Patents

Literature

119 results about "Zirconium tetrafluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

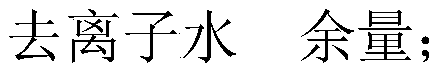

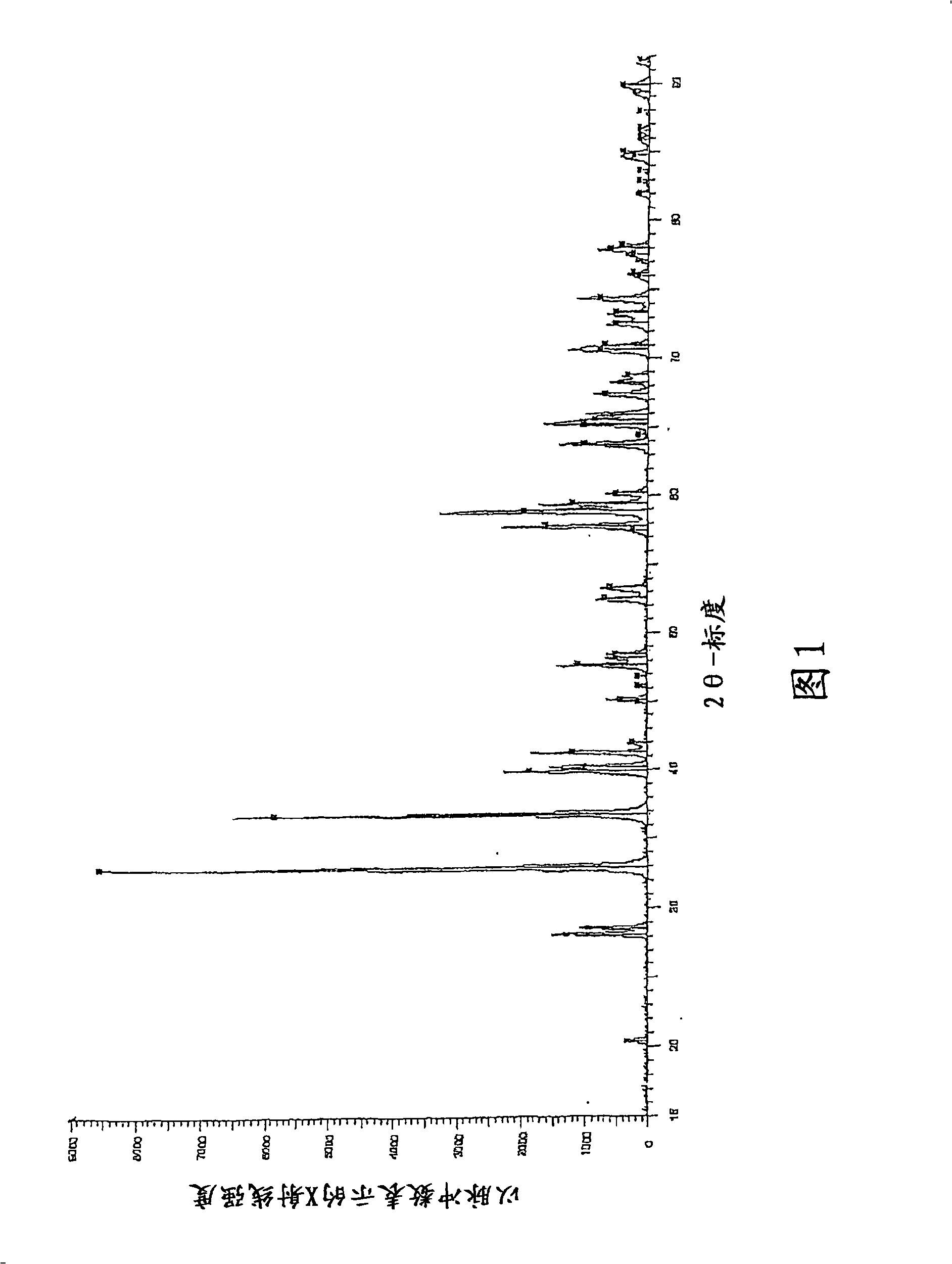

Zirconium(IV) fluoride (ZrF₄) is an inorganic chemical compound. It is a component of ZBLAN fluoride glass. It is insoluble in water. It is the main component of fluorozirconate glasses. Three crystalline phases of ZrF₄ have been reported, α (monoclinic), β (tetragonal, Pearson symbol tP40, space group P42/m, No 84) and γ (unknown structure). β and γ phases are unstable and irreversibly transform into the α phase at 400 °C.

Seal rubber for water pump of automobile and preparation method of seal rubber

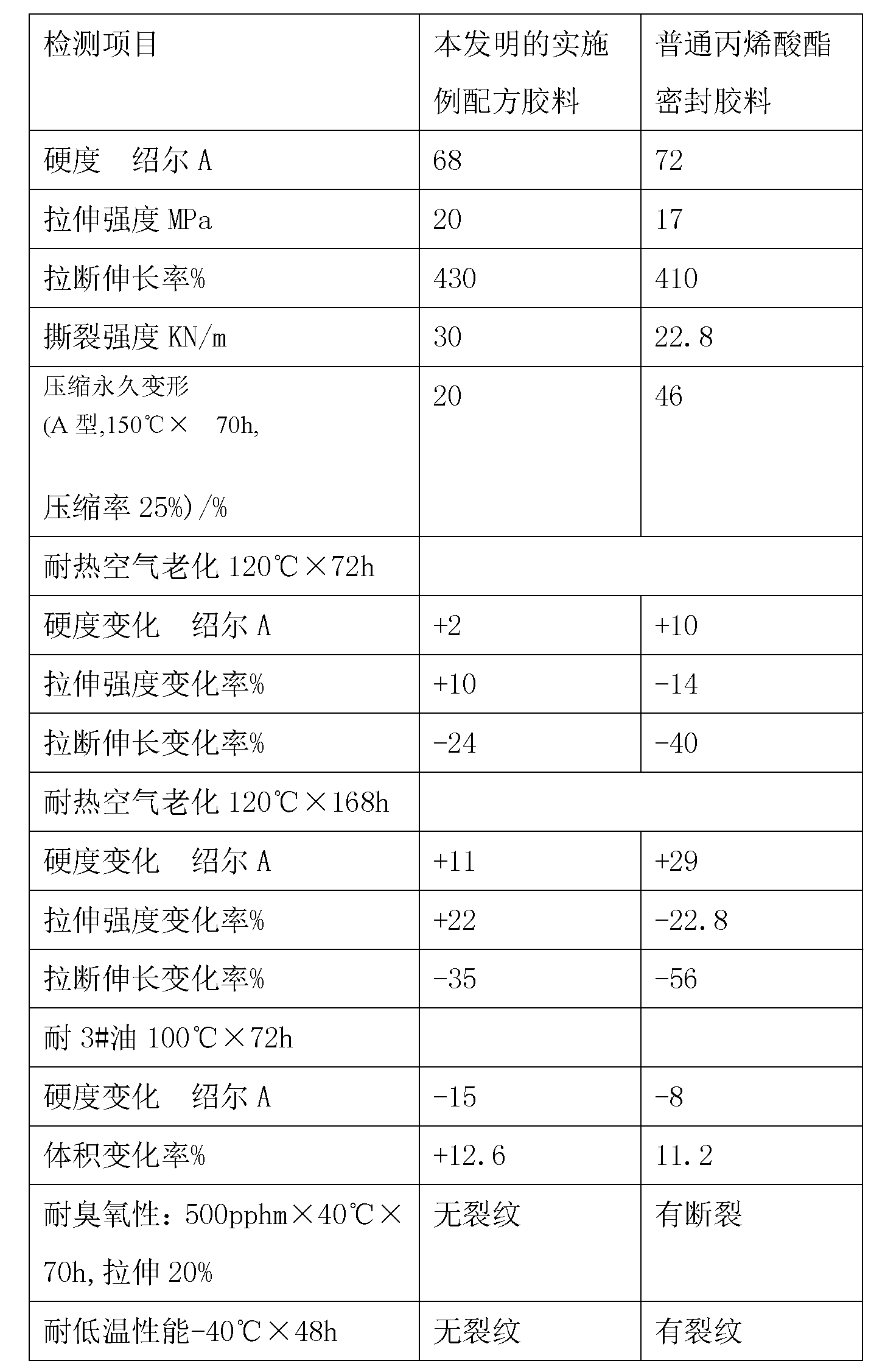

The invention discloses a seal rubber for a water pump of an automobile. The seal rubber comprises the following raw materials by weight: 50 to 60 parts of acrylic rubber, 10 to 15 parts of fluorinated silicone rubber, 10 to 15 parts of epichlorohydrin rubber T3100, 10 to 15 parts of butyl bromide rubber 221, 30 to 36 parts of high wear-resisting carbon black N330, 20 to 24 parts of precipitated white carbon black, 4 to 6 parts of light calcium carbonate, 5 to 10 parts of wollastonite in powder, 3 to 5 parts of zirconium tetrafluoride, 5 to 7 parts of barium sulfate, 3 to 5 parts of molybdenum disulfide, 9 to 11 parts of modified iron tailings powder, 1 to 2 parts of vulcanizing agent DCBP, 1 to 2 parts of antioxidant TPPD, 0.5 to 1 parts of accelerant H, 4 to 6 parts of magnesium oxide, 1 to 2 parts of 2-thiol benzimidazole, 1 to 2 parts of paraffin, 1 to 2 parts of isopropyl tri(dioctylpyrophosphate) titanate, and 17 to 19 parts of tri(2-ethylhexyl) acetocitrate. The rubber compound is excellent in ozone resistance, low-temperature resistance and heat resistance, wide in operating temperature wide and environment-friendly in process, and can be used for manufacturing various sealing gaskets.

Owner:马鞍山市中澜橡塑制品有限公司

Active carbon air filter element and preparation method thereof

InactiveCN103463868AFunction as a filterImprove wear resistanceFiltration separationPolyvinyl alcoholFiltration

The invention discloses an active carbon air filter element and a preparation method thereof. The active carbon air filter element comprises following raw materials, by weight, 12 to 14 portions of active carbon powder, 40 to 45 portions of microporous polyethylene powder, 1 to 2 portions of silver nitrate, 3 to 4 portions of sodium chloride, 2 to 3 portions of silane coupling agent KH550, 1 to 2 portions of zirconium tetrafluoride, 3 to 4 portions of graphite, 1 to 2 portions of silicon carbide, 4 to 6 portions of attapulgite, 2 to 3 portions of urea, 1 to 2 portions of azodicarbonamide, 12 to 14 portions of modified attapulgite, 3 to 4 portions of polyvinyl alcohol and an appropriate amount of water. Silver nitrate is taken as one of the raw materials of the active carbon air filter element, so that when the active carbon air filter element is used for filtration and adsorption, silver ions are capable of sterilizing, and realizing further purifying of air or water. Silicon carbide is taken as one of the raw materials, and is capable of improving wear resistance and strength of the active carbon air filter element. The active carbon air filter element is suitable to be used in severe environment; is high in purification efficiency, less in pressure loss, and long in service life; is resistant to high temperature and corrosion; and is capable of removing micro dust in the air.

Owner:天长市天乐电器厂

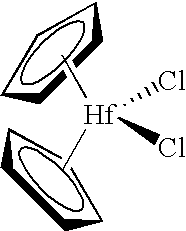

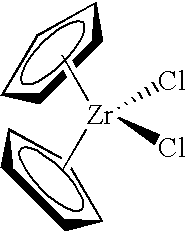

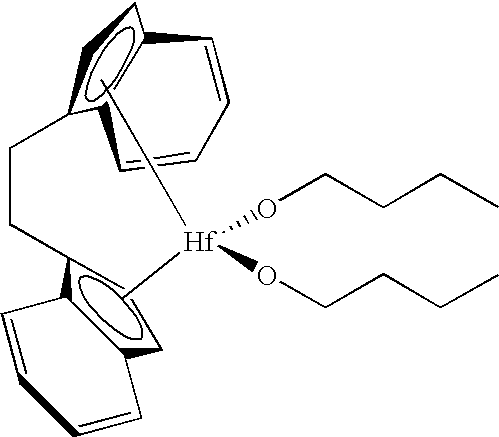

Organometal catalyst composition

InactiveUS6838533B2Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationTitanium tetrafluorideOrganometallic catalysis

This invention provides catalyst compositions that are useful for polymerizing at least one monomer to produce a polymer. This invention also provides catalyst compositions that are useful for polymerizing at least one monomer to produce a polymer, wherein said catalyst composition comprises contacting an organometal compound, an organoaluminum compound, and a solid, wherein said solid is selected from the group consisting of titanium tetrafluoride, zirconium tetrafluoride, and a treated solid oxide compound.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Bamboo charcoal filter element and preparation method thereof

InactiveCN103463867AImprove adsorption capacityCorrosion resistanceFiltration separationSodium metasilicateMicrocrystalline wax

The invention discloses a bamboo charcoal filter element and a preparation method thereof. The bamboo charcoal filter element comprises following raw materials, by weight, 20 to 24 portions of nanometer titanium dioxide, 24 to 26 portions of white clay, 12 to 14 portions of clay, 9 to 12 portions of bauxite, 4 to 6 portions of zirconium tetrafluoride, 6 to 8 portions of triolein, 32 to 34 portions of polypropylene, 1 to 2 portions of microcrystalline wax, 10 to 12 portions of nanometer silicon dioxide, 4 to 6 portions of sodium metasilicate, 90 to 100 portions of bamboo charcoal powder and 58 to 60 portions of modified attapulgite. The bamboo charcoal filter element possess excellent adsorption performance; is not harmful but benefit for the environment; is high in purification efficiency, and long in service life; is resistant to corrosion; and is capable of removing micro dust in the air.

Owner:天长市天乐电器厂

Modified calcium carbonate with excellent acid resistance and preparation method thereof

InactiveCN105111504AImprove the lubrication effectImprove water resistanceCoatingsPigment treatment with macromolecular organic compoundsPotassium persulfateSodium bicarbonate

The invention discloses modified calcium carbonate with the excellent acid resistance and a preparation method thereof. The modified calcium carbonate is characterized by comprising, by weight, 100 parts to 150 parts of calcium carbonate, 30 parts to 50 parts of sodium oleate, 0.3 part to 0.7 part of sodium dodecyl benzene sulfonate, 1 part to 3 parts of sodium bicarbonate, 4 parts to 8 parts of styrene, 0.02 part to 0.05 part of potassium persulfate, 3 parts to 5 parts of fumed silica, 2 parts to 3 parts of organobentonite, 2 parts to 3 parts of zirconium tetrafluoride, 1 part to 3 parts of epoxy castor oil, 2 parts to 3 parts of sodium tripolyphosphate, 3 parts to 5 parts of shell powder and a proper amount of deionized water. According to the modified calcium carbonate, as the added zirconium tetrafluoride, the added epoxy castor oil, the added sodium tripolyphosphate and the added shell powder are cooperatively used, the calcium carbonate is good in acid resistance and adsorbability, resistant to bacteria, capable of achieving bacteriostasis, resistant to ultraviolet rays and good in heat resistance and light resistance; the modified calcium carbonate can be crosslinked with film forming matter in rubber, plastics and coatings to generate the good surface decoration effect, the performance of a product can be improved, and the modified calcium carbonate is green, safe and worthy of popularization.

Owner:CHIZHOU CELT NANO TECH

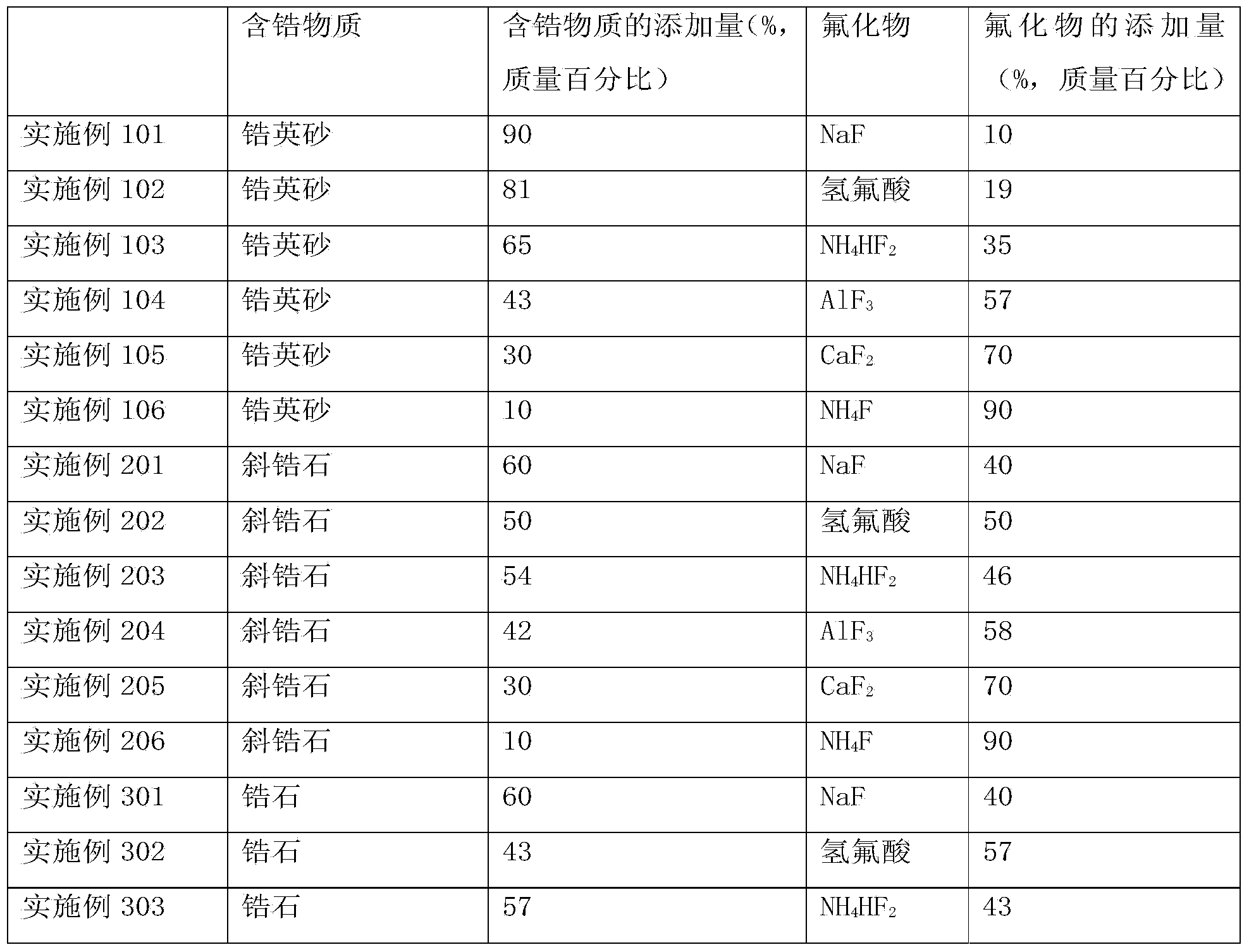

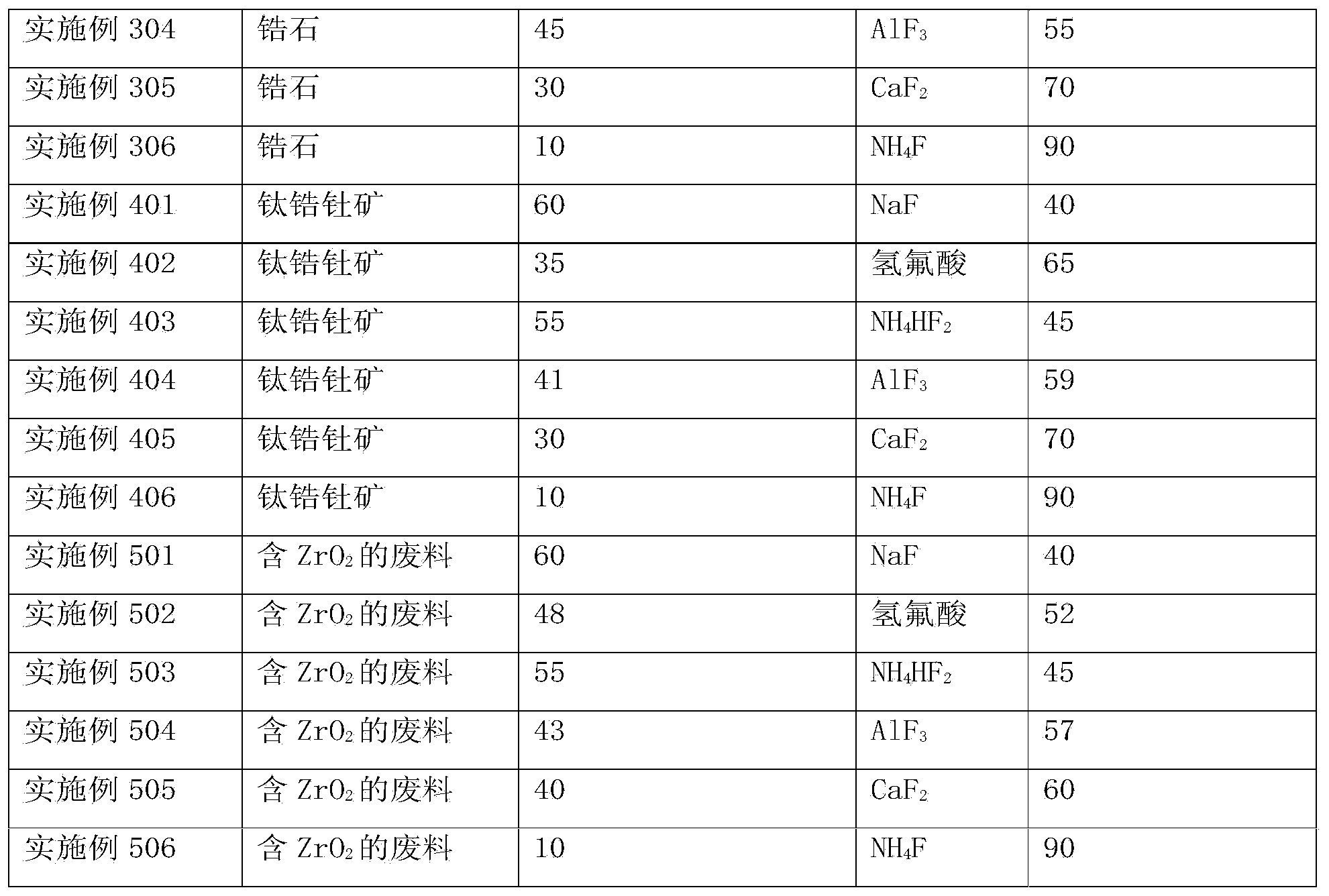

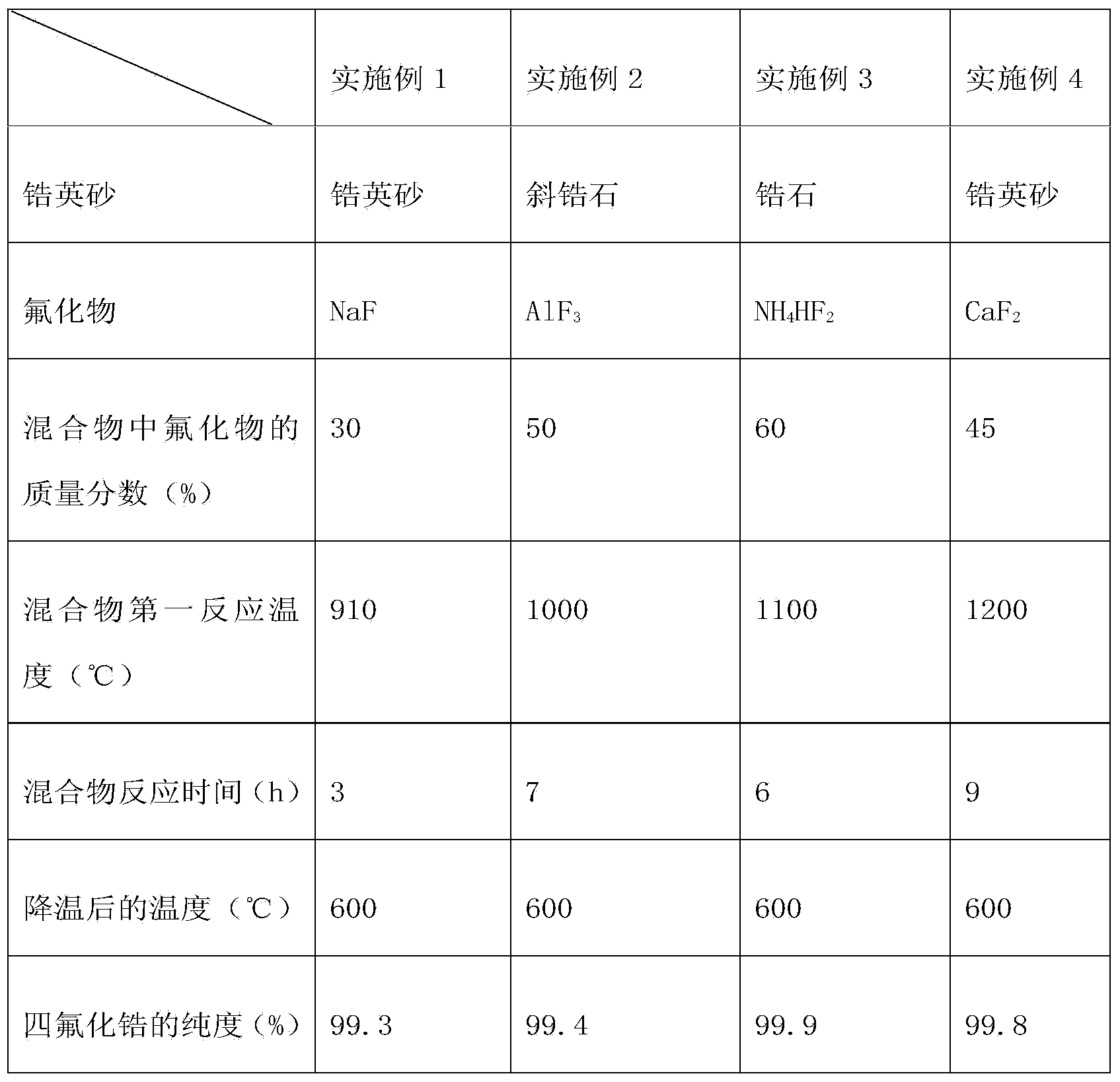

Preparation method of zirconium fluoride

ActiveCN103708550AWide variety of sourcesLow costZirconium halidesChemical industryZirconium tetrafluoride

The invention relates to the field of chemical industry and specifically relates to a preparation method of zirconium fluoride. The preparation method of zirconium fluoride comprises the following steps: mixing a zirconium-containing substance with a fluoride to obtain a mixture; reacting the mixture to obtain gaseous zirconium tetrafluoride and a solid oxide; carrying out gas-solid separation to obtain gaseous zirconium tetrafluoride, wherein the zirconium-containing substance comprises zirconium-containing minerals or scrap materials containing zirconium oxide. The preparation method of zirconium fluoride provided by the embodiment of the invention is low in cost and is simple.

Owner:贵州万方铝化科技开发有限公司

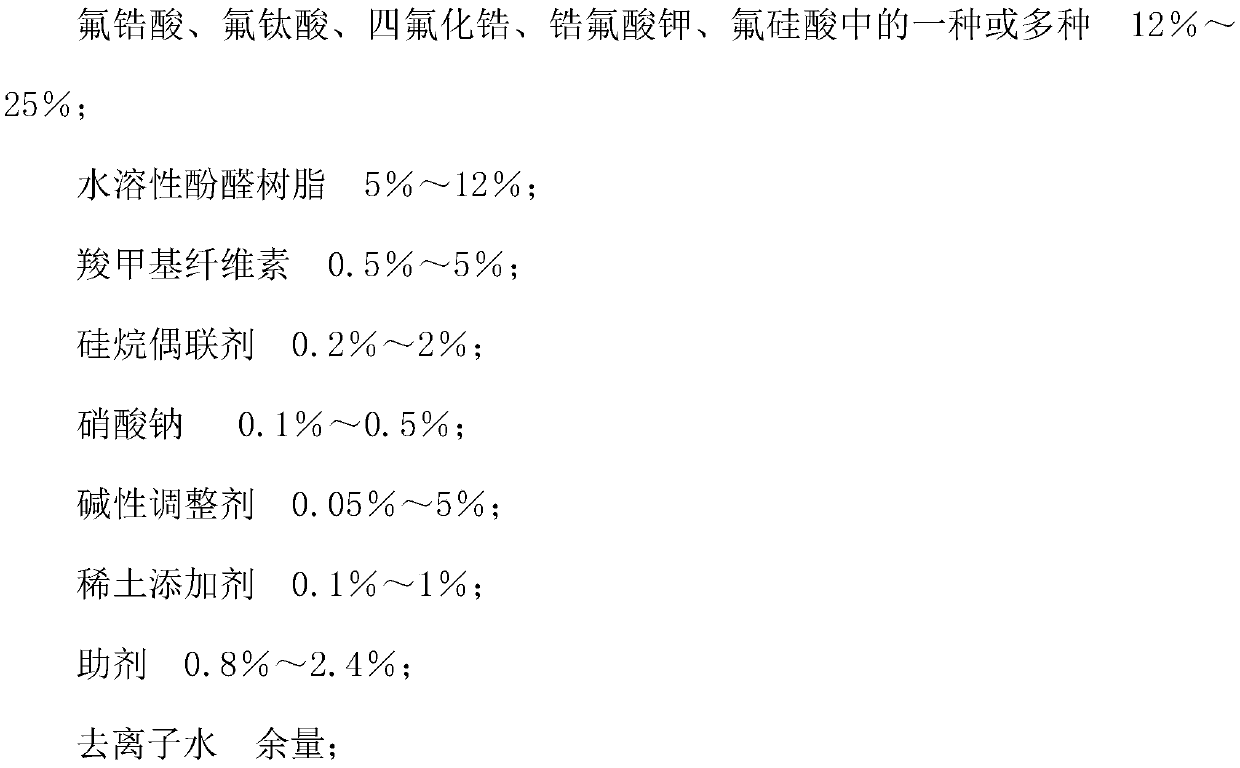

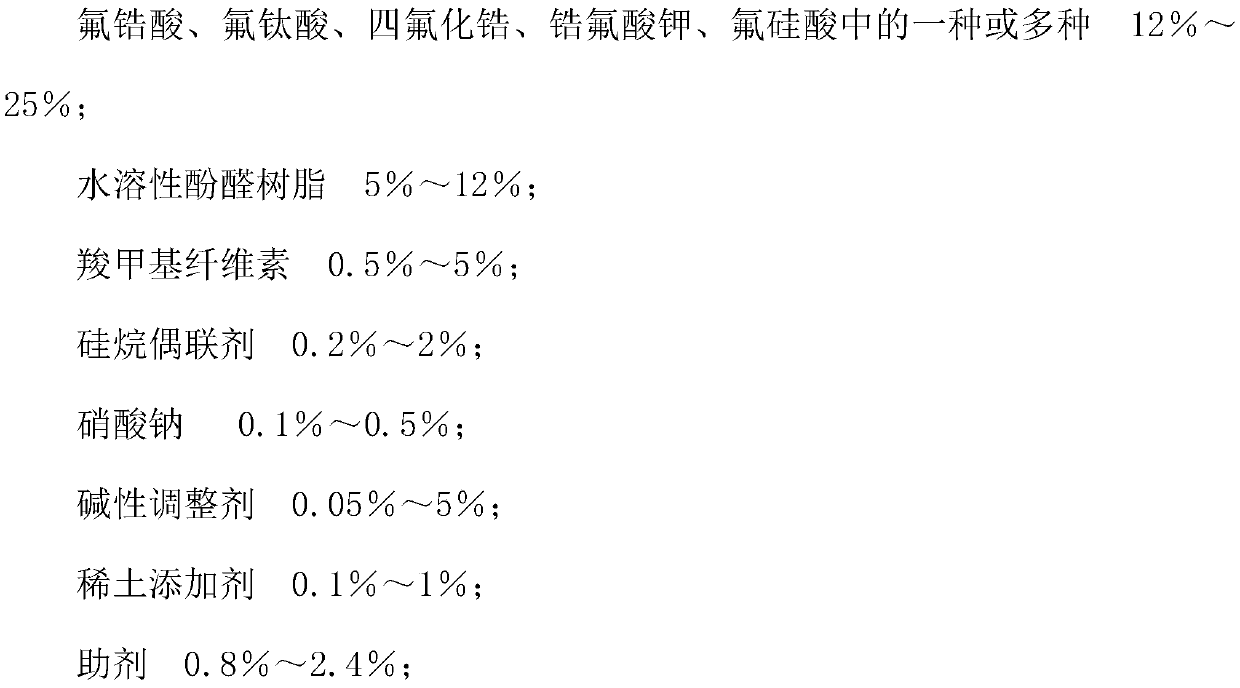

Aluminum profile chromate-free passivation agent

PendingCN110257809AImprove rust resistanceLow costMetallic material coating processesAntioxidantRare earth

Owner:浙江九合环保科技有限公司

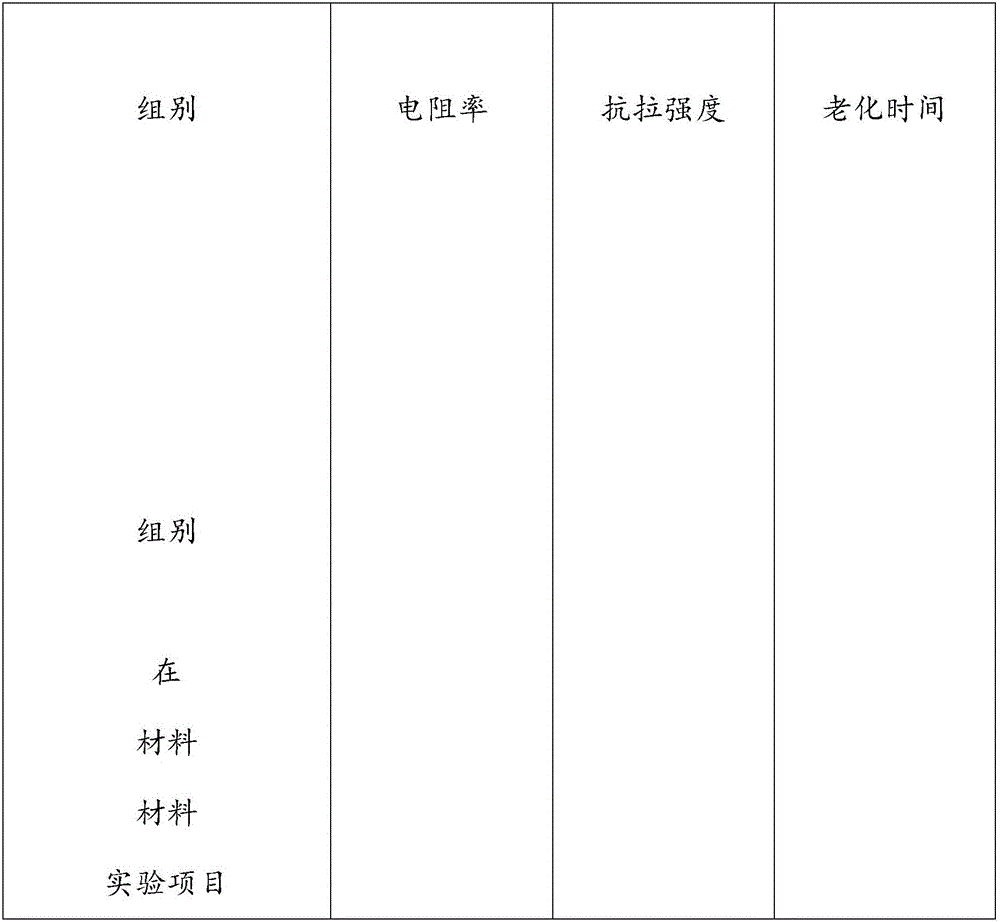

High-resistance polyurethane sponge and preparation method

ActiveCN103641986AImprove corrosion resistanceIncrease the performance of mildew bacteriaHigh resistancePolyethylene glycol

The invention discloses a high-resistance polyurethane sponge and a preparation method, and the sponge comprises the following raw materials by weight: 110-120 parts of methoxy polyethylene glycol, 50-60 parts of isophorone diisocyanate, 15-20 parts of polyurethane resin, 20-25 parts of dichloromethane, 0.35-0.50 parts of dibutyltin dilaurate, 0.7-0.8 parts of N,N-Dimethyl cyclohexyl amine, 4.0-5.5 parts of tung oil, 0.3-0.4 parts of antioxidant 168, 0.5-1.0 part of anti-ultraviolet agent, 5.5-7.5 parts of iso-tridecanol polyoxyethylene ether, 3-4 parts of modifier and 10-11 parts of water. The high-resistance polyurethane sponge has excellent oxidation resistance, light resistance and aging resistance, zirconium tetrafluoride has the characteristics of high tensile strength, good thermostability and strong corrosion resistance, polyurethane resin is a high polymer material with high strength, tear resistance and wear resistance, and the high resistance of the sponge can be greatly increased.

Owner:广州市恒辉体育设施有限公司

Acidproof metal surface silane treatment agent and preparation method thereof

The invention discloses an acidproof metal surface silane treatment agent, which is a mixed solution. Per liter of the mixed solution is composed of the following components by weight (g): 20-30 of 3-glycidyl ether oxypropyl trimethoxysilane, 20-30 of aminopropyl triethoxysilane, 2-3 of diethanolamine, 4-5 of sodium tripolyphosphate, 1-2 of N-methyl pyrrolidone, 8-10 of glycerol, 0.2-0.4 of zirconium tetrafluoride, 2-4 of a film forming aid, and the balance water. The treatment process of the acidproof metal surface silane treatment agent produced in the invention generates no dreg, the treatment time is short, and the treatment process is easy to control. Being free of harmful heavy metal ions, the acidproof metal surface silane treatment agent is safe and environment-friendly, and can form a silane coating having excellent corrosion resistance with a metal surface, thus prolonging the service life of the metal.

Owner:MAANSHAN TUORUI METAL SURFACE TECH

Method for recycling zirconium tetrafluoride to form zirconia

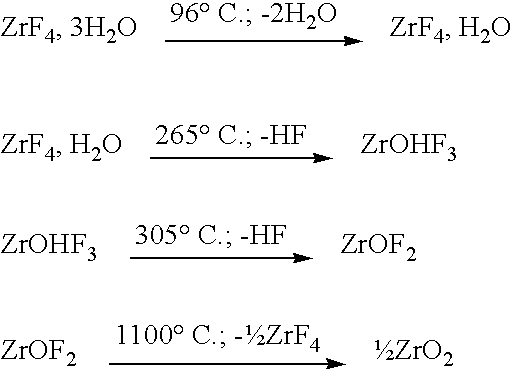

The invention relates to a method for converting ZrF4 into ZrO2 by thermally converting solid ZrF4 and water heated in a reactor, to form ZrO2. The initial weight ratio ZrF4 on water is especially between 1 / 5 and 1 / 500, preferably between 1 / 10 and 1 / 200, more specifically between 1 / 15 and 1 / 100, and said ratio is preferably maintained essentially throughout the conversion. The thermal conversion is carried out at a temperature which is higher than, or equal to, 300 DEG C, especially between 300 and 800 DEG C, preferably between 300 and 600 DEG C, more specifically between 350 and 450 DEG C. The invention especially relates to the recycling of the zirconium alloy stripping baths.

Owner:CO EURO ZIRCONIUM ZIRCONIUM CEZUS

Metal surface silicane treating agent containing diethanol amine and preparing method thereof

ActiveCN103060787AImprove corrosion resistanceExtended service lifeMetallic material coating processesDiethylene glycol monobutyl etherZno nanoparticles

The invention discloses a metal surface silicane treating agent containing diethanol amine. The metal surface silicane treating agent containing the diethanol amine is characterized by being a mixed solution which is prepared from following compositions of, by weight part ratio in every liter of the mixed solution, 28-35 parts of 1,2-bis (triethoxy silicon) ethane, 32-40 parts of gamma-aminopropyl triethoxy silicane, 100-160 parts of aqueous nanometer zinc oxide material, 2-3 parts of allyl alcohol, 1-2 parts of ethylene glycol, 2-3 parts of sodium tripolyphosphate, 2-4 parts of propylene glycol, 2-3 parts of zirconium tetrafluoride, 2-3 parts of diethanol amine, 2-3 parts of ammonium chloride, 1-2 parts of diethylene glycol monobutyl ether, 1-2 parts of trimethylolpropane, 0.3-0.5 part of sodium dodecyl benzene sulfonate, and the balance water. The metal surface silicane treating agent containing the diethanol amine has the advantages that, a silicane coating formed on the surface of metal after the metal is processed by using the surface silicane treating agent has good decay resistance, service life of the metal is prolonged, and a compact and firm coating is formed on the surface of the metal by combining the 1,2-bis (triethoxy silicon) ethane and the gamma-aminopropyl triethoxy silicane for use.

Owner:ANHUI LIUFANG ZHONGLIAN MECHANICAL SHARE

Fireproof door core plate and fireproof timber door

InactiveCN107082958AEasy to makeSimple processing technologyFireproof doorsDoor leavesDecabromodiphenyl etherPolyvinyl chloride

The invention discloses a fireproof door core plate and a fireproof timber door. The fireproof door core plate is prepared from the following raw materials in parts by weight: 10-20 parts of chitosan, 5-15 parts of magnesium-aluminum spinel, 15-25 parts of modified quartz powder, 4-8 parts of sepiolite, 3-7 parts of ammonium metavanadate, 2-4 parts of zirconium tetrafluoride, 4-8 parts of sodium borohydride, 2-6 parts of polyvinyl chloride, 5-15 parts of andalusite powder, 10-20 parts of nano-silica, 4-6 parts of hydroquinone, 3-5 parts of polyvinyl acetate, 2-4 parts of decabromodiphenyl ether, 15-25 parts of polypropylene fiber, 5-7 parts of starch sodium octenylsuccinate, 8-12 parts of mica powder, 1-5 parts of a fireproof aid, 1-5 parts of an anti-cracking agent, 1-3 parts of a water reducer and 1-3 parts of a water repellent. A preparation method of the fireproof door core plate comprises the steps of uniformly crushing the raw materials, and carrying out smelting and formation, so as to obtain the fireproof door core plate. The fireproof door core plate is located between a fireproof timber door panel and a backboard. The fireproof door core plate is low in production cost, light in mass and high in strength, has excellent flame retardance and thermal insulation property and sound insulation property. A preparation process of the fireproof timber door prepared from the fireproof door core plate is simple, and the large-scale production can be realized.

Owner:HEFEI YIZHI DOORS & WINDOWS CO LTD

High temperature resistant cable sheath material

InactiveCN107915880AReasonable ratio of ingredientsRaw materials are cheap and easy to getRubber insulatorsTemperature resistanceStearic acid

The invention relates to the technical field of high polymer materials and in particular to a high temperature resistant cable sheath material which consists of the following raw materials in parts byweight: 20-35 parts of polyisocyanates, 12-18 parts of a glass fiber, 2-7 parts of ceramsite, 10-20 parts of polyesteramide, 14-26 parts of chloroprene rubber, 3-9 parts of epoxy soybean oil, 5-9 parts of zirconium tetrafluoride, 3-15 parts of stearic acid, 2-7 parts of carbon black, 4-10 parts of silicon dioxide powder and 2-8 parts of a silane coupling agent. The high temperature resistant cable sheath material is reasonable in component proportioning, low in raw material price, easy in raw material obtaining, low in production cost, good in mechanical property and excellent in wearing resistance, corrosion resistance and high temperature resistance.

Owner:ANHUI HUAXING CABLE GROUP

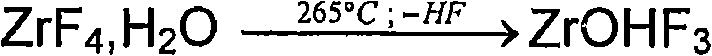

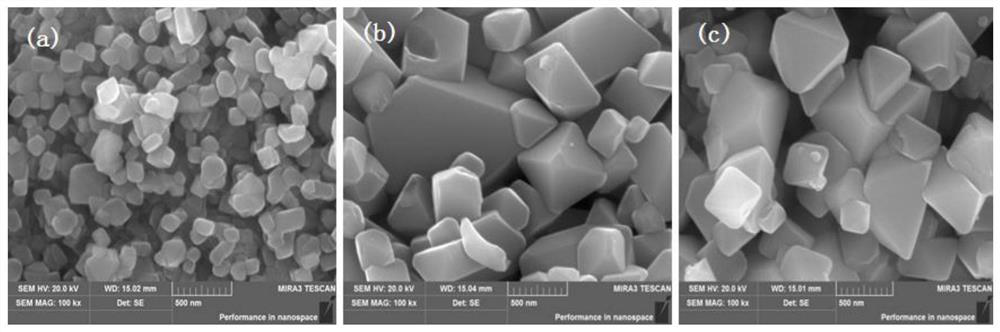

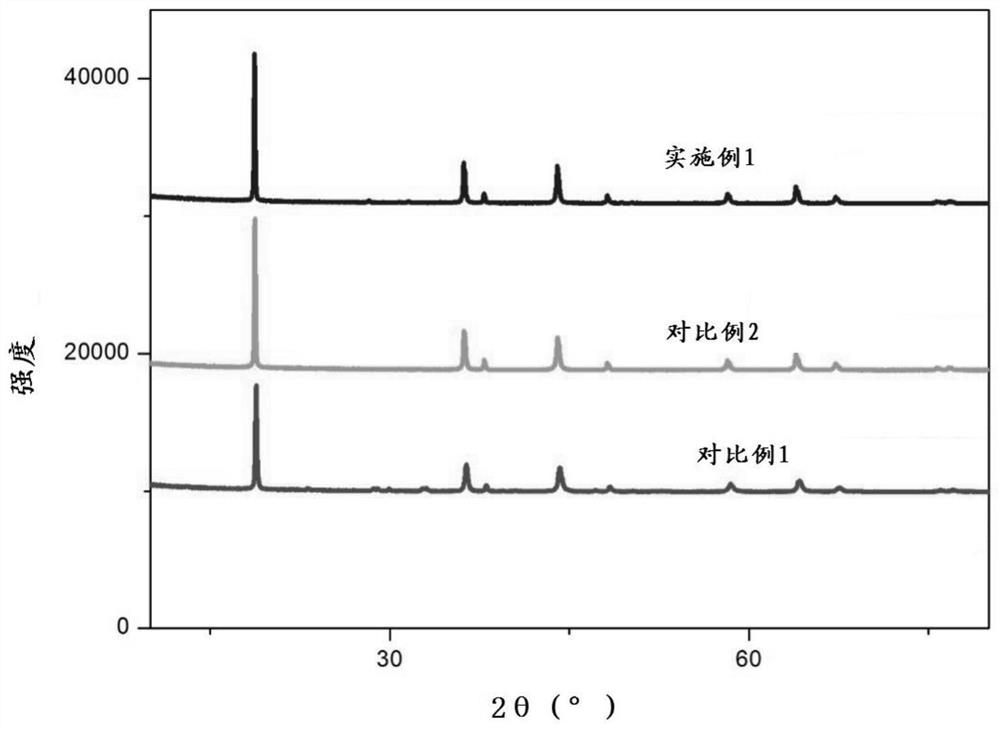

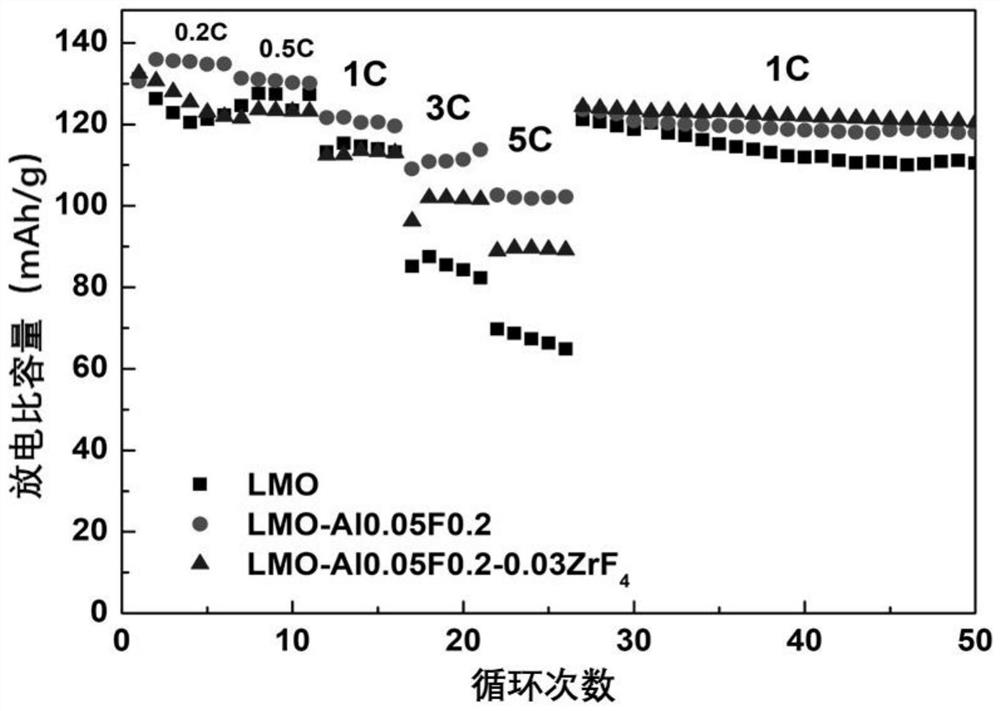

Zirconium tetrafluoride-coated fluorine-aluminum double-doped lithium manganate positive electrode material and preparation method thereof

PendingCN112002879AHigh degree of orderImproved magnification performanceSecondary cellsPositive electrodesElectrolytic agentElectrical battery

The invention provides a zirconium tetrafluoride-coated fluorine-aluminum double-doped lithium manganate positive electrode material and a preparation method thereof, and belongs to the field of lithium ion batteries. The zirconium tetrafluoride-coated fluorine-aluminum double-doped lithium manganate positive electrode material provided by the invention comprises a core and a shell layer; the corehas a chemical composition shown as a formula I: Li1+xAlyMn2-yO4-zFz, x is greater than or equal to 0 and less than or equal to 0.5, y is greater than 0 and less than or equal to 0.3, and z is greater than 0 and less than or equal to 0.2; and the shell layer is ZrF4. According to the invention, Al and F are used as binary ions for double-doped modification of lithium manganate to improve the order degree of the lithium manganate, stabilize the spinel structure and inhibit the lattice distortion, and ZrF4-coated fluorine-aluminum double-doped modified lithium manganate is used to effectively relieve the capacity attenuation, effectively prevent the corrosion of the electrolyte and reduce the dissolution of the manganese ions, and the obtained positive electrode material has advantages of excellent rate performance and excellent cycle stability.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Insulating shell of switch cabinet

The invention discloses an insulating shell of a switch cabinet. The insulating shell of the switch cabinet is prepared from the following raw materials in parts by weight: 25 to 28 parts of glass fiber, 6 to 14 parts of silicon dioxide, 9 to 12 parts of fiber cotton, 20 to 24 parts of polycarbonate resin, 7 to 13 parts of polyurethane, 2 to 8 parts of polypropylene, 16 to 20 parts of poly(1-butene), 2 to 4 parts of boric oxide, 7 to 8 parts of calcium carbonate, 8 to 10 parts of barium sulfate, 6 to 14 parts of aromatic polyamide fiber, 2 to 8 parts of molybdenum disulfide, 4 to 8 parts of dibutyl phthalate, 13 to 15 parts of diisobutyl phthalate, 7 to 9 parts of sodium citrate, 3 to 8 parts of zirconium tetrafluoride, 11 to 14 parts of ethyl acetate, 6 to 12 parts of butyl methacrylate and 18 to 20 parts of N-phenyl-beta-naphthylamine. The insulating shell of the switch cabinet has high structure strength, good insulating effect and good anti-ageing effect.

Owner:吕杰

Surface modified calcium carbonate packing and preparation method thereof

The invention discloses surface modified calcium carbonate packing which is prepared from the following raw materials in parts by weight: 1-2 parts of paraffin, 2-2.4 parts of methyl trichlorosilane, 3-4 parts of coal ash, 0.3-0.4 part of fumaric acid, 4-5 parts of zirconium tetrafluoride, 0.2-0.4 part of benzalkonium chloride, 2-3 parts of inositol hexaphosphate, 1-2 parts of glycerin abietate, 1-2 parts of 1,6 diethylene glycol diacrylate, 1-1.4 parts of trimethylolpropane triacrylate, 0.1-0.2 part of ammonium persulfate, 1-2 parts of sodium silicate, 80-85 parts of light calcium carbonate, 13-16 parts of additives and 120-140 parts of water. According to the packing, 1,6 diethylene glycol diacrylate, trimethylolpropane triacrylate and methyl trichlorosilane are adopted to react to modify calcium carbonate, so that the problem that calcium carbonate is easy to conglobate in a PVC product is solved, the oil absorption rate is reduced, the mechanical property of PVC is improved, and the toughness, the bending strength and the impact resistance are improved.

Owner:QINGYANG COUNTY YONGCHENG CALCIUM IND

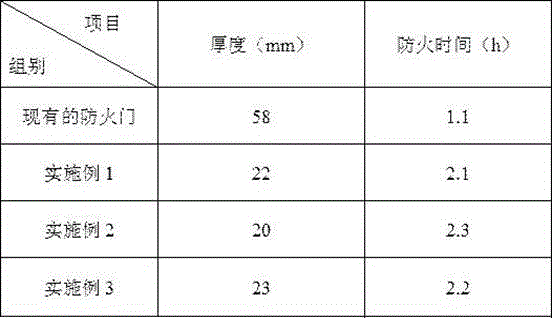

Fireproof layer and fireproof wooden door

InactiveCN106277945AImprove fire performanceReduce thicknessFireproof doorsDoor leavesCellulosePropolis

The invention discloses a fireproof layer and a fireproof wooden door. The fireproof layer is prepared from, by weight, 12-16 parts of aluminum oxide, 10-12 parts of kyanite powder, 5-7 parts of polyurethane, 16-18 parts of asbestos cellulose, 18-20 parts of sepiolite, 8-10 parts of ammonium metavanadate, 3-5 parts of zirconium tetrafluoride, 8-12 parts of inositol, 6-10 parts of propolis, 10-12 parts of titanium carbide, 8-12 parts of zirconium diboride, 16-18 parts of sandstone powder, 6-8 parts of hydroquinone, 3-5 parts of sodium borohydride and 6-10 parts of ammonium molybdate. The invention further provides the fireproof wooden door. Fireproofing can be effectively achieved, and the thickness of the fireproof wooden door can be remarkably reduced.

Owner:广州市蓝群木制品有限公司

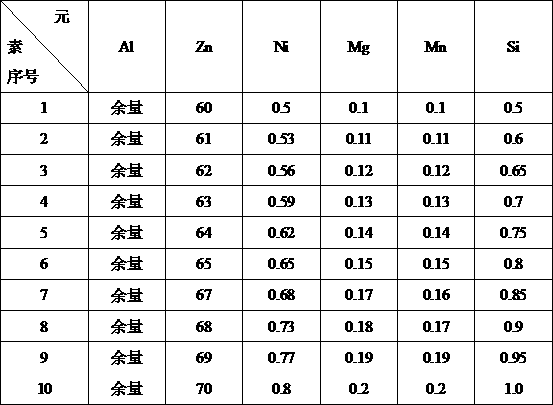

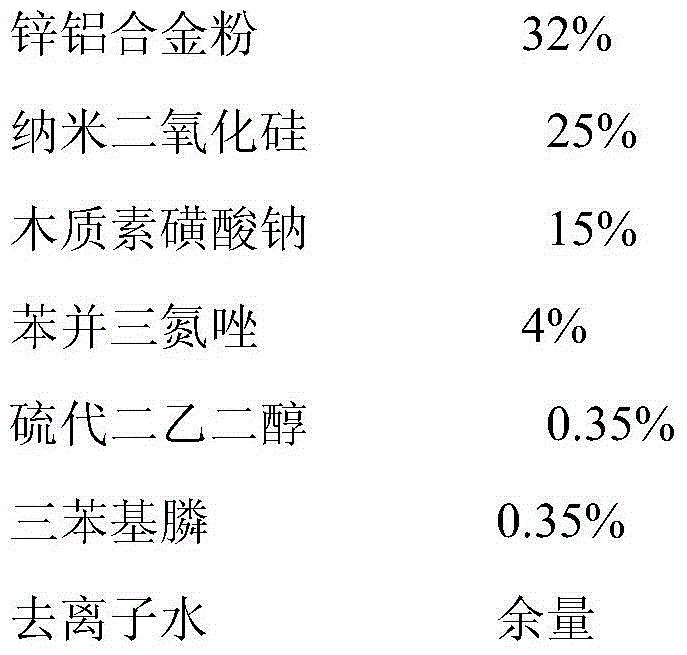

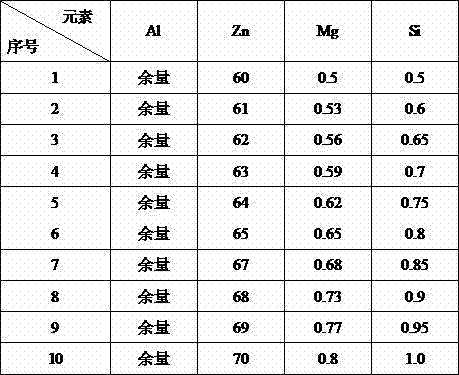

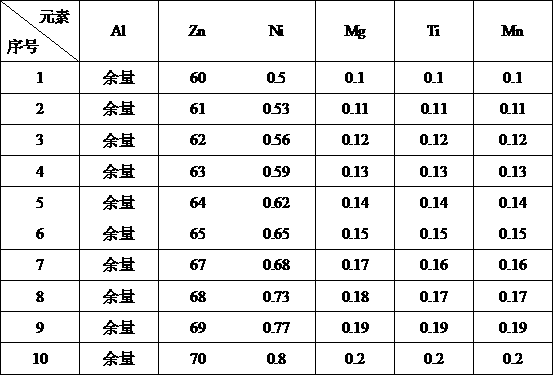

Chrome-free zinc-aluminum coating anticorrosive paint comprising nickel-magnesium-manganese-silicon

InactiveCN103232735AExcellent curing temperatureLow curing temperatureAnti-corrosive paintsCellulose acetateManganese

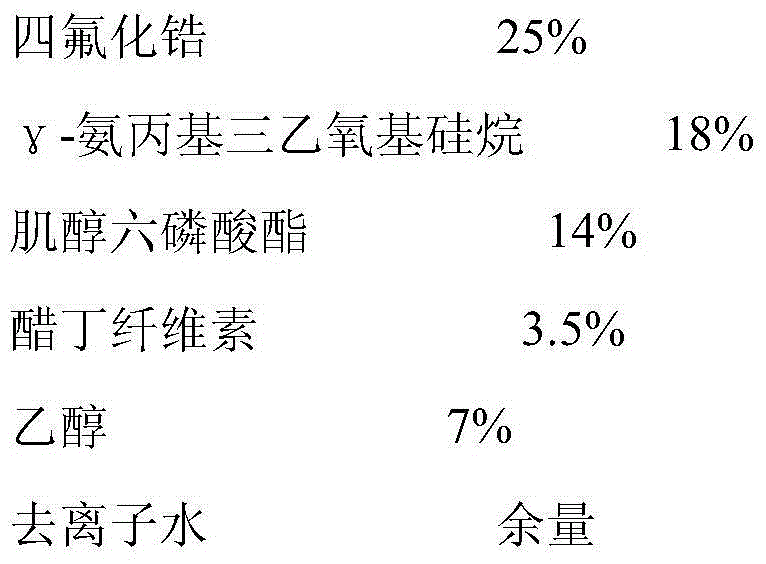

The invention discloses a chrome-free zinc-aluminum coating anticorrosive paint comprising nickel-magnesium-manganese-silicon. The paint is composed of a component A and a component B with a mass ratio of 3:1. The component A comprises the raw materials of zinc-aluminum alloy powder, nano-silica, lignin sodium sulfonate, benzotriazole, thio diethylene glycol, triphenylphosphine, and deionized water. The component B comprises zirconium tetrafluoride, gamma-aminopropyl triethoxysilane, inositol hexaphosphate, butyl cellulose acetate, ethanol, and deionized water. The zinc-aluminum alloy powder is composed of Zn, Al, Ni, Mg, Mn and Si. The product provided by the invention has the advantages of no toxicity, no harm, no pollution, low-temperature fast processing, simple operation, wide raw material source, low cost, clean production, and the like.

Owner:HUNAN QIANXIN PIPE IND

Preparation method of magnetic material

InactiveCN110739112AImprove stabilityEasy to operateInductances/transformers/magnets manufactureMagnetic materialsEpoxyKaolin clay

The invention discloses a preparation method of a magnetic material. The preparation method comprises the steps that iron powder, neodymium powder, boron powder, copper powder, magnesium powder, epoxyresin, and quartz stone are mixed and put into a ball mill for ball milling; the ground particulate materials are added with water, stirred, pressed into a block and put into a furnace for high temperature firing; the block material is crushed, added with iron oxide, barium carbonate, strontium carbonate, sodium chlorate, lanthanum oxide, manganese oxide, molybdenum oxide, nickel oxide, cobalt, kaolin and zirconium tetrafluoride and mixed; the mixed material is put into the ball mill for secondary grinding, and then the slurry is dehydrated; and the dehydrated material is pressed into a greenbody, sintered, and ground into the magnetic material product. The magnetic material made by the invention has the advantages of high stability, simple operation and low cost.

Owner:南京美帮磁业有限公司

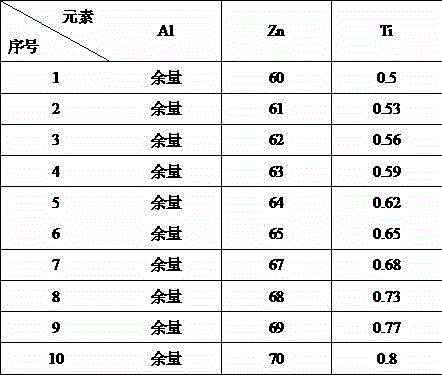

Titanium-containing chromium-free zinc-aluminum coating anti-corrosive paint

InactiveCN103044990BExcellent curing temperatureLow curing temperatureAnti-corrosive paintsChromium freeInositol hexaphosphate

The invention discloses titanium-containing chromium-free zinc-aluminum coating anti-corrosive paint which comprises an A component and a B component at a mass ratio of 3:1, wherein the A component comprises the following raw materials: allumen powder, nano-silica, sodium lignosulphonate, benzotriazole, sulpho-diethylene glycol, triphenylphosphine and deionized water; the B component comprises the following raw materials: zirconium tetrafluoride, gamma-aminopropyl triethoxy silane, inositol hexaphosphate, cellulose acetate-butyrate, ethanol and deionized water; and the allumen powder comprises Zn, Al and Ti. The paint has the characteristics of no toxicity, harmlessness, no pollution, low-temperature immediate processing, easiness in operation, extensive raw material sources, low price, cleaner production and the like.

Owner:RUGAO CITY LEHENG CHEM COMPANY

Magnesium-silicon-containing chromium-free zinc-aluminum coating anti-corrosive paint

InactiveCN103044988AExcellent curing temperatureLow curing temperatureAnti-corrosive paintsChromium freeSilanes

The invention discloses magnesium-silicon-containing chromium-free zinc-aluminum coating anti-corrosive paint which comprises an A component and a B component at a mass ratio of 3:1, wherein the A component comprises the following raw materials: allumen powder, nano-silica, sodium lignosulphonate, benzotriazole, sulpho-diethylene glycol, triphenylphosphine and deionized water; the B component comprises the following raw materials: zirconium tetrafluoride, gamma-aminopropyl triethoxy silane, inositol hexaphosphate, cellulose acetate-butyrate, ethanol and deionized water; and the allumen powder comprises Zn, Al, Mg and Si. The paint has the characteristics of no toxicity, harmlessness, no pollution, low-temperature immediate processing, easiness in operation, extensive raw material sources, low price, cleaner production and the like.

Owner:广西南宁维一防腐科技有限公司

Protective paint in metal product machining mold

InactiveCN105462490ALow costExtend your lifeConjugated diene hydrocarbon coatingsAnti-corrosive paintsDiethylenetriamineStearic acid

The invention discloses protective paint in a metal product machining mold and relates to the technical field of mold machining production. The protective paint is characterized by being prepared from materials in parts by weight as follows: 6 parts of aluminium powder, 3 parts of carbon powder, 1 part of monoethaneamine benzoate, 1 part of stearic acid, 1 part of calcium molybdate, 2 parts of butadiene styrene rubber powder, 4 parts of light calcium carbonate powder, 2 parts of tripropylene glycol diacrylate, 2 parts of diethylenetriamine, 5 parts of epoxidized soybean oil, 2 parts of dioctyl phthalate, 1 part of polyethylene wax, 2 parts of tricresyl phosphate, 3 parts of shell powder, 2 parts of zirconium tetrafluoride and 8 parts of a conditioning agent. The method is reasonable, operation is simple, the ratio is clear, and the protective paint is corrosion-resistant.

Owner:CHAOHU LETTER BUILDING MATERIALS MACHINERY & EQUIP LIMITED

A kind of straw powder filter element and preparation method thereof

InactiveCN103463869BHigh temperature resistantCorrosion resistanceOther chemical processesFiltration separationSodium metasilicatePolyvinyl alcohol

The invention discloses a straw powder filter element and a preparation method thereof. The straw powder filter element comprises following raw materials, by weight, 20 to 24 portions of straw powder, 12 to 14 portions of white clay, 3 to 5 portions of zirconium tetrafluoride, 6 to 8 portions of polyvinyl alcohol, 4 to 6 portions of propylene glycol, 4 to 5 portions of sodium metasilicate, 10 to 12 portions of charcoal, 20 to 22 portions of clay, 23 to 25 portions of modified attapulgite, and an appropriate amount of water. Straw powder is taken as a raw material, and is converted into active carbon by sintering; and active carbon possesses relatively high adsorption ability. The straw powder filter element is high in purification efficiency, and long in service life; is resistant to high temperature and corrosion; and is capable of removing micro dust in the air.

Owner:天长市天乐电器厂

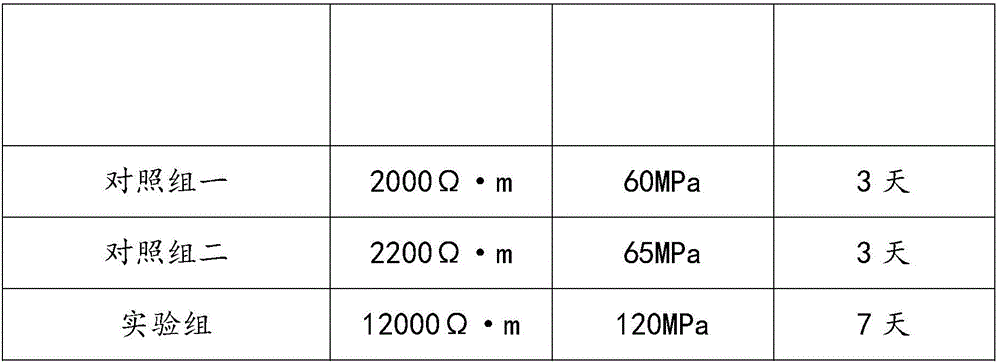

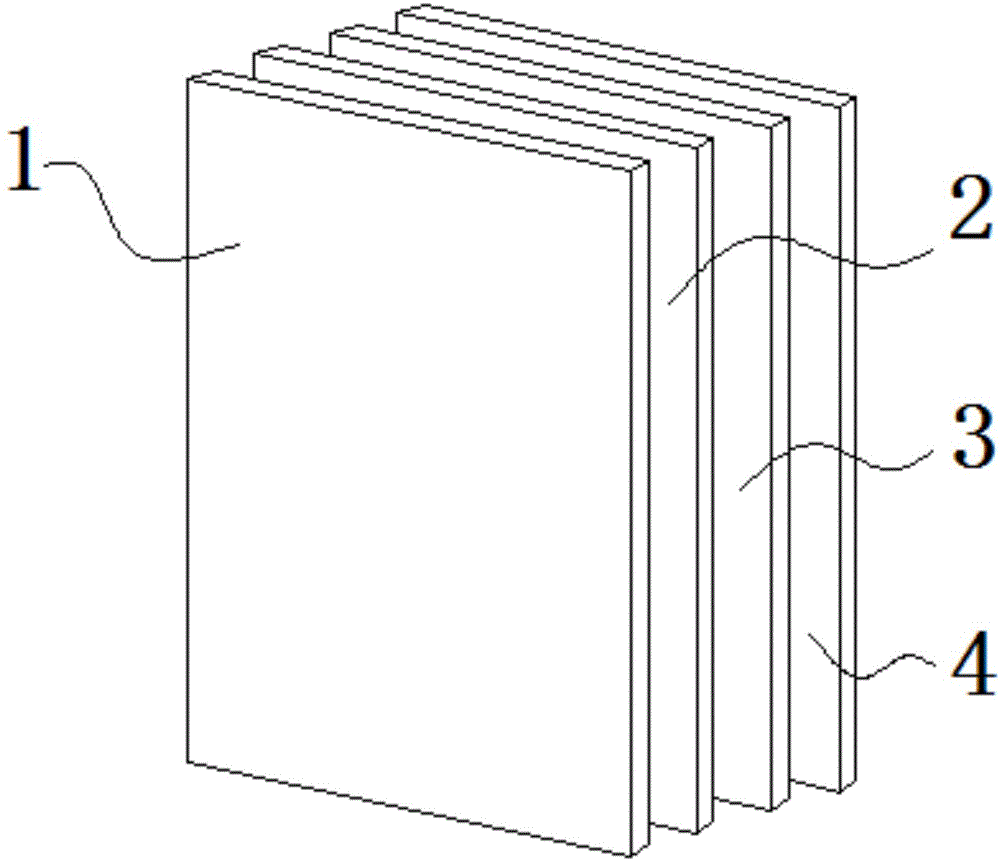

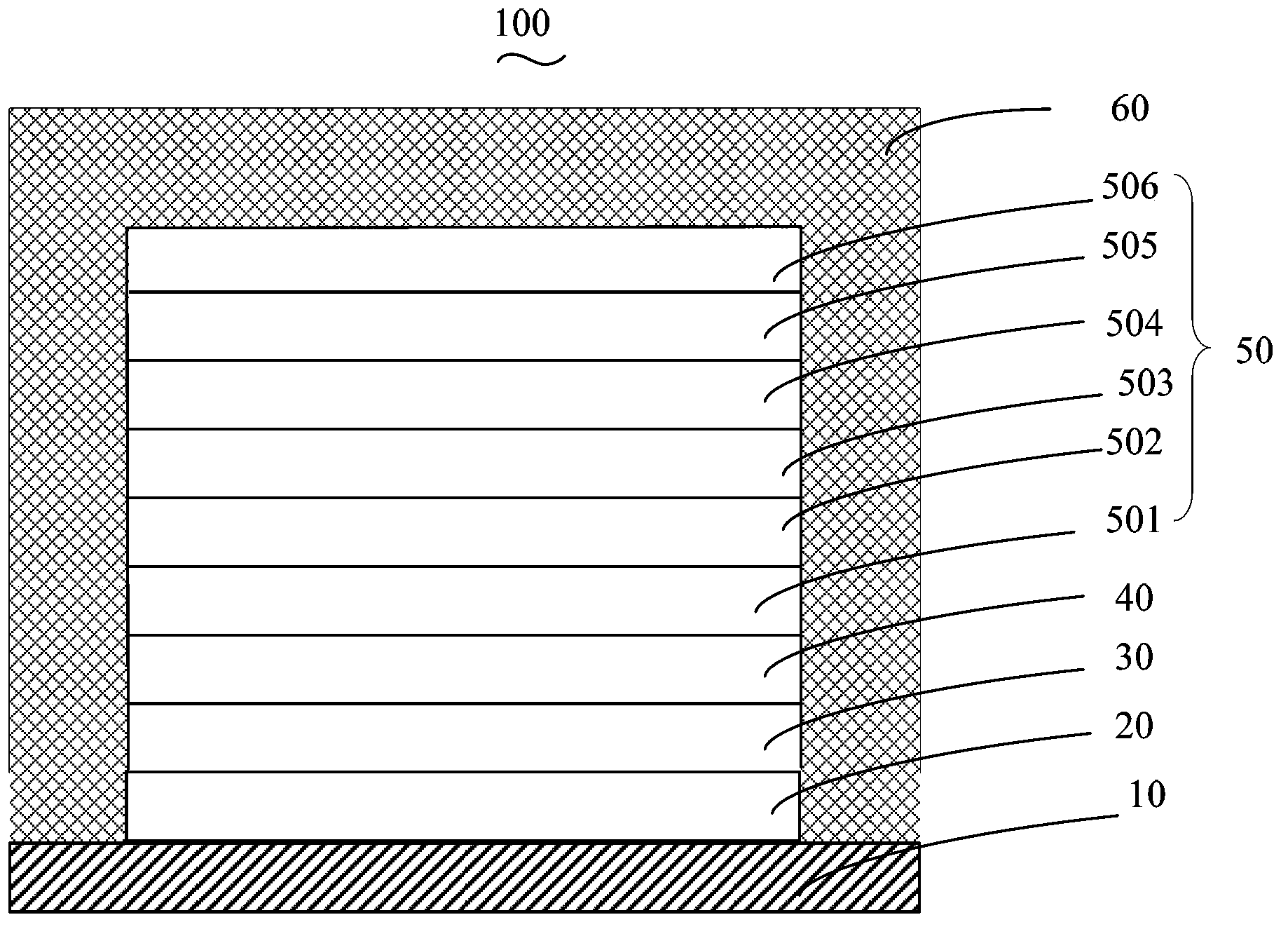

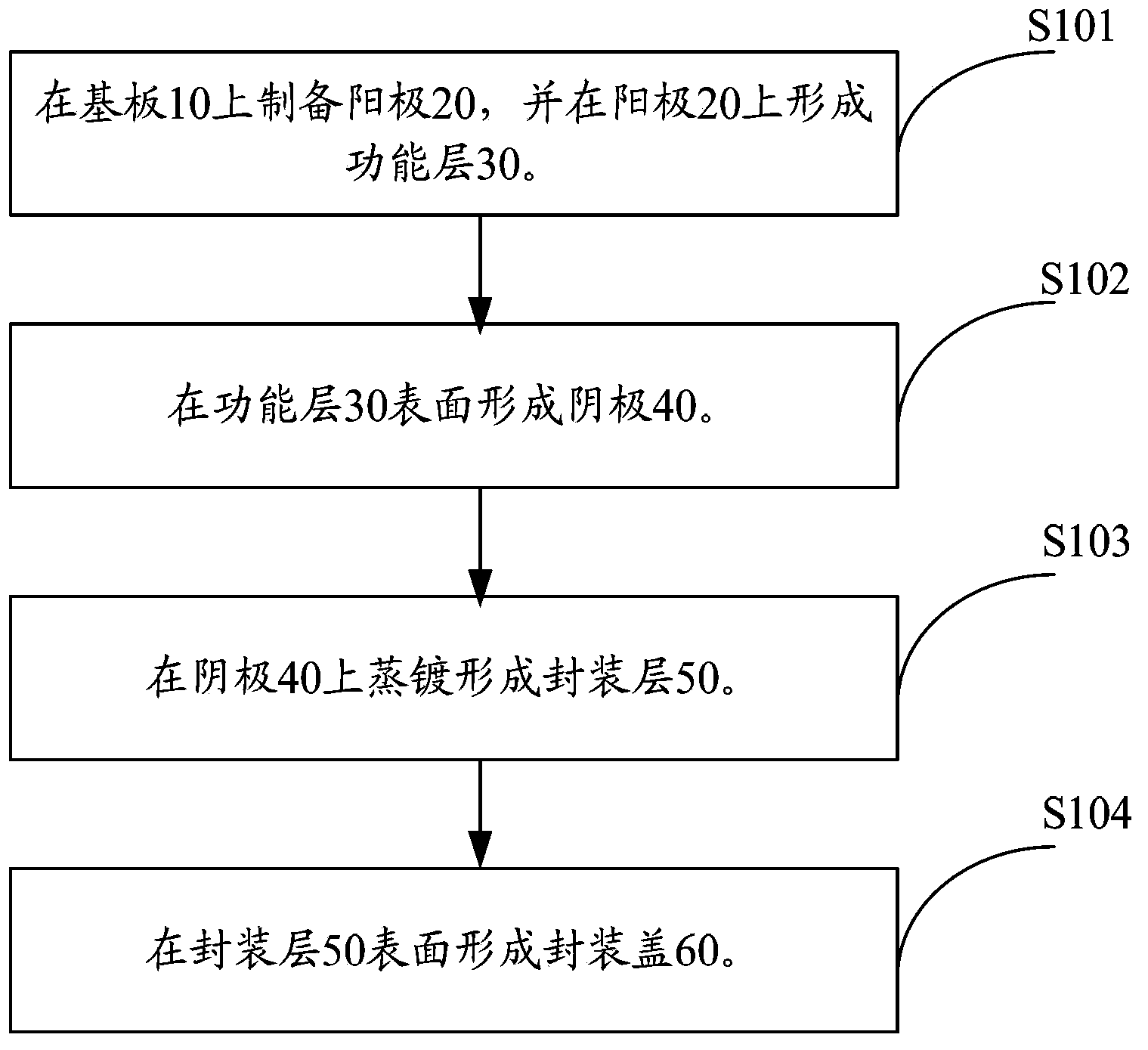

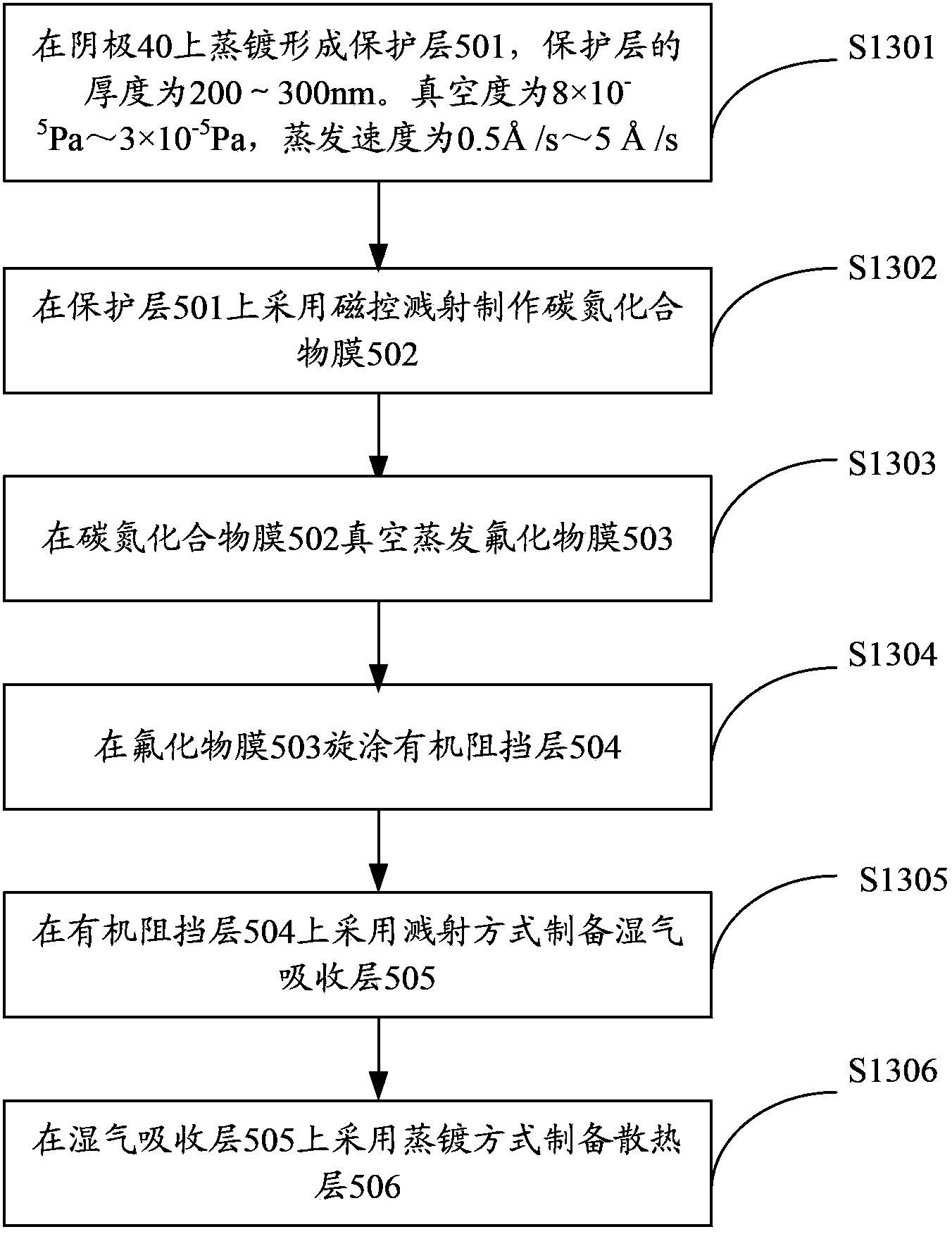

Organic light-emitting device and preparation method thereof

ActiveCN103855320AReduce erosionExtend your lifeSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringHafnium

Provided in the invention is an organic light-emitting device comprising a substrate, an anode, a functional layer, a cathode, a packaging layer, and a packaging cover. The substrate, the anode, the functional layer, the cathode, the packaging layer, and the packaging cover are successively laminated. The substrate and the packaging cover form an enclosed space; and the anode, the functional layer, the cathode, and the packaging layer are accommodated into the enclosed space. The packaging layer successively includes a protection layer, a carbon-nitrogen compound film, a fluoride film, an organic blocking layer, a moisture absorbing layer, and a cooling layer; the carbon-nitrogen compound film is a nitride film doped with carbide; and the material employed by the fluoride film is aluminum fluoride, hafnium fluoride, zirconium tetrafluoride, cerium fluoride, or iridium fluoride. In addition, the invention also provides a preparation method of the organic light-emitting device. With the method, erosion on the organic light-emitting device by moisture and oxygen can be effectively reduced, so that the device organic functional material and the electrode can be effectively protected and thus the service life of the organic light-emitting device can be obviously prolonged. The method is especially suitable for packaging of a flexible organic light-emitting device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Nickel-magnesium-titanium-manganese-containing chromium-free zinc aluminum coating corrosion-resistant coating

InactiveCN103059616AExcellent curing temperatureLow curing temperatureAnti-corrosive paintsIonTriethoxysilane

The invention discloses nickel-magnesium-titanium-manganese-containing chromium-free zinc aluminum coating corrosion-resistant coating. The nickel-magnesium-titanium-manganese-containing chromium-free zinc aluminum coating corrosion-resistant coating consists of a component A and a component B, wherein the mass ratio of the component A to the component B is 3:1; the component A comprises the following raw materials: zinc aluminum alloy powder, nano-silicon dioxide, sodium lignosulphonate, benzotriazole, sulfo-diethylene glycol, triphenylphosphine and deionized water; the component B comprises the following raw materials: zirconium tetrafluoride, gamma-aminopropyl triethoxysilane, inositol hexaphosphate, cellulose acetate-butyrate, ethanol and deionized water; and the zinc aluminum alloy powder consists of Zn, Al, Ni and Mg. The product has the characteristics of no toxicity, no harm, no pollution, low-temperature quick treatment, simplicity in operation, wide sources of raw materials, low price, clean production and the like.

Owner:江苏卫斯包装有限公司

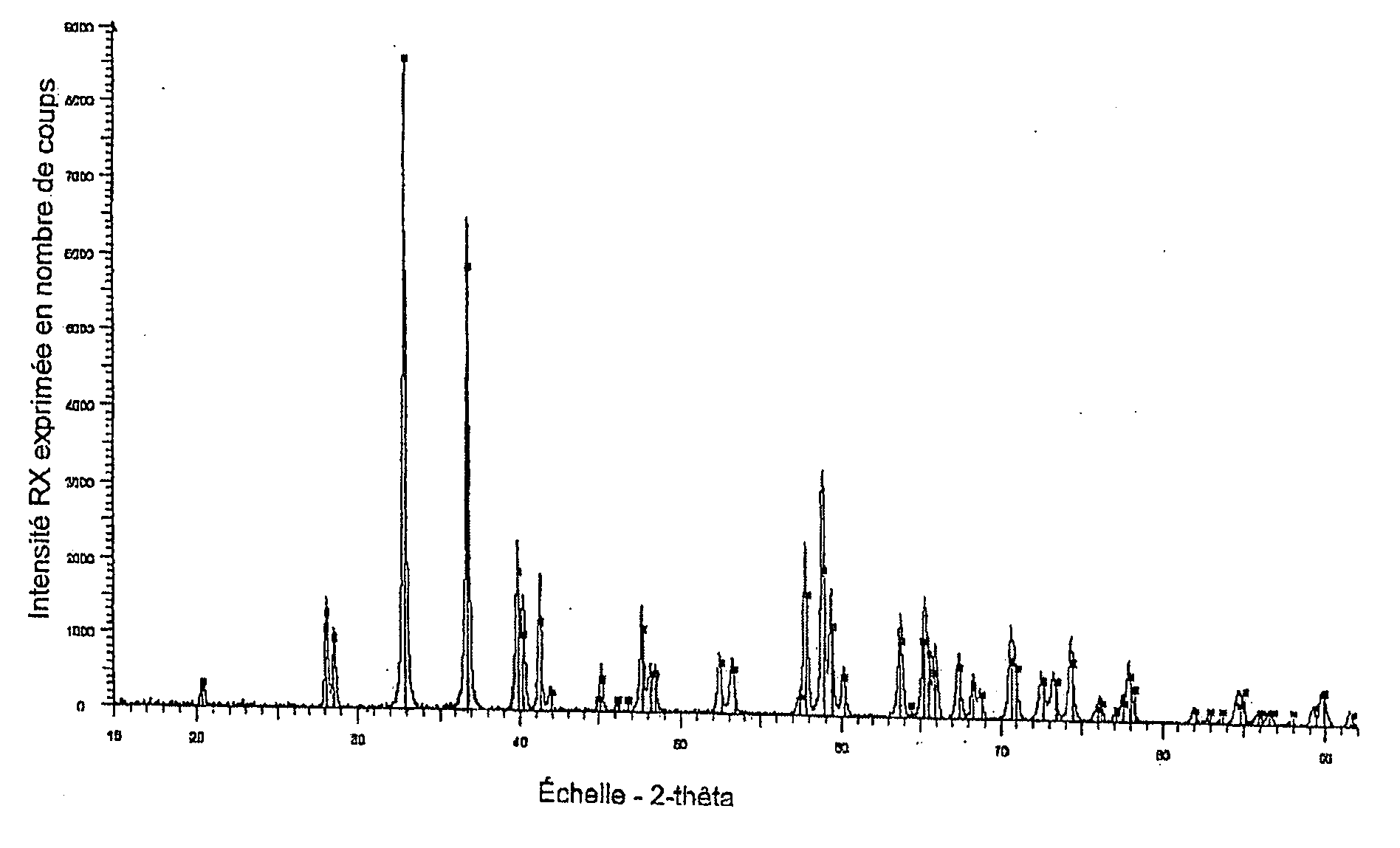

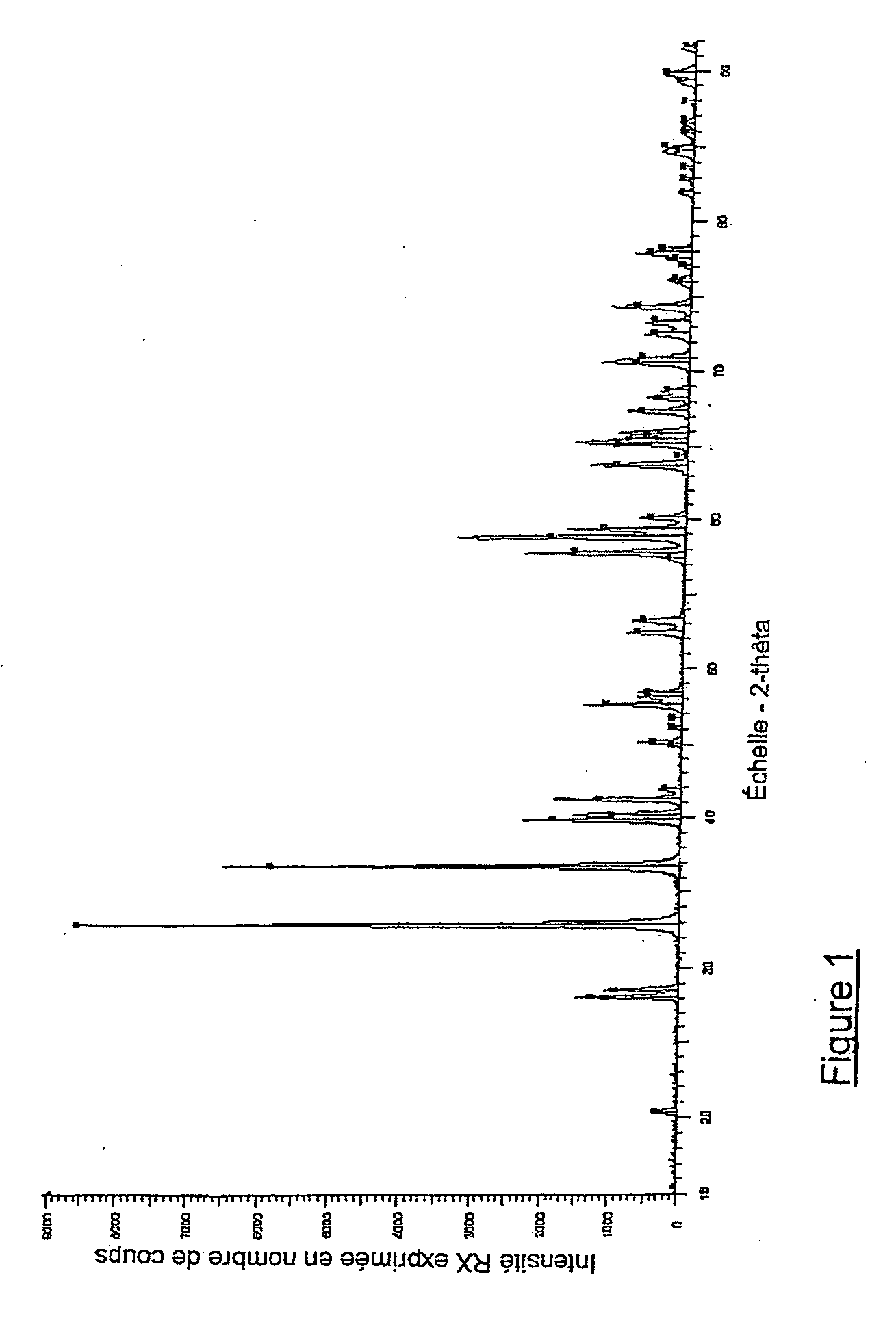

Method for recycling zirconium tetrafluoride into zirconia

InactiveUS20070003474A1Shorter spacingTitanium halidesZirconium oxidesZirconium tetrafluorideZirconium alloy

The method allows ZrF4 to be converted into ZrO2, by carrying out a thermal conversion operation based on solid ZrF4 and water which are heated in a reactor until converted into ZrO2. The initial ratio by weight of ZrF4 to water is in particular between 1 / 5 and 1 / 500, and this ratio is maintained substantially for the entire duration of the conversion. The thermal conversion is carried out at a temperature greater than or equal to 300° C. The invention is used in particular for recycling pickling baths for zirconium alloys.

Owner:CO EUROPENNE DU ZIRCONIUM CEZUS

Carborundum resin grinding head material

The invention relates to a carborundum resin grinding head material. The carborundum resin grinding head material comprises, by weight, 400-450 parts of 80-mesh carborundum, 10-15 parts of industrial alcohol, 540-560 parts of copper powder, 100-120 parts of zinc oxide, 80-85 parts of chromium sesquioxide, 480-500 parts of resin-oatmeal, 20-25 parts of ethidene diamine, 10-15 parts of hydroxypropyl methyl cellulose, 15-20 parts of calcium carbonate, 5-10 parts of aluminium dihydrogen phosphate, 3-5 parts of zirconium tetrafluoride, 3-5 parts of casein, 5-10 parts of sepiolite, 5-10 parts of graphite powder and 3-5 parts of nanometer titania. The carborundum resin grinding head material adopts a special formula, has the characteristics of being high in hardness, not prone to deformation, high in abradability, resistant to high temperature, resistant to wearing and the like, and is suitable for the high temperature abrasion environment.

Owner:TONGCHENG MINGLI BORON CARBIDE PROD CO LTD

A kind of activated carbon air filter element and preparation method thereof

InactiveCN103463868BFunction as a filterImprove wear resistanceFiltration separationPolyvinyl alcoholAir filter

Owner:天长市天乐电器厂

Light heat insulation building material and preparation method thereof

The invention discloses a light heat insulation building material and a preparation method thereof. The light heat insulation building material is prepared from, by weight, 120-150 parts of Portland cement, 5-10 parts of polyimide, 40-50 parts of straw chips, 20-30 parts of limestone powder, 10-15 parts of aluminum nitride powder, 4-5 parts of ammonium persulfate, 10-15 parts of superfine calcium carbonate, 6-10 parts of silicon carbide, 4-5 parts of barium carbonate, 2-4 parts of zirconium tetrafluoride, 4-6 parts of polyphenylene sulfide, 8-15 parts of organic montmorillonite, 4-5 parts of microcrystalline wax and 2-4 parts of chromium boride. Due to the reasonable proportion, the compressive strength and flexibility of the building material are improved; meanwhile, as aluminum nitride powder, silicon carbide, zirconium tetrafluoride and other ingredients are added, the material has the heat insulation and sound insulation effects and is low in heat conductivity coefficient and good in energy saving effect; the finished wall building material is very high in both compressive strength and impact strength and is an environment-friendly building material.

Owner:HEFEI QITENG AGRI TECH CO LTD

Synthetic plastic for manufacturing high temperature-resisting corrugated pipe

InactiveCN106751230AHigh economic valueHigh mechanical strengthFlexible pipesPolyvinyl chlorideEngineering

The invention discloses synthetic plastic for manufacturing a high temperature-resisting corrugated pipe. The synthetic plastic is prepared from the following raw materials in parts by weight: 2500 to 2800 parts of polyvinyl chloride, 300 to 600 parts of polypropylene, 2 to 5 parts of zirconium tetrafluoride, 30 to 35 parts of polyether ether ketone, 130 to 140 parts of diisodecyl phthalate, 400 to 460 parts of polysorbate, 15 to 25 parts of molybdenum boride, 70 to 80 parts of methyl ethyl ketoxime, 8 to 16 parts of Butylmercaptooxo stannane, 200 to 230 parts of palm wax and 180 to 220 parts of dioctyl azelate. The synthetic plastic for manufacturing the high temperature-resisting corrugated pipe, disclosed by the invention, has better mechanical strength and better fatigue resistance, and cannot deform after being used under a higher environment temperature for a long time; the preparation technology of the synthetic plastic is relatively simple, the raw materials are relatively lowcheap, the manufacturing cost is low, the production speed is fast, higher economic value is obtained, and the application field of plastic corrugated pipes can be greatly broadened.

Owner:江苏三水企业孵化器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com