Chemical device emptying tail gas treatment waste heat recovery device

A waste heat recovery device and exhaust gas treatment technology, applied in the field of waste heat recovery, can solve the problems of inconvenient discharge of water and liquid filtration, inconvenient pressurized gas outlet speed, lack of water and liquid heat exchange treatment, etc., to increase the speed of exhaust , Increase cleanliness and facilitate disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

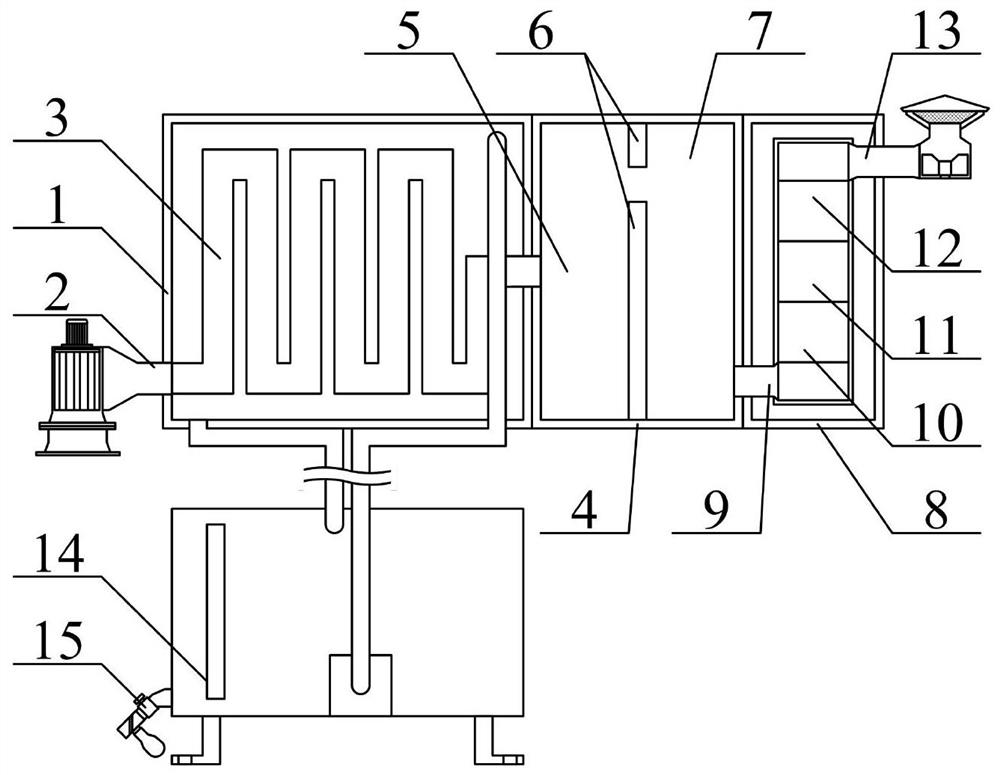

[0038] as attached figure 1 And attached figure 2 shown

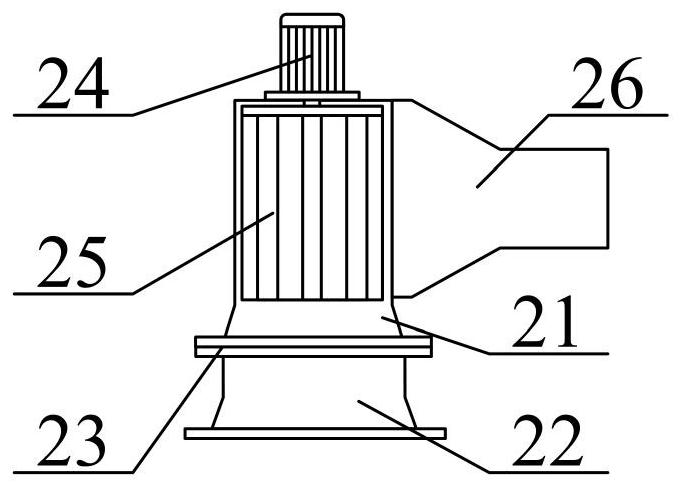

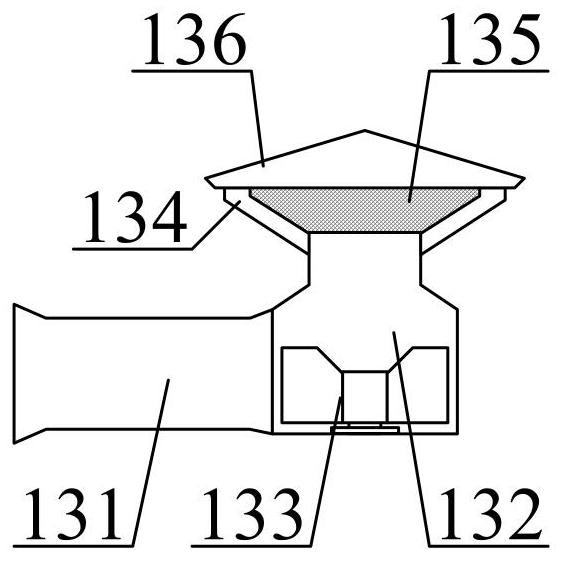

[0039]The present invention provides a waste heat recovery device for exhaust gas treatment of a chemical plant, which includes a heat exchange box 1, a waste gas introduction frame structure 2, a serpentine pipe 3, a fixed outer frame 4, a particle trap 5, a longitudinal partition 6, and a reaction chamber 7 , a protective outer frame 8, a bottom conduit 9, a first catalytic layer 10, a second catalytic layer 11, a third catalytic layer 12, an auxiliary gas deriving frame structure 13, a water-liquid circulation heat exchange device 14 and a water-liquid discharge filter frame structure 15 , the exhaust gas introduction frame structure 2 is installed on the lower left side of the heat exchange box 1; the serpentine pipe 3 bolts are installed on the inner side of the heat exchange box 1; the fixed outer frame 4 bolts are installed on the heat exchange box The right side of 1; the left and right sides of the interior ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com