Method for recycling zirconium tetrafluoride to form zirconia

A technology that has been converted into and used, applied in the direction of zirconia, etc., can solve the problems of high corrosiveness, difficulty and improvement of compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

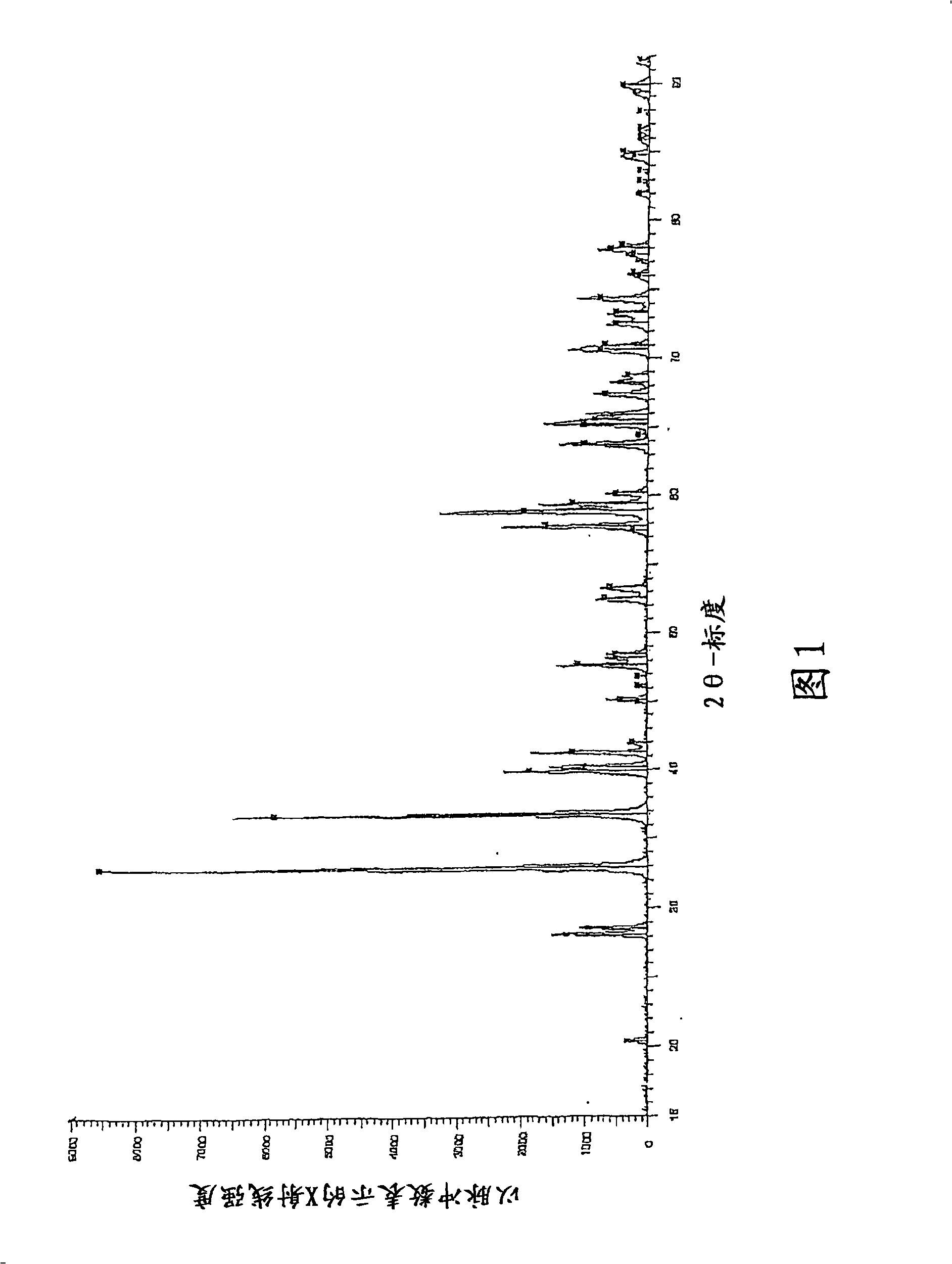

Image

Examples

Embodiment Construction

[0054] A horizontal tube furnace was used which was rotated to induce agitation of the reaction mixture. Inside the furnace is the reactor itself, shaped to enable a flow of neutral gas, in this case argon, to entrain and vent the acid gases (HF) that will form. The furnace is equipped with a temperature calibration and regulation system.

[0055] The parameters of the tests carried out are listed in Table 1 below, known to incorporate zirconium tetrafluoride in solid anhydrous form.

[0056] test

Pressure Ar

(bar)

FlowAr

(l.h -1 )

Water for injection

Volume (ml)

duration

(minute)

temperature

(℃)

ZrF 4 quality

(g)

1

0.4

250

500

200

685

9.187

2

0.4

250

500

200

500

8.050

3

0.4

250

500

200

600

8.040

4

0.4

250

500

200

550

8.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com