Shaftless reverse radial turbine blade steam generator

A reverse type, generator technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of unreasonable steam generator structure, large impact force between blades and steam particles, and inability to work continuously, achieving It is conducive to automatic control and remote operation, the body structure is compact and reasonable, and the effect of avoiding impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

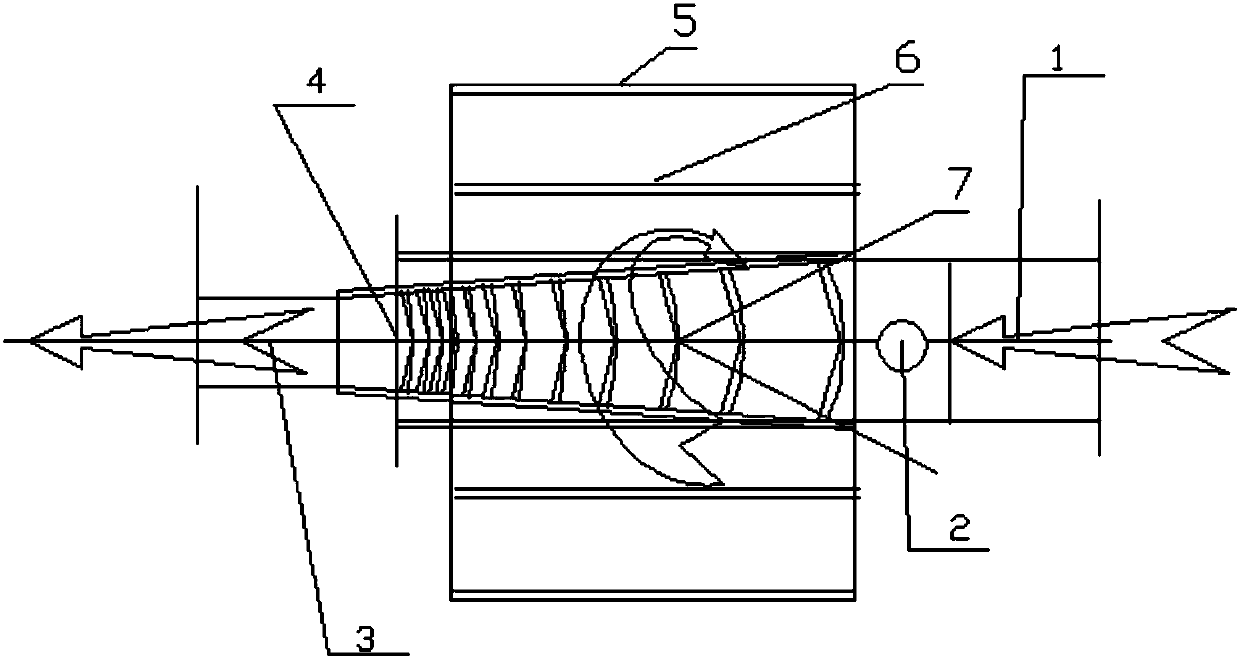

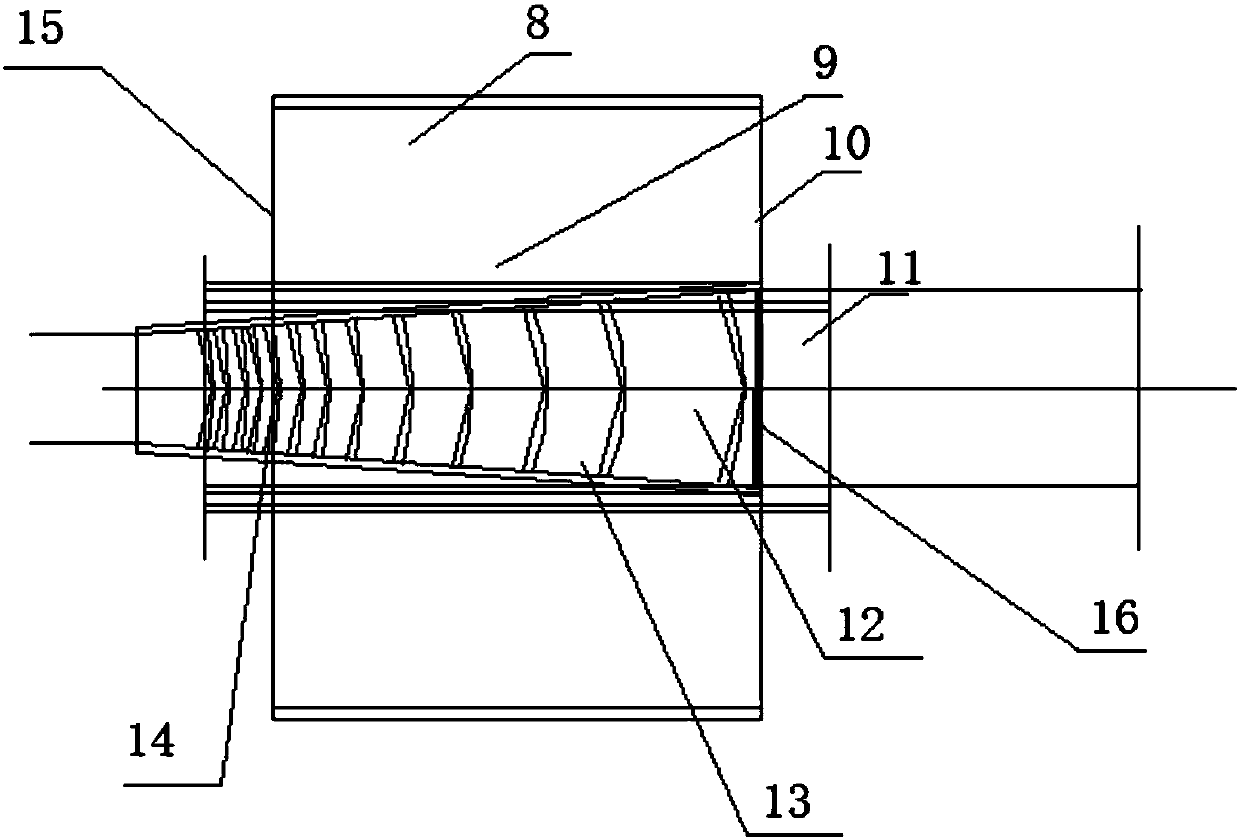

[0031] Attached below figure 1 , attached figure 2 and specific embodiments to further describe the application principle of the present invention.

[0032] The shaftless reverse centripetal turbine vane steam generator provided in the embodiment of the present invention is provided with a steam engine rotating cylinder 10, and the inside of the steam engine rotating cylinder 10 is provided with a continuous strip-shaped centripetal coil periodically surrounding it. Type vortex blades (shaftless reverse centripetal continuous elongated vortex blades) 12 and vortex blade passages 13, the outer edge of the continuous elong...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com