Patents

Literature

53results about How to "Improve hydrogenation reaction performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process of treating hydrogenation catalyst before application

ActiveCN101088615AImprove performanceSolve the problem of concentrated heat releaseCatalyst activation/preparationRefining by selective hydrogenationAs elementOrganic acid

Owner:CHINA PETROLEUM & CHEM CORP +1

Prepn process of vulcanized catalyst

ActiveCN101088620AImprove vulcanization effectImprove hydrogenation reaction performanceCatalyst activation/preparationRefining by selective hydrogenationChemistryThiram

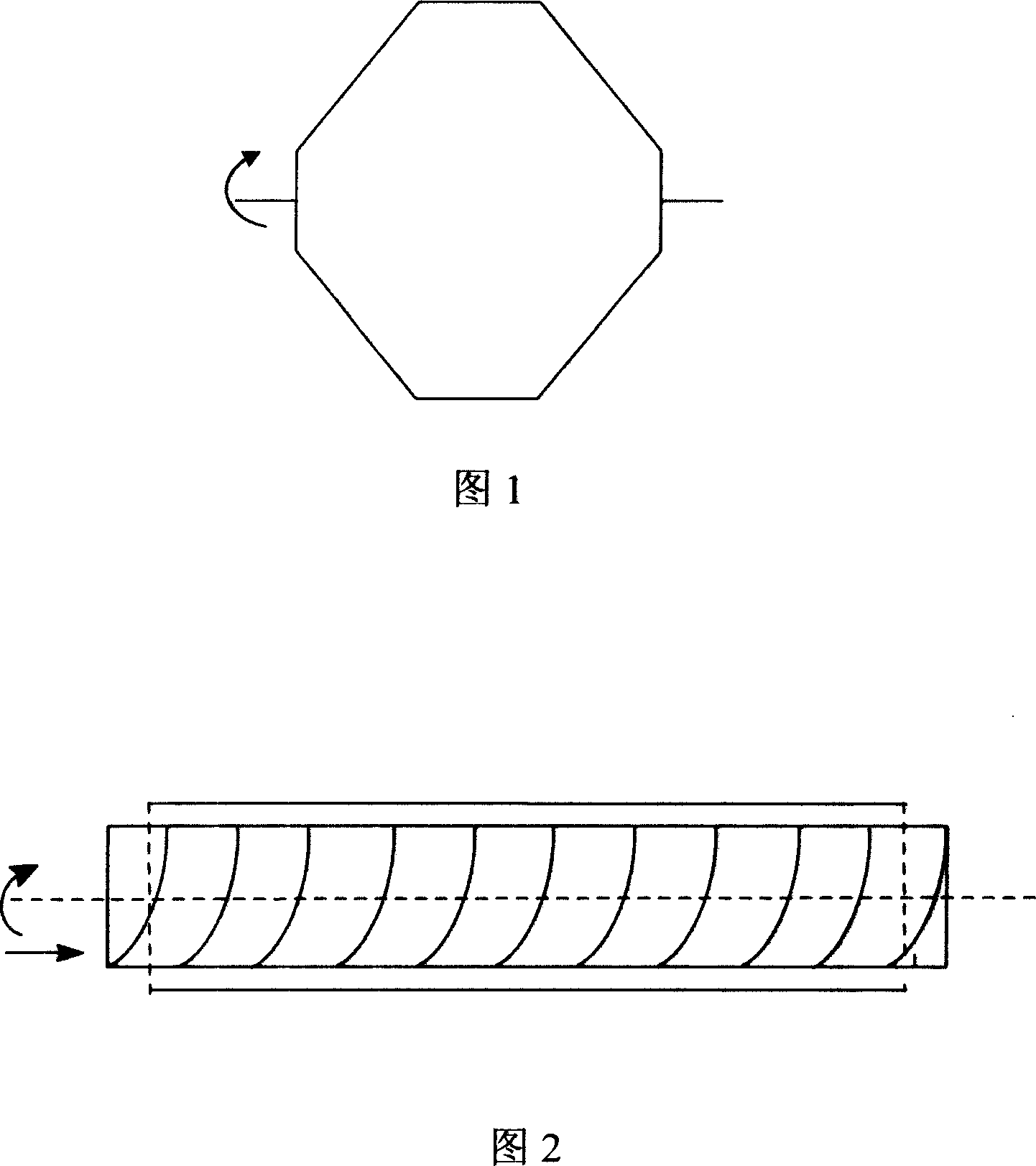

The present invention relates preparation process of vulcanized catalyst. During the preparation process, thiram in 0.5-25 wt% of the catalyst, sulfur element in 30-150 % of the theoretic sulfur demand of the catalyst and organic solvent in 0.1-50 wt% of the catalyst are first introduced into the catalyst in oxide state, and the catalyst is then heat treated in dynamic heating apparatus. The catalyst has raised sulfur holding rate, smooth heat release, shortened vulcanizing period and raised production efficiency. The method of the present invention may be used in the treatment of various kinds of hydrogenating catalyst before application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Treatment method before application of hydrogenation catalyst

ActiveCN1861257AImprove sulfur retentionHigh activityCatalyst activation/preparationRefining to eliminate hetero atomsOrganic solventOxidation state

A process for treating the hydrocatalyst before it is used features that the organic solvent and sulfur-contained substance are introduced to the oxidation-state hydrocatalyst for higher activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

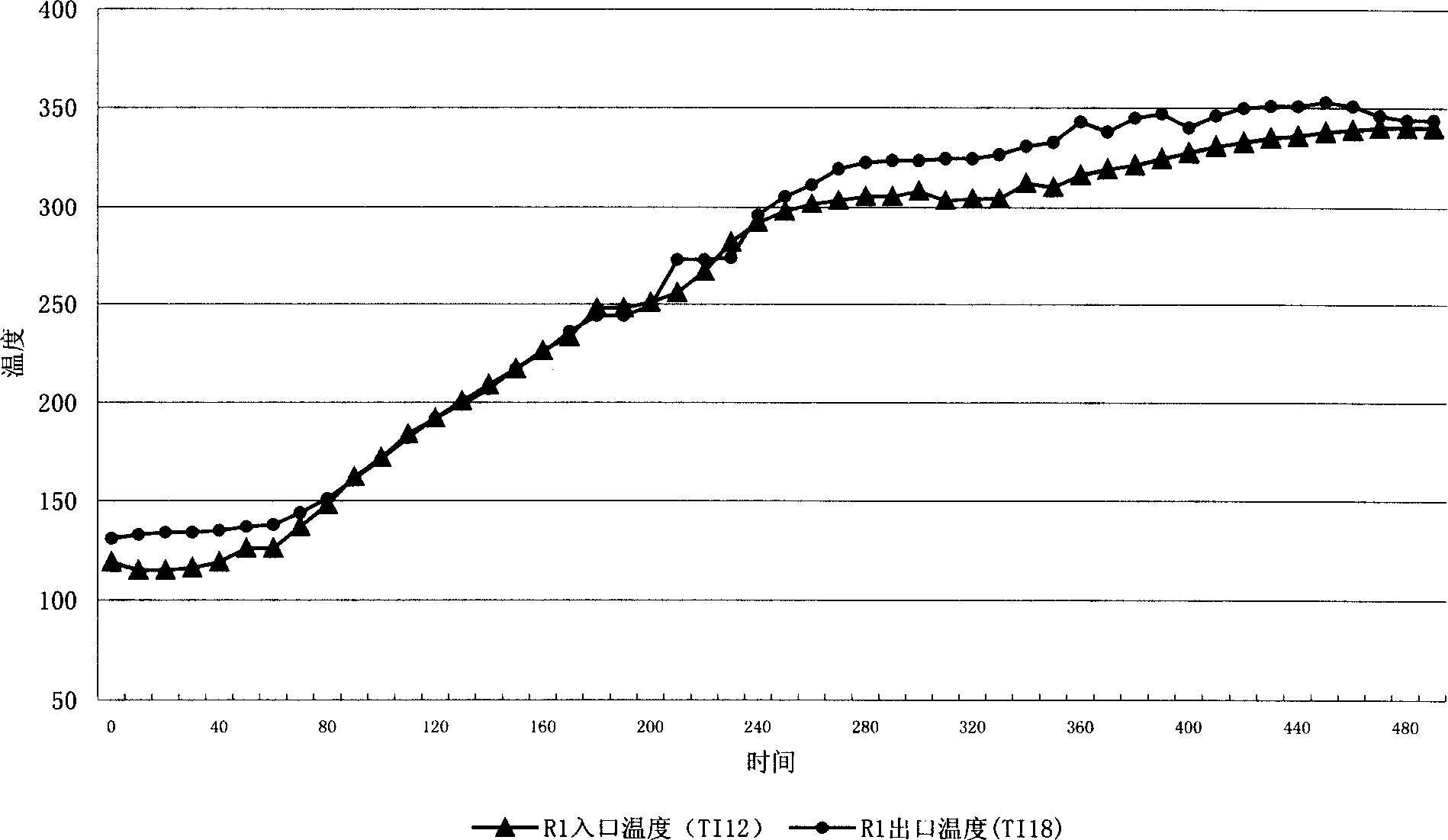

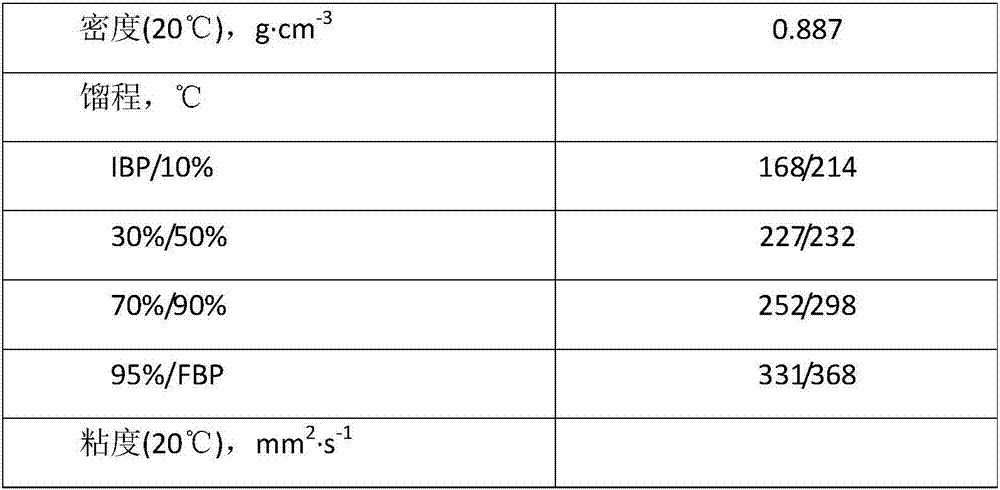

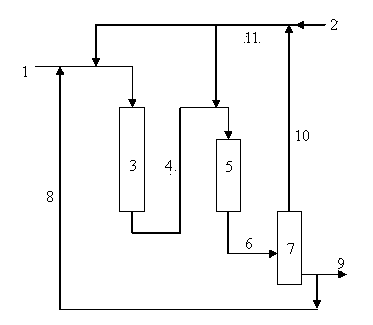

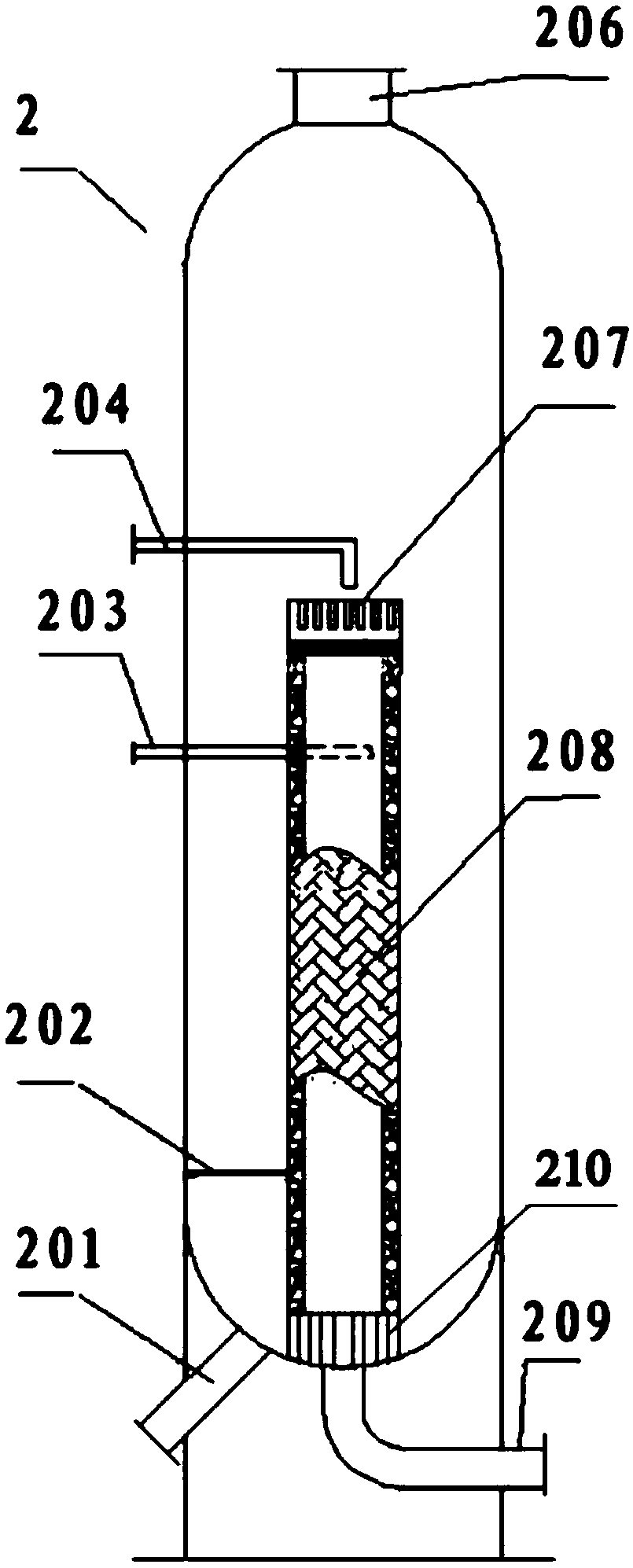

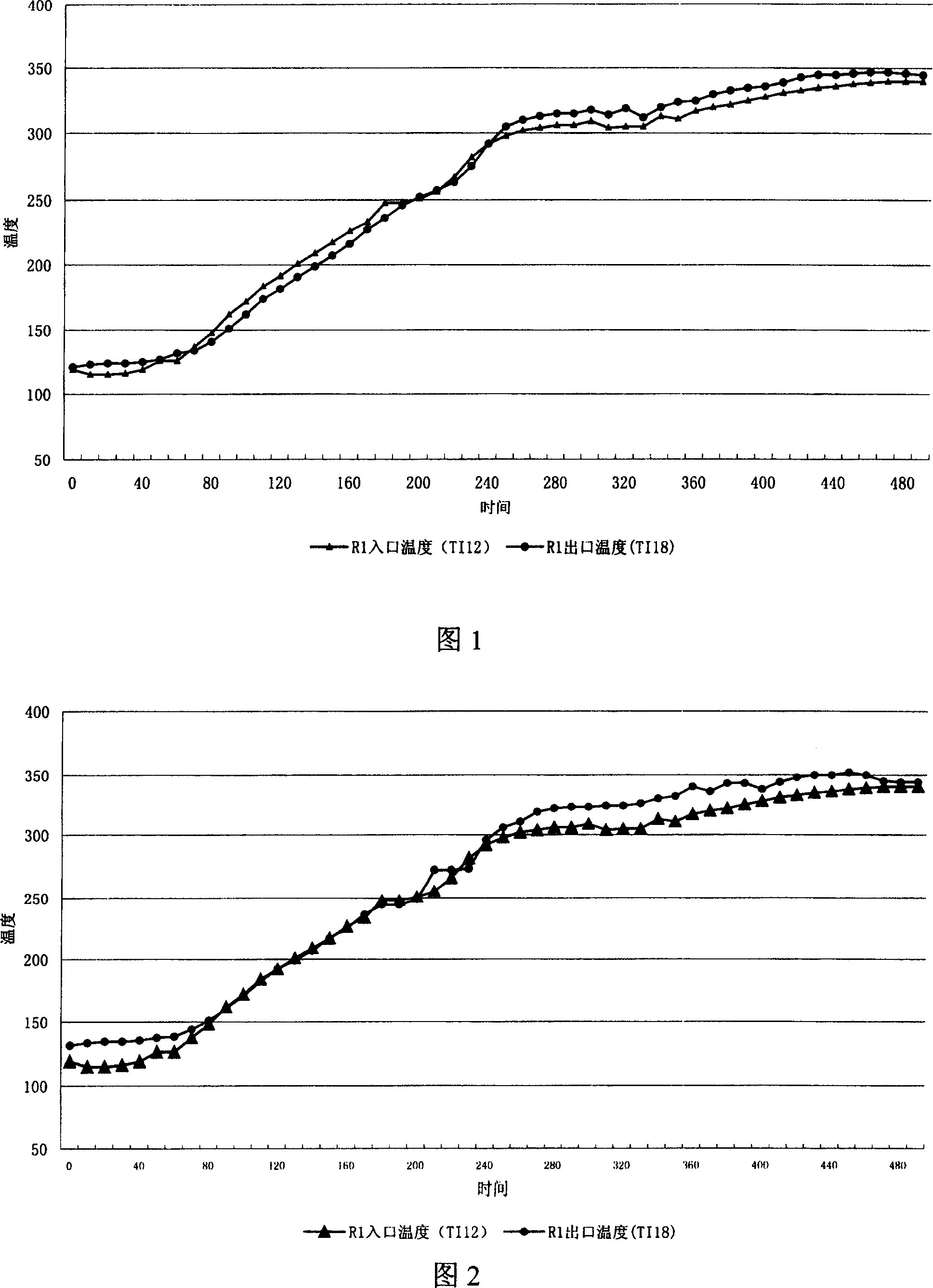

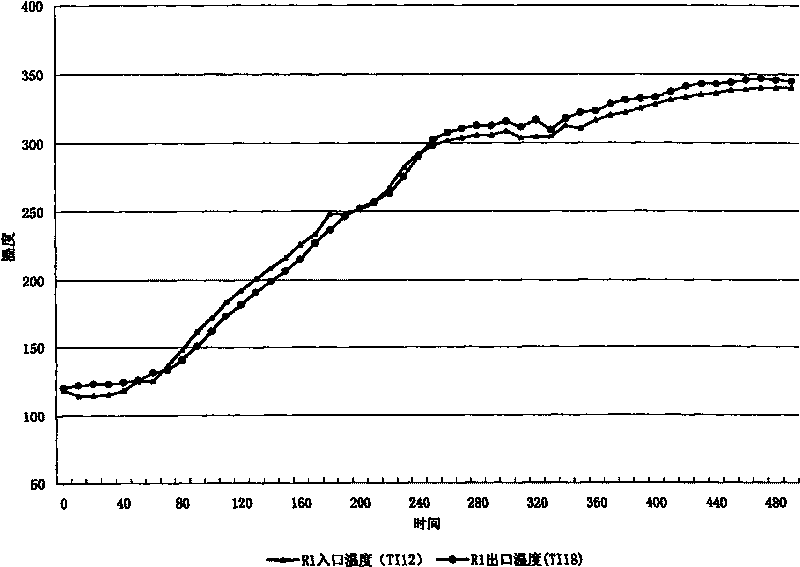

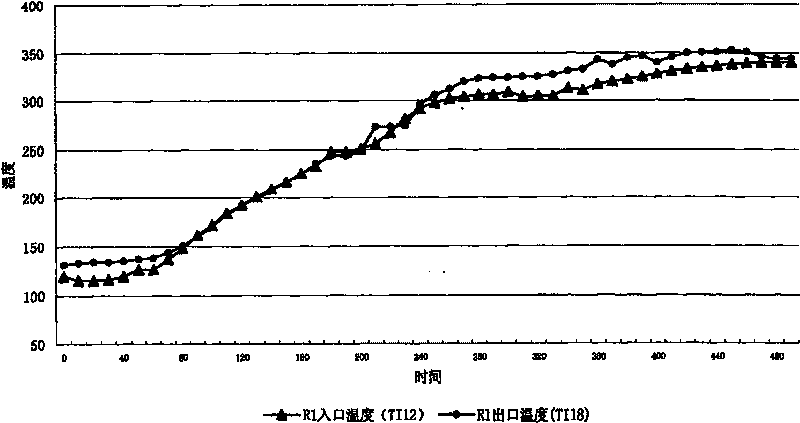

Shale oil one-stage in series hydrofining technological method

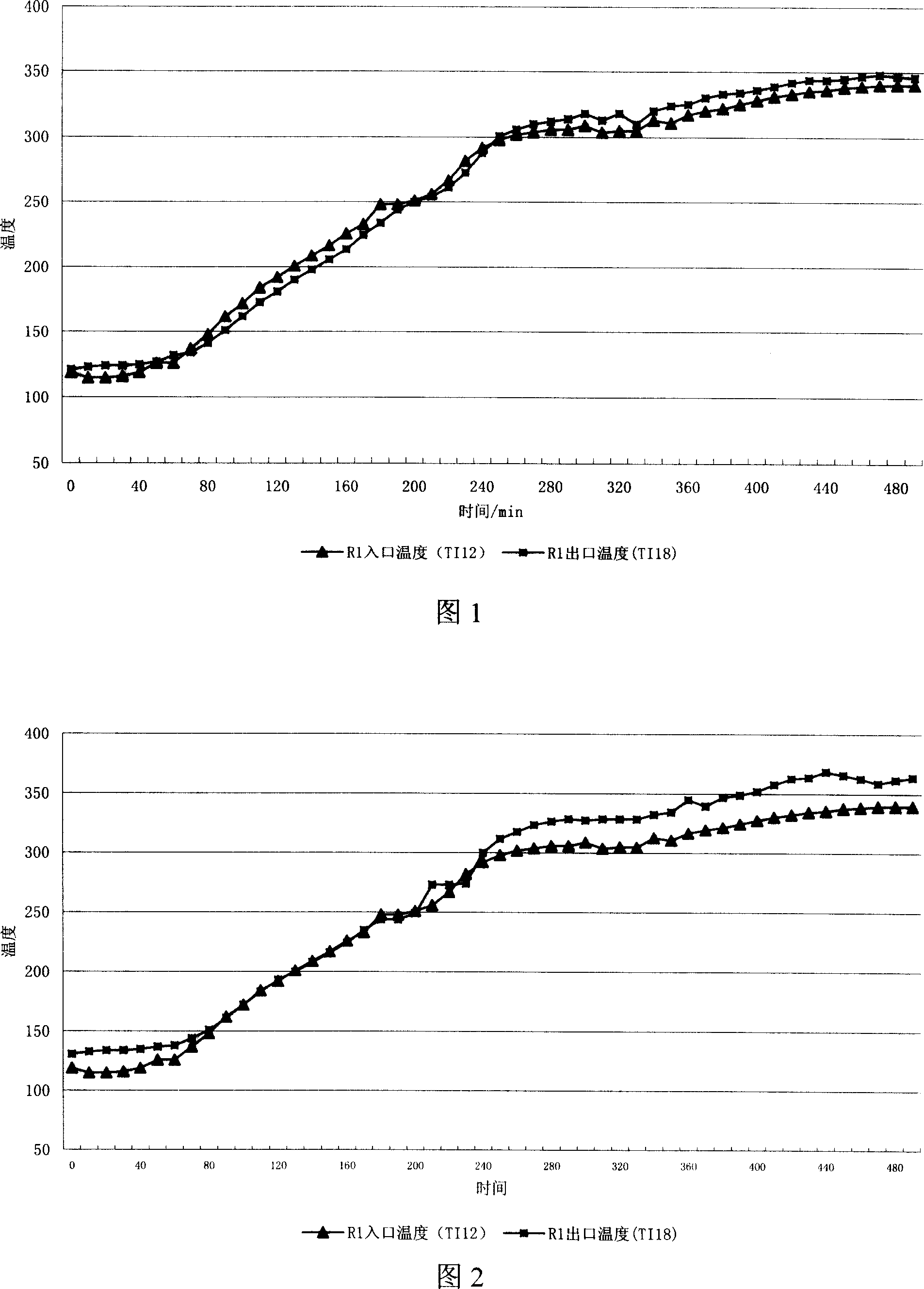

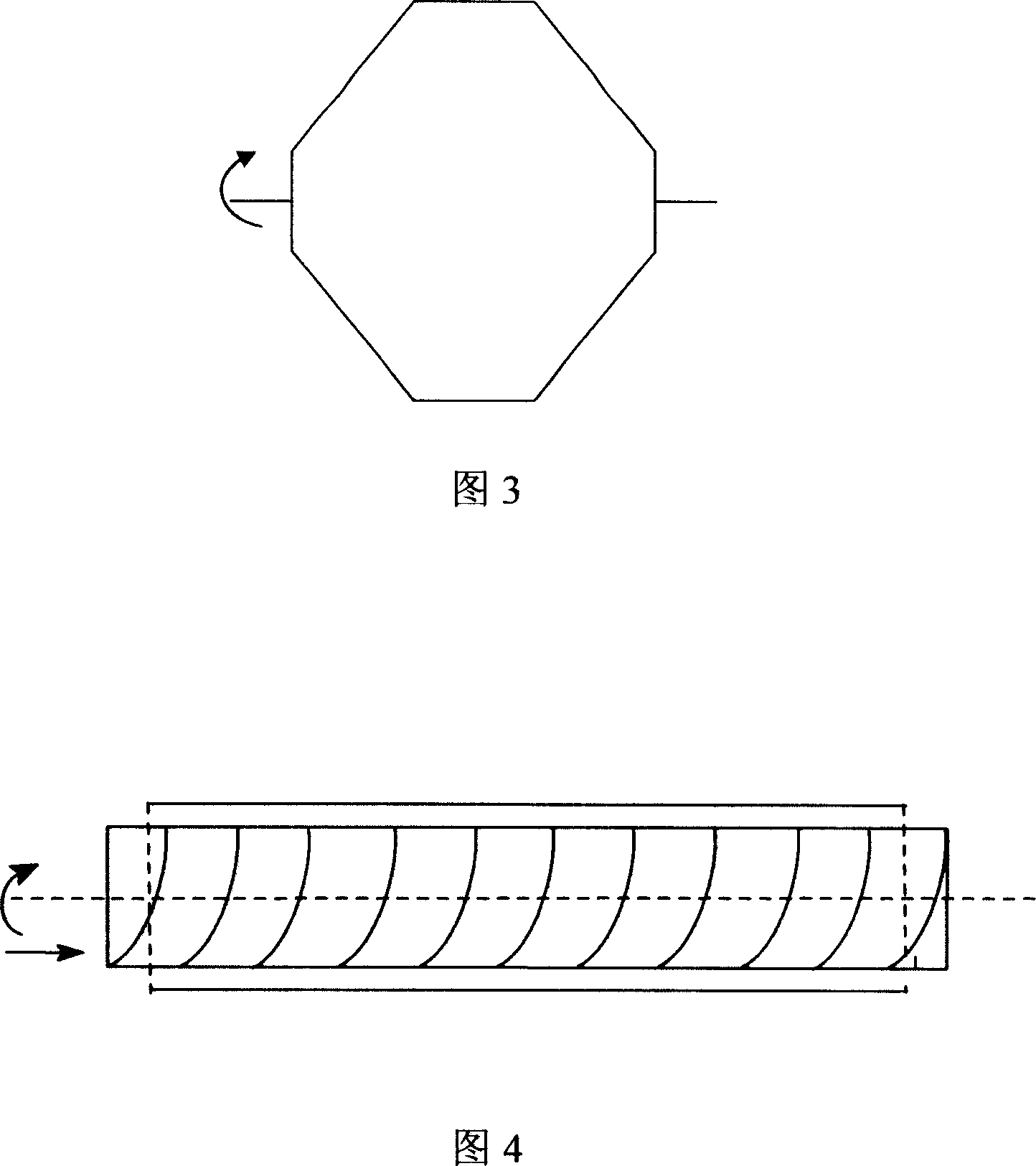

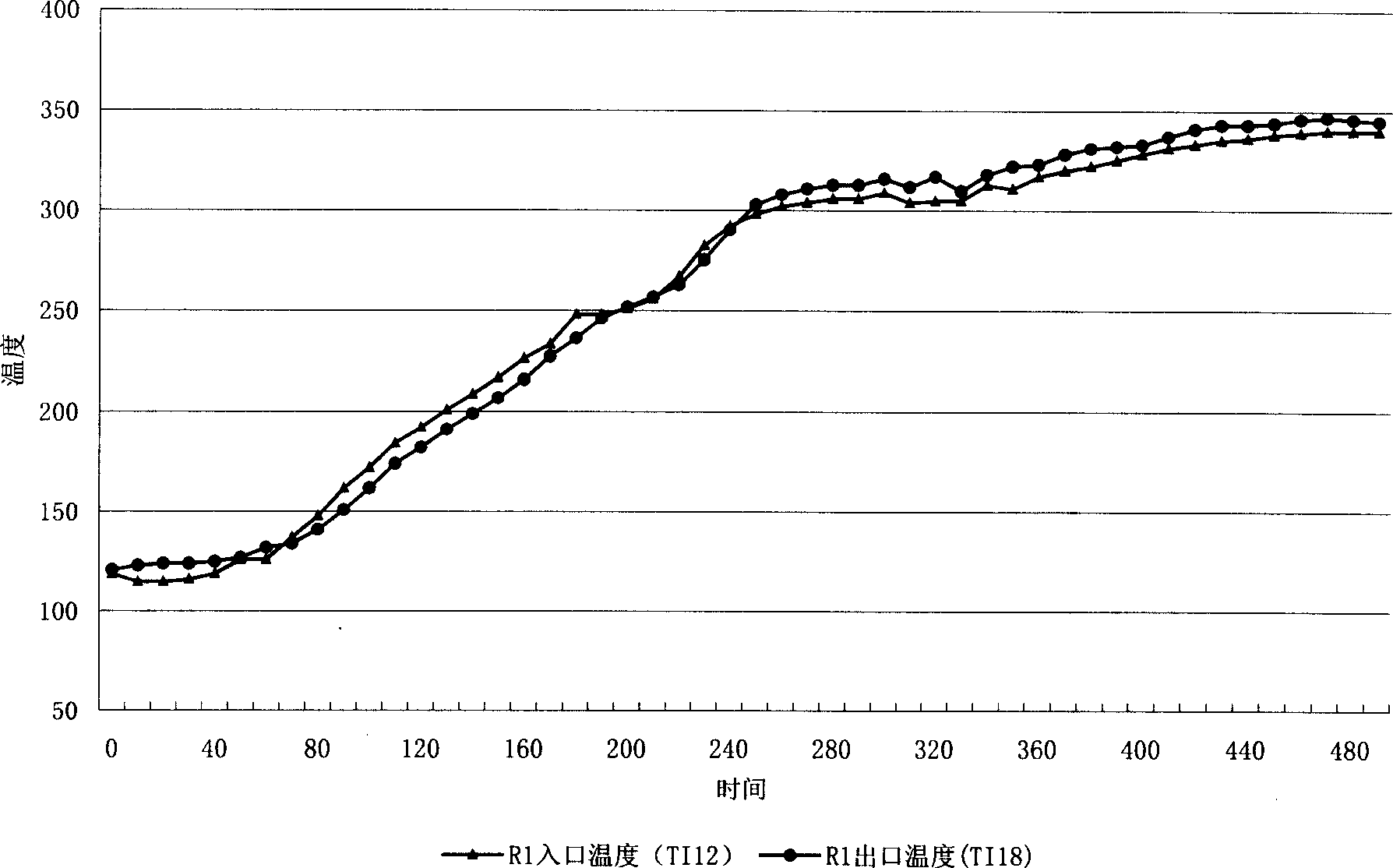

ActiveCN102311788AImprove hydrogenation reaction performanceTreatment with hydrotreatment processesHydrogenation reactionReaction temperature

The invention discloses a shale oil one-stage in series hydrofining technological method, which comprises the following step: shale oil raw material and hydrogen firstly exchange heat with thermal media to 200-280 DEG C, and pass through a first reactor by the volume per hour of 0.5h-1 to 4.0h-1, and high-voidage hydrofining catalysts are arranged in the first reactor; and materials flowing out of the first reactor directly pass through a second reactor by the volume per hour of 0.3h-1 to 1.0h-1 after being heated by a heating furnace, the average reaction temperature in the second reactor is 360-420 DEG C, and conventional hydrofining catalysts are arranged in the second reactor. With the method disclosed by the invention, the hydrogenation reaction effect is improved under the condition of ensuring the long-term stable operation of a shale oil hydrogenation device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation catalyst processing method

ActiveCN101417245AImprove vulcanization effectImprove hydrogenation reaction performanceMolecular sieve catalystsCatalyst activation/preparationOrganic solventWater vapor

The invention relates to a processing method used for a hydrogenation catalyst, comprising the detailed process as follows: the catalyst carrier is dipped in catalyst active metal component and dried to certain water content; subsequently, organic solvent and elemental sulfur are introduced; and finally, heating predisposal is carried out under a certain condition. The processing method before the application of the hydrogenation catalyst loads the sulfur-contained substance such as the elemental sulfur to the hydrogenation catalyst; a certain interaction is generated and little heat is discharged; and the water vapor which is generated during the heat disposal process of the water contained in the catalyst adjusts the interaction of the sulfur and the active composition of the catalyst and reduces the heat discharging degree during the heat disposal process. Compared with the prior art, the catalyst obtained by the method has the advantages of high utilization ratio of the sulfur-contained matter, gradual increment of the temperature of the catalyst bed and high activity of the catalyst when the activation is applied. The method can be used for processing before the application of various hydrogenation catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

Processing method before using hydrogenation catalyst

ActiveCN101417246AEasy to useIncrease profitCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsOrganic solventWater vapor

The invention relates to a processing method before the application of hydrogenation catalyst, comprising the detailed process as follows: organic solvent, elemental sulfur and water are introduced in oxidated hydrogenation catalyst; subsequently, heating predisposal is carried out under a certain condition. The processing method before the application of the hydrogenation catalyst loads the sulfur-contained substance such as the elemental sulfur to the hydrogenation catalyst; a certain interaction is generated and little heat is discharged; and the water vapor which is generated during the heat disposal process of the added water adjusts the interaction of the sulfur and the catalyst and reduces the heat discharging degree during the heat disposal process. Compared with the prior art, the catalyst obtained by the method has the advantages of high utilization ratio of the sulfur-contained matter, gradual increment of the temperature of the catalyst bed and high activity of the catalyst when the activation is applied. The method can be used for processing before the application of various hydrogenation catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

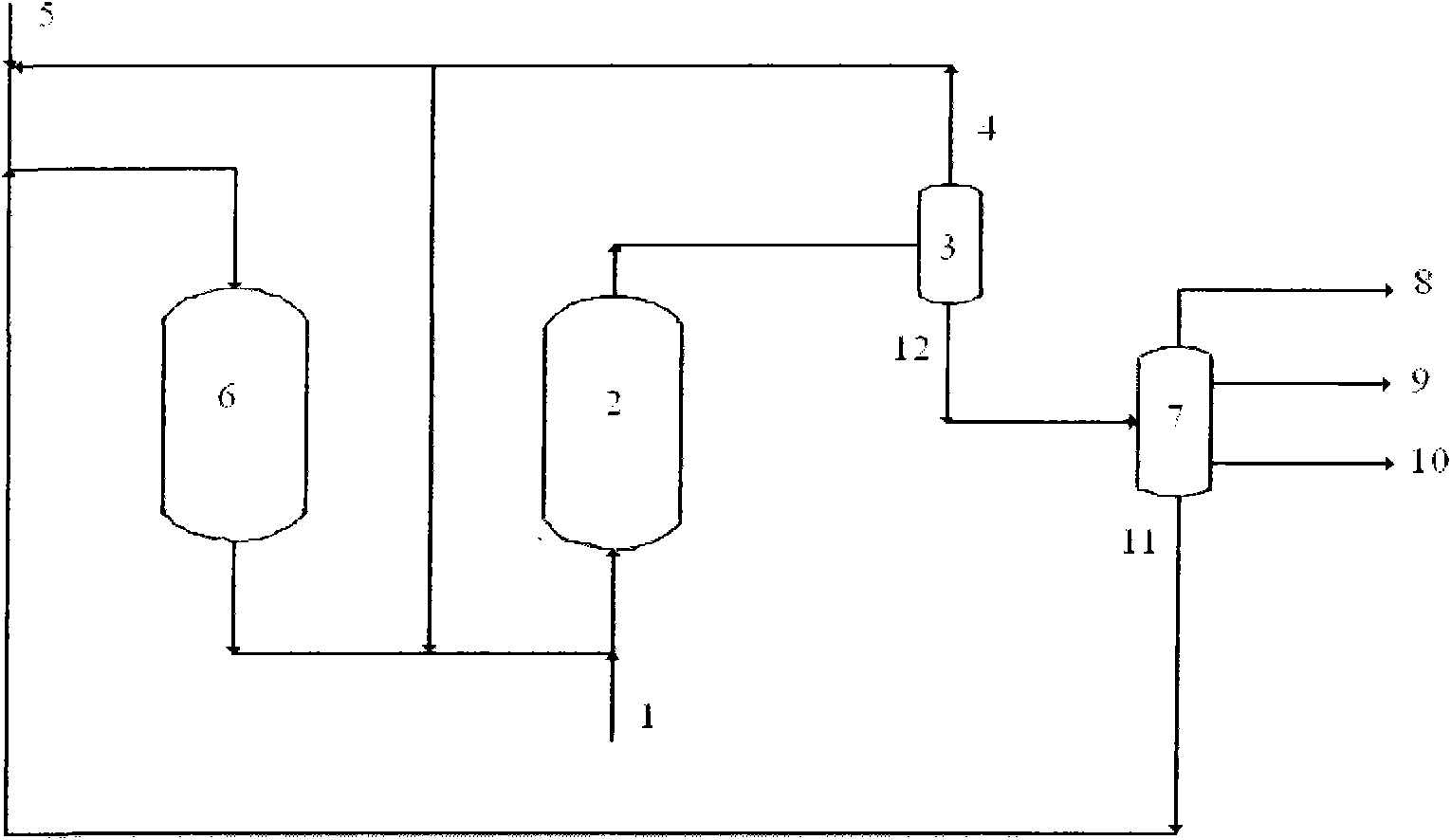

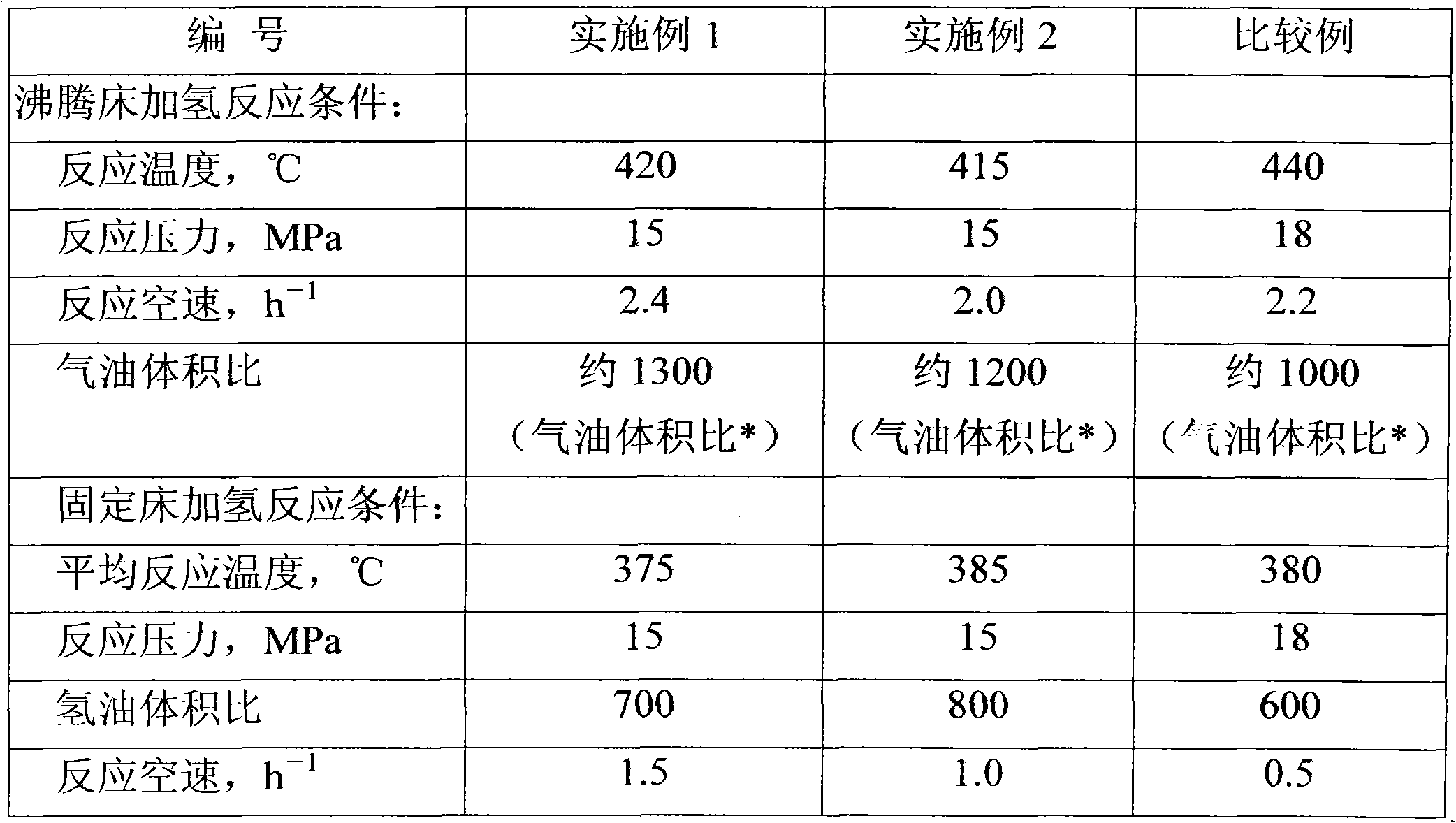

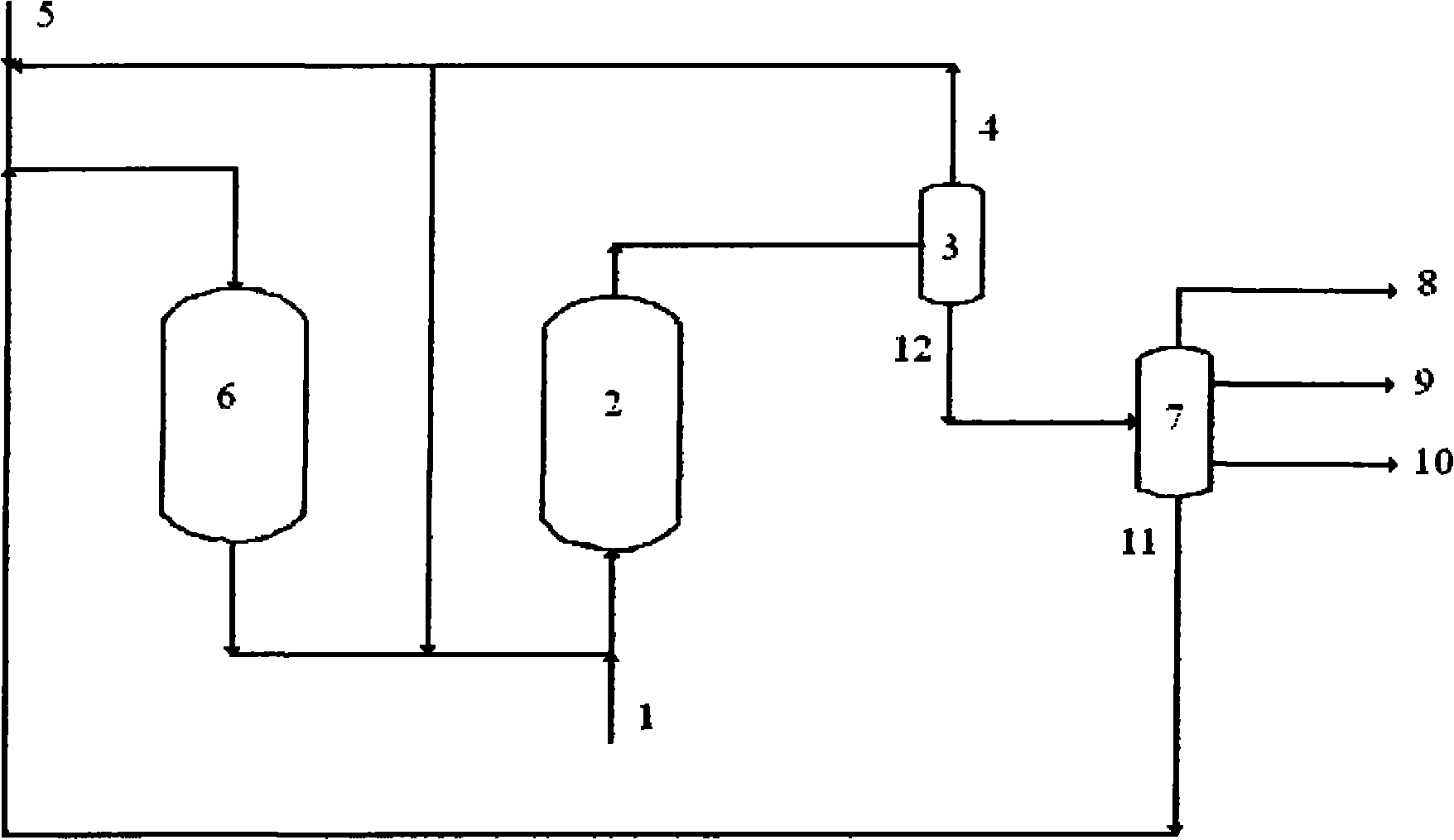

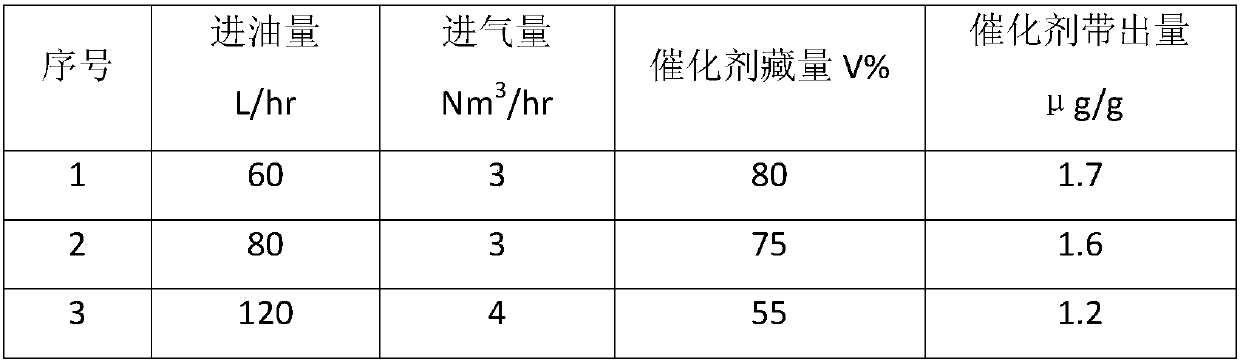

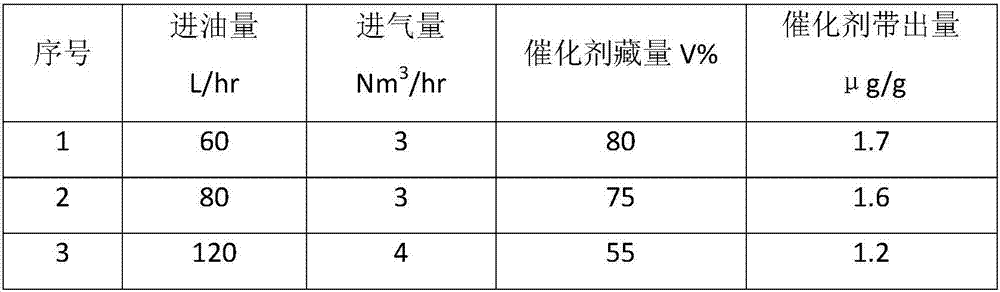

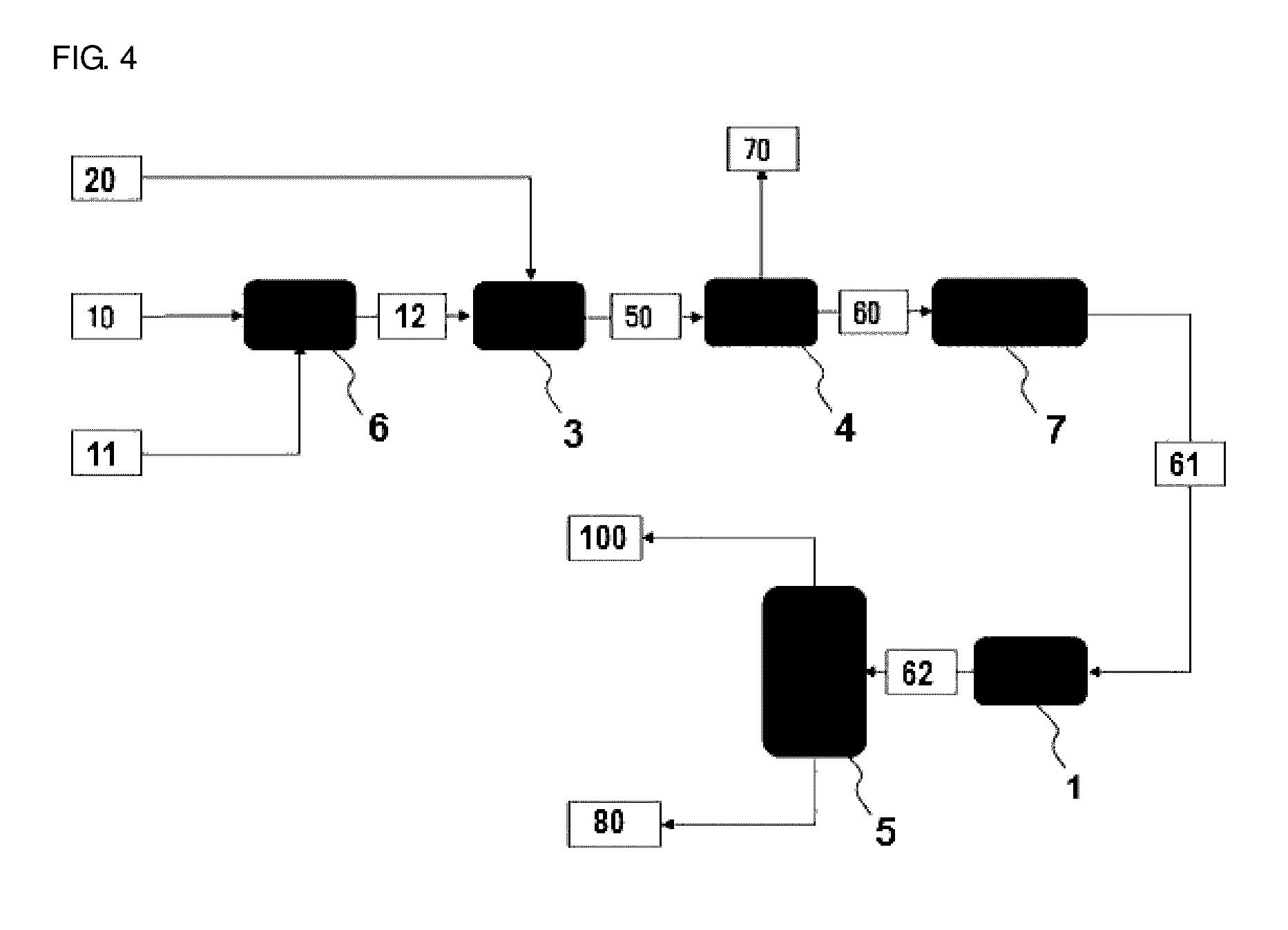

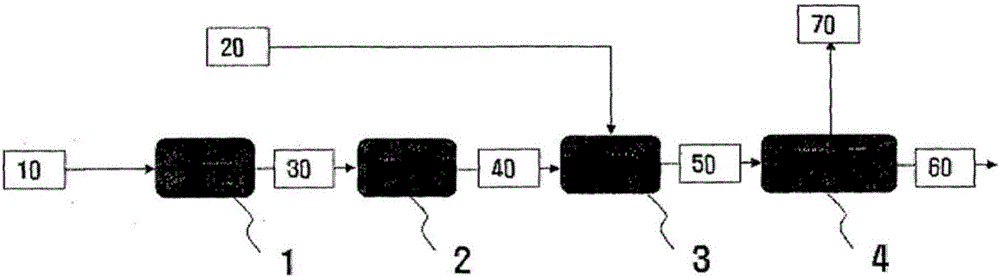

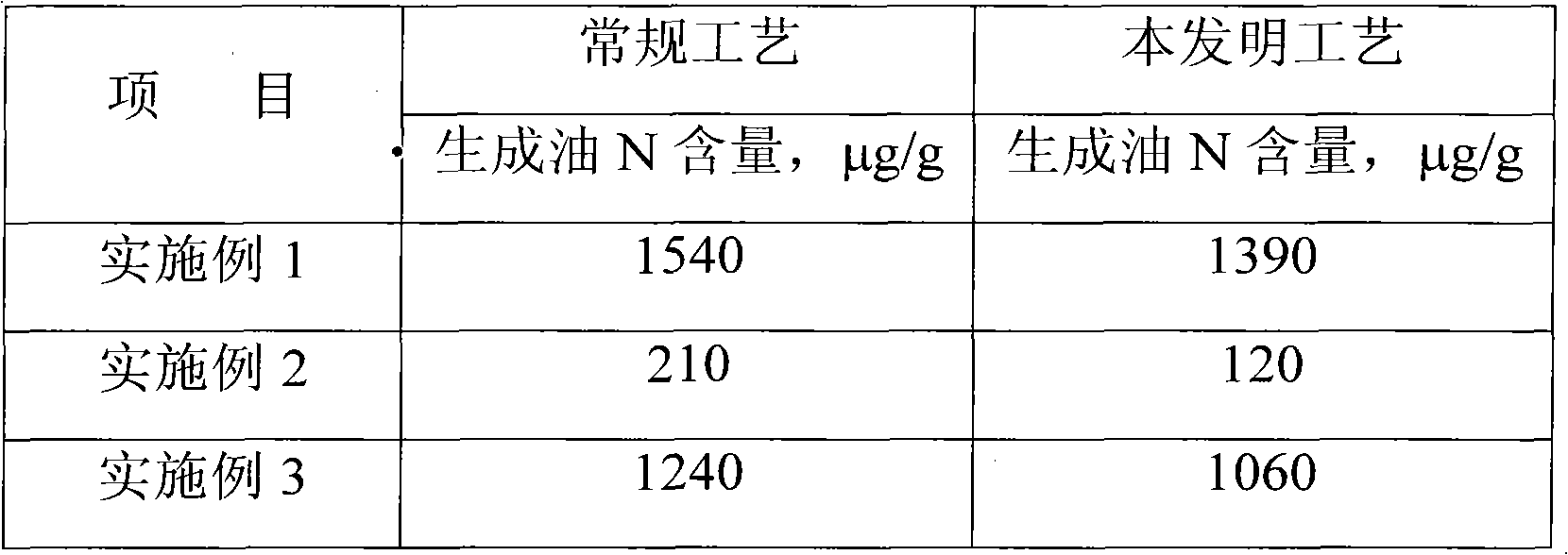

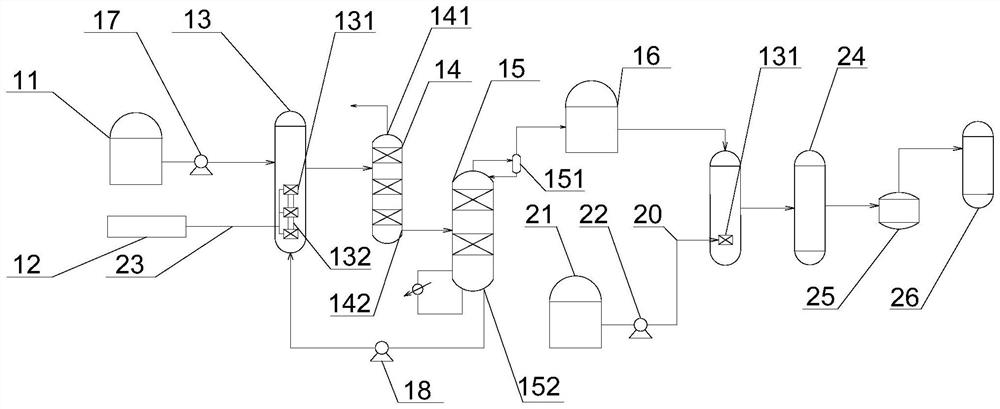

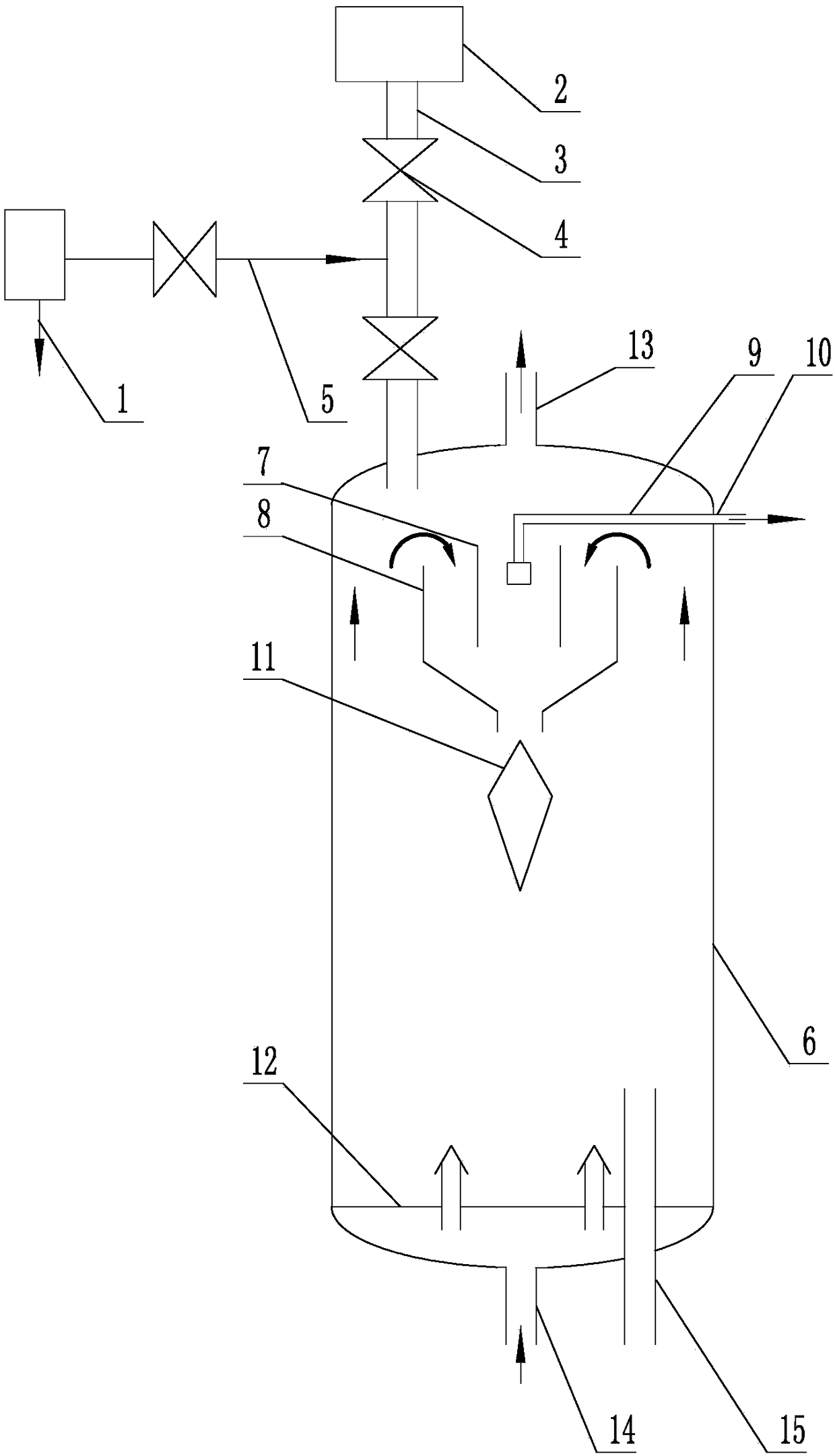

Coal tar whole-fraction fluidized bed hydrogenation method

ActiveCN107298984AIncrease profitImprove hydrogenation reaction performanceTreatment with hydrotreatment processesVapor–liquid separatorFluidized bed

The invention relates to a coal tar whole-fraction fluidized bed hydrogenation method which comprises the following steps: (1) heating coal tar whole fraction and mixing with circulation oil of a fluidized bed reactor; (2) mixing the mixture in the step (1) and hydrogen, dissolving the hydrogen, and enabling the mixture to enter a gas-liquid separator; (3) enabling a gaseous phase on the top of the gas-liquid separator in the step (2) to enter a fixed bed hydrogenation reactor from the top of the reactor, and enabling a liquid phase to enter the fluidized bed reactor from the bottom of the reactor so as to carry out a hydrogenation reaction; and (4) arranging a three-phase separator on the upper part inside the fluidized bed reactor in the step (3), discharging the gaseous phase separated from the three-phase separator from the top of the fluidized bed reactor to the fixed bed hydrogenation reactor in the step (3), and taking at least one part of the liquid phase through a circulatory system as the circulation oil in the step (1). Compared with the prior art, the method disclosed by the invention has the advantages that the steady operation problem existing in coal tar whole-fraction fluidized bed hydrogenation can be effectively solved, and the coal tar whole-fraction fluidized bed hydrogenation reaction effect is improved.

Owner:上海竣铭化工工程设计有限公司

Process of hydrogenation of heavy oil feedstock

ActiveCN102041082AImprove hydrogenation performanceQuality improvementTreatment with hydrotreatment processesHydrogenFixed bed

The invention discloses a process of hydrogenation of heavy oil feedstock, especially the process of hydrogenation of heavy oil feedstock using combination of boiling bed and fixed bed technologies. The process comprises the following steps: mixing heavy oil feedstock and the product obtained from the fixed bed hydrogenation; adding the mixture into boiling bed hydrogenation reactor, separating the materials obtained from boiling bed hydrogenation into to hydrogen-rich gas and liquid; recycling the hydrogen-rich gas; loading the liquid into the fractionate tower and for fractioning to obtain lightweight product and tail oil; mixing the tail oil and hydrogen, and adding the mixture into the fixed bed hydrogenation reactor; and adding all the materials obtained from fixed bed hydrogenation into the boiling bed hydrogenation reactor. Compared with existing technology, the method of the invention effectively combines the boiling bed and the fixed bed hydrogenation technology characteristics, allows the product obtained from fixed bed hydrogenation directly to enter the boiling bed reactor, thereby improves the flow state of the boiling bed feed, and enhances heat and mass transfer effects among gas, liquid and solid. Simultaneously, product properties are obviously improved after the tail oil obtained from the boiling bed hydrogenation is hydrogenated by the fixed bed. Employing the operation mode of the heavy oil hydrogenation can improve the product quality significantly and increase yield of the light oil obviously.

Owner:CHINA PETROLEUM & CHEM CORP +1

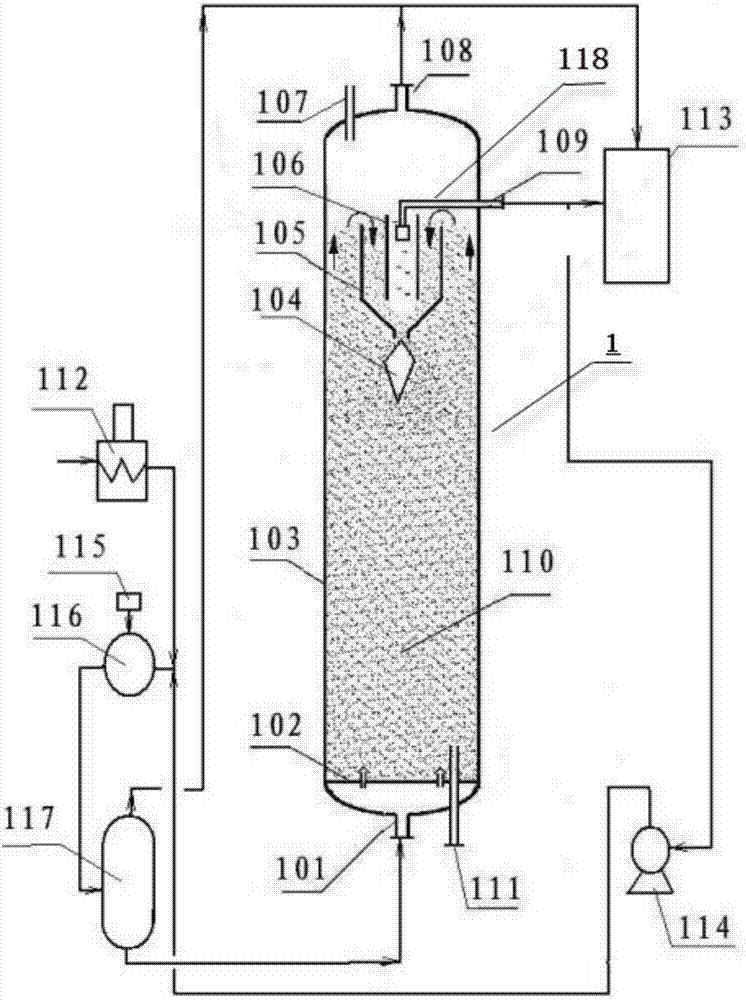

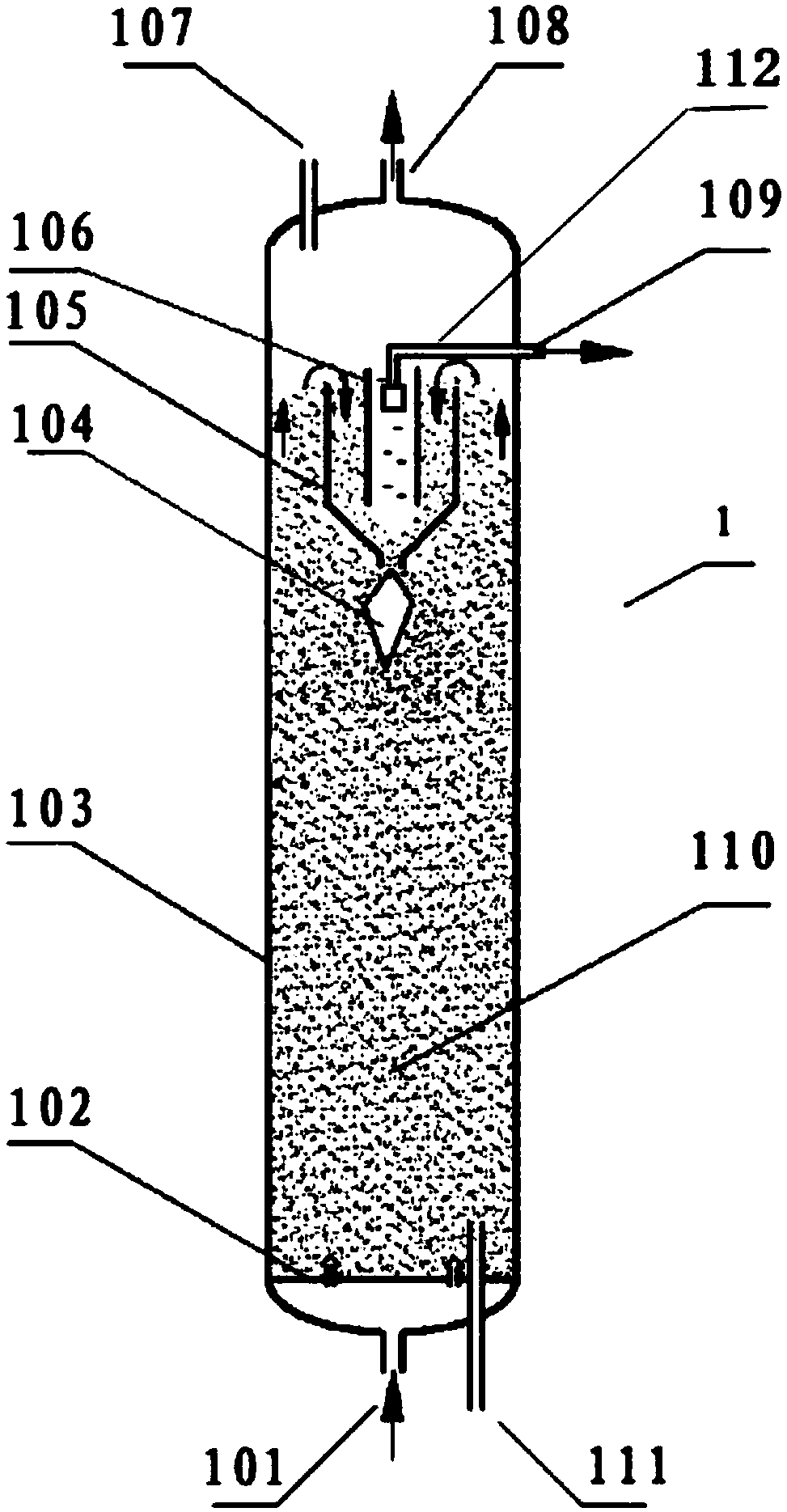

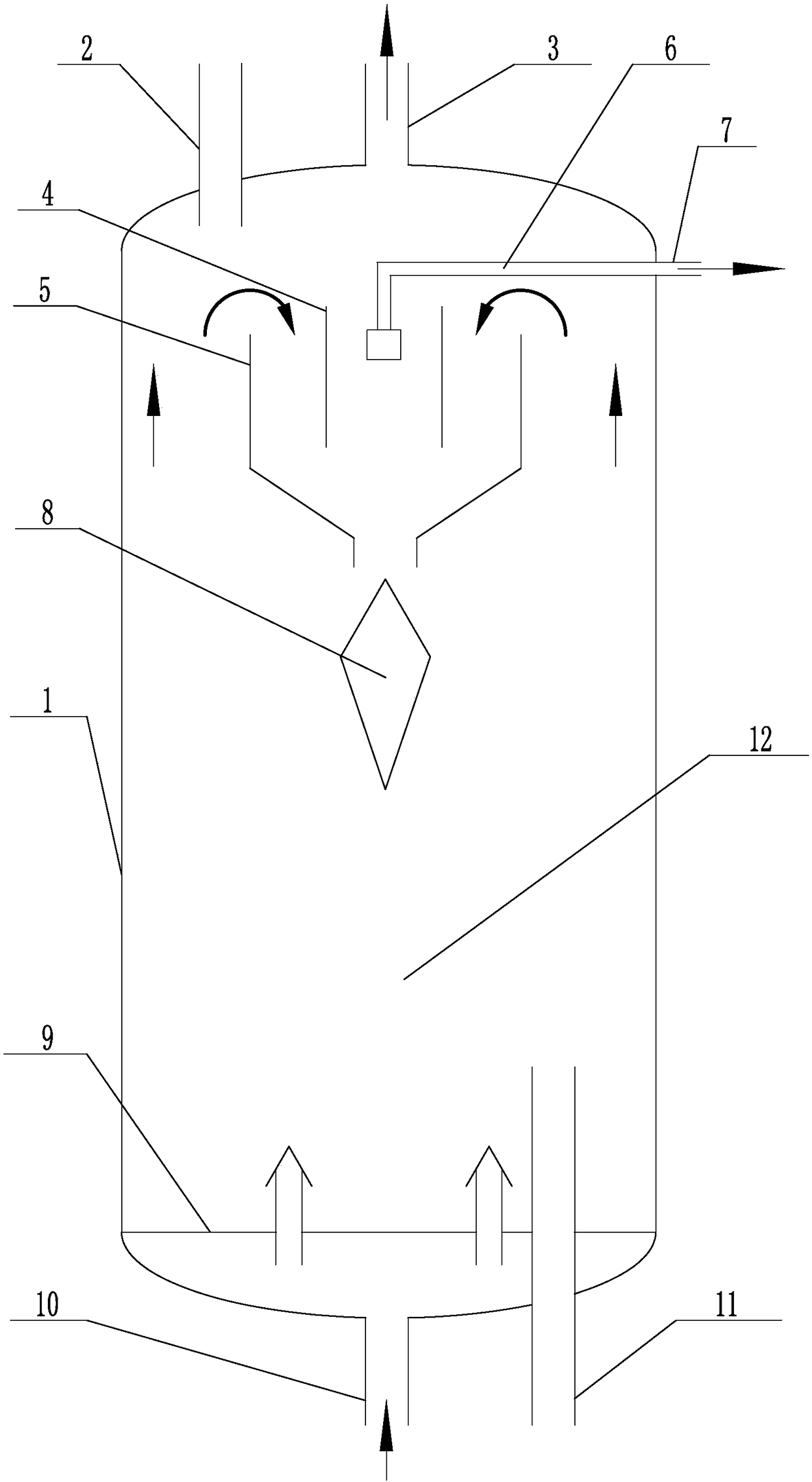

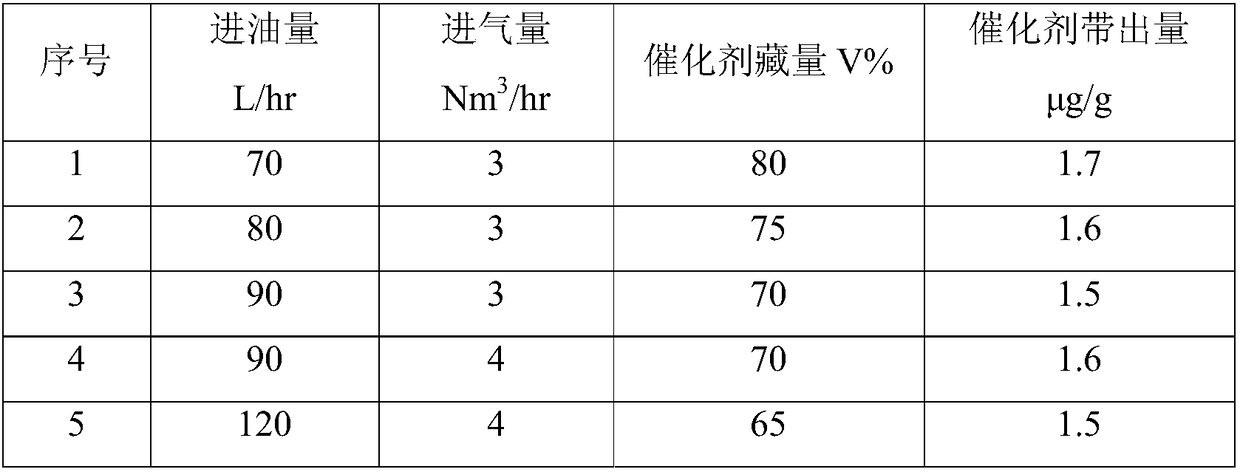

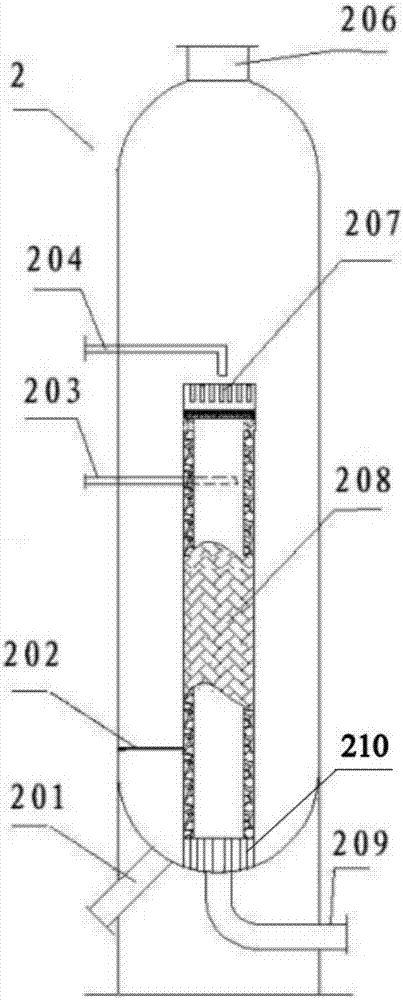

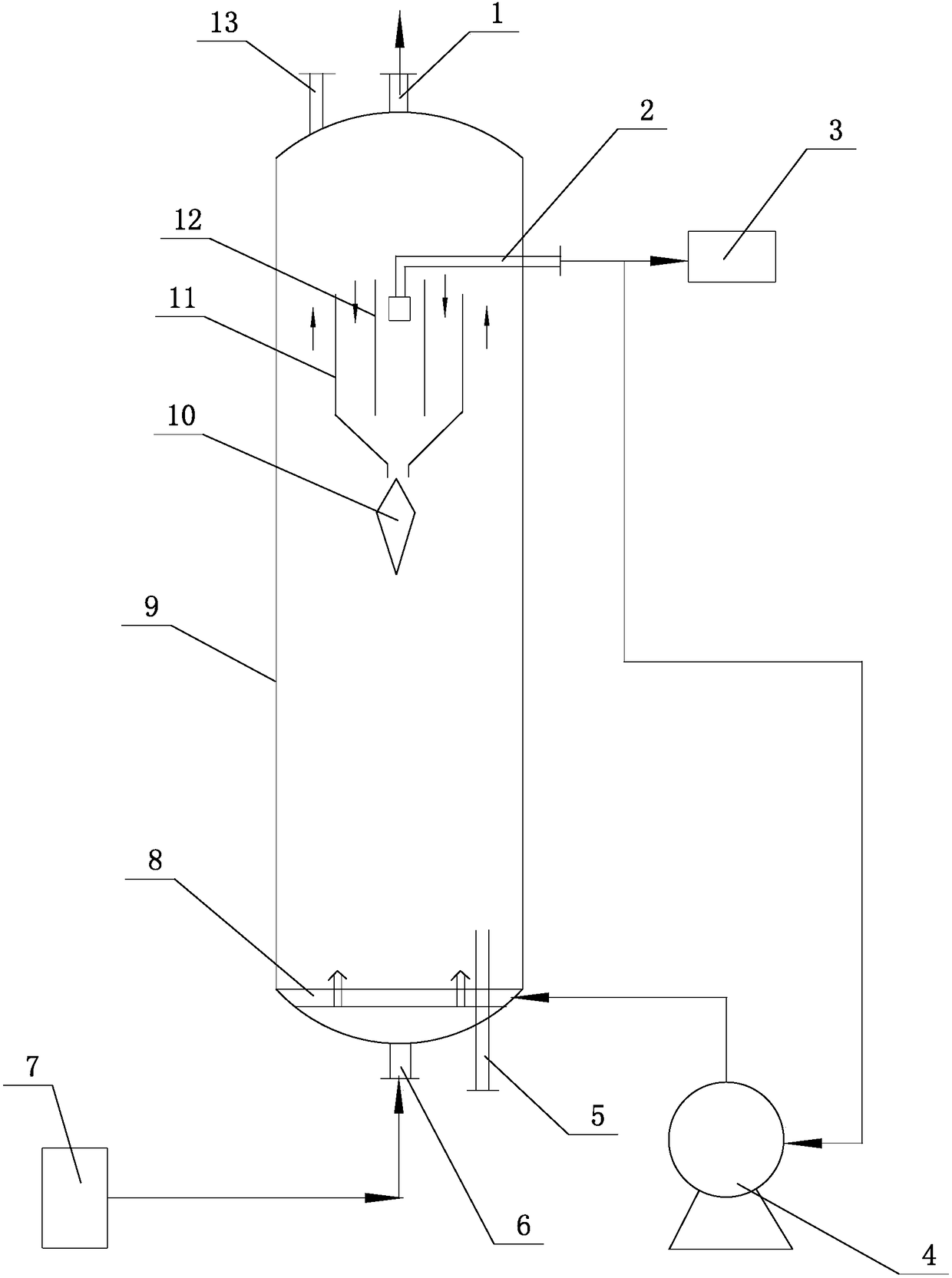

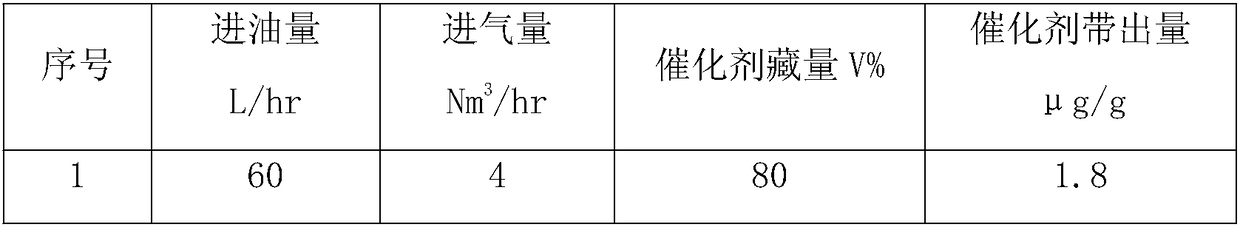

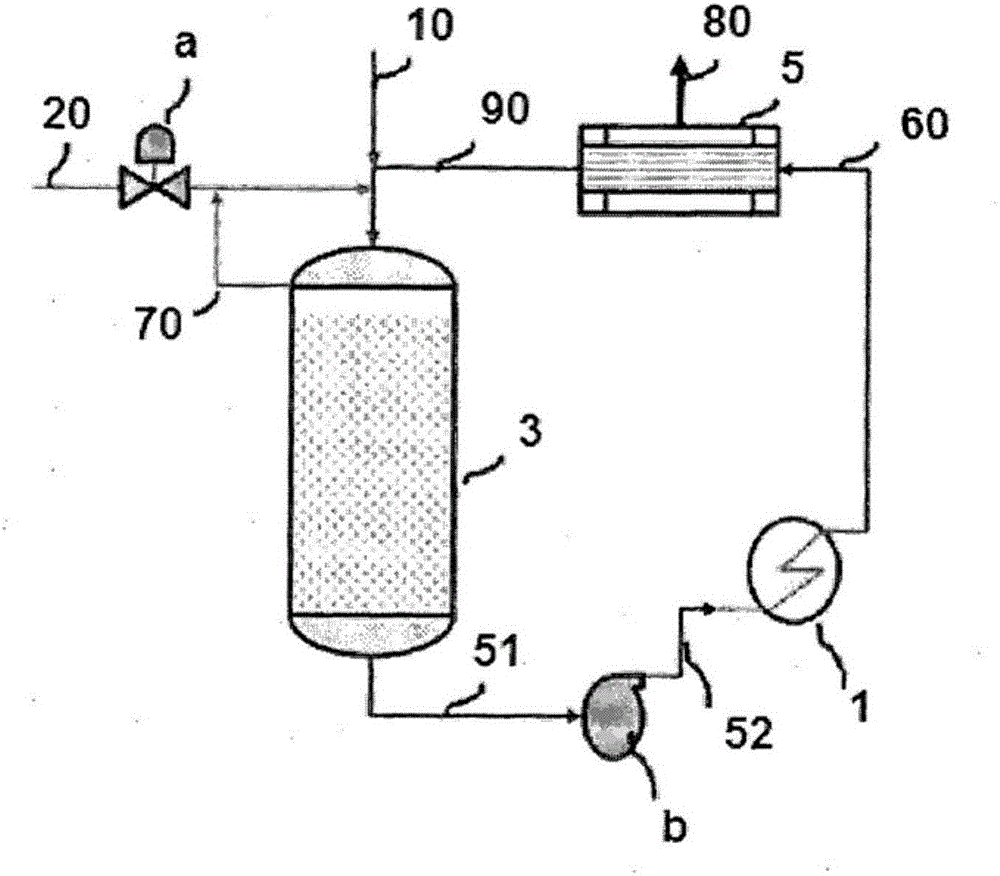

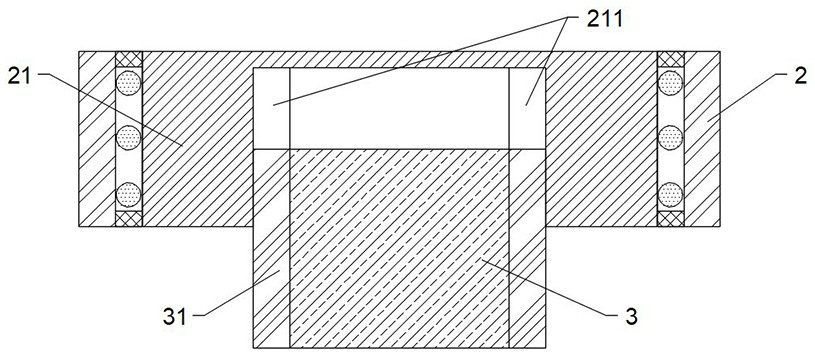

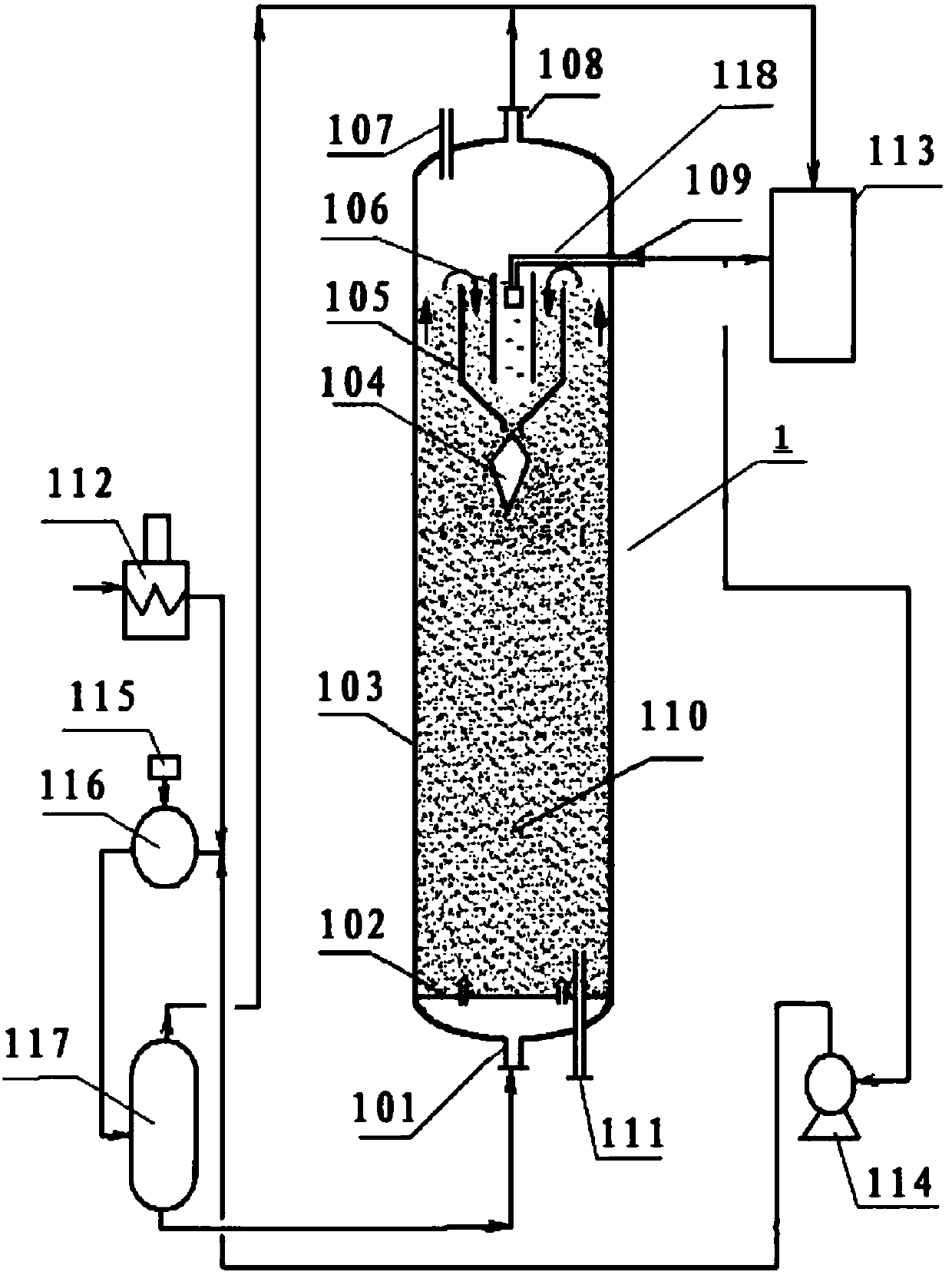

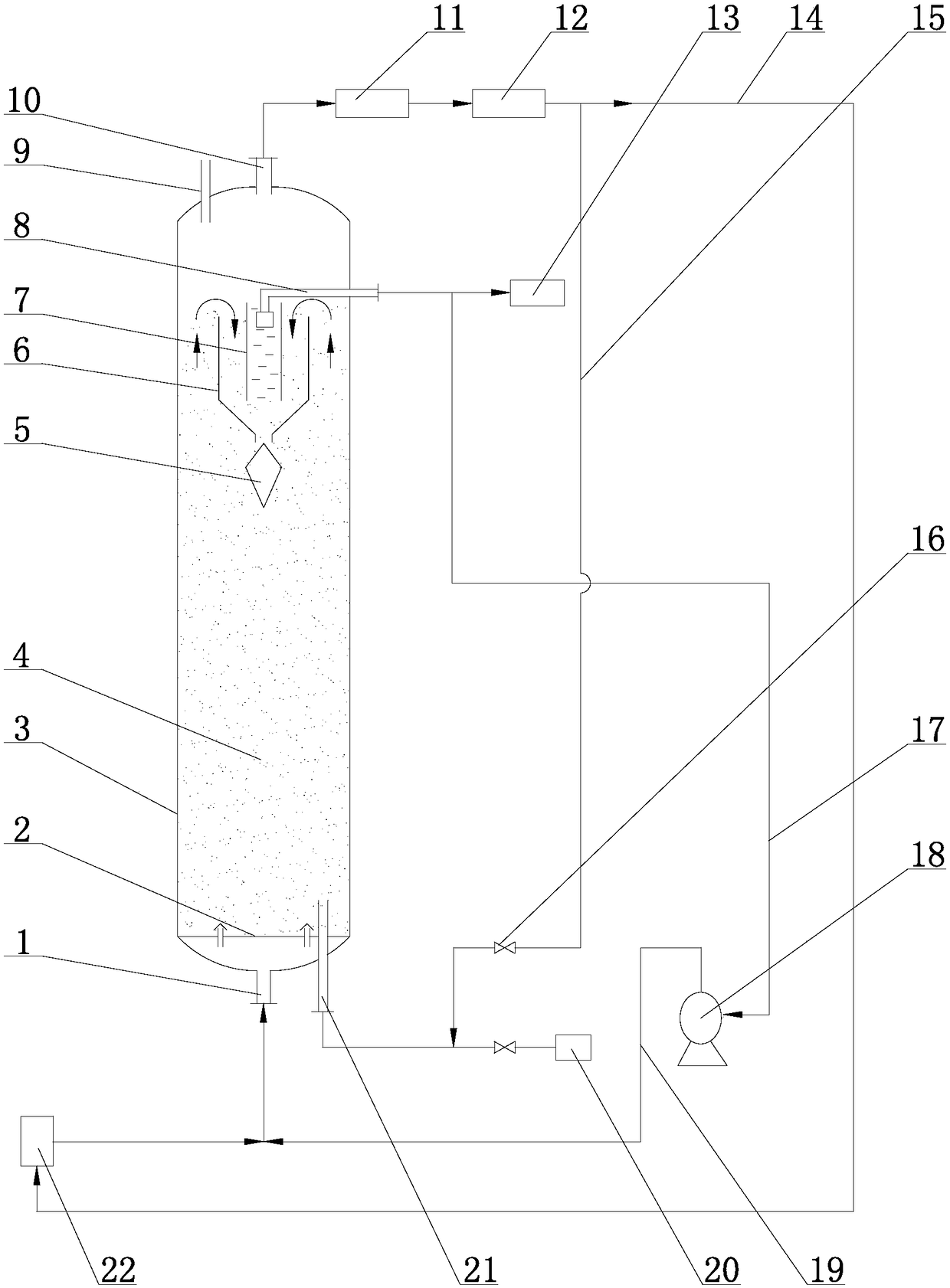

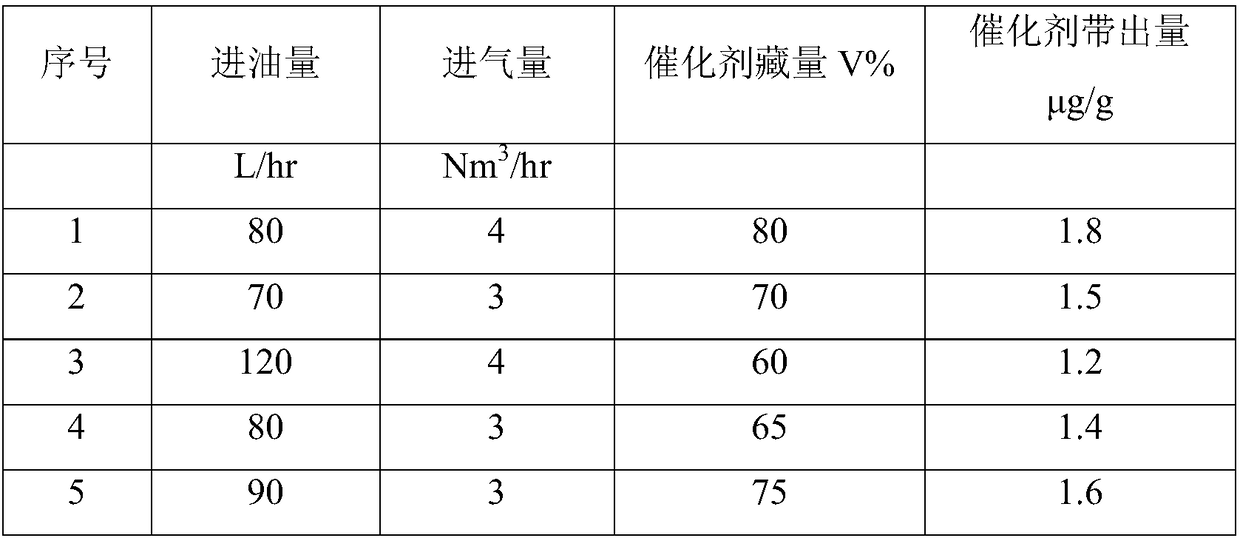

A kind of fluidized bed hydrogenation reaction system and fluidized bed hydrogenation method

ActiveCN107297186BEasy to separateSolve the resistanceChemical/physical processesHydrogenation reactionFluidized bed

The invention relates to a fluidized bed hydrogenation reaction system, which comprises a fluidized bed reactor, wherein the fluidized bed reactor comprises a reactor barrel; a three-phase separator is arranged at the upper part of the reactor barrel and comprises an inner barrel and an outer barrel; openings are formed in the upper ends and the lower ends of the inner barrel and the outer barrel; the opening in the upper end of the outer barrel is lower than that of the inner barrel and the opening in the lower end of the outer barrel is lower than that of the inner barrel; the inner barrel is a straight barrel segment; the straight barrel segment is arranged at the upper part of the outer barrel and a frustum-shaped contraction segment is arranged at the lower part; the opening in the lower end of the contraction segment is the opening in the lower end of the outer barrel; and a gap is arranged between the opening in the lower end of the inner barrel and the outer barrel contraction segment, so that a material passes through the gap. The fluidized bed hydrogenation reaction system is adopted by the fluidized bed hydrogenation method, so that the utilization rate (namely the catalyst inventory in the reactor) of the reactor is further improved, and the hydrogenation reaction effect can be further improved.

Owner:上海竣铭化工工程设计有限公司

Hydrocarbon hydroprocessing technique

ActiveCN101148608AEasy to makeSuitable for large-scale useRefining to eliminate hetero atomsOrganic solventSulfur

The present invention relates to hydrocarbon hydrotreating process including the steps of loading catalyst into the reactor, activating, reaction, etc. The hydrotreating catalyst contains organic nitrogen compound in 0.5-20 wt% of the catalyst, simple substance sulfur in the amount of 30-150 % of the theoretical sulfur demand of the catalyst, and organic solvent in 0.1-50 wt% of the catalyst. The hydrotreating catalyst with the common action of organic nitrogen compound, sulfur and organic solvent has high sulfur holding rate in activation, less concentrated heat release, lowered temperature rise in the catalyst bed and high activity. It may be applied in various kinds of hydrocarbon hydrotreating process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fluidized bed hydrogenated reactor and fluidized bed hydrogenating method

InactiveCN108148621AEasy to separateSolve the resistanceTreatment with moving solid particlesEarth's rotationHydrogenation reaction

The invention belongs to the technical field of hydrogenation, and particularly relates to a fluidized bed hydrogenated reactor and a fluidized bed hydrogenating method. The fluidized bed hydrogenatedreactor comprises a shell, wherein a catalyst adding opening and a gas outlet are formed in the top of the shell; a three-phase separator is arranged on the upper portion of the inside of the shell and comprises two concentric barrels with different inner diameters, namely an inner barrel and an outer barrel; a flow guiding body is arranged below an opening of the lower end of the outer barrel; the shape of the flow guiding body is in the shape of a spindle with the small upper and lower ends and the large middle; a distributing plate is arranged on the lower portion of the inside of the shell; and a material inlet and a catalyst discharging opening are formed in the bottom of the shell. While the capacity utilization ratio of the reactor is improved, a catalyst lean-phase zone is reducedor cancelled, the hydrogenation reaction effect is improved, and the problem that the reaction effect is affected due to uneven distribution of catalysts caused by earth rotation is solved.

Owner:上海竣铭化工工程设计有限公司

Fluidized bed hydrogenation reaction system and fluidized bed hydrogenation method

ActiveCN107297186AEasy to separateSolve the resistanceChemical/physical processesHydrogenation reactionFluidized bed

The invention relates to a fluidized bed hydrogenation reaction system, which comprises a fluidized bed reactor, wherein the fluidized bed reactor comprises a reactor barrel; a three-phase separator is arranged at the upper part of the reactor barrel and comprises an inner barrel and an outer barrel; openings are formed in the upper ends and the lower ends of the inner barrel and the outer barrel; the opening in the upper end of the outer barrel is lower than that of the inner barrel and the opening in the lower end of the outer barrel is lower than that of the inner barrel; the inner barrel is a straight barrel segment; the straight barrel segment is arranged at the upper part of the outer barrel and a frustum-shaped contraction segment is arranged at the lower part; the opening in the lower end of the contraction segment is the opening in the lower end of the outer barrel; and a gap is arranged between the opening in the lower end of the inner barrel and the outer barrel contraction segment, so that a material passes through the gap. The fluidized bed hydrogenation reaction system is adopted by the fluidized bed hydrogenation method, so that the utilization rate (namely the catalyst inventory in the reactor) of the reactor is further improved, and the hydrogenation reaction effect can be further improved.

Owner:上海竣铭化工工程设计有限公司

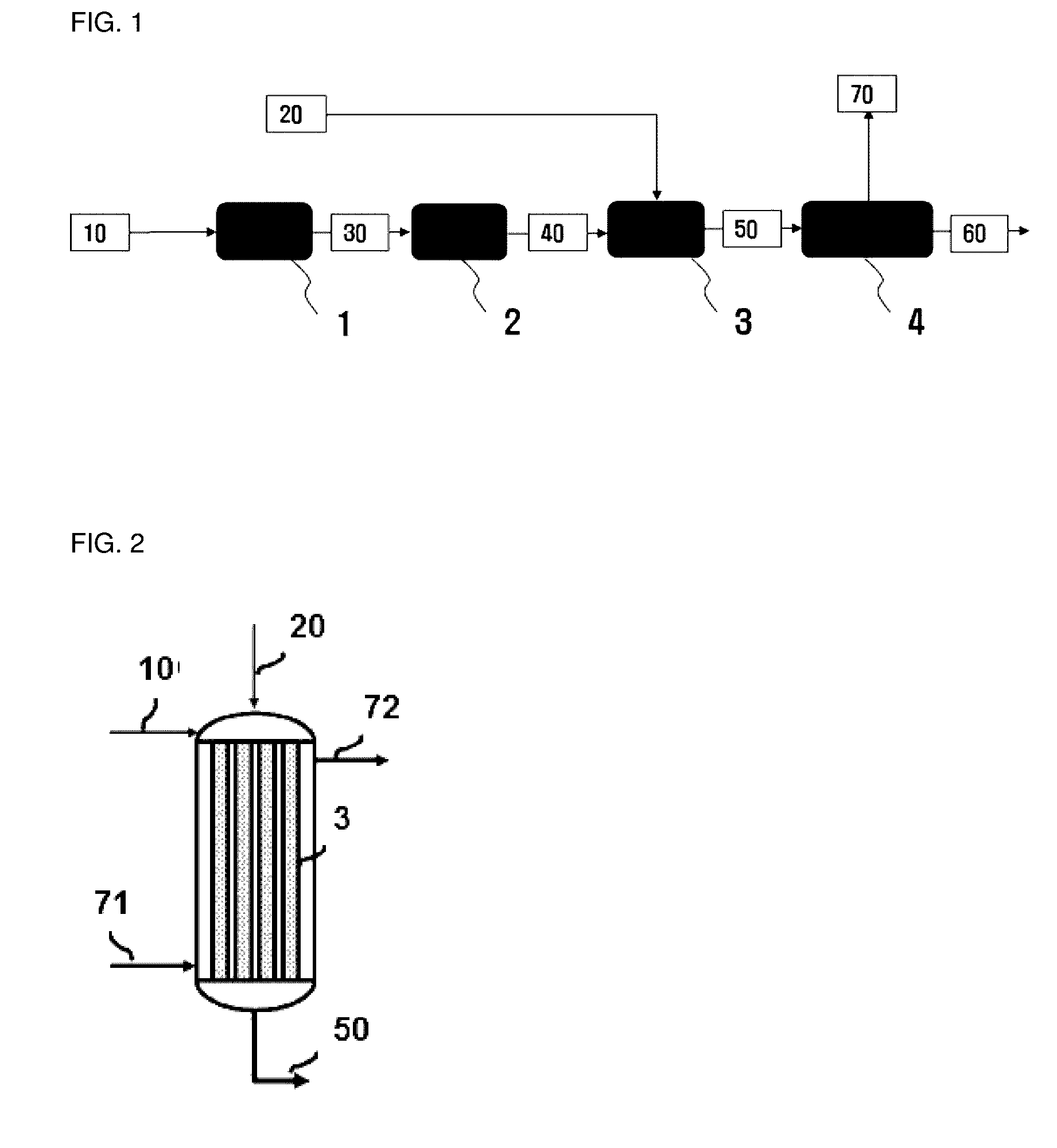

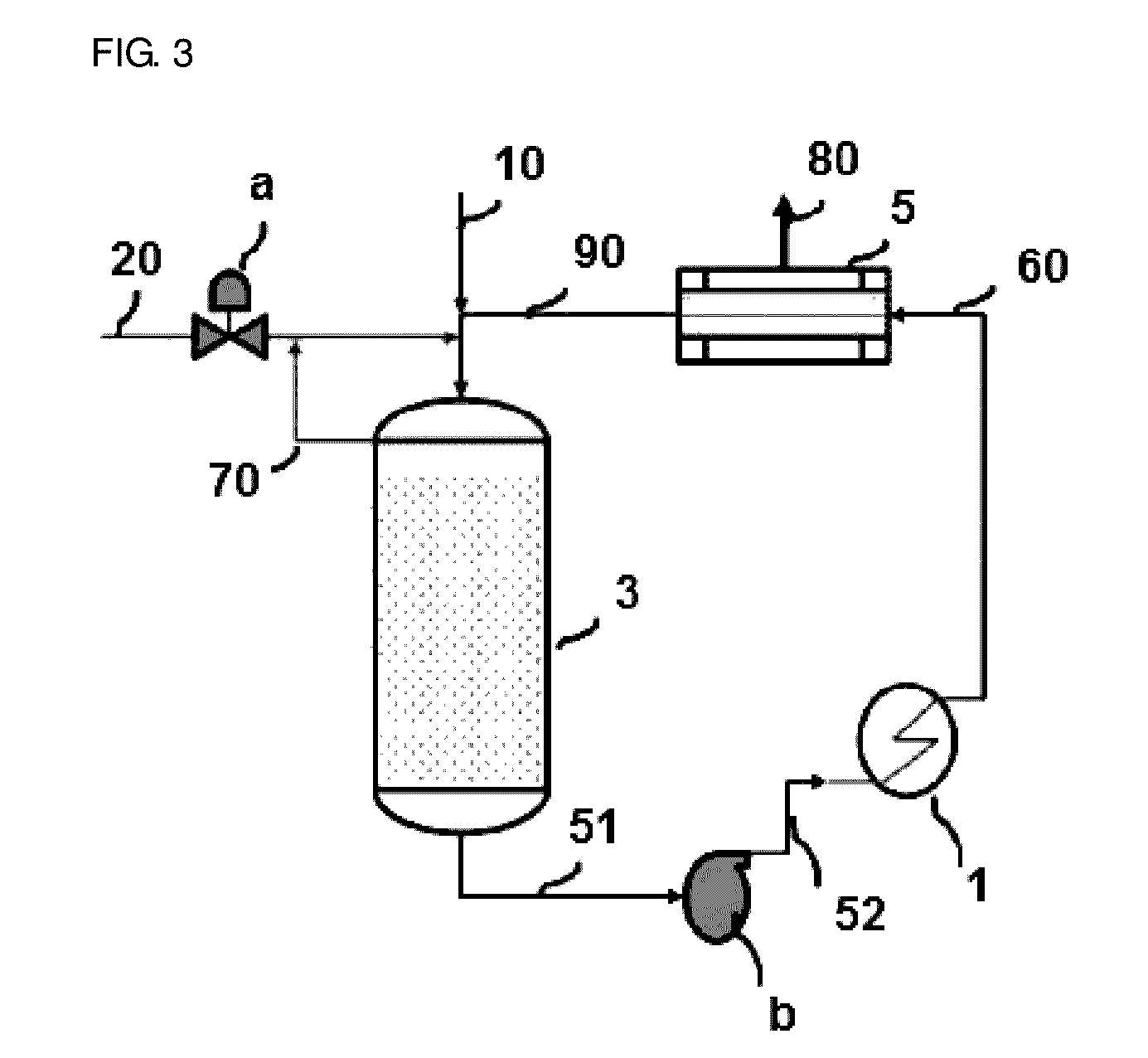

Hydrogenation method of phthalate compound

InactiveUS20160280629A1Improve hydrogenation reaction performanceHigh reaction yieldOrganic compound preparationCarboxylic acid esters preparationHydrogenation reactionHydrogenation process

There are provided a method for hydrogenation of a phthalate compound. According to the method for hydrogenation of the present invention, a hydrogenation reaction is performed in a multi-pipe type reactor in a state in which a viscosity of only a liquid-phase phthalate based raw material is lowered, such that a yield of a hydrogenation reaction process may be improved, and operation stability and economical efficiency on a commercial scale may be improved by hot spot control. According to another method of the present invention, long-term activity of a catalyst used in a reaction is maintained, and performance of the catalyst may be improved, such that stability and economical efficiency of a hydrogenation process may be improved. Therefore, a total amount of the catalyst required in the reaction may be decreased, and a replacement cycle may be extended, thereby making it possible to improving operation stability of the process and economical efficiency at the time of performing the process on a commercial scale.

Owner:HANWHA CHEMICAL CORPORATION

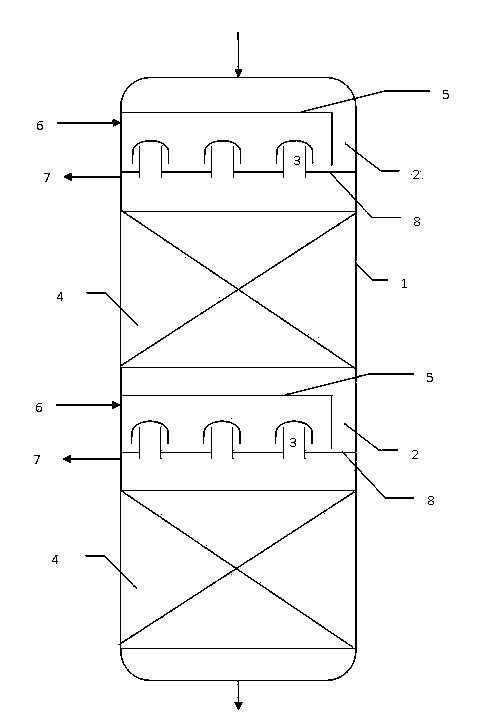

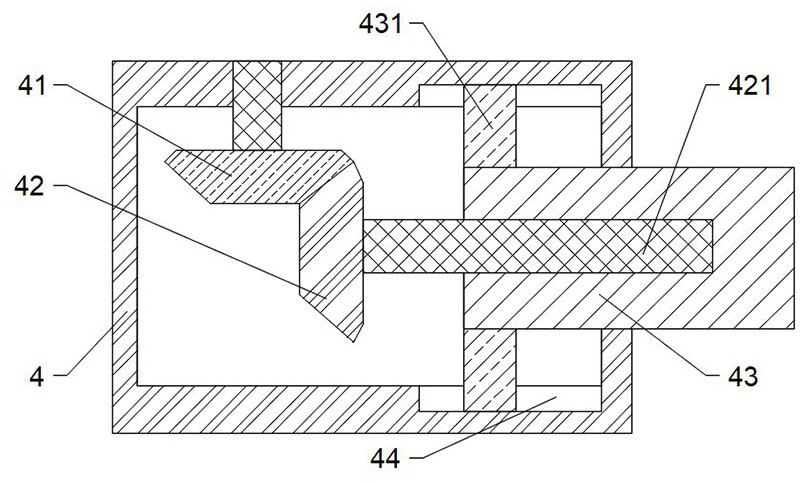

Boiling bed reactor

ActiveCN108067169AEasy to separateSolve the resistanceHydrocarbon oils refiningChemical/physical processesThree-phaseEngineering

The invention relates to the technical field of boiling beds, in particular to a boiling bed reactor. The boiling bed reactor comprises a reactor cylinder, a three-phase separator is arranged at the upper side inside the reactor cylinder, a gas-liquid distributor is arranged at the lower side inside the reactor cylinder and comprises a material distributing pipe, an upper tray and a lower tray, the upper tray and the lower tray form a dual-layer tray structure, gaps are formed by the upper tray and the lower tray, the material distributing pipe penetrates through the upper tray and the lower tray, a hood is arranged at an upper end opening of the material distributing pipe, a pipe wall opened hole is formed in the portion, between the upper tray and the lower tray, of the material distributing pipe, and a circulating oil reactor inlet is further formed between the upper tray and the lower tray. By means of the boiling bed reactor, a solid catalyst which is separated from the three-phase separator is settled in the radial center area of the reactor and flows back into the reactor, the problem that when the three-phase separator is filled with a large dosage of catalyst, the settlingand backflow resistance of the catalyst is large is solved, and it is guaranteed that the three-phase separator still has a good separating effect when filled with a large dosage of catalyst.

Owner:上海竣铭化工工程设计有限公司

Hydrogenation method of phthalate compound

ActiveCN105793228AImprove hydrogenation reaction performanceHigh reaction yieldOrganic compound preparationCarboxylic acid esters preparationHydrogenation reactionHydrogenation process

The present invention relates to a hydrogenation method of a phthalate compound. According to the hydrogenation method of the present invention, a hydrogenation addition reaction occurs in a multi-tube type reactor or the like while the viscosity of only a liquid phthalate based raw material is lowered, thereby improving the yield of a hydrogenation reaction process, improving driving stability through hot spot control, and increasing commercial-scaled economic efficiency. In addition, according to another method of the present invention, the stability and economic efficiency of the hydrogenation process can be increased by maintaining the activity of a catalyst for a long time and improving the performance of the catalyst. Therefore, the present invention can reduce the total use amount of the catalyst required in the reaction and extend the replacement period, thereby improving process driving stability and economic efficiency when running a commercial-scaled process.

Owner:HANWHA CHEMICAL CORPORATION

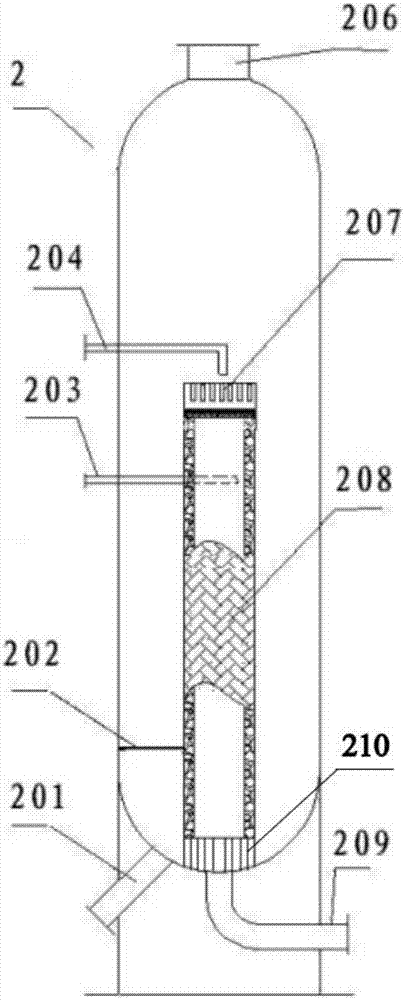

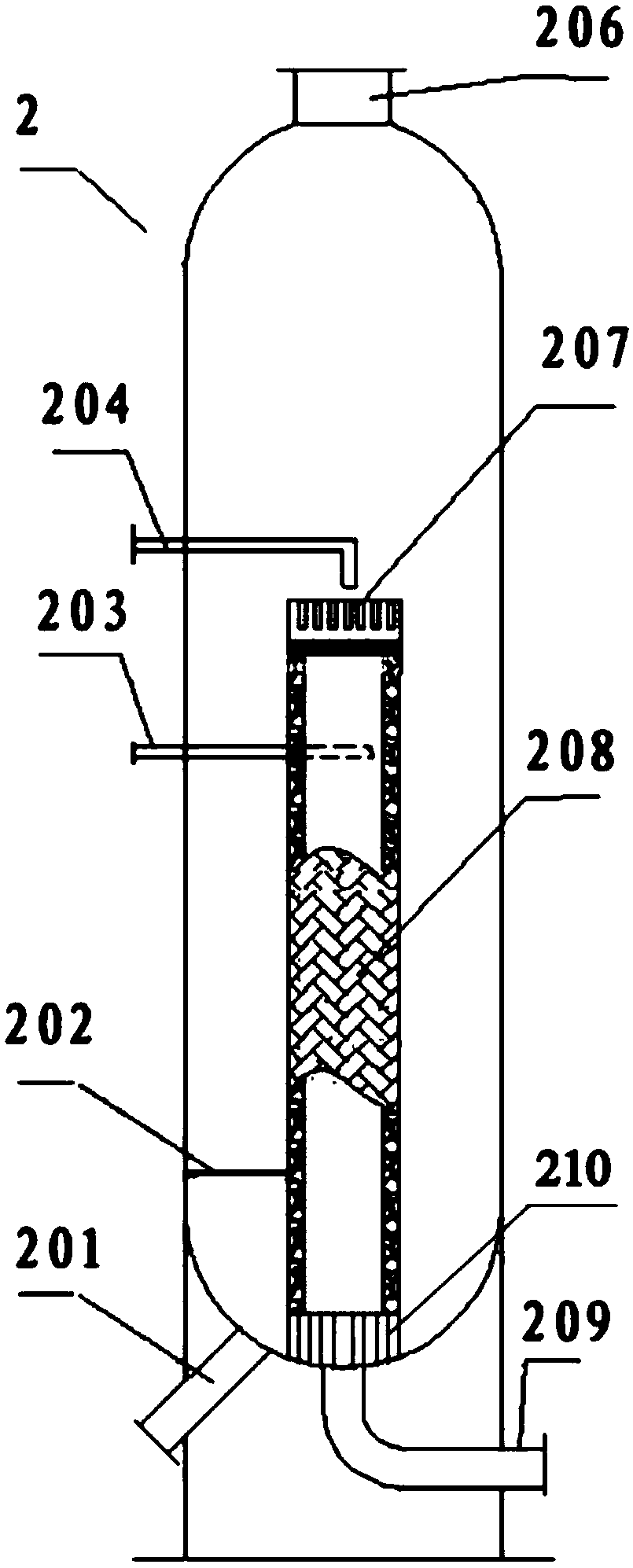

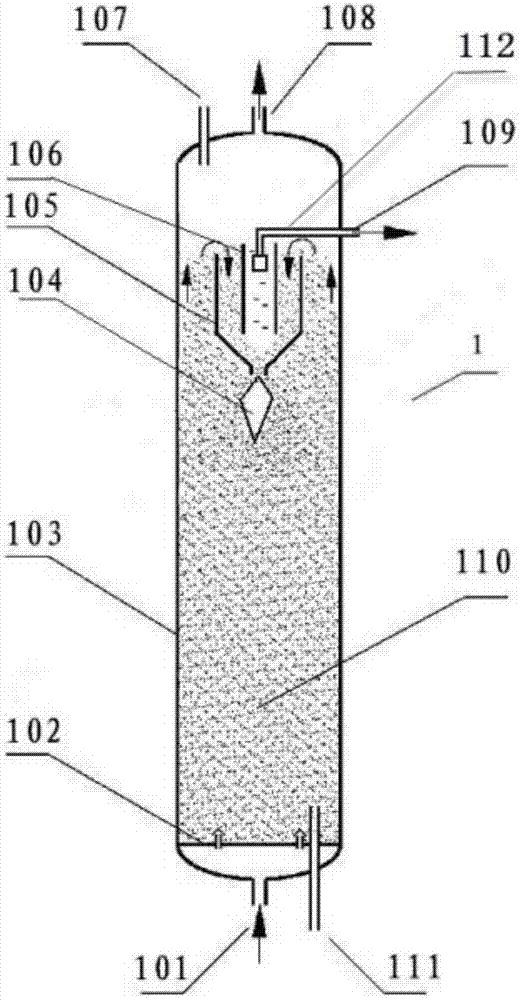

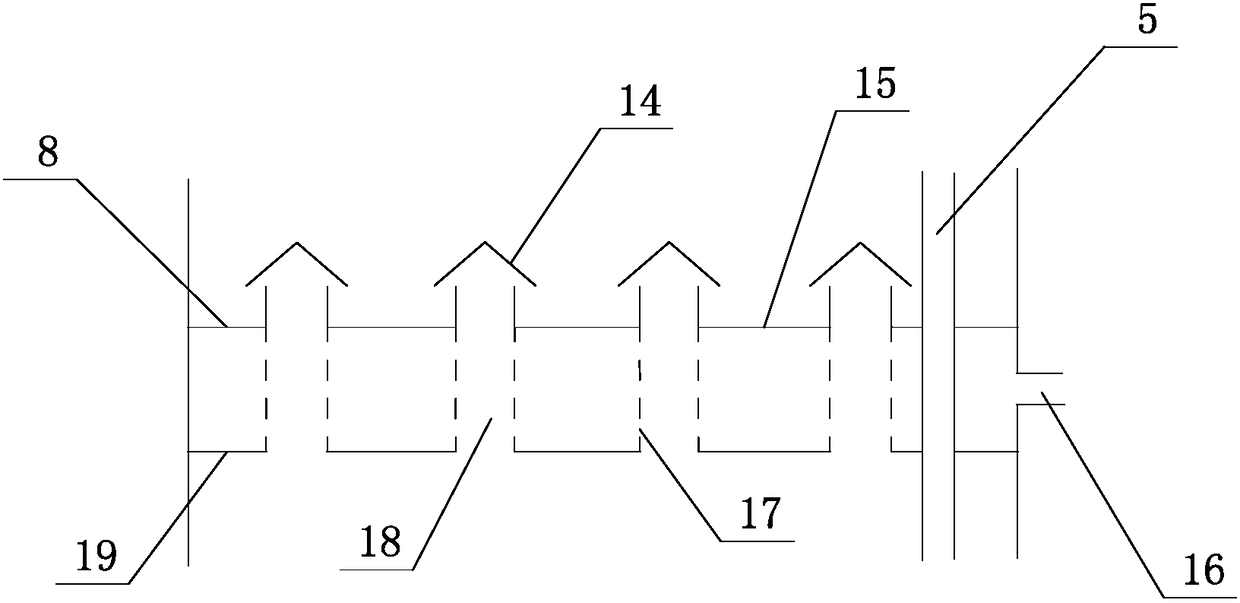

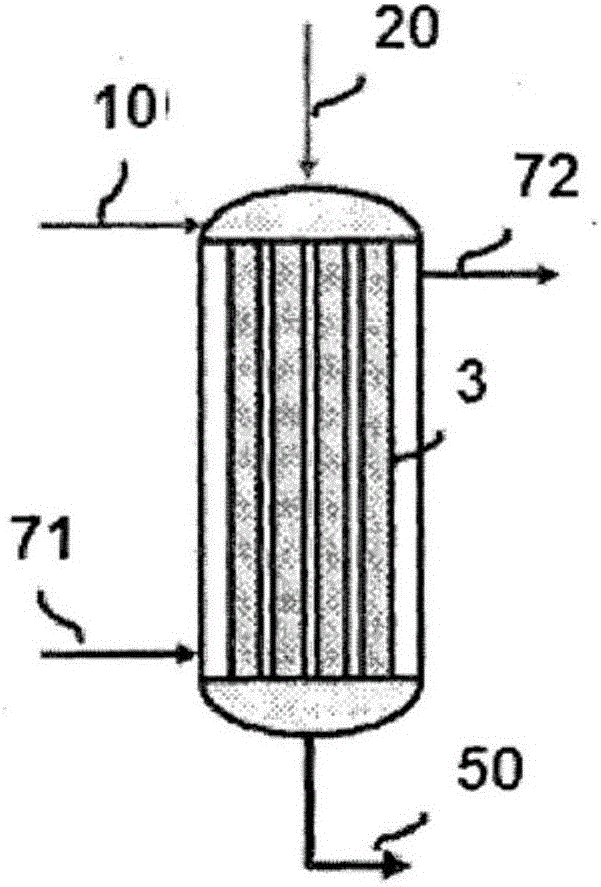

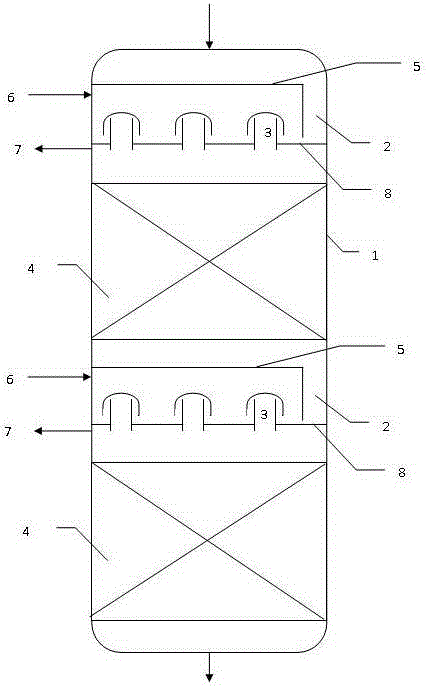

A two-phase hydrogenation reactor and a two-phase hydrogenation method

ActiveCN103789006AReduce volumeHigh hydrogen dissolving efficiencyHydrocarbon oil crackingTreatment with hydrotreatment processesGas phaseHydrogenation reaction

The invention provides a two-phase hydrogenation reactor and a two-phase hydrogenation method. Each space surrounded by the upper parts of each gas-liquid distributor, a corresponding liquid-phase collecting tray and a corresponding downcomer is a gas-phase chamber. Hydrogen is introduced into the gas-phase chambers from outside of the reactor. The liquid phase in the upper part of the reactor is collected by the liquid-phase collecting trays and flows onto gas-liquid distributing trays through the downcomers. The gas phase and the liquid phase are subjected to violent mass transfer by the gas-liquid distributors so that the hydrogen can be dissolved in the liquid phase well. The gas phase and the liquid phase in gas and liquid materials are separated after passing through the gas-liquid distributing trays. The liquid phase where the hydrogen is dissolved goes downward into catalyst bed layers to perform hydrogenation. The gas phase converges under the gas-liquid distributors and is discharged from the reactor. The two-phase hydrogenation reactor and the two-phase hydrogenation method can further enhance reaction effects of two-phase hydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

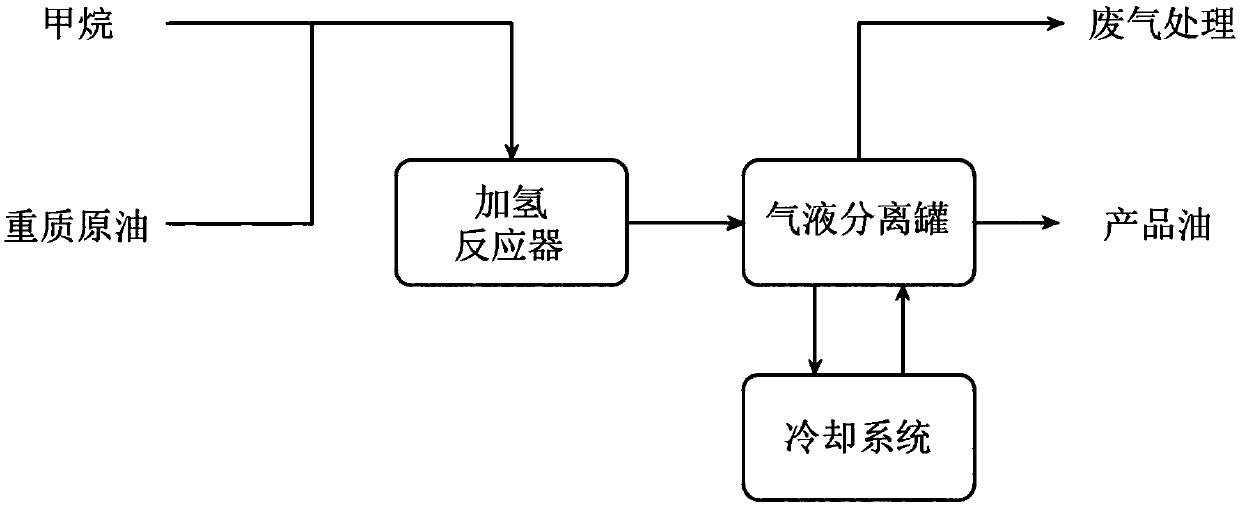

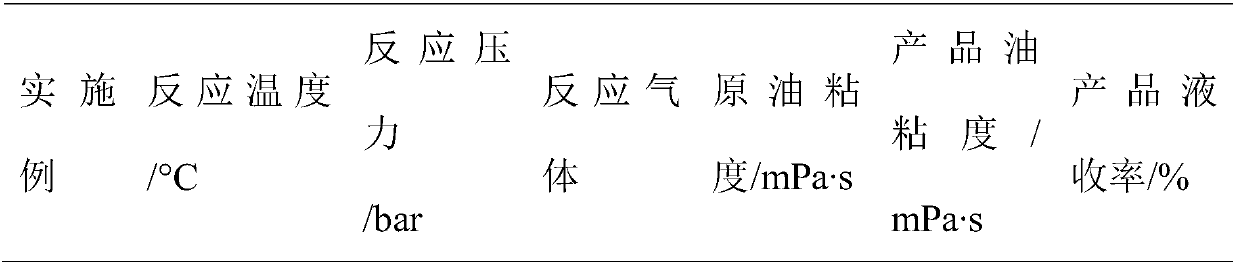

Method for catalytic hydrogenation of heavy crude oil by using methane

InactiveCN109517624ARealize green operationEliminate the step of reforming to produce hydrogenTreatment with hydrotreatment processesAlkaneHydrogenation reaction

The invention discloses a method for catalytic hydrogenation of heavy crude oil by using methane. Heavy crude oil is pumped into a hydrogenation reactor containing catalysts; methane is used as reaction gas for catalytic hydrogenation reaction; macromolecules in the heavy crude oil are decomposed into alkane and light-weight aromatic compounds; product oil flows out from a lower side of the hydrogenation reactor and is introduced into a gas-liquid separation tank for gas-liquid separation; tail gas flows out from the pipeline from the top of the gas-liquid separation tank and is used for subsequent treatment; product oil flows into a product tank from the bottom of the gas-liquid separation tank to be collected; the gas liquid separation tank is connected with a cooling system for reducingthe temperature of the product oil; the viscosity of the obtained product oil is 107 to 379 mPa.s; the density is 0.9511 to 0.9642 g / ml; the total acidity is 0.02 to 1.55 mg KOH / g; the average molecular weight is 172 to 210 g / mol; the water content is 0.21 to 0.30 weight percent; the product liquid yield is 96.9 to 104 percent. The operation cost of the technical flow process is reduced; the hydrogenation reaction effect is effectively improved; the operation pressure is reduced; a green and environmental-friendly process is achieved.

Owner:广西华大骄阳能源环保科技有限公司

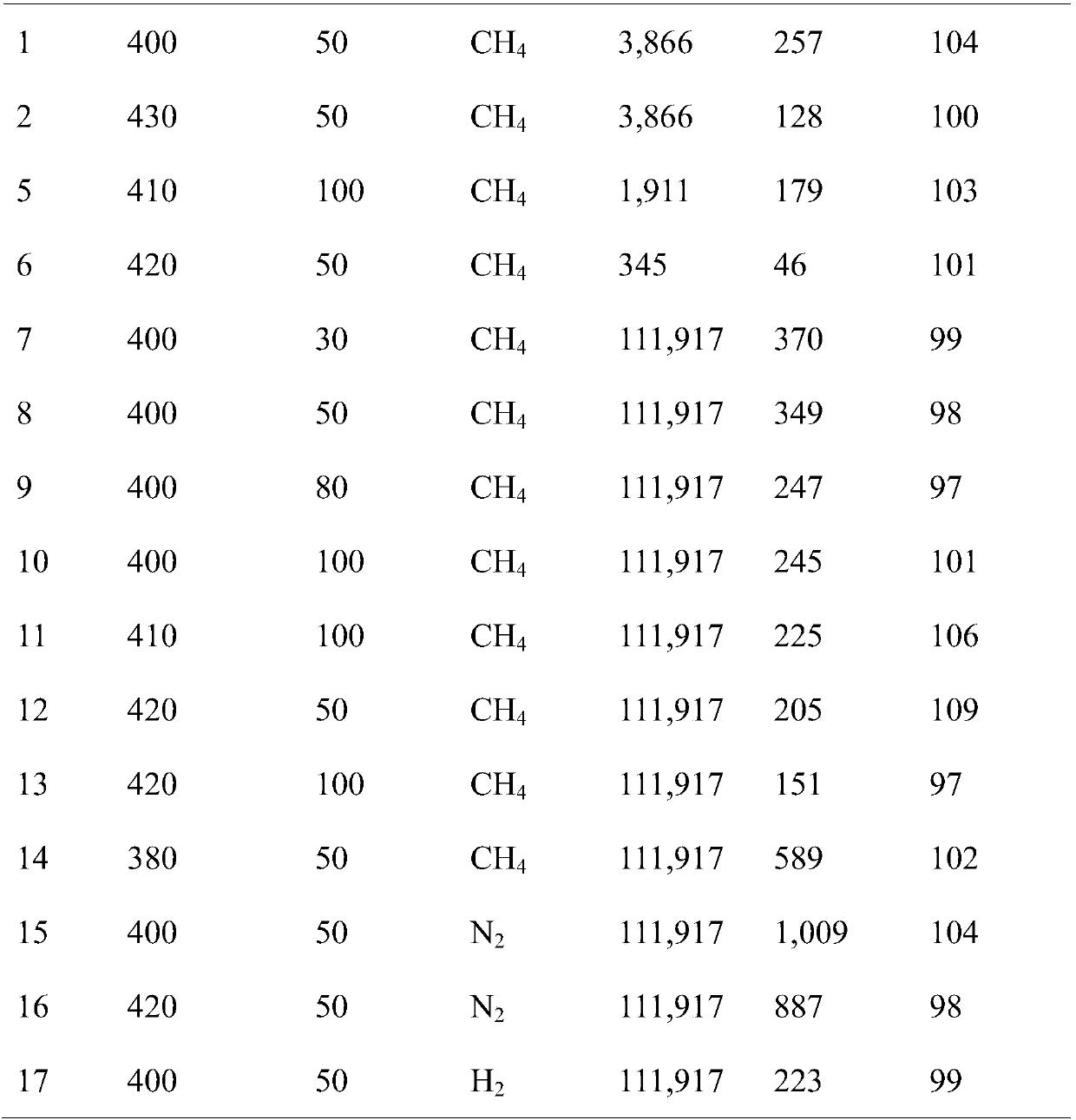

Catalytic hydrogenation device for laboratory

ActiveCN114471382ASmooth rotationEasy to moveChemical/physical processesPtru catalystHydrogenation reaction

The invention relates to the field of experimental equipment, in particular to a laboratory catalytic hydrogenation device which comprises a shell, a rotating groove is formed in the top of the shell, a rotating rod is slidably connected into the rotating groove, the bottom of the rotating rod is inserted into a base in the shell, a guide column is arranged on the upper portion of the rotating rod, and a guide groove is formed in the periphery of the guide column; a gear box is arranged on the left side of the guide column, a driving bevel gear is arranged in the gear box, and a hand wheel is connected to the top of the driving bevel gear and arranged on the top outside the shell; the right side of the driven bevel gear is connected with a threaded rod, the threaded rod is in threaded connection with a transmission block, the right side of the transmission block penetrates out of the gearbox, and the right end of the transmission block is connected with a guide piece. And a plurality of filling assemblies are arranged on the rotating rod. Therefore, the catalyst and reactants can be uniformly mixed, the hydrogenation reaction effect is improved, after the reaction is completed, the catalyst is quickly replaced, and the time is saved.

Owner:WEIFANG UNIVERSITY

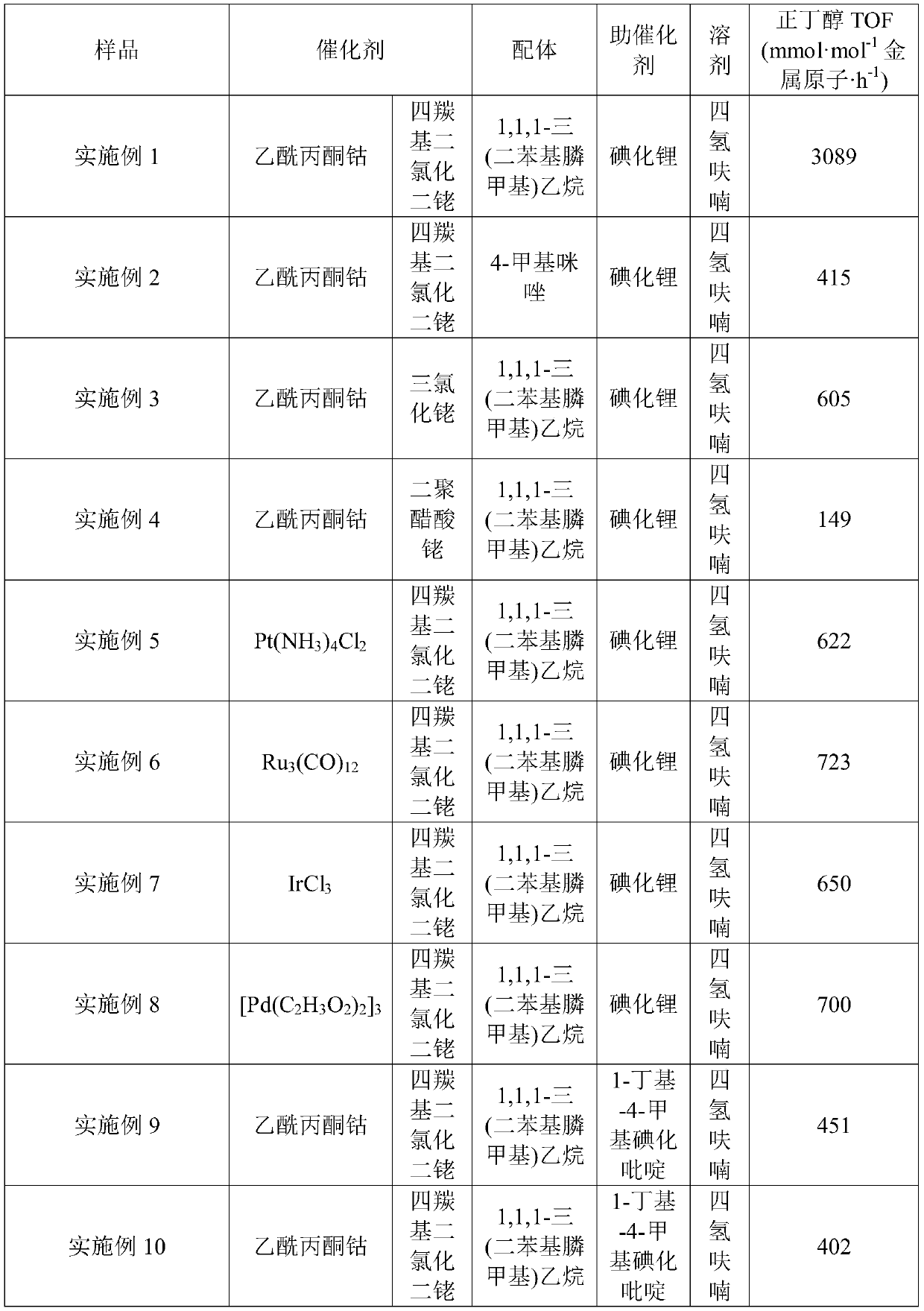

Catalytic system for hydrogenation of carbon dioxide and method for synthesizing n-butanol

InactiveCN109908960AImprove hydrogenation reaction performanceImprove reaction efficiencyOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsIodideCarbon dioxide

The invention provides a catalytic system for hydrogenation of carbon dioxide and a method for synthesizing n-butanol. The catalytic system comprises a compound containing transition metal elements, an organic ligand and an iodide cocatalyst. Compared with a single catalyst, the homogeneous catalytic system provided by the invention greatly improves reaction efficiency through a synergistic effectof the compound containing transition metal elements, the organic ligand and the iodide cocatalyst, can improve effect of hydrogenation of carbon dioxide, particularly the effect of preparing n-butanol by hydrogenation of carbon dioxide, has the advantages of low cost and readily available raw materials, can directly utilize carbon dioxide, has important significance for recycling carbon resources, and particularly provides an economical and feasible method for synthesizing n-butanol.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

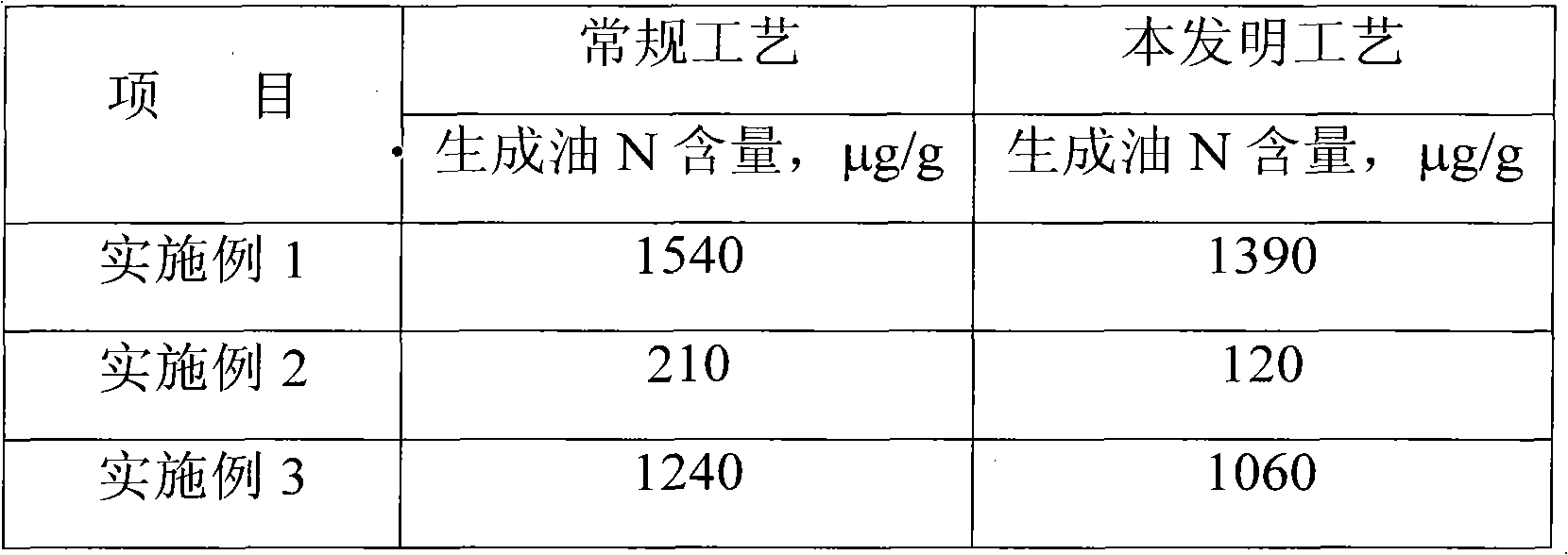

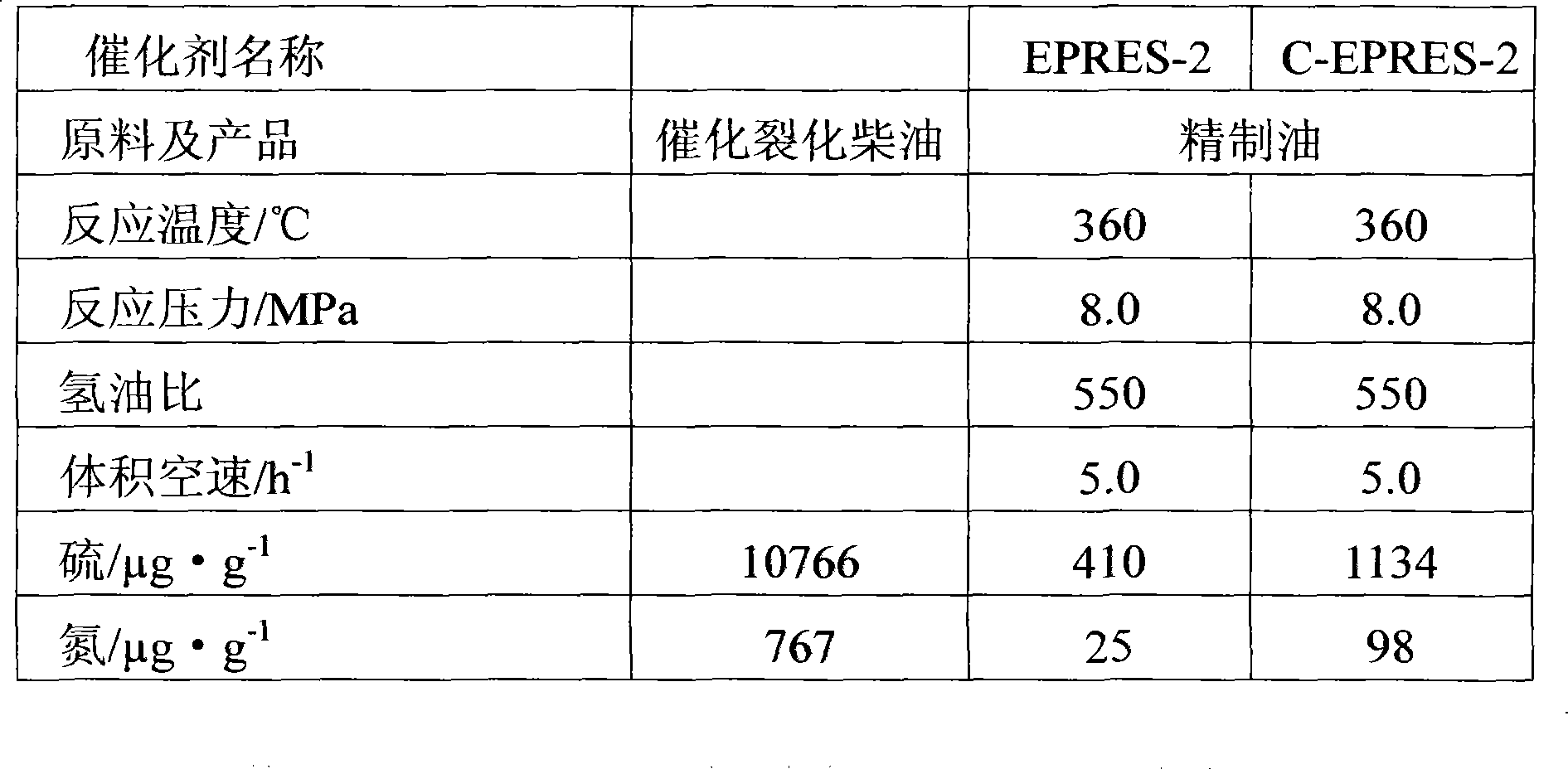

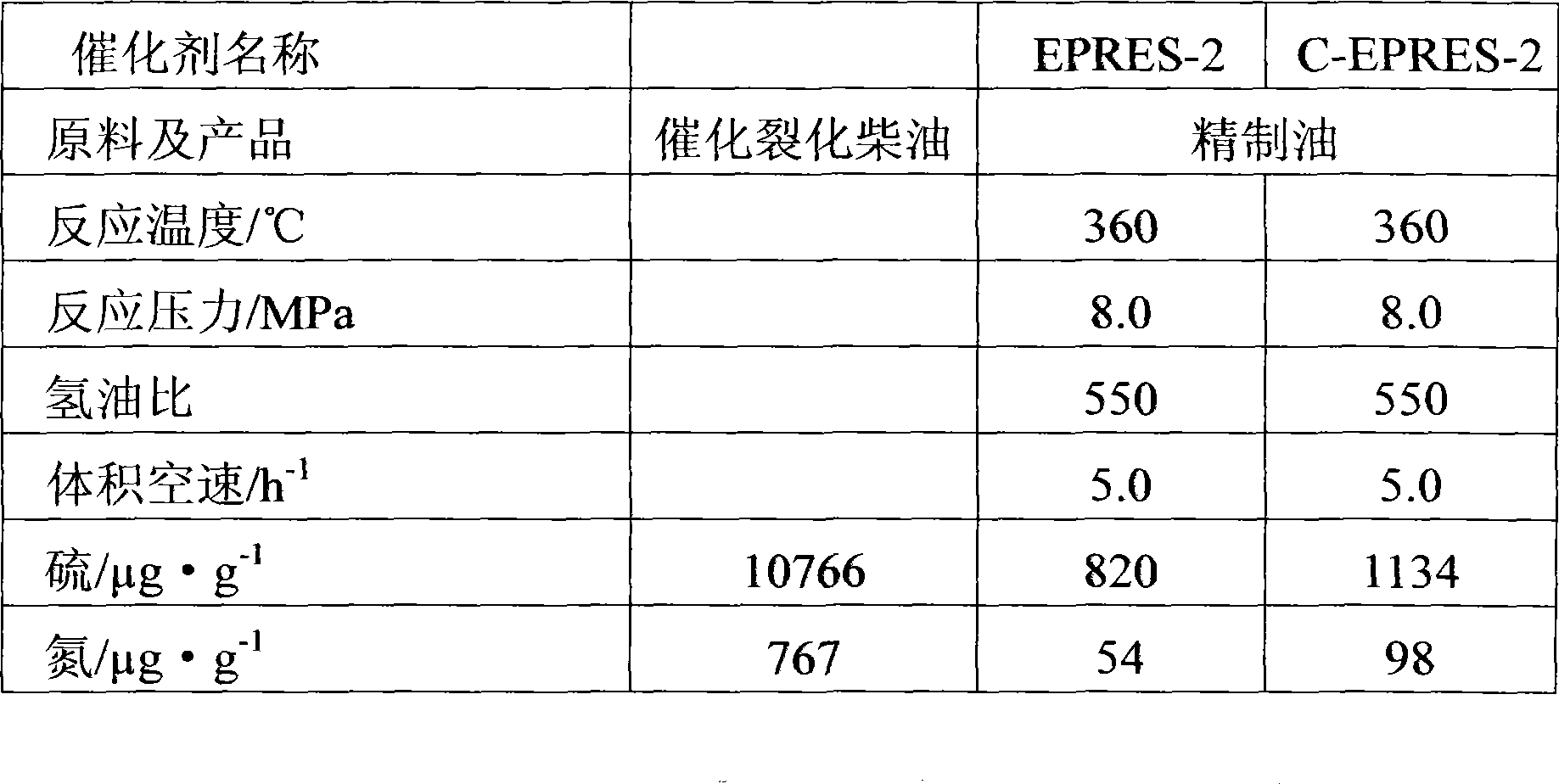

Shale oil diesel fraction single-stage serial hydrorefining method

ActiveCN103773460AHigh saturationQuality improvementTreatment with hydrotreatment processesPtru catalystSpace velocity

The invention discloses a shale oil diesel fraction single-stage serial hydrorefining method which is as follows: before a shale oil and diesel fraction and hydrogen enter a first reactor, the shale oil and diesel fraction and the hydrogen firstly are mixed with part of generated oil for direct heat transfer to 150-250 DEG C, then pass in a volume space velocity of 0.5-4.0h<-1> through the first reactor which is filled with a high-porosity hydrofining catalyst and conventional hydrotreating catalyst mixture; after heat transfer, a first reactor effluent directly passes in a volume space velocity of 0.3-1.0h<-1> through the second reactor in which the average reaction temperature is 350-390 DEG C, and the second reactor is filled with a conventional hydrofining catalyst. The method can improve the diene saturation performance of a whole reaction system, avoids coking of raw oil in heating or heat transfer processes, prolongs the running period of a device, and improves the quality of products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Shale oil one-stage in series hydrofining technological method

ActiveCN102311788BImprove hydrogenation reaction performanceTreatment with hydrotreatment processesHydrogenation reactionReaction temperature

The invention discloses a shale oil one-stage in series hydrofining technological method, which comprises the following step: shale oil raw material and hydrogen firstly exchange heat with thermal media to 200-280 DEG C, and pass through a first reactor by the volume per hour of 0.5h-1 to 4.0h-1, and high-voidage hydrofining catalysts are arranged in the first reactor; and materials flowing out of the first reactor directly pass through a second reactor by the volume per hour of 0.3h-1 to 1.0h-1 after being heated by a heating furnace, the average reaction temperature in the second reactor is 360-420 DEG C, and conventional hydrofining catalysts are arranged in the second reactor. With the method disclosed by the invention, the hydrogenation reaction effect is improved under the condition of ensuring the long-term stable operation of a shale oil hydrogenation device.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of coal tar full-fraction ebullating bed hydrogenation method

ActiveCN107298984BIncrease profitImprove hydrogenation reaction performanceTreatment with hydrotreatment processesCoal tar distillateVapor–liquid separator

Owner:上海竣铭化工工程设计有限公司

Preparation system and method of polyglycolic acid

PendingCN112058184AFully dispersed and brokenImprove hydrogenation reaction performanceChemical/physical processesHydrogenation reactionGlycolic acid

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Boiling bed hydrogenation reaction system and boiling bed hydrogenation process method

PendingCN108144556ASolve easy cokingEasy to operateHydrocarbon oil crackingHydrocarbon oils refiningHydrogenation reactionHydrogenation process

The invention belongs to the technical field of hydrogenation, and particularly relates to a boiling bed hydrogenation reaction system and a boiling bed hydrogenation process method. On one hand, theproblem of coking of parts of pipelines caused by intermittent operation of a catalyst discharge system can be effectively solved. On the other hand, the use ratio of a reactor can be further increased (namely, reserve of catalysts in the reactor is improved), hydrogenation reaction effects are further improved, operating stability of the system is improved, and particularly, stable boiling stateof the catalysts can be maintained in start, in stop and under unusual service conditions.

Owner:上海竣铭化工工程设计有限公司

Hydrogenating catalyst composition and preparation process thereof

ActiveCN100360231CSolve the problem of concentrated heat releaseImprove vulcanization effectPhysical/chemical process catalystsRefining to eliminate hetero atomsOrganic solventSulfur

This invention relates to the compound of hydro catalyst and its preparation method. The compound contains the hydro catalyst, the organic nitrogen compound the content of which is 0.5-20%, the sulfur element which is composed of 30-150% sulfur demand of the hydro catalyst and the organic solution the weight of which is 0.1-50% of the catalyst. The preparation processes is leading-in the demanded mater when the hydro catalyst is oxide. This hydro catalyst compound can improve the sulfur holding ratio of the catalyst which is activated, and slow up the concentrate heat release, decrease the elevated temperature of the catalyst bed, and increase the activity of the catalyst through the lead-in organic nitrogen, sulfur and organic solution. This invention can be applied to the treatment processes of any hydro catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process of treating hydrogenation catalyst before application

ActiveCN101088616BImprove vulcanization effectImprove hydrogenation reaction performanceCatalyst activation/preparationRefining by selective hydrogenationAs elementOrganic solvent

Owner:CHINA PETROLEUM & CHEM CORP +1

Fluidized bed hydrogenation reaction equipment and fluidized bed hydrogenation method

ActiveCN108148620AEasy to separateSolve the resistanceChemical/physical processesHydrocarbon oils treatmentFluidized bedHydrogenation reaction

The invention belongs to the technical field of hydrogenation, and particularly relates to fluidized bed hydrogenation reaction equipment and a fluidized bed hydrogenation method. The fluidized bed hydrogenation reaction equipment comprises a fluidized bed hydrogenation reactor, a catalyst adding system and a catalyst adding pipeline, wherein the catalyst adding system comprises a catalyst storagetank and a catalyst delivering pipeline; the catalyst delivering pipeline communicates with the catalyst storage tank and inner space of the fluidized bed hydrogenation reactor; at least two valves are arranged on the catalyst delivering pipeline; the catalyst delivering pipeline between the two valves communicates with the catalyst adding pipeline by a hydrogen sulfide leakage prevention pipeline; and at least one valve is arranged on the hydrogen sulfide leakage prevention pipeline. By the fluidized bed hydrogenation reaction equipment, potential safety hazards caused by internal leakage due to frequent operation under special working conditions when a catalyst is added in a system are solved; the utilization rate of the reactor is further increased, the hydrogenation reaction effect isimproved, and the stability of operation of the device is improved; and the fluidized bed hydrogenation method is scientific and reasonable, and simple and practicable.

Owner:上海竣铭化工工程设计有限公司

A kind of two-phase hydrogenation reactor and two-phase hydrogenation method

ActiveCN103789006BReduce volumeHigh hydrogen dissolving efficiencyHydrocarbon oil crackingTreatment with hydrotreatment processesHydrogenGas phase

The invention provides a two-phase hydrogenation reactor and a two-phase hydrogenation method. Each space surrounded by the upper parts of each gas-liquid distributor, a corresponding liquid-phase collecting tray and a corresponding downcomer is a gas-phase chamber. Hydrogen is introduced into the gas-phase chambers from outside of the reactor. The liquid phase in the upper part of the reactor is collected by the liquid-phase collecting trays and flows onto gas-liquid distributing trays through the downcomers. The gas phase and the liquid phase are subjected to violent mass transfer by the gas-liquid distributors so that the hydrogen can be dissolved in the liquid phase well. The gas phase and the liquid phase in gas and liquid materials are separated after passing through the gas-liquid distributing trays. The liquid phase where the hydrogen is dissolved goes downward into catalyst bed layers to perform hydrogenation. The gas phase converges under the gas-liquid distributors and is discharged from the reactor. The two-phase hydrogenation reactor and the two-phase hydrogenation method can further enhance reaction effects of two-phase hydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydroprocessing technique

ActiveCN101148609AImprove vulcanization effectImprove hydrogenation reaction performanceRefining to eliminate hetero atomsHydrocarbonOrganic solvent

The present invention relates to hydrocarbon hydrotreating process including the steps of loading catalyst into the reactor, activating, reaction, etc. The hydrotreating catalyst contains thiourea compound in 0.5-20 wt% of the catalyst, simple substance sulfur in the amount of 30-150 % of the theoretical sulfur demand of the catalyst, and organic solvent in 0.1-50 wt% of the catalyst. The hydrotreating catalyst with the common action of thiourea compound, sulfur and organic solvent has high sulfur holding rate in activation, less concentrated heat release, lowered temperature rise in the catalyst bed and high activity. It may be applied in various kinds of hydrocarbon hydrotreating process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocarbons hydrocracking technique

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com