Composite calcium-zirconium-based lubricating grease and preparation method thereof

A technology of zirconium-based lubricating grease and lubricating grease, which is applied in the field of lubricating grease, can solve the problems that other properties of lubricating grease need to be further improved, and achieve the effects of low cost, improved colloidal stability, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

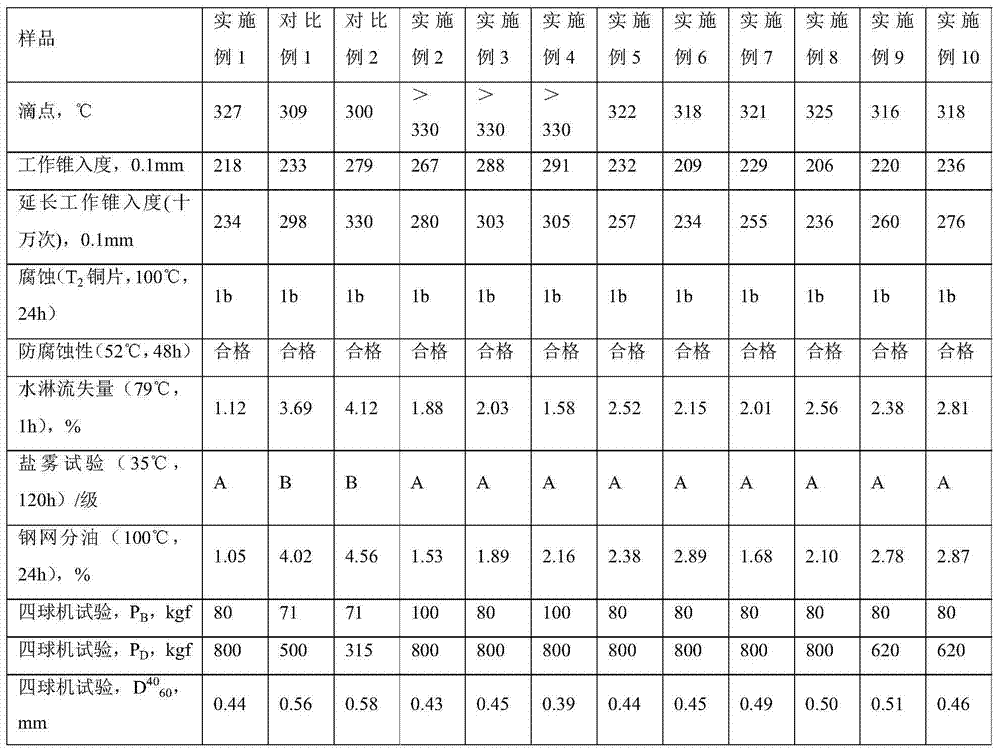

Examples

preparation example Construction

[0030] In a second aspect, the present invention provides a method for preparing a composite calcium-zirconium-based grease, the method comprising:

[0031] (1) Mix Component A, Component B and Component C in the base oil, and saponify by heating and draining water, wherein Component A is a mixture of higher fatty acids and aromatic acids, and Component B is calcium oxide and / or Hydroxide, component C is at least one of zirconium oxide, zirconium hydroxide and alkoxy zirconium;

[0032] (2) Heat up the temperature of the reaction mixture obtained in step (1) to 180-230°C for constant temperature refining, add the remaining base oil, cool, and add necessary additives to obtain the finished product.

[0033] According to the present invention, although the composite calcium-zirconium-based grease is prepared according to the above method, the purpose of the present invention can be achieved, that is, the prepared composite calcium-zirconium-based grease has good high temperature...

Embodiment 1

[0046] This example is used to illustrate the composite calcium-zirconium-based lubricating grease prepared by the present invention.

[0047] Put 150g of HVI500SN lubricating base oil (100℃ kinematic viscosity is 10mm 2 / s, the same below), 48g of 12-hydroxystearic acid and 26.6g of phthalic acid were added to the normal pressure fat kettle, stirred, heated to 75°C, 31.5g of zirconium n-propoxide, 3.6g of Ca(OH) 2 and 15.3g Zr(OH) 4 Add it successively to react, the molar ratio of calcium and zirconium is 1:4, calculated by zirconium, Zr(OH) 4 The molar ratio with zirconium n-propoxide is 1:1, heat up to 105°C, drain and saponify, then heat up to 200°C for 10 minutes, add 200g of HVI500SN lubricating base oil, stir and cool down, wait until the temperature cools down to 110°C, circulate filter and homogenize , Degassing to get the finished product. The test results are shown in Table 1.

[0048] In the lubricating grease obtained in this embodiment, based on the weight of...

Embodiment 2

[0050] This example is used to illustrate the composite calcium-zirconium-based lubricating grease prepared by the present invention.

[0051] Put 400g of HVI150BS lubricating base oil (100℃ kinematic viscosity is 30mm 2 / s, the same below), 48g of 12-hydroxystearic acid and 80g of isophthalic acid were added to the normal pressure fat kettle, stirred, heated to 90 ° C, and 17g of Ca(OH) 2 , 8.9g Zr(OH) 4 and 76g of zirconium ethylate were successively added to react, the molar ratio of calcium to zirconium was 1:1.5, calculated as zirconium, Zr(OH) 4 The molar ratio with zirconium ethylate is 1:5, heat up to 120°C, drain and saponify, then heat up to 230°C and keep the temperature for 5 minutes, add 600g of HVI150BS lubricating base oil, stir and cool down, wait until the temperature is cooled to 120°C, circulate filtration, homogenize, Degassing to get the finished product. The test results are shown in Table 1.

[0052] In the lubricating grease obtained in this embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com