Capturing device for magnetic impurities in liquid metal

A liquid metal, magnetic impurity technology, applied in high gradient magnetic separators and other directions, can solve the problems of less research, unpublished service performance results of magnetic traps, and few patent results, and achieve the effect of increasing the strength of the air gap magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

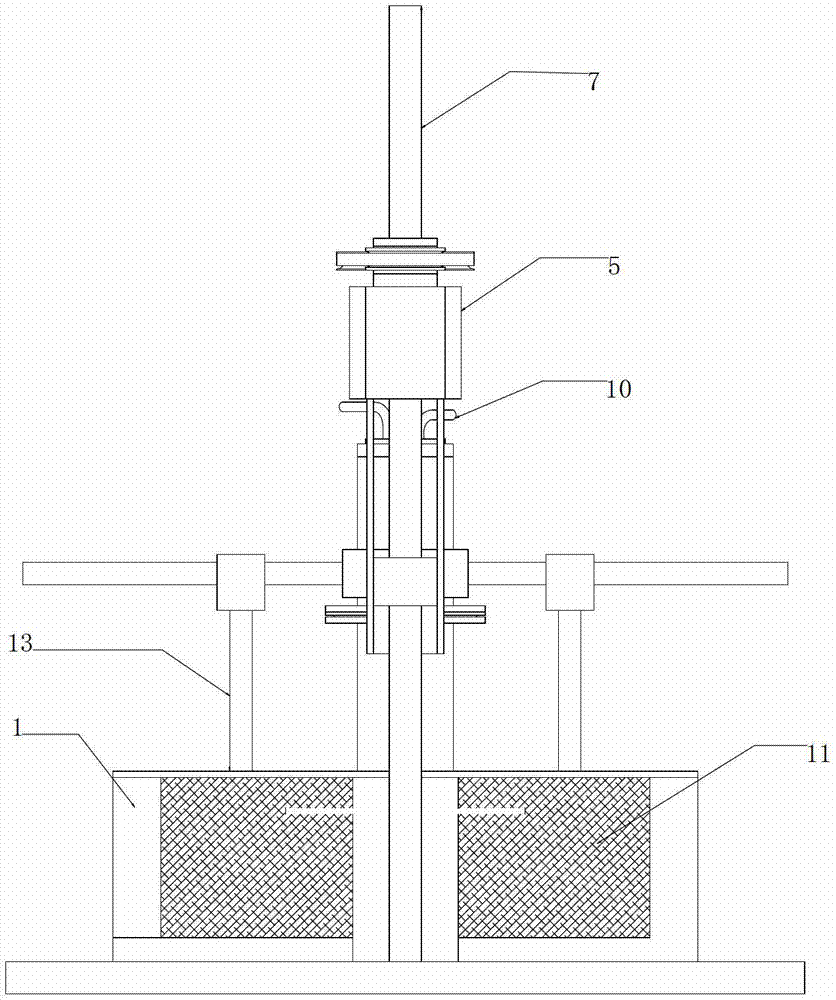

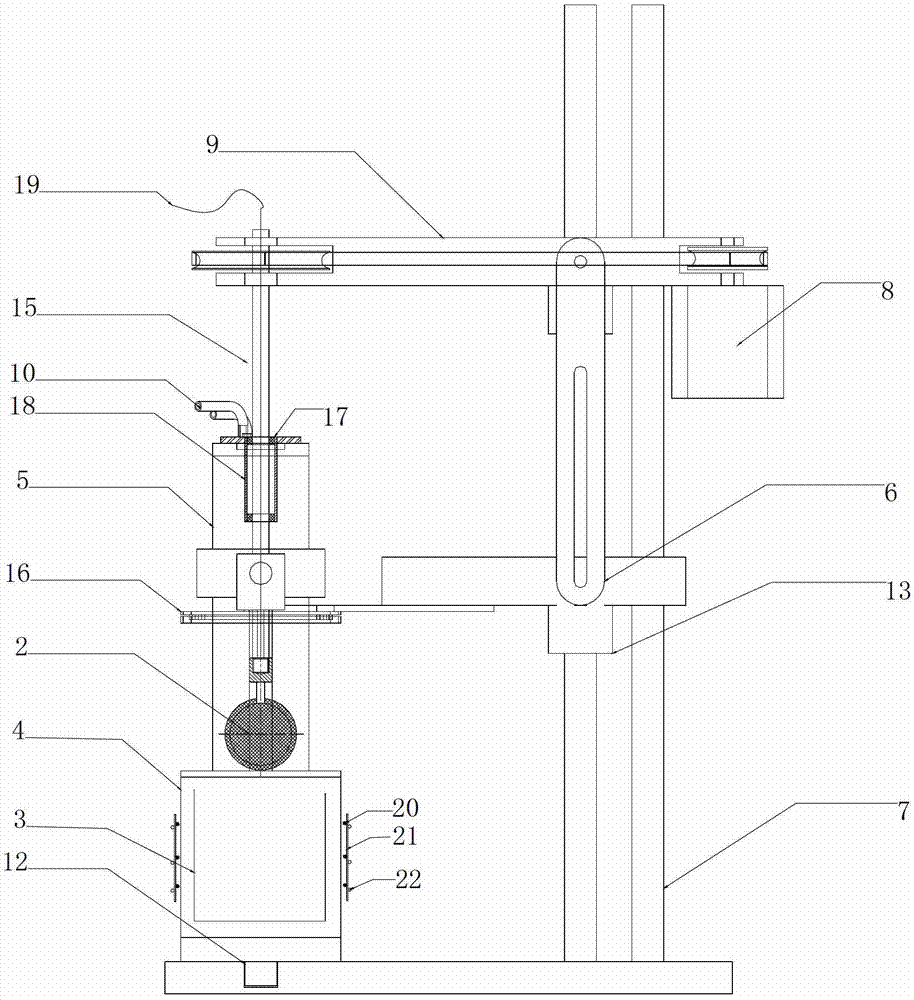

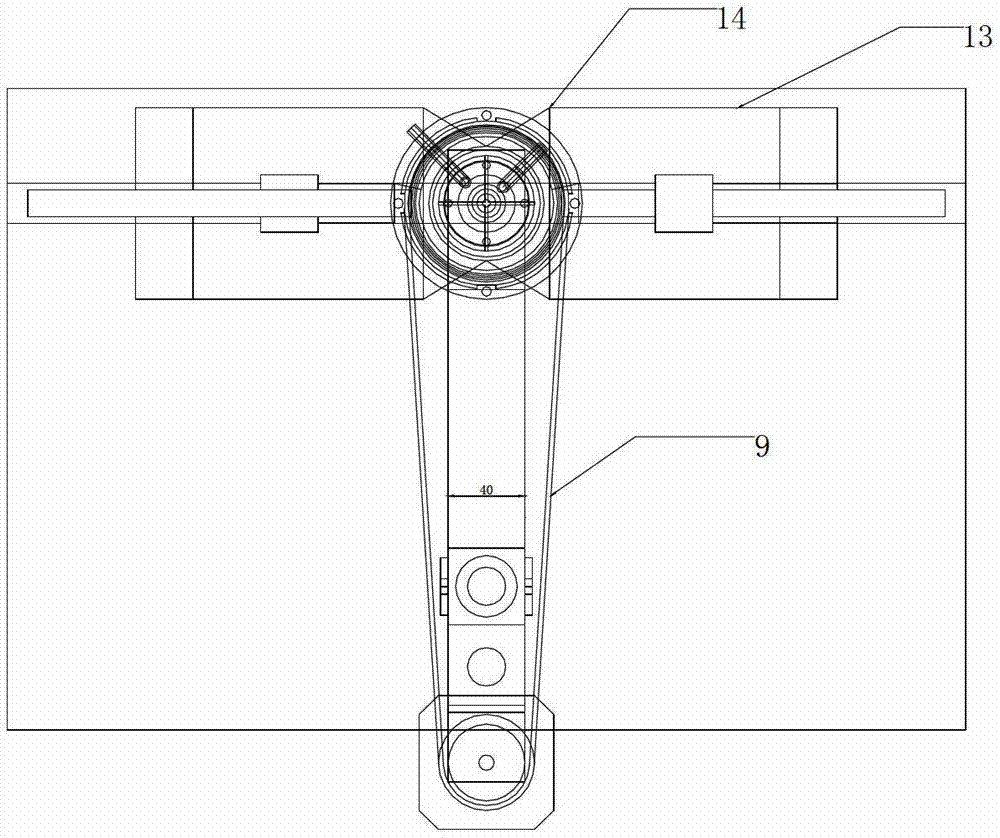

[0030] Depend on Figure 1-4 It can be seen that the embodiment of the present invention includes: a magnetic field system 1 , a wire mesh 2 , a crucible 3 , a melting tank 4 , a sealing system 5 , a fastening link 6 , a support stand 7 , a motor 8 , a belt 9 and a gas inlet and outlet 10 . Depend on Figure 1-3 It can be seen that the magnetic field system 1 has two permanent magnets 11 of the same specification, the permanent magnets 11 are placed in the limit slider 13 on the guide rail 12 , and the magnetic field is provided by the yoke 14 . Depend on figure 2It can be seen that the crucible 3 is placed in the melting tank 4, the wire mesh 2 is vertically placed in the liquid metal in the crucible 3 through the rotating shaft 15, and the heating wire 20, the thermal insulation material 21 and the cooling water copper pipe 22 are arranged in sequence outside the melting tank 4 Sealing system 5 is made up of rotating shaft 15, sealing flange 16, copper sleeve 17 and seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com