Combined rotor structure of permanent-magnetic motor

A rotor structure, permanent magnet motor technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., can solve the problems of motor rotor strength deterioration, high processing defective rate, motor power loss, etc., to achieve increased The effect of large air gap magnetic field strength, improving efficiency and reducing magnetic flux leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, the combined rotor structure of a permanent magnet motor of the present invention will be described in detail with reference to the accompanying drawings and embodiments:

[0040] In the drawings, the same symbols are used for the same components in the present invention as in the prior art.

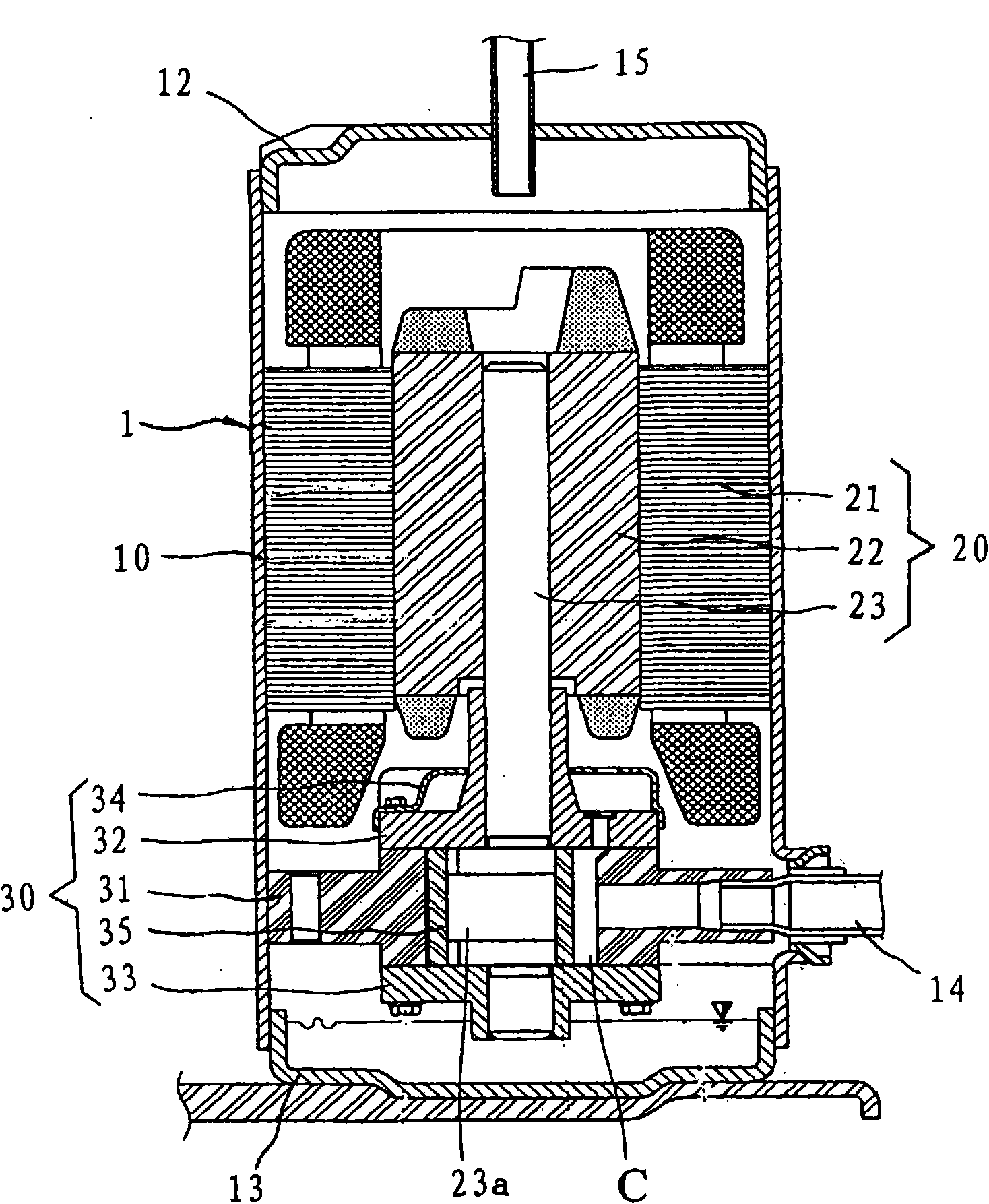

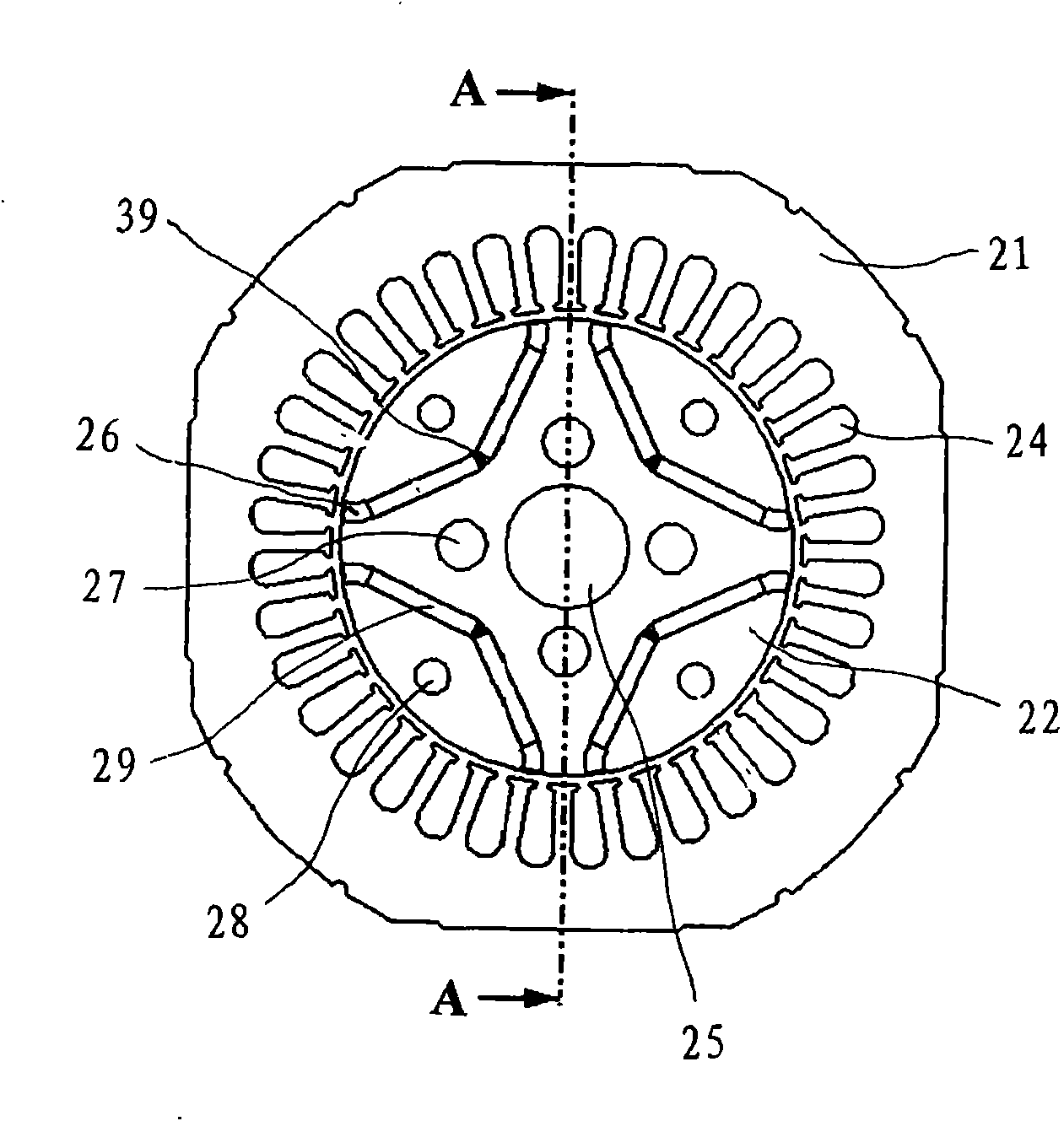

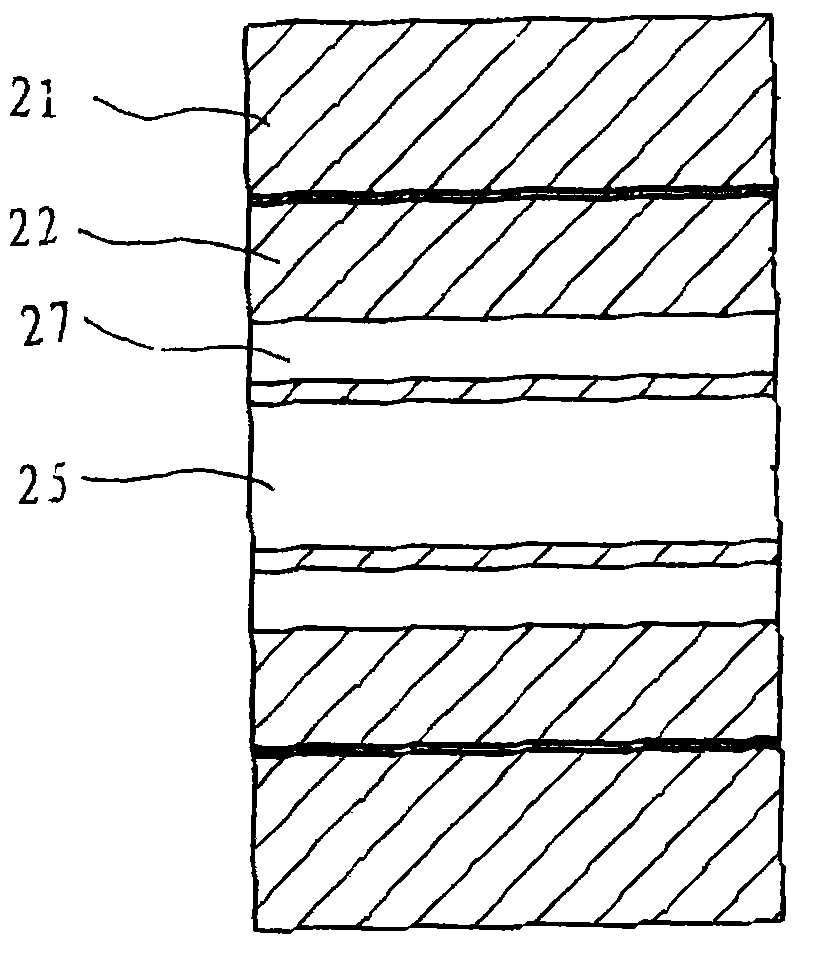

[0041] like Figure 1-7 As shown, a permanent magnet motor combined rotor structure, the motor assembly 20 is composed of a stator 21, a rotor 22, and a rotating crankshaft 23 that is pressed into the center of the rotor 22 and transmits rotational force.

[0042] The stator 21 is composed of a stator core and a stator winding. The stator core is the main part of the main magnetic circuit. A plurality of slots 24 of the same shape are formed in the stator 21 for embedding the stator winding.

[0043] A plurality of permanent magnet slots 43 are formed on the rotor 40, and the plurality of permanent magnet slots 43 divide the rotor 40 into a rotor block 41 and a plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com