Efficient integrated oil tank integrating functions of settlement, cooling, filtration and adsorption and application of efficient integrated oil tank

A high-efficiency and functional technology, which is applied in the direction of oil supply tank device, fluid pressure actuation device, fluid pressure actuation system components, etc., can solve the restrictions on the application and promotion of hydraulic technology, increase the difficulty of hydraulic system layout, low cooling and filtration efficiency, etc. problem, achieve the effect of saving external space, saving work space and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

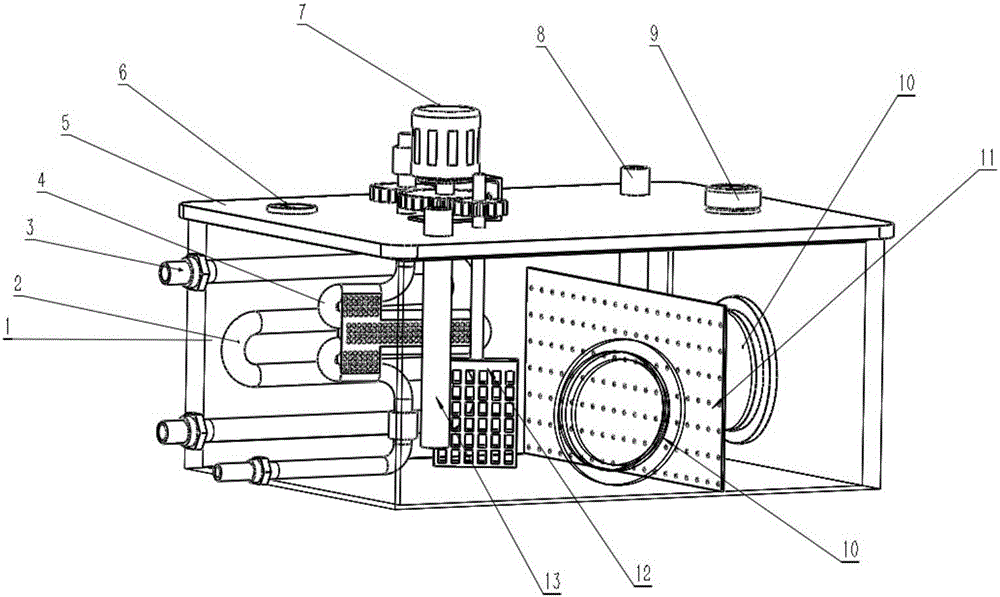

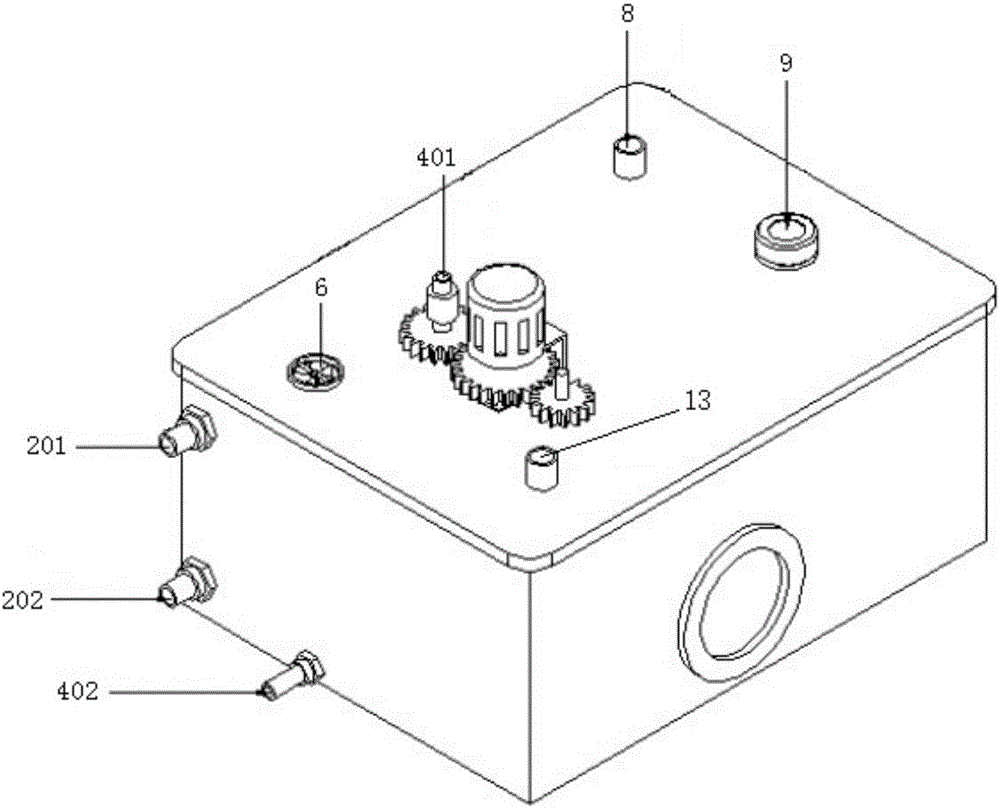

[0038] like Figure 1 to Figure 5 As shown, this embodiment provides an integrated fuel tank with efficient integration of sedimentation, cooling and filtration and adsorption functions, including a box body 1, the box body is a cuboid, and its length x width x height is 2m x 1.6m x 1.2m. A tank cover 5 is arranged above, and the tank cover 5 is a detachable and sealed fuel tank upper cover. The tank cover is provided with an oil inlet pipe 8 and an oil outlet pipe 13, and a filter screen 11 is arranged in the tank body, and the filter screen is a coarse filter screen. , mainly to filter some large impurities in the hydraulic oil, the filter screen divides the inside of the box into a left chamber and a right chamber, and a side wall cooling pipe 2 is arranged in the left chamber, and the liquid inlet 202 and the outlet of the side wall cooling pipe The liquid port 201 runs through the side wall of the box body, the oil inlet pipe 8 is located in the right chamber, and the oil...

Embodiment 2

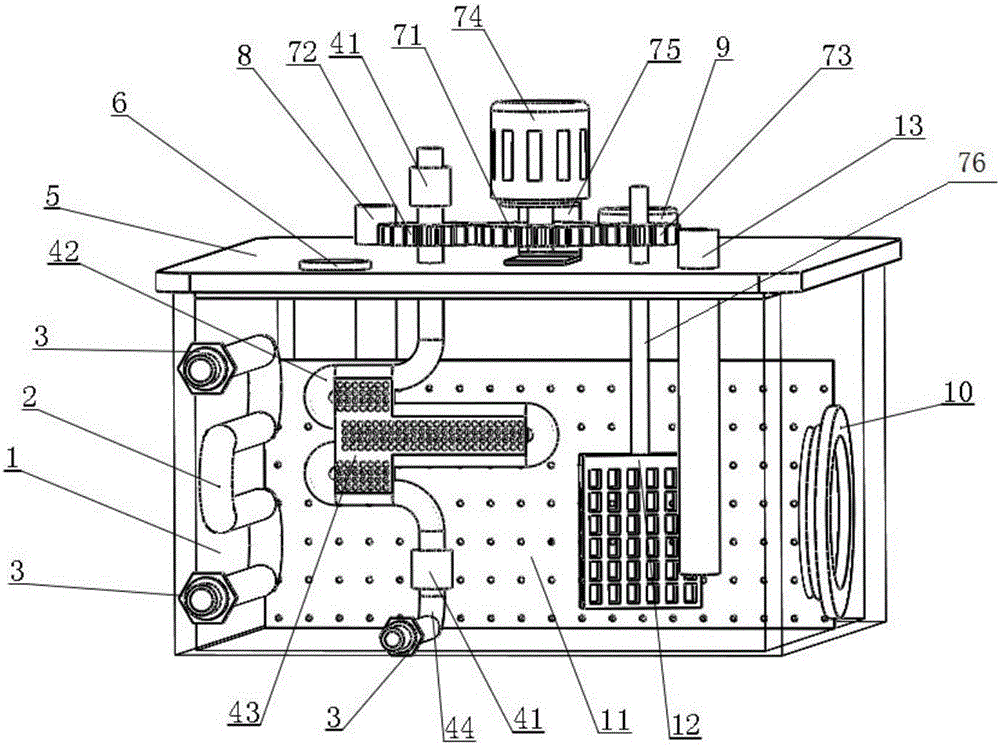

[0046] This embodiment provides an integrated oil tank with efficient integration of settling, cooling, and filtration and adsorption functions. The upper end of the upper end is provided with driven gear 73, and driven gear 73 meshes with driving gear 71, and one end of gear shaft 76 is placed in the left chamber and is connected with described adsorption device 12. The adsorption device is a net bag composed of metal wires, and an adsorption material is arranged in the net bag. The hydraulic oil can enter its inner space through the square hole of the net bag and contact with the adsorption material, and the adsorption material absorbs the fine impurities in the hydraulic oil to purify the oil quality.

[0047] The adsorption material is the same as the adsorption material filled in the metal mesh, and can be selected from one or more combinations of activated carbon, coarse-pore silica gel, and adsorption resin.

[0048] Through the adsorption device added in this embodime...

Embodiment 3

[0050] This embodiment provides an integrated oil tank that efficiently integrates the functions of sedimentation, cooling and filtration and adsorption. The structure is as described in Embodiment 1, and the difference is that a ventilation fan 6 and an air filter 9 are arranged on the tank cover. , Ventilation fan 6 is located in the left chamber, and air filter 9 is located in the right chamber. Exhaust air through the ventilation fan to promote the air to enter the box after being purified by the air filter, thereby increasing the air circulation above the oil level of the hydraulic oil, accelerating heat exchange and further improving the cooling efficiency of the hydraulic oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com