Patents

Literature

137results about How to "Add filter function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

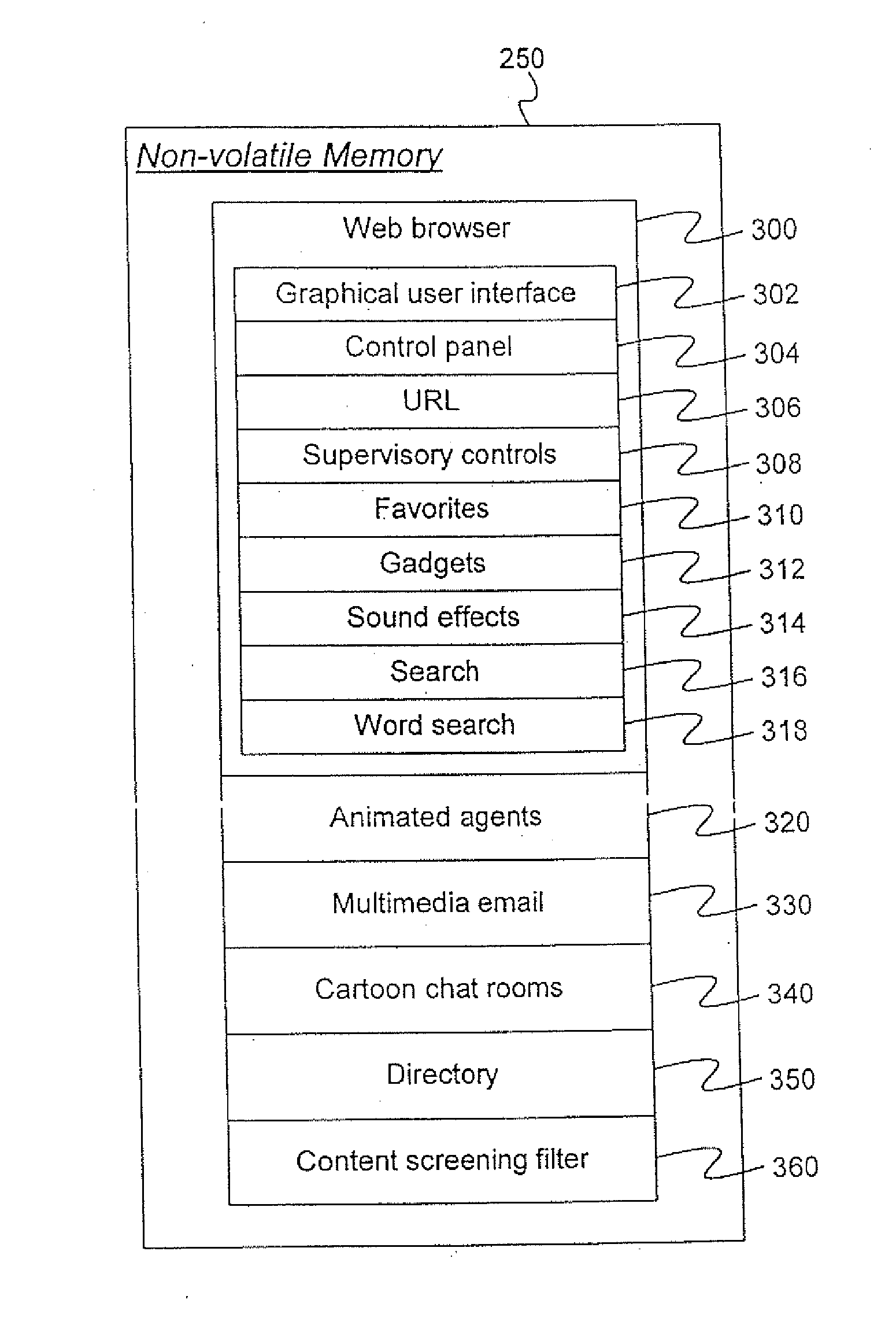

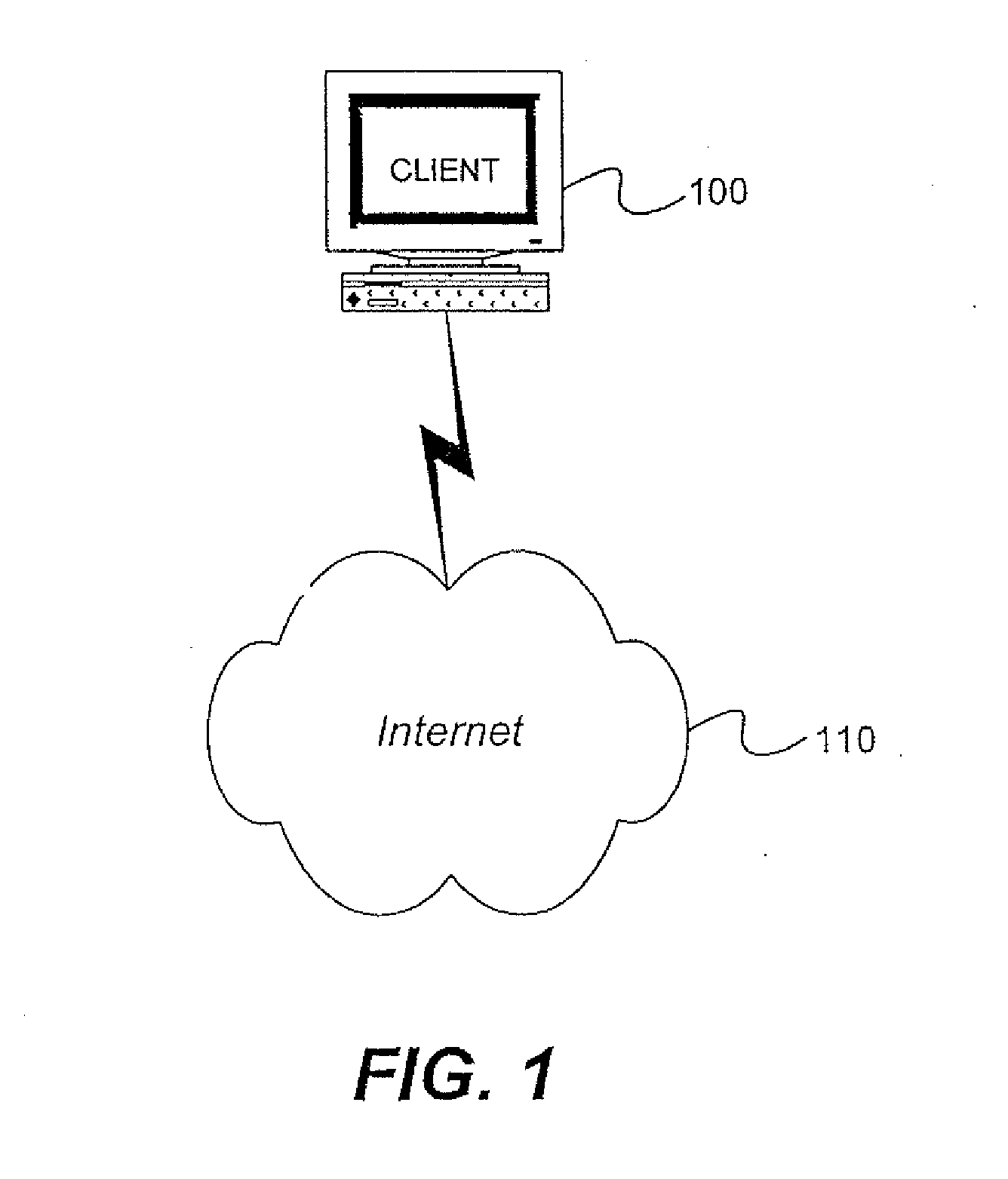

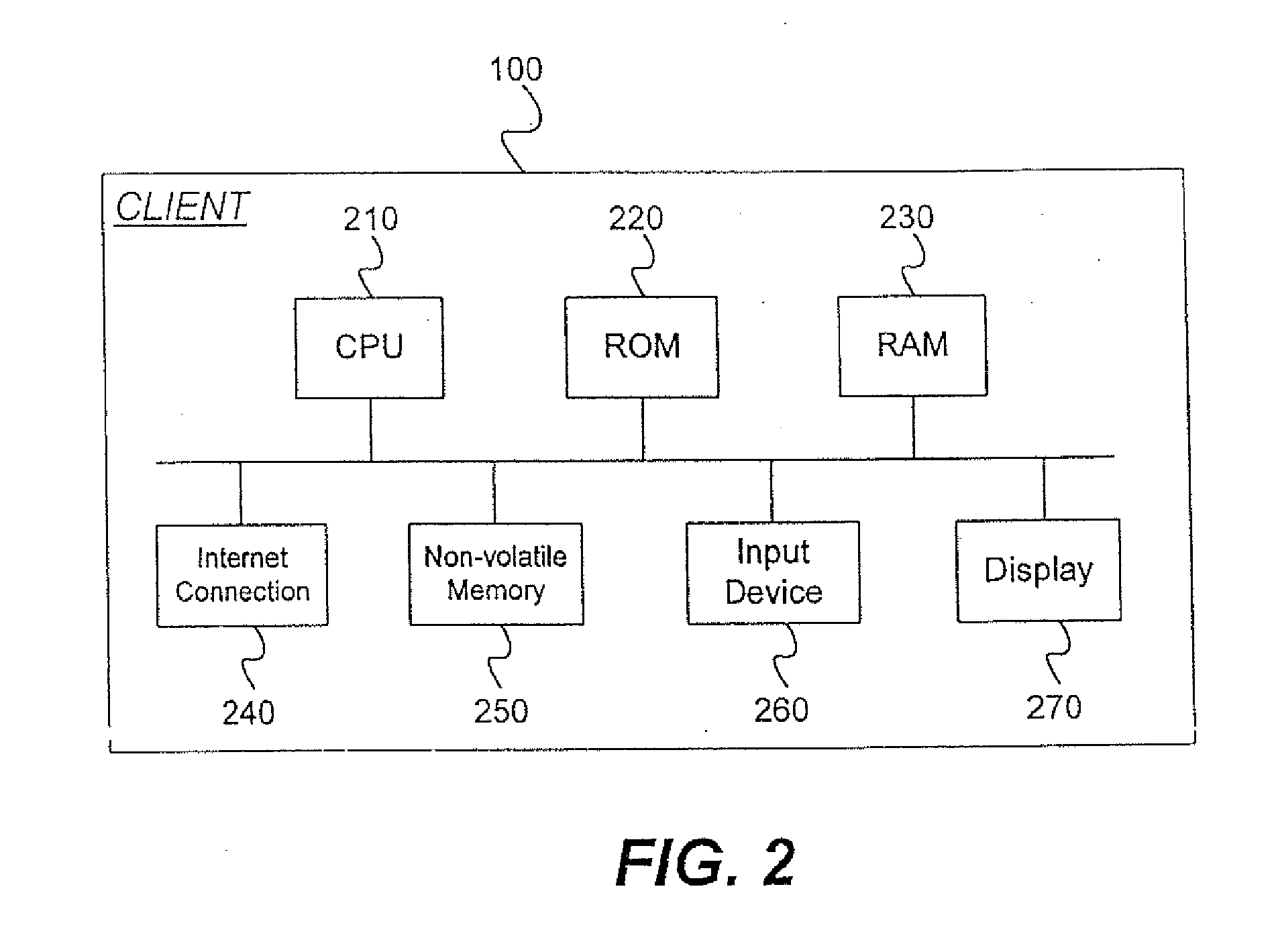

System and Method of a Web Browser with Integrated Features and Controls

InactiveUS20070157098A1Improve experienceConvenient teachingMultimedia data retrievalSound input/outputWeb browserRemote control

A web browser for Internet access distinguishes between client users and supervisory users. Supervisory users are authorized to create and / or modify local content access settings to Internet resources that are stored in a local data structure and / or a remote data structure. Client users are prevented from accessing these local content access settings. When a client user logs on, the all-in-one environment retrieves the local content access settings and connects to a predetermined remote site to retrieve additional content access control information. Modules embedded within the all-in-one environment coordinate local and remote control access settings to provide regulation, in the form of control and / or screening of the Internet resources, of the content that the client user can access. The amount of regulation afforded is readily modified through the setting of local content access settings by a local supervisor and by the selection of the remote site(s) contacted for additional content access control information. The all-in-one environment also encompasses one or more interactive agents to assist and / or entertain client users during Internet access. In some embodiments of the present invention. the all-in-one web browser is rendered to have a three-dimensional look and feel and provide unique features to enhance the web browsing experience.

Owner:CHUPIN FABRICE +3

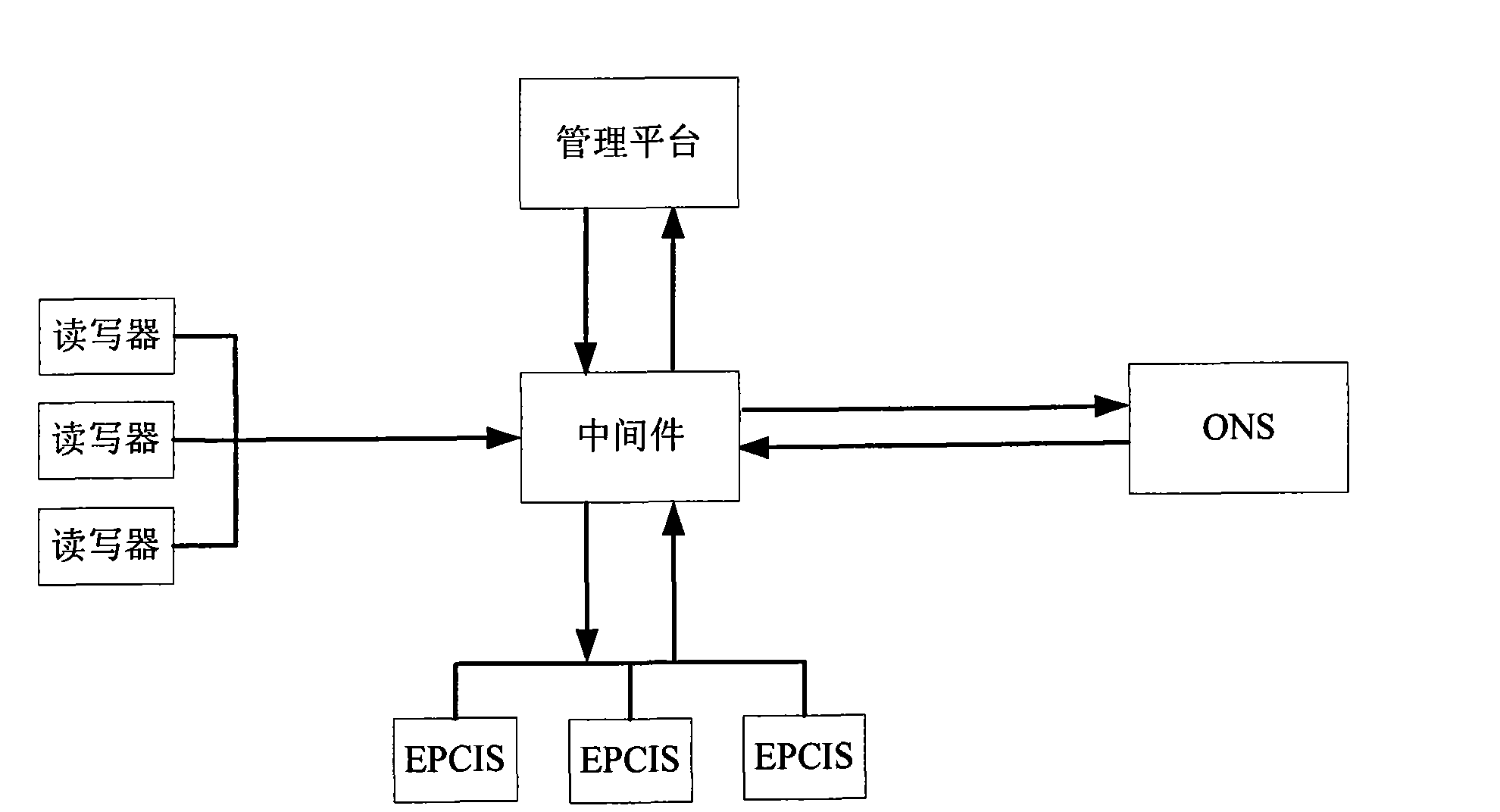

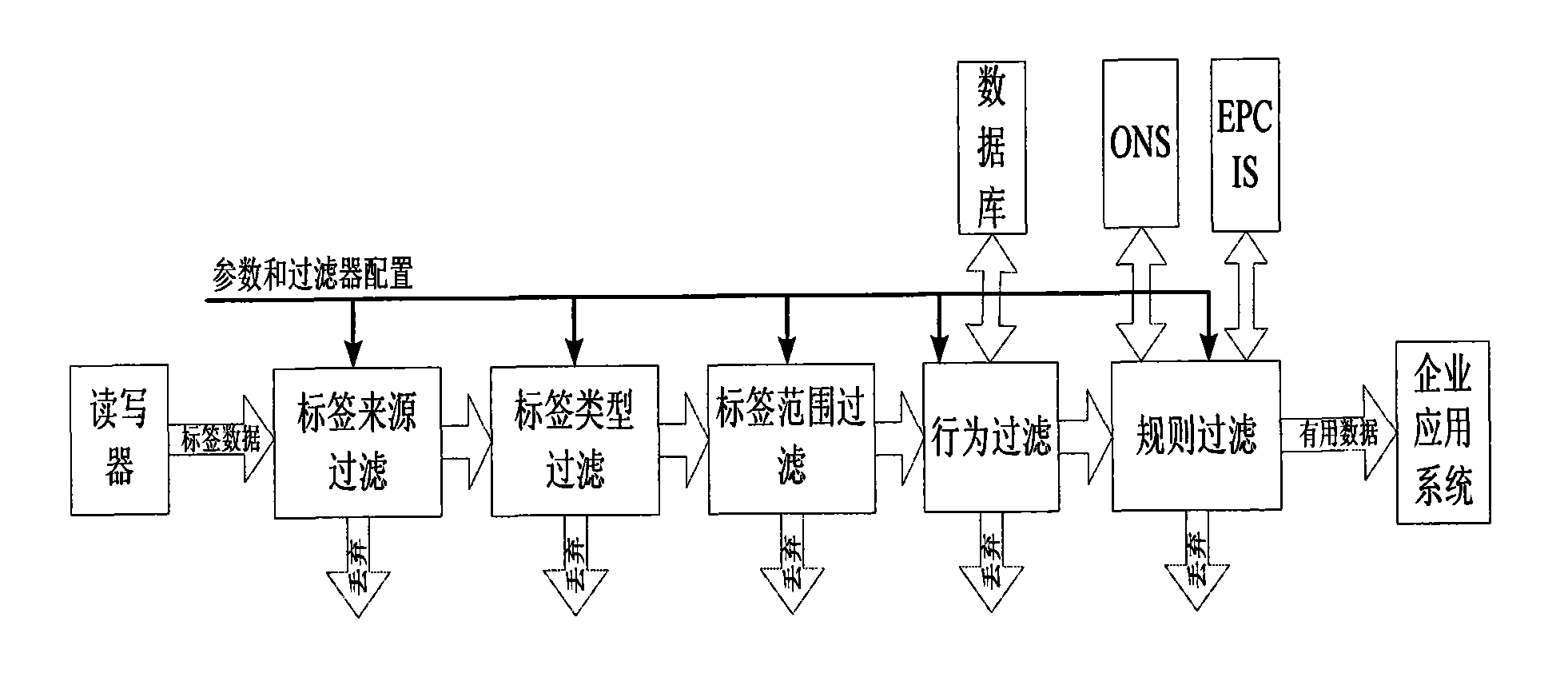

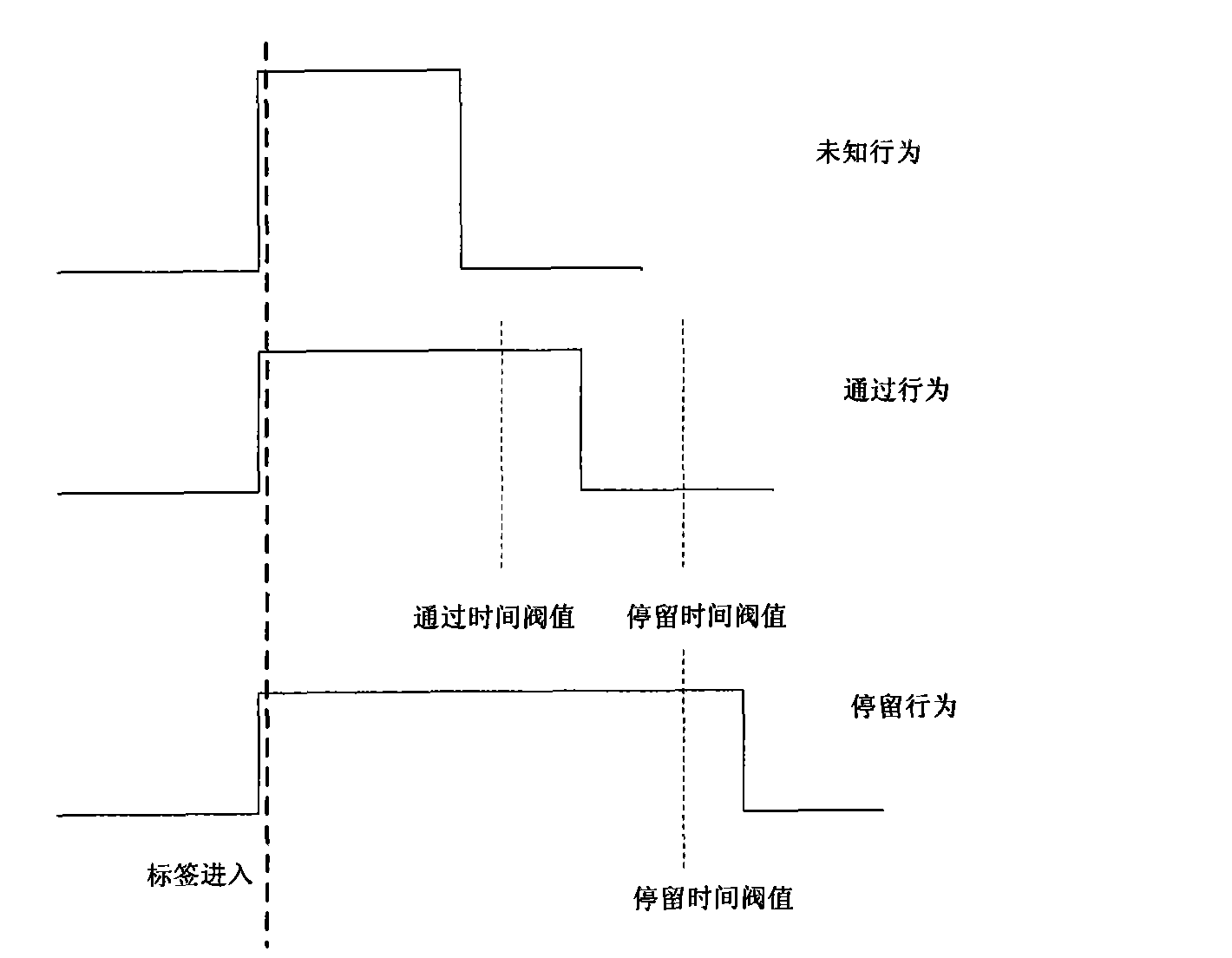

Electronic tag data filtering method used for radio frequency identification middleware

InactiveCN101515334AData load reductionImprove data processing capabilities and overall throughputCo-operative working arrangementsData miningRadio-frequency identification

The invention provides an electronic tag data filtering method used for a radio frequency identification middleware. The middleware sequentially filters according to the source, type, coding range, behavior type and entity attribute of an electronic tag. The method comprehensively considers the attribute, behavior information and EPC network information of the tag, greatly reduces the redundant data and realizes the efficient screening of data.

Owner:HUAZHONG UNIV OF SCI & TECH

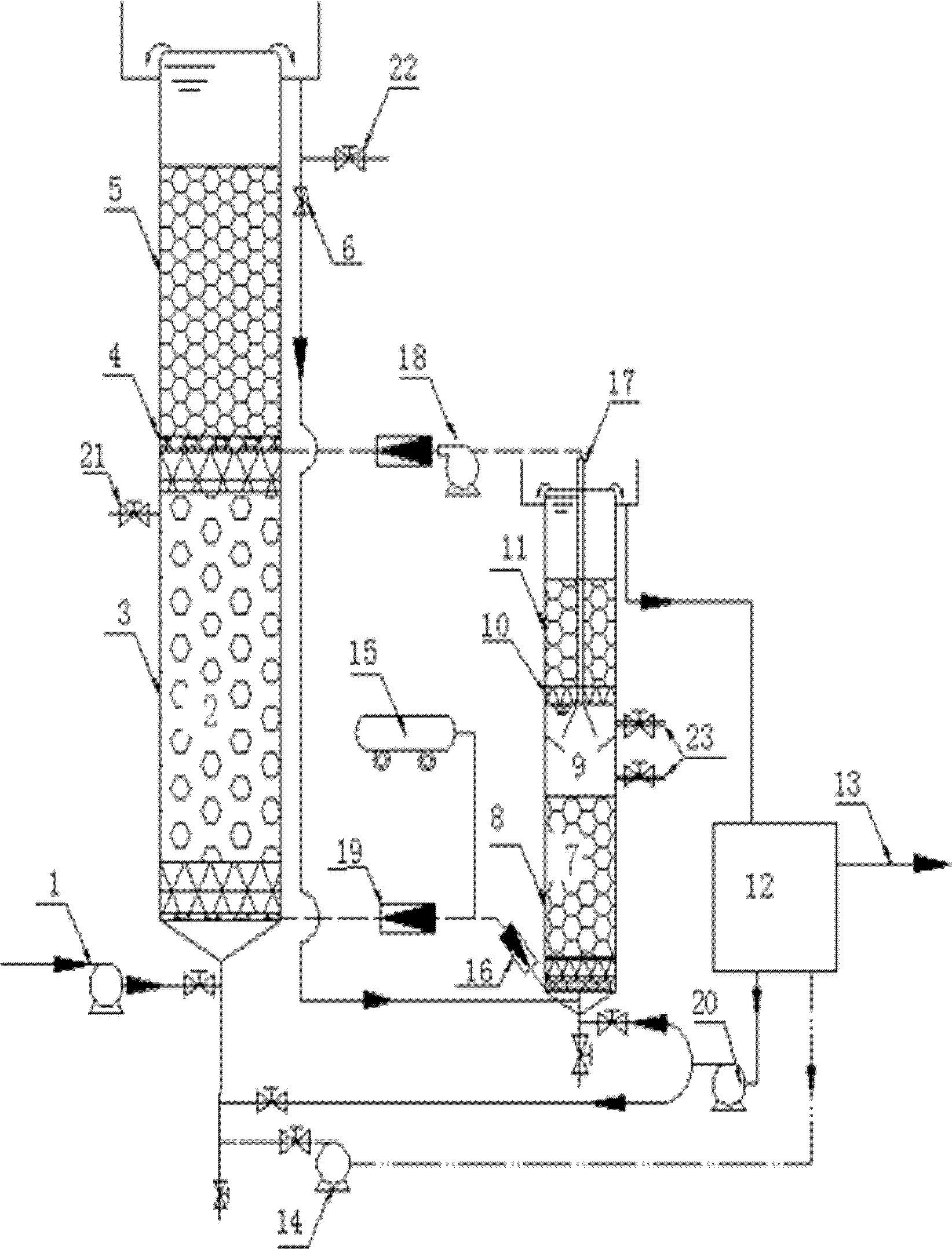

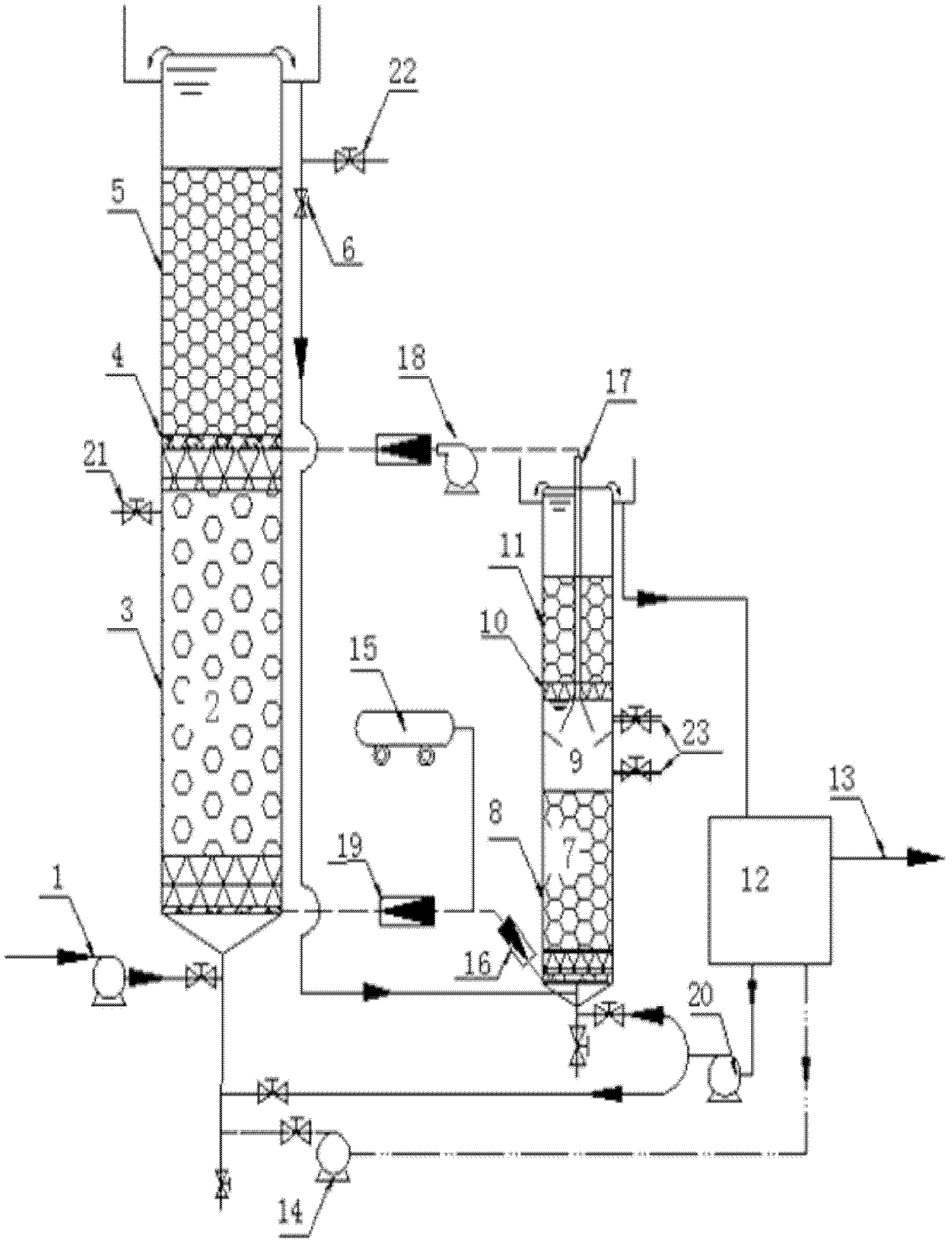

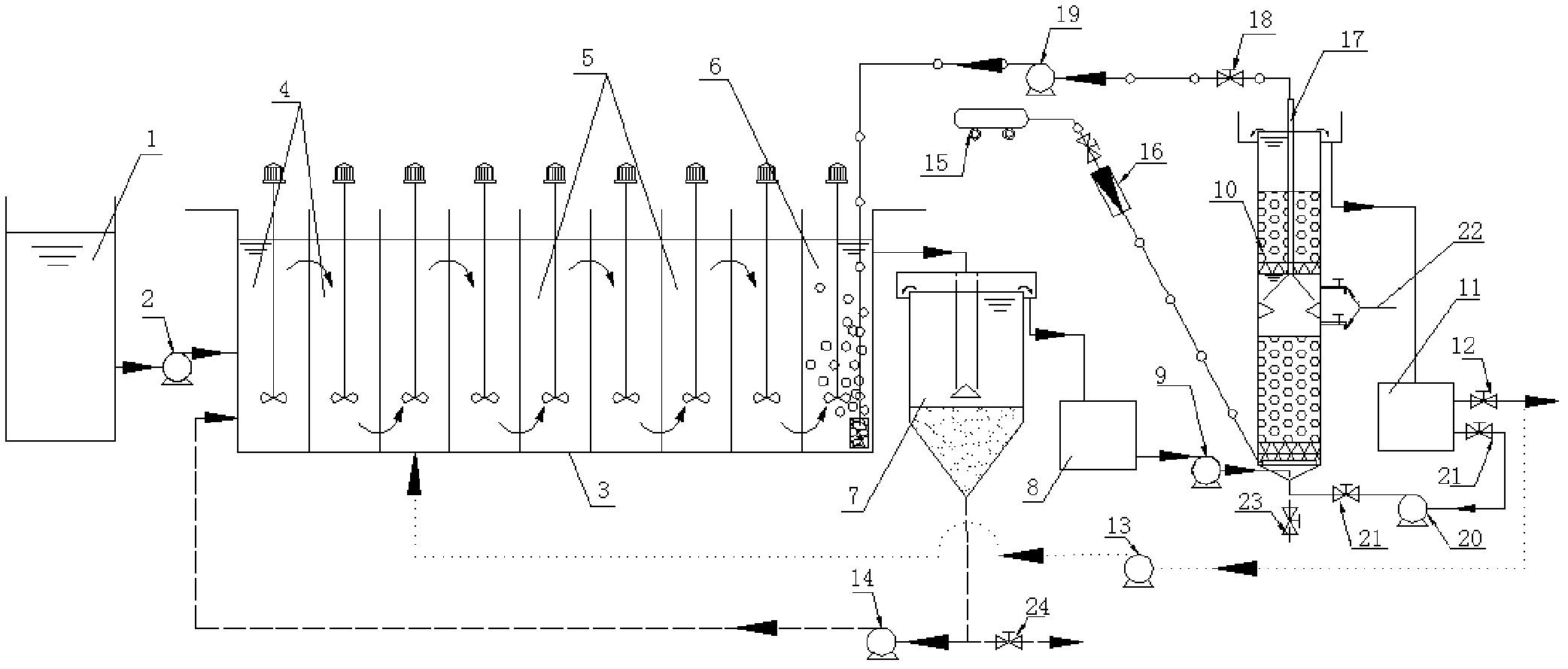

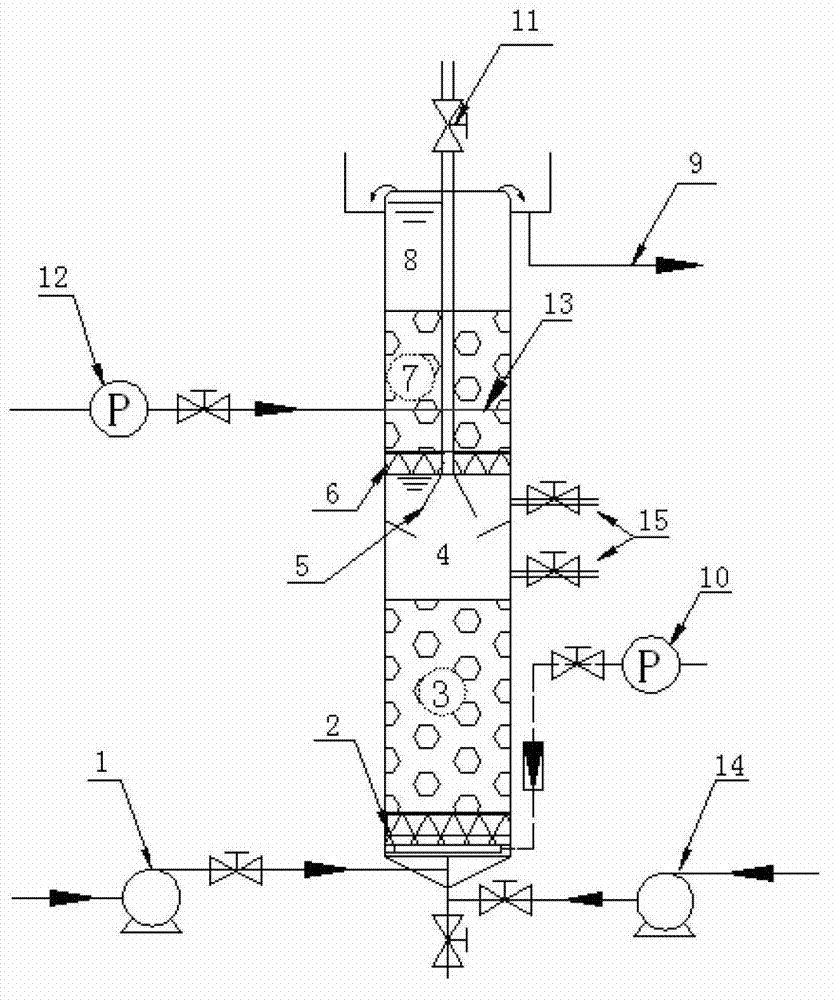

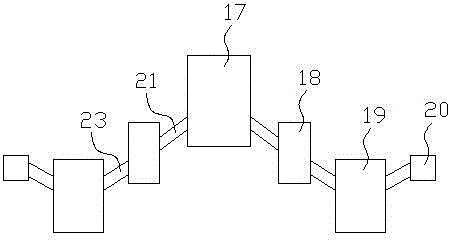

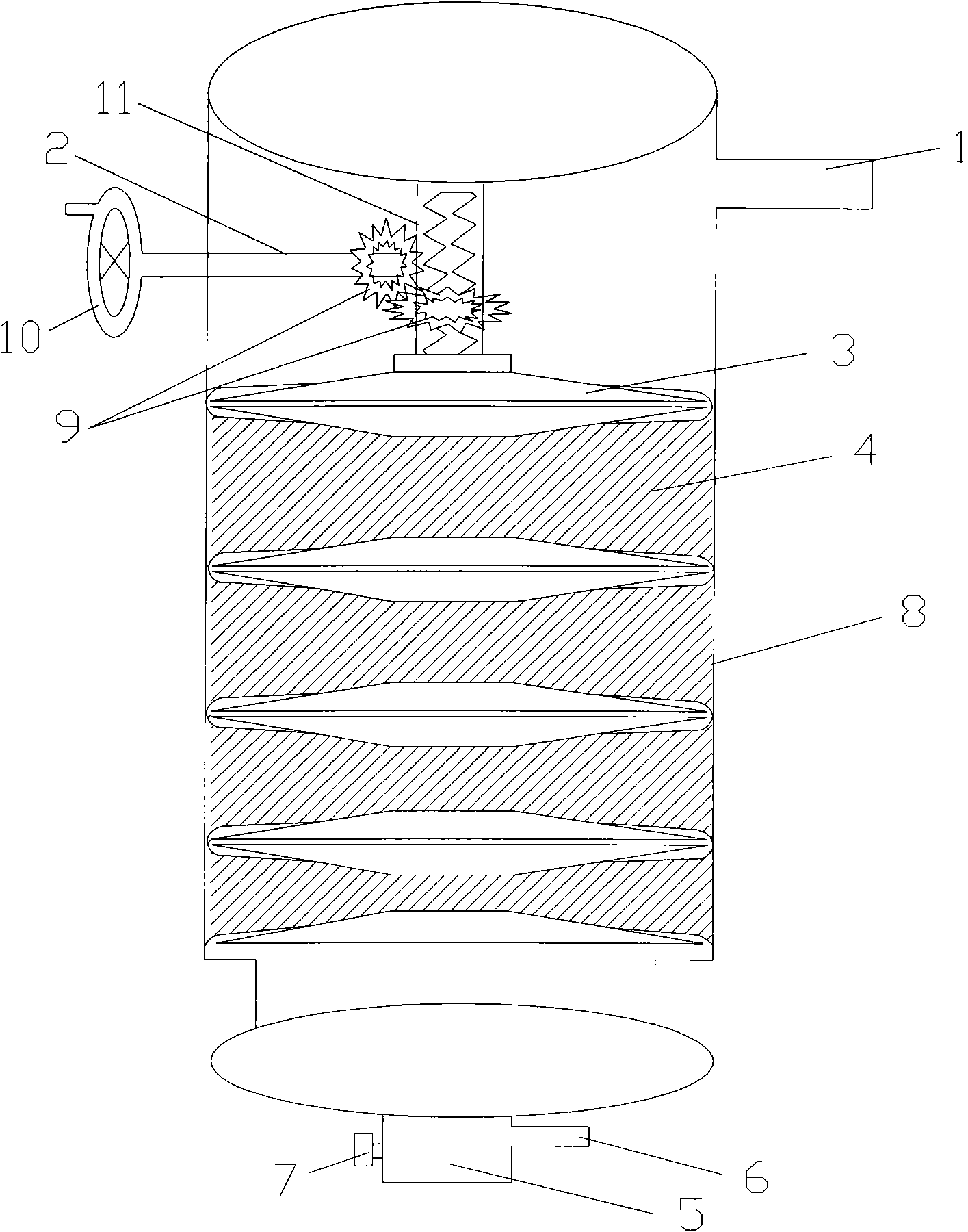

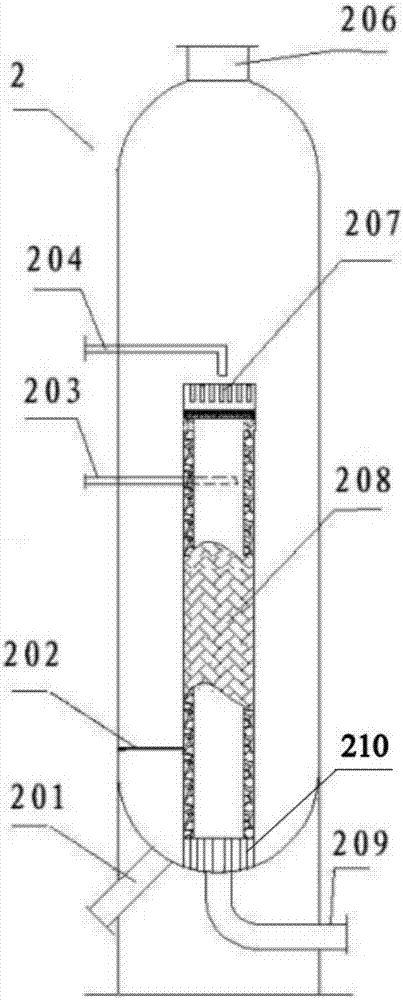

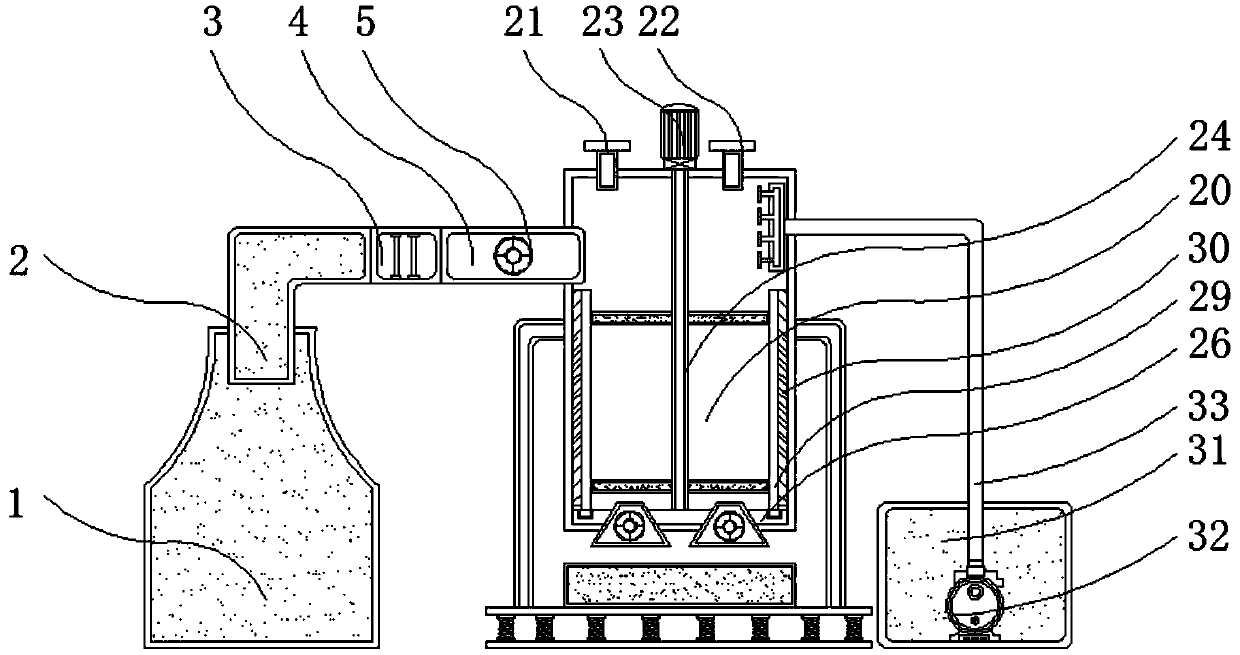

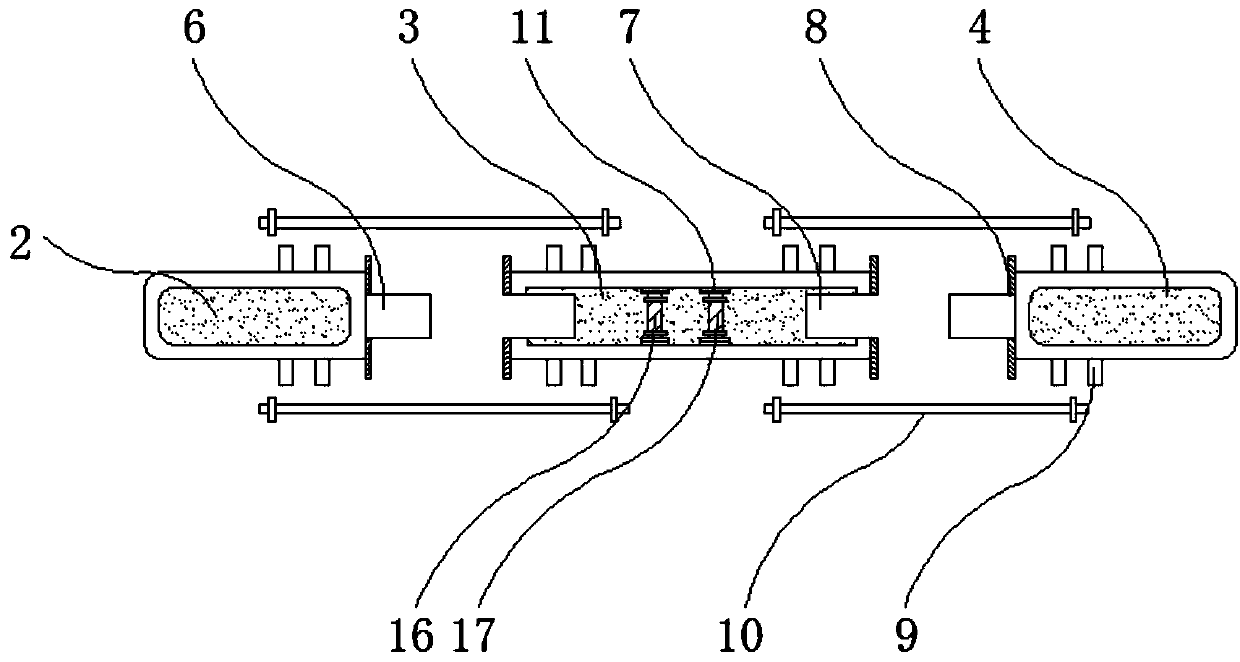

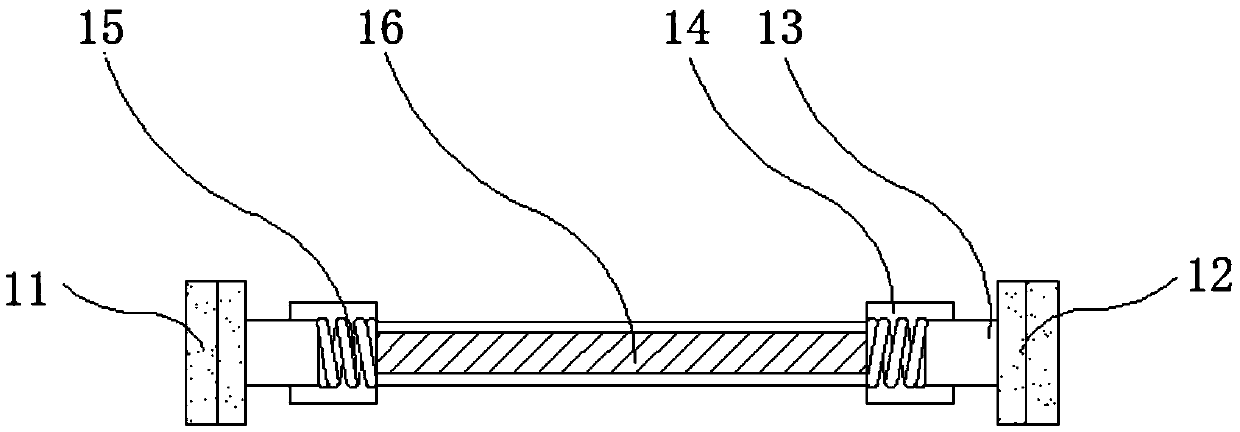

Nitration denitrificatoin and filter method and nitration denitrification and filter device for double-sludge series-connection aeration biofilter

ActiveCN102627353AAchieve separationImprove nitrogen removal efficiencyTreatment with aerobic and anaerobic processesDeoxidizationSewage

The invention discloses a nitration denitrificatoin and filter method and a nitration denitrification and filter device for a double-sludge series-connection aeration biofilter. The nitration denitrification and filter device is mainly composed of a water inlet system, a first section aeration biofilter, a second section aeration biofilter and a clean water tank, wherein the first section aeration biofilter is divided into a denitrification zone and a decarburization zone, suspended biological carriers serving as fillers are arranged in the denitrification zone, the second section aeration biofilter is connected with the decarburization zone of the first section aeration biofilter through a gas-water separator arranged in a middle water layer, and the second section aeration biofilter is divided into a nitration zone and a nitration deoxidization filter zone. The nitration denitrification and filter method comprises that denitrification and aerobic decarburization of waste water are respectively achieved through the denitrification zone and the decarburization zone of the first section aeration biofilter, ammonia nitrogen is converted into nitrate nitrogen through the second section aeration biofilter, electron acceptors are provided for the denitrification zone of the first section aeration biofilter, and chemical oxygen demand (COD), nitrogen (N) and suspended solid (SS) areremoved. The system nitration denitrificatoin and filter method and the nitration denitrification and filter device for the double-sludge series-connection aeration biofilter can achieve function separation of denitrification, decarburization and nitration and have the advantages of saving energy, being stable and denitrifying efficiently.

Owner:北控水务(中国)投资有限公司

Dual-sludge denitrification dephosphorizing and denitrifying A/A-O device and method

ActiveCN102583743AReduce yieldImprove filtering effectTreatment with aerobic and anaerobic processesSludgePrecipitation

The invention discloses a dual-sludge denitrification dephosphorizing and denitrifying A / A-O device which mainly comprises a primary precipitation pool, an anaerobic-anoxic device, a secondary precipitation pool, a middle pool, a biological aerated filter and a clear water pool, wherein the primary precipitation pool is connected with an anaerobic zone of the anaerobic-anoxic device, a degassing zone of the anaerobic-anoxic device is connected with the secondary precipitation pool, and the secondary precipitation pool is connected with the anaerobic zone of the anaerobic-anoxic device througha sludge pump; the outflow water of the secondary precipitation pool is connected to the middle pool, the middle pool is connected with the biological aerated filter, and the biological aerated filter is connected with the clear water pool; and the clear water pool is connected with the anaerobic-anoxic device. By the process adjustment, denitrifying phosphorus accumulating bacteria becomes dominant bacteria of an AAO unit. The dual-sludge denitrification dephosphorizing and denitrifying A / A-O device realizes the separation of phosphorus accumulating bacteria and nitrobacteria, the separationof the precipitation function and the sludge storage function of the secondary precipitation pool, and the separation of the nitrification function and the filtering function of the biological aerated filter, thereby realizing energy conservation of a combined system, stability and efficiency in denitrification and dephosphorization, and sludge reduction.

Owner:上海立源生态工程有限公司

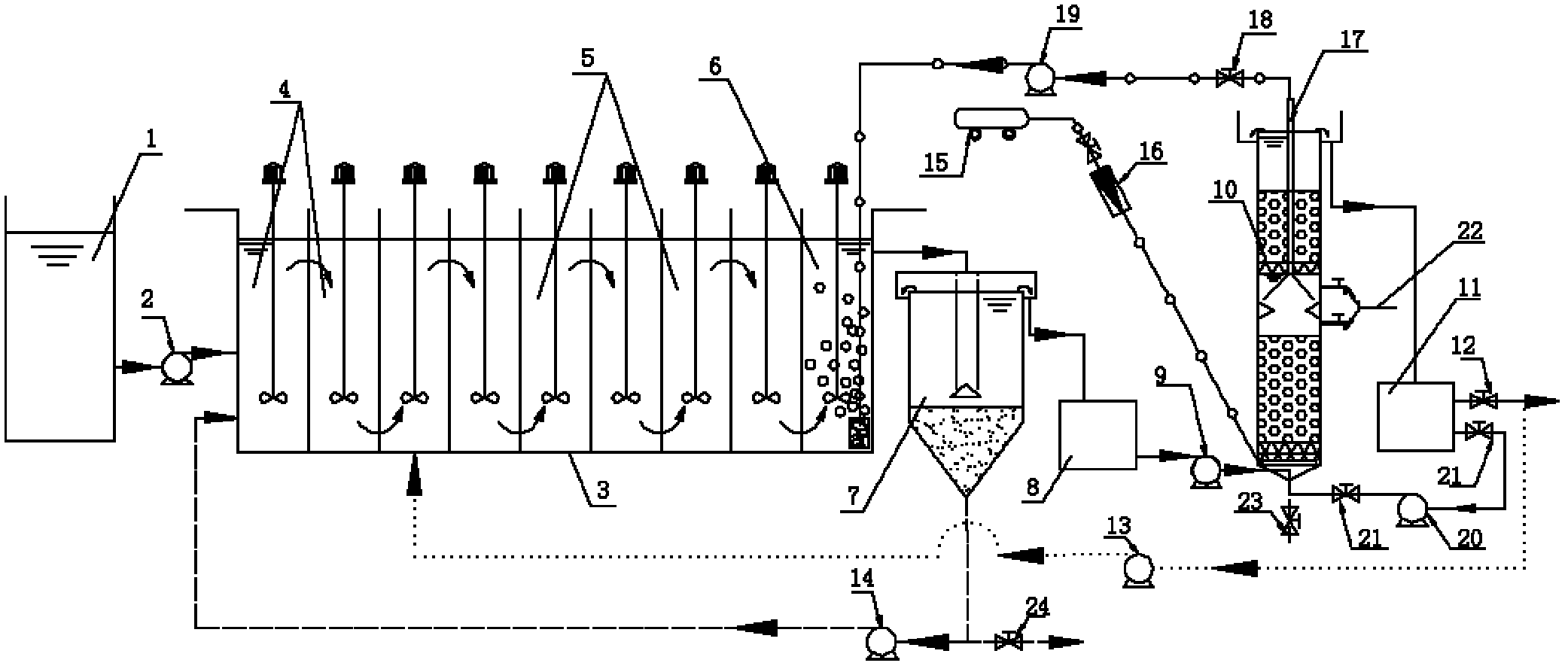

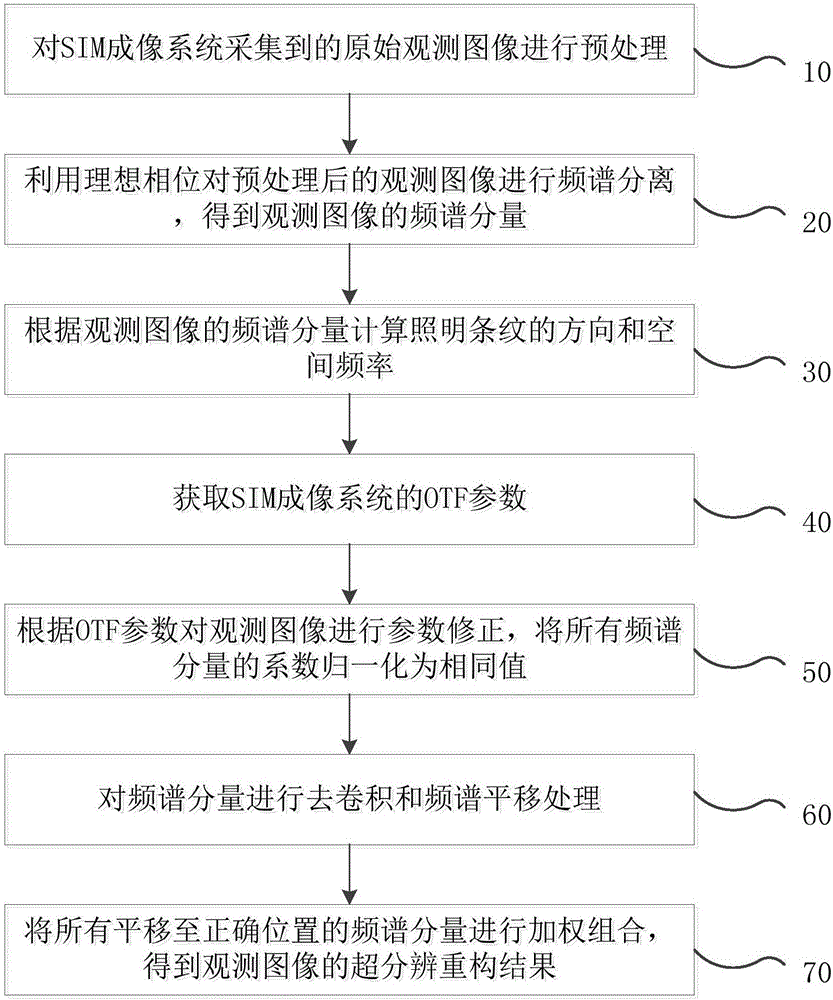

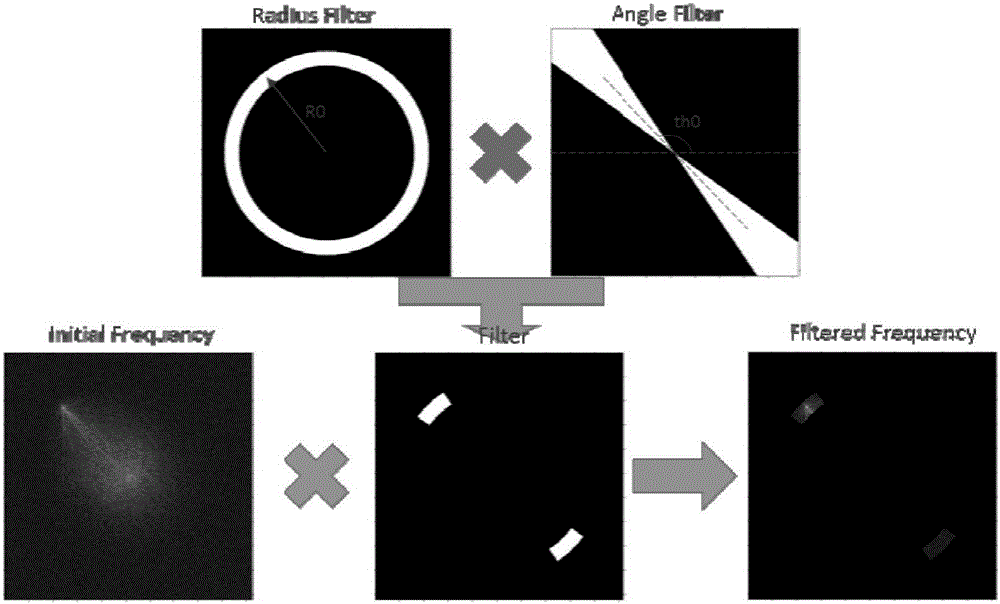

Image reconstruction method and system

ActiveCN107180411AHigh solution accuracyAvoid cumbersomeImage enhancementImage analysisConvolutionReconstruction method

The present invention relates to the image reconstruction technology field, especially to an image reconstruction method and system. The image reconstruction method comprises: the step a: performing frequency spectrum separation of an image, and obtaining the frequency spectrum component of the image; the step b: performing peak point search of the frequency spectrum component, and obtaining the lighting luminous direction and space frequency; the step c: calculating the lighting luminous modulation degree and initial phase through the linear fitting algorithm, performing correction of the frequency spectrum component through lighting luminous modulation degree and initial phase, and performing normalization of the coefficients of the frequency spectrum component; and step d: performing deconvolution and translation processing for the normalization frequency spectrum component, performing frequency spectrum combination of the frequency spectrum component after deconvolution and translation processing, and obtaining the reconstruction result of the image. The image reconstruction method and system set a filter function according to the lighting luminous space frequency initial value, perform filtering of the separation frequency spectrum, and perform peak point search so as to improve the solution precision and effectively improve the quality of the reconstruction image.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

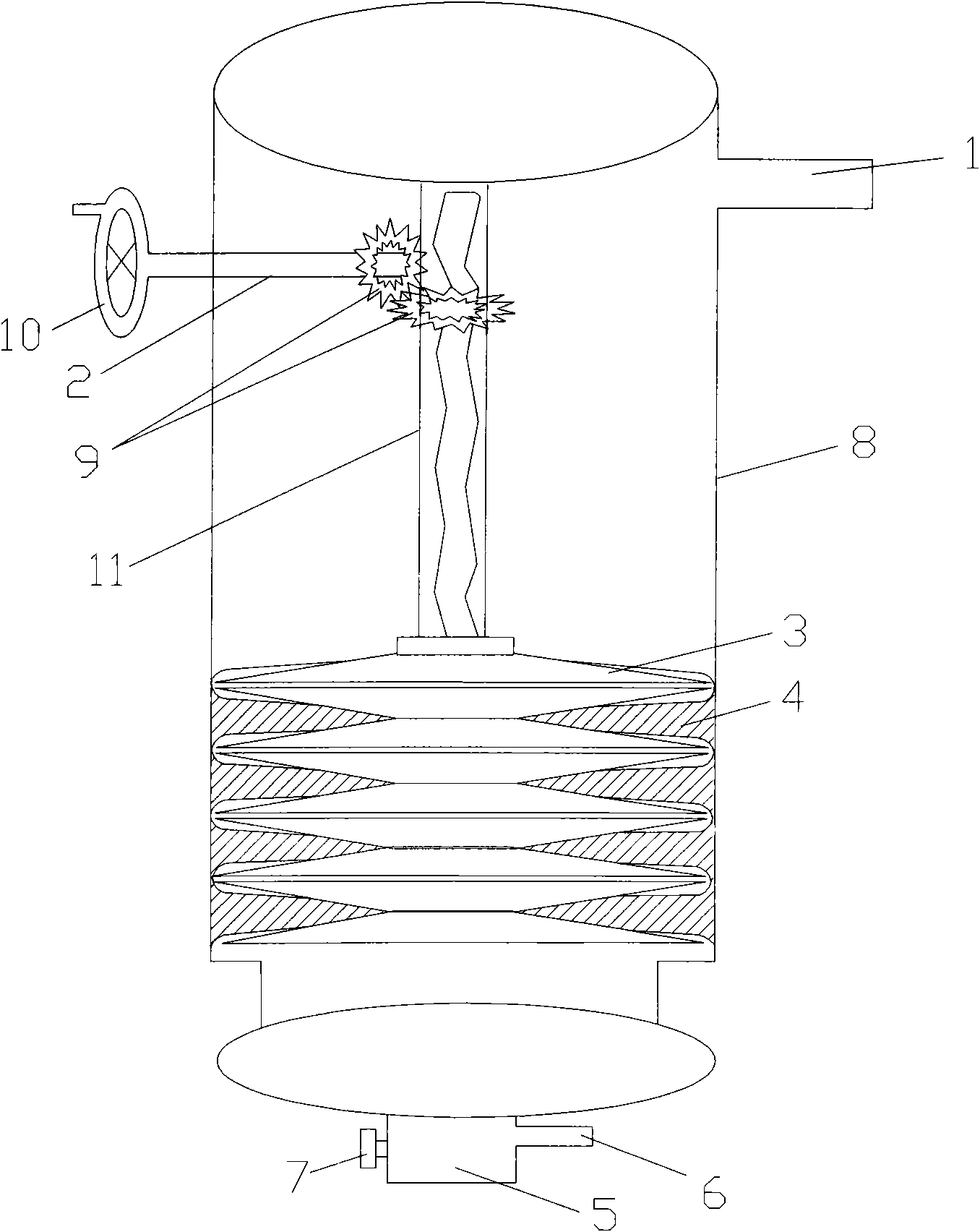

Method for deep denitrification of integrated biological aerated filter

ActiveCN102963981AClear waterLow energy consumption for backwashingTreatment with aerobic and anaerobic processesEngineeringOperation mode

Belonging to the technical field of biological sewage treatment, the invention relates to a method for deep denitrification of an integrated biological aerated filter, and the method is suitable for deep denitrification of sewage and wastewater. A device for deep denitrification of the integrated biological aerated filter mainly comprises: a water inlet system, the integrated biological aerated filter, a carbon source adding system and a back washing system. The integrated biological aerated filter adopts an upward flow operation mode, and is divided into a nitrification area and a denitrification area through a gas-water separator. The method includes: subjecting nitrogen-containing sewage and wastewater to ammonia nitrogen oxidation by the nitrification area at the lower part of the biological aerated filter; passing the gas through an intermediate water layer, then conducting separation and discharge; and making use of the electronic donor provided by an external carbon source in the denitrification area to complete deep removal of nitrogen. The device has a small floor area and a simple process, and is easy to form integrated equipment.

Owner:北控水务(中国)投资有限公司

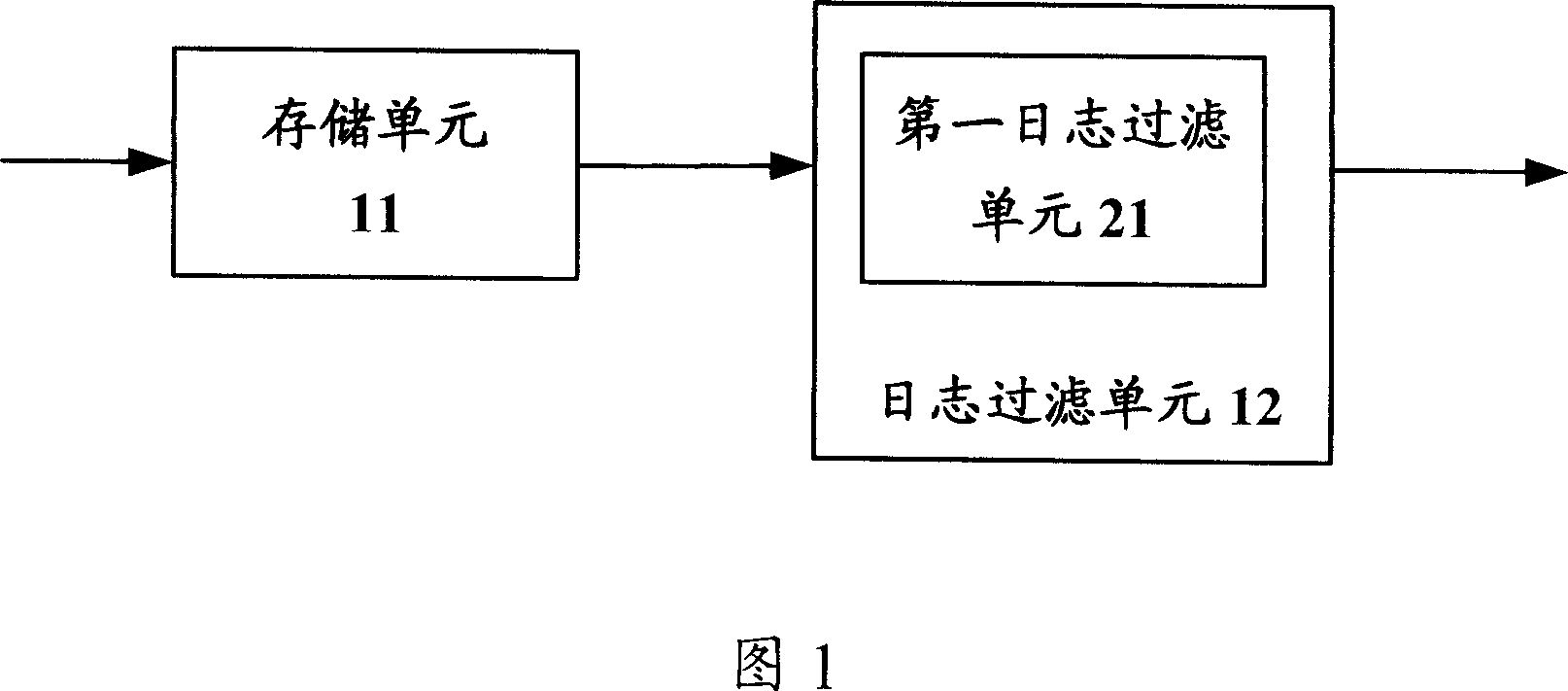

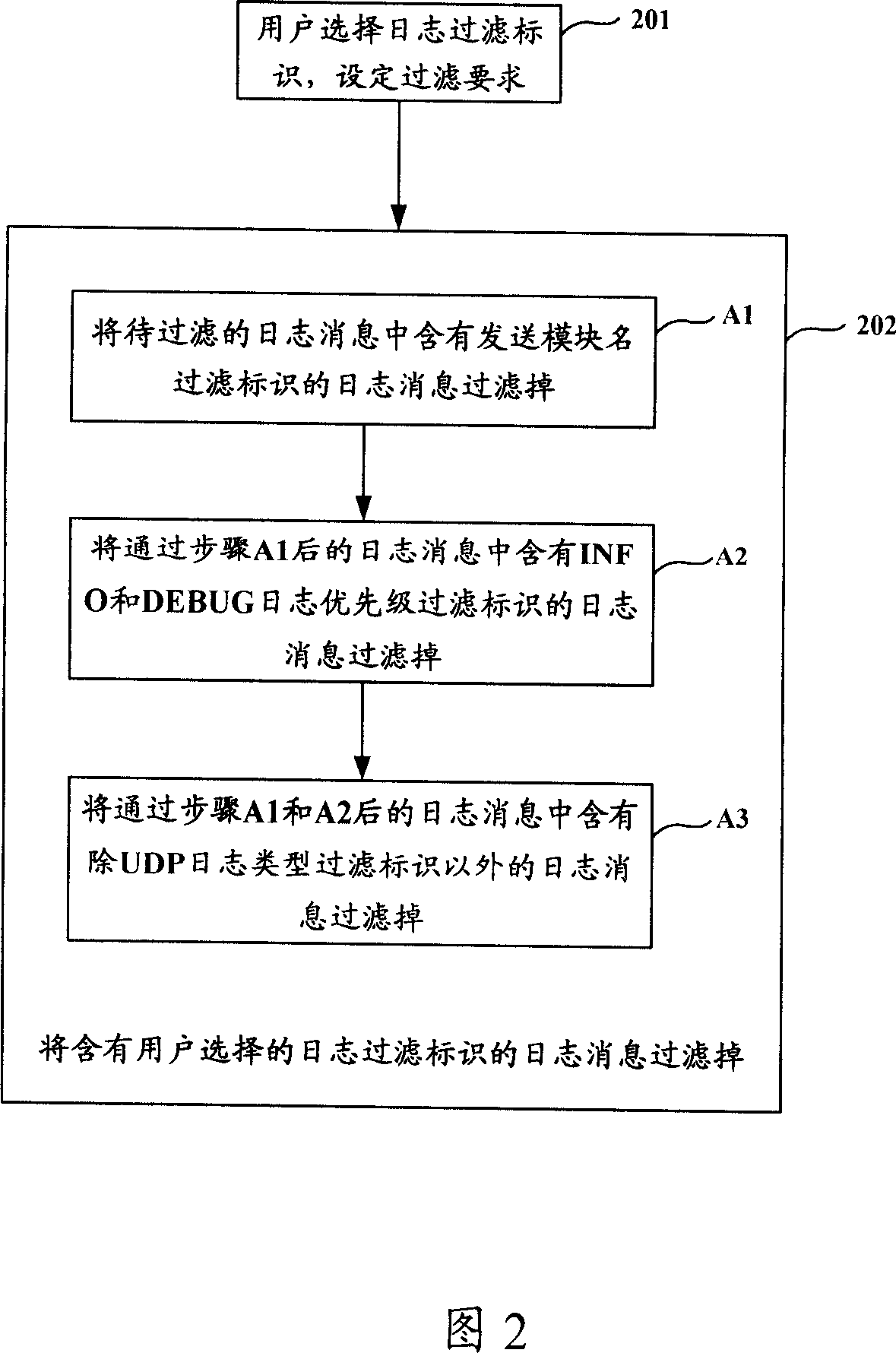

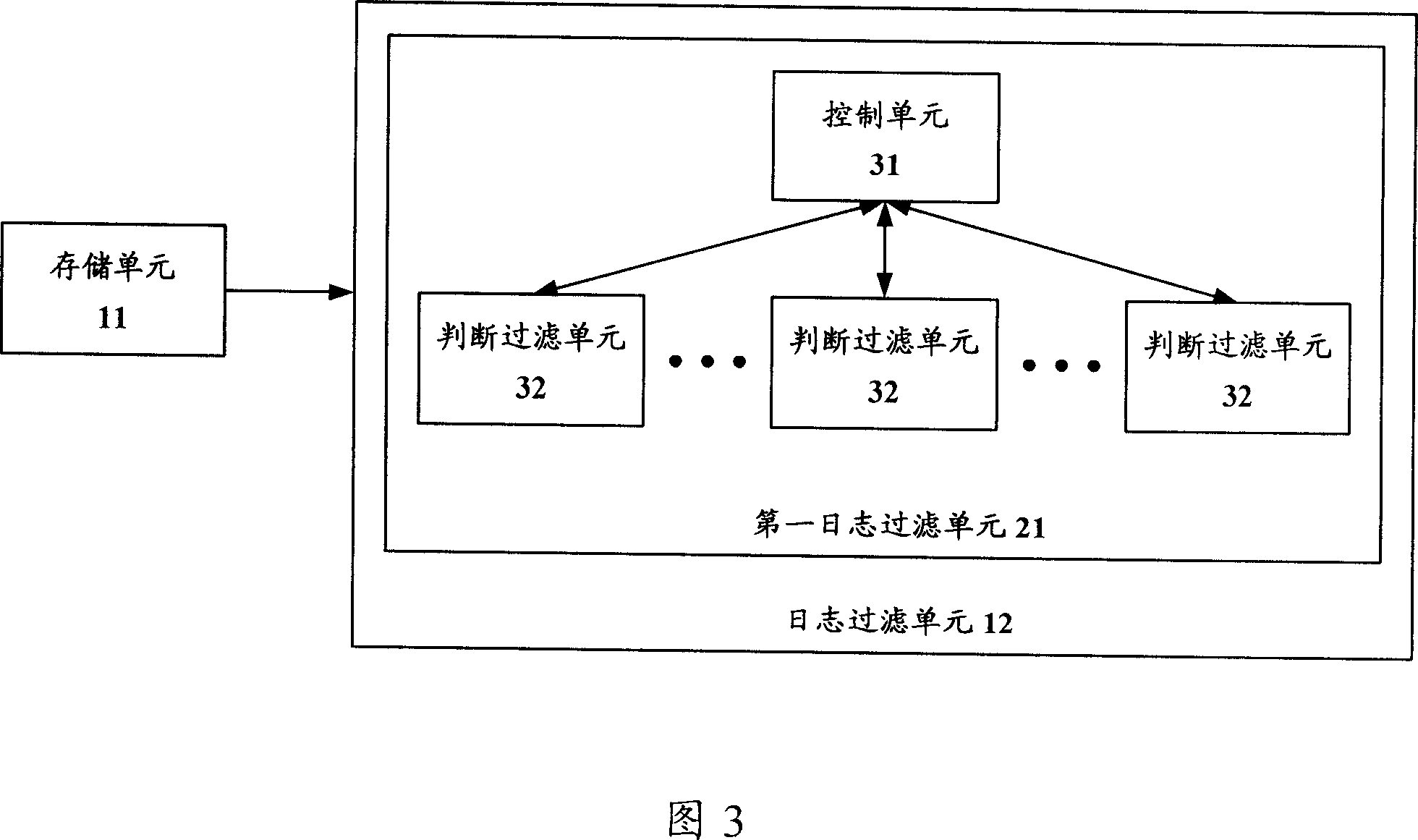

System and method for filtering journal message

InactiveCN1949725AEnhanced log filtering functionAvoid duplication of redundant log messages written to log filesData switching networksSpecial data processing applicationsData miningFilter system

The invention discloses a log information filtering method, comprising: according to the user-selected log filtering identification, filtering to-be-filtered log information meeting the filtering conditions corresponding to the identification, where the log filtering identification is an identification of log information filtering conditions. And it enhances log filtering function, making a user able to perfectly filter by external configuration. And it also discloses a log information filtering system.

Owner:HUAWEI TECH CO LTD

Integrated machine for grading production of anti-radiation mortar

ActiveCN105921248ASimple structureScreening boundaries are clearSievingDischarging apparatusRotational axisCrusher

The invention relates to an integrated machine for grading production of anti-radiation mortar. The integrated machine comprises a screening and grading device connected to a crushing machine, a quantitative conveying device, a material mixing device and a raw material box, wherein the screening and grading device comprises a screening drum; a screen mesh is arranged at an upper part in the screening drum and a mounting tube is arranged at a bottom center of the screening drum; turnover shafts penetrating through the screening drum are arranged on the two sides of the screen mesh; the turnover shafts on the two sides are respectively mounted on a bearing pedestal and a turnover motor; partition plates are evenly arranged between the mounting tube and the screening drum; material collection cavities are formed between adjacent partition plates; a rotary cover is arranged above the mounting tube; a notch matched with the material collection cavity is formed in the rotary cover; the rotary cover is connected to a rotary shaft; and the rotary shaft is connected to a rotary motor. According to the screening and grading device, by screening by the simple screen mesh, the limit for screening is obvious, the structure is simple, meanwhile, the classified collection is facilitated, then the anti-radiation mortar of different grades is produced via the quantitative conveying device and the simple material mixing device, and further the economic effects are improved.

Owner:YIYANG JINYU BUILDING MATERIAL TECH CO LTD

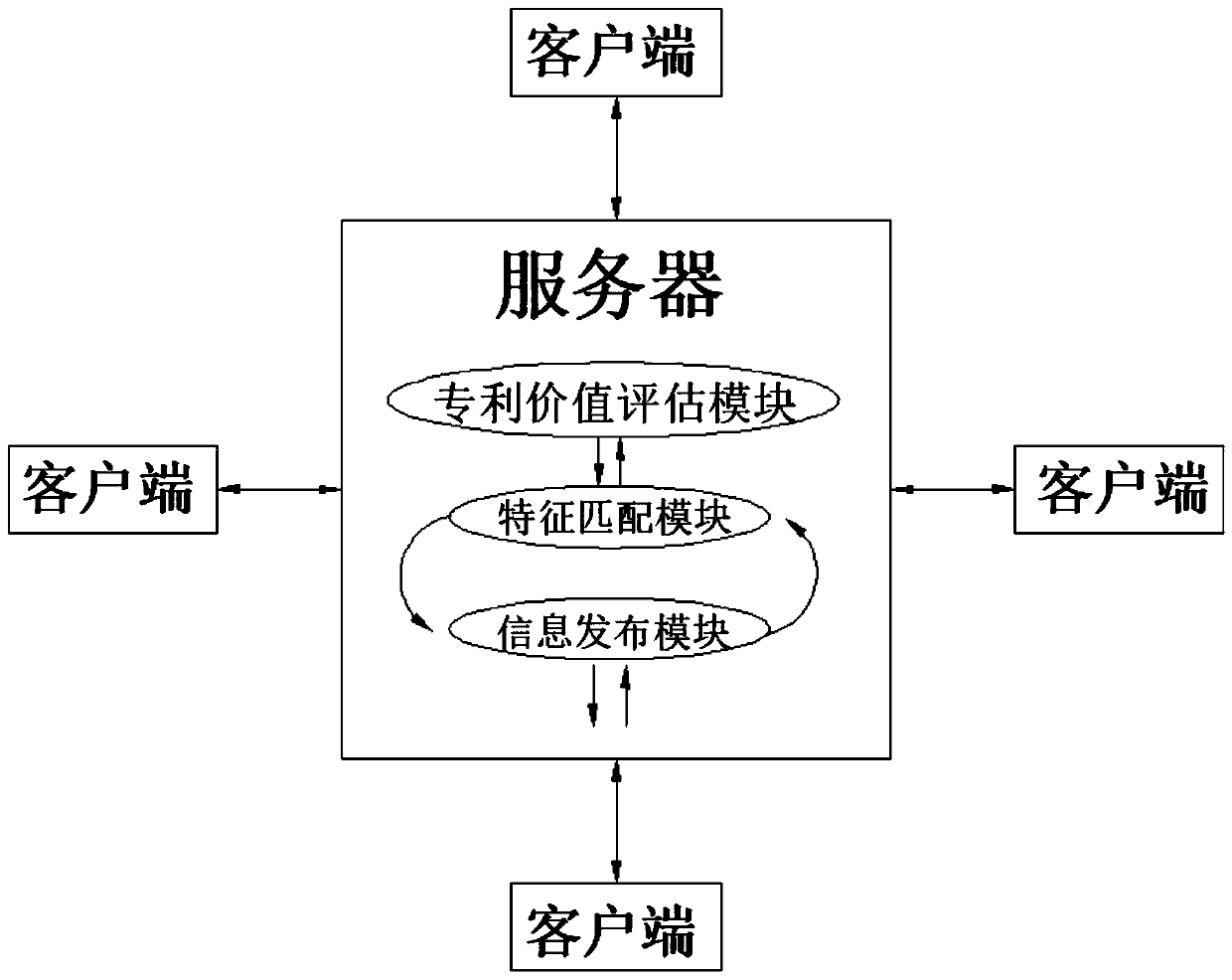

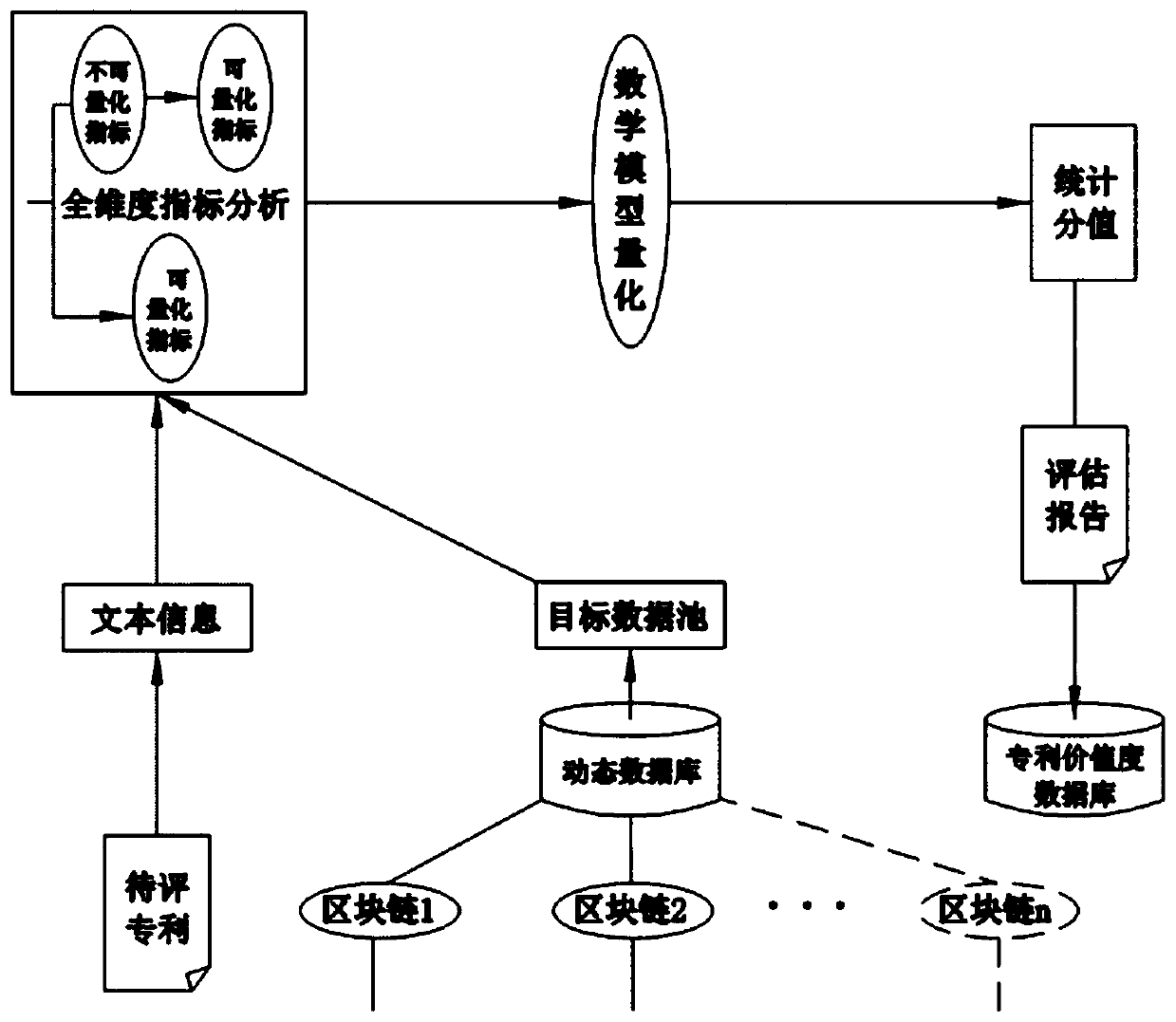

Patent transaction system

PendingCN110457441AImprove exchange efficiencyIncrease contactProduct appraisalBuying/selling/leasing transactionsGraphicsGraphical user interface

A patent transaction system comprises a server coupled to a graphical user interface. The server is provided with an information publishing module, a feature matching module and a patent value evaluation module which are associated with one another, and at least one client can publish, inquire and receive information on the server. The patent transaction system has the characteristics that the scientific and technological achievement transfer and conversion efficiency is improved, the value and price of the patent are conveniently known, the judgment and reference basis of patent pricing is enriched, the waiting time of the transaction process is shortened, and the information transparency in the service process is improved.

Owner:佛山市木记信息技术有限公司

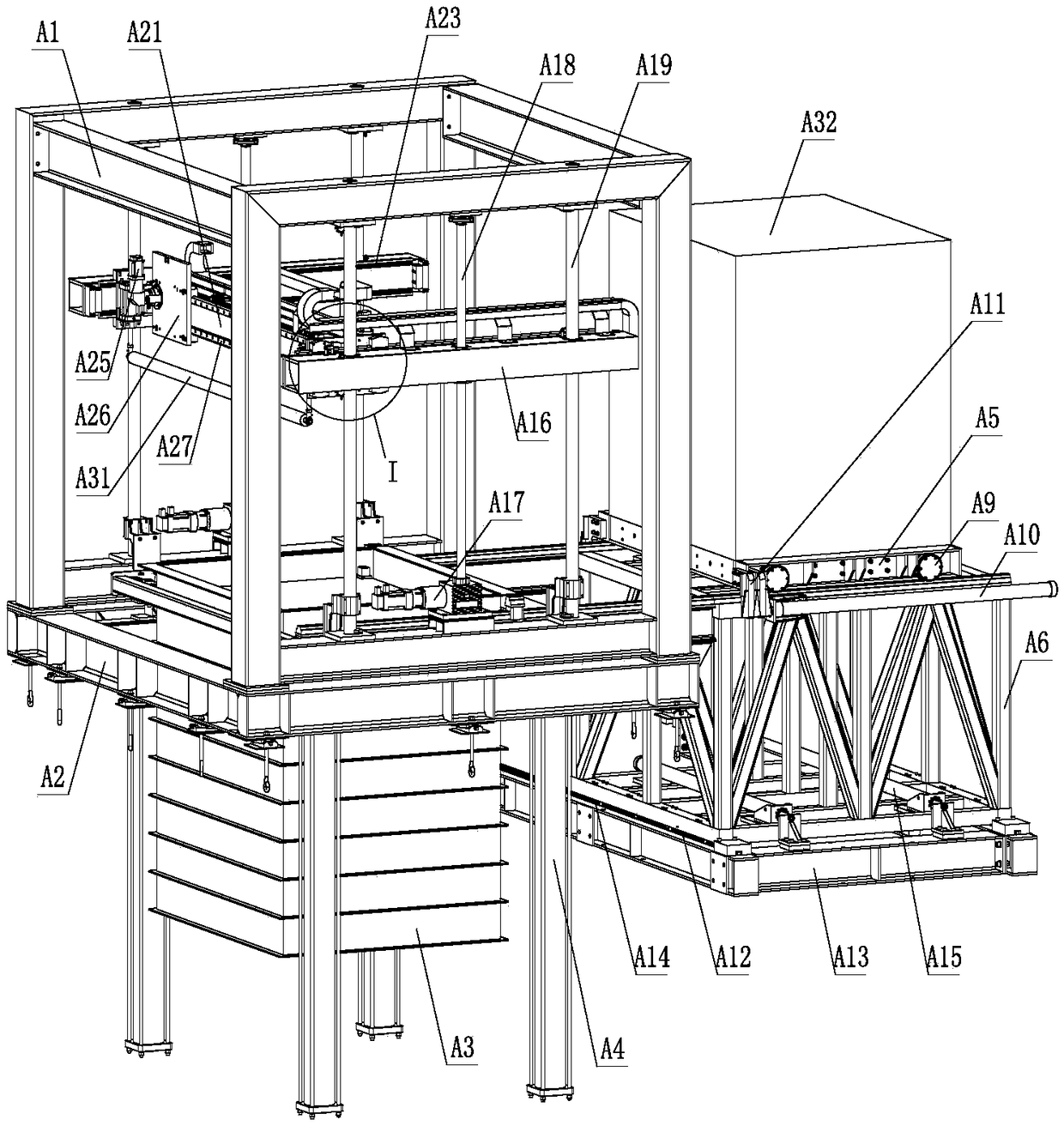

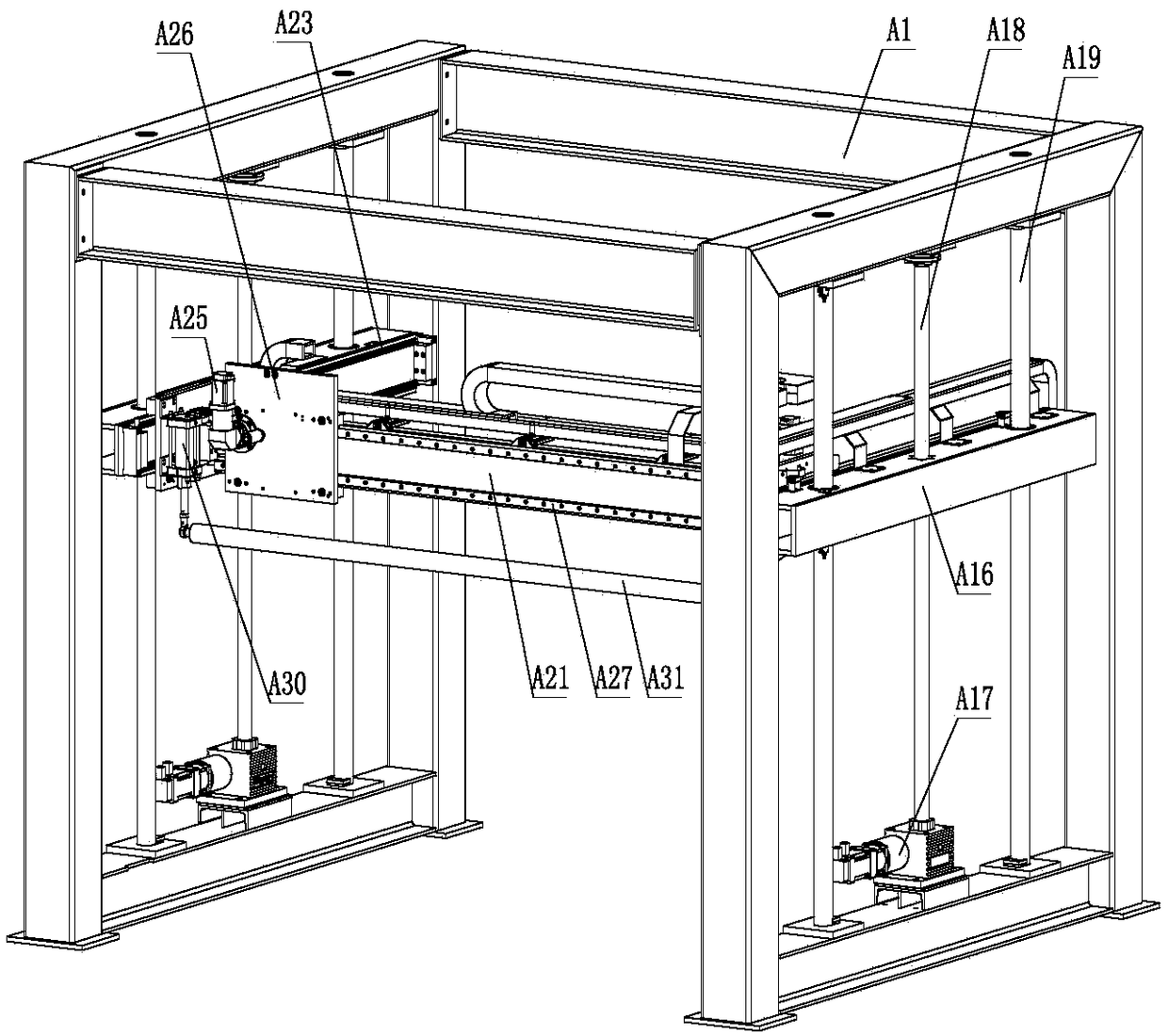

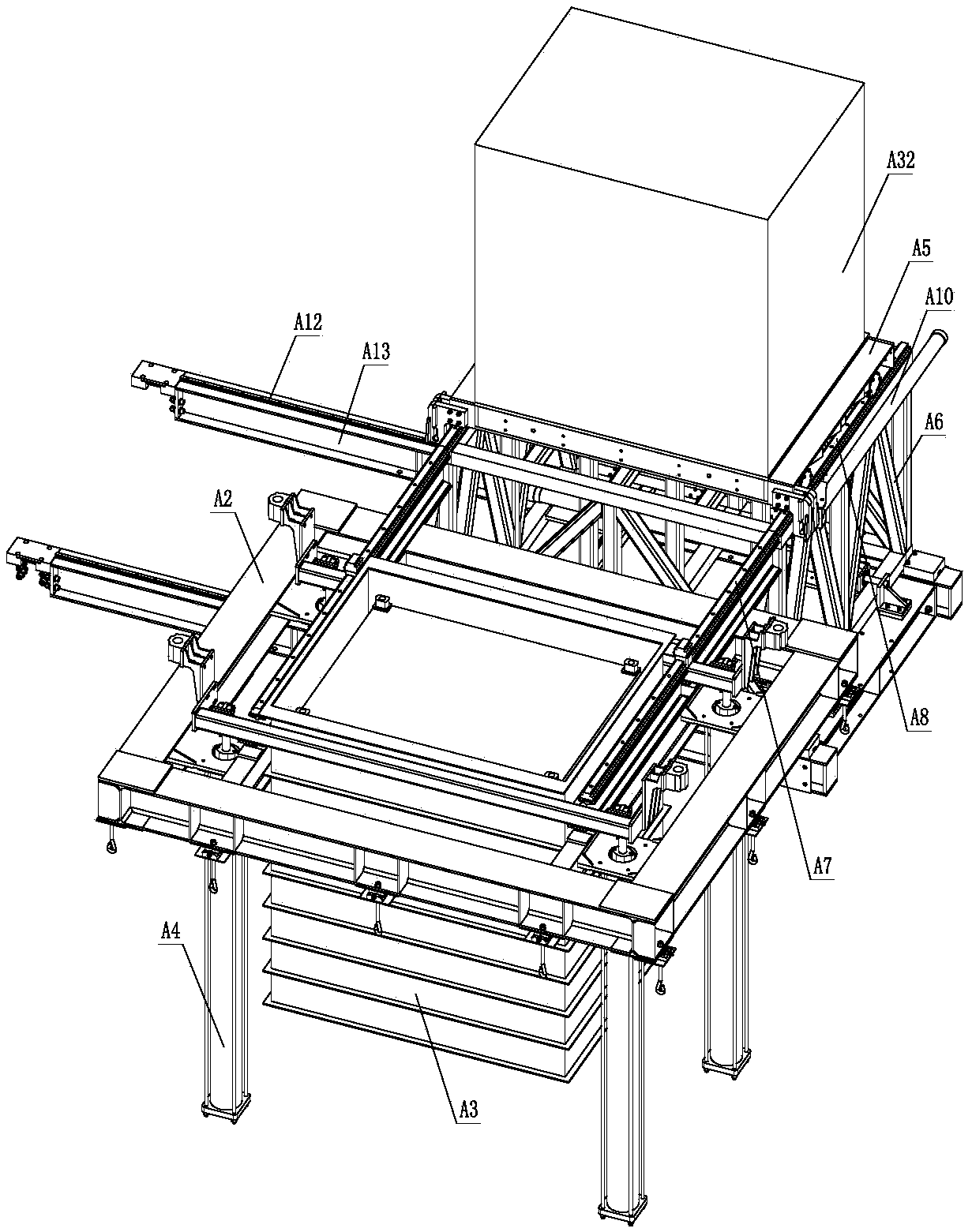

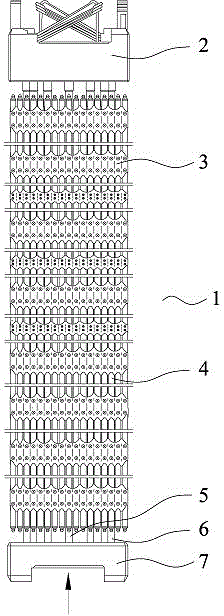

Large complex geology physical model 3D forming system

ActiveCN108638289AStop blockingWith anti-clogging functionAdditive manufacturing apparatusCeramic shaping apparatusMulti materialMotor drive

A large complex geology physical model 3D forming system comprises a 3D forming machine, a stirring machine, a feeding controller, a printing head and a control table. The printing head is arranged onthe 3D forming machine and connected with the stirring machine through the feeding controller, and the stirring, feeding and printing processes are controlled in a unified manner through the controltable. The feeding controller comprises two structure forms including an air pump drive type structure and a motor drive type structure. The 3D forming machine has the model compactness adjusting capability, and many materials can be printed; the integral seal design is adopted in the stirring machine, the dust removal function is achieved, full-automatic feeding and stirring are achieved, the filter function is achieved in the stirring process, particles with the grain size exceeding the standard can be removed from similar materials, and printing head blockage is avoided; the feeding controller can accurately control the discharging amount, the discharging amount adjusting capability is high, and detaching and cleaning can be conducted; and through the printing head, the printing precision can be rapidly adjusted, and the similar material circulation anti-blockage function and the similar material flushing purification anti-blockage function are achieved.

Owner:NORTHEASTERN UNIV

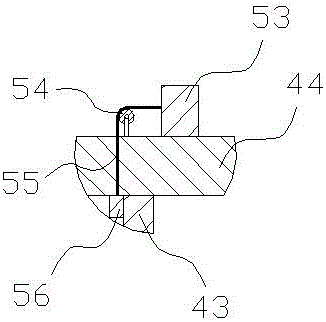

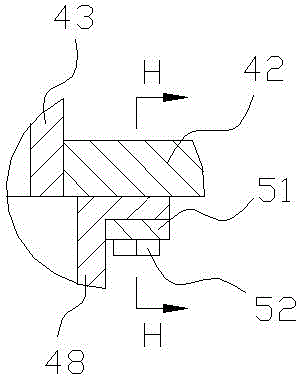

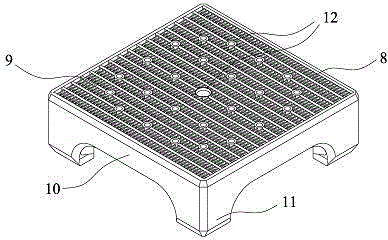

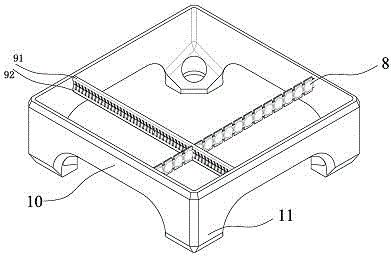

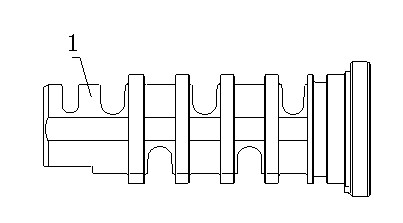

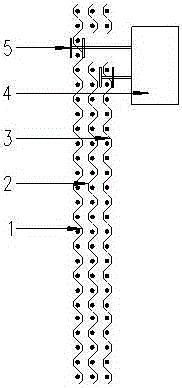

Lower tube socket with function of filtering foreign matters

ActiveCN103337262AIncrease stiffnessHigh strengthNuclear energy generationFuel element assembliesForeign matterEngineering

The invention discloses a lower tube socket with a function of filtering foreign matters. The lower tube socket comprises a plurality of blades having mutually paralleled axles and a plurality of fillet assemblies having mutually paralleled axles, the axles of the fillet assemblies are vertical to the axles of the blades; the fillet assembly is composed of two symmetric fillets, the opposite facesof the two fillets are respectively provided with clamping slots having number corresponding to that of the blades, the blades are clamped in the clamping slots; the blade comprises a plurality of bulges having the same convex directions, two adjacent bulges are connected by a straight section, the upper end surface and the lower end surface of the straight section are provided with grooves, theopening direction of the groove is vertical to the convex direction of the bulge, and the fillet assembly is clamped in the groove. The lower tube socket disclosed by the invention is good in structure strength, filtering ability and coolant pressure drop.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

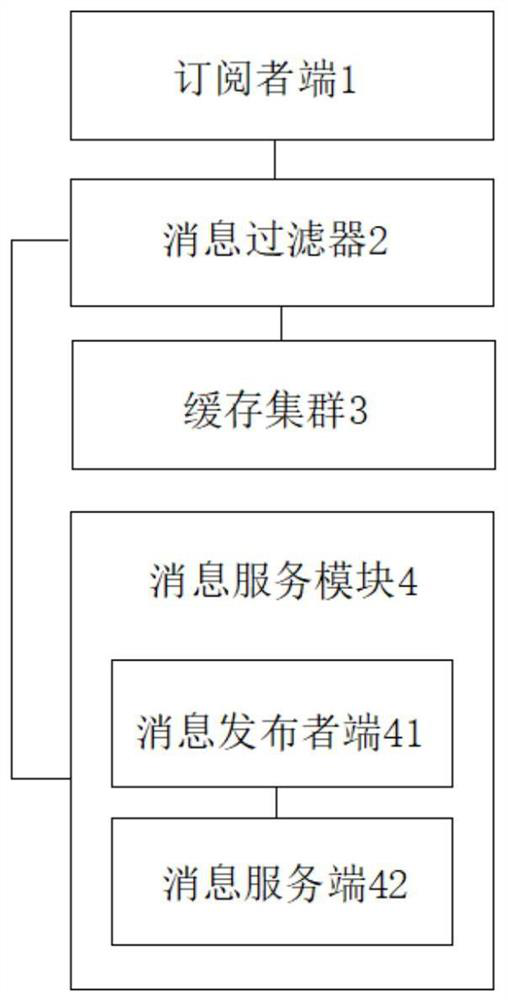

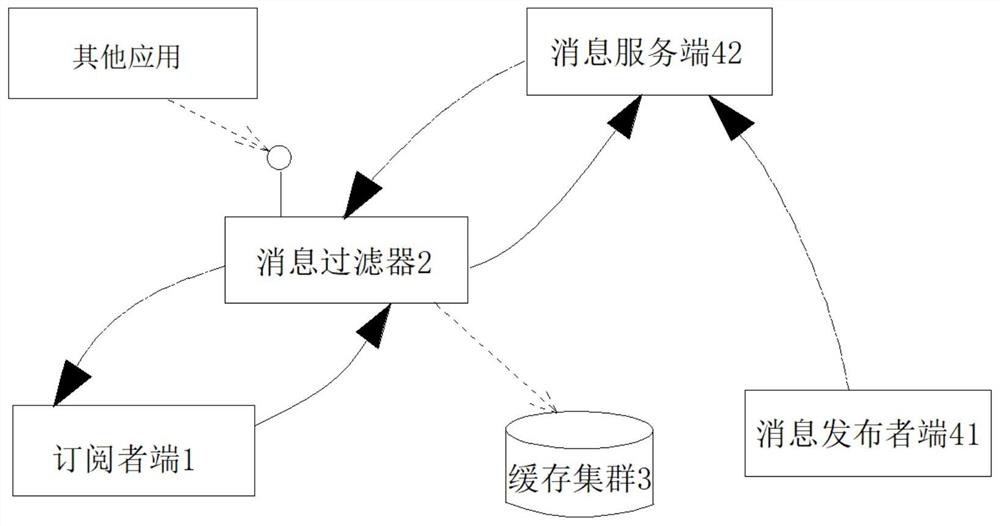

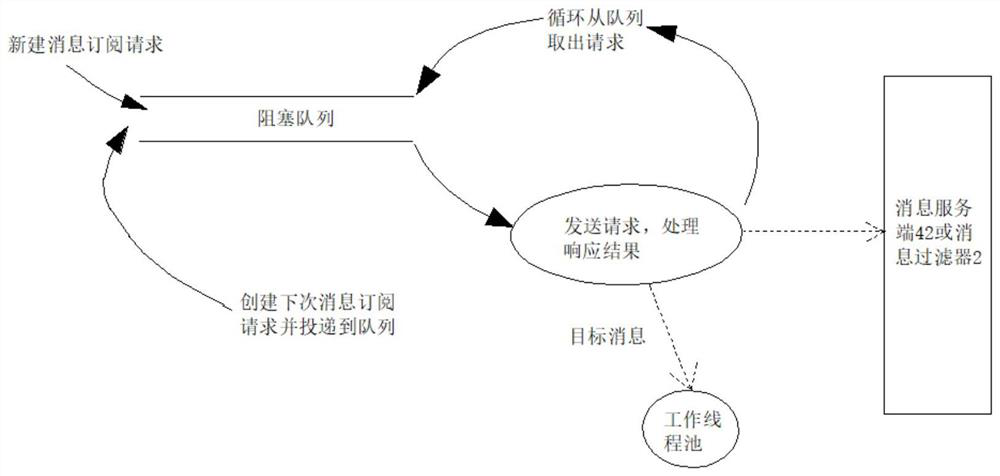

Extension method, application system and application method of message filter

The invention discloses an extension method, an application system and an application method of a message filter, and relates to the field of universal software. The method comprises the following steps that: the message filter receives a filtering rule sent from the outside and stores the filtering rule in a cache cluster; and the message filter is externally provided with a rule interface, receives an updating instruction sent from the outside through the rule interface, and dynamically updates the filtering rule stored in the cache cluster in real time according to the updating instruction.The extension method, the application system and the application method of the message filter have the beneficial effects that a user can dynamically update and set the filtering rule in the cache cluster in real time through the rule interface according to the service requirement, and custom expansion of the filtering rule is realized; and a large number of message subscription requests can be efficiently processed, a message filter is dynamically added and deleted, and the filtering function of the message filter is enhanced.

Owner:FENGHUO COMM SCI & TECH CO LTD

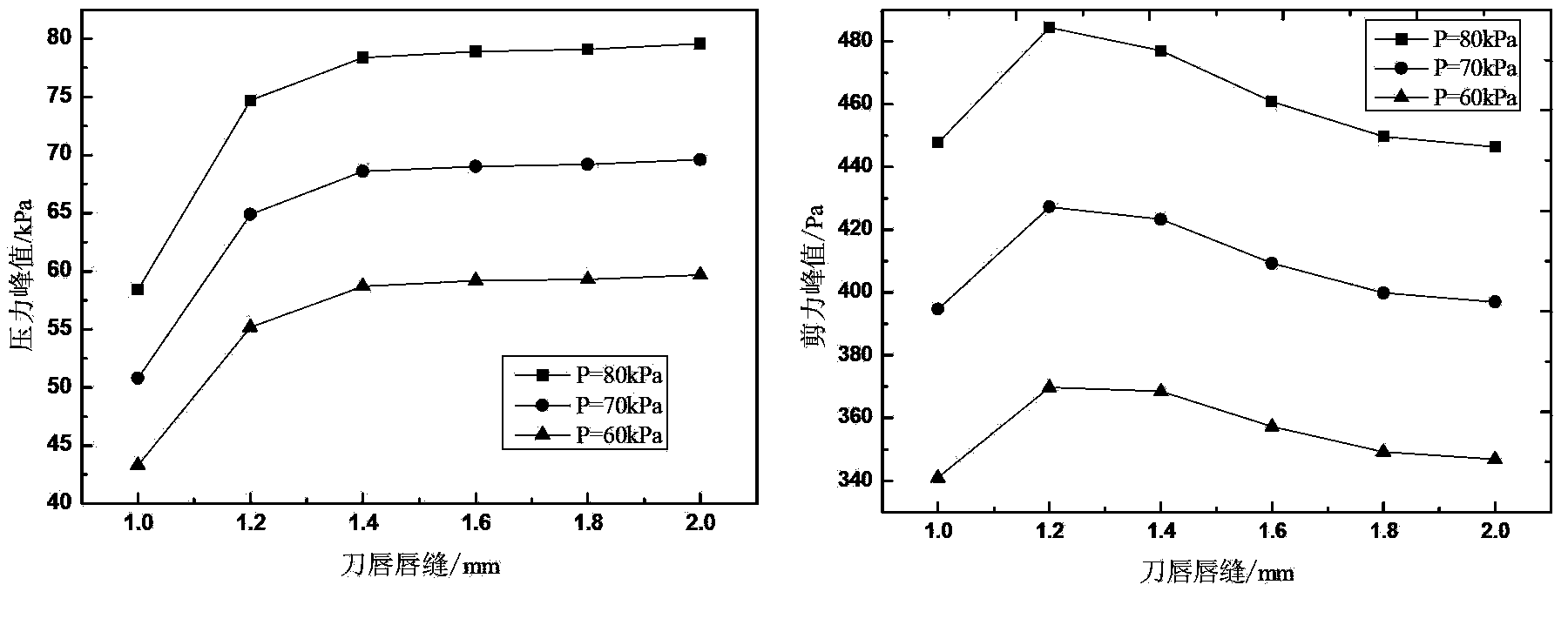

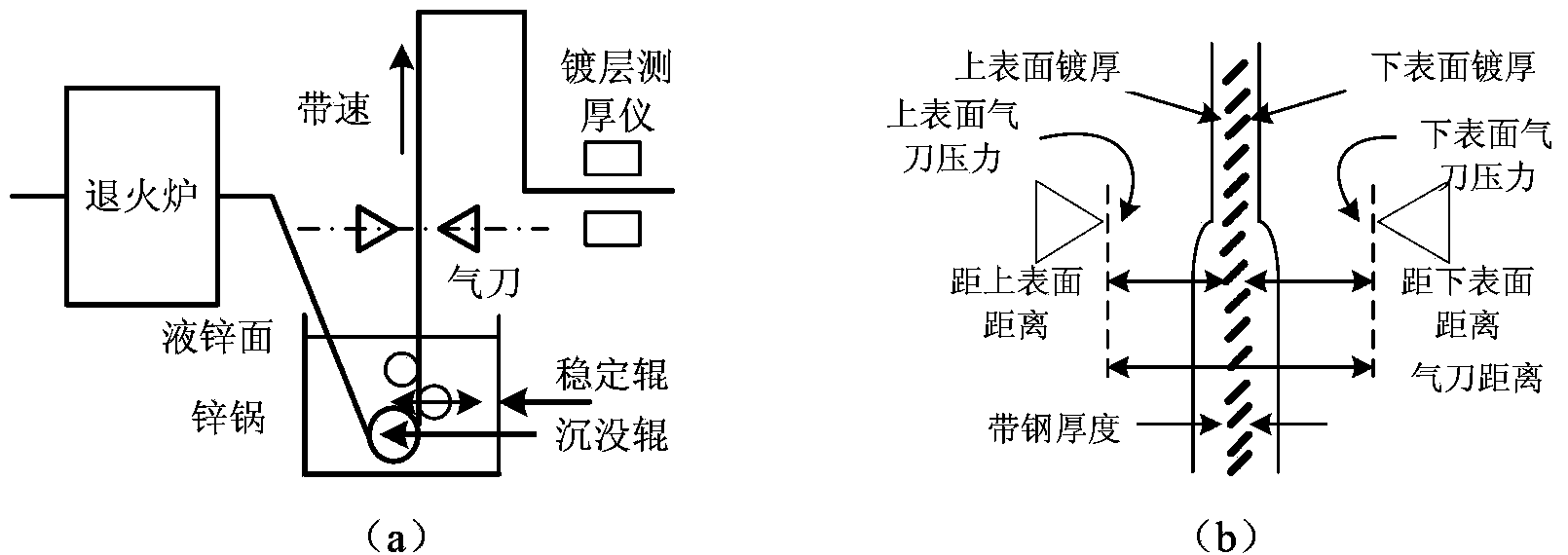

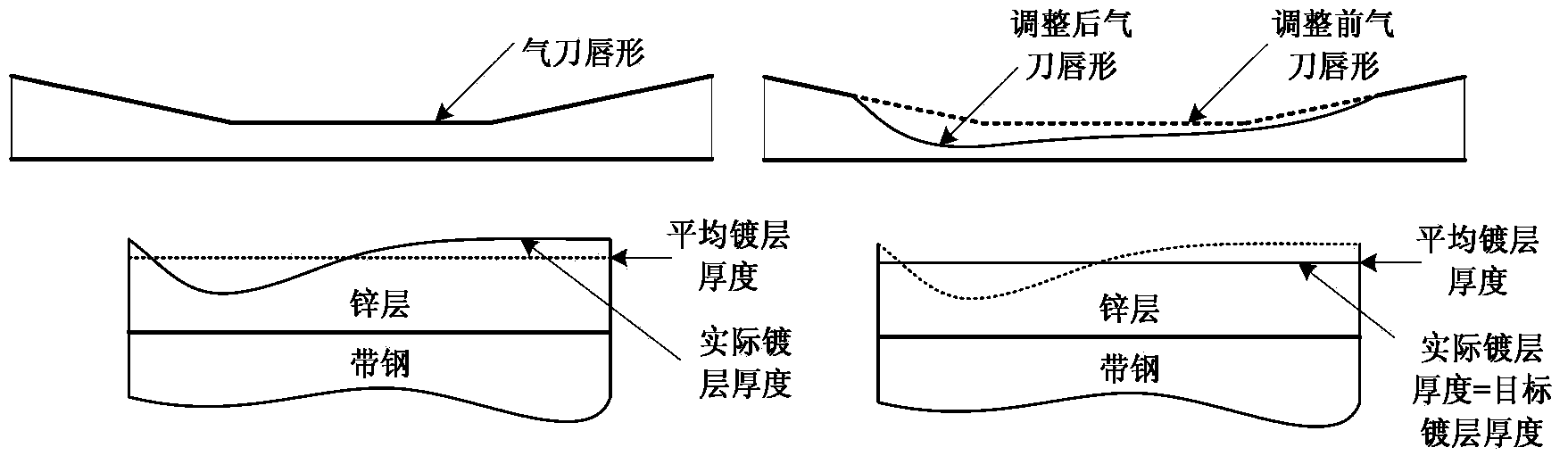

Deviation value control method for cold rolling hot galvanizing coating uniformity

ActiveCN103510032ARealize automatic and precise adjustmentAdd filter functionHot-dipping/immersion processesEngineeringError function

The invention provides a deviation value control method for cold rolling hot galvanizing coating uniformity. The method comprises the steps of: 1) establishing an influence model of the knife lip opening degree on coating thickness; 2) establishing an influence efficiency function matrix determining the influence weight of each air knife lip servo motor adjustment amount on each coating; 3) solving a motor adjustment amount according to a quadratic error function minimum principle; and 4) considering the actual application features in terms of correcting the quadratic error function, when the galvanizing thickness measured value of a point deviates from most measuring points, in order to avoid the interference of an extreme value on the coating control of other areas, adding a filtering function in an error function, thus finally obtaining a needed air knife lip opening degree. The invention provides a new galvanized layer thickness calculation model suitable for industrial application, introduces the influence efficiency function matrix, enhances the coating uniformity control accuracy, and simultaneously adds the cost function and the filtering function to improve the coating error function accuracy, thereby enhancing the coating uniformity calculation accuracy, and improving the surface quality of a galvanized product.

Owner:ANGANG STEEL CO LTD

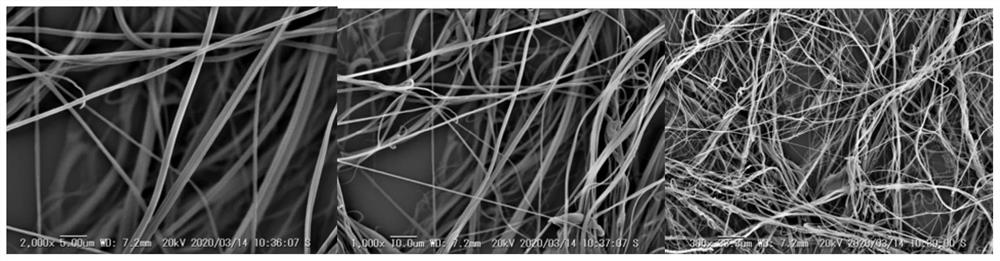

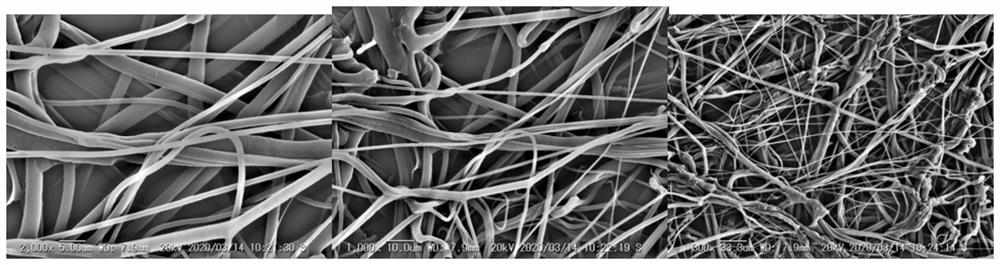

Deep filter element with crude and fine fiber mixed structure and preparation method of deep filter element

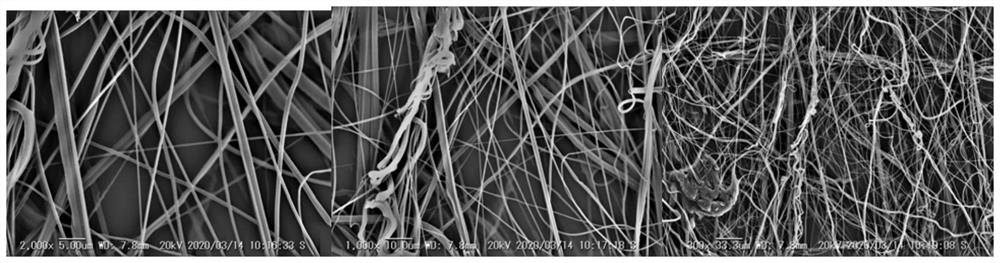

PendingCN111603846AEnsure structural stabilityDoes not increase filter resistanceMembrane filtersMelt spinning methodsCrude fibreFiber diameter

The invention discloses a deep filter element with a crude and fine fiber mixed structure. The deep filter element at least comprises two filtering layers; each filtering layer comprises a crude fiberset and a fine fiber set which are interwoven with each other; the average diameter of the crude fiber set of each filtering layer is reduced from the outer side to the inner side; the average diameter of the fine fiber set of each filtering layer is reduced from the outer side to the inner side; the fiber diameter of the fine fiber set of the innermost filtering layer is not larger than 1 micrometer; the fiber diameter of the crude fiber set of the outermost filtering layer is not smaller than 5 micrometers. The invention further discloses a preparation method of the deep filter element withthe crude and fine fiber mixed structure. The preparation method comprises the following steps of: 1) melt spinning; and 2) receiving a finished screen. The crude coarse fiber sets play a role in bonding the fine fiber sets and play a role in supporting, and therefore, the filter element is prevented from being compressed in a using process, and a dirt containing amount is increased, the fine fiber sets play a role in filtering and intercepting, so that filtering precision is improved, and the filter element has the functions of high filtering precision, high dirt containing capacity and longservice life and is good in filtering effect.

Owner:HANGZHOU COBETTER TECH CO LTD

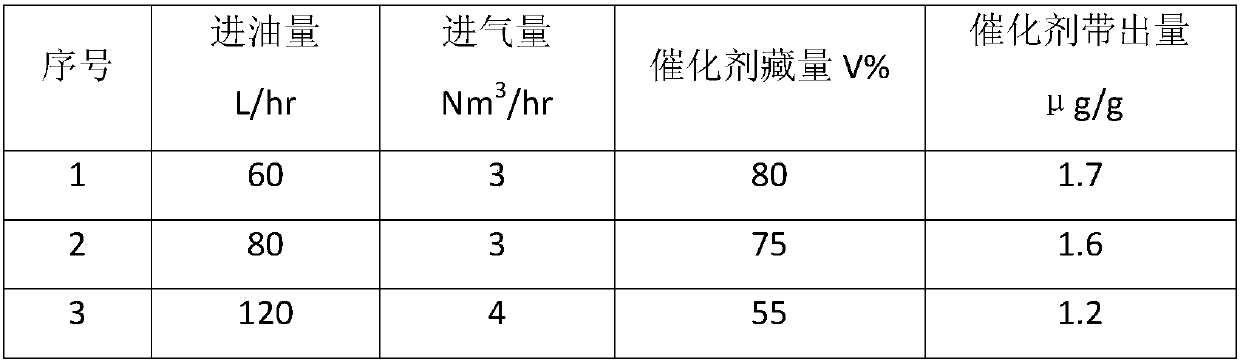

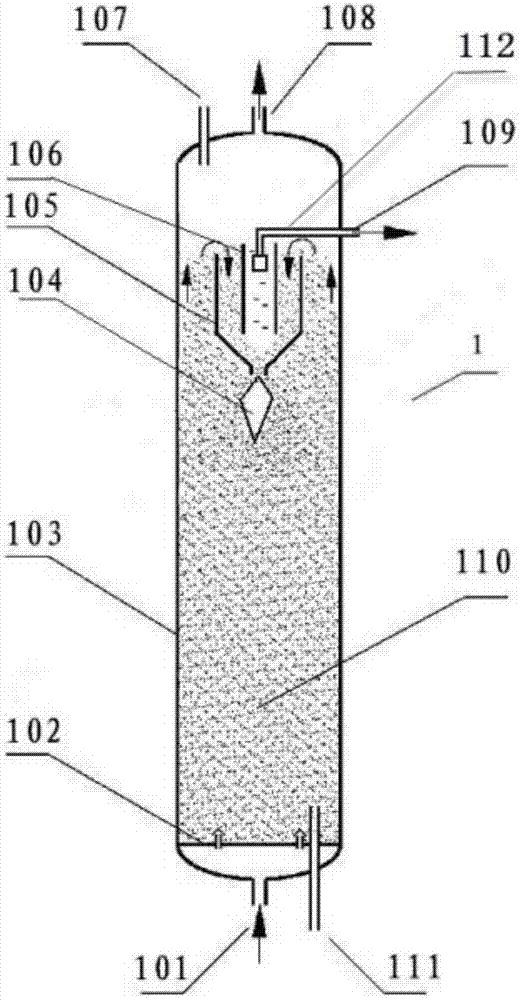

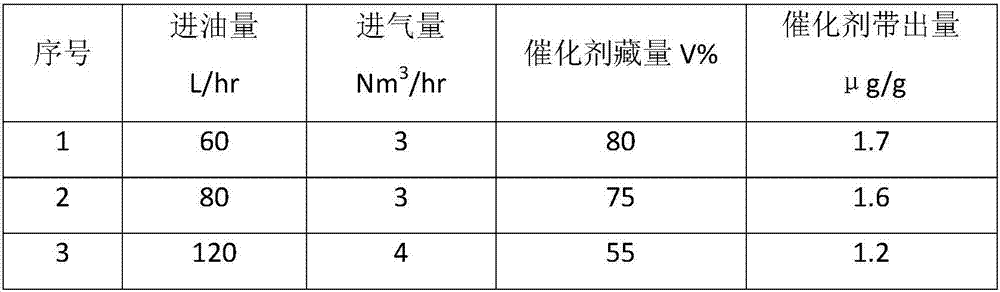

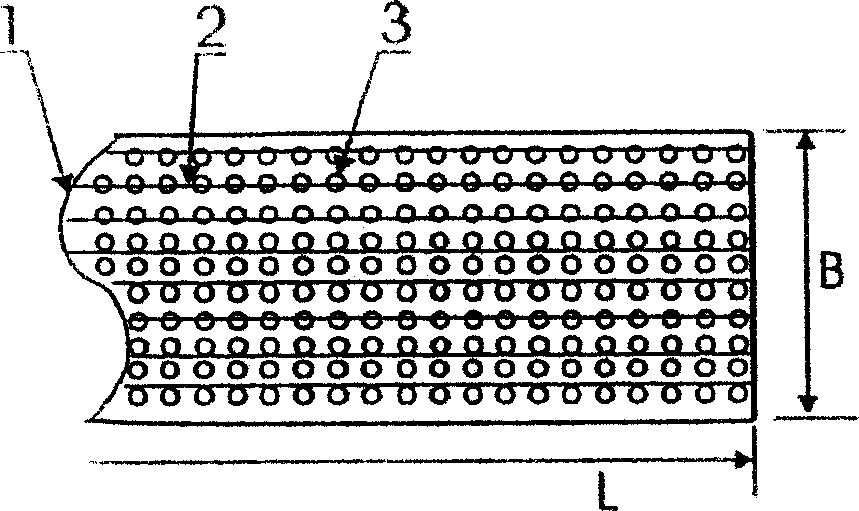

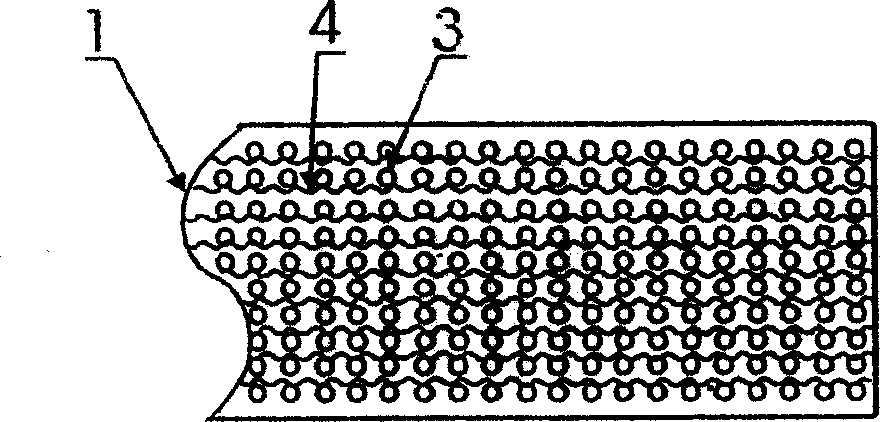

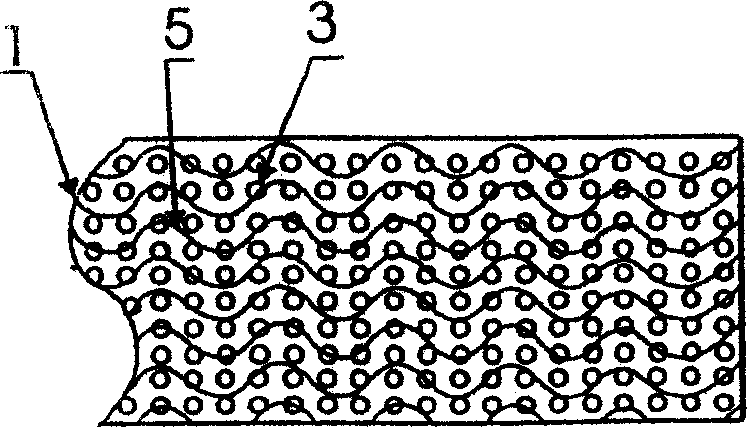

A kind of fluidized bed hydrogenation reaction system and fluidized bed hydrogenation method

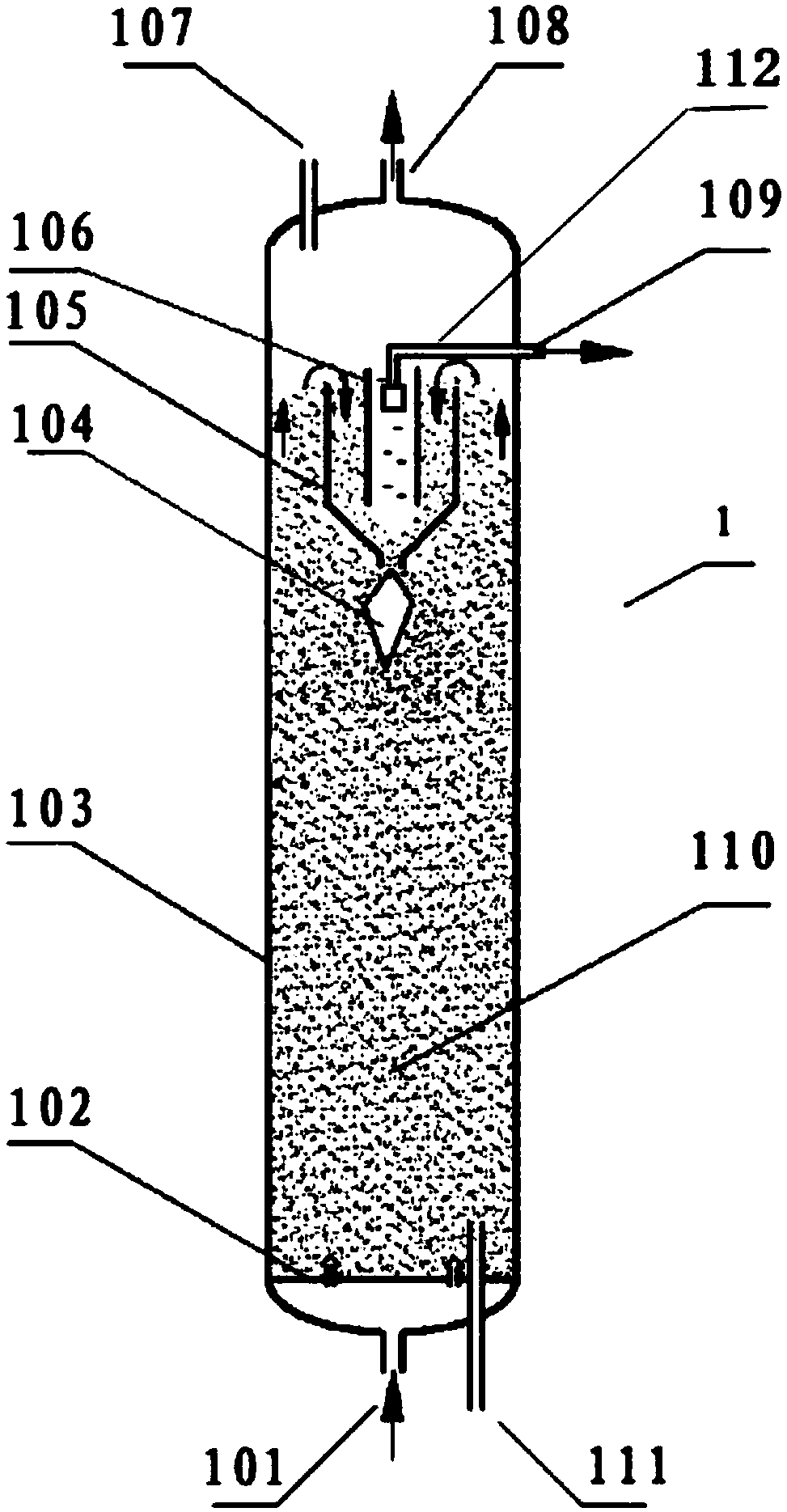

ActiveCN107297186BEasy to separateSolve the resistanceChemical/physical processesHydrogenation reactionFluidized bed

The invention relates to a fluidized bed hydrogenation reaction system, which comprises a fluidized bed reactor, wherein the fluidized bed reactor comprises a reactor barrel; a three-phase separator is arranged at the upper part of the reactor barrel and comprises an inner barrel and an outer barrel; openings are formed in the upper ends and the lower ends of the inner barrel and the outer barrel; the opening in the upper end of the outer barrel is lower than that of the inner barrel and the opening in the lower end of the outer barrel is lower than that of the inner barrel; the inner barrel is a straight barrel segment; the straight barrel segment is arranged at the upper part of the outer barrel and a frustum-shaped contraction segment is arranged at the lower part; the opening in the lower end of the contraction segment is the opening in the lower end of the outer barrel; and a gap is arranged between the opening in the lower end of the inner barrel and the outer barrel contraction segment, so that a material passes through the gap. The fluidized bed hydrogenation reaction system is adopted by the fluidized bed hydrogenation method, so that the utilization rate (namely the catalyst inventory in the reactor) of the reactor is further improved, and the hydrogenation reaction effect can be further improved.

Owner:上海竣铭化工工程设计有限公司

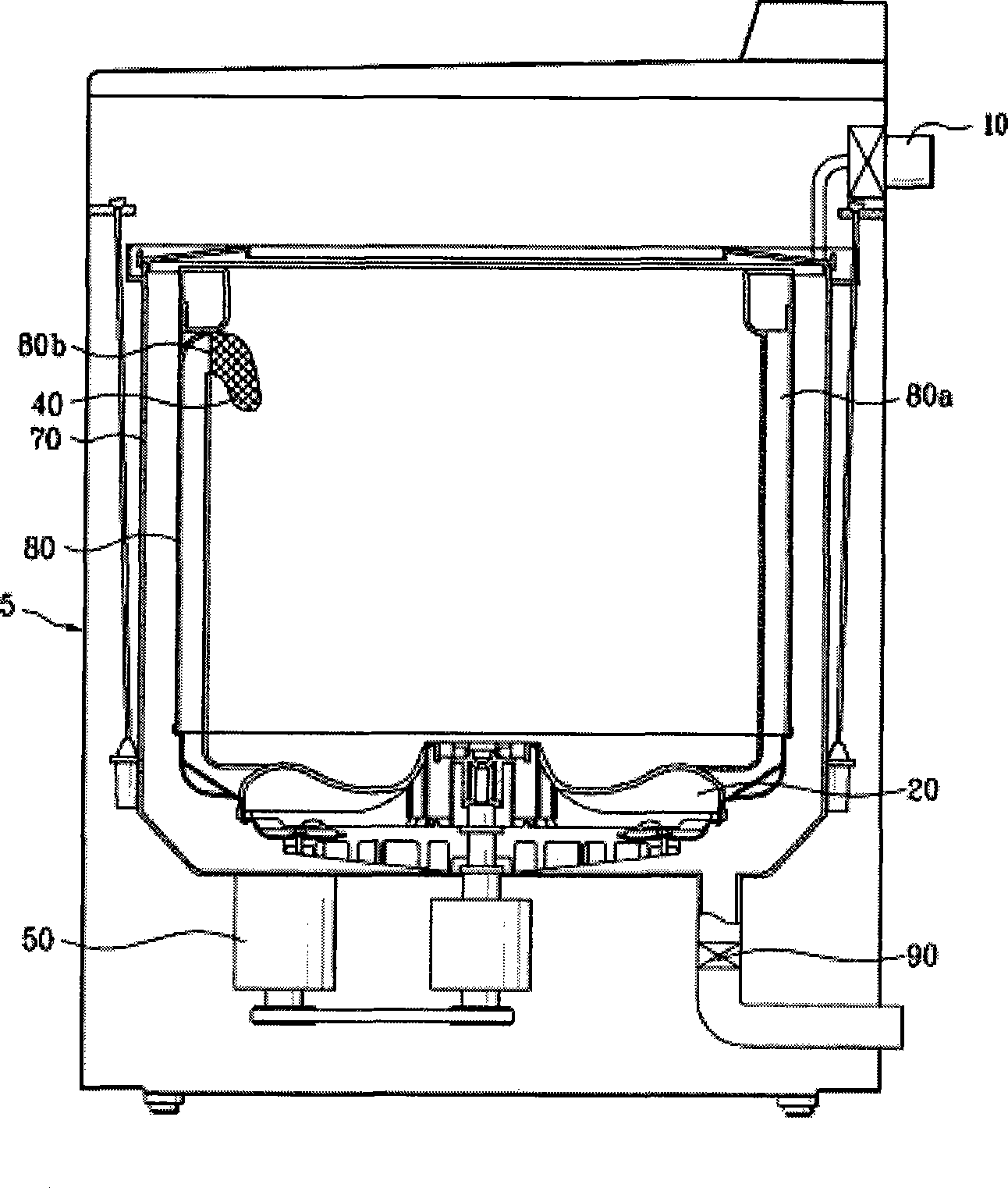

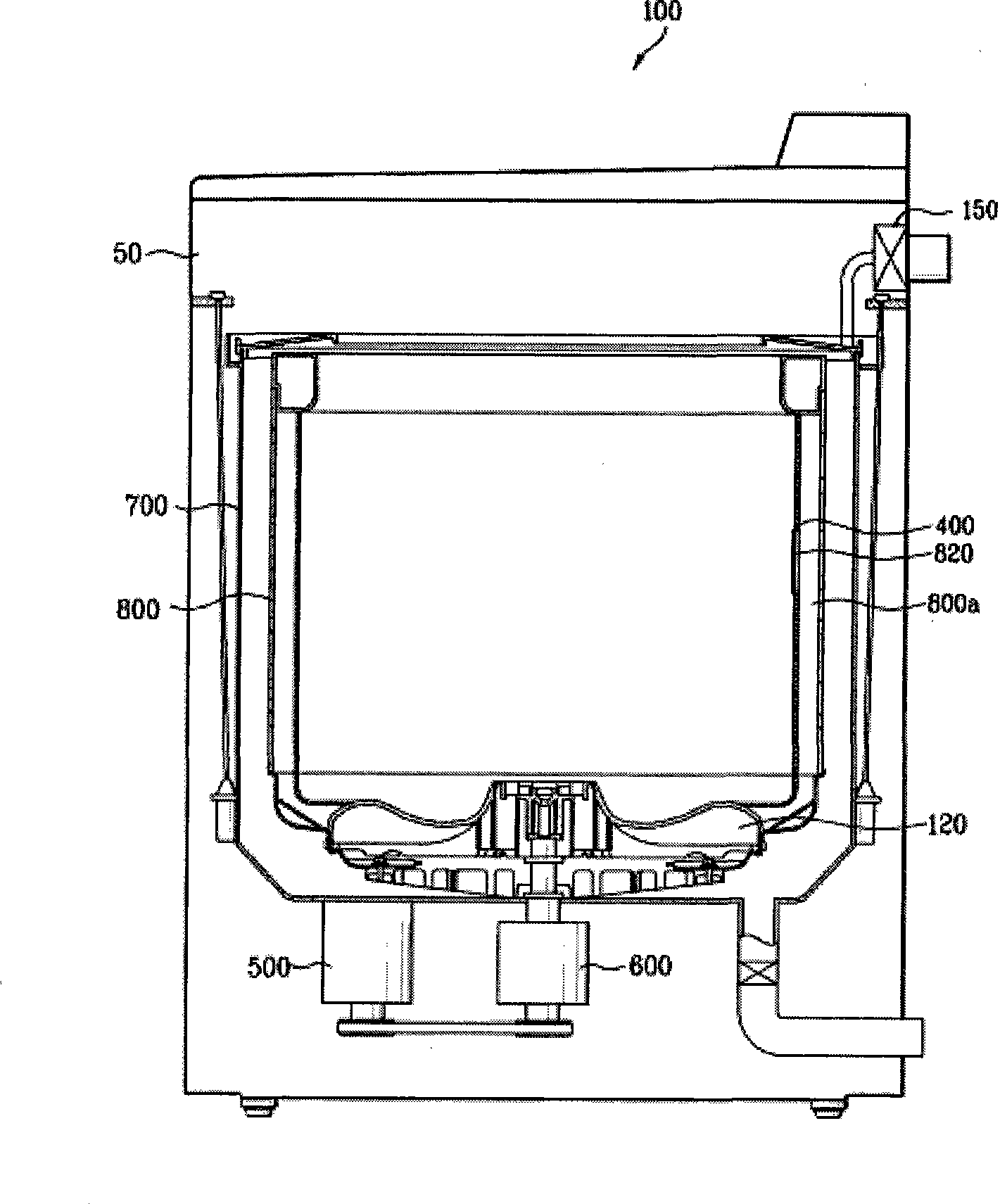

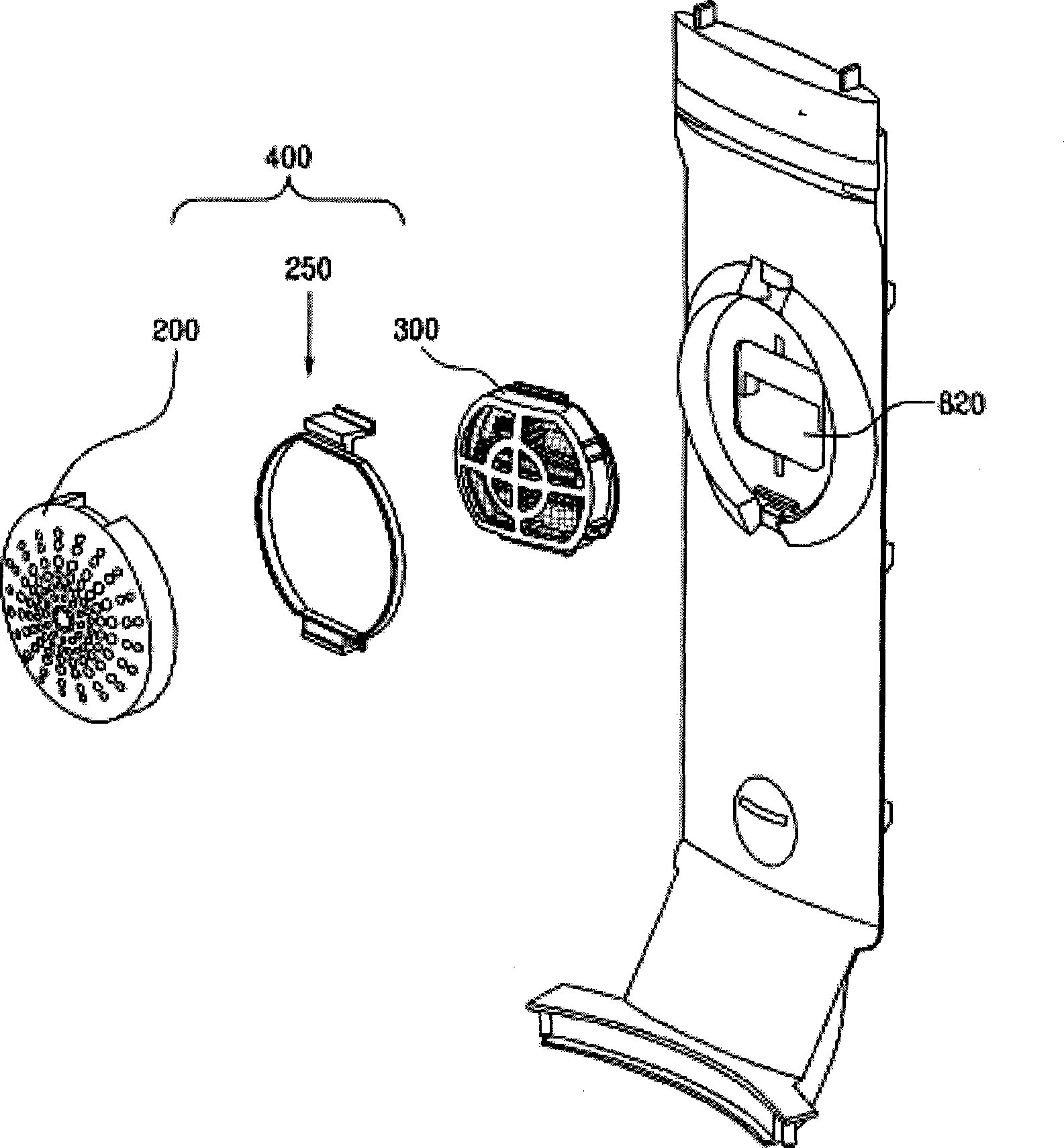

Filtering apparatus of washing machine

InactiveCN101377050AAdd filter functionAvoid damageOther washing machinesTextiles and paperForeign matterWaste management

The invention relates to a washing machine filter, particularly a washing machine filter capable of filtering the foreign matters in the washing water effectively and preventing the washed articles from being damaged while washing. According to the invention, the washing machine filter is disposed at the draining opening formed on the inner side wall of the washing tank for filtering the foreign matters in the washing water pumped out by the revolving force of the washing tank. The washing machine filter is characterized in that it comprises: a cover unit with multiple spraying holes for spraying washing water to the washing tank; and a closed type filter assembly combined with the cover unit in a demountable way for filtering the foreign matters in the washing water from the draining opening while it flowing thereinto.

Owner:NANJING LG PANDA APPLIANCES

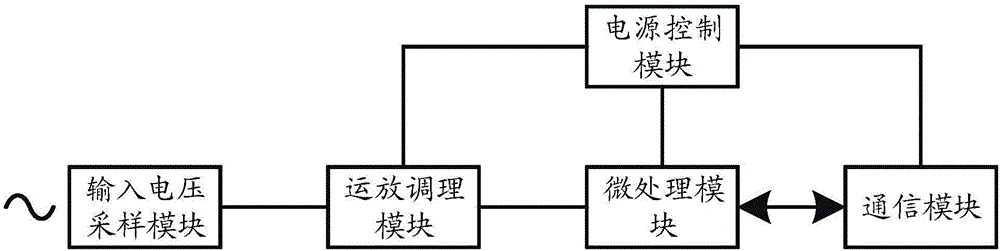

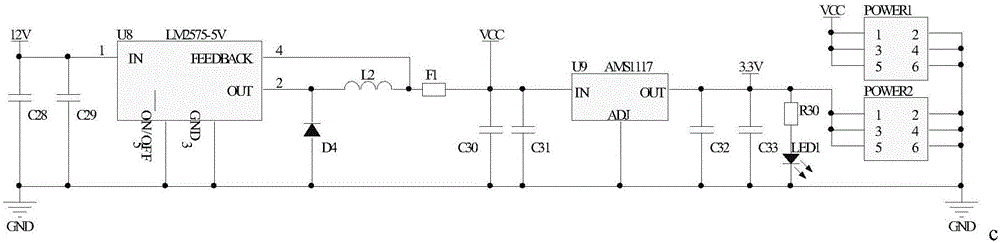

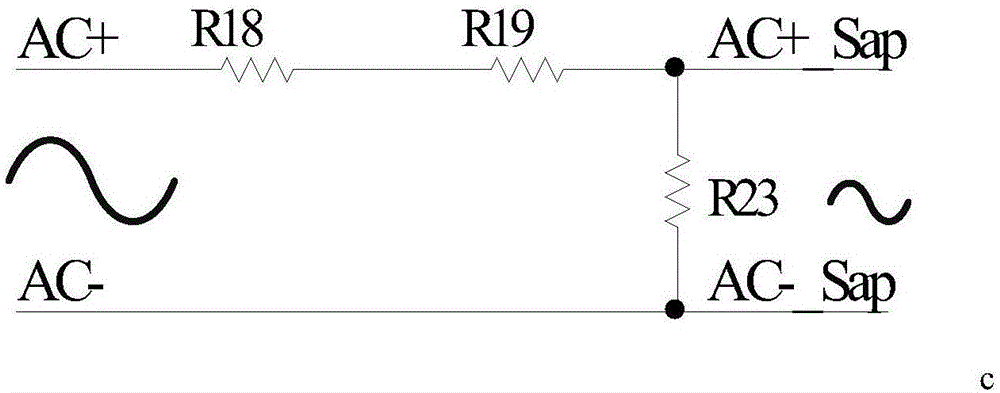

Single phase voltage synchronization signal detection system and method

ActiveCN106680577AHigh precisionEasy to detectMeasurement using digital techniquesEngineeringMaster controller

The invention relates to a single phase voltage synchronization signal detection system. The single phase voltage synchronization signal detection system includes a power control module, an input voltage sampling module, an operational amplifier conditioning module, a micro processing module and a communication module, wherein the power control module is used for supplying power for the system; the input voltage sampling module is used for converting AC (Alternating Current) commercial power voltage into a 1-2.5V AC signal; the operational amplifier conditioning module is used for performing differential amplification and conditioning on the AC signal output from the input voltage sampling module and outputting an AC signal which changes according to a sine rule; the micro processing module is used for performing AD sampling on the AC signal output from the operational amplifier conditioning module, and obtaining a synchronization signal of AC voltage through comparison and determination of the obtained signal through sampling; and the communication module is used for realizing communication between a USB and a serial port. The invention also includes a single phase voltage synchronization signal detection method. By means of the single phase voltage synchronization signal detection system and method, and by means of combination of the advantages of hardware and the advantages of software, detection and output of the synchronization signal with high accuracy can be realized; communication between the synchronization signal and other main controllers becomes convenient; and the single phase voltage synchronization signal detection system and method have a wide application range.

Owner:SHANGHAI ZHONGKE SHENJIANG ELECTRIC VEHICLE

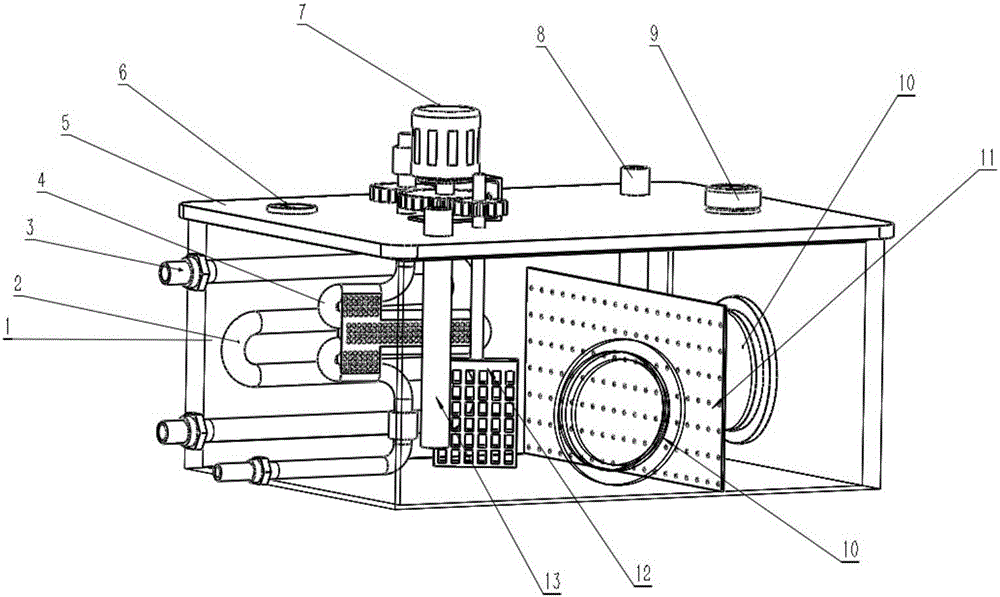

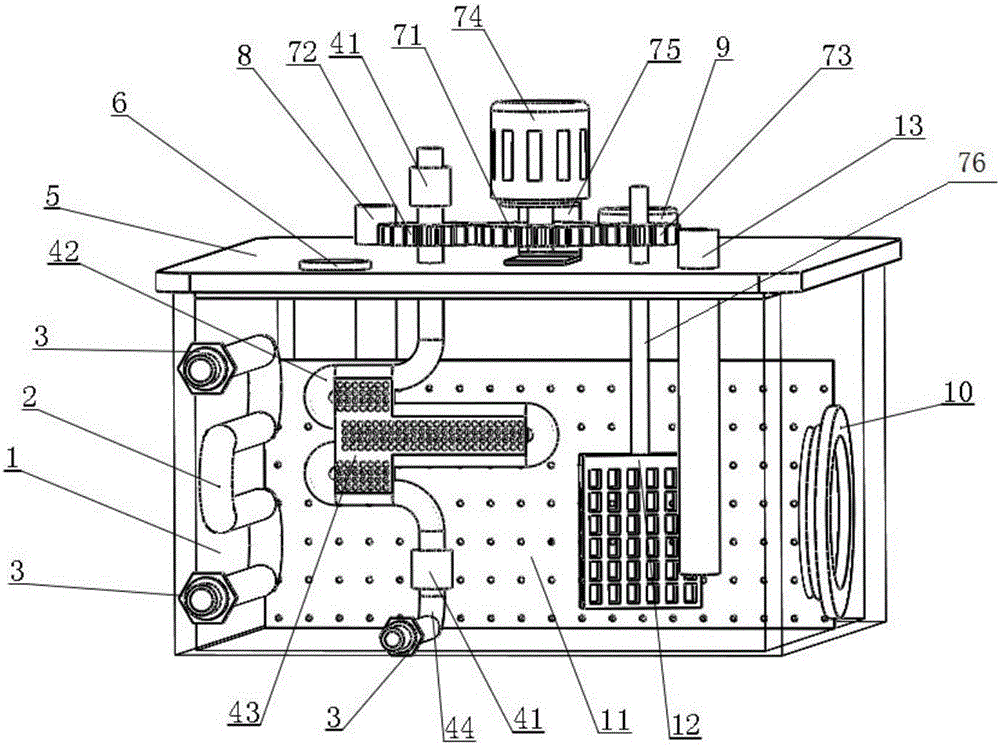

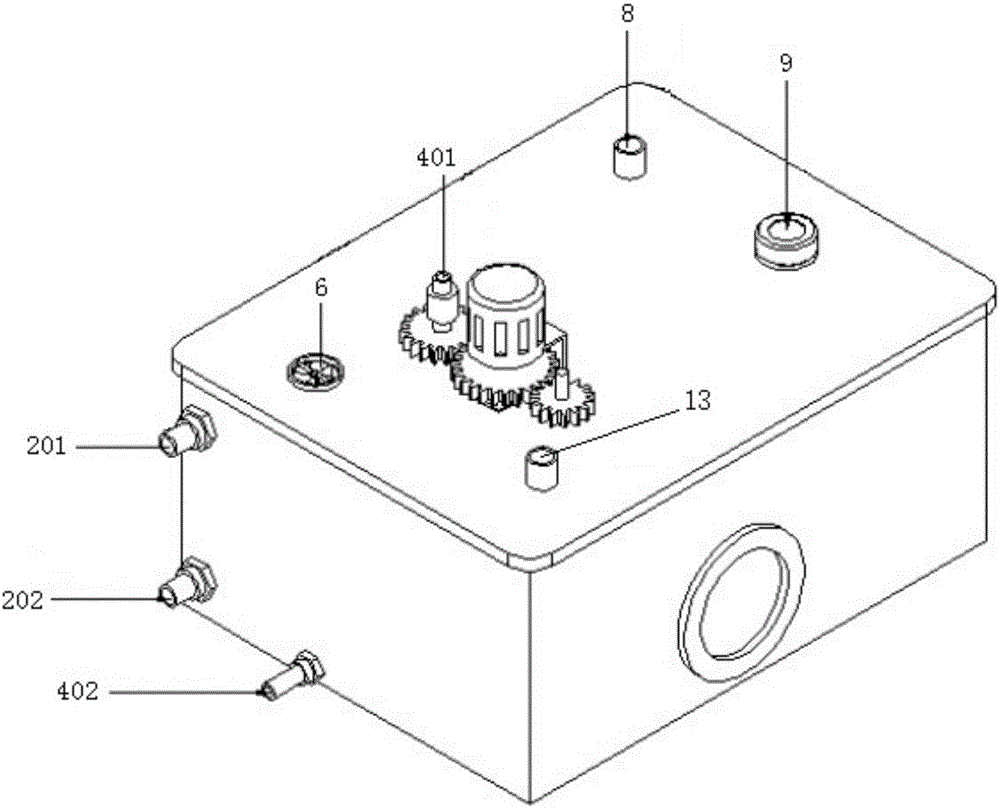

Efficient integrated oil tank integrating functions of settlement, cooling, filtration and adsorption and application of efficient integrated oil tank

ActiveCN105736487AOptimize layoutAdd filter functionPump assembliesFluid-pressure actuator componentsFiltrationFuel tank

The invention relates to an efficient integrated oil tank integrating functions of settlement, cooling, filtration and adsorption and application of the efficient integrated oil tank. The integrated oil tank comprises a tank body, wherein a tank cover is arranged above the tank body, and is provided with an oil inlet pipe and an oil outlet pipe, a filter screen is arranged in the tank body, and divides the interior of the tank body into a left chamber and a right chamber, a sidewall cooling pipe is arranged in the left chamber, the oil inlet pipe is arranged in the right chamber, and the oil outlet pipe is arranged in the left chamber. A rotary cooling adsorption system is further arranged on the tank body, and can improve cooling and adsorption effects on hydraulic oil. Compared with the prior art, a rotatable cooling pipe, the filter screen and the rotary cooling adsorption system are added, and impurity settlement and filtering of the hydraulic oil and cooling of oil temperature can be completed. Meanwhile, the devices are all arranged in the oil tank, so that the outer space is saved and the arrangement of other hydraulic components is facilitated, diverse functions are integrated, the work efficiency is improved and the work space is saved.

Owner:SHANDONG UNIV OF SCI & TECH

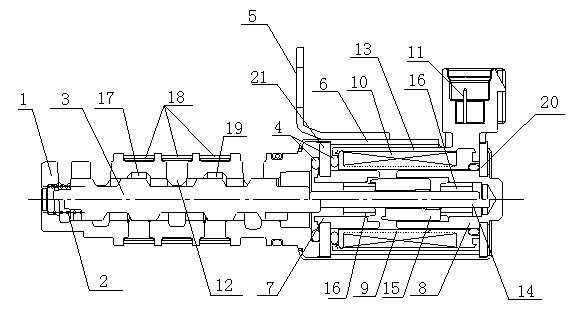

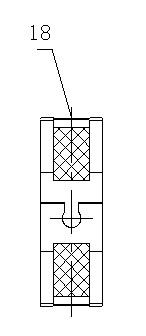

Large-flow continuous variable valve timing (CVVT) fuel control valve with filter screen

InactiveCN102003233AAdd filter functionHigh working reliabilityValve arrangementsDispersed particle filtrationForeign matterEntrance angle

The invention discloses a large-flow continuous variable valve timing (CVVT) fuel control valve with a filter screen. The large-flow CVVT fuel control valve with the filter screen comprises a valve bush component, a rear yoke iron component, a front yoke iron component, an iron core component, a winding component and an outer yoke sleeve component, wherein the valve bush component consists of a valve bush (1), a return spring (2), a valve core (3) and a ring; the valve bush (1) is provided with a fuel feed port (12), an entrance angle oil port (17) and a lag angle oil angle (19); and the fuel feed port (12), the entrance angle oil port (17) and the lag angle oil angle (19) are pressed into the filter screen (18) respectively. The large-flow CVVT fuel control valve with the filter screen controls the fuel flow to increase by 50 percent, improves the quick response time of a valve timing actuator, increases a filtering function of the filter screen, effectively protects foreign matters from entering the fuel control valve, guarantees that the valve core can slide in the valve bush freely, reduces the possibility of the clamping stagnation of the valve core, increases the working reliability of a valve timing system, reduces the requirements of a motor on the using environment and prolongs the service life of a product.

Owner:成都恒高机械电子有限公司

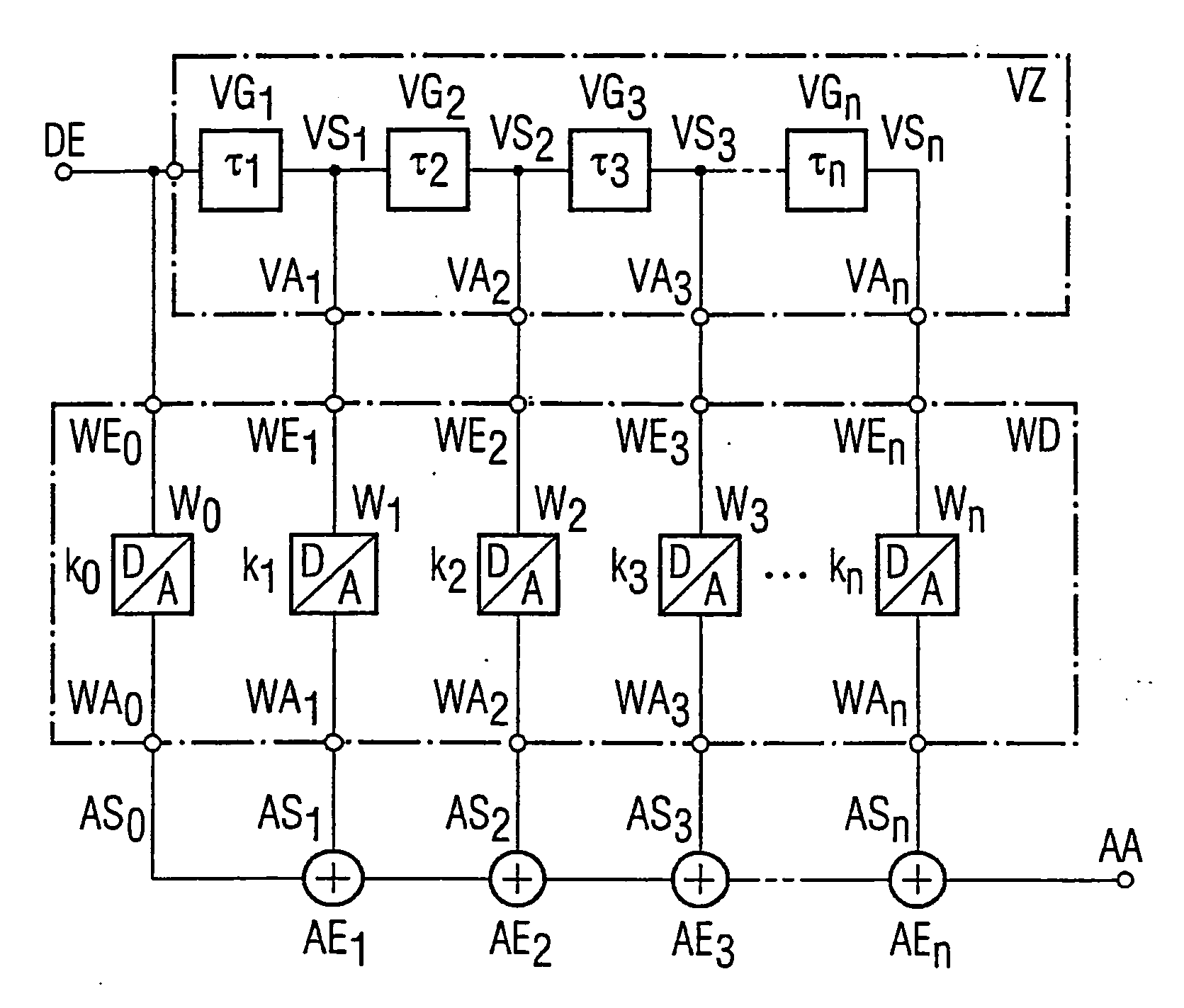

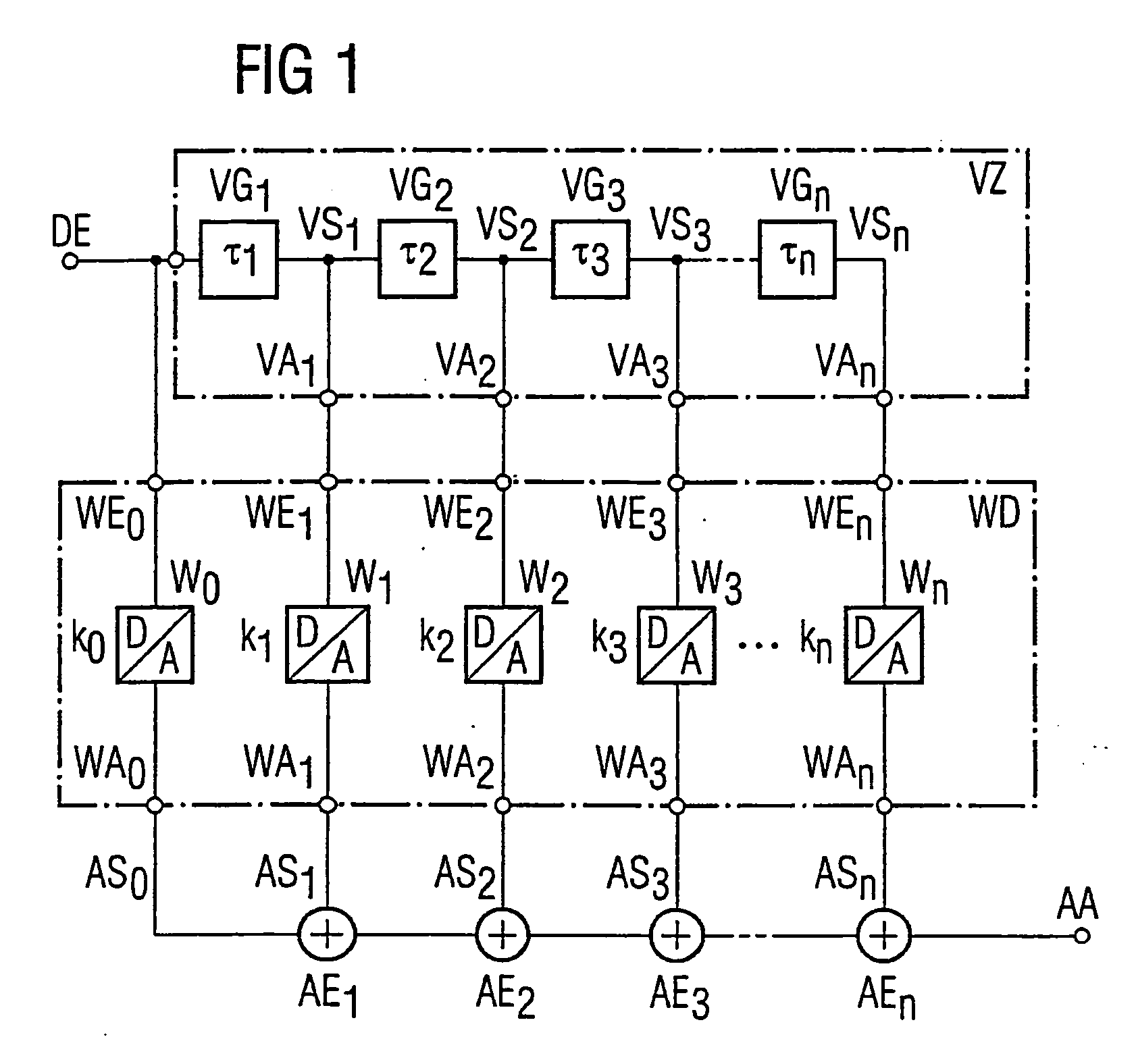

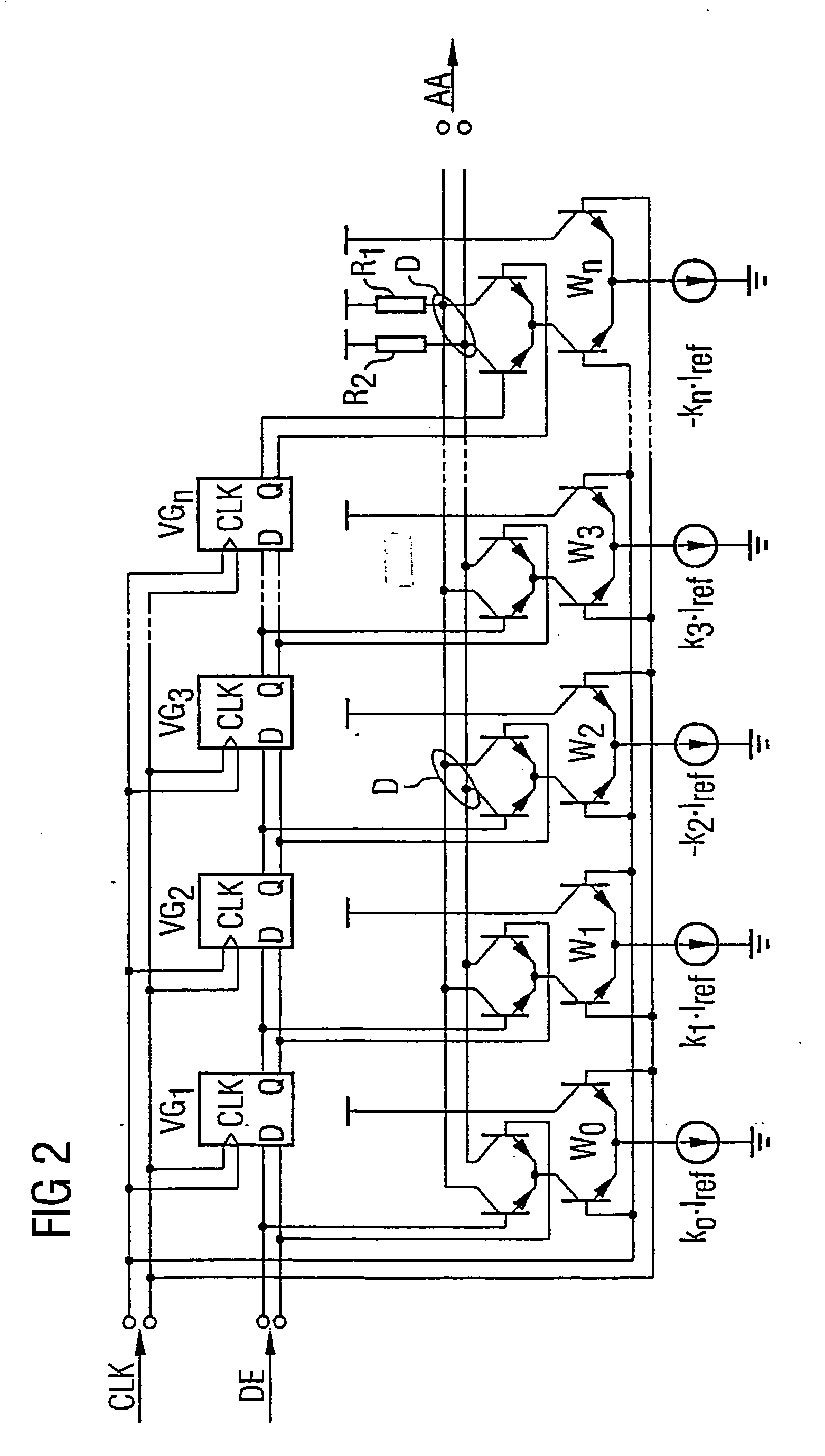

Configuration for digital-analog conversion of high-frequency digital input signal into carrier-frequency analog output signal

InactiveUS20060164275A1Quality improvementReduce expenditureElectric signal transmission systemsDelta modulationDigital inputDigital analog

A delay device has at least one first delay element and optional additional delay elements connected downstream from the first in a serially consecutive manner. The digital input signal is connected to an input of the first delay element and is connected to an input of a first D / A converter. The output of the first delay element is connected to an input of another D / A converter assigned thereto. The optional additional delay elements each have outputs connected to an input of another D / A converter assigned to the respective delay elements. All D / A converters are combined on the output side in a step-by-step manner so that output signals of all D / A converters form the analog output signal or the device. A specific coefficient is assigned to each D / A converter, and a specific delay time is assigned to each delay element for realizing a filter characteristic.

Owner:HMD GLOBAL

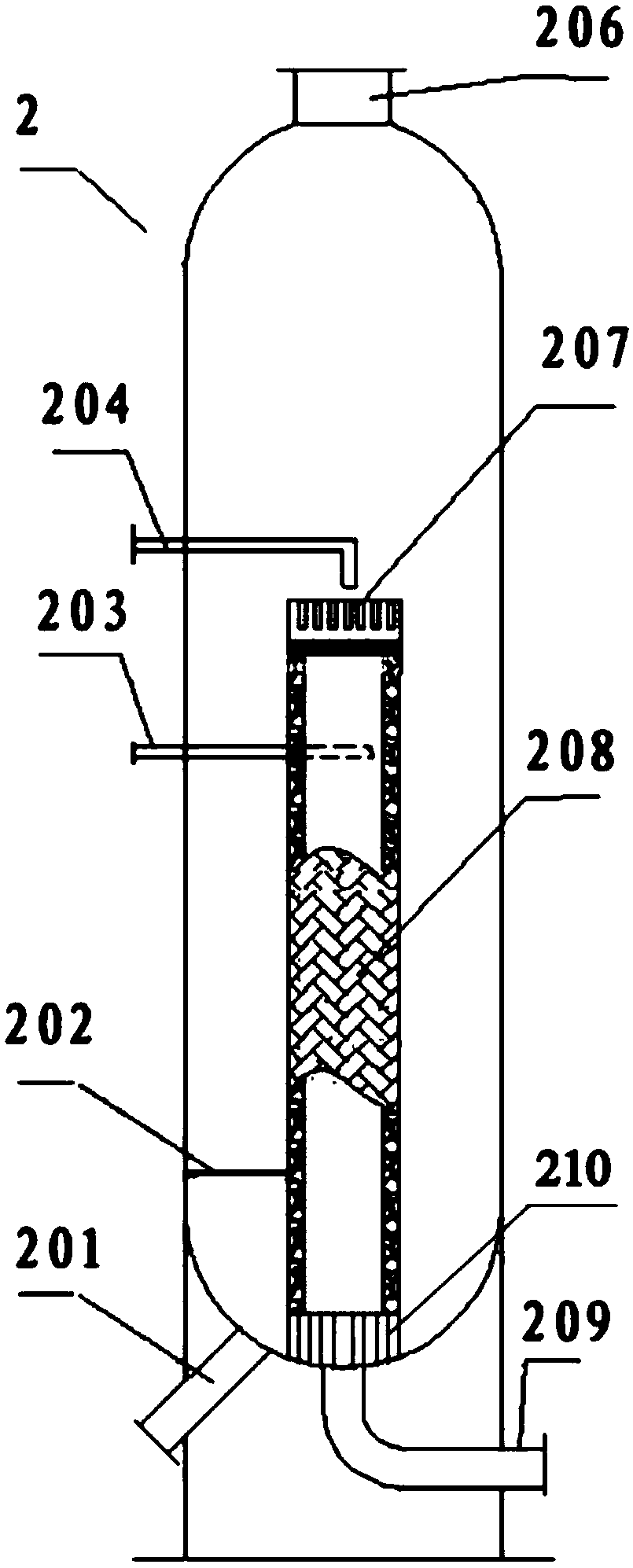

Continuous composite environmental-friendly filter

InactiveCN101648088AImprove filtration and cleaning functionsThe body structure is compact and reasonableLoose filtering material filtersGravity filtersFlexible fiberOil pressure

The invention relates to a continuous composite environmental-friendly filter. The inside of a main body of the filter is provided with a density regulator and a plurality of fiber plates, wherein theplurality of fiber plates are sequentially and orderly arranged; and a multi-layer environmental-friendly filter material is arranged between the adjacent fiber plates. The environmental-friendly filter material is made from flexible fiber bundles, and has the density divided into a plurality of different layers from top to bottom. The density regulator consists of a regulating part, a stretchingpart and a screw; the screw is connected with a handwheel outside the main body of the filter, and the regulating part can consist of a gear set or an oil pressure component. The regulating part is connected with one end of the screw and the stretching part respectively; and one end of the stretching part is connected with the fiber plates, while the other end is connected with the inner side surface of the main body of the filter. The filter drives the fiber plates to squeeze or release the environmental-friendly filter material through the stretching part so as to control the density of theenvironmental-friendly filter material, not only improves the functions of filtration and cleaning of an organism, but also realizes the effect of deep filtration, and can be widely applied to the continuous filtration of liquids.

Owner:上海久洁科技有限公司

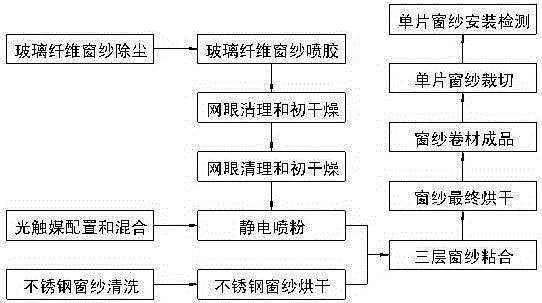

Window screen based on electrostatic adsorption and photocatalysts

ActiveCN105298369AActive adsorptionWith electrostatic adsorption functionDispersed particle separationInsect protectionEconomic benefitsEngineering

The invention provides a window screen based on electrostatic adsorption and photocatalysts and belongs to the technical field of building materials. The window screen comprises meshes and is characterized by being provided with a drive plate. The meshes comprise an external conduction mesh, a middle insulation mesh and an internal conduction mesh. The external conduction mesh and the internal conduction mesh are connected with a positive electrode and a negative electrode of the drive plate through connectors respectively. The surface of the middle insulation mesh is covered with the nanometer photocatalysts. The sterilizing ability, the disinfecting ability and the ability to remove organic pollutants in air of the window screen are improved. The window screen is a healthy and environment-friendly window screen which belongs to the field of the building materials, and market demands are large; meanwhile, according to the window screen, specific technical parameters and the production process are put forward, high operability is achieved, and therefore economic benefits are considerable after the window screen is industrialized.

Owner:YANGZHOU UNIV

Fluidized bed hydrogenation reaction system and fluidized bed hydrogenation method

ActiveCN107297186AEasy to separateSolve the resistanceChemical/physical processesHydrogenation reactionFluidized bed

The invention relates to a fluidized bed hydrogenation reaction system, which comprises a fluidized bed reactor, wherein the fluidized bed reactor comprises a reactor barrel; a three-phase separator is arranged at the upper part of the reactor barrel and comprises an inner barrel and an outer barrel; openings are formed in the upper ends and the lower ends of the inner barrel and the outer barrel; the opening in the upper end of the outer barrel is lower than that of the inner barrel and the opening in the lower end of the outer barrel is lower than that of the inner barrel; the inner barrel is a straight barrel segment; the straight barrel segment is arranged at the upper part of the outer barrel and a frustum-shaped contraction segment is arranged at the lower part; the opening in the lower end of the contraction segment is the opening in the lower end of the outer barrel; and a gap is arranged between the opening in the lower end of the inner barrel and the outer barrel contraction segment, so that a material passes through the gap. The fluidized bed hydrogenation reaction system is adopted by the fluidized bed hydrogenation method, so that the utilization rate (namely the catalyst inventory in the reactor) of the reactor is further improved, and the hydrogenation reaction effect can be further improved.

Owner:上海竣铭化工工程设计有限公司

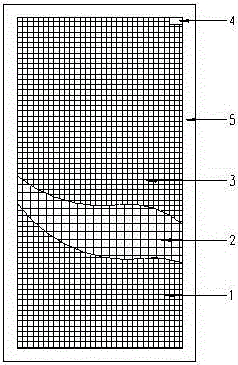

Paper for enclosing filter-tip of cigarette having porous and groove structure

InactiveCN1718122AMix well and evenlyEffective filteringTobacco smoke filtersVolumetric Mass DensityBiomedical engineering

A wrapping paper with millipores and slots for the tip filter of cigarette features that it has at least two slots in its width direction, multiple slots in its length direction and multiple millipores with the diameter less than 2 mm and the density of 4-500 / sq.cm. Its advantages are the scientifically controlled air permeability and high filtering effect.

Owner:曾立 +1

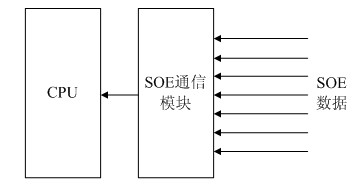

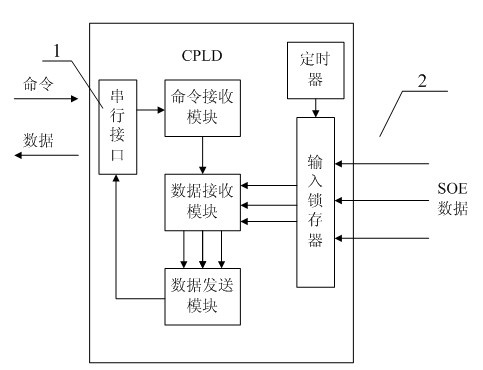

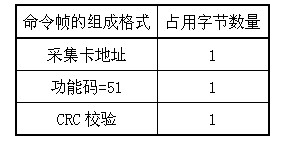

SOE (sequence of event) acquisition card and acquisition method thereof

InactiveCN102566460AIncrease the number of collectionsImprove processing efficiencyProgramme control in sequence/logic controllersElectric power systemComplex programmable logic device

The invention discloses an SOE (sequence of event) acquisition card and an acquisition method thereof, and belongs to the field of electric power systems. According to the SOE acquisition card disclosed by the invention, CPLDs (complex programmable logic devices) are increased between a SOE communication module and parallel channels for being used as the SOE acquisition cards, one CPLD can receive data from a plurality of the parallel channels, and when the data is uploaded, only one I / O (input / output) port in the SOE communication module is required, so that the acquisition quantity of the SOE data can be expanded; the processing of the SOE data is respectively performed in the CPLDs, and the SOE data does not need to be transmitted to a CPU (central processing unit) for unified processing, so that the data processing efficiency is further improved and the resolution capability of events can be further improved; and furthermore, a timer and an input latch are increased, so that the filtering function of the SOE data is increased and the possible external interference is eliminated.

Owner:CHONGQING UNIV

Clean sealed boiler flue gas desulfurization and denitration device with filtering function

InactiveCN109248550AEasy to clean and unclogImprove sealing performanceDispersed particle filtrationHollow article cleaningDrive motorEngineering

The invention discloses a clean sealed boiler flue gas desulfurization and denitration device with a filtering function. The device comprises a boiler body, a placement strip, a cooling tower, a fixing ring, and a water pump, the upper end of the boiler body is seamlessly connected with a smoke-outlet pipe, the outer wall of the cooling tower is seamlessly connected to the input end of a smoke-inlet pipe, the output end of a driving motor is flanged to a rotating shaft, the fixing ring is fixedly welded to the inner bottom end of the cooling tower, and the output end of a condensing tube is injection-connected to a collecting pipe. The clean sealed boiler flue gas desulfurization and denitration device with filtering function has a connection manner of slot connection between the smoke-outlet pipe and the connecting pipe and between the connecting pipe and the smoke-inlet pipe, a user can conveniently perform disassembly and assembly between the smoke-outlet pipe and the connecting pipe and between the connecting pipe and the smoke-inlet pipe, the situation that the pipe connection is too long and the inside is prone to blockage is avoided, so that the user can timely dredge and clean the inside of the pipe, and a sealing gasket is beneficial to increase of the sealing performance between the pipes.

Owner:余汉锡

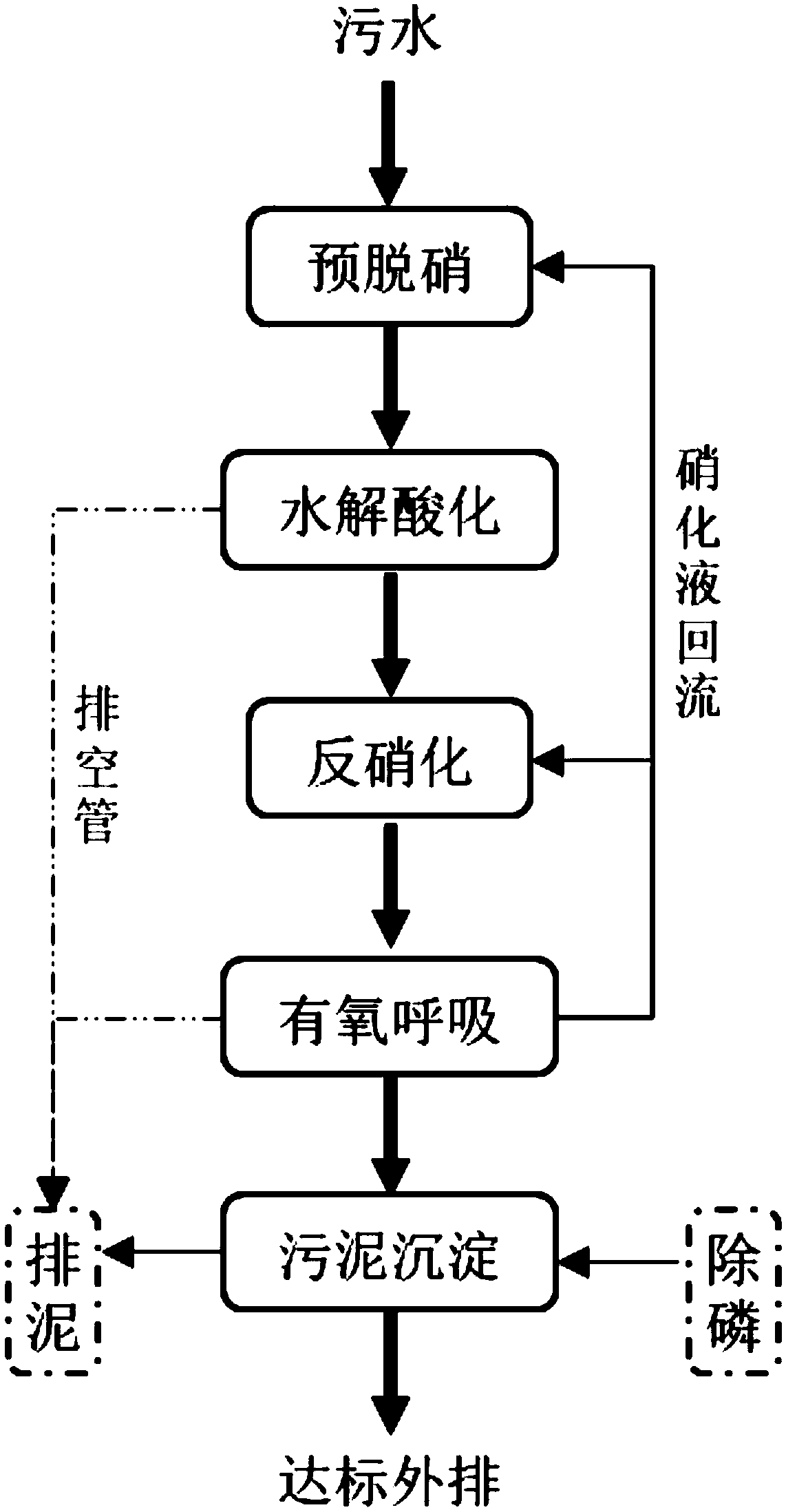

Sewage treatment method based on A<3>/O-BAF process

InactiveCN109019835AAdd filter functionIncrease varietyTreatment using aerobic processesWater contaminantsActivated sludgeReflux

The invention relates to the technical field of sewage treatment, and discloses a sewage treatment method based on an A<3> / O-BAF process. The method comprises the following main steps: pre-denitrification, hydrolysis acidification, denitrification, aerobic respiration and sludge sedimentation. A filtering function is adopted and improved in order to meet solid-liquid separation requirements of high sludge concentration and subsequent sedimentation in the aerobic respiration; and nitrification liquid reflux and sludge discharge measures are adopted to make the sewage treatment achieve high-efficiency nitrogen and phosphorus removal operation. The sewage treatment method integrates an activated sludge process (A / O) and a biomembrane process (BAF), fully utilizes the advantages of the processes to complement each other, and has the advantages of small occupied area, low cost, low noises, environmental protection, high efficiency and energy saving; and effluent water is superior to grade Astandards of Discharge Standard of Pollutants for Municipal Wastewater Treatment Plant (GB18918-2002).

Owner:GUANGZHOU RESOURCE ENVIRONMENTAL PROTECTION TECH CO LTD

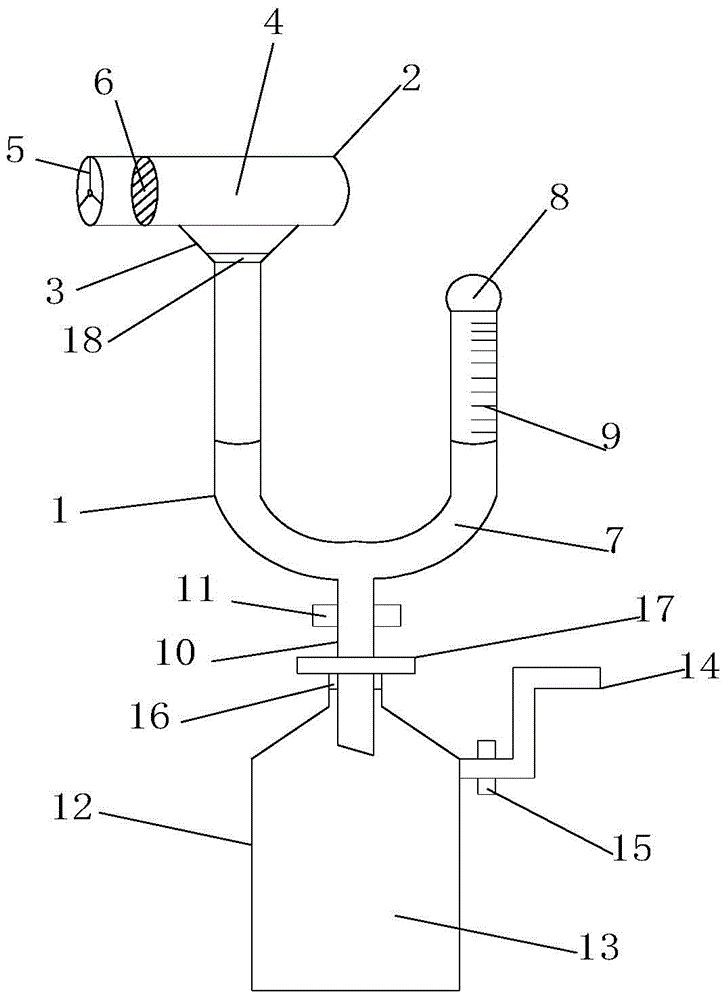

Device for detecting, filtering, and gathering microbes in air

InactiveCN105039148AAvoid enteringAvoid cloggingBioreactor/fermenter combinationsBiological substance pretreatmentsBottleIndustrial engineering

The invention discloses a device for detecting, filtering, and gathering microbes in the air. The device comprises a detection device, an air-suction device, and a gathering device; the detection device is communicated with the air-suction device through a connection member, the air suction device is composed of a sleeve and a fan, a first filtering screen is arranged in the sleeve and the joint between the sleeve and the fan, the detection device is composed of a U-shape pipe and a plug, one end of the U-shape pipe is connected to the connection member, the other end is connected to the plug, the joint between the U-shape pipe and the plug is provided with a scale, the detection device is communicated with the gathering device through a communication pipe, a valve is arranged on the communication pipe, the gathering device is composed of a gathering bottle and a vacuumizing pipe, a unidirectional valve is arranged on the vacuumizing pipe, and the opening of the gathering bottle is provided with a rubber sealing ring. The device has the advantages of simple structure, convenient operation, low investment cost, high detection precision, and obstruction resistant performance.

Owner:UNIV OF JINAN

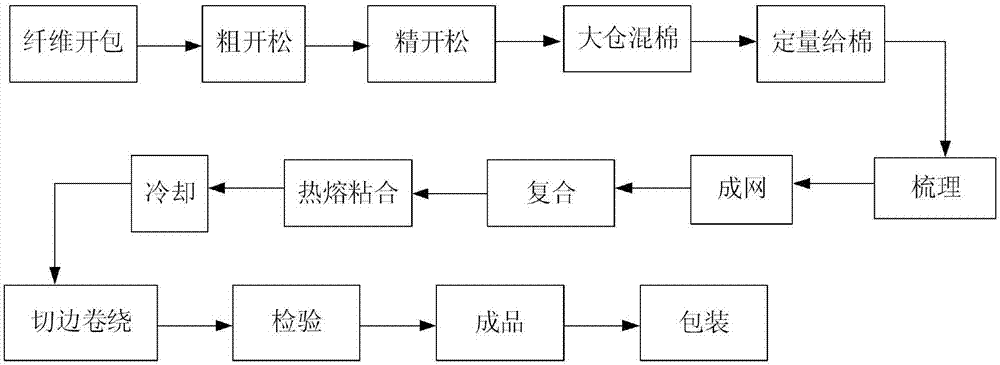

Production process of hot-molten non-woven fabric electrostatic fiber filter screen

InactiveCN106863868AOvercome sticking and rollingHigh technology contentNon-woven fabricsDomestic netsPolymer scienceHot melt

The invention relates to a production process of a hot-molten non-woven fabric electrostatic fiber filter screen, and belongs to the technical field of new material processing. The production process comprises the following steps of firstly, fiber unpacking and mixing, secondly, carding, thirdly, web forming, fourthly, compounding, fifthly, hot melting bonding, sixthly, cooling and seventhly, edge cutting, winding and packaging. According to the production process, the hot-molten non-woven fabric electrostatic fiber filter screen can be obtained without adopting an electret technology. Odorless electrostatic adsorbed polypropylene fibers are adopted as raw materials, a hot-molten non-woven fabric production process method is utilized, in the carding process, electrostatic rods with the polarity opposite to that of the odorless electrostatic adsorbed polypropylene short fibers are arranged in front of a carding machine, meanwhile, a humidifier is mounted below the carding machine, and it is guaranteed that relative humidity in the carding process is 60% or above; and under the combined action of the electrostatic rods and the humidifier, electrostatic fibers overcome the electrostatic fiber bonding phenomenon in the carding process, and the hot-molten non-woven fabric electrostatic fiber filter screen is manufactured.

Owner:JILIN PROVINCE HUAFANG ELECTROSTATIC MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com