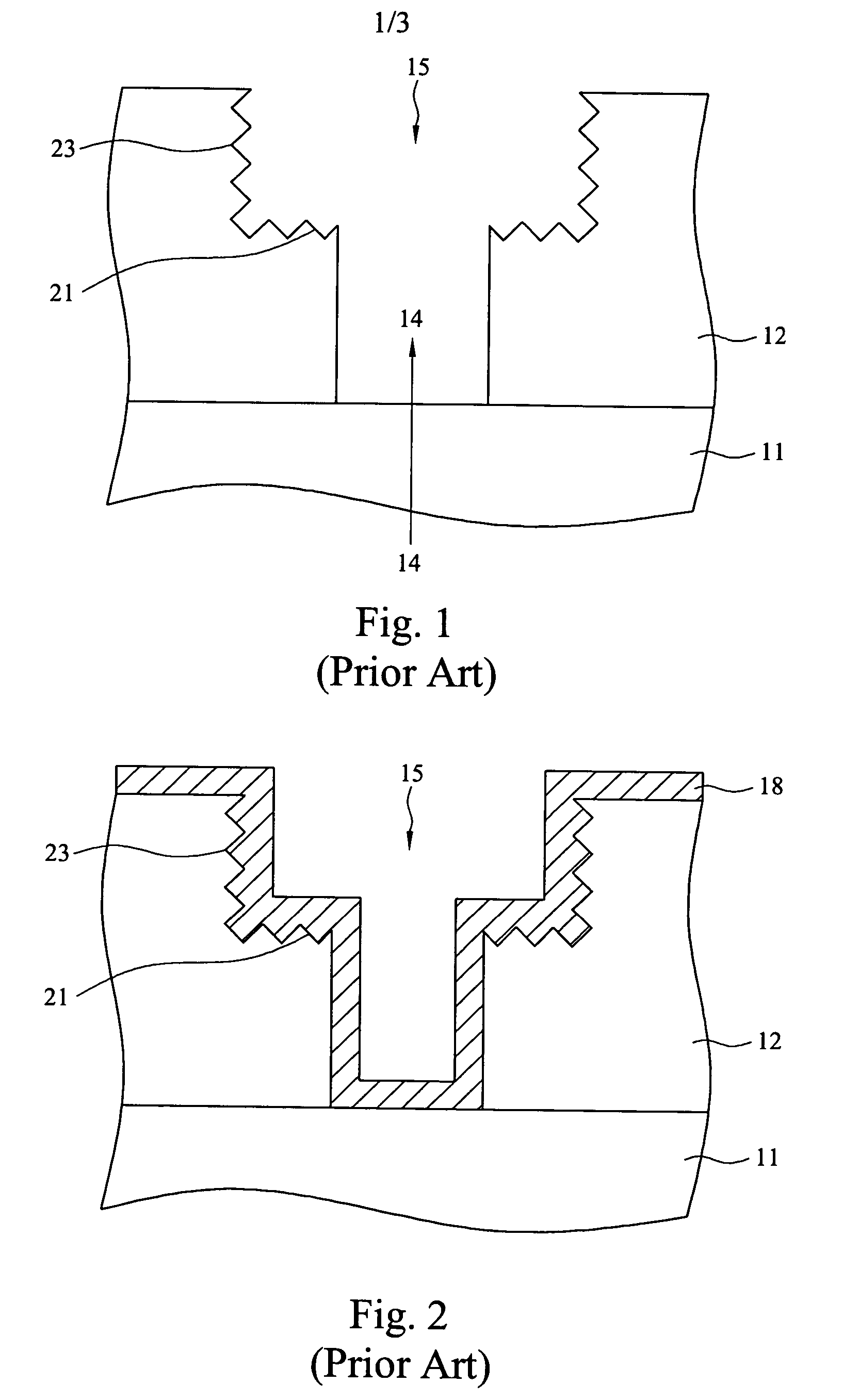

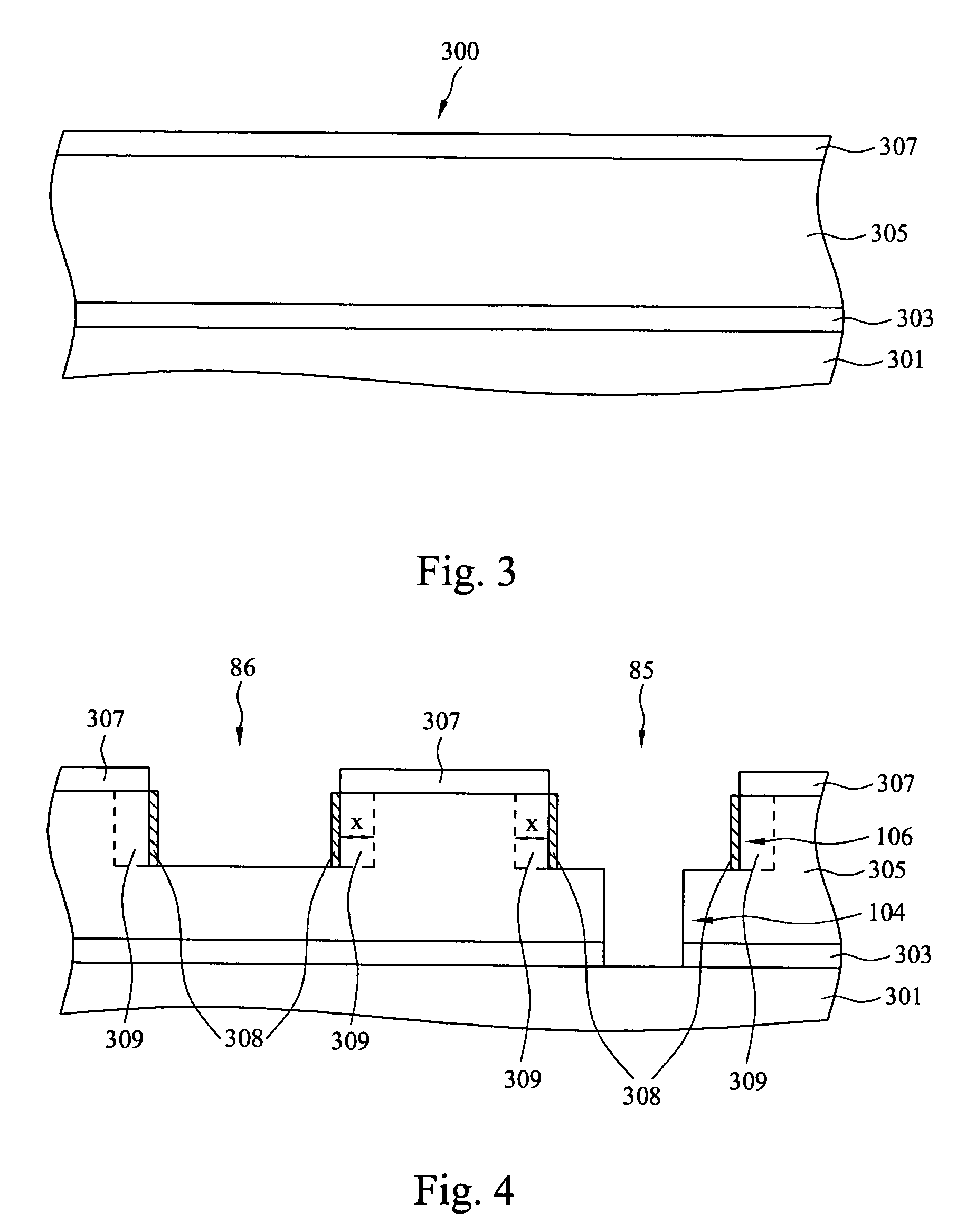

CxHy sacrificial layer for cu/low-k interconnects

InactiveUS20060172530A1Reducing low-k dielectric damageAvoid damageSemiconductor/solid-state device detailsSolid-state devicesEtchingHydrocotyle bowlesioides

A semiconductor method of manufacturing involving low-k dielectrics is provided. The method includes depositing a hydrocarbon of the general composition CxHy on the surface of a low-k dielectric. The hydrocarbon layer is deposited by reacting a precursor material, preferably C2H4 or (CH3)2CHC6H6CH3, using a PECVD process. In accordance with embodiments of this invention, carbon diffuses into the low-k dielectric, thereby reducing low-k dielectric damage caused by plasma processing or etching. Other embodiments comprise a semiconductor device having a low-k dielectric, wherein the low-k dielectric has carbon-adjusted dielectric region adjacent a trench sidewall and a bulk dielectric region. In preferred embodiments, the carbon-adjusted dielectric region has a carbon concentration not more than about 5% less than in the bulk dielectric region.

Owner:TAIWAN SEMICON MFG CO LTD

Resin particles and producing method thereof, toner for developing electrostatic latent image and producing method thereof, electrostatic latent image developer as well as image forming method

InactiveUS20050255397A1DevelopersElectrographic processes using charge patternLatent imageComposition B

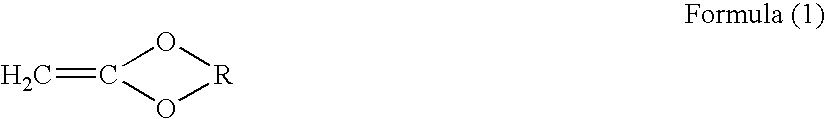

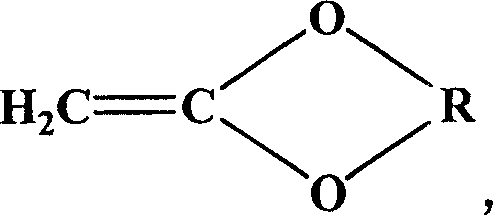

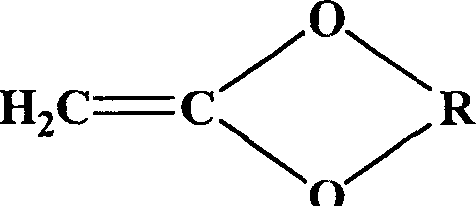

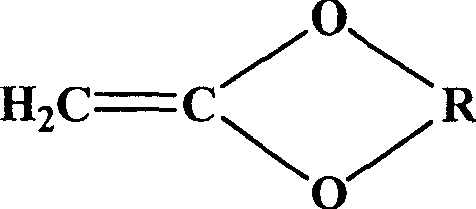

A producing method of resin particles, which comprises at least an emulsification step of emulsifying a composition containing at least a polymerizable monomer and a polymerization step to form droplets of the composition, and a polymerization step of polymerizing the polymerizable monomer in the droplets to synthesize resin particles, wherein the composition is one selected from Composition A, Composition B, or Composition C: (Composition A): a composition containing a vinyl-based monomer, lactone, a vinyl-based monomer polymerization catalyst for polymerizing the vinyl-based monomer, and a lactone polymerization catalyst for polymerizing the lactone (Composition B): a composition containing a polyester resin, lactone, and a lactone catalyst for polymerizing the lactone (Composition C): a composition containing a vinyl-based monomer, a cyclic keteneacetal compound represented by the following general formula (1), and a radical polymerization initiator (in the general formula (1), R represents a chain or cyclic divalent aliphatic group optionally containing an ether linkage, and the aliphatic group may have a substituent.)

Owner:FUJIFILM BUSINESS INNOVATION CORP

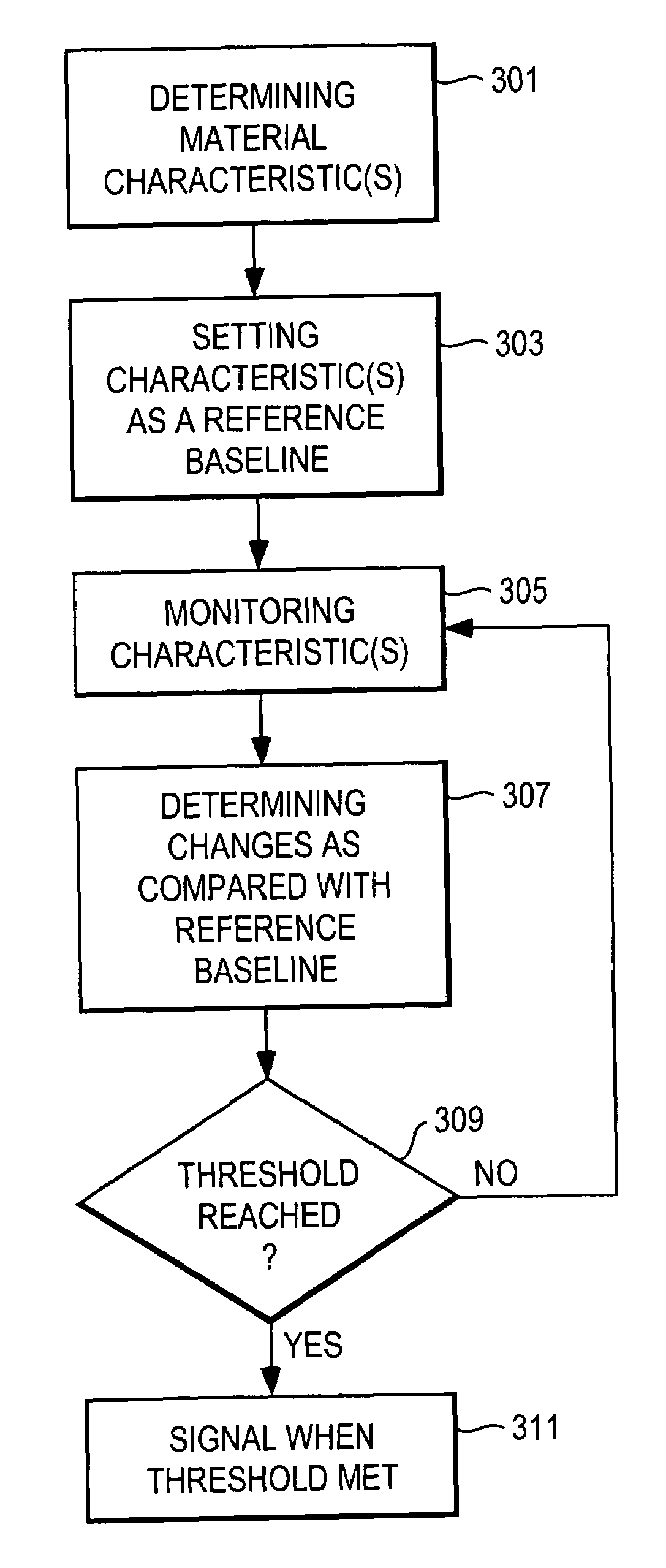

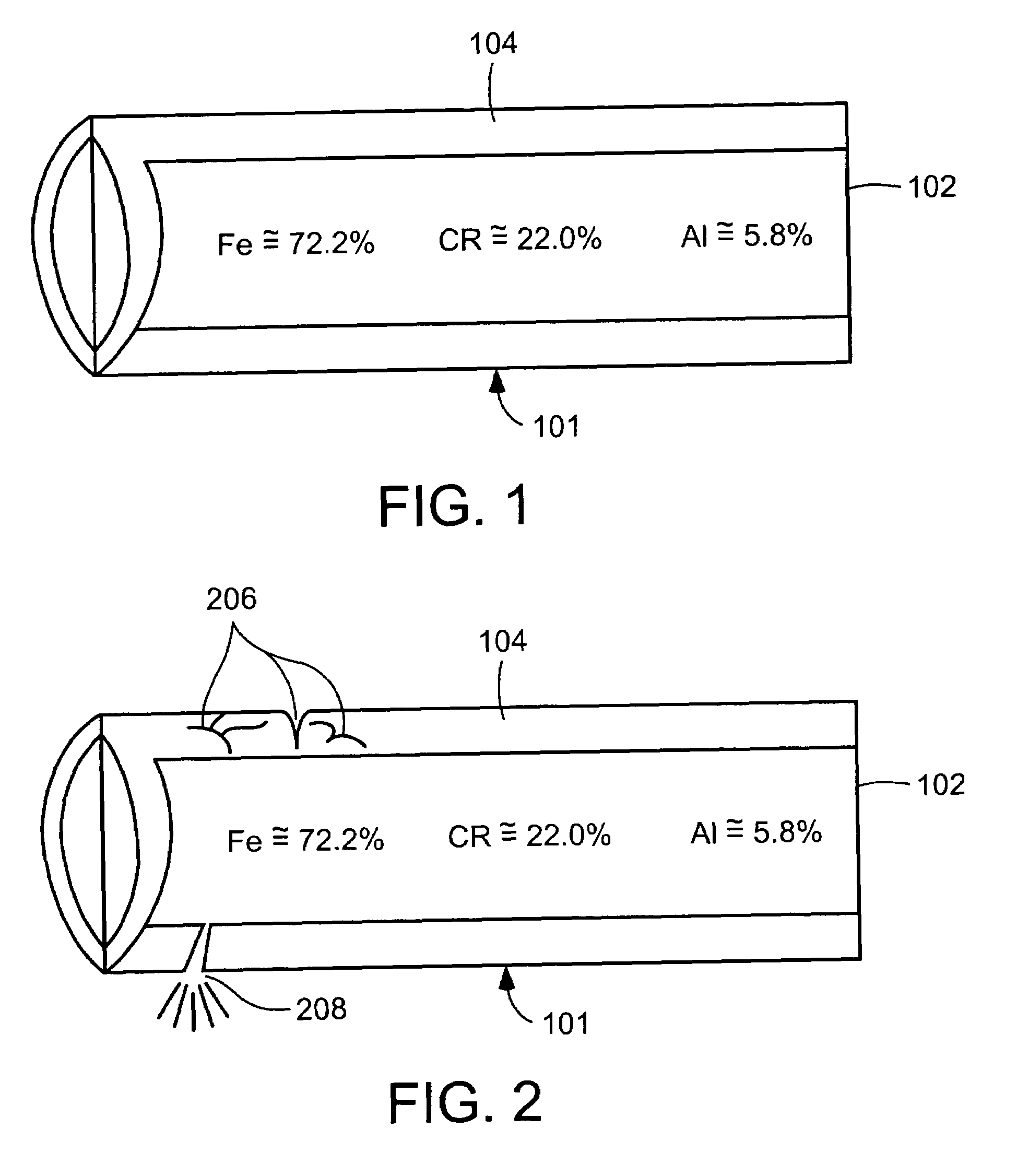

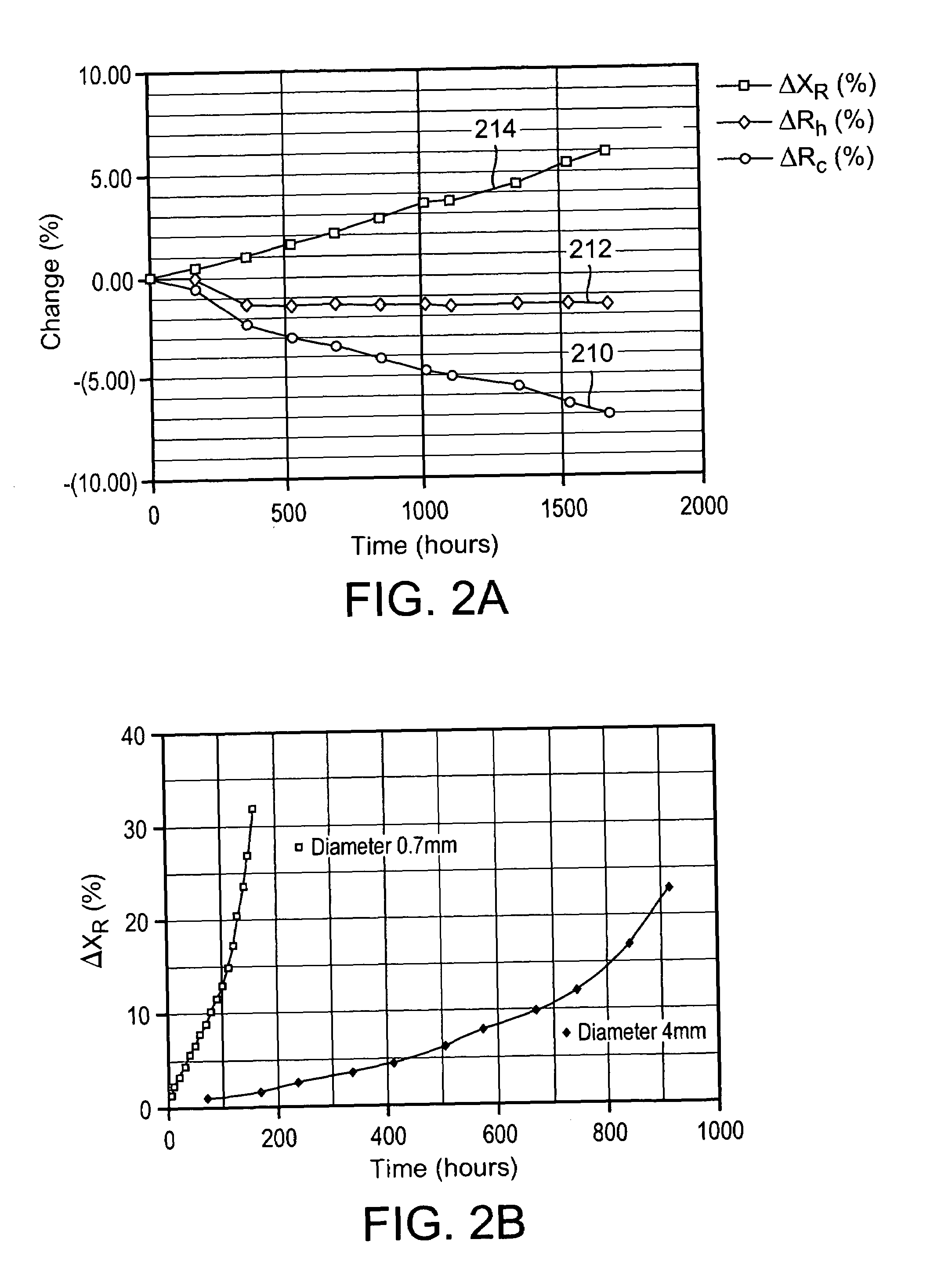

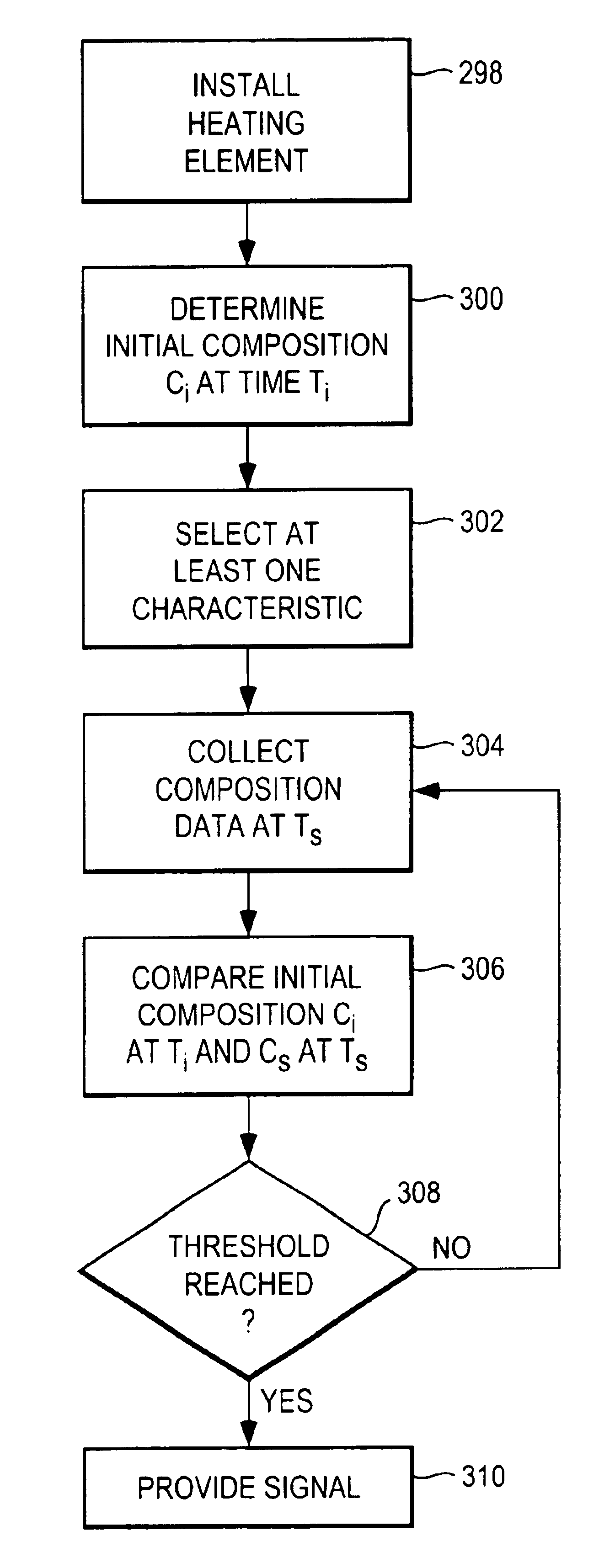

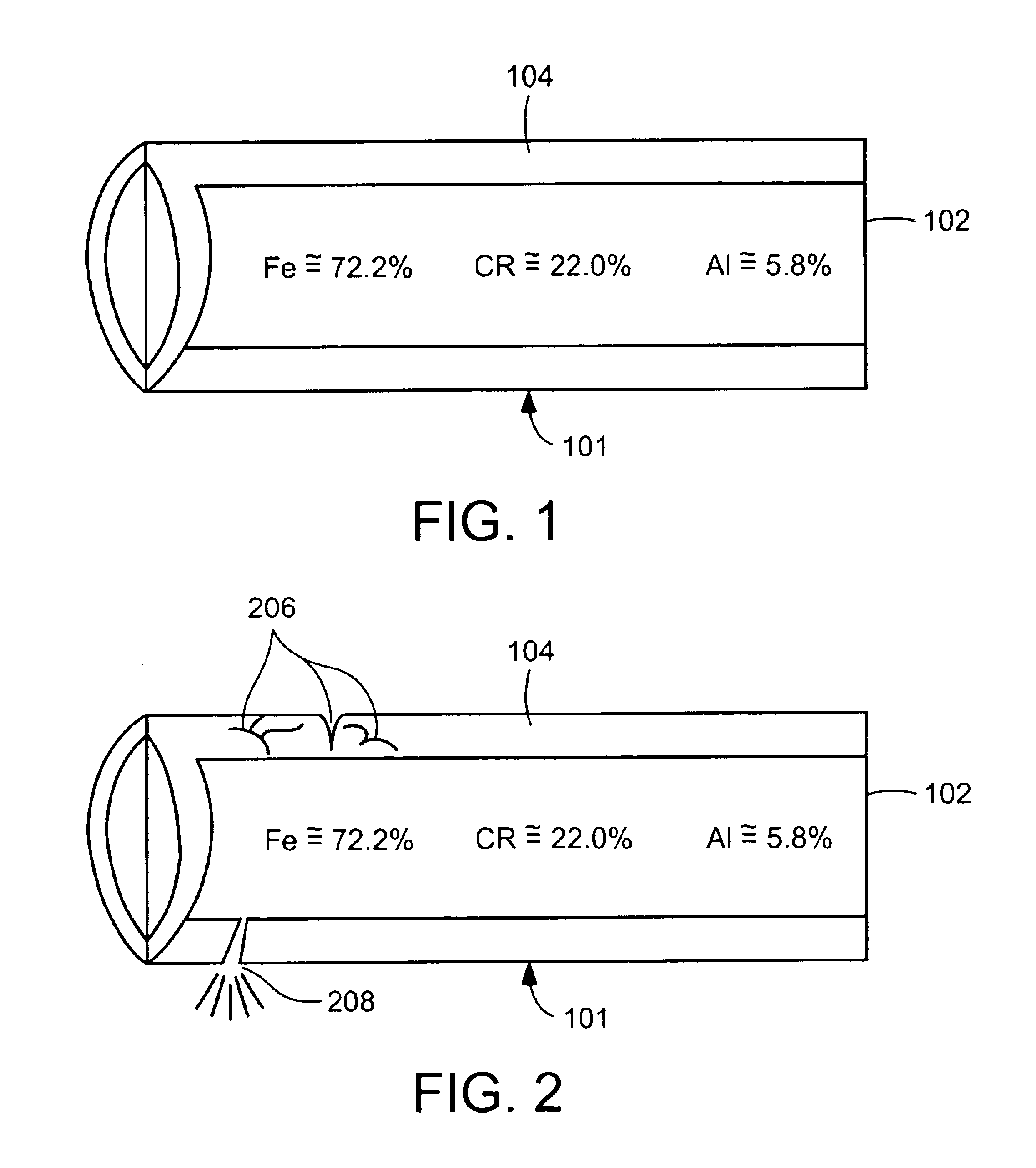

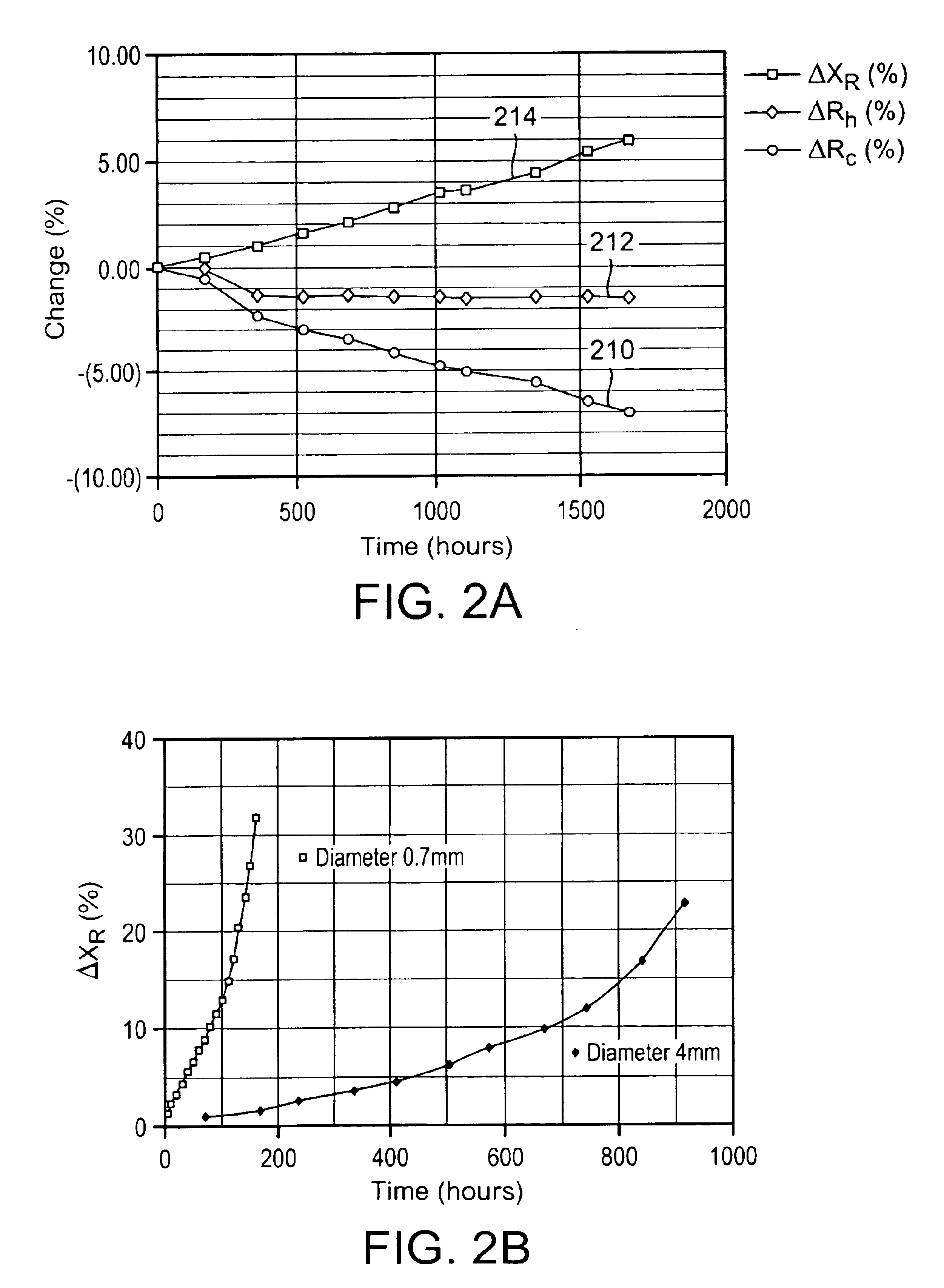

Heating element condition monitor

InactiveUS7012538B2Easy to set upWeather/light/corrosion resistanceElectric heatingMicrocontrollerEngineering

A method for monitoring the condition of a heating element involving installing the heating element in a location and setting the initial composition Ci of the material as a reference baseline at an initial time Ti corresponding to said installation of the heating element. Data is then collected reflecting the subsequent composition Cs of the heating element material after a subsequent time Ts at the installed location and any change in the material composition of the heating element between Ti and Ts is monitored. An alarm is sent when the change reaches a threshold value indicating a possible failure condition. According to one embodiment, an impedance monitor is provided that calculates and compares impedance at the required levels of accuracy to determine changes in material composition. The impedance monitor, or portions thereof can be embedded within a microcontroller for increased portability and functionality.

Owner:KANTHAL THERMAL PROCESS INC

Edible products with low content of saturated and trans unsaturated fats

ActiveUS20090068318A1Acceptable textureGreat tasteFatty acid chemical modificationConfectioneryTriglycerideUnsaturated fat

The present invention relates to a structured, fat continuous edible product, wherein the edible product contains, expressed on total product basis, a) less than 30 wt. % of saturated fatty acids, b) between 20 and 100 wt. % of a triglyceride composition c) between 0 and 80 wt % of a filler material d) less than 15 wt. % of water wherein the triglyceride composition contains with respect to the weight of the triglyceride composition e) less than 45 wt. % of saturated fatty acids, f) less than 10 wt. % of trans unsaturated fatty acids g) at least 8 wt. % of SUS triglycerides, wherein S is a C16-18 saturated fatty acid, U is unsaturated fatty acid having at least 18 C atoms, h) less than 15 wt. % of S3, i) at least 90 wt. % of C8-18 fatty acids, j) at least 75 wt. % of C18 fatty acids including saturated and unsaturated fatty acids, k) has an SFC at 20° C. of between 5 and 50%. The present invention also relates to the use of this structured product in the preparation of fat continuous as well as non-fat continuous products.

Owner:FUJI OIL CO LTD

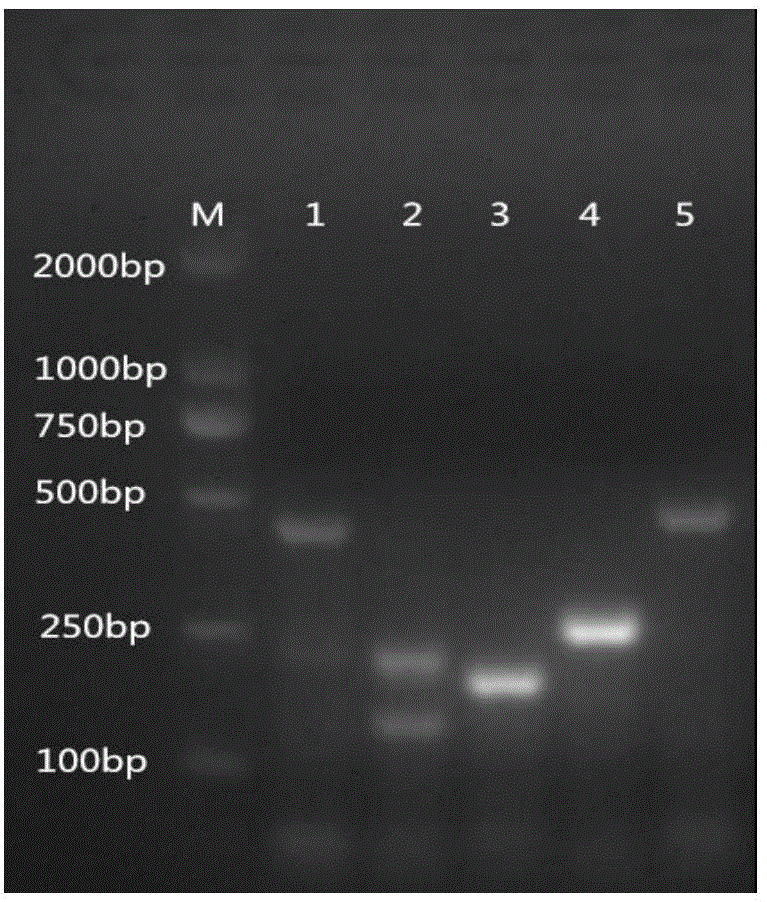

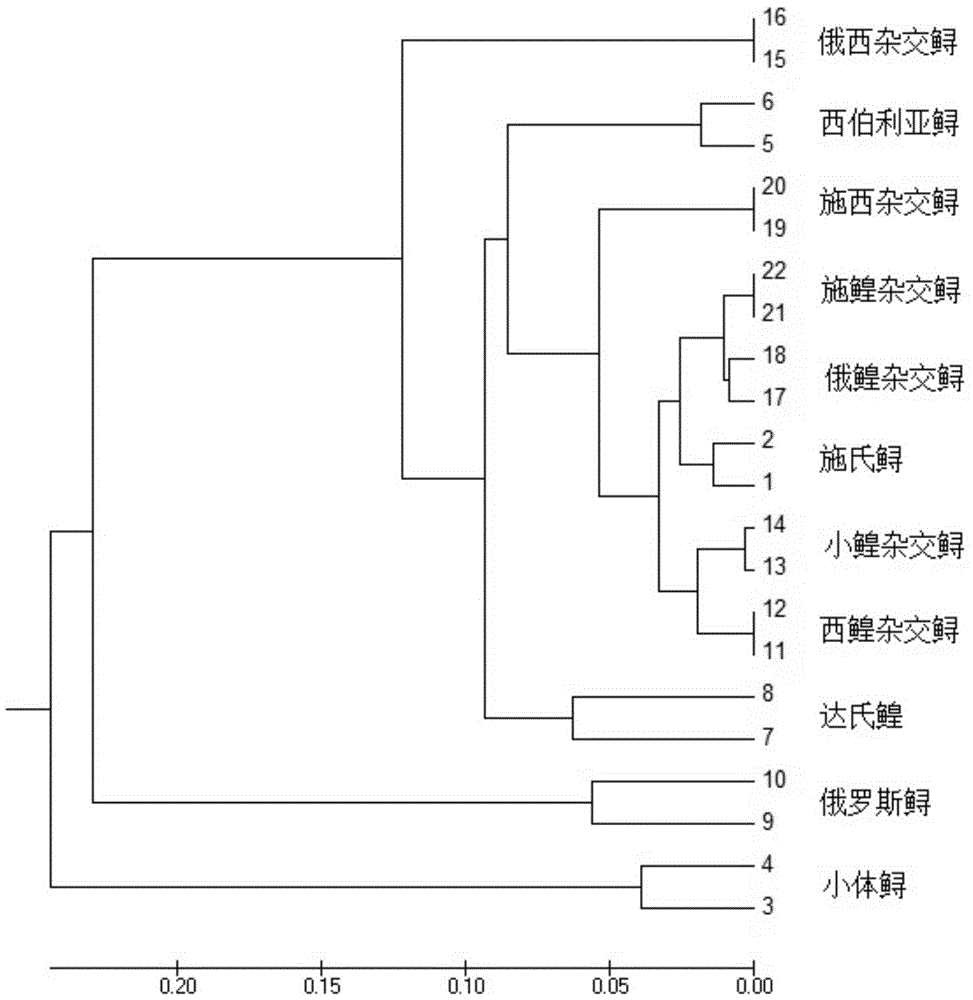

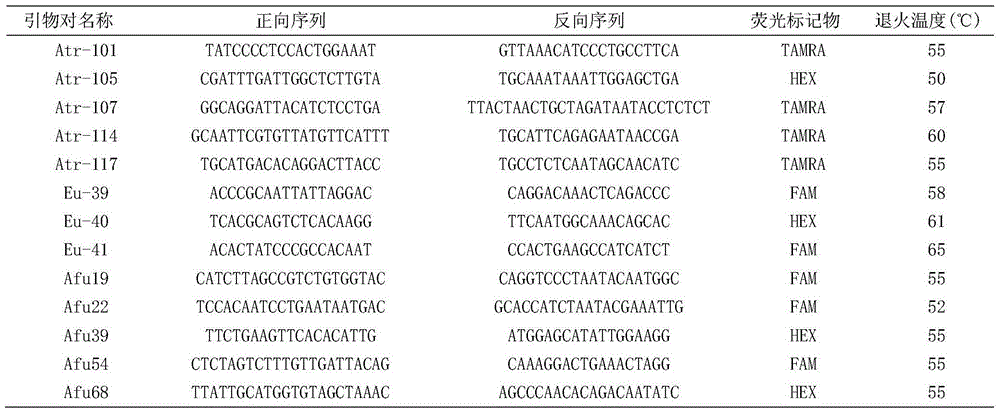

PCR primer pair composition for identification or assisted identification of idioplasm of sturgeon, and applications thereof

ActiveCN105567789AAvoid damageAvoid interferenceMicrobiological testing/measurementDNA/RNA fragmentationComposition BSturgeon

The present invention discloses a PCR primer pair composition for identification or assisted identification of the sturgeon female parent and the sturgeon male parent, and applications thereof. The composition comprises a composition A for identification or assisted identification of the sturgeon female parent, a composition B for identification or assisted identification of the sturgeon parent, and a composition C for identifying or assistedly identifying whether the sturgeon female parent is Acipenser ruthenus, wherein the compositions A, B and C are separately packaged, the composition A comprises AGF, ABF, ABRM, DauF and SchF, the composition B comprises Atr-101, Atr-105, Atr-107, Atr-114, Atr-117, Eu-39, Eu-40, Eu-41, Afu19, Afu22, Afu39, Afu54 and Afu68, and the composition C comprises RutF.

Owner:BEIJING FISHERIES RES INST

Electrolyte for dye-sensitized solar cell and preparation method thereof

InactiveCN101572192AReduce volatilityImprove long-term stabilityLight-sensitive devicesFinal product manufactureMass ratioAdhesive

The invention relates to electrolyte for a cell, in particular to electrolyte for a dye-sensitized solar cell. The electrolyte comprises a composition A, a composition B and a composition C, wherein the mass ratio of the composition A to the composition B to the composition C is 2-17:1-2:1-2; the composition A is a mixed solution formed by a redox couple, an additive which is chelated with a photo anode, and an ionic liquid; the redox couple comprises elementary iodine; the ionic liquid is an imidazole salt ionic liquid which is in the liquid state at room temperature; the molar ratio of the elementary iodine to the additive is 1:0.2-2; the concentration of the elementary iodine in the composition A of the mixed solution is between 0.01 and 1 mol / L; the composition B is an adhesive for increasing the viscosity of a system; and the composition C is a viscosity regulator for regulating the leveling property of the system under the condition of silk-screen printing. The invention has the advantages that the electrolyte system has small volatility and good long-term stability, and can perform silk-screen printing and meet the requirements of industrialized production.

Owner:IRICO

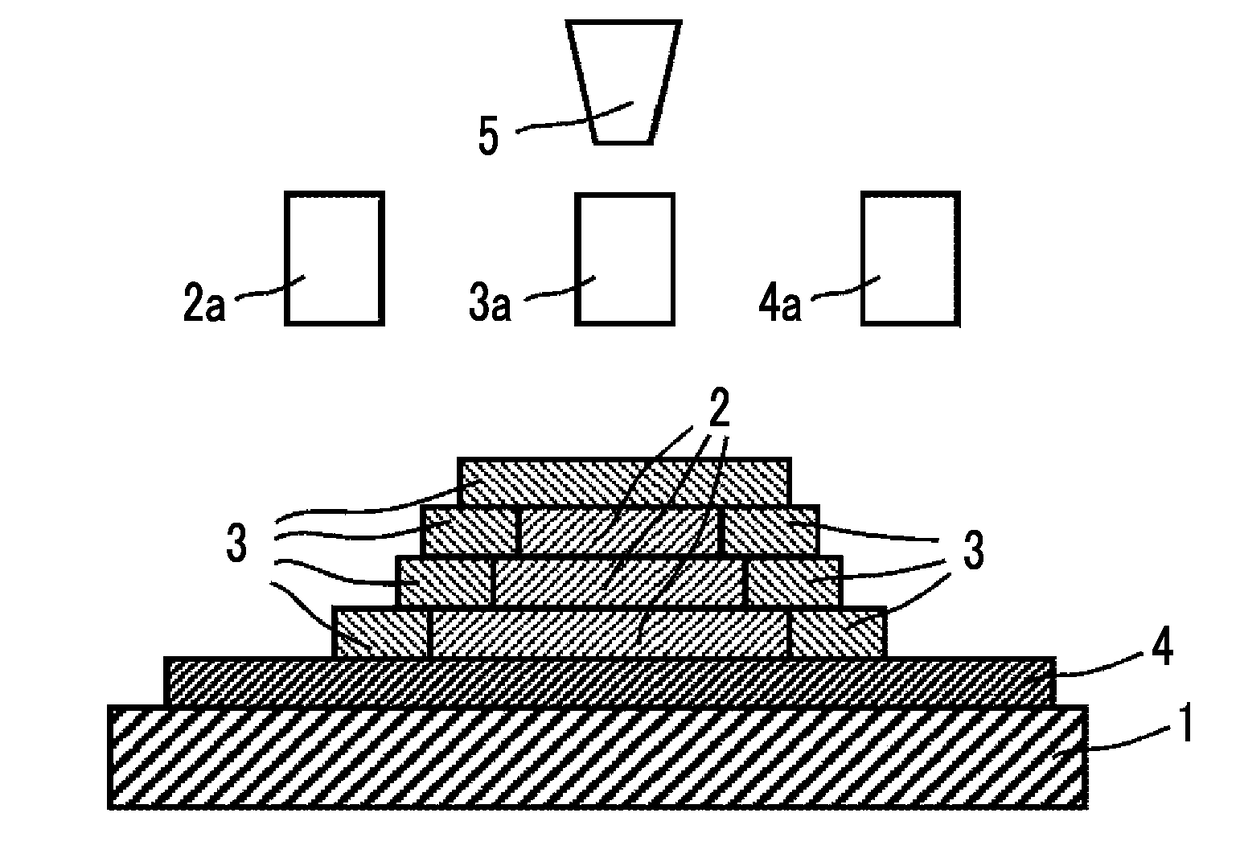

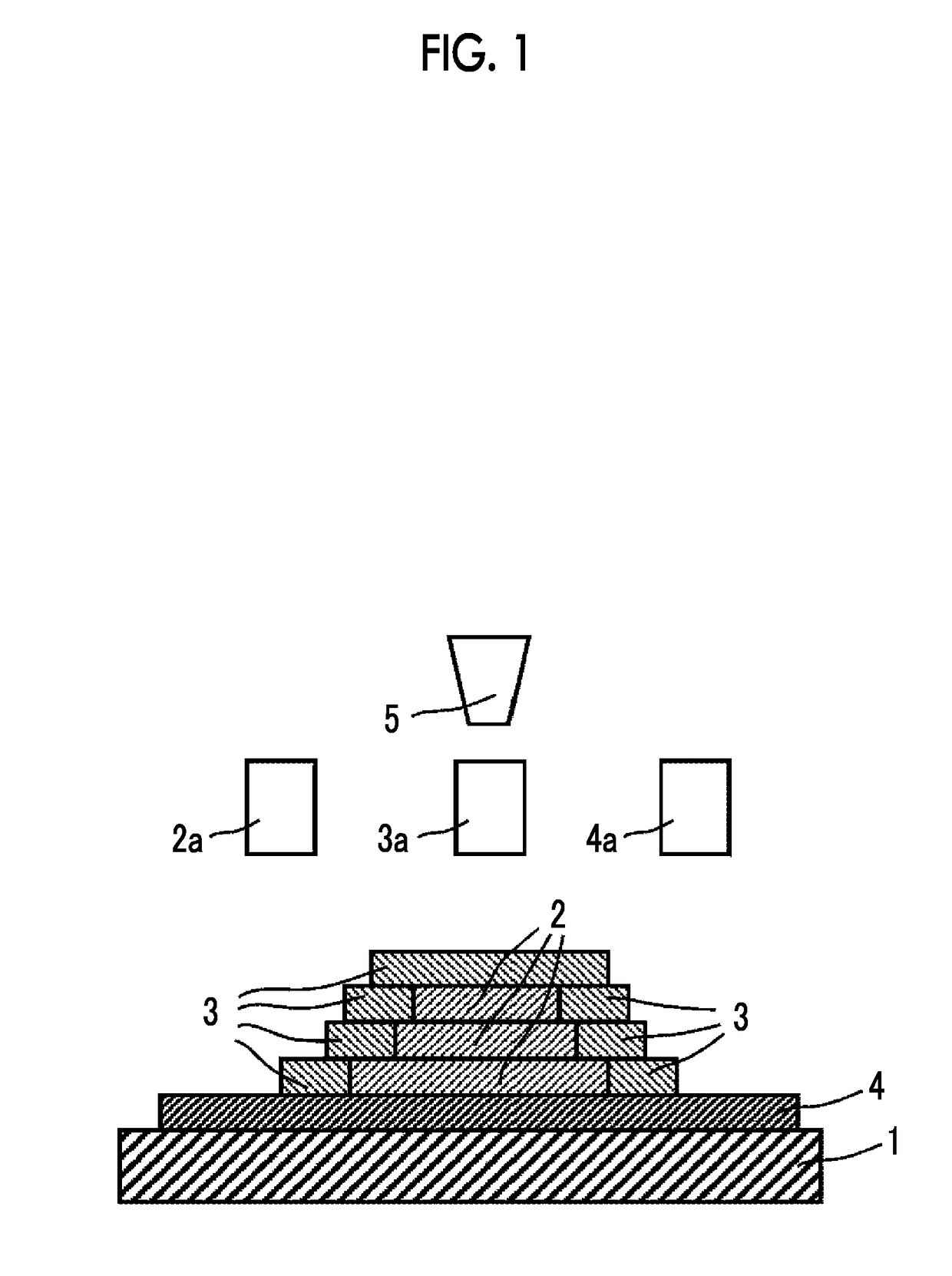

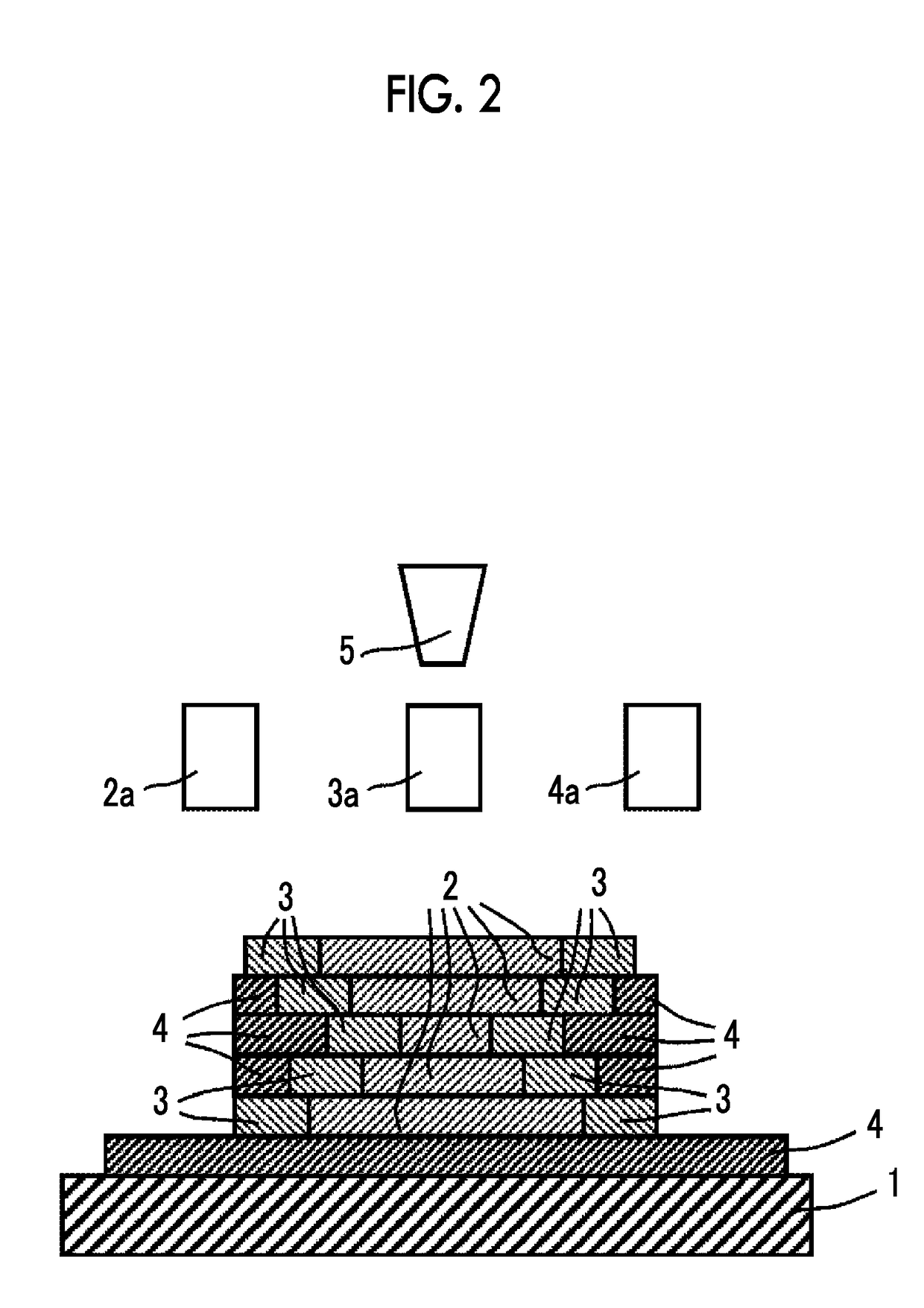

Actinic ray-curable-type inkjet ink set for three-dimensional printing, three-dimensional printing method, and three-dimensional printing system

ActiveUS20180079923A1Good moldabilityMaintain good propertiesAdditive manufacturing apparatusDuplicating/marking methodsActinic RaysEngineering

An actinic ray-curable-type inkjet ink set for three-dimensional printing and a three-dimensional printing system are provided. The actinic ray-curable-type inkjet ink set for three-dimensional printing includes a white ink composition W and a color ink composition C. The three-dimensional printing system includes printing means for jetting out, a plurality of times, each of a white ink composition W and a color ink composition C using an inkjet head so as to form a color layer on a white modeled object, based on cross-sectional information of a three-dimensional modeled object.

Owner:FUJIFILM CORP

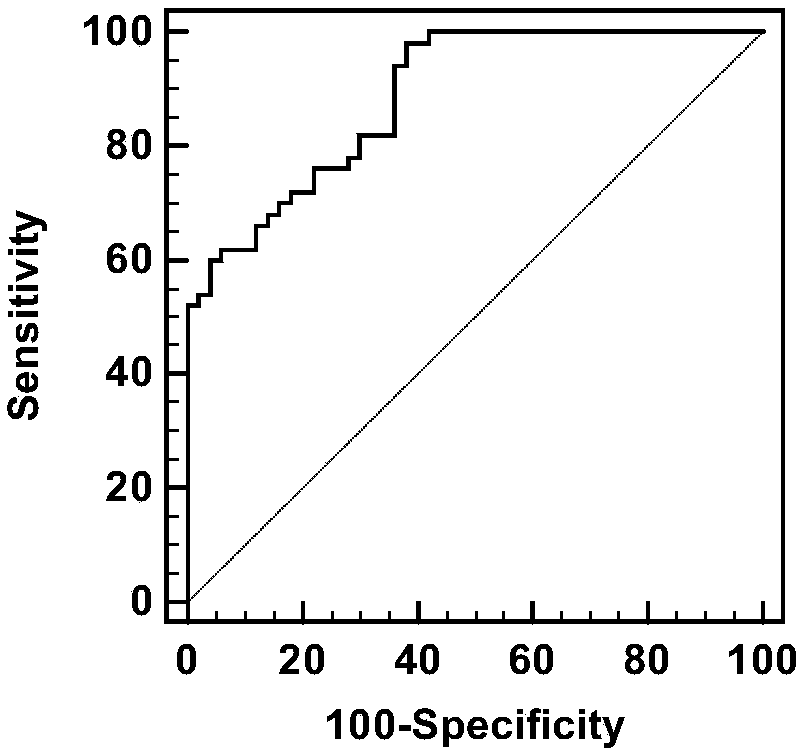

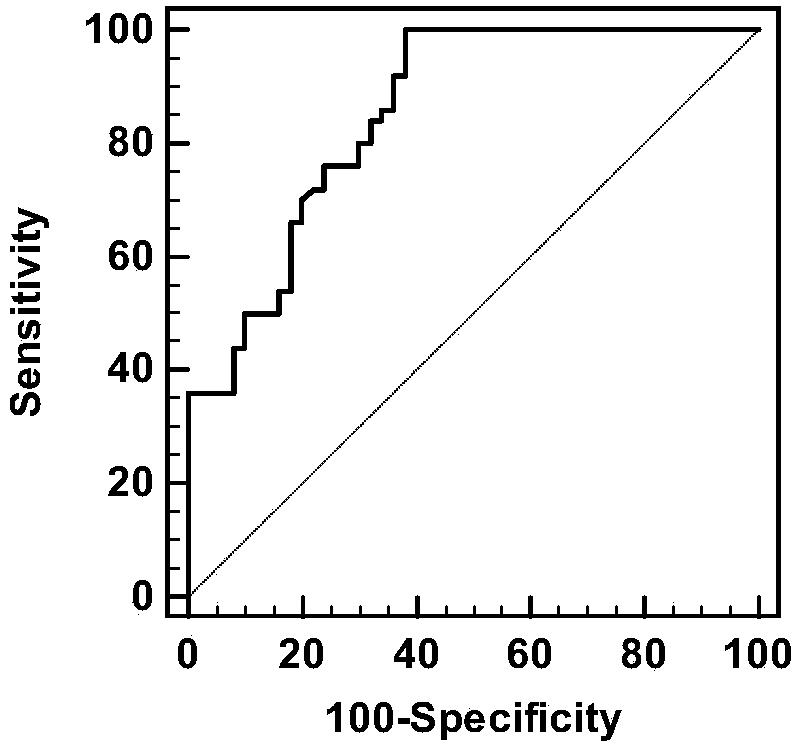

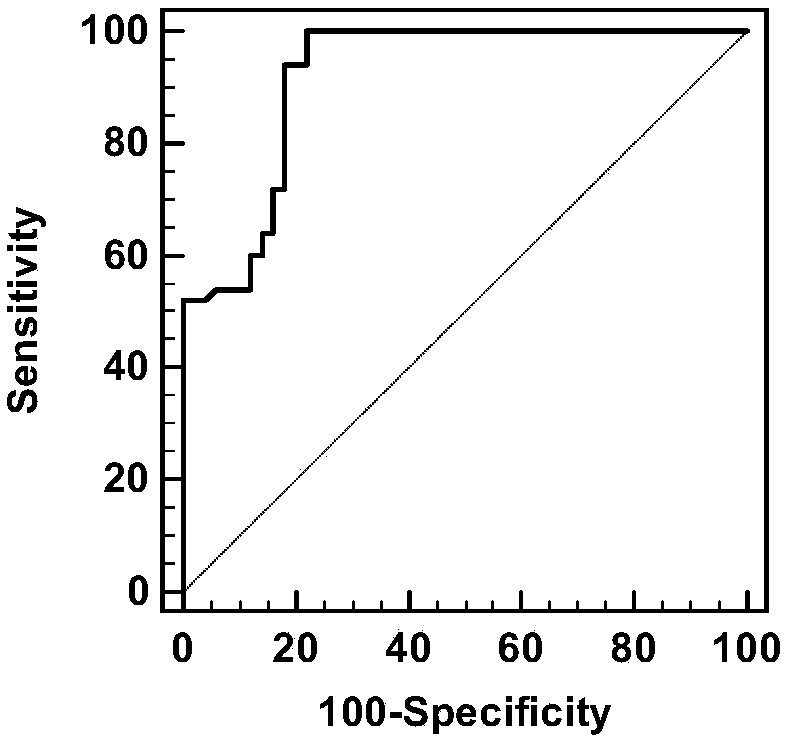

Detection kit for diagnosis of patient with lung cancer based on multiple genes

InactiveCN108342477AHigh sensitivityStrong specificityMicrobiological testing/measurementBiologyGenetic diagnosis

The invention relates to a detection kit for diagnosis of a patient with lung cancer based on multiple genes. The detection kit comprises a primer probe composition A, a primer probe composition B, aprimer probe composition C, a primer probe composition D and a primer probe composition E, wherein the primer probe composition A comprises a specific primer pair A, a blocking primer A and a probe A;the primer probe composition B comprises a specific primer pair B, a blocking primer B and a probe B; the primer probe composition C comprises a specific primer pair C, a blocking primer C and a probe C; the primer probe composition D comprises a specific primer pair D, a blocking primer D and a probe D; and the primer probe composition E comprises a specific primer pair E, a blocking primer E and a probe E. The kit provided by the invention can be applied to diagnosis of the lung cancer, and provides a novel, rapid, reliable and accurate way for the diagnosis of the lung cancer; and the kitis expected to play an important role in the field of medical detection.

Owner:BEIJING EXELLON MEDICAL TECH CO LTD

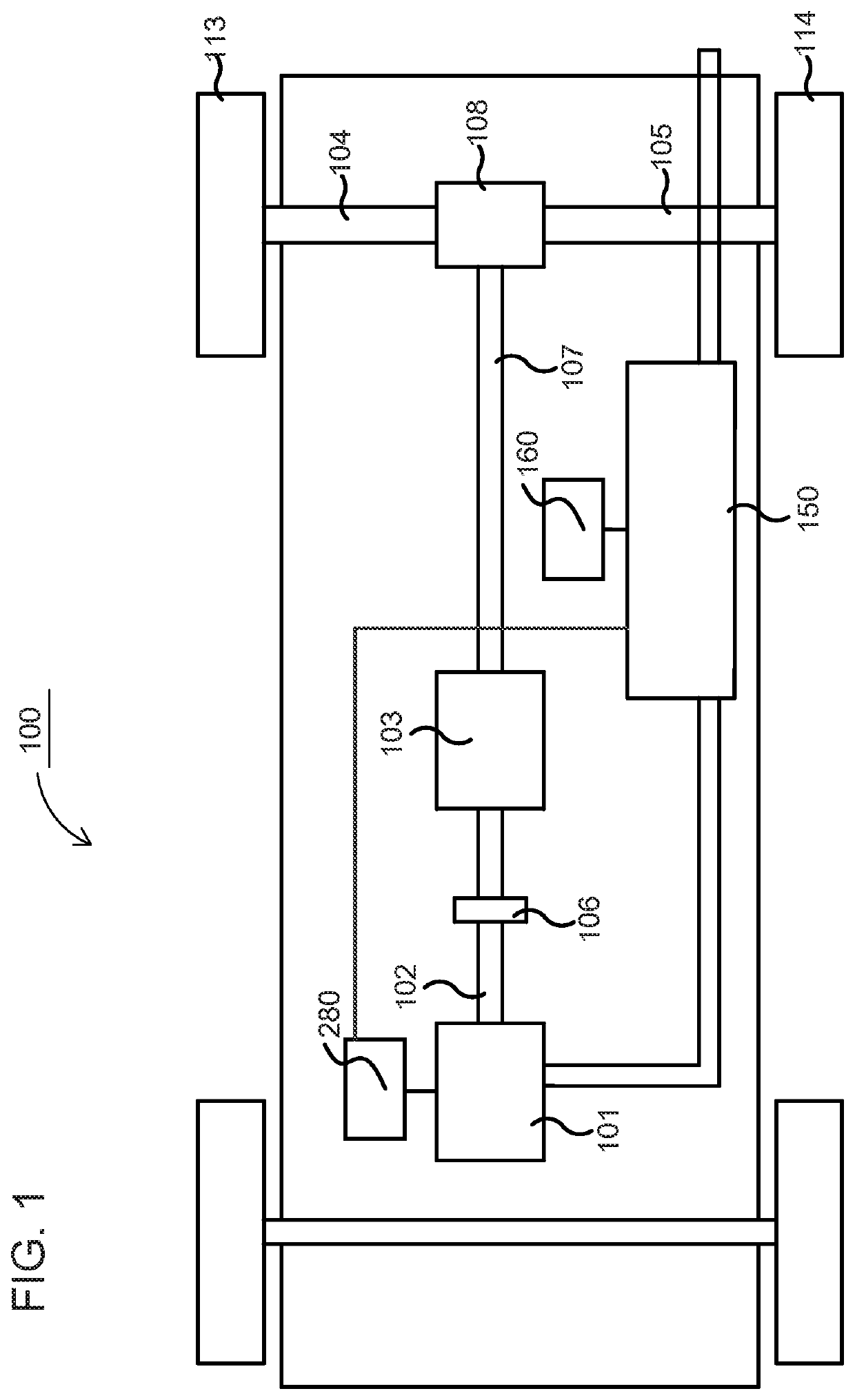

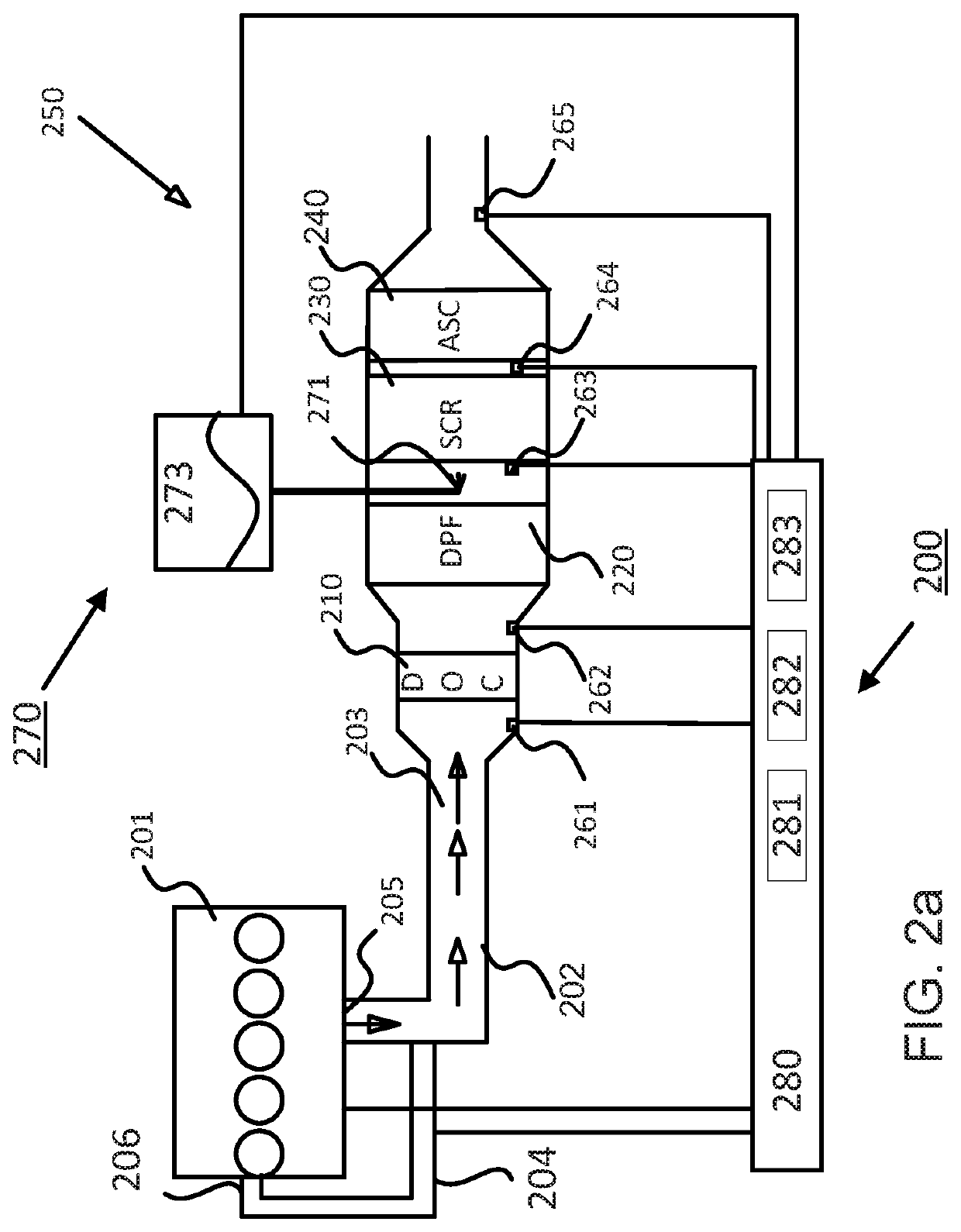

Method and system for controlling an ammonia coverage degree profile

ActiveUS20190345861A1Efficient reduction of nitrogen oxidesInternal combustion piston enginesExhaust apparatusNitrogen oxideInternal combustion engine

A method (and a system that executes the method) for control of at least one sectional ammonia coverage degree profile NH3_profile for at least one SCR catalyst included in an exhaust gas treatment system, the method includes determining at least one ammonia sectional coverage degree profile NH3_profile_det for the at least one SCR catalyst based on a flow F, a temperature T and a composition C of the exhaust stream upstream of the at least one SCR catalyst. The method also includes comparing the at least one sectional ammonia coverage NH3_profile_ref with at least one sectional reference profile for an ammonia coverage degree NH3_profile_ref for the at least one SCR catalyst. The method further includes controlling, based on the comparison, at least one of a concentration of nitrogen oxides CNOX in the exhaust stream to be output from the combustion engine and a dosage of a reductant including ammonia NH3 to be injected into the exhaust stream upstream of the at least one SCR catalyst.

Owner:SCANIA CV AB

Plasticiser Compositions

C9 to C11 alkyl benzoates are used as plasticisers for polyvinyl chloride in particular in combination with plasticisers such as di-2-ethyl hexyl phthalate, diisononyl phthalate, di-2-propyl heptyl phthalate, diisodecyl phthalate or di-2-ethyl hexyl terephthalate. The use of the C9 to C11 alkyl benzoates provides low viscosity low volatility plasticisers, which are fast fusing with lower hot bench gelation temperature and which can be used to reduce the staining problems associated with use of di-2-ethyl hexyl phthalate and diisononyl phthalate. The low viscosity of the C9 to C11 alkyl benzoates allows the formulation of solvent free flexible PVC formulations meeting stringent VOC limitations.

Owner:EXXONMOBIL CHEM PAT INC

Resin particles and producing method thereof, toner for developing electrostatic latent image and producing method thereof, electrostatic latent image developer as well as image forming method

A producing method of resin particles, which comprises at least an emulsification step of emulsifying a composition containing at least a polymerizable monomer and a polymerization step to form droplets of the composition, and a polymerization step of polymerizing the polymerizable monomer in the droplets to synthesize resin particles, wherein the composition is one selected from Composition A, Composition B, or Composition C: (Composition A): a composition containing a vinyl-based monomer, lactone, a vinyl-based monomer polymerization catalyst for polymerizing the vinyl-based monomer, and a lactone polymerization catalyst for polymerizing the lactone (Composition B): a composition containing a polyester resin, lactone, and a lactone catalyst for polymerizing the lact

Owner:FUJIFILM BUSINESS INNOVATION CORP

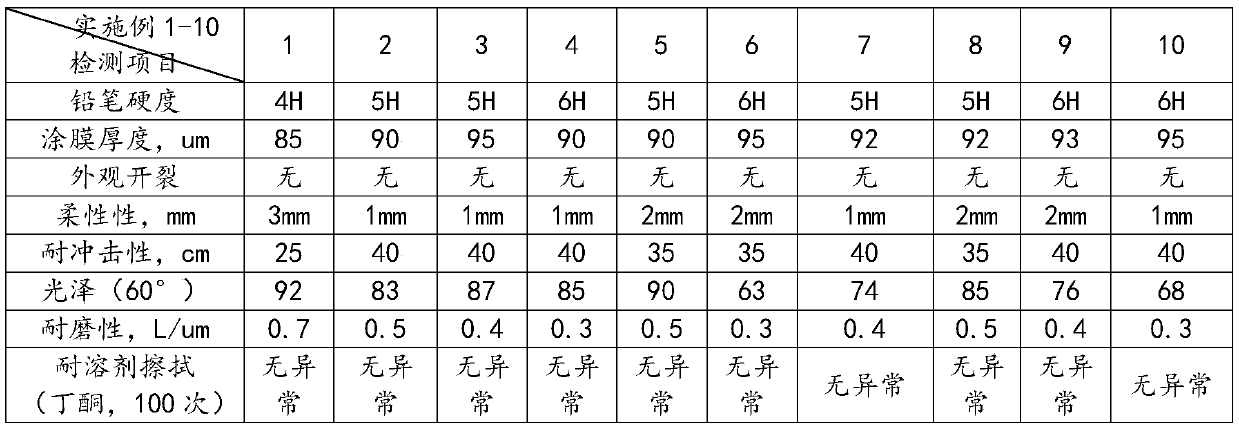

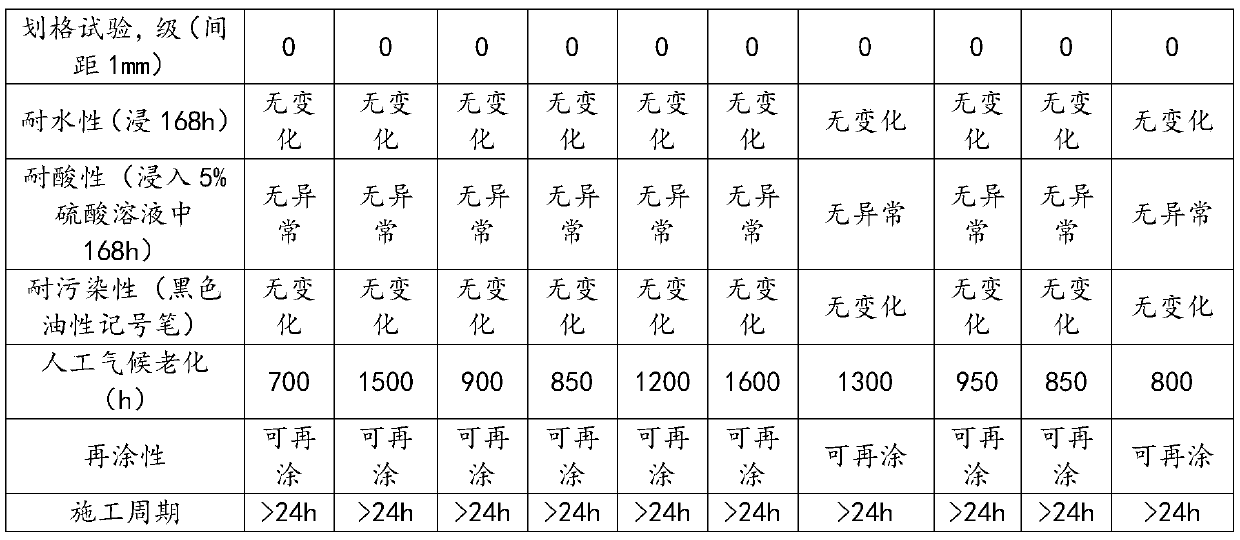

Flexible ceramic coating and preparation method thereof

ActiveCN109796871AGood compatibilityAvoid crackingAntifouling/underwater paintsPaints with biocidesSilanesCeramic coating

The invention relates to the technical field of coatings, in particular to a flexible ceramic coating and a preparation method thereof. The flexible ceramic coating is prepared by mixing a compositionA, a composition B and a composition C, wherein the composition A mainly comprises, by mass, 10-99 parts of acidic silica sol, 0-35 parts of pigments, 0-28 parts of a filler, 0-40 parts of deionizedwater, 0-10 parts of a dispersant, 0-0.7 part of an anti-settling aid, 0.2-0.5 part of a defoaming agent and 0.8-1.5 parts of a wetting leveling agent; the composition B mainly comprises, by mass, 85-93 parts of alkoxy silane monomers, 2-5 parts of a titanate coupling agent and 5-10 parts of an organic solvent; the composition C is an organosilicon-modified acrylic emulsion. The flexible ceramic coating is low in curing temperature, high in toughness and excellent in recoating property, and the phenomena of cracking, shedding and the like cannot occur when the thickness of a film reaches 90 micrometers.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

Toner

Provided is a toner exhibiting satisfactory fixability even in high-speed fixing process involving a double-sided printing mechanism, keeping stable toner image even after a conveyance step, and doesn't cause curling to a fixing roller even in thin paper. In a toner including toner particles, each of which contains polyester resins A and B, a coloring agent, and a resin composition C, the resin A includes a crystal nucleating agent bonded to a polyester molecular chain including a moiety capable of forming a crystalline structure. The resin B doesn't include a moiety capable of forming a crystalline structure. The composition C is obtained by copolymerizing a vinyl-based resin component with a polyolefin resin component. SP values the resin A, the resin B, the agent, the polyolefin component, and the vinyl-based component satisfy the particular relationships.

Owner:CANON KK

Preparation method of epoxidized 1, 2-polybutadiene

The invention relates to a preparation method of a polymeric material, in particular to a preparation method of epoxidized 1, 2-polybutadiene. Preparation steps of the preparation method are as follows: composition A and composition B are added to a reaction flask and stirred by magnetic force at the temperature of 65 DEG C until the composition A is dissolved; composition C and composition D are added to the reaction flask and stirred fully and uniformly; quantitative composition E is added to a system and reacted for a period at the constant temperature; after the reaction is finished, a product is poured out; absolute ethyl alcohol is added for precipitating a solid, sedimentation is performed for a period, suction filtration is performed, and a sodium bicarbonate solution and distilled water are used for washing a product solid for a plurality of times respectively; and the washed product solid is put into an oven for vacuum drying for 12 h at the temperature of 60 DEG C, and a product is obtained. The invention provides a synthesis method for epoxidizing 1, 2-polybutadiene. The prepared epoxidized 1, 2-polybutadiene can be used for toughening modification of other high polymer materials (such as nylon, epoxy resin and the like).

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Flame-resistant polycarbonate resin composition

The invention provides a flame-retardant panlite composition having excellent flame retardance, appearance and hydrolysis resistance, comprising 75% to 99.98% by weight of aromatic panlite (composition A), 0.01% to 5% by weight of polyfluortetraethylene mixture (composition B) and 0.001% to 20% by weight of flame retardance (composition C), wherein the polyfluortetraethylene mixture (composition B) is composed of polyfluortetraethylene particles and an organic polymer.

Owner:TEIJIN KASEK KK

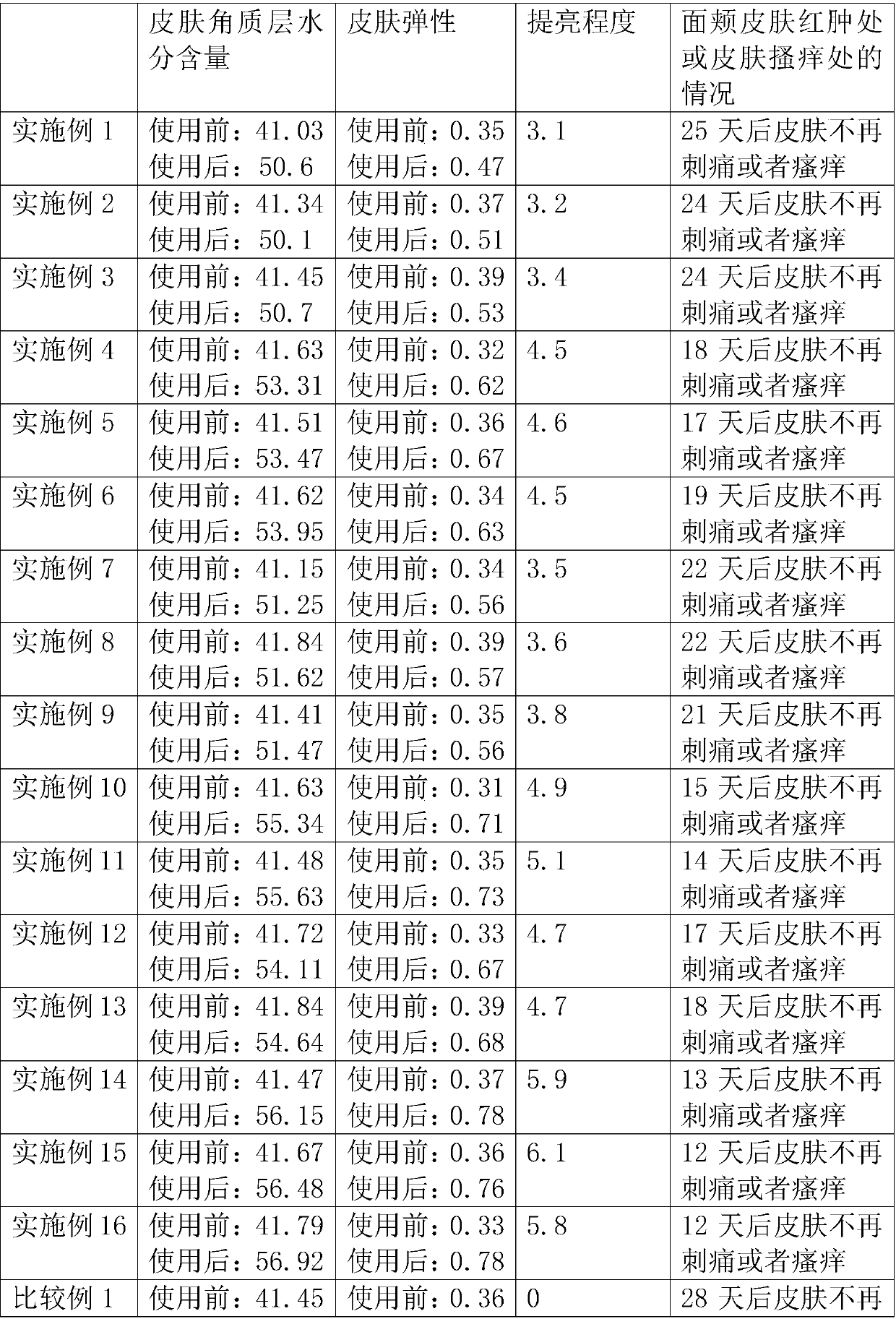

Tone-up cream

ActiveCN110179740AImprove smoothnessHigh transparencyCosmetic preparationsToilet preparationsSkin colorComposition B

The invention relates to the technical field of cosmetics, and provides a tone-up cream aiming at the problem that skin color is difficult to improve by a tone-up cream. The tone-up cream dprovided bythe invention comprise a composition A, a composition B and a composition C. The composition A is prepared from the following ingredients in parts by mass: 0.5 parts of pammonium acryloyldimethyltaurate-VP copolymer and 1-2 parts of propylene glycol dicaprylate / dicaprate. The composition B is prepared from the following ingredient in parts by mass: 1-4 parts of titanium dioxide, 1-4 parts of cetyl alcohol, and 1-4 parts of sodium polyacrylate / / polydimethylsiloxane / / decamethylcyclopentasiloxane / / tridecyl polyether-6 / / PEG / PPG-18 / 18 polydimethylsiloxane. The composition C is prepared from the following ingredients in parts by mass: 0.5-0.75 parts of 4-butyl resorcinol, 0.01-0.1 parts of Chinese galla extract, and 5-10 parts of nicotinamide. 4-Butyl resorcinol, Chinese gall extract and nicotinamide are adopted to cooperate so as to achieve a synergistic effect, which is beneficial to improve the smoothness and transparency of the skin, and is beneficial to improve the skin color effect ofthe one-up cream.

Owner:广州市瑞芬化妆品有限公司

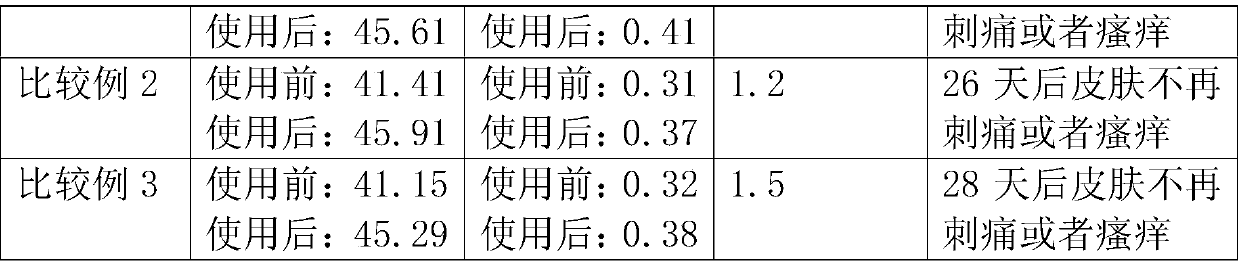

Composite calcium-zirconium-based lubricating grease and preparation method thereof

ActiveCN104513690AImprove high temperature resistanceGood mechanical stabilityThickenersTemperature resistanceAromatic acid

The invention discloses composite calcium-zirconium-based lubricating grease which comprises following components, on the basis of the weight of the lubricating grease, by weight, 5-50% of a composite calcium-zirconium-based thickening agent and 50-95% of basic oil, wherein the composite calcium-zirconium-based thickening agent is a calcium-zirconium soap generated through a reaction among a component A, a component B and a component C. The component A is a mixture composed of a higher fatty acid and an aromatic acid. The component B is an oxide and / or a hydroxide of calcium. The component C is at least one of an oxide of zirconium, a hydroxide of zirconium and alkoxyl zirconium. The invention also discloses a preparation method of the composite calcium-zirconium-based lubricating grease. Compared with zirconium-based lubricating grease, the composite calcium-zirconium-based lubricating grease is better in high-temperature resistance, mechanical stability, water resistance, adhesivity, salt fog resistance, colloid stability and extreme-pressure wear resistance. The lubricating grease is simple in the preparation method, is low in cost and is stable in quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and kit for modifying the coloration of keratinous fibres

A method for permanently modifying a color of keratinous fibers which comprises the steps of:—first providing a mixture of three compositions A, B and C, wherein said composition A comprises at least a reducing agent and optionally a coloring compound, said composition B comprises at least an alkalizing compound and said composition C comprises at least an oxidizing compound:—applying said mixture to keratinous fibers for a suitable period of time for modifying the color of said keratinous fibres: and—removing said mixture from said keratinous fibers.

Owner:6569048 CANADA

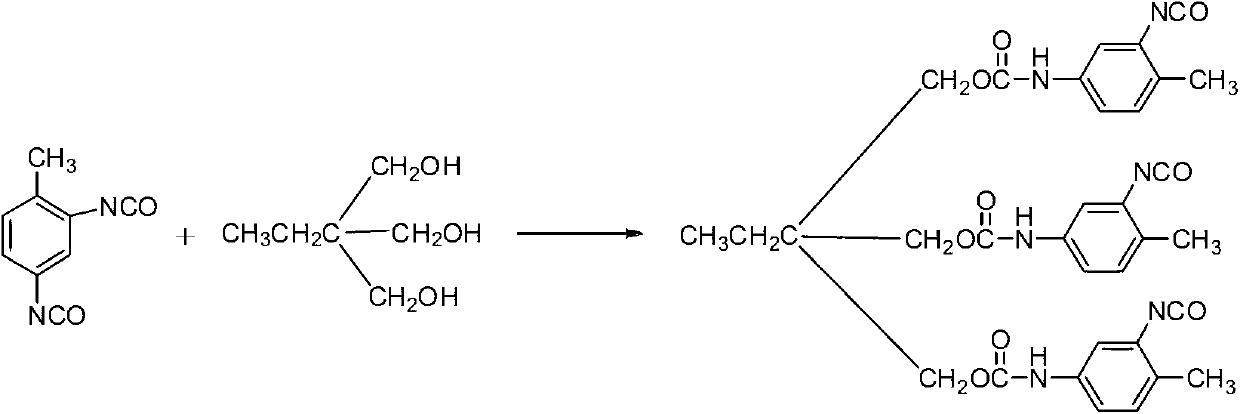

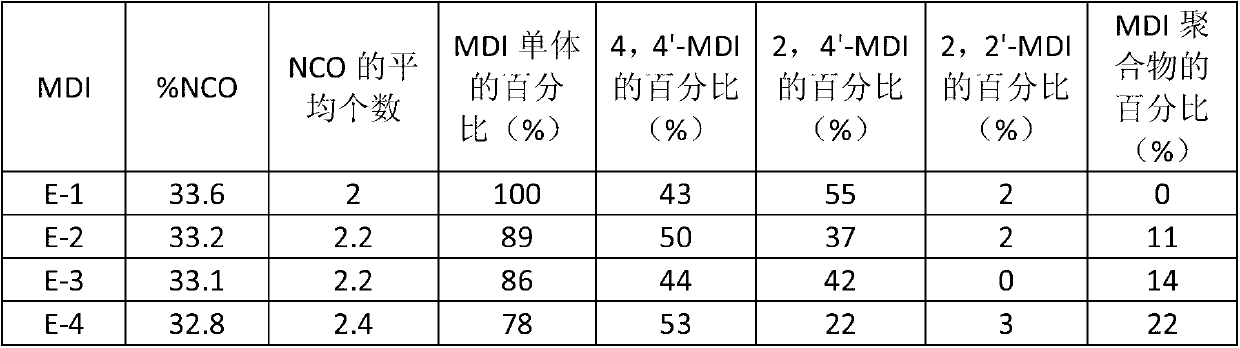

Preparation method for low free toluene diisocyanate (TDI) polyurethane pre-polymer curing agent

InactiveCN103130980AGood adhesionConstruction time limit growthCoatingsToluene diisocyanateTrimethoprim

The invention discloses a preparation method for a low free toluene diisocyanate (TDI) polyurethane pre-polymer curing agent. The preparation method for the low free TDI polyurethane pre-polymer curing agent comprises that a composition A and a composition B are put into a reaction kettle, nitrogen is injected and mixed, a molten composition C is added, and thus TDI / Trimethoprim (TMP) pre-polymer is obtained through reaction; a composition E is added, heated to 60-80 DEG C and reacted for 30-60 minutes; a composition D is added and reacted for 2-6 hours; and the low free TDI polyurethane pre-polymer curing agent with free TDI content which is lower than 0.4 % is obtained. The composition A is 2,4-TDI or TDI-80, the composition B is solvent with boiling point which is less than or equal to 200 DEG C, the composition C is trimethylolpropane which is dewatered by agent, the composition D is an aliphatic compound which contains 1-3 hydroxyls, and the molecular weight is 60-3000, and the composition E comprises one or a plurality of four kinds of diphenyl methane diisocyanates, namely, E-1, E-2, E-3 and E-4. The pre-polymer curing agent which is prepared by the preparation method for the low free TDI polyurethane pre-polymer curing agent is low in viscosity and good in stability.

Owner:SOUTH CHINA UNIV OF TECH

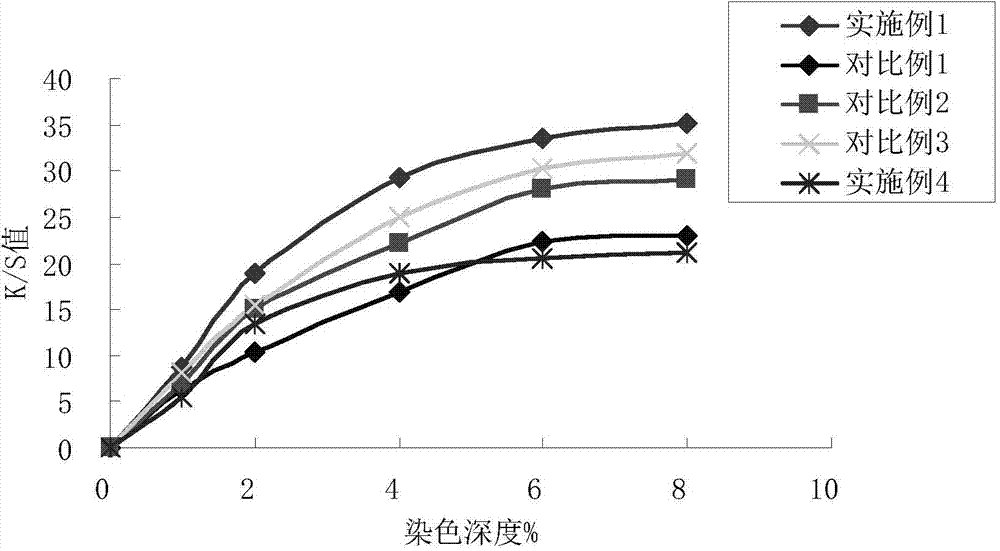

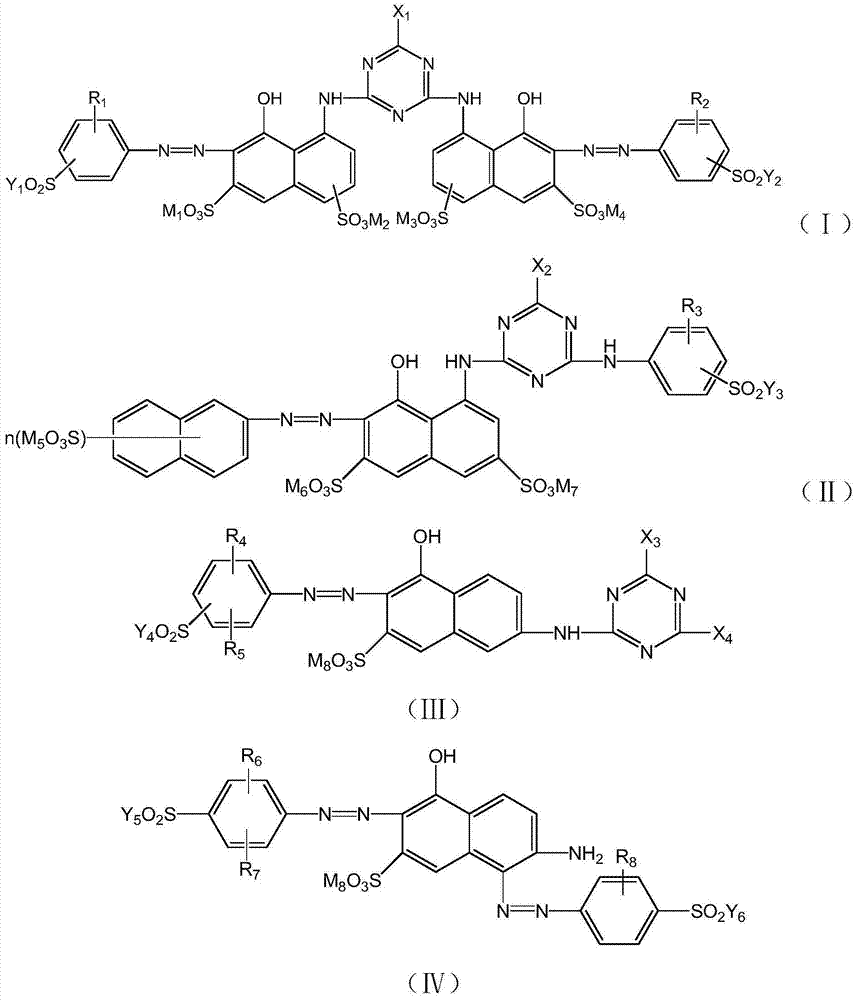

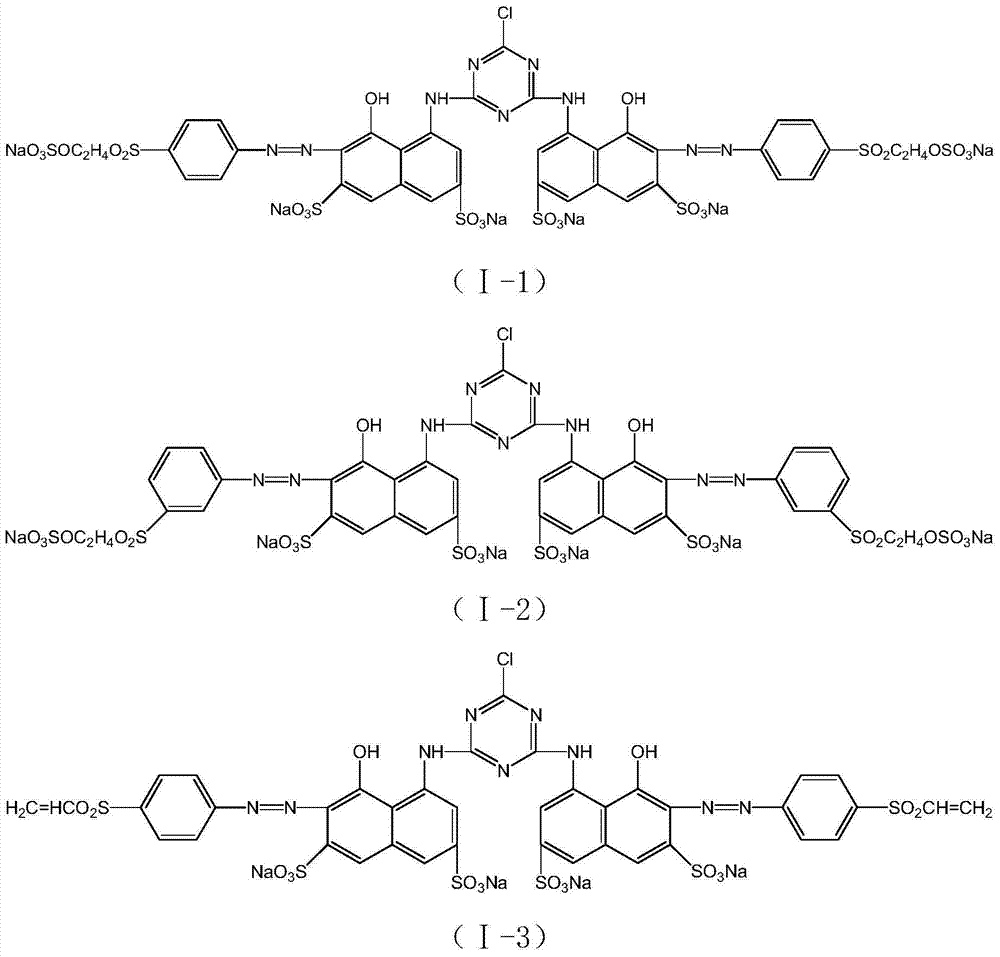

Active red dye composition and dye product

The invention discloses an active red dye composition and a dye product. The active red dye composition mainly comprises 40-90 parts by mass of a composition A, 5-40 parts by mass of a composition B, 0-20 parts by mass of a composition C, and 0-20 parts by mass of a composition D; the composition A is selected from at least one of dye monomer compounds with the structure shown as a formula (I) in the specification; the composition B is selected from at least one of dye monomer compounds with the structure shown as a formula (II) in the specification; the composition C is selected from at least one of dye monomer compounds with the structure shown as a formula (III) in the specification; the composition D is selected from at least one of dye monomer compounds with the structure shown as a formula (IV) in the specification. The active red dye product comprises the active red dye composition. The dye product is good in level-dyeing property, high in build up index, excellent in various color fastness and protrude especially in color fastness to washing and color fastness to friction when being applied to printing and dyeing of cellulose-containing fiber materials.

Owner:ZHEJIANG KEYONG CHEM CO LTD +1

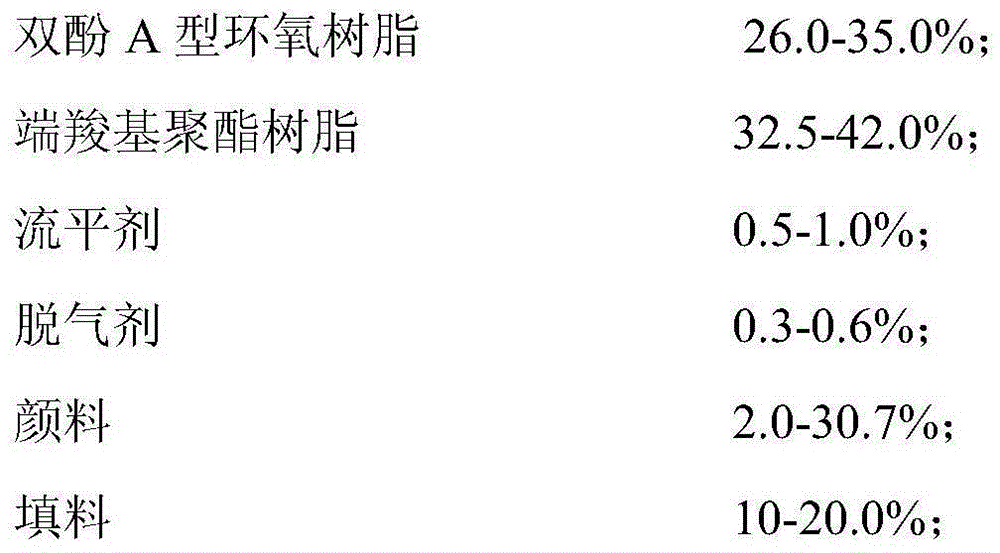

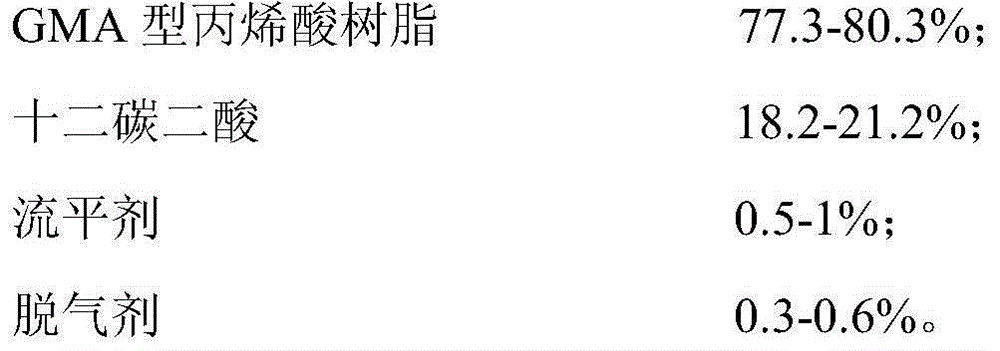

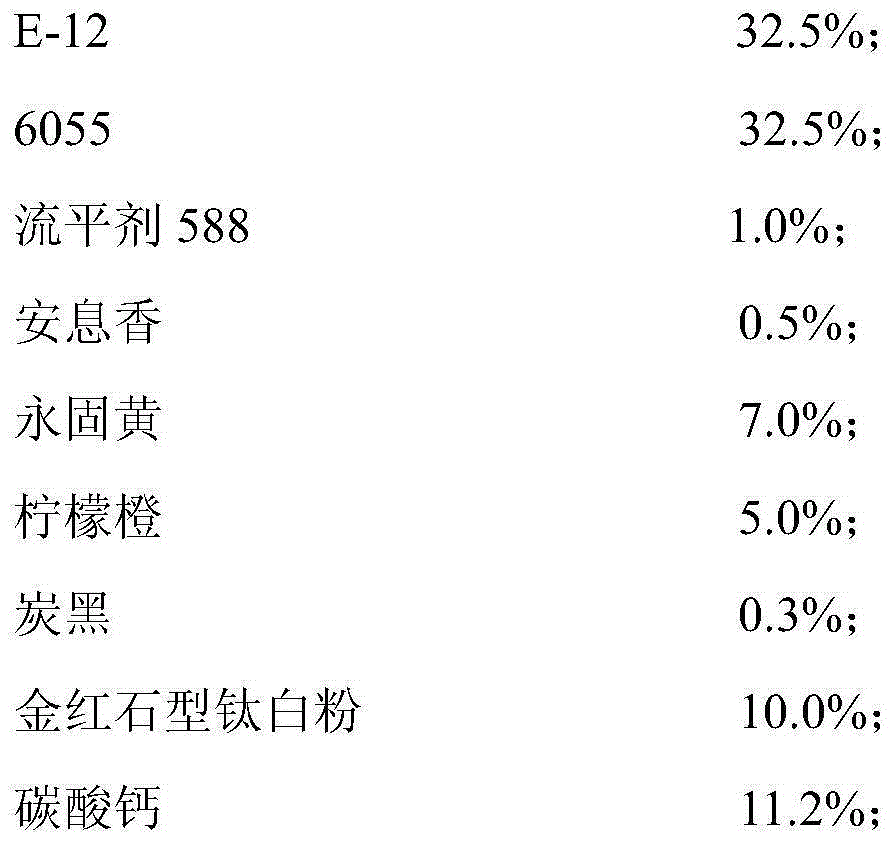

Powder coating with metal flashing effect, as well as preparation method and application method of powder coating

InactiveCN105038447AImprove impact resistanceImprove bending effectPowdery paintsEpoxy resin coatingsEpoxyAcrylic resin

The invention belongs to the field of functional powder coating, and particularly relates to powder coating with a metal flashing effect, as well as a preparation method and an application method of the powder coating. The powder coating is prepared by combining a composition A, a composition B and a composition C, wherein the composition A comprises the following raw materials in percentage by weight: 26.0-35.0% of bisphenol A-type ethoxyline resin, 32.5-42.0% of carboxyl terminated polyester resin, 0.5-1.0% of a leveling agent, 0.3-0.6% of a degassing agent, 2.0-33.5% of one or more pigments and 10-20.0% of a filler; the composition B comprises the following raw materials in percentage by weight: 90-99% of the composition A and 1-10% of one or more metal pigments; the composition C comprises the following raw materials in percentage by weight: 77.3-80.3% of GMA-type acrylic resin, 18.2-21.2% of dodecanedioic acid, 0.5-1% of the leveling agent and 0.3-0.6% of the degassing agent. A double-layer coating film is formed after application of the powder coating, so that the powder coating is high in impact resistance and bending resistance. The invention further provides the preparation method and the application method of the powder coating.

Owner:SAIGAO POWDER TECH YANTAI

CxHy sacrificial layer for cu/low-k interconnects

InactiveUS7365026B2Avoid damageSemiconductor/solid-state device detailsSolid-state devicesEtchingSemiconductor

Owner:TAIWAN SEMICON MFG CO LTD

Heating element condition monitor

InactiveUS6956489B2Electric signal transmission systemsWeather/light/corrosion resistanceMicrocontrollerEngineering

A method for monitoring the condition of an electric current-carrying heating element involving installing the heating element in a location and setting the initial composition Ci of the material as a reference baseline at an initial time Ti corresponding to said installation of the heating element. Data is then collected reflecting the subsequent composition Cs of the heating element material after a subsequent time Ts at the installed location and any change in the material composition of the heating element between Ti and Ts is monitored. An alarm is sent when the change reaches a threshold value indicating a possible failure condition. According to one embodiment, an impedance monitor is provided that calculates and compares impedance at the required levels of accuracy to determine changes in material composition. The impedance monitor, or portions thereof may be embedded within a microcontroller for increased portability and functionality.

Owner:HITACHI LTD +1

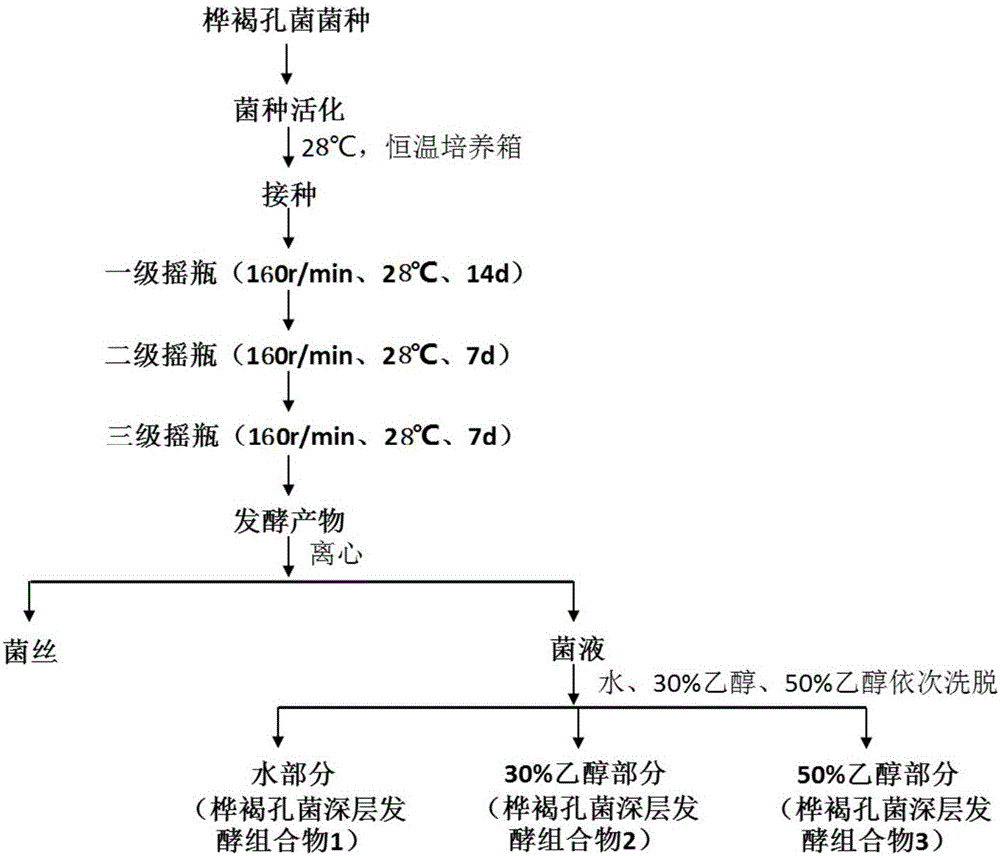

Inonotus obliquus submerged fermentation product and application

InactiveCN106434755AImprove adsorption capacityReduce loss rateMetabolism disorderMicroorganismsGlycosidase inhibitorSubmerged fermentation

The invention discloses an inonotus obliquus submerged fermentation product and application. The inonotus obliquus submerged fermentation product comprises a composition A, a composition B and a composition C. By the utilization of a biological fermentation technology, inonotus obliquus strains are fermented to obtain the new composition, and the composition belongs to a natural alpha-glucosidase inhibitor, and is low in price and environmentally friendly; the preparation technology is easy to industrialize. The inonotus obliquus submerged fermentation product is suitable for a broad crowd of people, convenient to eat and capable of serving as a daily drink to be drunk by people with diabetes, will not generate adverse reactions such as abdominal discomfort, flatulence and exsufflation, and can achieve a health-care effect after being drunk by average persons.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com