Resin particles and producing method thereof, toner for developing electrostatic latent image and producing method thereof, electrostatic latent image developer as well as image forming method

A resin particle, electrostatic latent image technology, applied in the direction of developer, electric recording process applying charge pattern, electric recording process applying charge pattern, etc., can solve the problem of promoting uneven distribution of toner particles and widening toner. Particle size distribution, difficulty in toner particle size homogenization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

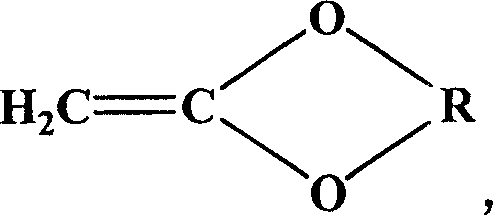

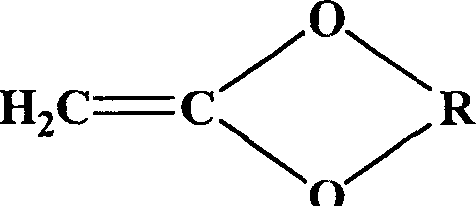

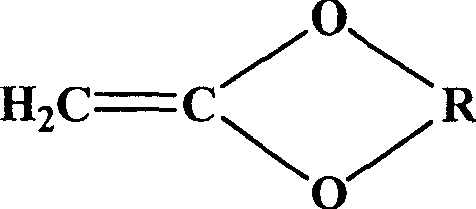

[0122] The third mode of the method for producing resin particles of the present invention includes at least: an emulsification step, that is, a step of emulsifying a resin precursor composition to form droplets of the resin precursor composition, the resin precursor composition comprising ethylene a radical monomer, a cyclic ketene acetal compound represented by the following general formula (1), and a radical polymerization initiator; and a polymerization step, that is, making the vinyl monomer and cyclic vinyl in the droplets A step in which ketal diethyl alcohol compounds are polymerized to synthesize vinyl-based copolymers.

[0123] Formula (1)

[0124]

[0125] In the general formula (1), R represents a chain or cyclic divalent aliphatic group optionally containing an ether bond. This aliphatic group may have a substituent.

[0126] The vinyl-based monomer and the cyclic ketene acetal compound contained in the resin precursor composition are polymerized in the polym...

Embodiment 1

[0258]

[0259] γ-decalactone 200 parts

[0260] Scandium trifluoromethanesulfonate 2 parts

[0261] Styrene 100 parts

[0262] Butyl acrylate 100 parts

[0263] Acrylic 4 parts

[0264] AIBN (azobisisobutyronitrile) 10 parts

[0265] The above components (both manufactured by Wako Pure Chemical Industries, Ltd.) were mixed and dissolved, and the substance was dispersed in a flask in a solution in which 8 parts of nonionic surfactant was dissolved in 582 parts of ion-exchanged water (trade name: Nonipol 85, manufactured by Sanyo Chemical Industry Co., Ltd.) and 10 parts of anionic surfactant (trade name: Neogen SC, manufactured by Daiichi Kogyo Pharmaceutical Co., Ltd.), emulsifying this material so that the average particle diameter is 1 μm Or less, and the ring-opening polymerization of lactone was carried out at a reaction temperature of 50 for 15 hours. Then, nitrogen substitution was performed while slowly mixing the raw materials for 10 minutes, the flask was heat...

Embodiment 2

[0267]

[0268] Cyclopentadecanolide 200 parts

[0269] Lipase (derived from Pseudomonas genus organisms) 50 parts

[0270] Styrene 100 parts

[0271] Butyl acrylate 100 parts

[0272] Acrylic 4 parts

[0273] AIBN (azobisisobutyronitrile) 10 parts

[0274] The above components (both manufactured by Wako Pure Chemical Industries, Ltd.) were mixed and dissolved, and the substance was dispersed in a flask in a solution in which 8 parts of nonionic surfactant was dissolved in 582 parts of ion-exchanged water (trade name: Nonipol 85, manufactured by Sanyo Chemical Industry Co., Ltd.) and 10 parts of anionic surfactant (trade name: Neogen SC, manufactured by Daiichi Kogyo Pharmaceutical Co., Ltd.), emulsifying this material so that the average particle diameter is 1 μm or less, and the lactone ring-opening polymerization was carried out at a reaction temperature of 50° C. for 50 hours. Then, nitrogen substitution was performed while slowly mixing the raw materials for 10 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com