Patents

Literature

58results about How to "Function as a filter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

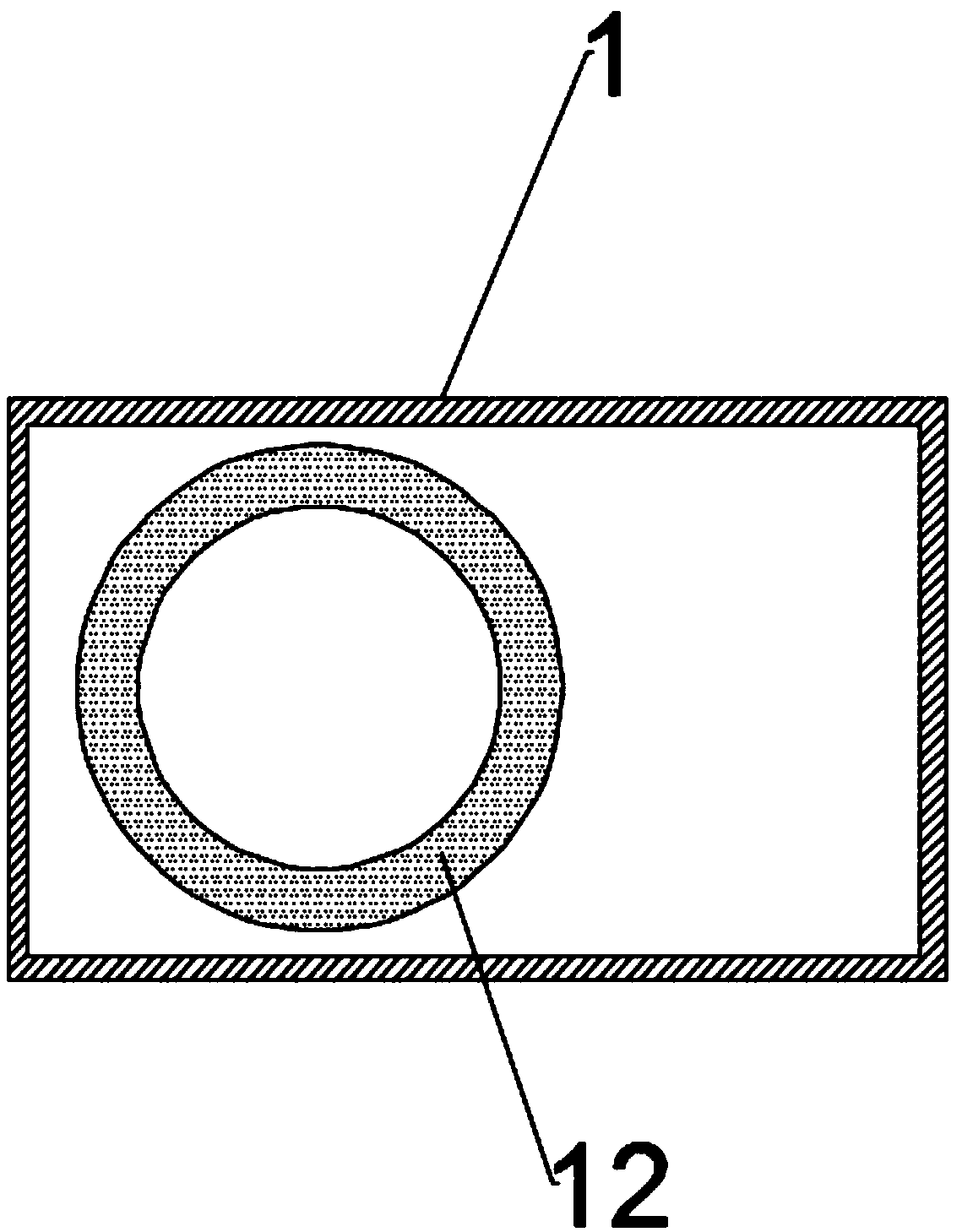

Two-in-one paper fiber powder activated carbon filter element and preparation method thereof

InactiveCN102698506AImprove adsorption capacityOvercome the disadvantages of impermanent bubblesOther chemical processesMembrane filtersFiberActivated charcoal powder

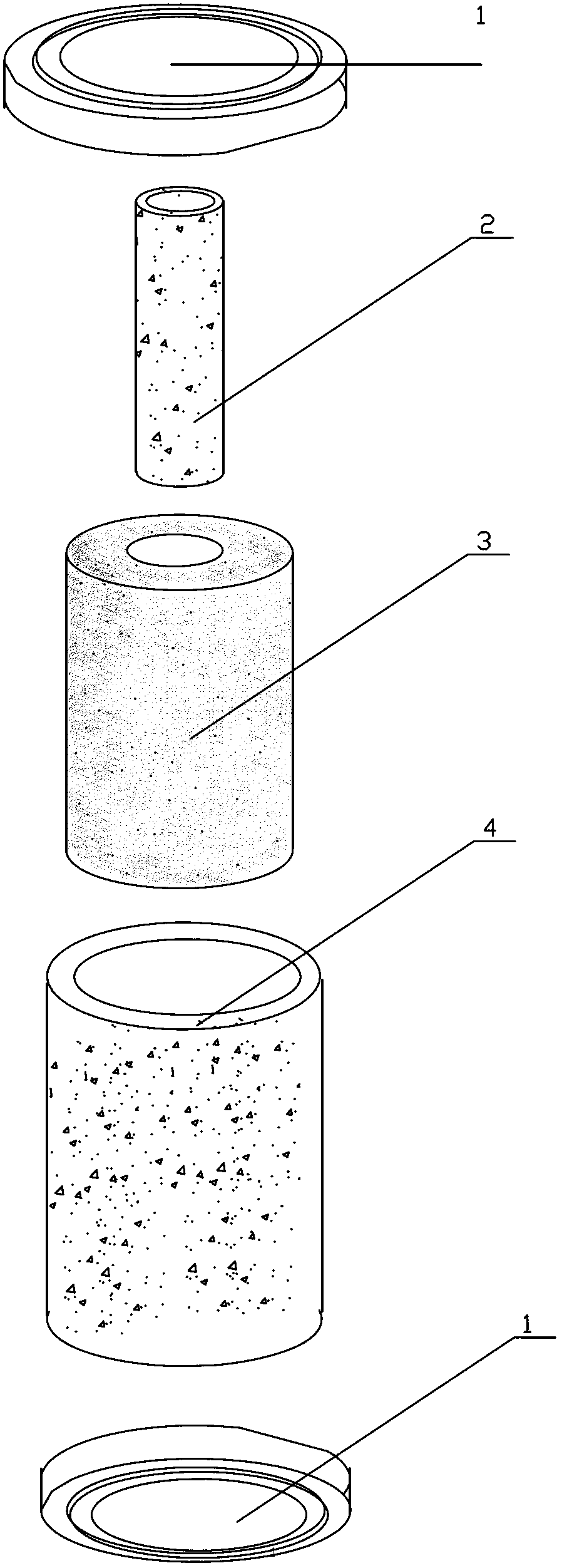

A two-in-one paper fiber powder activated charcoal filter element comprises at least three filtering layers which are in sleeve joint coaxially and tightly, the three layers sequentially comprise an inner layer, namely a PP (Propene Polymer) filter element which is tubular, an intermediate layer, namely a two-in-one paper fiber powder activated charcoal kryptol which is tubular and sleeved outside the PP filter element, an outer layer, namely a fixed protective layer sleeved outside the two-in-one paper fiber powder activated charcoal kryptol, as well as an end cover which is used for sealing the two ends of each filtering layer of two-in-one paper fiber powder activated charcoal filter element, from inside out. According to the invention, paper fiber is taken as main raw material, activated charcoal powder is added, the advantage of strong adsorbability of activated charcoal powder and the character of branching and tangling of the paper fiber are utilized in a combined manner, and the defects of reeled winding form and incapability of resisting long time soaking in the prior art can be overcome.

Owner:李昆洋

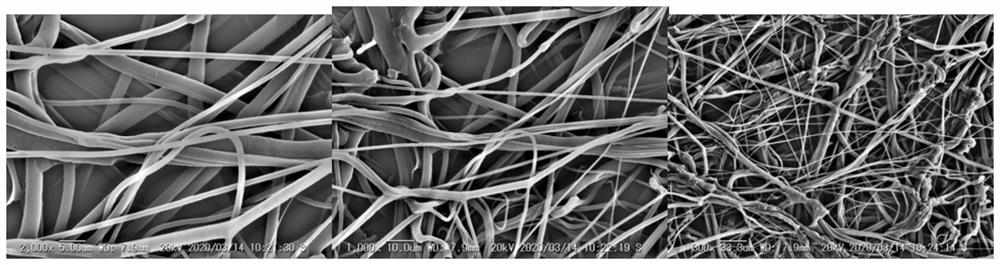

Deep filter element with crude and fine fiber mixed structure and preparation method of deep filter element

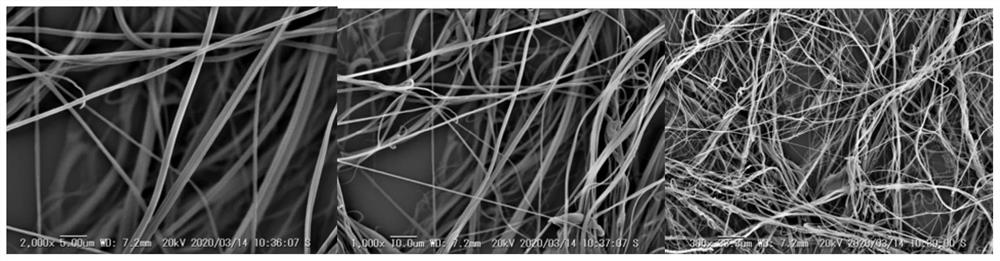

PendingCN111603846AEnsure structural stabilityDoes not increase filter resistanceMembrane filtersMelt spinning methodsCrude fibreFiber diameter

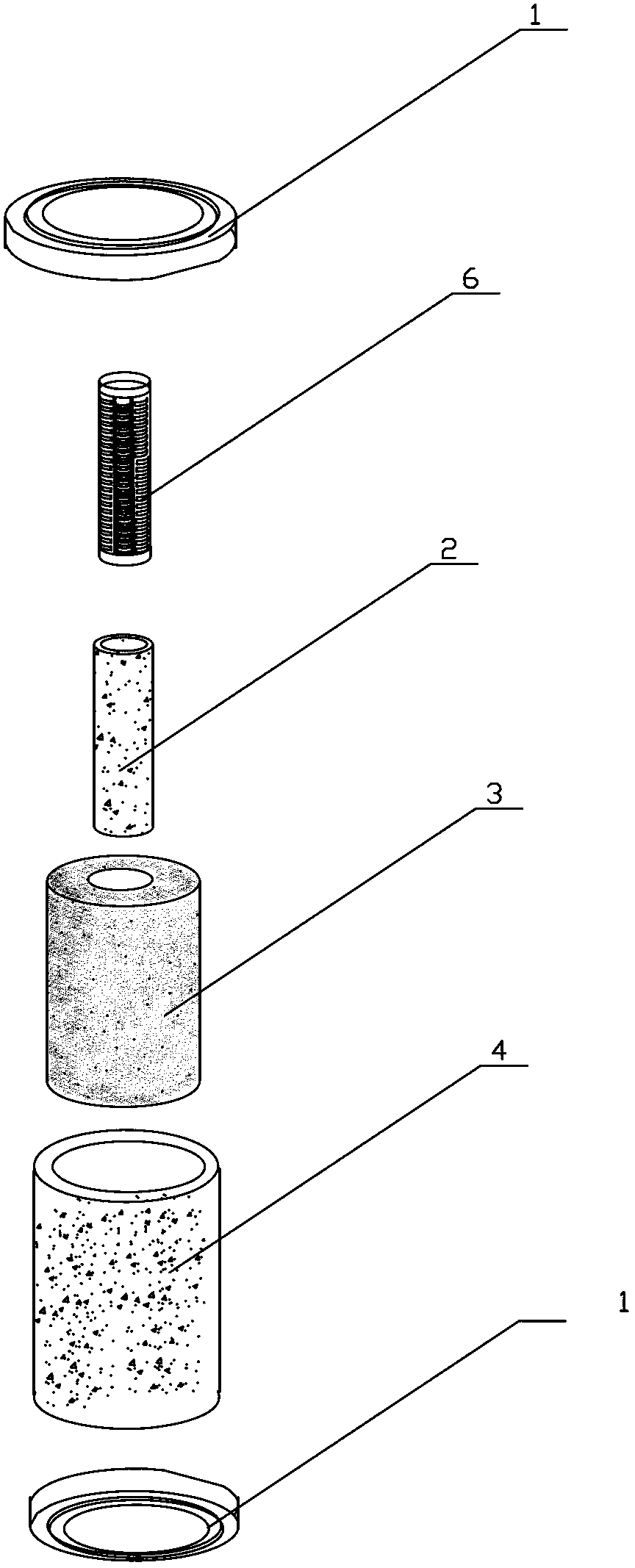

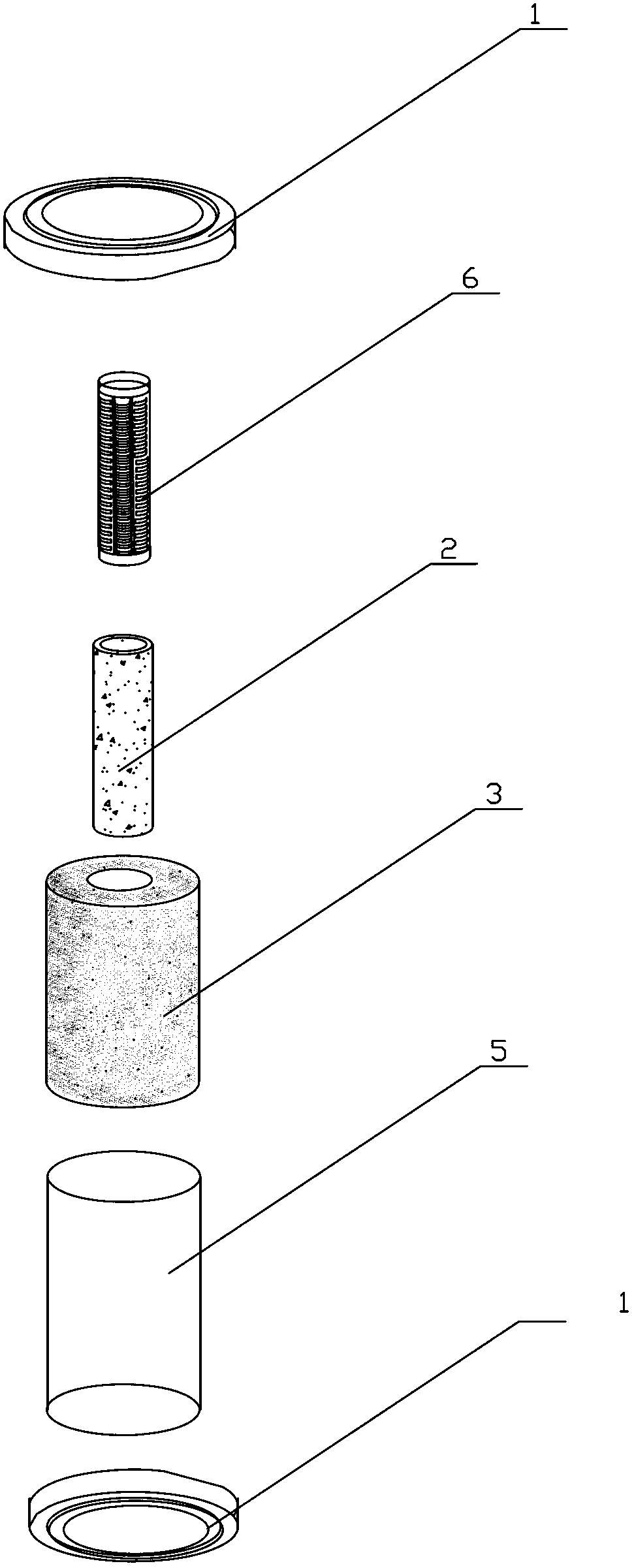

The invention discloses a deep filter element with a crude and fine fiber mixed structure. The deep filter element at least comprises two filtering layers; each filtering layer comprises a crude fiberset and a fine fiber set which are interwoven with each other; the average diameter of the crude fiber set of each filtering layer is reduced from the outer side to the inner side; the average diameter of the fine fiber set of each filtering layer is reduced from the outer side to the inner side; the fiber diameter of the fine fiber set of the innermost filtering layer is not larger than 1 micrometer; the fiber diameter of the crude fiber set of the outermost filtering layer is not smaller than 5 micrometers. The invention further discloses a preparation method of the deep filter element withthe crude and fine fiber mixed structure. The preparation method comprises the following steps of: 1) melt spinning; and 2) receiving a finished screen. The crude coarse fiber sets play a role in bonding the fine fiber sets and play a role in supporting, and therefore, the filter element is prevented from being compressed in a using process, and a dirt containing amount is increased, the fine fiber sets play a role in filtering and intercepting, so that filtering precision is improved, and the filter element has the functions of high filtering precision, high dirt containing capacity and longservice life and is good in filtering effect.

Owner:HANGZHOU COBETTER TECH CO LTD

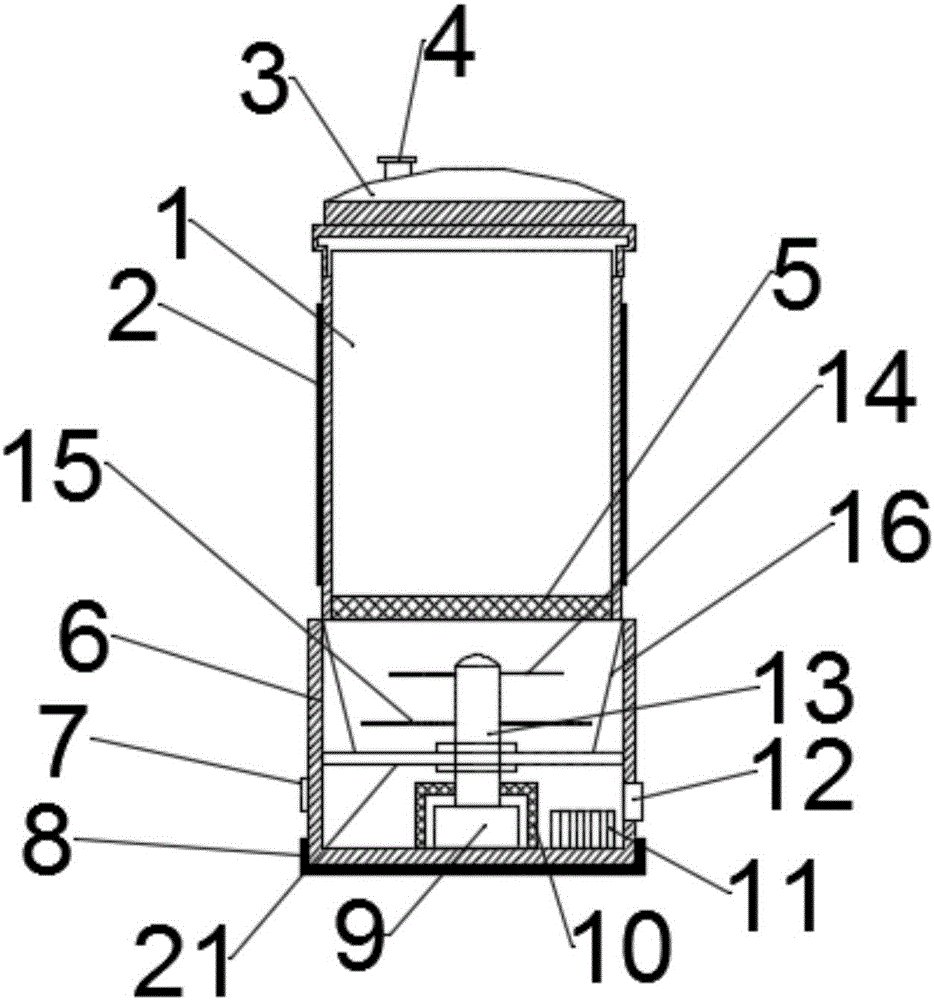

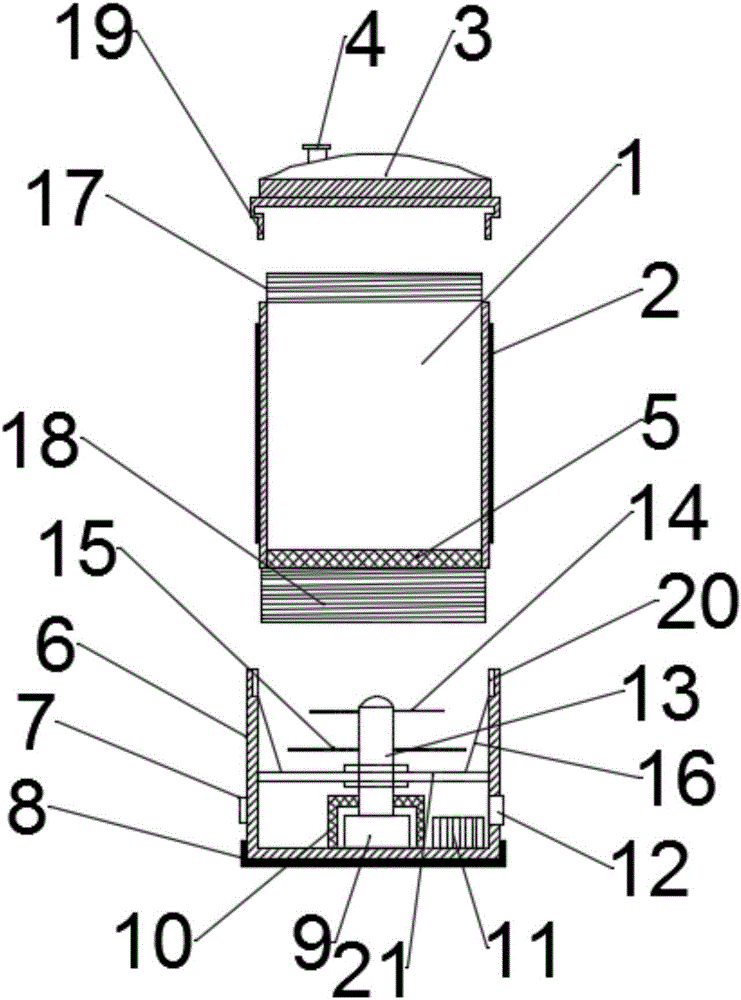

Multi-functional cup with fruit juicing function

InactiveCN106562552ANoise-proofAnti-noiseTravelling sacksDrinking vesselsFruit juiceThermal insulation

The invention discloses a multi-functional cup with a fruit juicing function. The cup comprises an upper cup body, a cup lid and a lower cup body, wherein a baffle is disposed inside the lower cup body; a noise reduction device is disposed on the lower end of the baffle; a motor is disposed in the noise reduction device; a rotation shaft is disposed on the upper end of the motor; short cutters and long cutters are disposed on the rotation shaft respectively; and a thermal insulation layer is disposed on the outer wall of the upper cup body. According to the invention, the structural design is simple and rational; before installation and fixation of the cup, a fruit used for juicing is placed in the lower cup body; then the cup is installed; the power source is switched on and the motor starts working; the short cutters and the long cutters will be rotated rapidly; at the moment, the fruit can be cut rapidly; and finally, fruit juice is formed. Through combined use of the short cutters and the long cutters, juicing efficiency can be increased; during the juicing, a filter screen can prevent fruit blocks from splashing the upper part; when the fruit juice is poured out, the filter screen can be used for filtering; and when the cup is used for tea making, the filter screen can also implement a filtering function.

Owner:ZHENGZHOU RENHONG PHARMA CO LTD

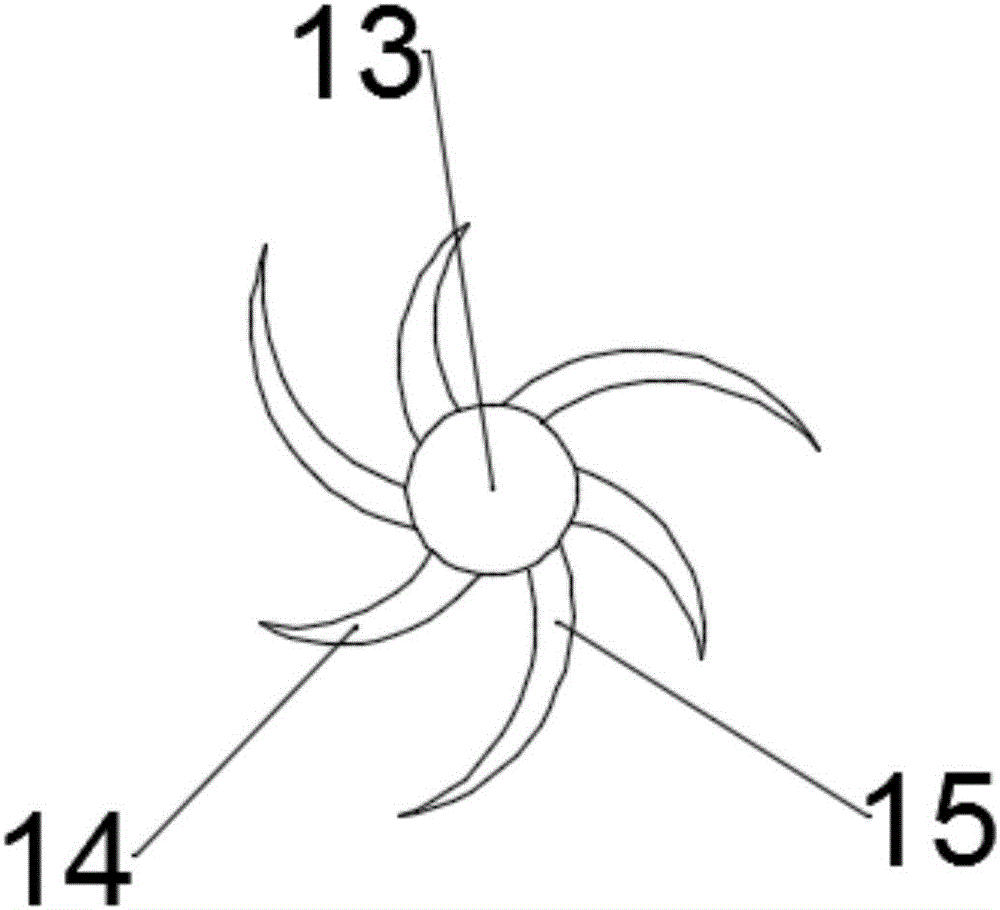

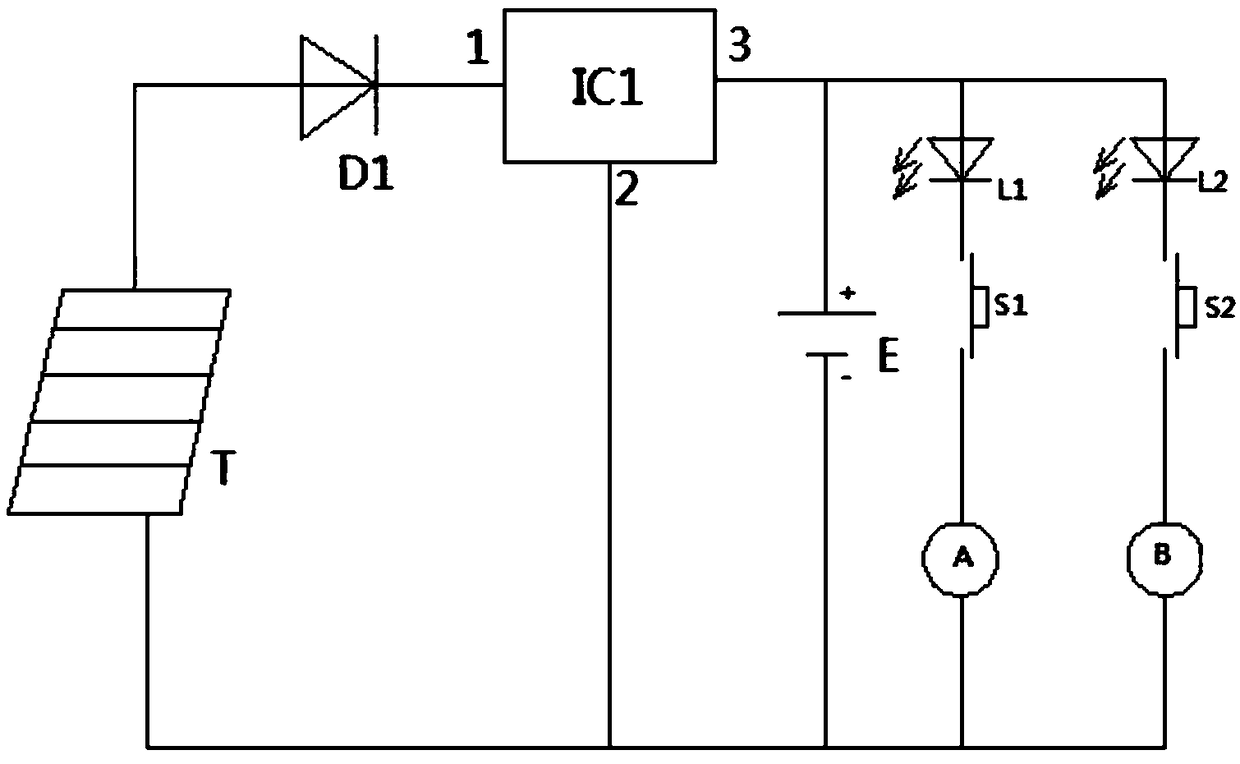

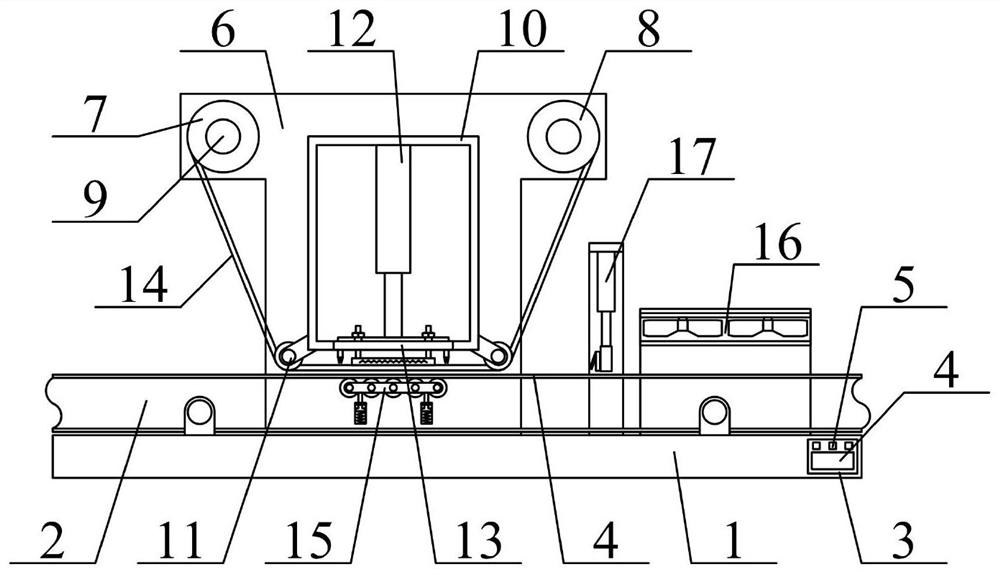

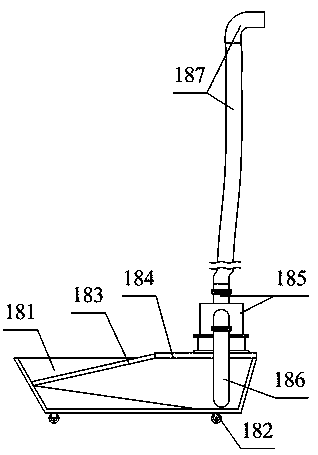

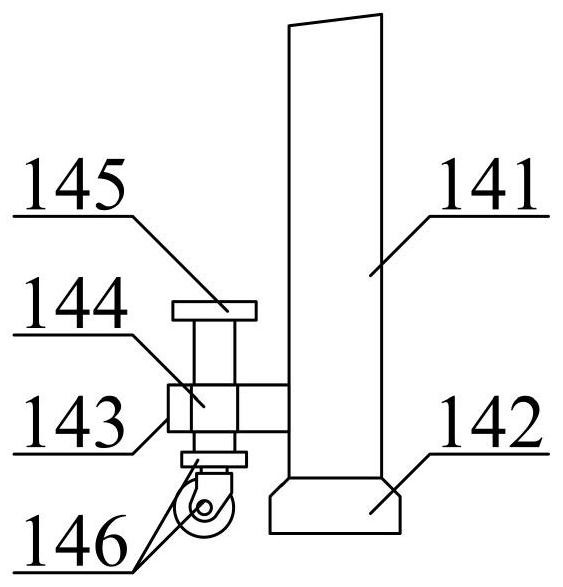

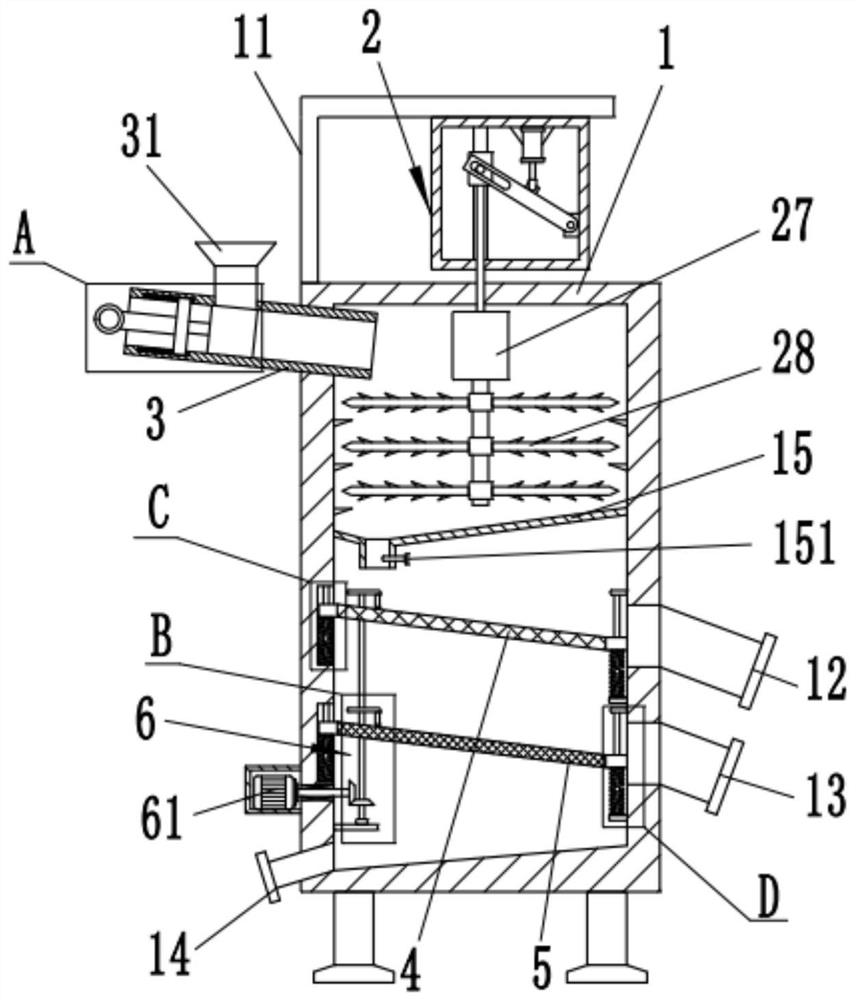

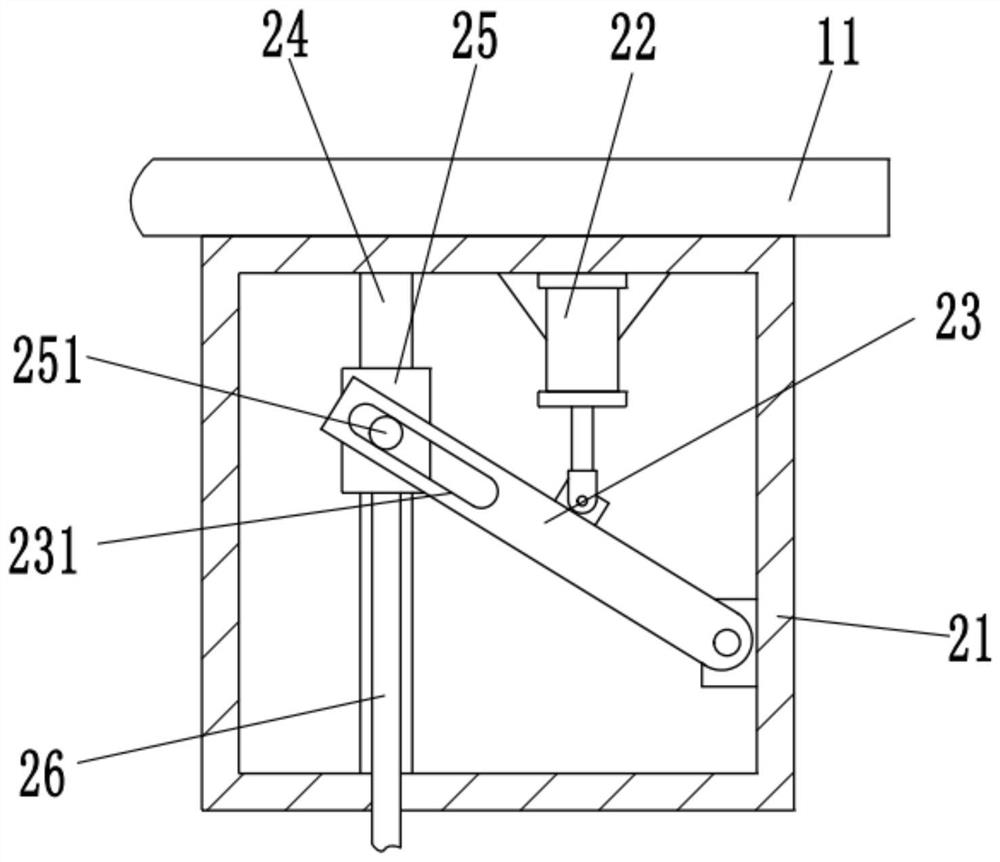

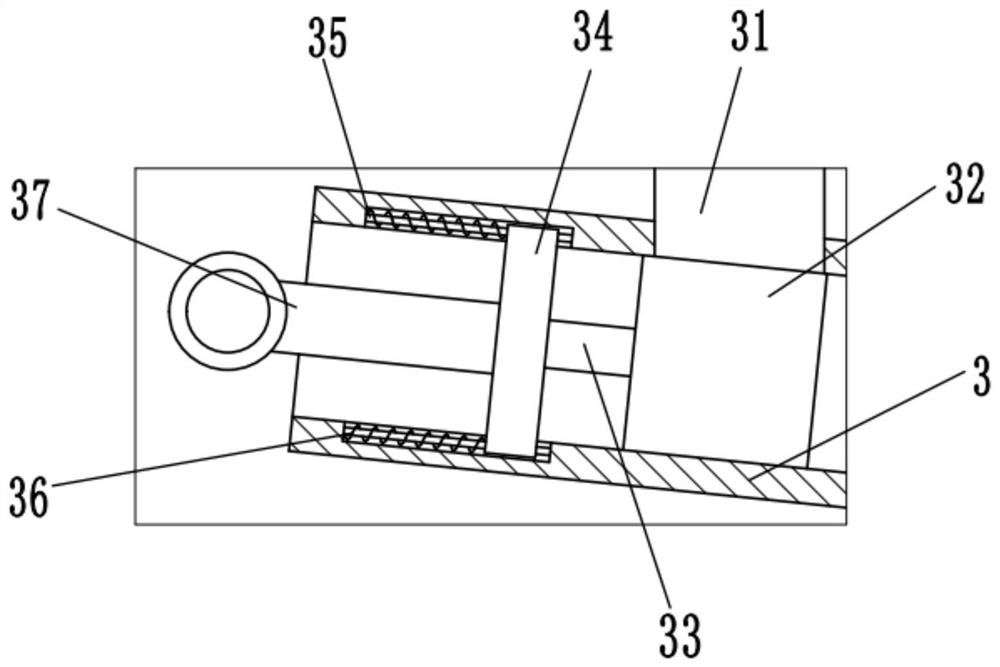

A portable pesticide sprayer

InactiveCN108684641AImprove overall utilizationIncrease profitBatteries circuit arrangementsRotary stirring mixersElectricitySprayer

The invention discloses a portable pesticide sprayer, the whole device uses photovoltaic power supply, which is energy-saving and electricity-saving, the device is convenient and quick to use, and hashigh practicality. The direction rotation of the device can be realized only by rotating the water tank. Because the sliding groove is a circular shape, the pulley can slide in the sliding groove, sothat the rotation of the water tank can be realized, a better visual field can be provided to an operator, and the range of the pesticide spraying can be increased, thus contributing to improving theefficiency of the pesticide spraying; a scale plate is convenient for dosing, so that the preparation of the pesticide liquid is scientific and reasonable; a stirring shaft is provided with stirringblades, so that the pesticide liquid can be uniformly mixed, and the utilization rate of the pesticide liquid can be improved; a filtering device can provides a filtering function, so that the pesticide spraying device is prevented from being blocked; a water outlet pipe is wound on a rotating disc, and the length of the water outlet pipe can be extended by rotating the rotating disc during long-distance operation, so that the range of the pesticide spraying is increased, the applicability of the device is improved, and the efficiency of the pesticide spraying is improved.

Owner:武汉思异汇创科技有限公司

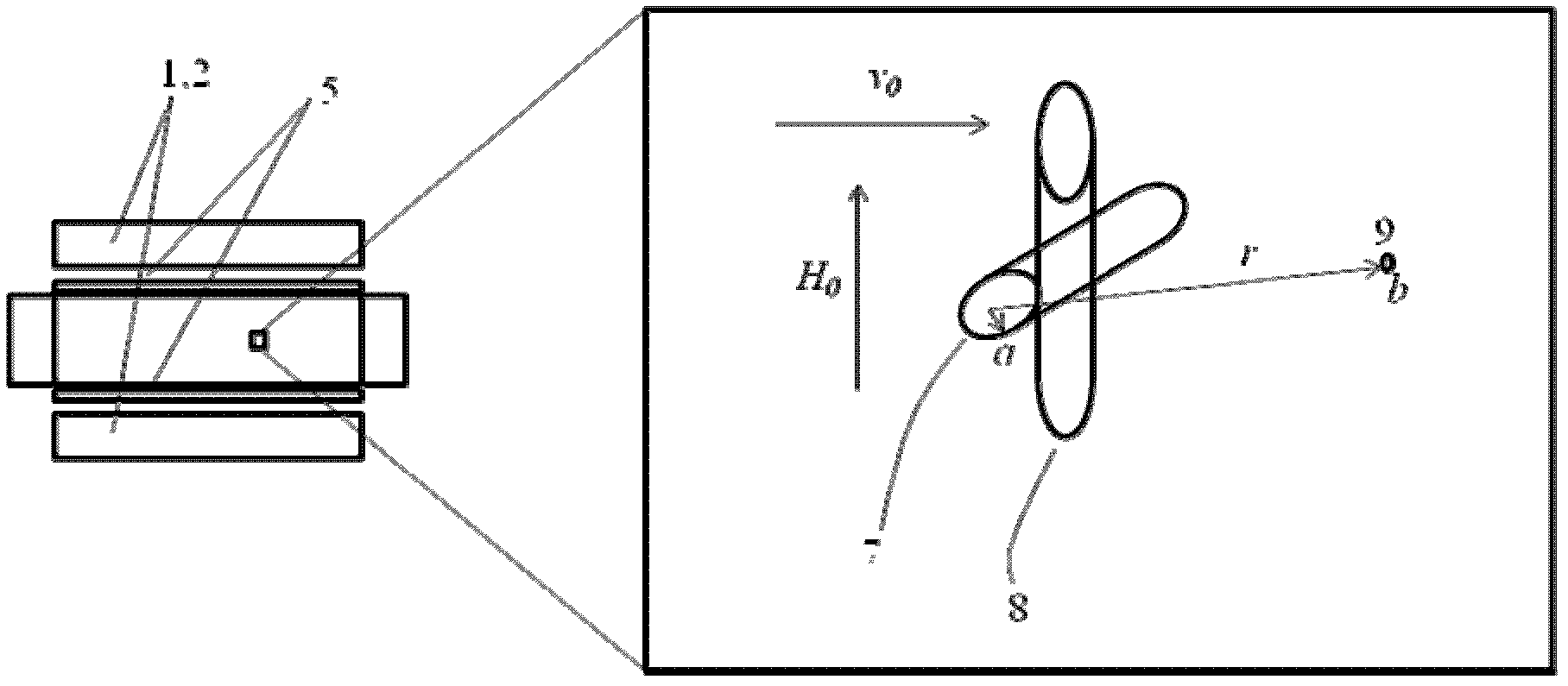

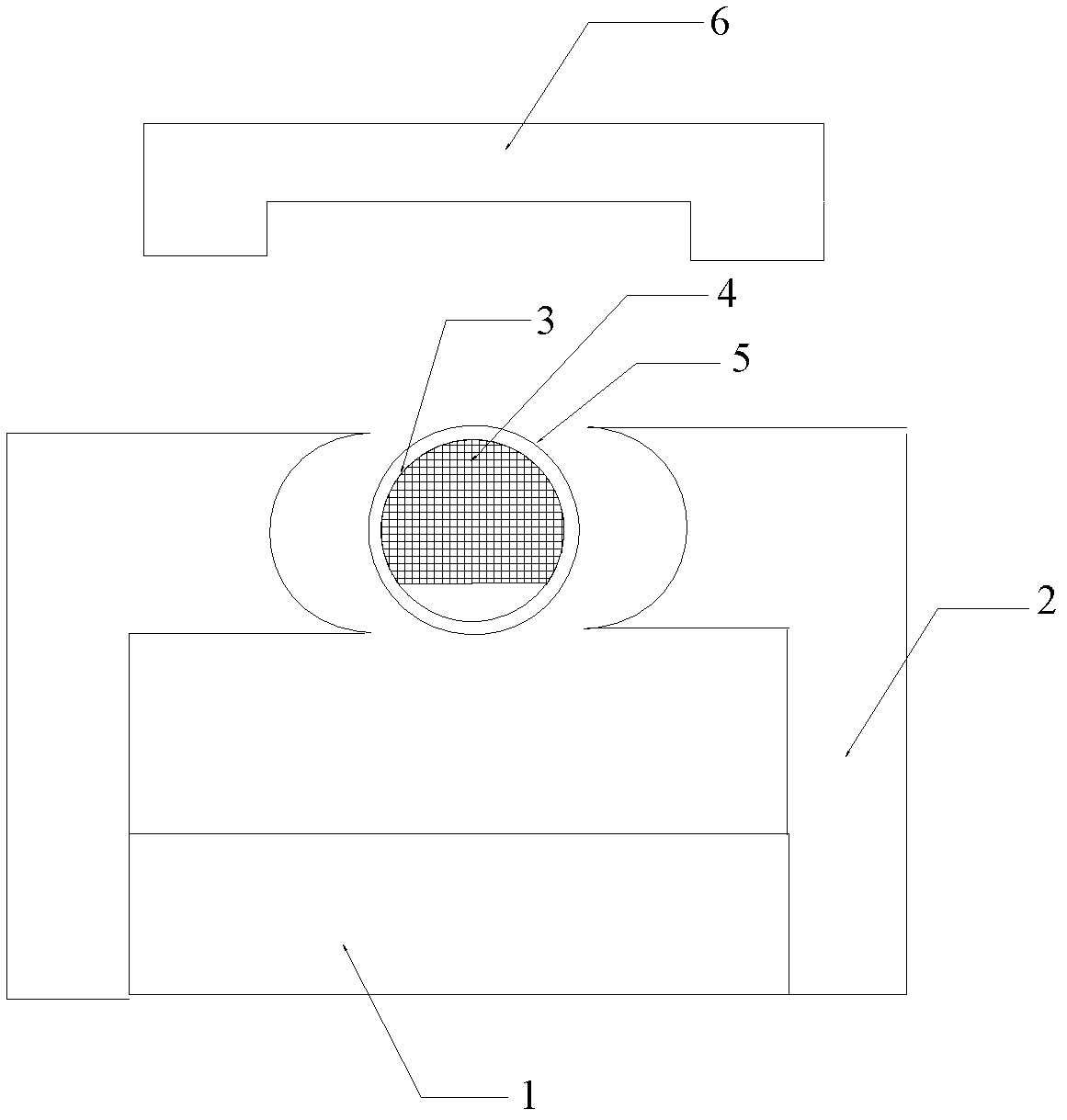

Magnetic well device for purifying high-temperature liquid metal

InactiveCN102614982AIncrease contact areaReduced risk of screen collapseHigh gradient magnetic separatorsMagnetic tension forceMetal

The invention relates to a magnetic well device for purifying high-temperature liquid metal, which comprises a permanent magnet, a magnet yoke, separation space and an armature, wherein an arch magnetism gathering medium silk screen with the arc length larger than a semicircle is arranged in the separation space in a staggered way, and is formed by magnetic stainless steel furs and non-magnetic stainless steel wires; for a magnetic field direction and a liquid metal flowing direction, the magnetic stainless steel furs are vertical to the two directions, and the non-magnetic stainless steel wires are in parallel to the magnetic field direction and vertical to the liquid metal flowing direction; and the armature, the permanent magnet and the magnet yoke form a closed magnetic circuit so as to be convenient to postprocess. The magnetic well device for purifying the high-temperature liquid metal has a simple structure and reasonable arrangement, is convenient to manufacture, is simple and easy to postprocess, and is an energy-saving high-gradient magnetic force purification device applied to the high-temperature liquid metal.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

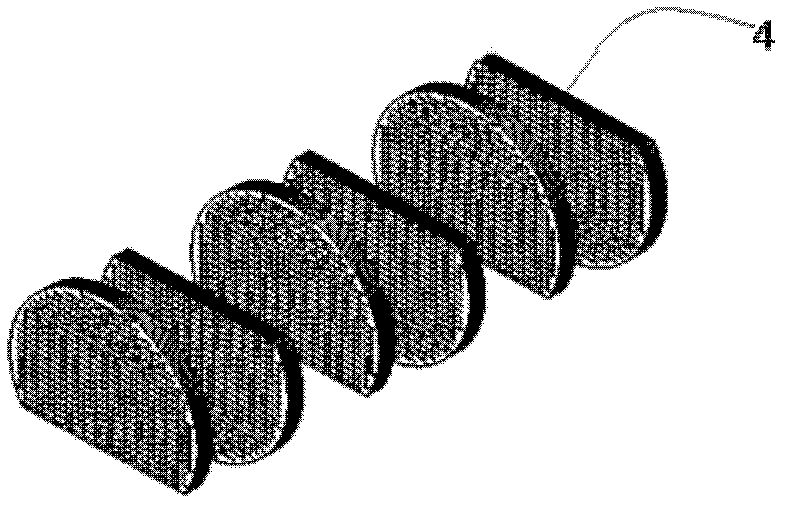

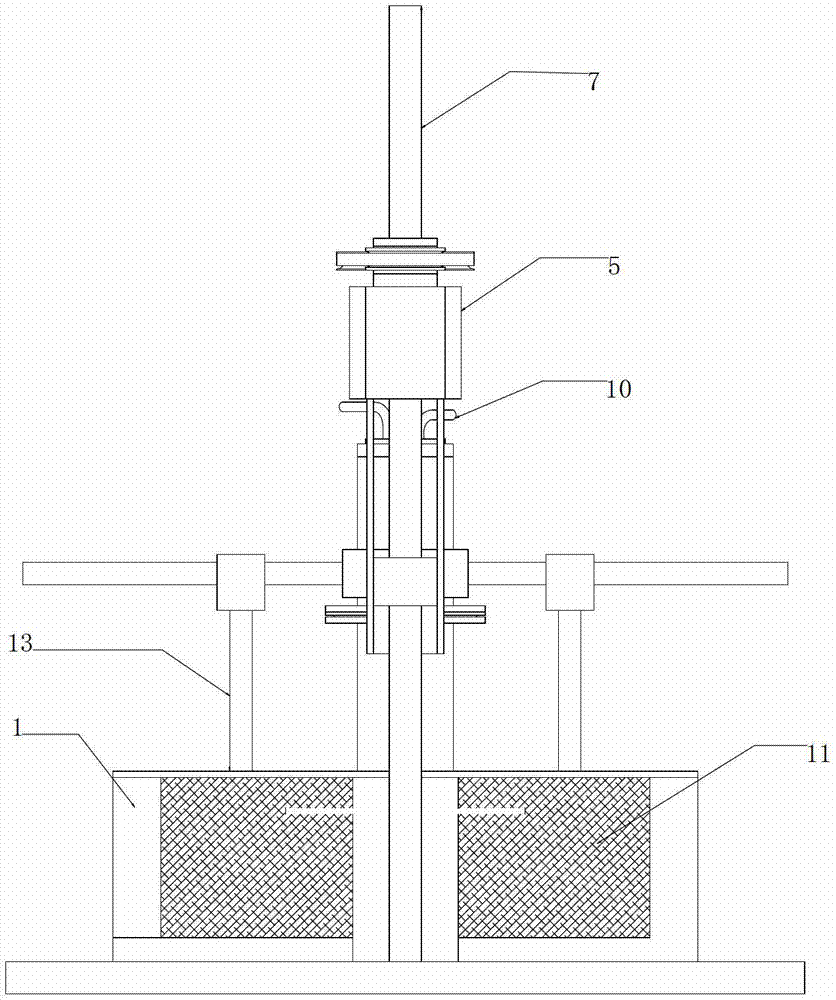

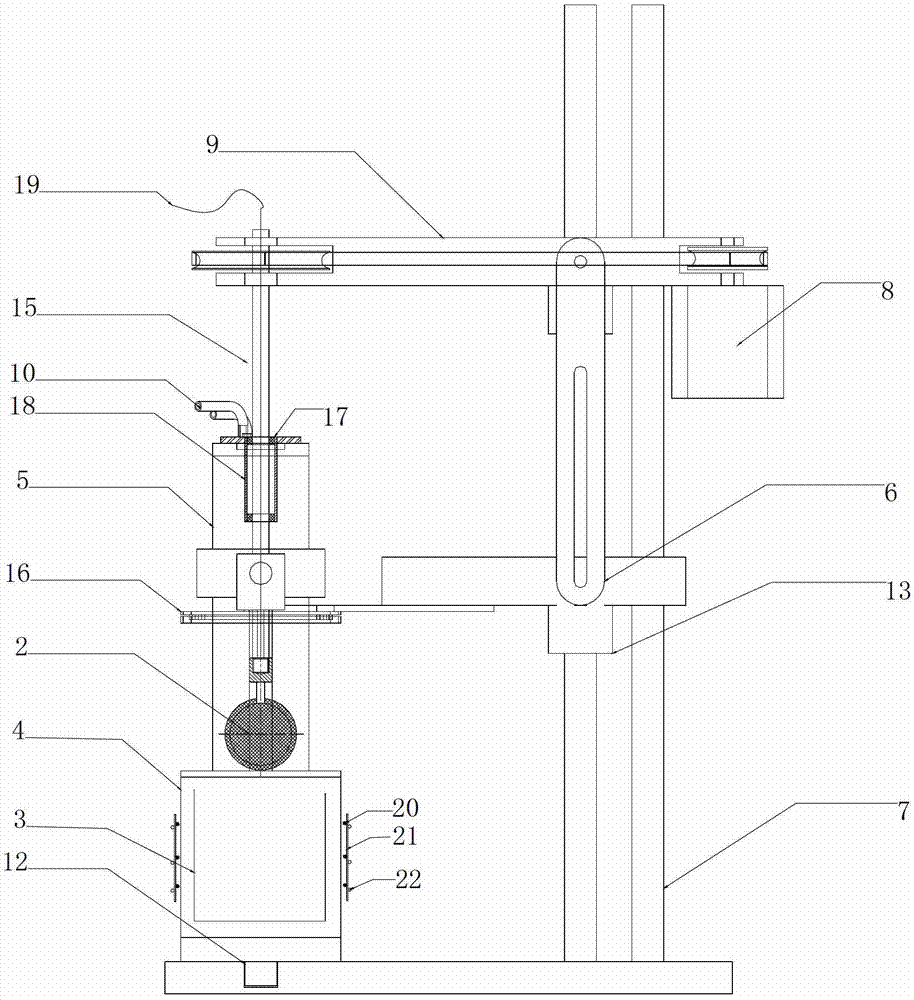

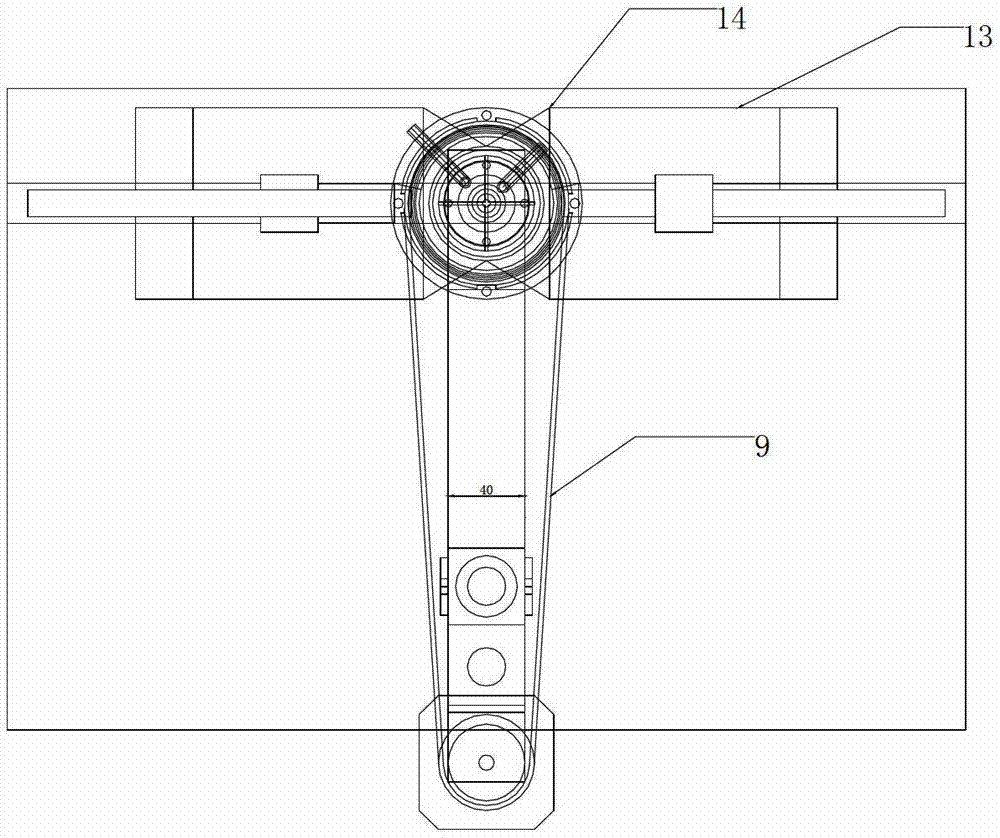

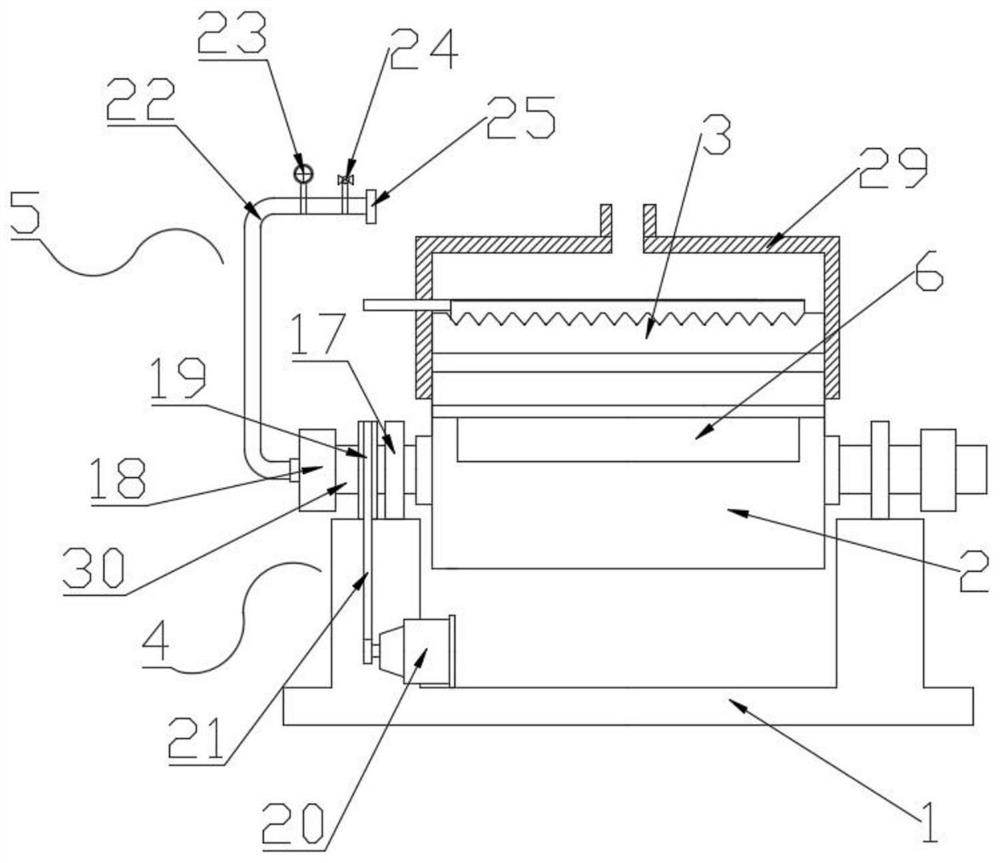

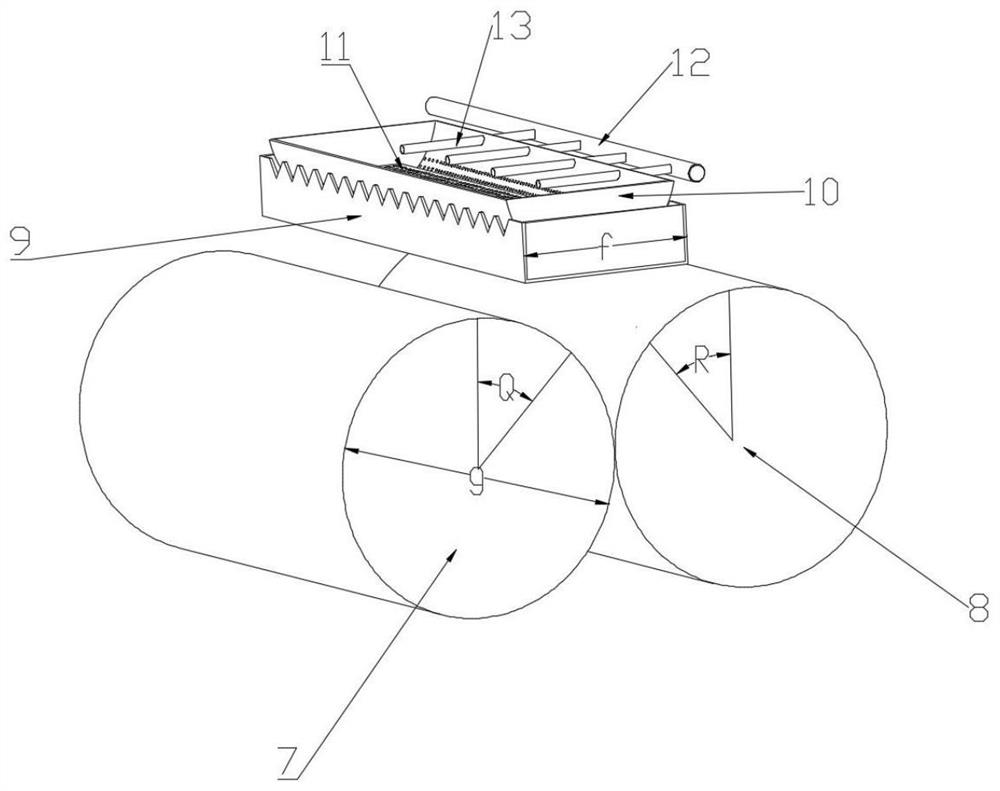

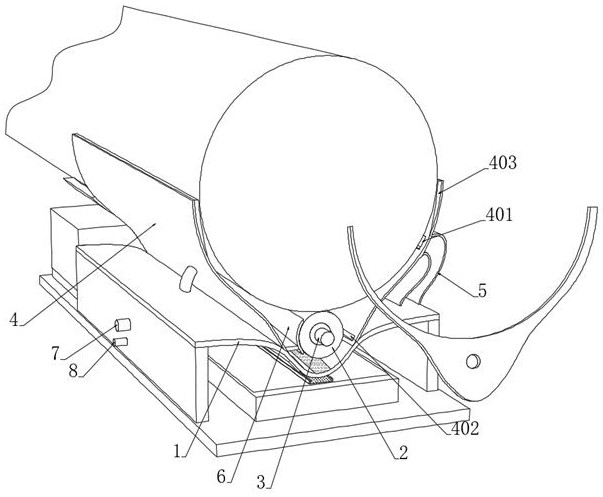

Capturing device for magnetic impurities in liquid metal

InactiveCN102784716AIncrease the air gap magnetic field strengthMultiple captureHigh gradient magnetic separatorsMotor driveCopper

A capturing device for magnetic impurities in liquid metal comprises a magnetic field system, a wire net, a crucible, a smelting tank, a sealing system, a fastening connecting rod, a support platform, a motor, a belt and a gas passageway; permanent magnets in the magnetic field system are placed in limit slide blocks on a guide rail and provide a magnetic field through a magnetic yoke; the crucible is arranged in the smelting tank as a liquid metal container; the wire net is vertically arranged in liquid metal through a rotating shaft; the sealing system comprises a sealing flange, the rotating shaft, a copper sleeve and a sealing oil trough; the position of the wire net in the liquid metal can be changed by adjusting the lifting height of the rotating shaft, and the fastening connecting rod is fixed through a fastening screw so as to fix the rotating shaft; the motor drives the rotating shaft through the belt; and the gas passageway is arranged at the upper end of the sealing oil trough and is used for allowing liquid metal protective gas to pass in and out. The capturing device for magnetic impurities can be used for simulating part of working parameters of magnetic traps in liquid metal and capturing magnetic impurities and is a simple and effective device for research on action of magnetic impurities in liquid metal.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

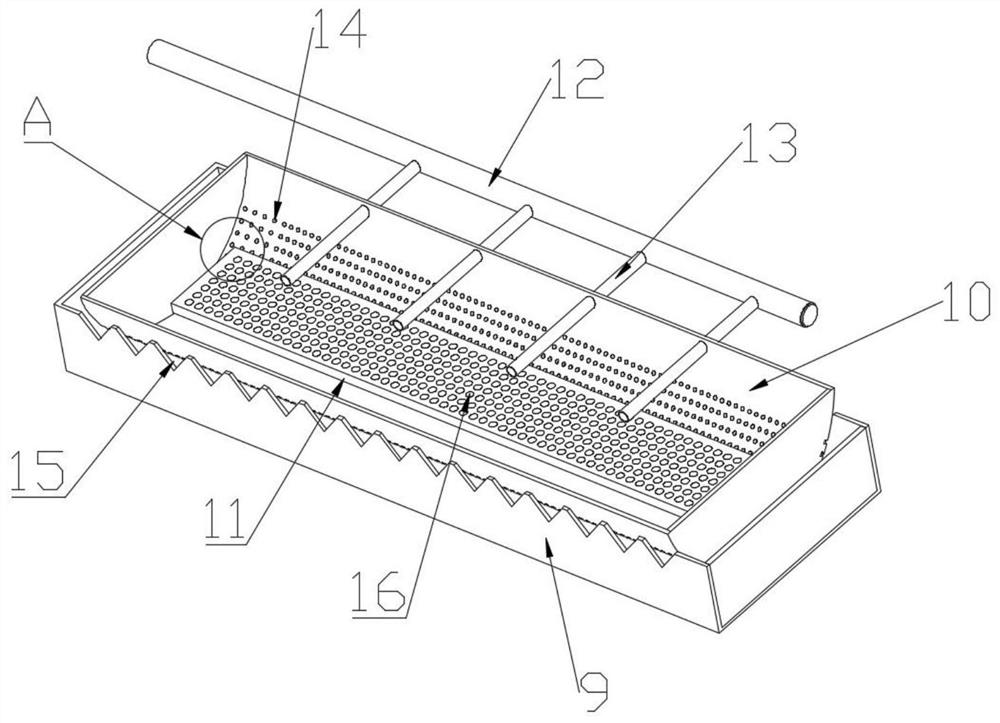

Two-stage groove type distributing device provided with pressure stabilizing plate and used for thin-layer drying equipment

PendingCN112028157AGuaranteed uniformityImprove work efficiencyWater distributersSolution crystallizationEngineeringStructural engineering

The invention discloses a two-stage groove type distributing device provided with a pressure stabilizing plate and used for thin-layer drying equipment. A two-stage distributing mechanism comprises arectangular overflow groove, a U-shaped main groove, a flow stabilizing plate, a liquid conveying header pipe and liquid conveying pipes; the rectangular overflow groove is formed in the upper end ofa drying rotary column; the U-shaped main groove is formed in the upper end of the rectangular overflow groove; the flow stabilizing plate is arranged in the U-shaped main groove; a liquid conveying header pipe is arranged on one side of the U-shaped main groove; the plurality of liquid conveying pipes are arranged between the liquid conveying header pipe and the U-shaped main groove; and one endof each liquid conveying pipe penetrates into the U-shaped main groove; According to the two-stage distributing mechanism, on one hand, mother liquor descending kinetic energy is relieved, so that thetwo-stage d distributing mechanism is prevented from being directly impacted by large-flow mother liquor; on the other hand, feed liquid splashing caused by sharp fluctuation of the liquid level is avoided, the distribution uniformity of the mother liquor is effectively improved; and a complete, uniform and stable liquid film can be rapidly formed on the outer surface of a drying rotary column under the action of the gravity and surface tension of the mother liquor and the centrifugal force of the drying rotary column.

Owner:江苏固环环境科技有限公司

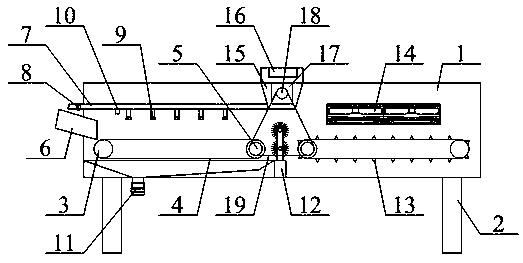

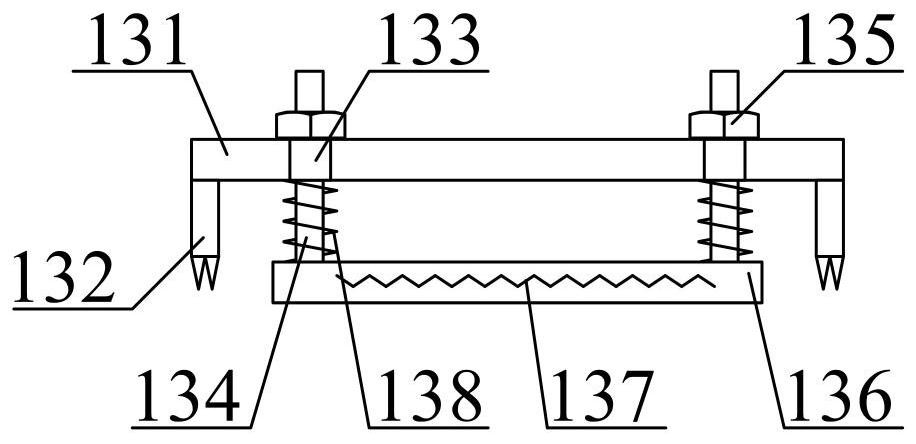

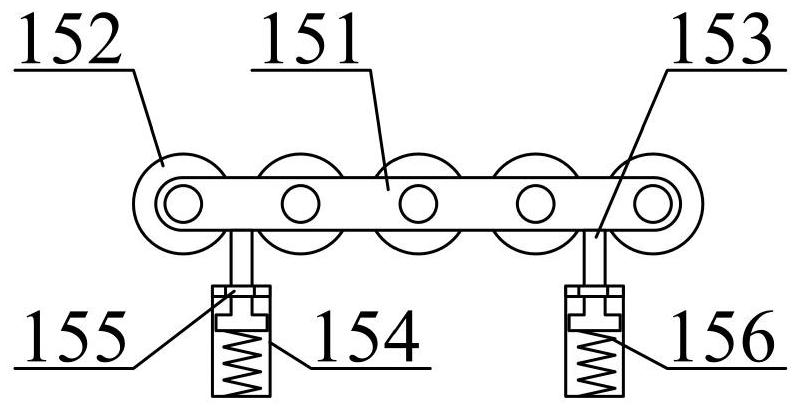

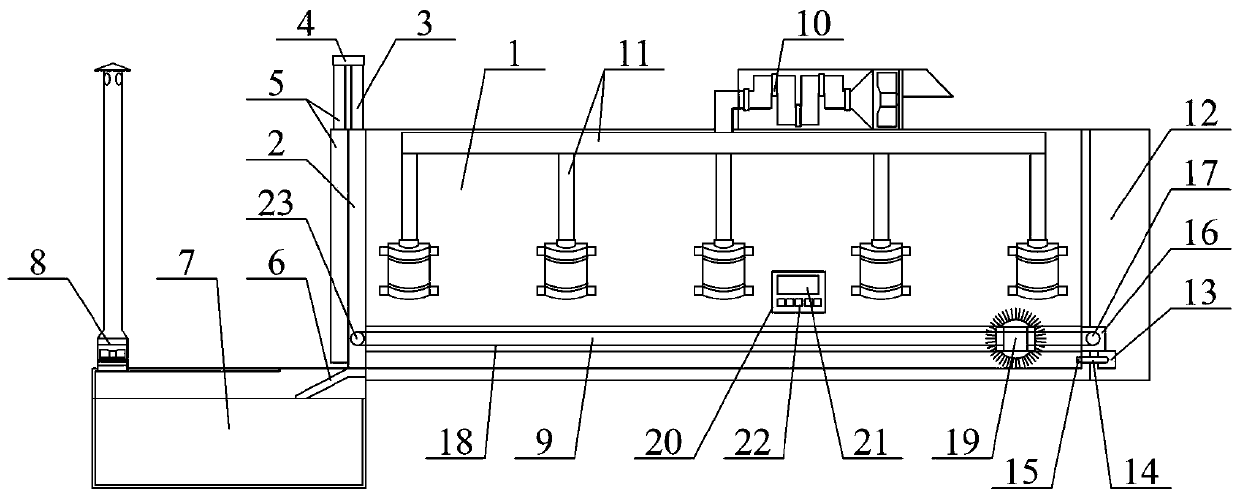

Intelligent automatic plate cleaning machine

InactiveCN111266331AImprove cleanlinessFunction as a filterDrying gas arrangementsCleaning using toolsDrive wheelThreaded pipe

The invention provides an intelligent automatic plate cleaning machine. The machine comprises a fixing outer frame, four vertical supporting legs, two left conveying rollers, a left conveyor belt, a left driven wheel, a guide-in frame, a horizontal water conveying pipe, an electromagnetic valve, spray nozzles, a sensor, a waste filtering discharging rack structure, a cleaning rack structure, a support conveying rack structure, a drying rack structure, a protection cover, a controller, a driving motor, a drive wheel and a transmission belt. The four vertical supporting legs are installed on thefour corners of the lower portion of the fixing outer frame through bolts. According to the intelligent automatic plate cleaning machine, a lower rolling brush and an upper rolling brush are arrangedon the inner side of a side connection plate separately, which helps to conveniently clean up plates passing through the inner sides of the lower rolling brush and the upper rolling brush during use.An activated carbon filter screen is glued to the lower portion of the inner side of a thread pipe, which helps to conveniently achieve a filtering function on fluid guided out of the thread pipe viaa guide-out pipe during use.

Owner:陈明

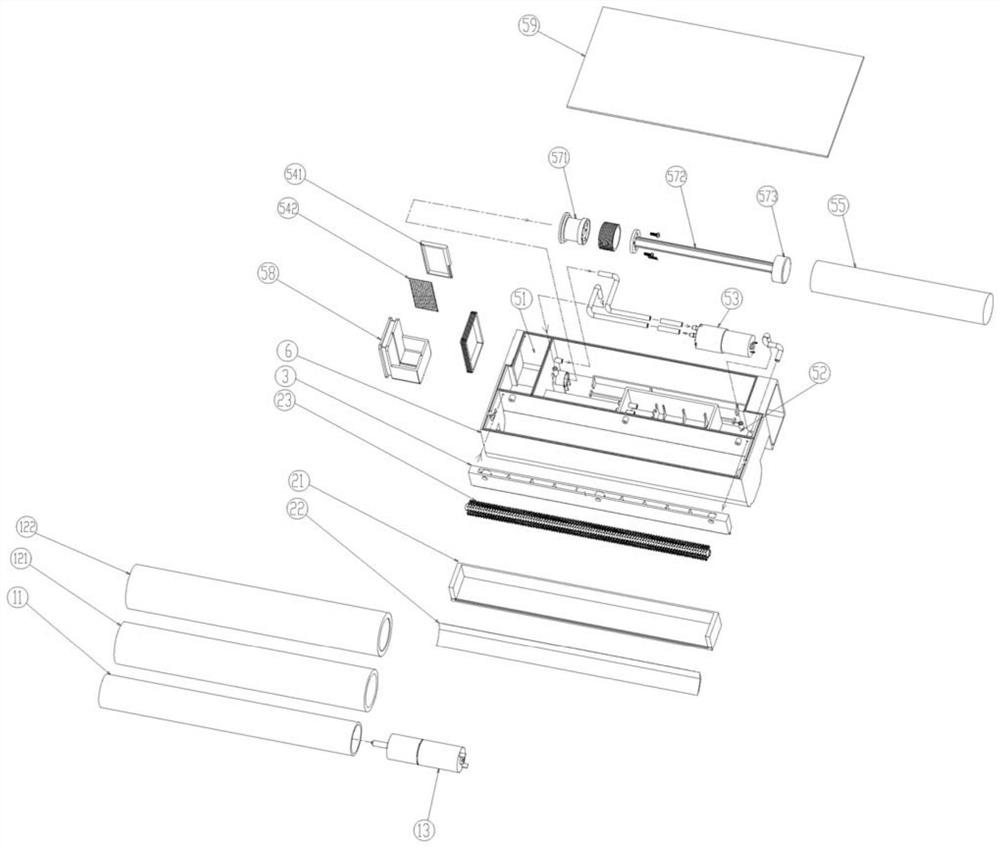

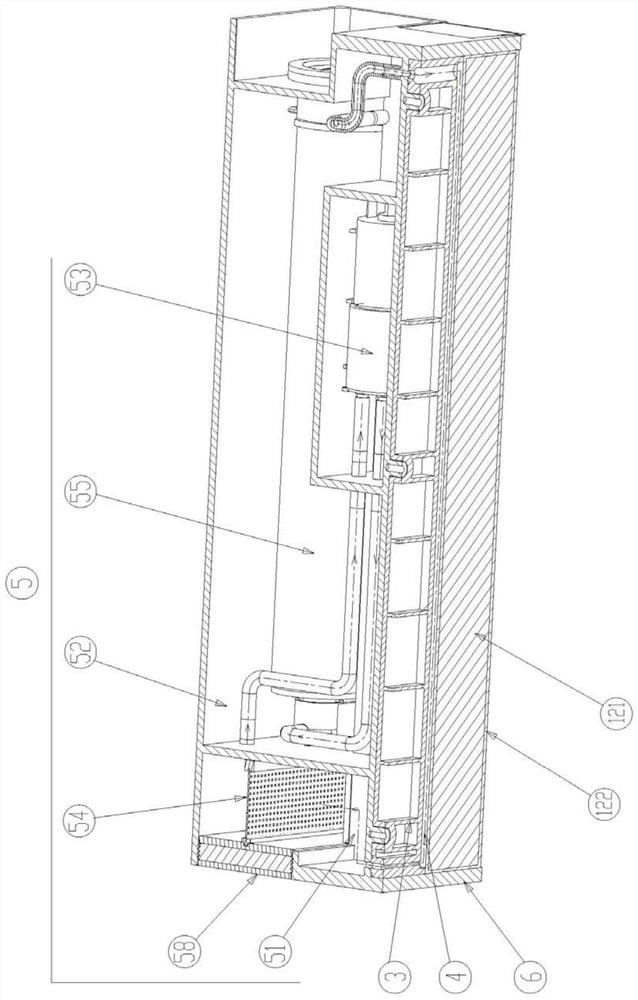

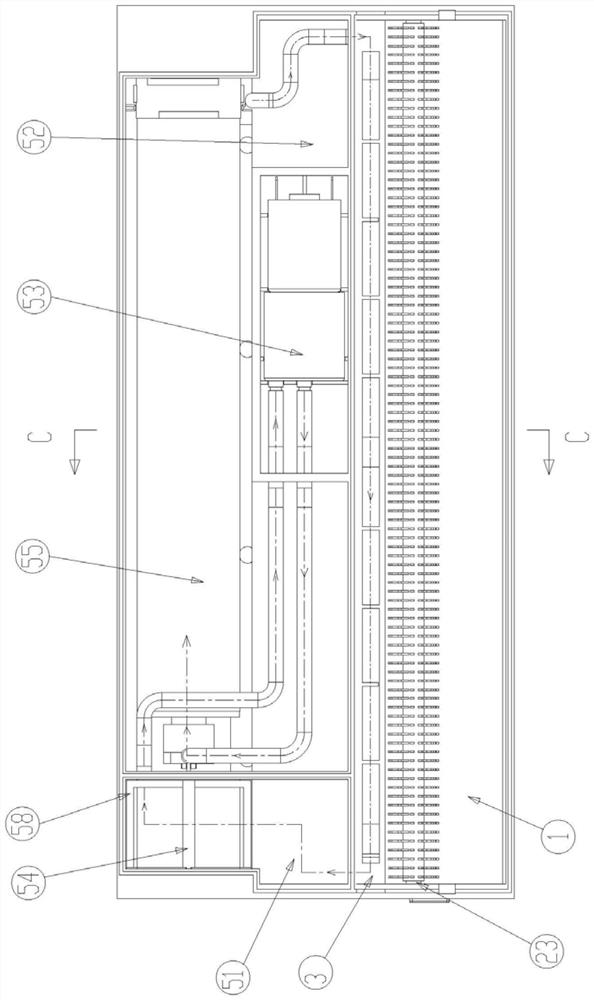

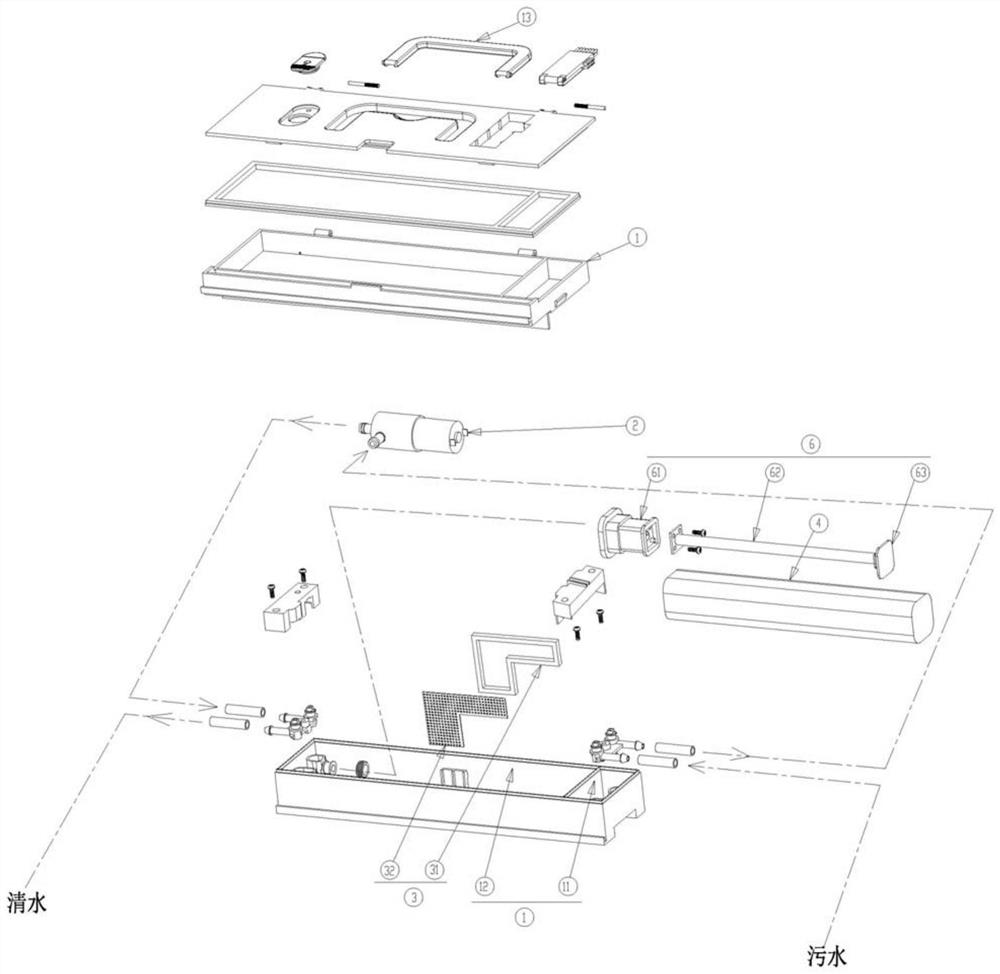

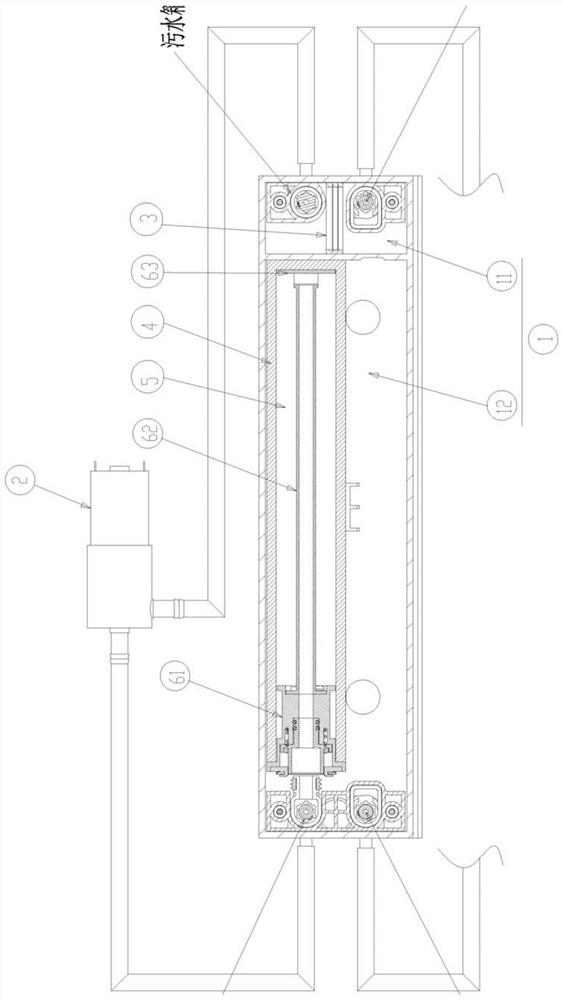

Scrubber integrated system capable of circularly filtering and recycling sewage

ActiveCN113440076AHigh circulation filtration efficiencyImprove filtering effectCarpet cleanersFloor cleanersWater flowSewage

The invention discloses a scrubber integrated system capable of circularly filtering and recycling sewage. The scrubber integrated system is characterized by comprising a shell, a roller assembly, a dust collection assembly, a water tank and a water circulation assembly are arranged in the shell, the roller assembly is arranged at the front end of the shell and used for sweeping garbage and collecting the garbage into the dust collection assembly, the water tank abuts against the roller assembly, a closed cavity for water to pass through is formed between the water tank and the roller assembly and communicated with the water circulation assembly through a liquid inlet pipeline and a liquid outlet pipeline, and the water circulation assembly can drive water to flow through the closed cavity, sewage flowing out of the liquid outlet pipeline enters the water circulation assembly to be purified and then flows into the closed cavity through the liquid inlet pipeline to achieve water circulation utilization. The system has the advantages of being exquisite in structure, capable of achieving product miniaturization, good in cleaning effect, good in use experience, low in production and manufacturing cost and beneficial to saving water, and the market application prospect is good.

Owner:GUANGDONG YUNHAN INTELLIGENT TECH CO LTD

Intelligent paper surface labeling device for bogus kraft paper bag production

InactiveCN111891516APlay the function of blowing and coolingAvoid adsorptionLabelling machinesProduction lineElectric machinery

The invention provides an intelligent paper surface labeling device for bogus kraft paper bag production. The labeling device comprises a transverse bottom plate, a production line conveyor belt body,a control frame, a controller, a control button, a rear side T-shaped plate, a first roller, a second roller, a driving motor, a rectangular outer frame, pulleys, a telescopic air cylinder, a cuttingframe structure, a film pasting device, a conveyor belt auxiliary support frame structure, a finished product heat dissipation air drying frame structure and an adjustable limiting frame structure, wherein the production line conveyor belt body is mounted on the upper portion of the transverse bottom plate through bolts, the control frame is embedded in the right side of the front portion of thetransverse bottom plate, the controller is mounted on the inner side of the control frame through screws, and the control button is embedded in the upper portion of the front side of the control frame. According to the labeling device, blowers are arranged on the inner side of a fan frame, and are mounted on the left side and the right side of the lower portion of a transverse rod through screws,so that a finished product passing from the upper side of the production line conveyor belt body is conveniently blown for heat dissipation during use, and an adhesive layer of the finished product isprevented from sucking dust.

Owner:ZHEJIANG RONGSHENG PAPER IND HLDG

Mobile phone auto-answer method

InactiveCN104348946AImprove experienceFeel goodAutomatic call-answering/message-recording/conversation-recordingRing back toneRadio frequency signal

The invention relates to a mobile phone auto-answer method. The method comprises the steps: (1) setting user-defined color ring back tones for all incoming calls; (2) receiving radio-frequency signals, and enabling a terminal transmitting the radio-frequency signals to be matched with contacts in a local phone contact list; (3) judging whether the terminal is a contact in the local phone contact list or not according to a matching result; (4) judging whether user-defined color ring back tones are set for the contact or not, playing the color ring back tones for the contact if the user-defined color ring back tones are set for the contact, and playing call waiting warning tones if the user-defined color ring back tones are not set for the contact; (5) judging whether the transmitting terminal appears for the first time or not, playing color ring back tones for a stranger if the transmitting terminal appears for the first time, judging whether contact color ring back tones among the user-defined color ring back tones are set for the terminal or not if the transmitting terminal does not appear for the first time, playing the contact color ring back tones if the contact color ring back tones among the user-defined color ring back tones are set for the terminal, and playing the call waiting warning tones provided by an operator if the contact color ring back tones among the user-defined color ring back tones are not set for the terminal. The mobile phone auto-answer method provided by the invention can be used for carrying out preliminary filtering on the incoming calls without any cost.

Owner:XIAN YIPU COMM TECH

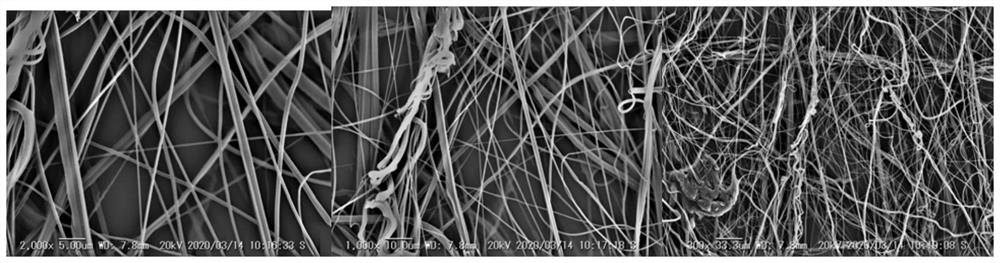

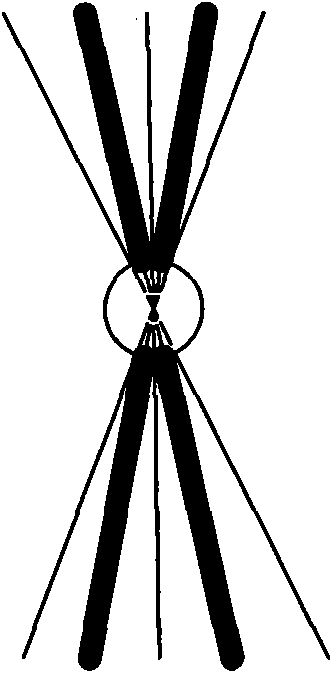

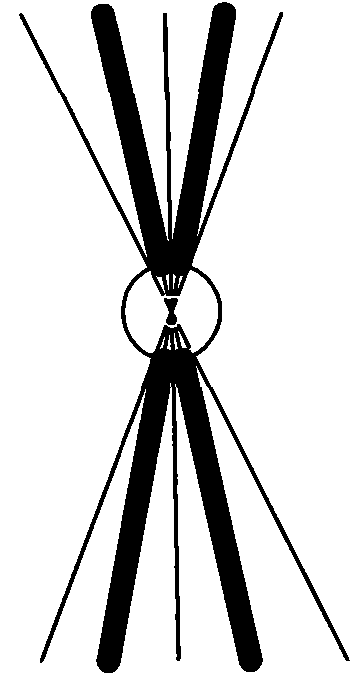

Novel comet type composite fiber filtering material

InactiveCN101766930AImprove tanglesHigh filtration precisionFiltration separationFilter materialEnvironmental capacity

The invention belongs to the field of fiber filtering material and particularly relates to a novel comet type composite fiber filtering material. The novel comet type composite fiber filtering material comprises a comet nucleus and a comet tail connected on the comet nucleus, wherein the comet tail is a fiber filament bundle consisting of fiber filaments; and the fiber filament bundle consists of at least two types of fiber filament materials. The composite fiber filtering material can improve the knotting phenomenon of the fiber filaments well, plays a role in filtering and blocking dirt in water in a better way, enhances filtering accuracy and water environmental capacity, has high filtering material cleanliness after backwashing, and saves energy and water.

Owner:陈俊杰 +1

Coke tower decoking device for needle coke production process

ActiveCN112080293AImprove cleanlinessEasy to exportOven incrustations prevention/removalGear wheelLiquid storage tank

The invention provides a coke tower decoking device for a needle coke production process, which belongs to the technical field of decoking equipment, and comprises a coking tower, an eduction tube, aneduction flange, a mounting cover, a driving motor, a driving gear, a driven gear and a scraping jet frame structure, the eduction tube is welded at the lower part of the coking tower; the leading-out flange is welded at the lower part of the leading-out pipe; the mounting cover is mounted at the upper part of the coking tower through bolts; the driving motor is mounted on the right side of the upper part of the mounting cover through bolts; and the driving gear is arranged on the inner side of the mounting cover. Through the arrangement of the liquid pumping pipe, the liquid storage tank andthe booster pump, water liquid in the liquid storage tank is pumped through the liquid pumping pipe by utilizing the booster pump, so that the water liquid is sprayed from the spray head to the innerwall of the coking tower through the liquid guide pipe, the liquid leading-in pipe, the confluence pipe and the inner ring of the sealing bearing and finally through the longitudinal transmission pipe and the transverse material conveying pipe; therefore, the cleanliness of the inner wall of the jet coking tower is improved.

Owner:SHANDONG LIANHUA NEW MATERIAL CO LTD

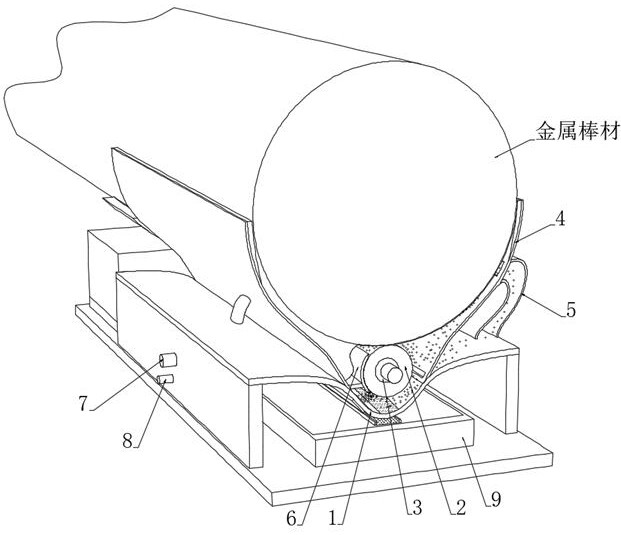

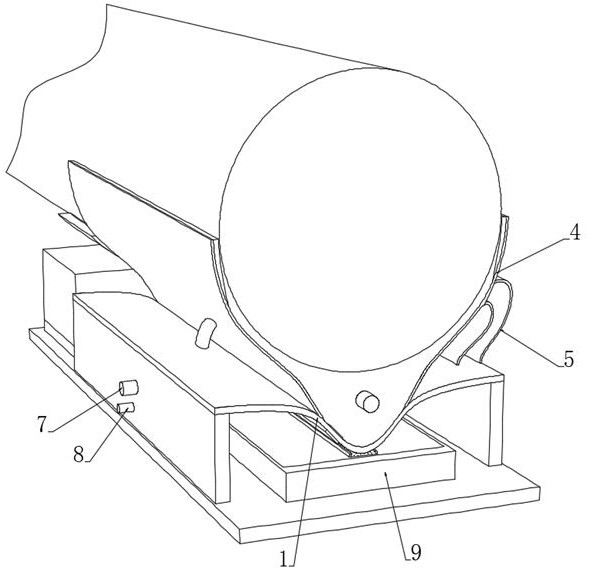

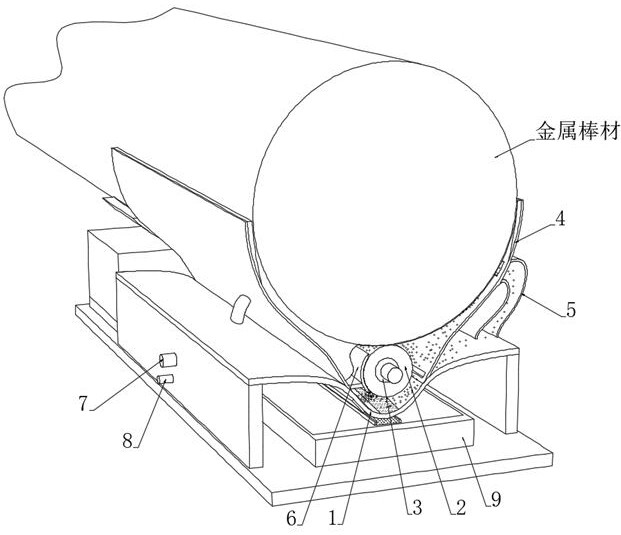

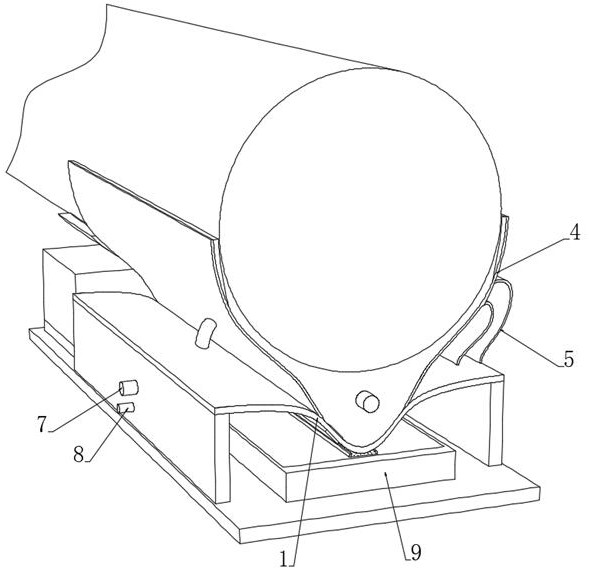

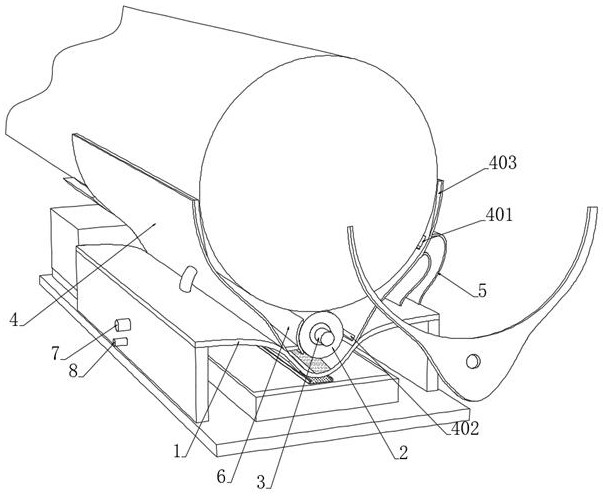

Powder throwing magnetic attraction type metal bar polishing device

ActiveCN113334220AEasy to polishPlay a cooling roleGrinding machinesGrinding work supportsPolishingMetallic materials

The invention discloses a powder throwing magnetic attraction type metal bar polishing device, and belongs to the technical field of polishing machining of metal materials. An inwards-concave arc-shaped bearing and a pair of flow deflectors are arranged, a magnetic polishing roller is located above a particle falling cooling part, and a plurality of magnetic particles are arranged at the particle falling cooling part; and after an inner electromagnetic roller is powered on and magnetic, the outer wall of the magnetic polishing roller is magnetic, so that the magnetic particles are attached to the outer wall of the magnetic polishing roller, the magnetic particles are rubbed between the magnetic polishing roller and a metal bar, and the polishing effect is improved. Meanwhile, an air supply pipe is used for supplying air to the particle falling cooling part, gas pushes part of magnetic particles which are not magnetically attracted to the magnetic polishing roller to be thrown to the end wall of the metal bar, multi-point impact type damage is achieved on impurities such as oxide skin, and therefore subsequent polishing of the magnetic polishing roller is facilitated, in addition, water is used for leaching the magnetic particles, on one hand, dust is removed, and on the other hand, the effect of cooling the polished end face is achieved.

Owner:南通英富泰电气科技有限公司

Multi-functional fecal cleaning device for electric automatic breeding

InactiveCN111248091AImprove cleanlinessEasy extractionGas treatmentDispersed particle filtrationAnimal scienceSynchronous motor

The invention provides a multi-function fecal cleaning device for electric automatic breeding. The multi-function fecal cleaning device for electric automatic breeding includes a breeding room, a longitudinal U-shaped frame, a longitudinal baffle, a connecting frame, a lifting cylinder, a guide plate, a fecal storage tank, an odor discharge frame structure, a lateral sliding chute, a fresh air introducing frame structure, a fresh air entering protective frame structure, a water storage tank, a water suction pump, a water suction pipe, a high-pressure spray head, a forward and reverse motor, adriving gear, a transmission chain, a mobile cleaning frame structure, a mounting frame, a controller, a power switch and a driven gear; and the bolts of the longitudinal U-shaped frame are installedat the left and right ends of the breeding room. According to the invention, synchronous motor bolts are installed on one end of a rectangular hollow frame away from a rotating tube, and the output shaft and the rotating tube are connected by a key, which is beneficial to increase the cleaning effect on the ground of the breeding room; and an exhaust fan is arranged on the inside of the introducing frame, and meanwhile, the bolt is installed on the left side of a stainless steel mesh plate, which is conducive to adding fresh air to the breeding room, and can improve the air quality and oxygencontent in the breeding room.

Owner:魏中云

Sewage treatment membrane material and preparation method thereof

ActiveCN112169604ASimple manufacturing methodReduce dependenceSemi-permeable membranesWater/sewage treatment by irradiationEthoxidineTriazine

The invention discloses a preparation method of a sewage treatment membrane material, which is characterized by comprising the following steps: S1, preparing a polymerizable sulfuryl diimidazolium salt monomer, S2, preparing ethoxysilane modified 2, 4, 6-tri [(p-carboxyphenyl) amino]-1, 3, 5-triazine, and S3, preparing a membrane material. The invention also discloses the sewage treatment membranematerial prepared according to the preparation method of the sewage treatment membrane material and application of the sewage treatment membrane material in sewage treatment. The sewage treatment membrane material disclosed by the invention is excellent in comprehensive performance, good in performance stability, remarkable in sewage treatment effect, capable of effectively catalyzing organic matters in sewage to be decomposed and adsorbing and separating heavy metal ions in the sewage, and long in service life.

Owner:中煤(北京)环保股份有限公司

Anti-blocking device for injection molding machine nozzle and mould feed points

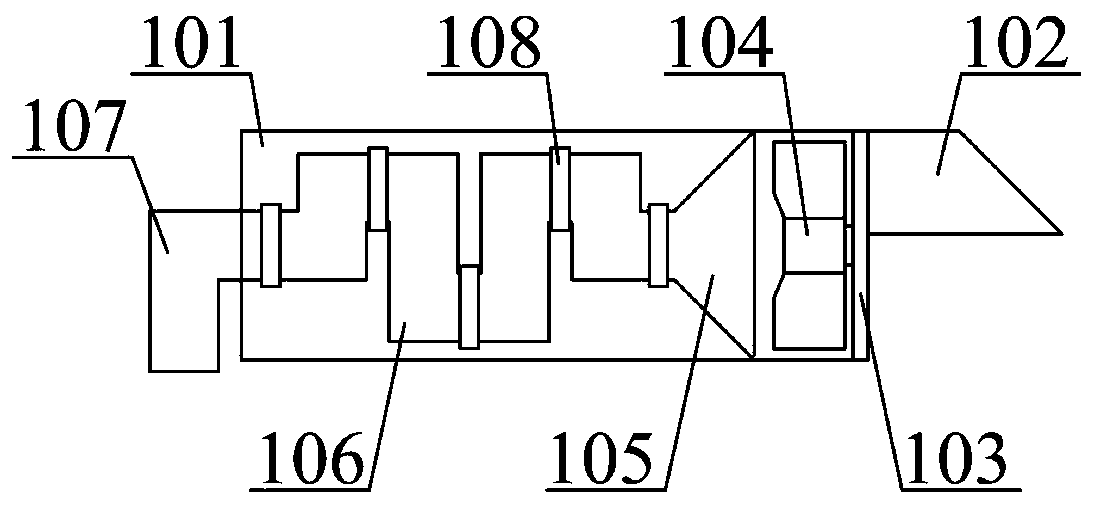

ActiveCN102765163BIncrease the circulation areaAvoid downtime for maintenanceInjection molding machineLarge size

The invention discloses an anti-blocking device for an injection molding machine nozzle and mould feed points. A filtering column is mounted at the rear end of a central hole of the injection molding machine nozzle or mounted on a portion, located in the rear of the injection molding machine nozzle, in an injection molding machine material tube, and is provided with feeding grooves, discharging grooves and filtering grooves, raw materials enter the filtering column from each feeding grooves of the filtering column and enter the discharging grooves after being filtered via the filtering grooves, and foreign materials in the raw materials are intercepted by the filtering grooves while the raw materials enter the injection molding machine nozzle and a mould from the discharging groove, therefore, halt and maintenance caused by blocking of the injection molding machine nozzle and the mould feed points are avoided. Feeding grooves and discharging grooves in large size can be cut on the filtering column, and a plurality of filtering grooves can be cut on shared groove walls among the feeding grooves and the discharging grooves, so that processing is facilitated, flow areas of the raw materials is increased greatly, and the anti-blocking device plays a role in intercepting and has small influences on injection flow and speed of the nozzle.

Owner:镒生电线塑料(昆山)有限公司

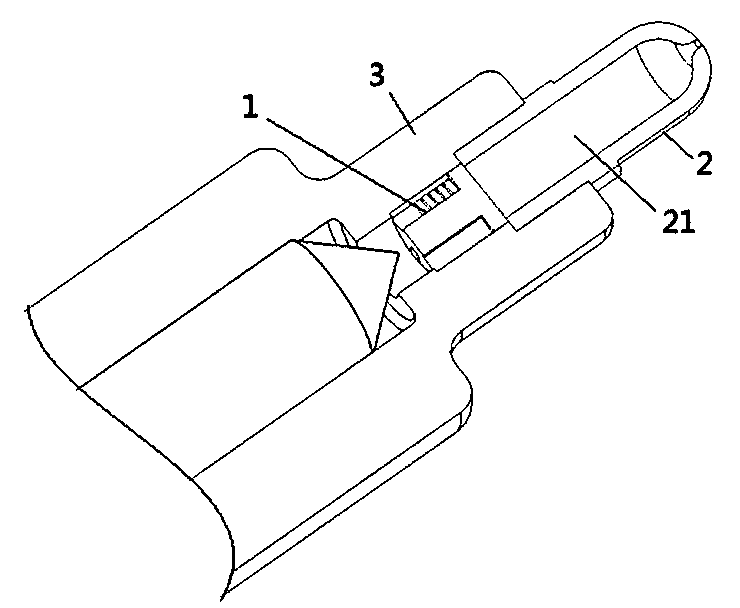

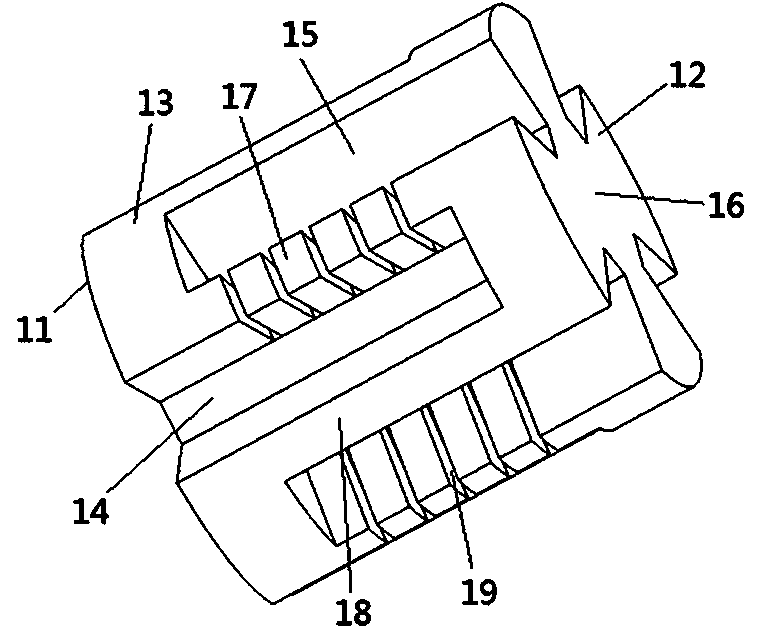

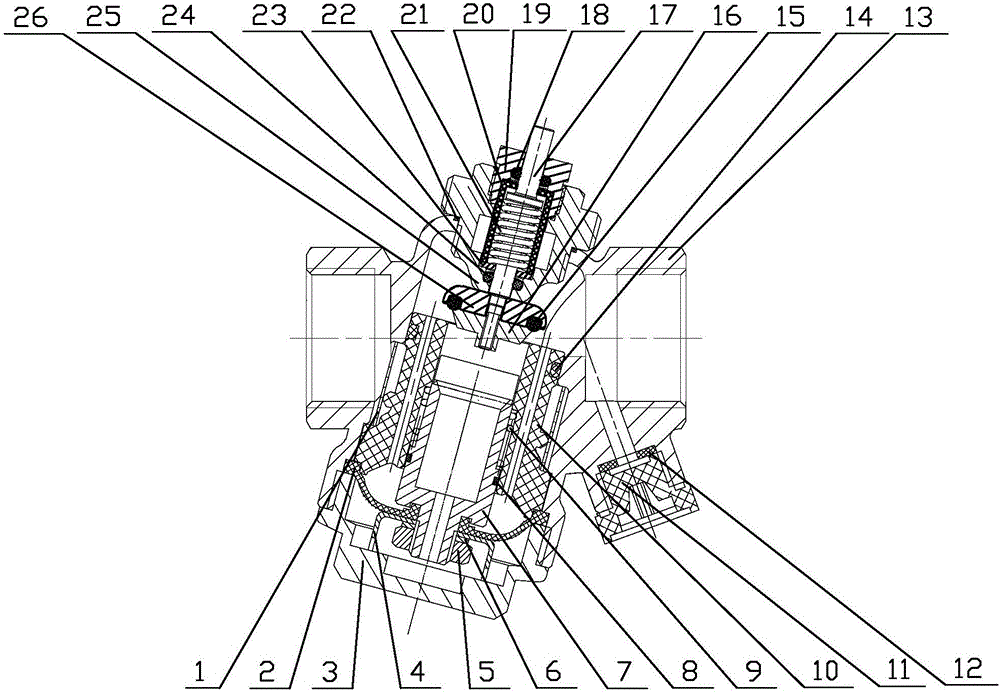

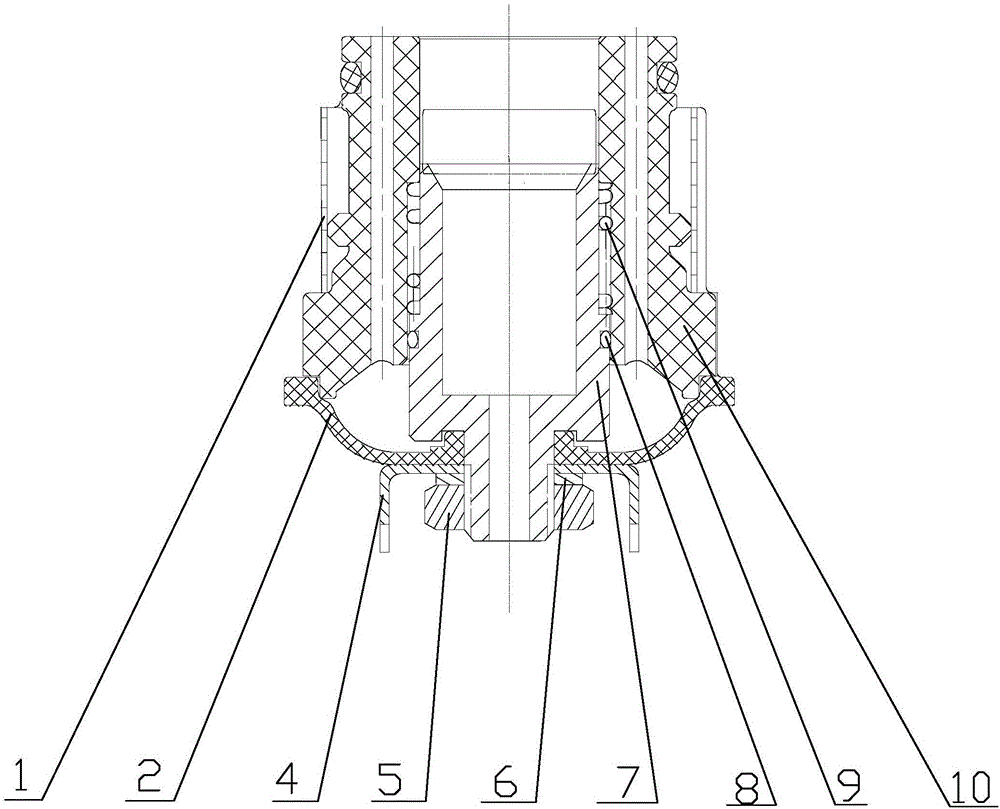

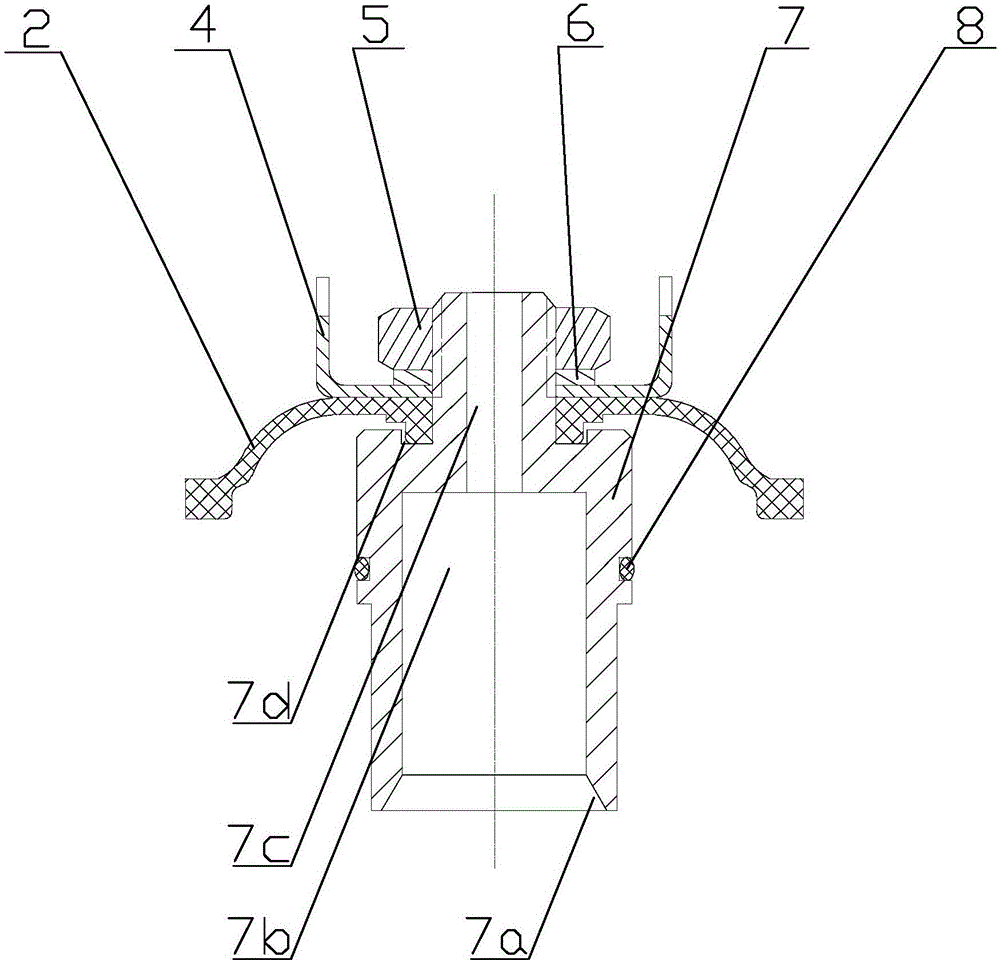

Automatic valve core component and differential pressure-independent type flow control valve

ActiveCN106352128ASmall pressure lossFast pressure transferOperating means/releasing devices for valvesEqualizing valvesDifferential pressureControl system

The invention relates to an automatic valve core component and a differential pressure-independent type flow control valve and belongs to the technical field of balance valves. The automatic valve core component comprises a pressure-sensitive diaphragm, a compressing disc, a regulating valve core and a valve core sleeve, wherein the valve core sleeve is of a cylinder multi-boss sleeve structure, a water guiding hole is formed in the upper end face of the valve core sleeve, the regulating valve core is of a cylinder sleeve structure provided with steps, a thin-wall cutting edge is formed in the upper end face of the regulating valve core, a groove is formed in the lower end of the regulating valve core, the groove is matched with an intermediate hole boss of the pressure-sensitive diaphragm, and the groove runs through a center hole of the pressure-sensitive diaphragm to the compressing disc below the pressure-sensitive diaphragm; and the valve core sleeve sheathes on the outer wall of the regulating valve core. The automatic valve core component provided by the invention has the advantages of high regulation precision, small size, no influence on flow and guarantee of independent implementation of regulating and closing functions.

Owner:ZHEJIANG DUNAN INTELLIGENT CONTROL TECH CO LTD

A kind of activated carbon air filter element and preparation method thereof

InactiveCN103463868BFunction as a filterImprove wear resistanceFiltration separationPolyvinyl alcoholAir filter

Owner:天长市天乐电器厂

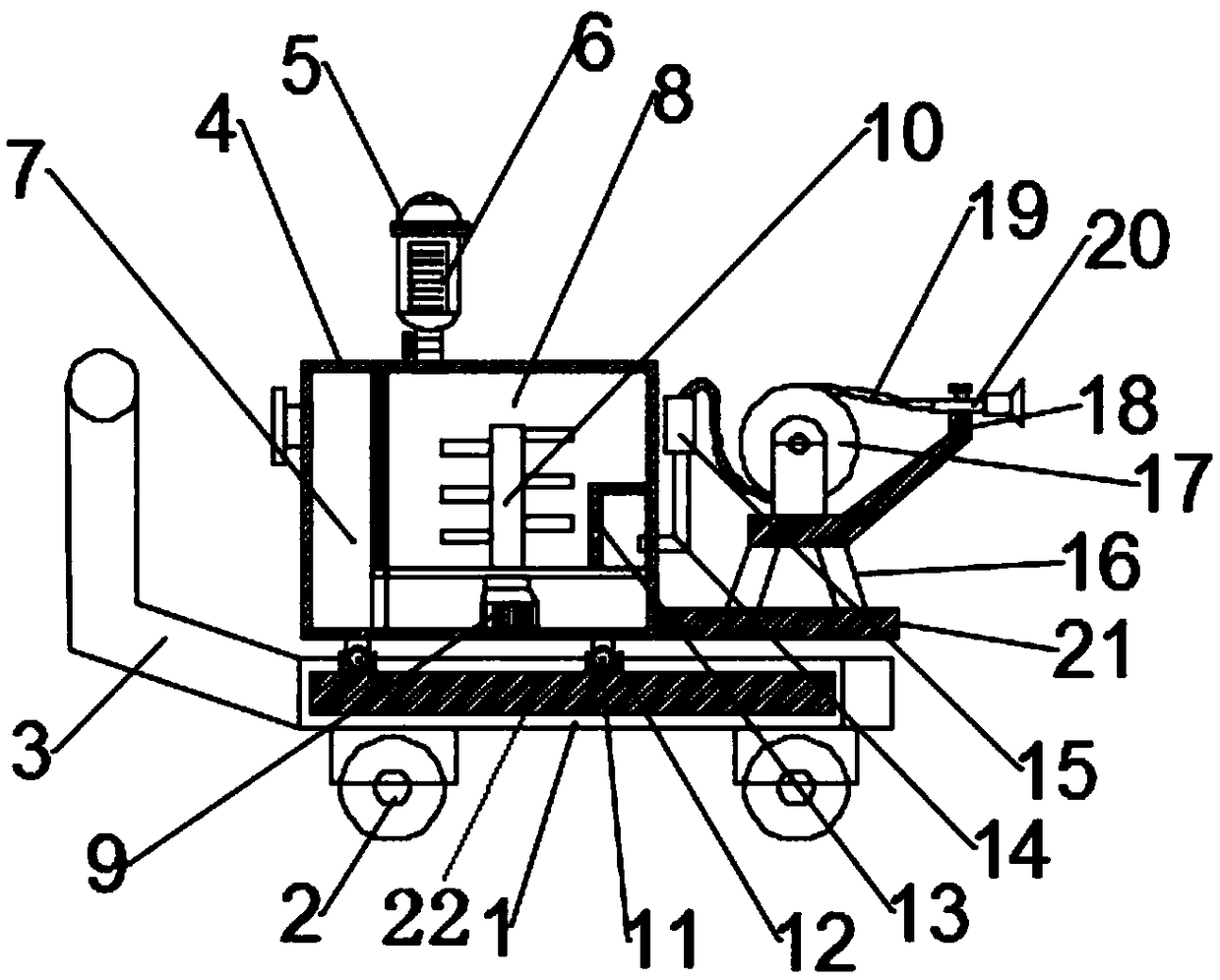

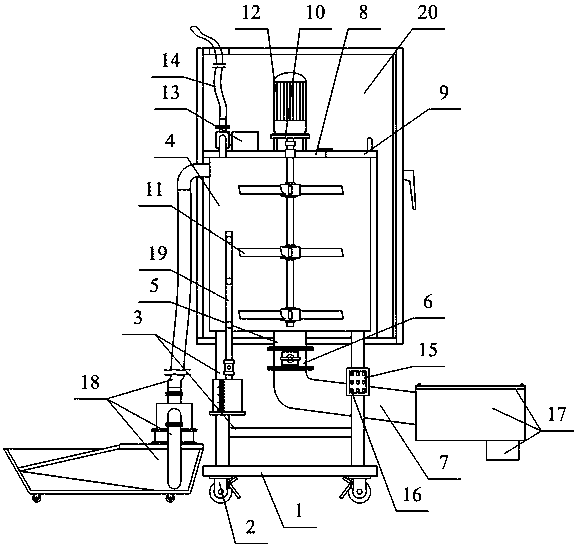

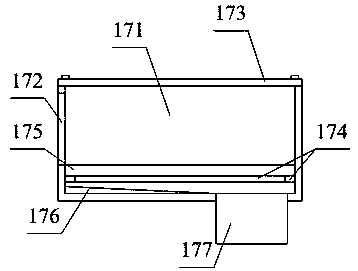

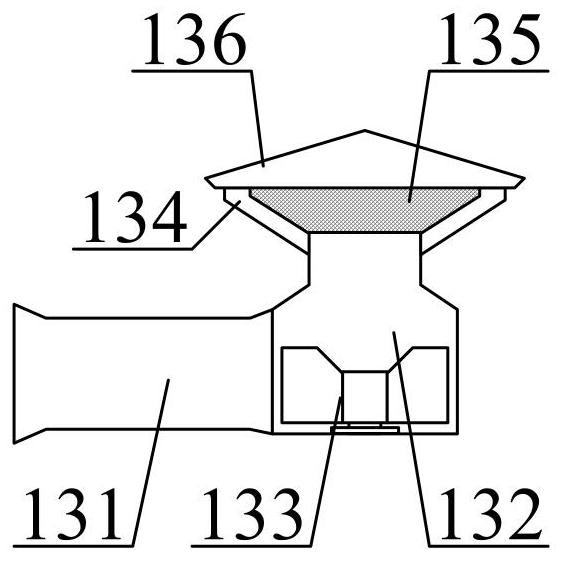

Intelligent large cement foaming machine

InactiveCN111015952AImprove functionalityEasy to disassemble and replaceDischarging apparatusMixing operation control apparatusElectric machineNylon filter

The invention provides an intelligent large cement foaming machine which comprises a bottom plate, moving wheels, a supporting frame, a foaming tank, a discharging head, a flap valve, a conveying pipe, a sealing plate, an overturning plate, a rack, a stirring frame, a rotating motor, a suction pump, a connecting hose, a PLC, a switch, an auxiliary filter box structure, an auxiliary conveying box structure, a sampling observation pipe frame structure and a noise reduction protection cover structure. The moving wheels are installed on the periphery of the lower surface of the bottom plate through bolts. The supporting frame is welded to the periphery of the upper surface of the bottom plate, and the foaming tank is welded to the upper end of the supporting frame. The discharging head is welded in the middle of the lower end of the foaming tank; and the flap valve is connected to the lower end of the discharging head through a flange. The intelligent large cement foaming machine has the beneficial effects that due to the arrangement of the auxiliary filter box structure, when cement is discharged, the function of filtering impurities through a nylon filter screen can be achieved, andthen the functionality of the cement is improved.

Owner:无棣国梁防腐保温工程有限公司

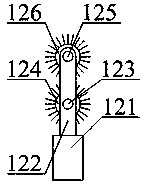

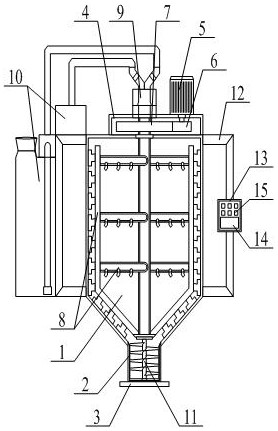

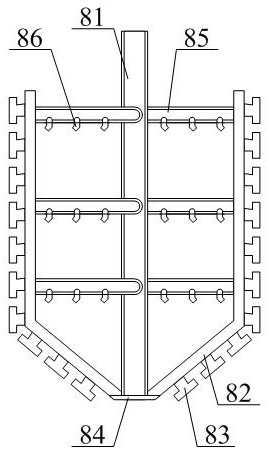

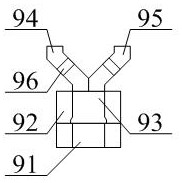

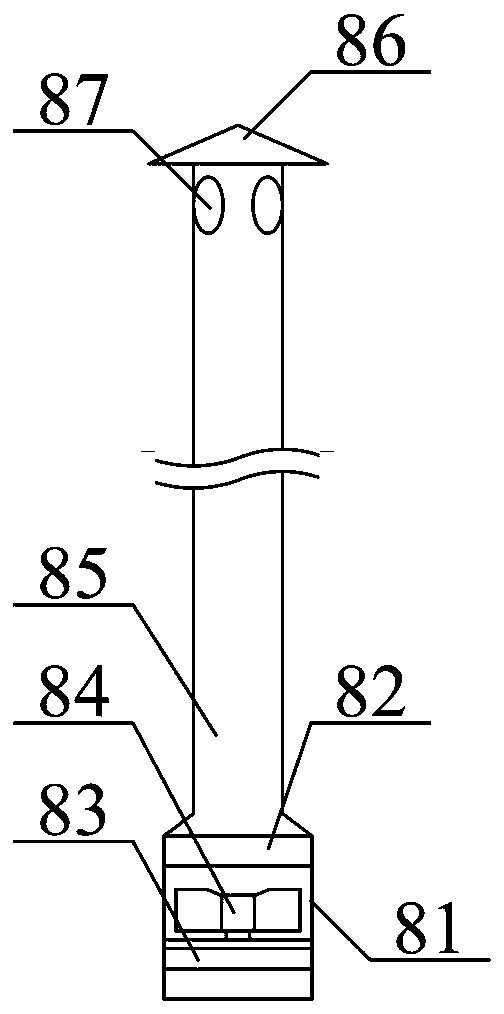

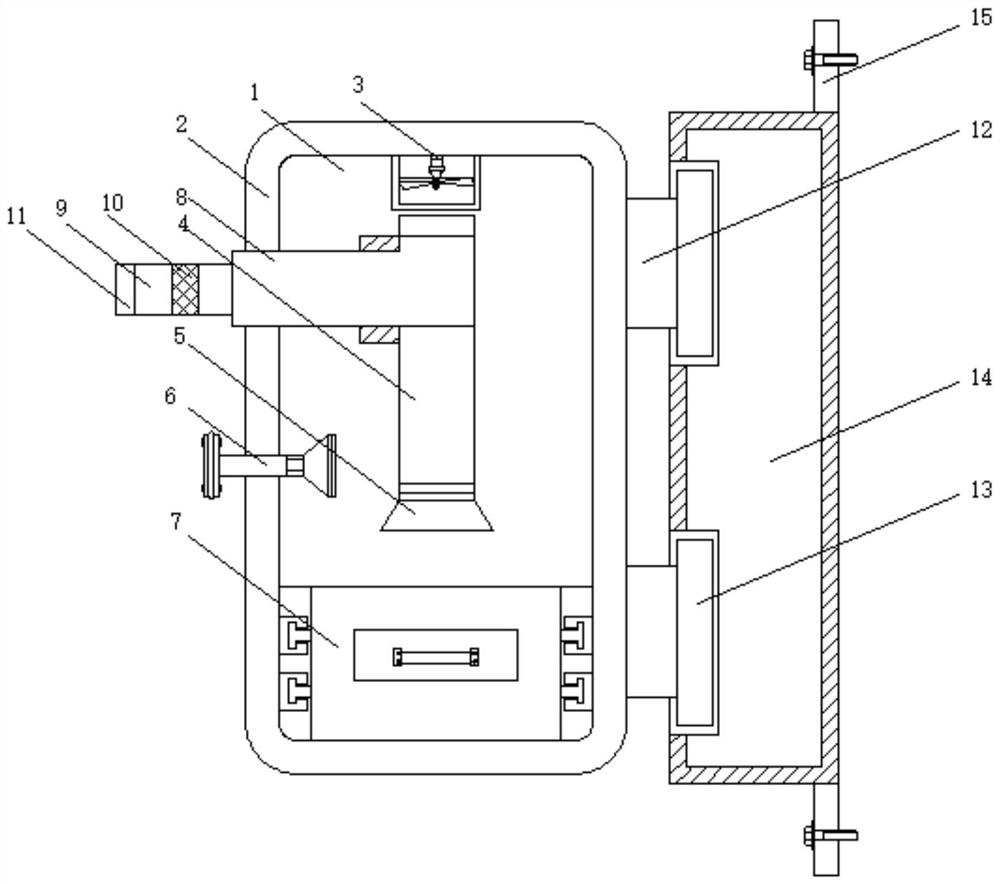

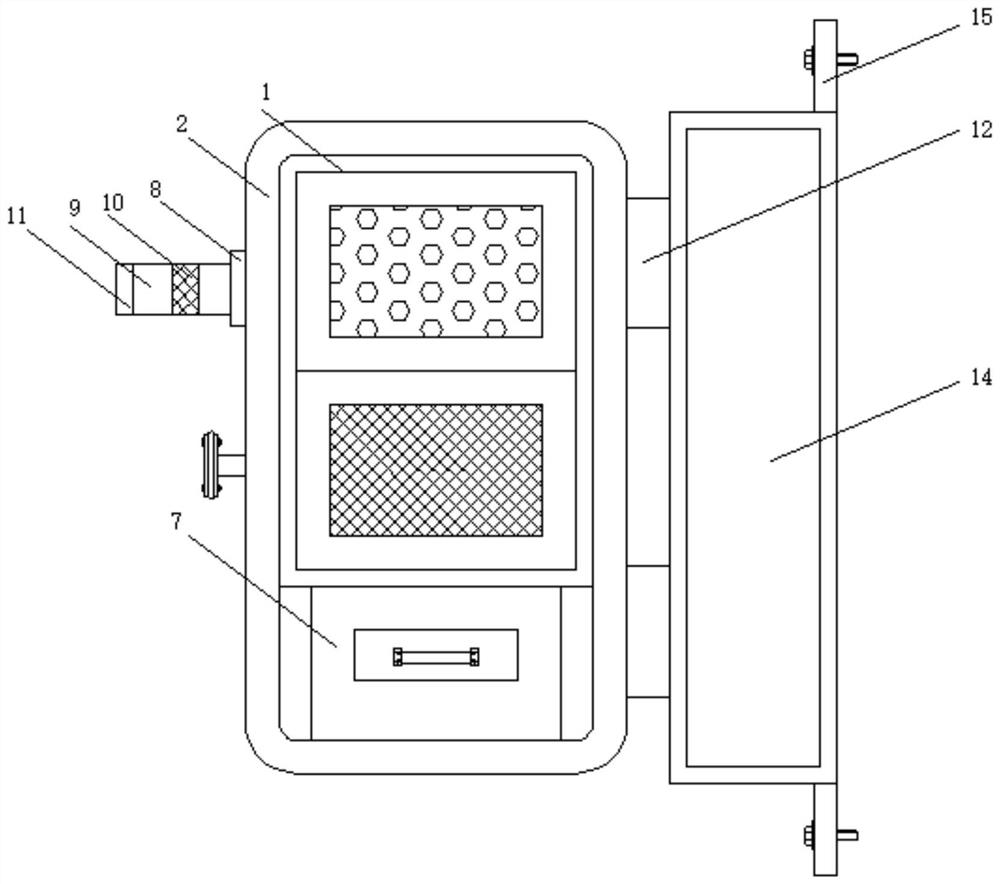

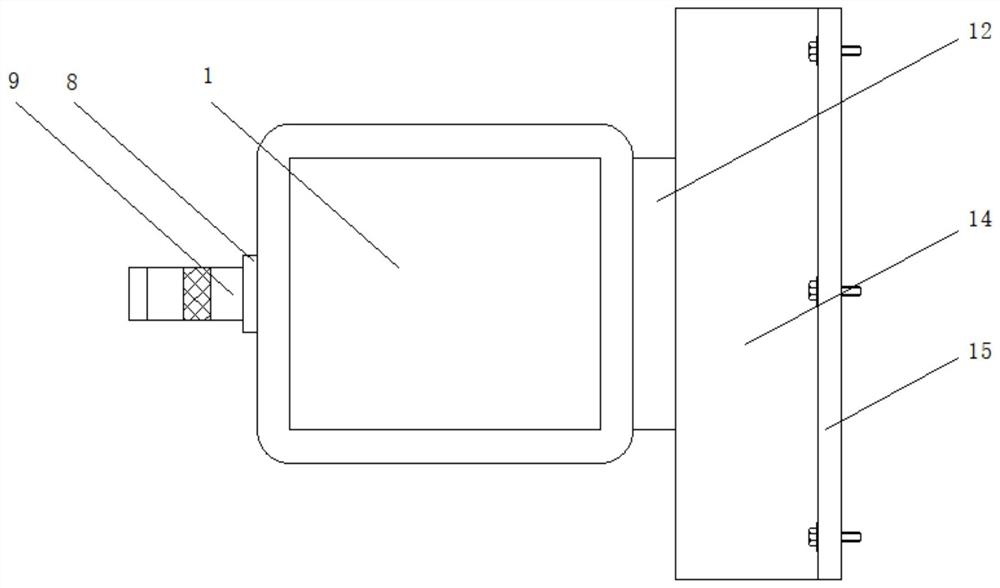

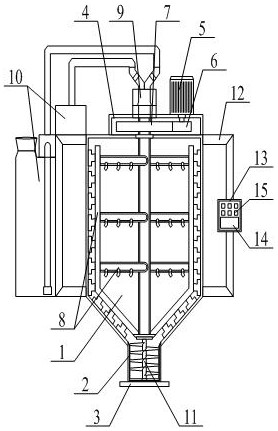

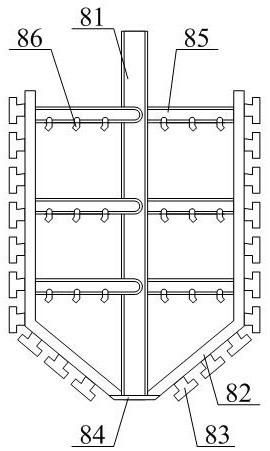

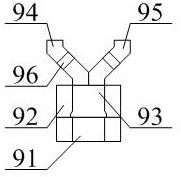

Built-in wall-mounted dust remover for graphite production

InactiveCN111672214AReduce noiseFunction as a filterDispersed particle filtrationCarbon compoundsDust controlEngineering

The invention belongs to the technical field of dust removers, and particularly discloses a built-in wall-mounted dust collector for graphite production. The dust collector comprises a box body and aconnecting plate; a sound absorption layer is arranged above the box body; a connecting pipe is arranged below a fan; a spray head is arranged on the left side of a guide opening; the front end of theconnecting pipe is movably connected with a dust inlet pipe; a filter screen is arranged in a dust conveying pipe; the connecting plate is positioned on the right side of the box body; the rear end of a sliding block is connected with a fixing plate. According to the built-in wall-mounted dust remover for graphite production, compared with an existing common graphite production dust removal device, through the arrangement of the connecting plate, the sliding block and the fixing plate, the connecting plate and the fixing plate form a sliding structure through the sliding block, the box body is mounted on the fixing plate in a sliding mode and then mounted in a wall-mounted mode through the mounting plate, the labor and time for carrying the device at ordinary times are saved through the wall-mounted structure, only the sliding block needs to be moved, connection is firm, and dust removal operation is not affected.

Owner:PINGDINGSHAN ORIENTAL CARBON

Polluted soil in-situ circulation leaching treatment method adopting electrochemical treatment leacheate

PendingCN114309031ASpread evenlyFacilitated DiffusionContaminated soil reclamationElectrochemical responseChemical reaction

A contaminated soil in-situ circulation leaching treatment method adopting an electrochemical treatment leacheate comprises the following steps that firstly, an electrochemical reactor is arranged on a contaminated soil ground, the upper portion of the chemical reactor is open, the leacheate enters from the upper portion, and the upper portion of the chemical reactor is open; the bottom of the electrochemical reactor is communicated with a leacheate discharge pipe network arranged in the polluted soil through a discharge pipe; 2, after entering the contaminated soil, the leacheate absorbs pollutants in the soil and then is enriched in a water collecting well, and then the leacheate in the water collecting well is sent back into the electrochemical reactor through a sewage pump, so that circulation of the leacheate is achieved; and step 3, after the leacheate is circulated stably, electrifying the positive electrode plate and the negative electrode plate to enrich heavy metal ions in the leacheate and degrade organic pollutants so as to realize efficient circulating operation of the leacheate. The leacheate subjected to electrochemical treatment enters the leacheate discharge pipe network system below again, so that efficient cyclic utilization of the leacheate is realized.

Owner:QILU UNIV OF TECH

Drought-resistant dendrobium officinale planting auxiliary equipment

InactiveCN113207504AEasy to wrap and put awayPlay a protective effectRotary stirring mixersTransportation and packagingWater storage tankAgricultural engineering

The invention provides drought-resistant dendrobium officinale planting auxiliary equipment. The drought-resistant dendrobium officinale planting auxiliary equipment comprises a storage hopper, longitudinal mounting plates, side edge inserting grooves, side edge inserting plates, planting hoppers, a handle, a water storage tank, a circulating pump, a water guide pipe, a transverse connecting pipe, a spraying pipe, an adjustable protection frame structure, a metal plate, an adjustable moving frame structure, a water liquid circulating filtering frame structure and a material stirring and mixing frame structure. The longitudinal mounting plates are mounted on the left side and the right side of the upper part of the storage hopper through bolts; and the planting hoppers are inserted into the inner sides of the side edge inserting grooves through the side edge inserting plates. A protective curtain penetrates through a collecting cover and is wound on the outer side of a winding roller, so that the winding roller is conveniently driven to rotate by using the rotating handle according to requirements during use, and then the protective curtain is conveniently wound and collected; and a sealing cover is in threaded connection with the lower part of the outer side of a longitudinal guide pipe, so that the sealing cover can be detached during use, and residual material slag and waste liquid in the longitudinal guide pipe can be discharged conveniently.

Owner:LAIWU VOCATIONAL & TECHNICAL COLLEGE

Crushing and screening equipment for construction waste

InactiveCN113304826APrevent everywhereFunction as a filterDirt cleaningGrain treatmentsDrive shaftArchitectural engineering

The invention discloses crushing and screening equipment for construction waste. The crushing and screening equipment comprises a crushing box body, a crushing mechanism and a feeding pipe; the crushing mechanism comprises a fixing box, an air cylinder, a swing rod sliding mechanism and a crushing component; a feeding opening is formed in the feeding pipe, a dust prevention mechanism used for limiting dust flying at the feeding opening is installed in the feeding pipe, wherein a screening mechanism is arranged in the crushing box body; the screening mechanism comprises a motor, a transmission shaft, a first-stage screening plate and a second-stage screening plate; the transmission shaft is sleeved with a transmission assembly; and the second-stage screening plate is obliquely arranged in the crushing box body. Due to the fact that the dust prevention mechanism and the screening mechanism are arranged in the device, construction waste dust at the position of the feeding pipe can be effectively prevented from rising all around, the screening function on construction waste is achieved, and the screening work efficiency is improved.

Owner:WENZHOU POLYTECHNIC

Sewage circulating filtration system

PendingCN113461226AHigh circulation filtration efficiencyImprove filtering effectWater treatment parameter controlSpecific water treatment objectivesFiltrationFilter system

The invention discloses a sewage circulating filtration system. The system comprises a sewage tank, a clear water tank, a pump assembly and a filtering device, a purification filter element is arranged in the clear water tank, the purification filter element is of a hollow structure, and a cavity is formed in the purification filter element; the pump assembly can form negative pressure in the sewage tank so as to pump sewage in the sewage tank into the cavity of the purification filter element after passing through the filter device; a flocculating agent is contained in the cavity and is used for polymerizing impurities in the sewage into granular aggregates and settling the granular aggregates in the cavity; the pump assembly can form positive pressure in the cavity, so that the polymerized and settled sewage is filtered by the filter element and then is pressed out of the water purification tank for recycling. The sewage circulating filtration system is good in cleaning effect, low in production and manufacturing cost, convenient and flexible to use, favorable for saving water and good in market popularization prospect.

Owner:GUANGDONG YUNHAN INTELLIGENT TECH CO LTD

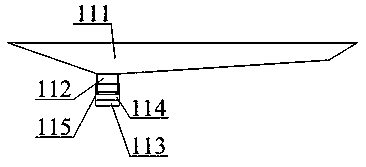

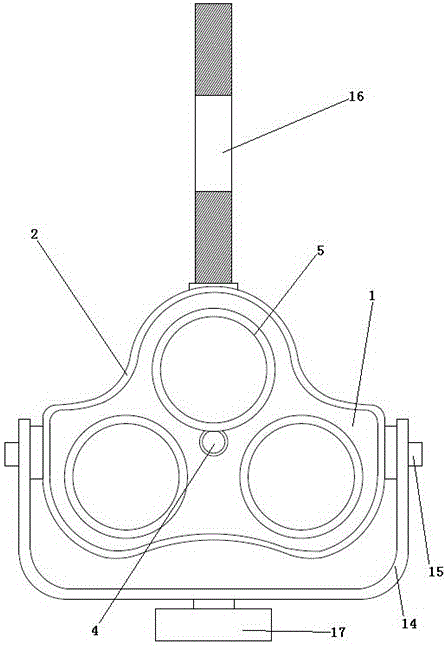

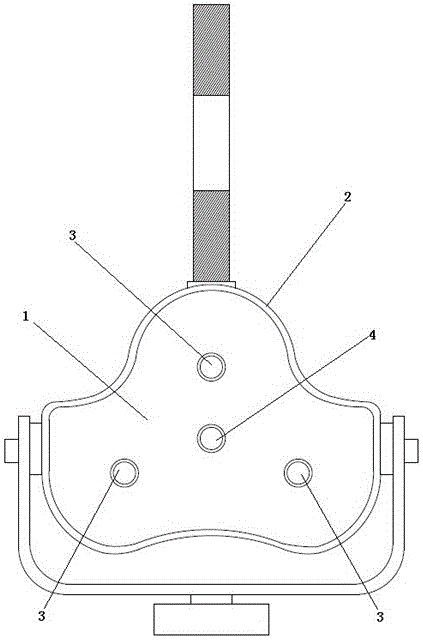

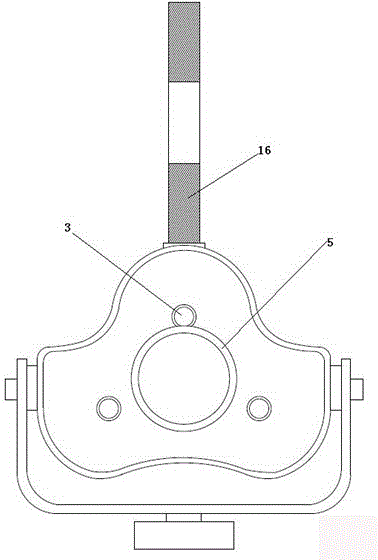

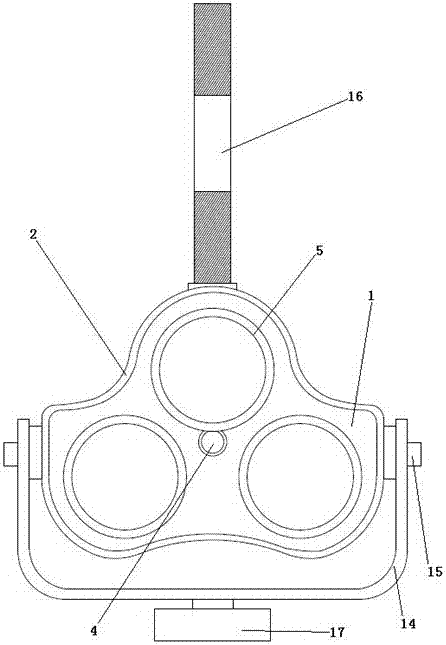

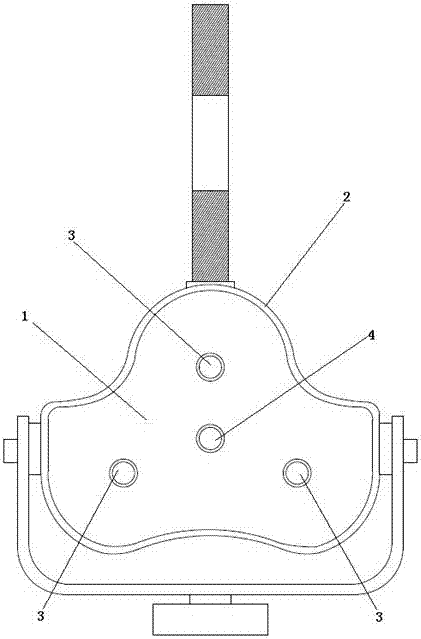

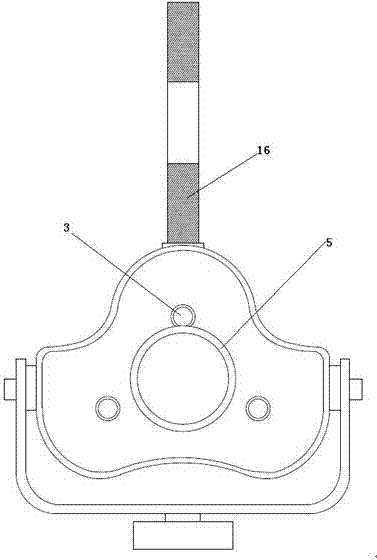

Optical surveying and mapping prism adjusting base

The invention relates to an optical surveying and mapping prism adjusting base which comprises a fixation plate and a guard board fixedly encircling the circumference of the fixation plate. The adjusting base is characterized in that the fixation plate is provided with three first fixation holes arranged like the Chinese character "pin"; the fixation plate in a triangle formed by connecting the three first fixation holes is provided with a second fixation hole; when the three first fixation holes in the fixation plate are respectively provided with a prism unit simultaneously, the second fixation hole cannot be provided with a prism unit; and when the second fixation hole in the fixation plate is provided with the prism unit, the three first fixation holes cannot be provided with the prism unit. Through the arrangement of the three first fixation holes and the second fixation hole, three prism units can form a group to carry out reflection work simultaneously; and through switching, the state that only one prism unit works can also be realized; and thus reflection condition flexibility of the surveying and mapping work is better.

Owner:NANTONG MEELAIN ELECTRIC APPLIANCE CO LTD

Prism Adjustment Base for Optical Surveying and Mapping

The invention relates to a prism adjustment seat for optical surveying and mapping, which comprises: a fixed plate, and a guard plate fixed around the circumference of the fixed plate, characterized in that, the fixed plate is provided with three a first fixing hole, and a second fixing hole is arranged on the fixing plate in the triangle formed by the connecting lines of the three fixing holes; when the three first fixing holes on the fixing plate are respectively provided with a prism lens, At this time, the second fixing hole cannot be provided with a prism lens; when one second fixing hole on the fixing plate is provided with a prism lens, at this time, the three first fixing holes cannot be provided with a prism lens. Three first fixing holes and one second fixing hole are set, so that three prism lenses can be used for reflection work at the same time, and it can also be switched to only one prism lens for work, and the reflection conditions of surveying and mapping work are more flexible it is good.

Owner:NANTONG MEELAIN ELECTRIC APPLIANCE CO LTD

A coke tower decoking device for needle coke production process

ActiveCN112080293BImprove cleanlinessEasy to exportOven incrustations prevention/removalElectric machineGear wheel

The invention provides a coking tower decoking device used in the production process of needle coke, which belongs to the technical field of coking equipment and includes a coking tower, an outlet pipe, an outlet flange, a mounting cover, a driving motor, a driving gear, a driven gear and Scraping spray rack structure, the outlet pipe is welded at the lower part of the coking tower; the outlet flange is welded at the lower part of the outlet pipe; the installation cover bolt is installed at the upper part of the coking tower; the drive motor bolt It is installed on the upper right side of the installation cover; the driving gear is arranged on the inner side of the installation cover. The arrangement of the liquid suction pipe, the liquid storage tank and the booster pump of the present invention uses the booster pump to extract the water liquid in the liquid storage tank through the liquid suction pipe, so as to pass through the catheter tube, the liquid introduction tube, the confluence tube and the sealed bearing Finally, through the longitudinal transmission pipe and the transverse feed pipe, the water is sprayed from the nozzle to the inner wall of the coking tower, thereby increasing the cleanliness of the inner wall of the spraying coking tower.

Owner:SHANDONG LIANHUA NEW MATERIAL CO LTD

A polishing device for throwing magnetic suction type metal rods

ActiveCN113334220BEasy to polishPlay a cooling roleGrinding machinesGrinding work supportsPolishingMetallic materials

The invention discloses a polishing device for throwing particles and magnetic suction type metal rods, which belongs to the technical field of grinding processing of metal materials. By setting an inner concave arc support and a pair of deflectors, the magnetic grinding roller is located in the falling temperature cooling part There are several magnetic particles at the top of the falling particle cooling part. When the inner electromagnetic roller is electrified and magnetized, the outer wall of the magnetic grinding roller is attached with magnetism, so that the magnetic particles are attached to the outer wall of the magnetic grinding roller, and the magnetic particles rub against the magnetic grinding roller. Between it and the metal bar, it is beneficial to improve the grinding effect. At the same time, the air supply pipe is used to supply air to the falling particle cooling part, and the gas pushes the magnetic particles that are not magnetically attracted on the magnetic grinding roller to throw on the end wall of the metal bar. On the one hand, it can achieve multi-point impact damage to impurities such as scale, which is beneficial to the subsequent polishing of the magnetic grinding roller. In addition, the magnetic particles are rinsed with water, on the one hand to remove dust, and on the other hand to cool down the grinding end surface.

Owner:南通英富泰电气科技有限公司

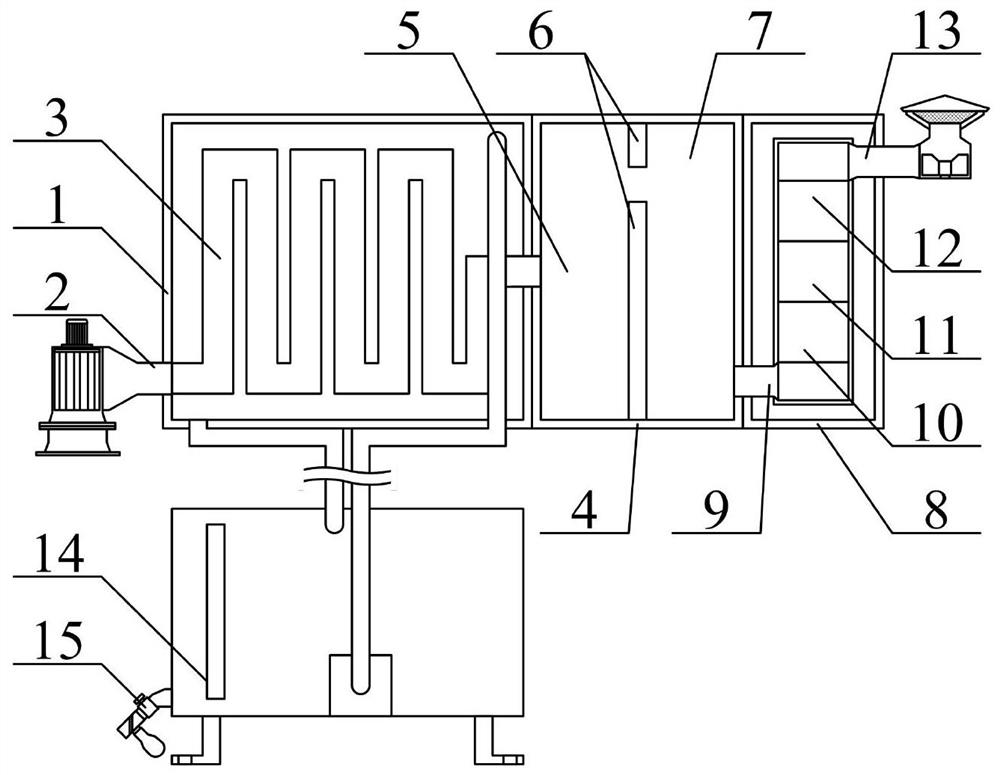

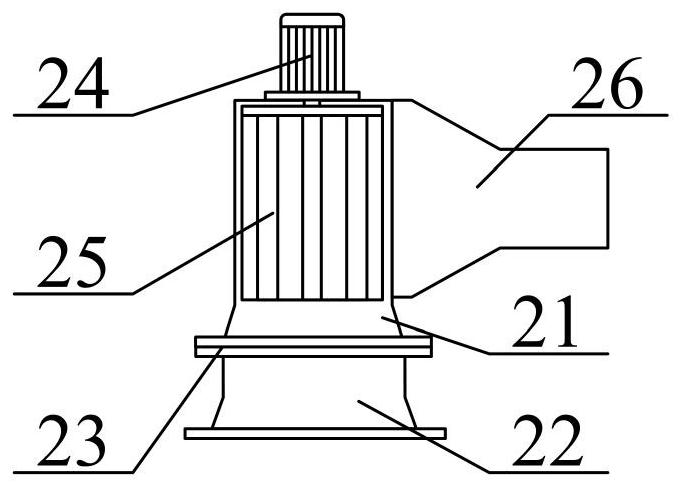

Chemical device emptying tail gas treatment waste heat recovery device

InactiveCN113218195AHigh speedFunction as a filterDispersed particle separationDirt cleaningThermodynamicsExhaust fumes

The invention provides a chemical device emptying tail gas treatment waste heat recovery device which comprises a heat exchange box, a waste gas guide-in frame structure, a snakelike pipeline, a fixed outer frame, a particle trap, a longitudinal partition plate, a reaction cavity, a protective outer frame, a bottom guide pipe, a first catalyst layer, a second catalyst layer, a third catalyst layer, an auxiliary gas guide-out frame structure, a water circulation heat exchanging device and a water discharging filtering frame structure, and the waste gas guiding-in frame structure is installed on the lower portion of the left side of the heat exchange box. The snakelike pipeline is installed on the inner side of the heat exchange box through bolts. The fixed outer frame is installed on the right side of the heat exchange box through bolts. The centrifugal fan blades are arranged at the upper part of the inner side of a conveying fixing frame, so that the speed of conveying waste gas into an output pipe can be increased during use. A longitudinal filter screen is mounted on the left side of the interior of an external pipe through a screw, so that water guided out of the external pipe can be conveniently filtered during use, and the cleanliness of the water guided out can be improved.

Owner:山东三岳化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com