A kind of fluidized bed hydrogenation reaction system and fluidized bed hydrogenation method

A technology of ebullating bed reactor and hydrogenation reaction, which is applied in the direction of chemical instruments and methods, chemical/physical processes, etc., can solve the problems of affecting the effect of hydrogenation reaction, affecting the effect of gas-liquid separation, and the amount of catalyst should not be too much, etc., to achieve Improve the effect of hydrogenation reaction, improve the volume utilization rate, and the effect of good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

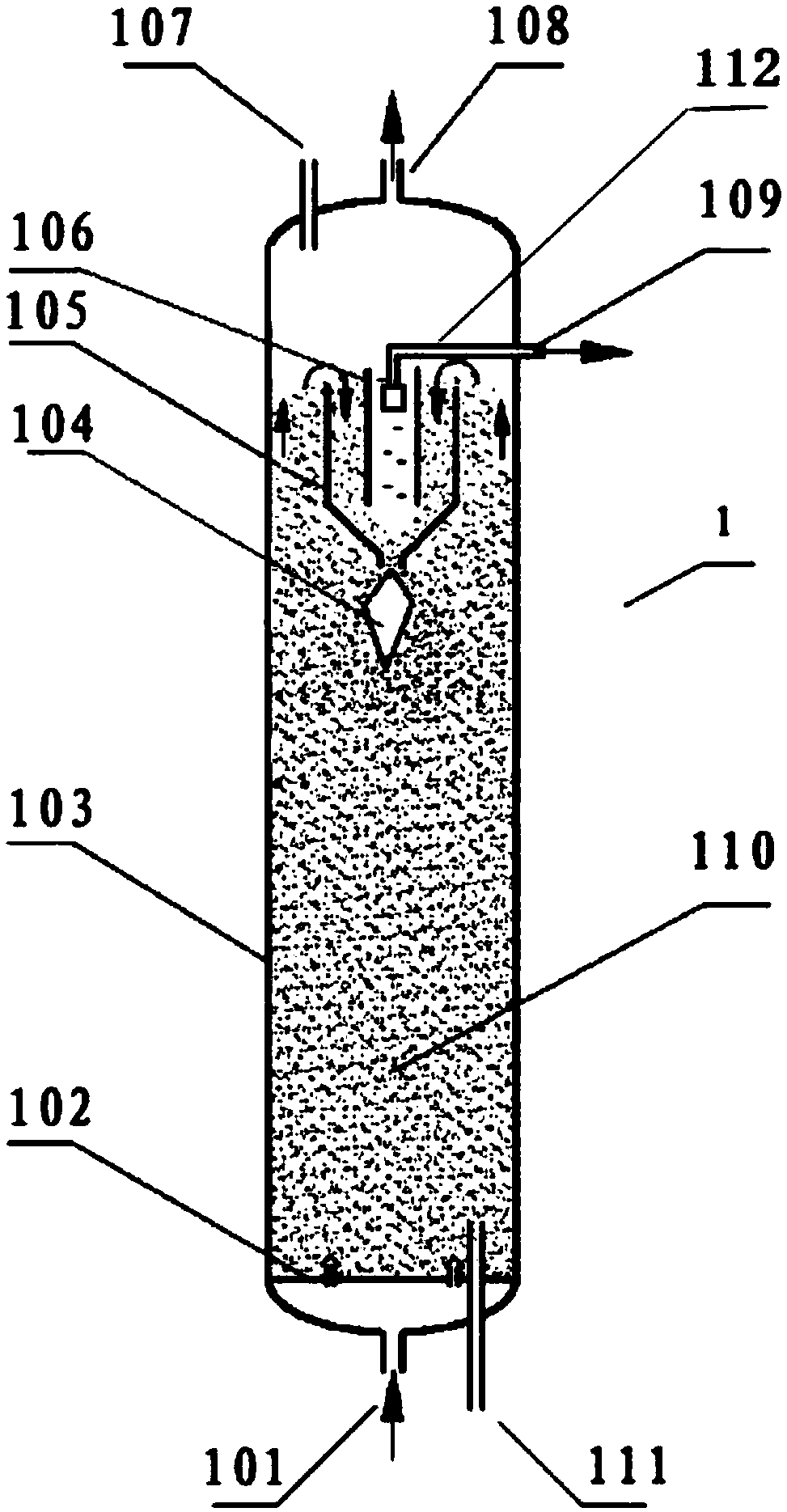

[0052] The ebullating bed reactor and the three-phase separator structure used in embodiment 1 are as follows figure 1 , The separation effect of the three-phase separator is simulated by the cold model. The size of the cold mold device is: the inner diameter of the reactor cylinder is 300mm, the height of the reactor cylinder is 3500mm, the height of the three-phase separator is 400mm, the diameter of the upper straight section of the outer cylinder of the three-phase separator is 200mm, the distance between the inner cylinder and the outer cylinder The distance between the annular gap is 80mm, the height difference between the upper end of the inner cylinder and the upper end of the outer cylinder is 60mm, the gap between the lower end opening of the inner cylinder and the contraction section of the outer cylinder is 60mm, the diameter of the lower opening of the contraction section of the outer cylinder is 90mm, and the outer cylinder The shrinkage angle of the lower frustu...

Embodiment 2

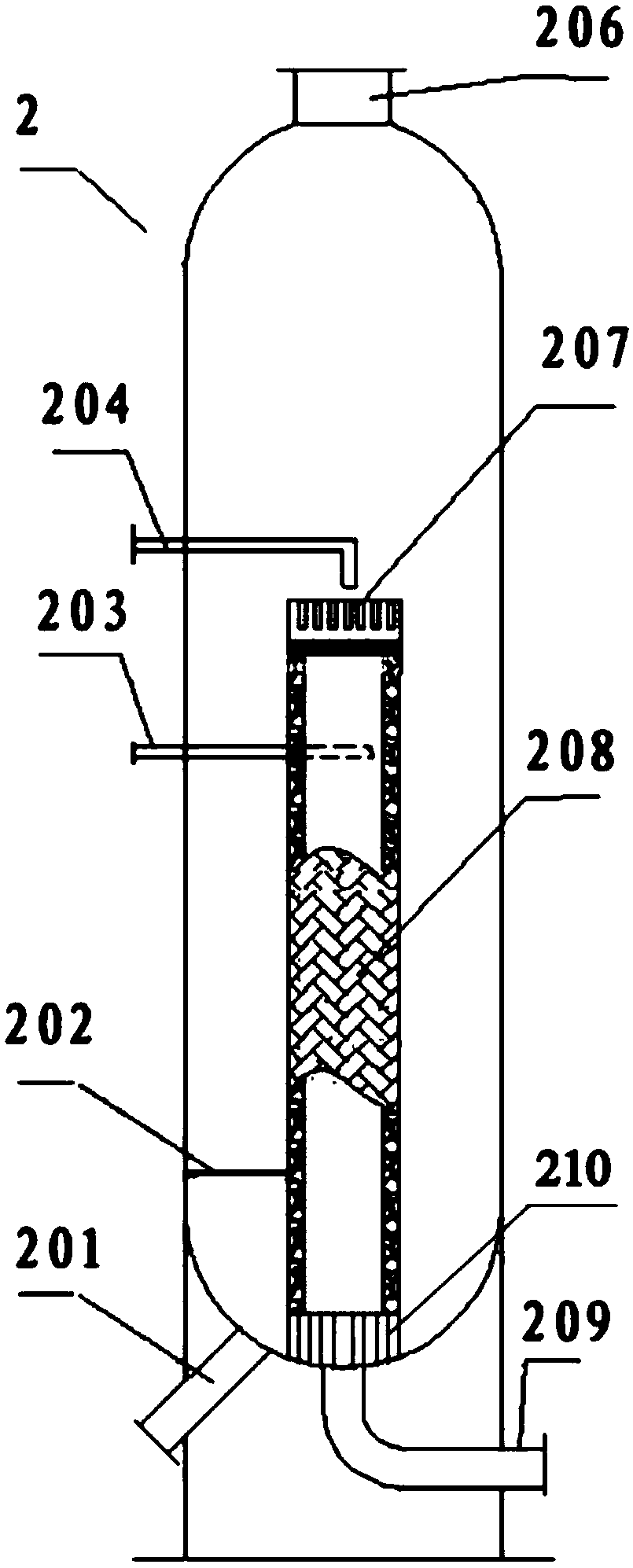

[0066] according to figure 2 Structural design of thermal high-pressure separator to simulate gas-liquid separation operation under filtration conditions. The pressure is 10MPa, the temperature is 270°C, and the liquid phase is residual oil at atmospheric pressure. Prepare catalyst solid powder with a content of 15 μg / g below 100 mesh (100 mesh sieve), and the filtration accuracy of the filter cartridge is designed to be 30 mesh. Nitrogen, the gas-liquid volume ratio is 600:1, and the filtration strength is 3600Kg / (m2 filter material·hour). After 2000 hours of operation, the pressure drop (the difference between the gas phase pressure and the liquid outlet pressure) of the hot high-pressure separator normally increased (compared to the initial value) by 3.7%, and the filtration capacity did not decrease. It is expected to be able to operate stably for 2 to 3 years.

Embodiment 3

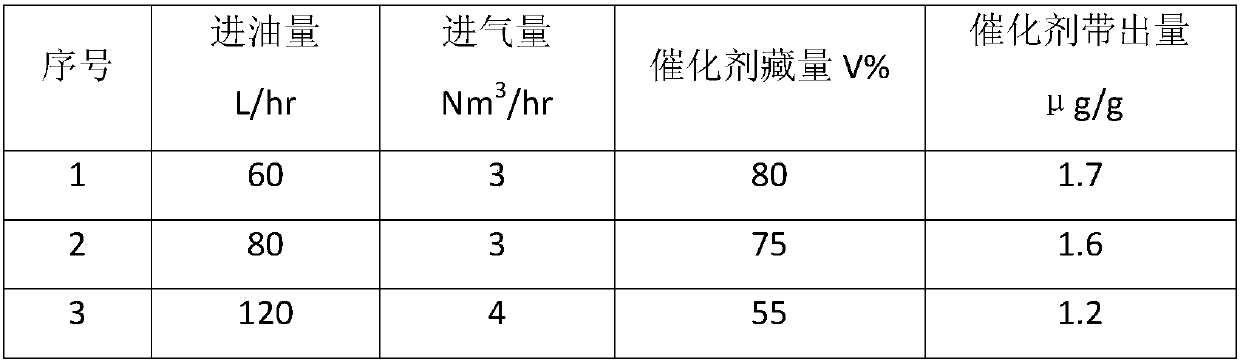

[0070] Coal tar hydrogenation test was carried out by using the fluidized bed hydrogenation method of the present invention. Described ebullating bed reactor and three-phase separator are by the conditions described in embodiment 1, and described heat high pressure separator is by the conditions described in embodiment 2, the gas phase outlet 108 of ebullating bed reactor and the gas phase inlet of heat high pressure separator 203 is connected, and the liquid phase outlet 109 of the ebullated bed reactor is connected with the liquid phase inlet 204 of the hot high-pressure separator. The hydrogenation catalyst used in the test is an alumina microsphere catalyst with a particle size of 1.5 mm, and the catalyst storage (calculated at rest) is 75% of the effective volume of the reactor (excluding the head space). The reaction pressure of the ebullated bed reactor is 15MPa, the reaction temperature is 410°C (in the middle of the reactor), and the volume space velocity of the raw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com