Production process of hot-molten non-woven fabric electrostatic fiber filter screen

A non-woven fabric, electrostatic fiber technology, applied in the direction of non-woven fabrics, textiles, papermaking, nets, etc., can solve the problem that the electrostatic effect is not as good as the hot-melt non-woven electrostatic fiber filter, and the hot-melt non-woven electrostatic fiber cannot be produced. Filters, inability to remove harmful gases and biological aerosols, etc., to achieve ideal purification effects, improve technology content, and improve filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

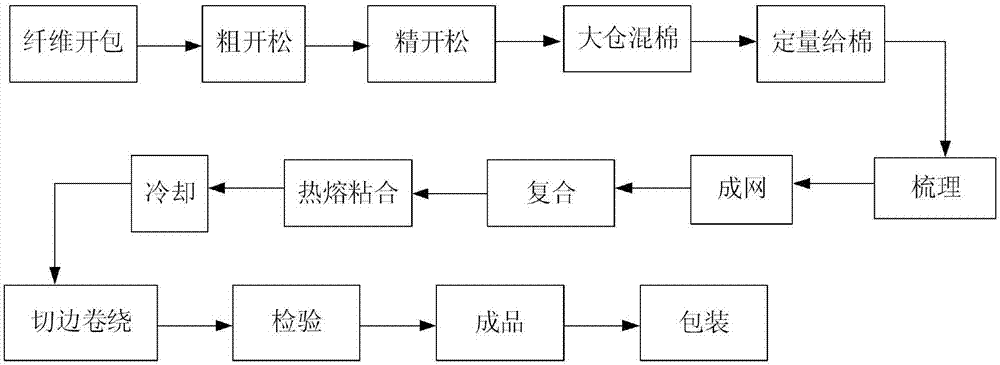

[0025] The present invention proposes a production process of hot-melt nonwoven electrostatic fiber filter net, please refer to figure 1 , the production process includes the following steps, and is carried out sequentially according to the following steps,

[0026] Step 1. Fiber unpacking and mixing

[0027] The raw material is odorless polypropylene staple fiber with static electricity, the fiber is roughly opened by the coarse gear roller of the opener, and the coarsely opened fiber is finely opened by the fine tooth roller to obtain loose fibers with reduced electrostatic field; The loose fiber enters the large warehouse blender through the conveying pipe for fiber mixing;

[0028] Step two, combing

[0029] The fibers fully mixed by the Dacang cotton blender in the step 1 are transported to the air pressure quantitative cotton feeding machine by air flow, and the mixed fibers are transported to the carding machine by pressure, and carded into a single-layer fiber web, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com