Continuous composite environmental-friendly filter

A filter and environmental protection technology, applied in the direction of gravity filter, loose filter material filter, filtration and separation, etc., can solve the problems of increasing the adsorption volume of the filter material, shortening the resource use time, speeding up the filter material, etc., to improve the filtration efficiency. Cleaning function, compact and reasonable body structure, and the effect of restoring filtration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

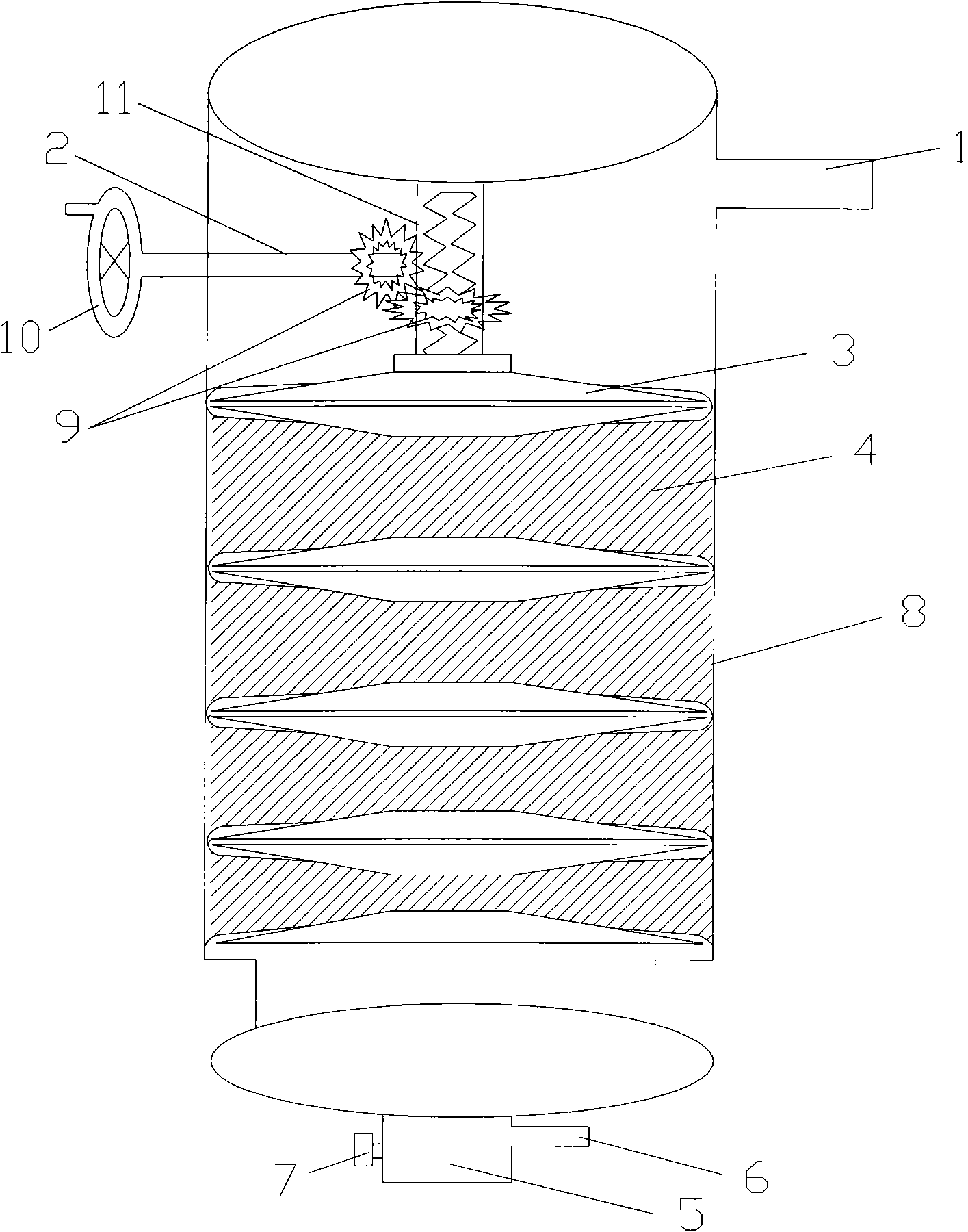

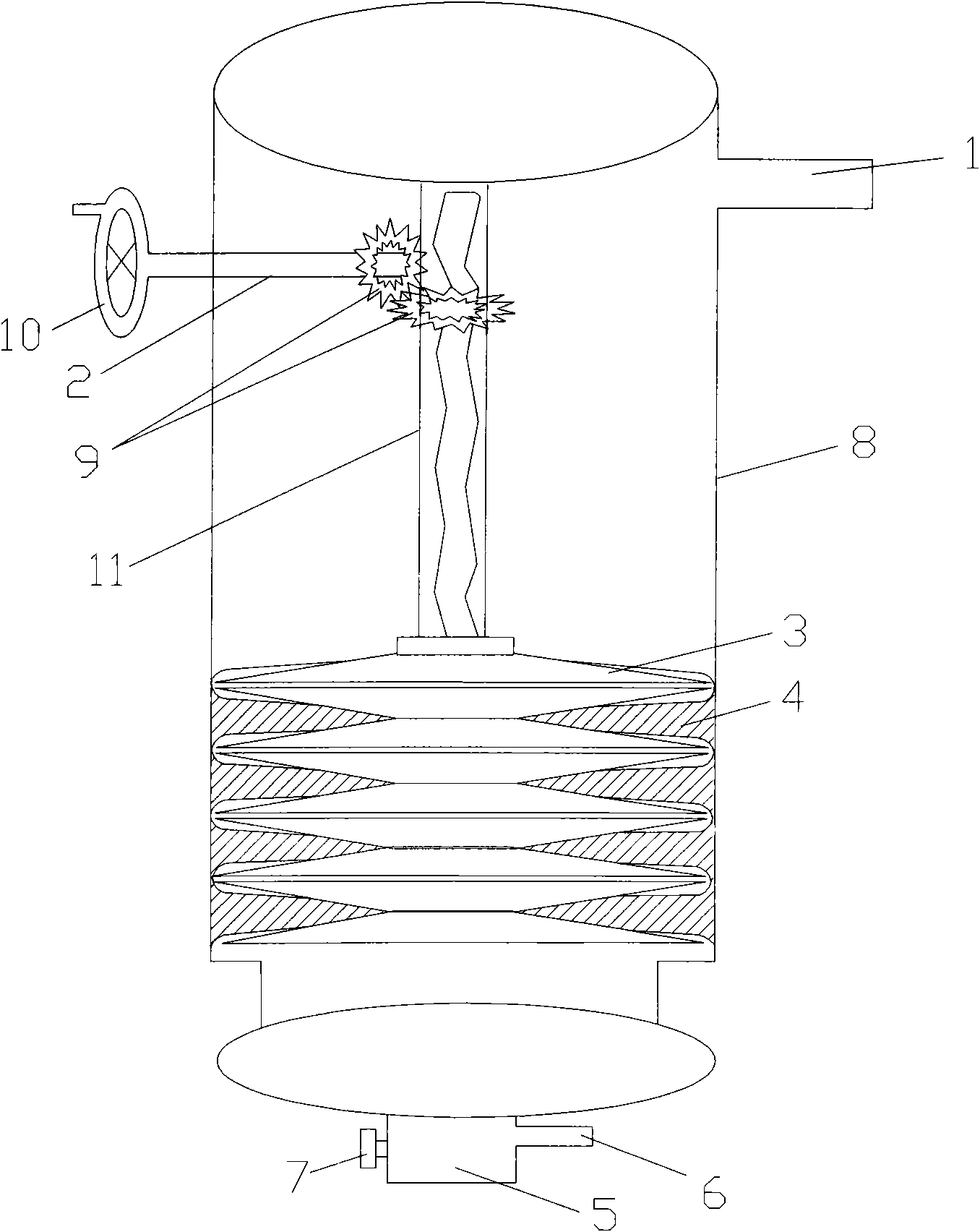

[0024] figure 1 It is a schematic diagram of the internal structure of the present invention, including a filter body 8 , a fiber disc 3 , an environmental protection filter material 4 , an adjustment component 9 , a screw 2 , a manual turntable 10 and a stretching component 11 . The outer surface of the filter main body 8 is provided with a water inlet pipe 1 connected to the filter main body 8, and a density regulator and a fiber disc 3 are arranged inside, and the density regulator is composed of a stretching part 11, an adjusting part 9 and a screw rod 2 , the adjusting part 9 can be constituted by a gear set or a hydraulic part, and the hydraulic part can adjust the stretching part 11 manually or automatically. The gear set is provided with two gears, and the two gears are connected in a vertical and horizontal meshing manner, wherein the vertical gear is connected to one end of the screw 2, and the horizontal gear is arranged on the surface of the tensile member 11 . T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com