Halbach disc type magnetic coupling

A magnetic coupler and disc type technology, which is applied in the field of new disc magnetic couplers, can solve the problems of air transmission gap flux density, low utilization rate of permanent magnets, thick guide discs, and limited coupler applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention are explained below in conjunction with the accompanying drawings.

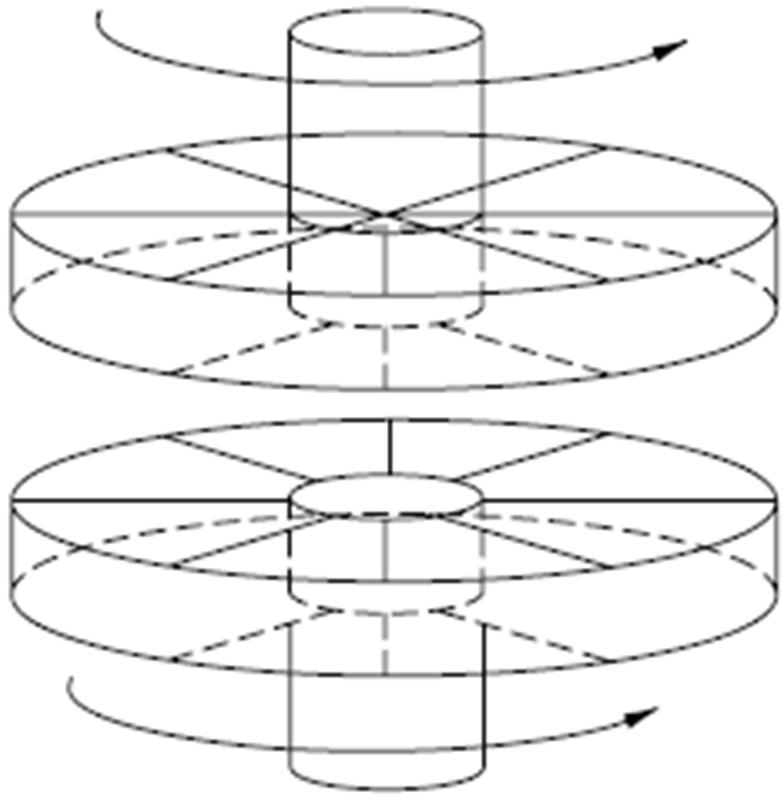

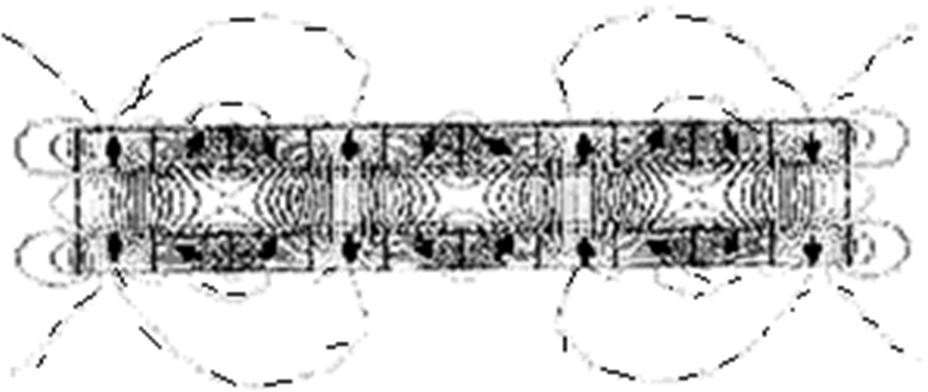

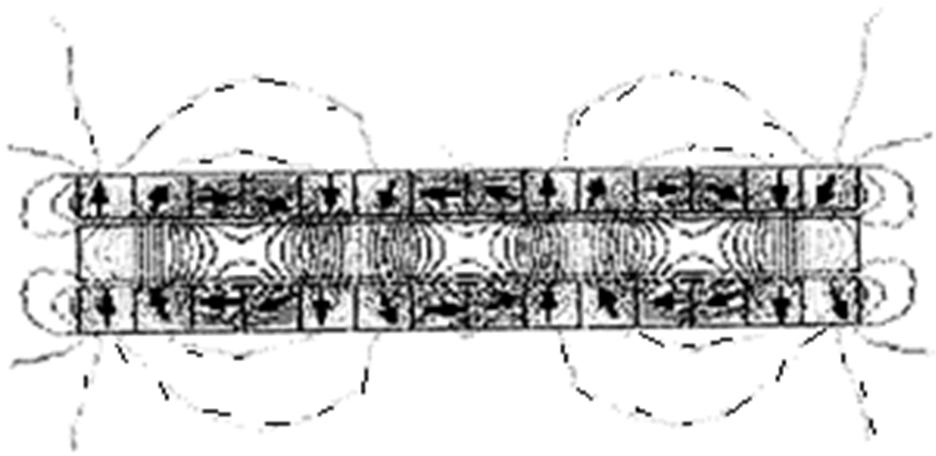

[0028] See attached Figure 5 , a Halbach disc magnetic coupling, comprising a driving disc 51 fixed by a driving shaft 53 and a driven disc 52 fixed by a load shaft 54, the driving disc 51 comprising a disc body (not labeled) and a Halbach column permanent magnet 512 The permanent magnets 512 of the Halbach row are arranged on the surface of the disc body facing the driven disk 52, the permanent magnets 512 of the Halbach row are evenly distributed around the driving shaft, and the magnetization direction of the permanent magnets 512 of the Halbach row is along the axial direction ( See Figure 7 ).

[0029] The Halbach disc coupler of the present invention includes a driving disc 51 , a driven disc 52 , a driving shaft 53 and a load shaft 54 . A Halbach column permanent magnet 512 is glued on the driving disk 51 and is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com