Patents

Literature

39results about How to "Solve easy coking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

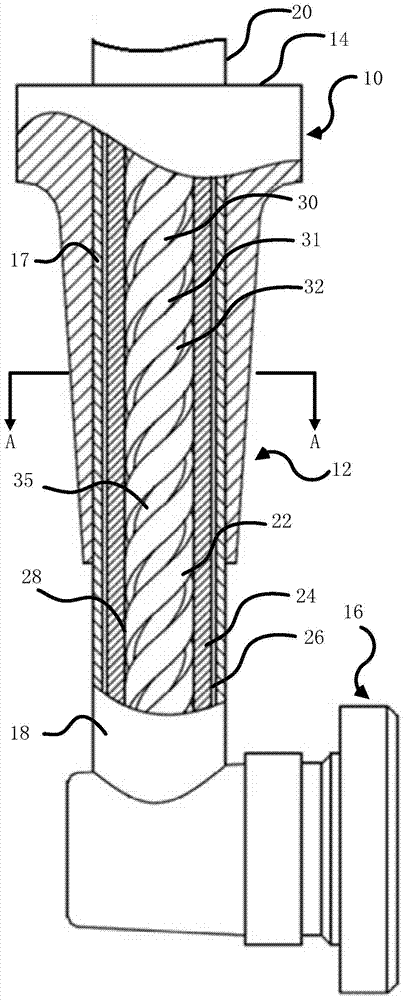

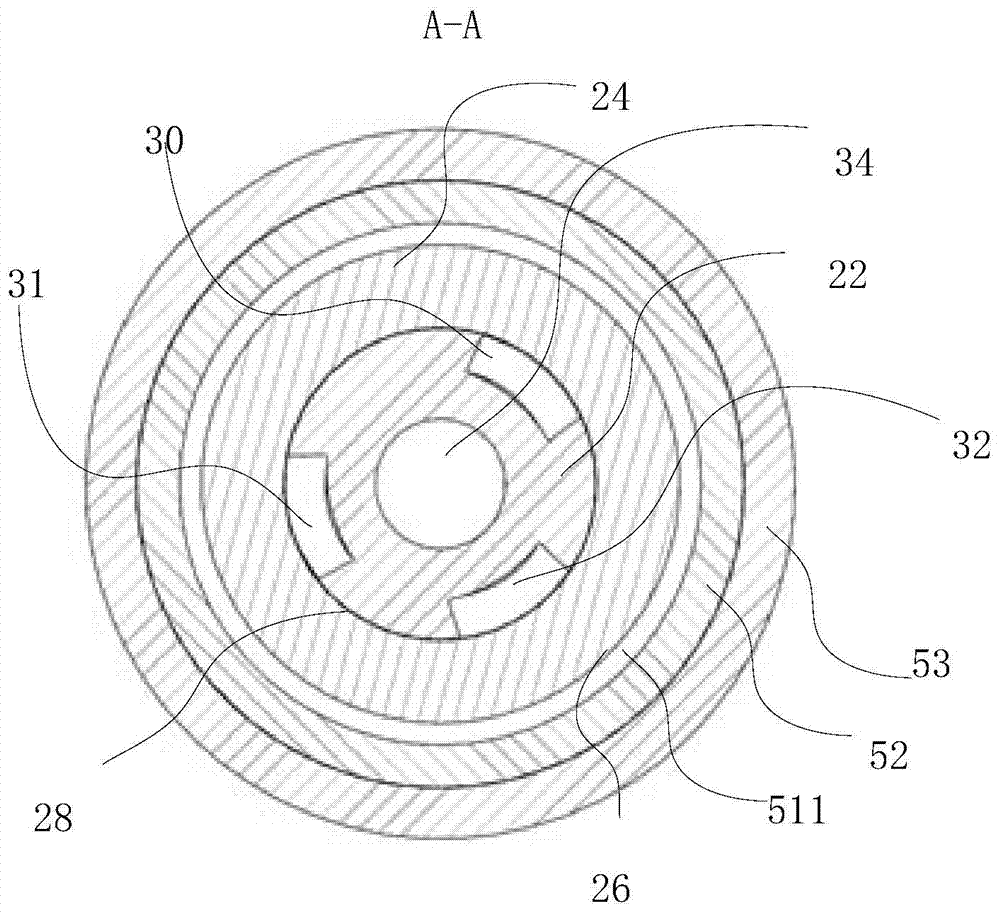

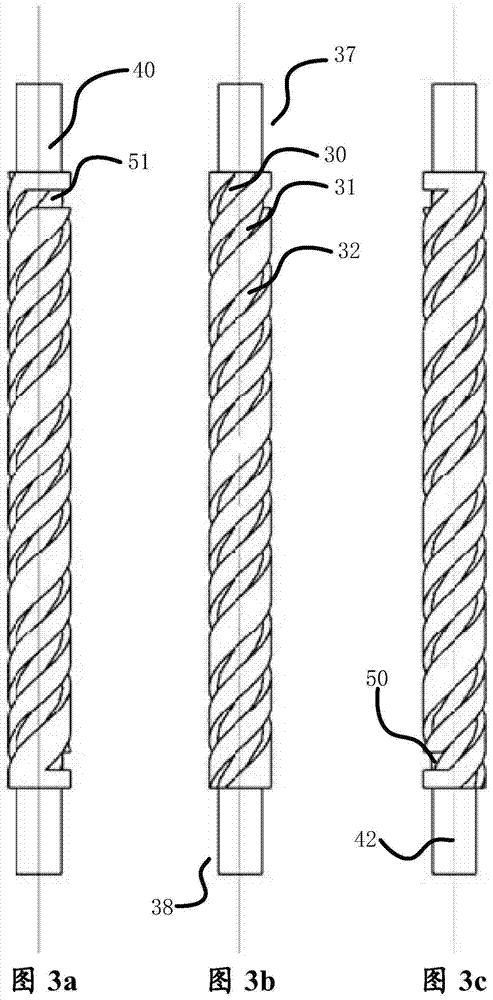

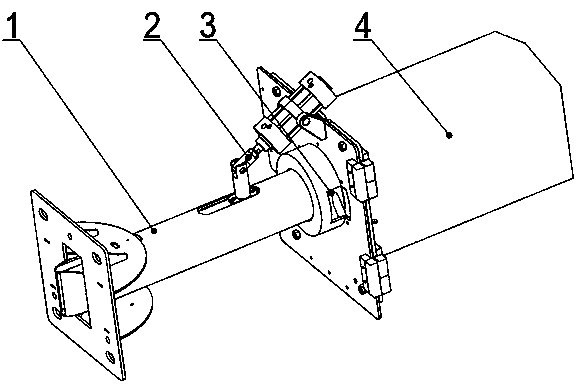

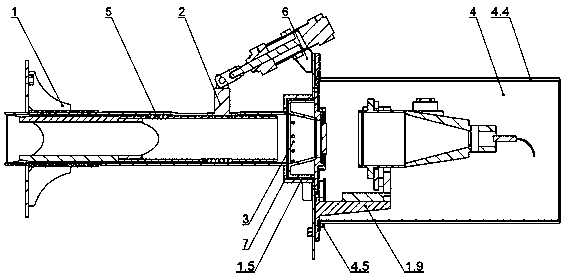

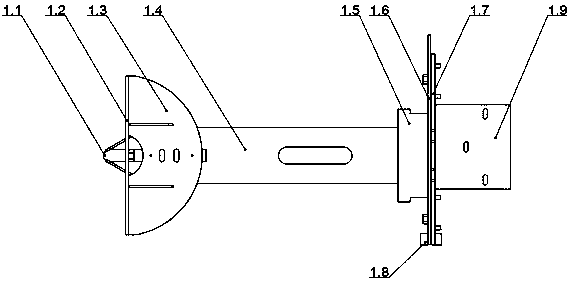

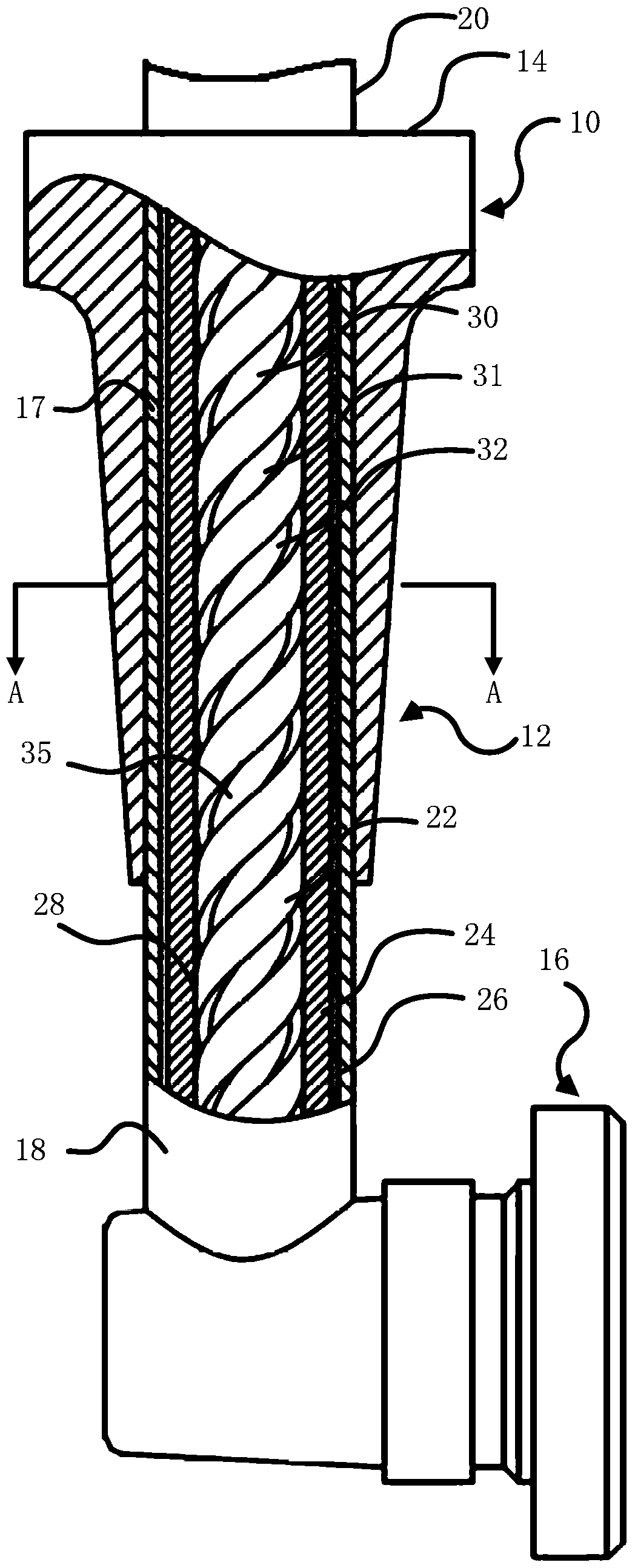

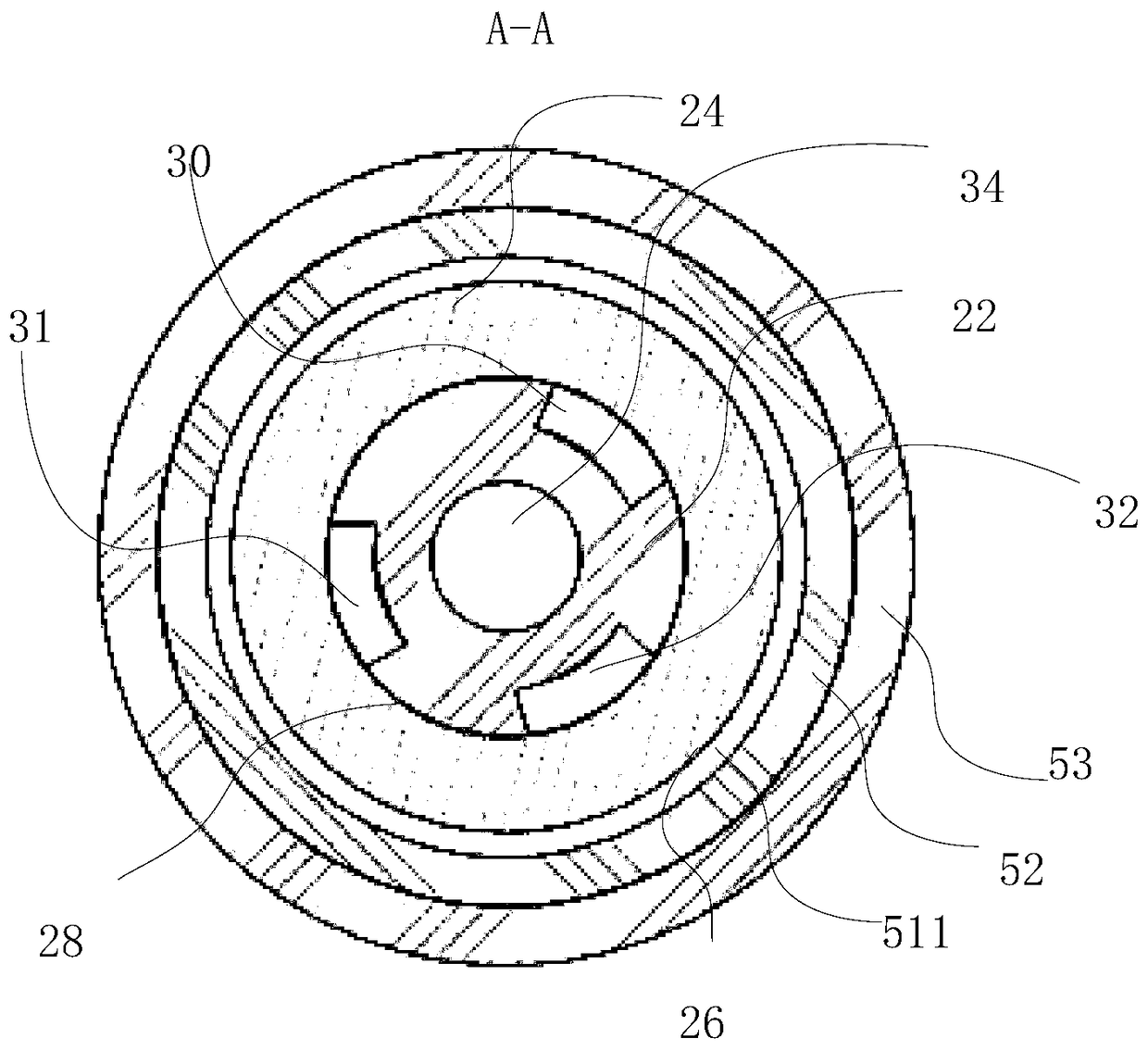

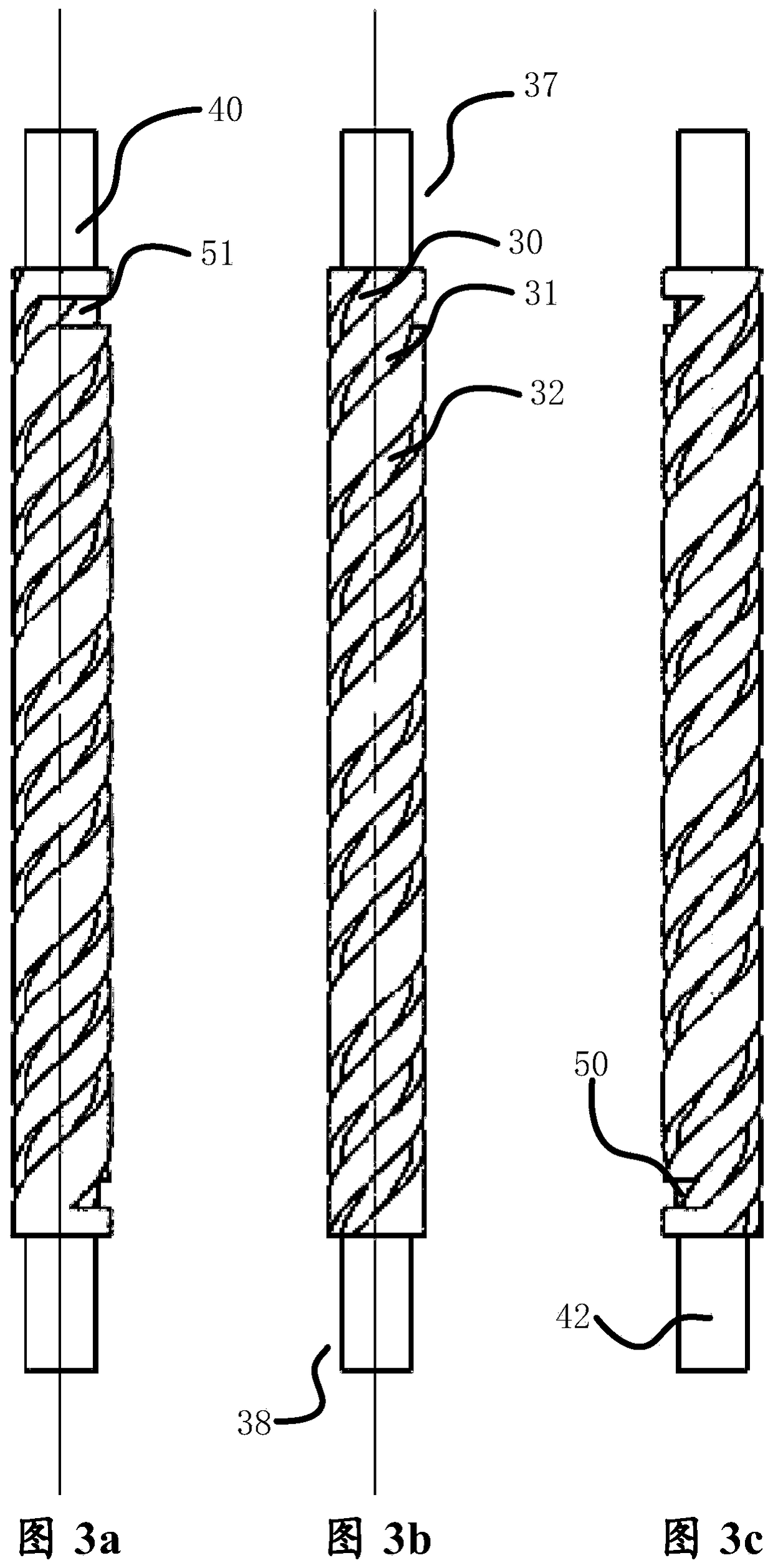

Nozzle rod part, fuel nozzle and aero-engine gas turbine

ActiveCN104713128ASolve easy cokingReduce temperature differenceContinuous combustion chamberAviationEngineering

The invention discloses a nozzle rod part, a fuel nozzle and an aero-engine gas turbine, relates to the technical field of aero-engines, and is used for solving the problems of easy coking of fuel of the nozzle rod part and short service life of the fuel nozzle in a working state in a fuel supply scheme of using a main fuel way as a discontinuous working fuel way and using a secondary fuel way as a continuous working fuel way in the prior art. The nozzle rod part comprises a rod body, a main fuel way and a secondary fuel way. The secondary fuel way is arranged at the periphery of the main fuel way; a fluid in the main fuel way and a fluid in the secondary fuel way can exchange heat; the fluid entering from a fluid inlet of the main fuel way can flow out through a fluid outlet of the main fuel way; and the fluid entering from a fuel inlet of the secondary fuel way can at least experience once of the process of returning to a position near the fluid inlet of the main fuel way from a position near the fluid outlet of the main fuel way in the secondary fuel way, and then flows out by the fuel outlet of the secondary fuel way. The nozzle rod part can prevent the fuel coking problem, and can prolong the service life of the fuel nozzle.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

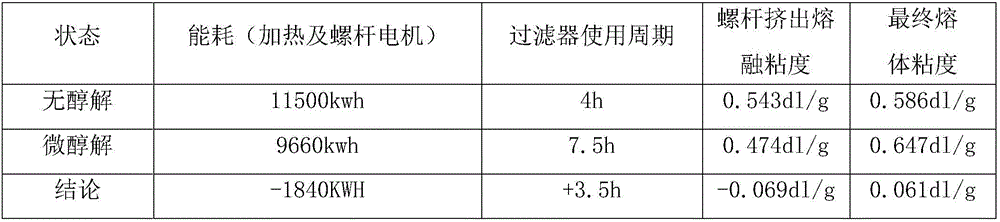

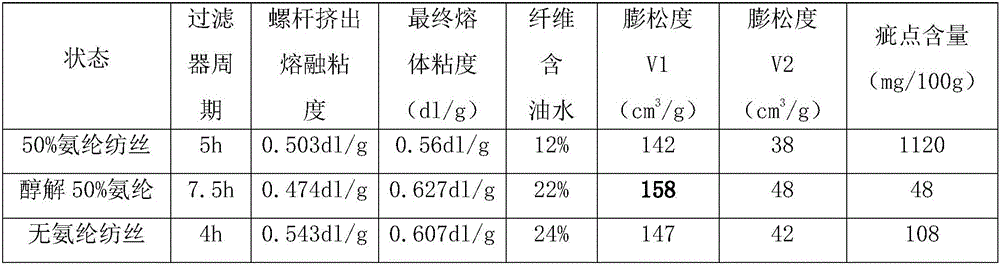

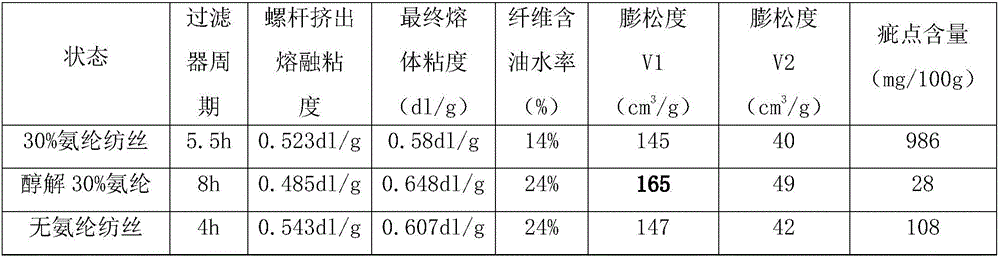

Method for preparing high-quality fusant from waste polyester textiles

InactiveCN106283226ARapid alcoholysisHigh intrinsic viscositySpinning solution de-aeratingFilament forming substance formingPolyesterPolymer science

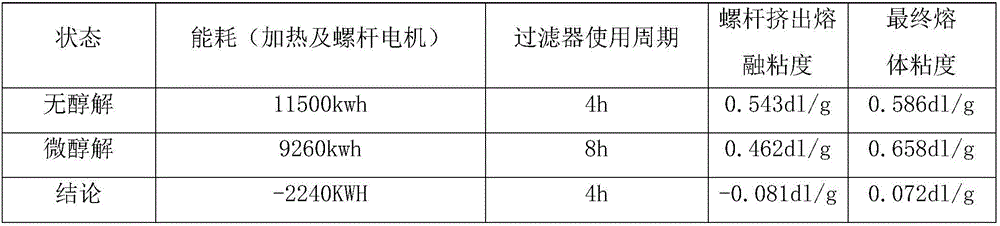

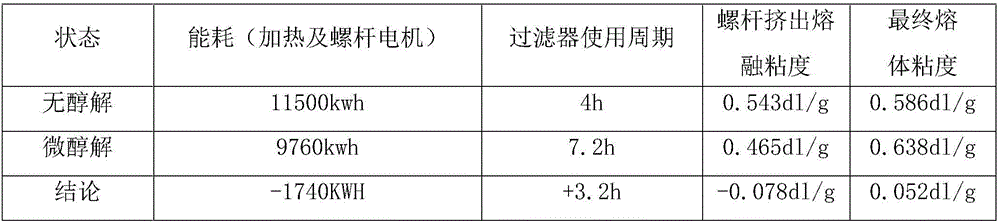

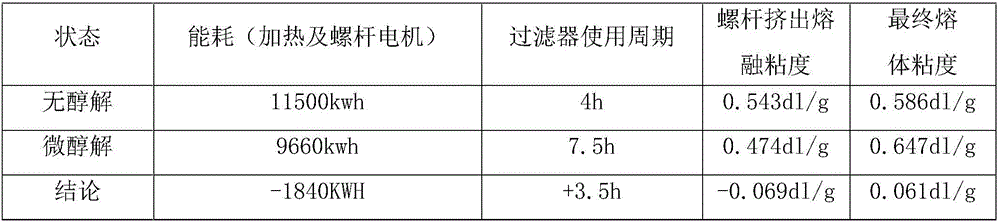

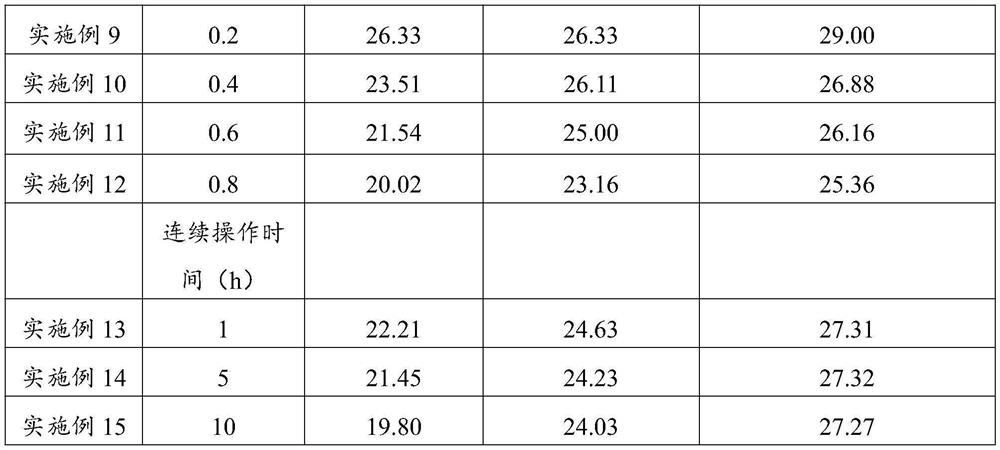

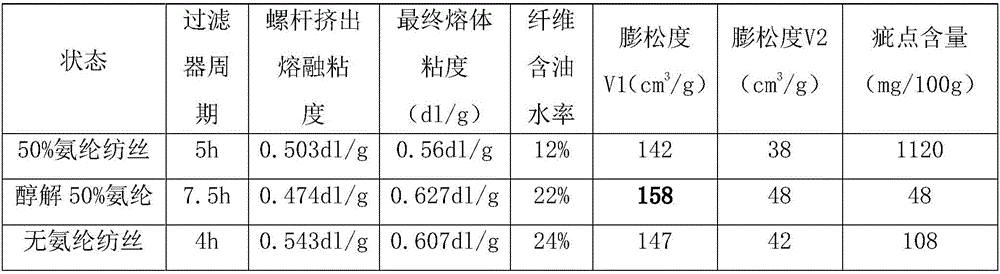

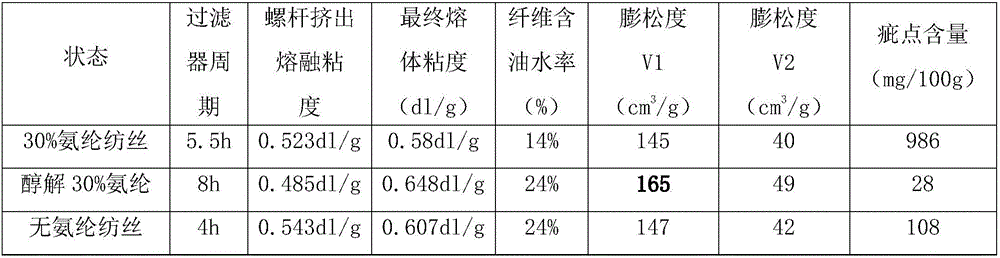

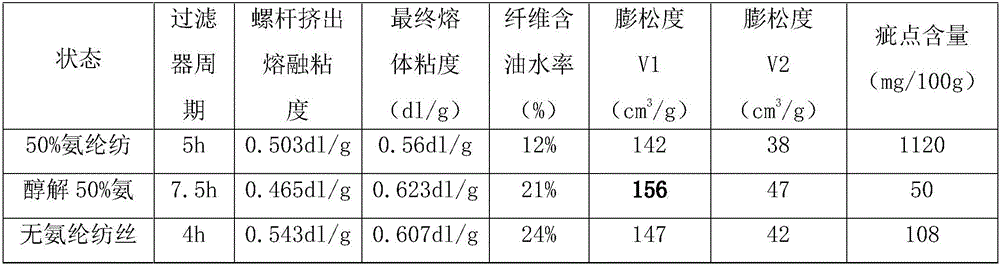

The invention relates to high-value cycling and reusing techniques of waste polyester and particularly relates to a method for preparing a high-quality fusant from waste polyester textiles. The method comprises the following steps: adding 1-8% of alcohol into the raw material according to the mass of the raw material, and carrying out blending and melt extrusion by virtue of a screw extruder, wherein the melt viscosity of the fusant from the screw extruder is 0.40dl / g-0.50dl / g; and then adding the material into a tempering and viscosity-regulating device, wherein the melt viscosity of the fusant from the tempering and viscosity-regulating device is 0.620dl / g-0.685dl / g. According to the method, by adding a proper amount of glycol, the melt viscosity is increased, meanwhile, the problems that the cycle of a filter is short, and the maintenance quantity of a vacuum system is great are further effectively solved, the production cost is lowered, and the additional value of products is further increased.

Owner:NINGBO DAFA CHEM FIBER

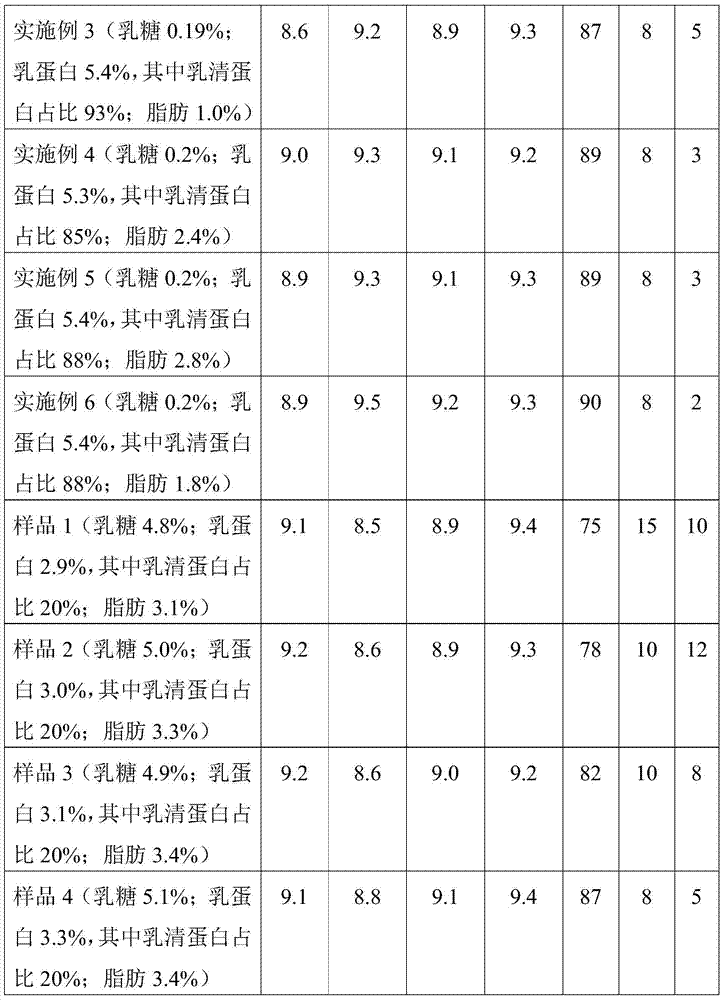

High-protein lactose-free milk and preparation method thereof

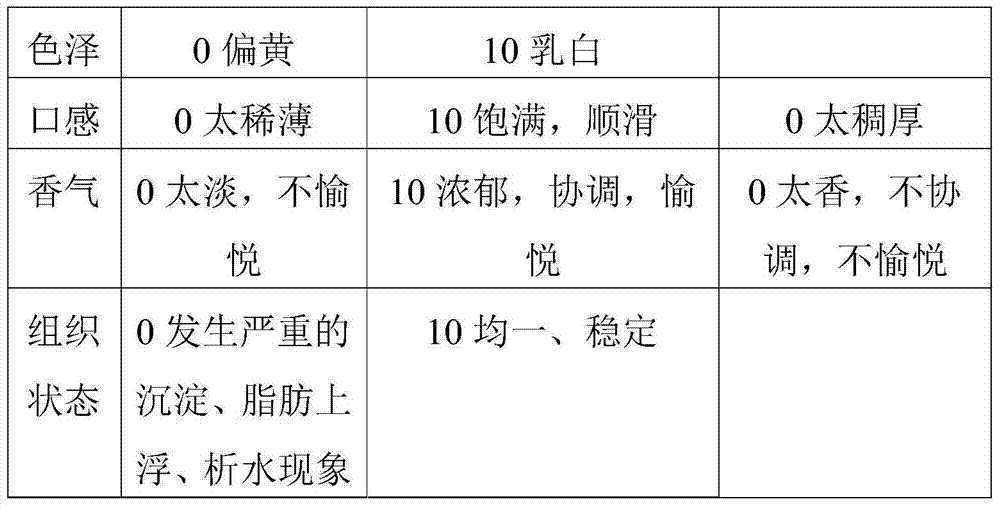

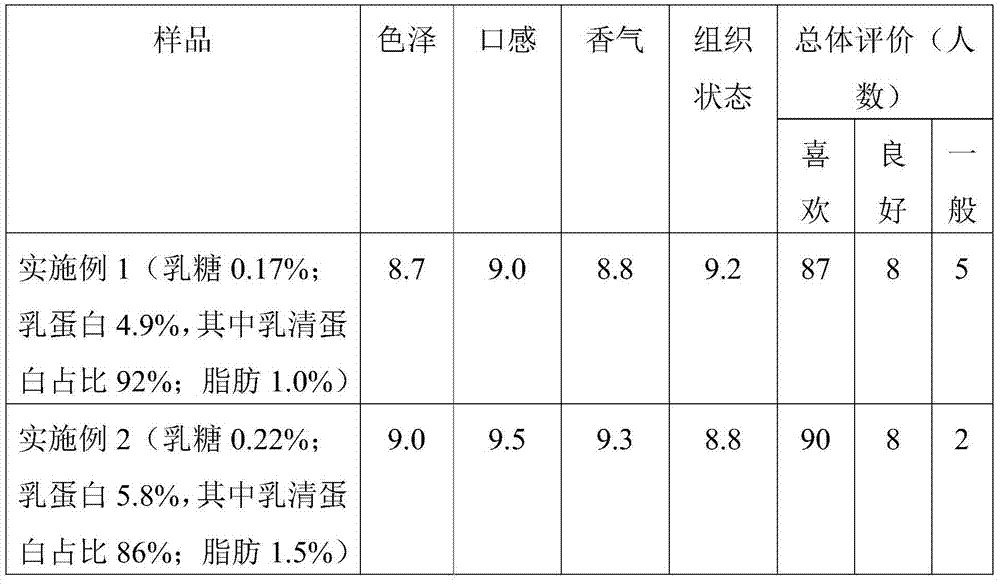

ActiveCN104489096ASolve problems that are not conducive to blood sugar stabilitySolve easy cokingMilk preparationLactose free milkSlurry

The invention provides high-protein lactose-free milk and a preparation method thereof. The raw materials of the high-protein lactose-free milk are prepared from the following components in percentage by weight: 0.5-1% of milk protein concentration, 5.0-5.5% of desalted separated whey proteins, 2.5-3.5% of watery cream and the balance of water, totaling 100%, wherein the percentage by weight is that relative to the total mass of the raw materials. The preparation method comprises the following steps: (1) mixing the milk protein concentration, the desalted separated whey proteins and water, standing and filtering by virtue of a ceramic membrane to obtain slurry A; (2) carrying out pasteurization on the watery cream to obtain slurry B; (3) mixing the slurry A and the slurry B; (4) homogenizing; and (5) cooling and filling. According to the ceramic membrane filtration process, the problem that a high-protein product is easily coked on tubular or platy sterilization equipment is solved, and the final product helps solve the problem that the common milk drank by the diabetic patient is adverse to glucostasis and has the function of controlling blood glucose of the type 2 diabetic patient in an assistant manner.

Owner:BRIGHT DAIRY & FOOD CO LTD

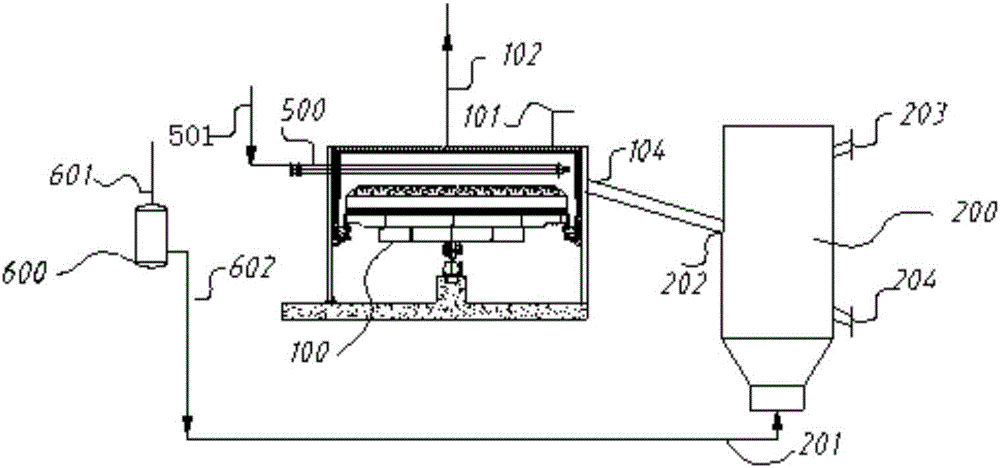

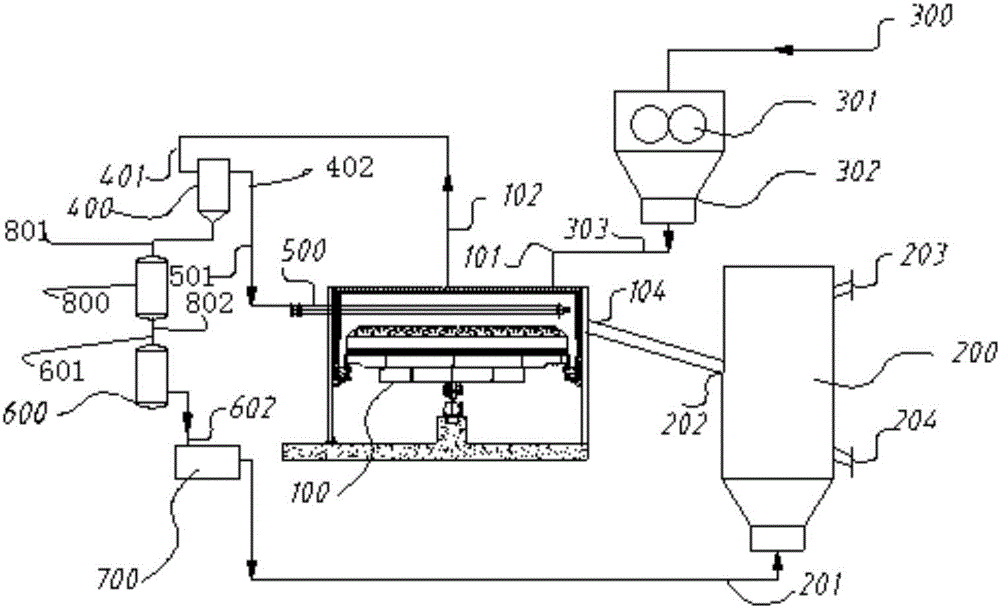

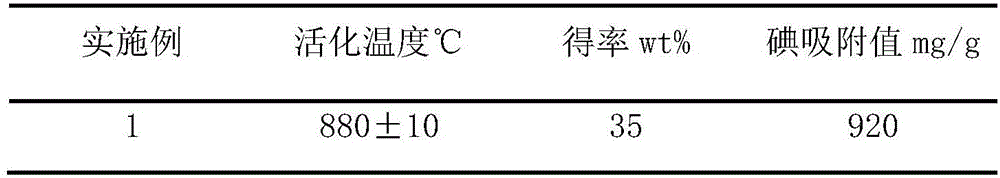

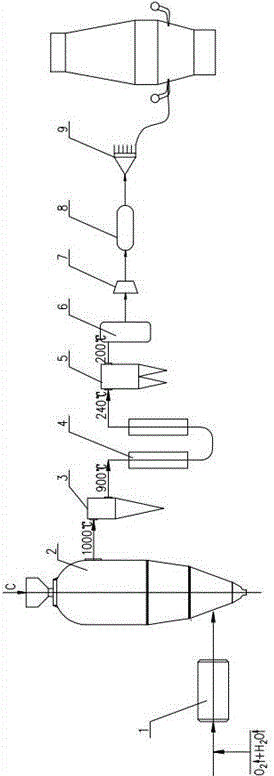

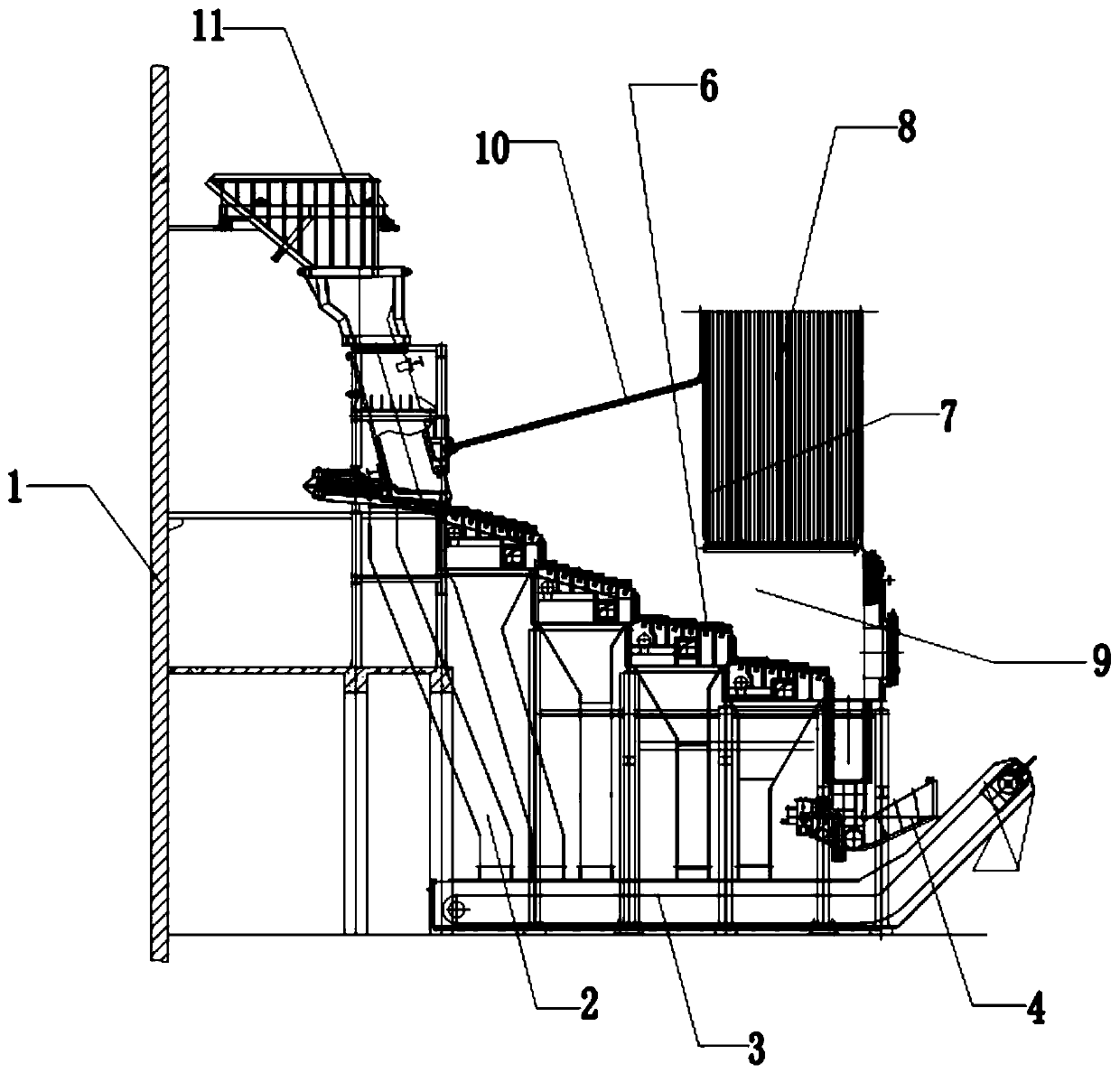

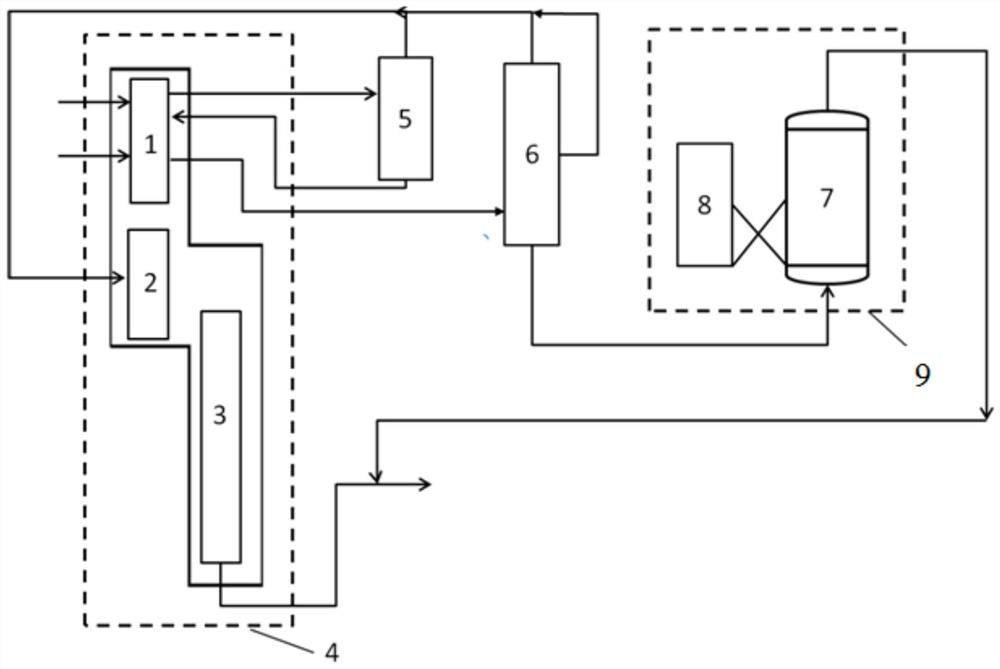

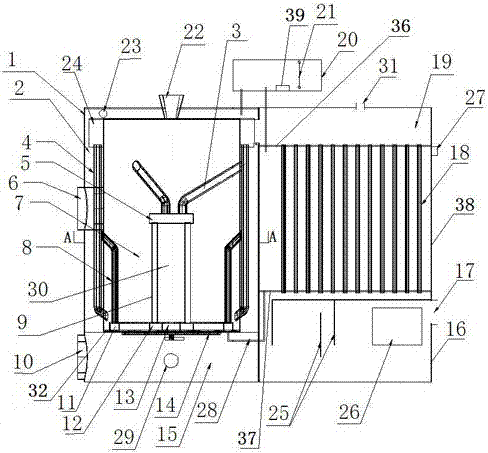

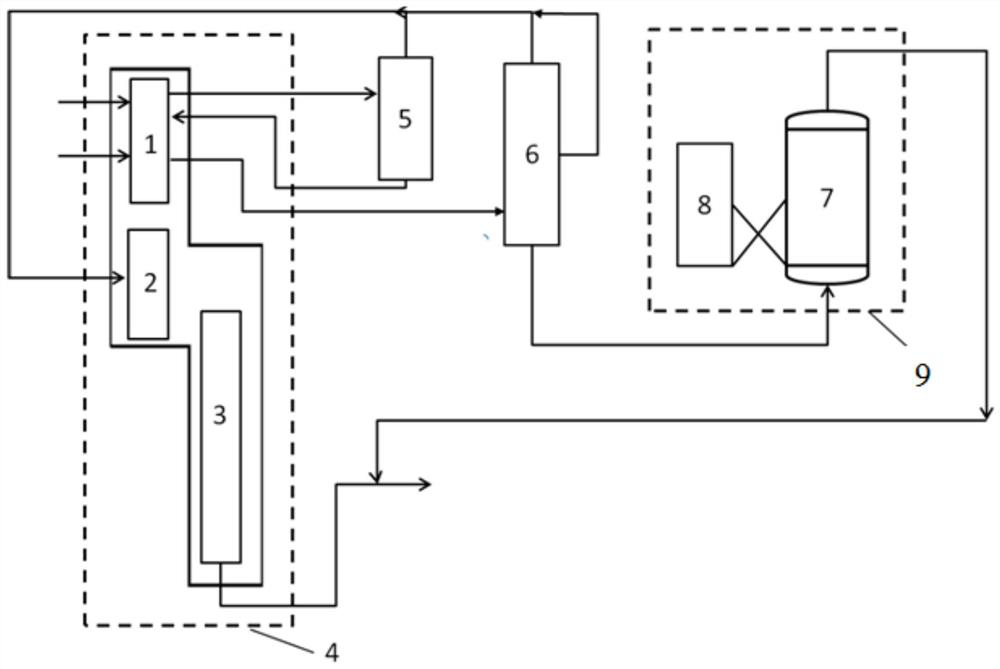

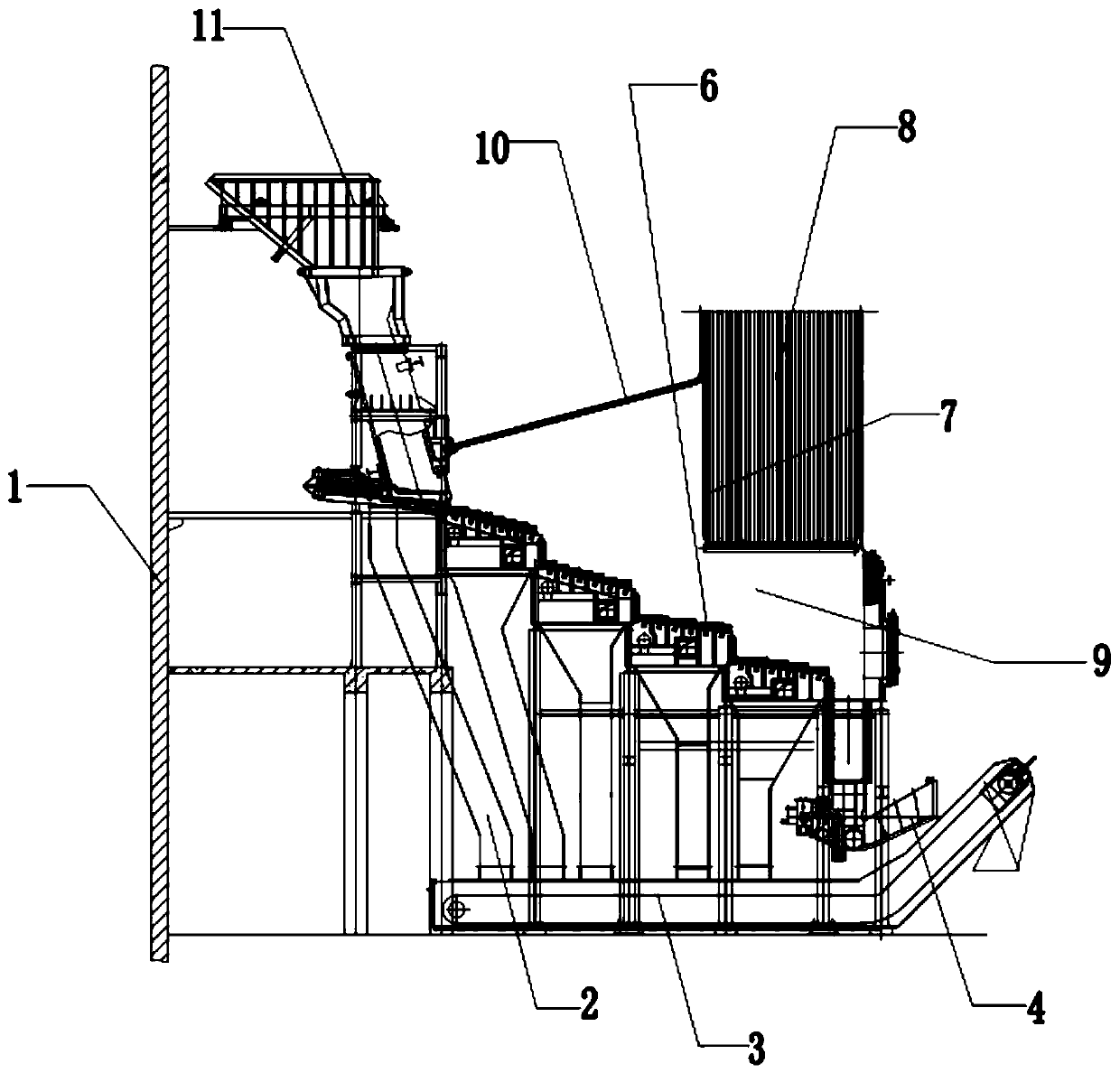

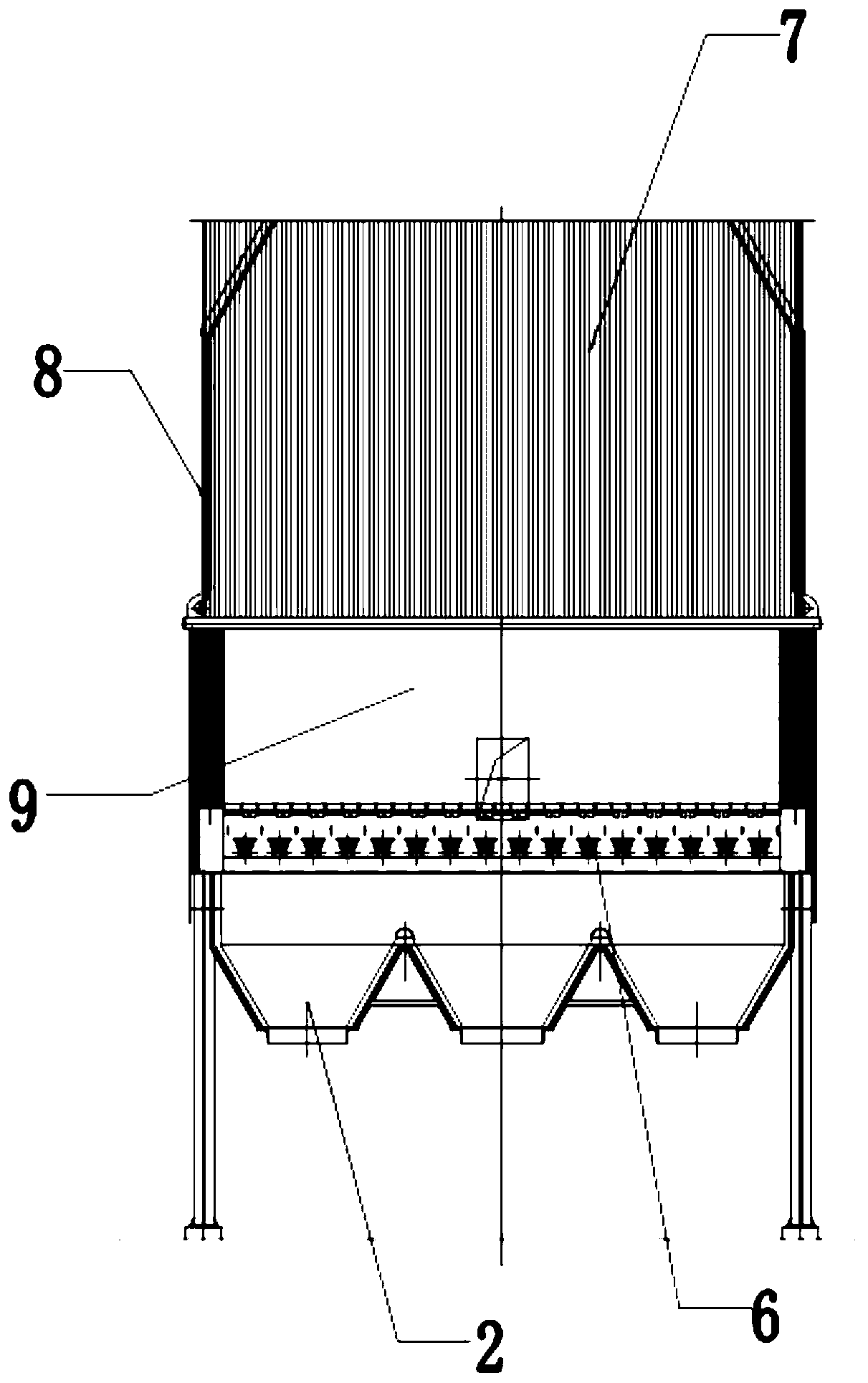

System and method for preparing active carbon by biomass

PendingCN106629715ASolve the blockageSolve heavy dustCarbon compoundsSpecial form destructive distillationCombustorWater vapor

The invention relates to a system and a method for preparing active carbon by biomass. The system comprises a pyrolyzing furnace, a combustor, a steam boiler and a fluidized bed, wherein the pyrolyzing furnace is used for pyrolyzing raw material biomass to generate pyrolyzed oil gas and carbon residue; the combustor is used for heating the raw material biomass to pyrolyze the raw material biomass; the steam boiler is used for heating water to obtain steam; and the fluidized bed is used for activating the carbon residue to generate active carbon. According to the system and the method, the existing fluidized bed does not need to be transformed, heat loss is reduced, energy consumption is reduced, the productivity of the pyrolyzing furnace is improved, and reduction, harmless treatment and resource utilization of the materials is realized.

Owner:SHENWU TECH GRP CO LTD

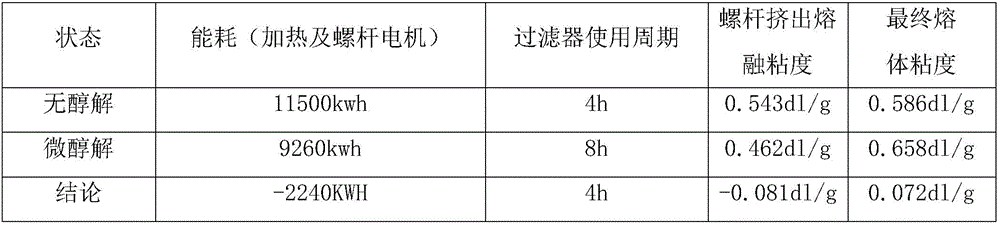

Method for preparing high-quality melt through alcoholysis of waste polyester textile with ethylene glycol

InactiveCN106279757ARapid alcoholysisHigh intrinsic viscosityArtificial thread manufacturing machinesPlastic recyclingPolyesterPolymer science

The invention relates to a waste polyester high-value circulation reuse technique, and in particular to a method for preparing a high-quality melt through alcoholysis of a waste polyester textile with ethylene glycol. The method for preparing the high-quality melt through alcoholysis of the waste polyester textile with ethylene glycol comprises the following steps: adding ethylene glycol which accounts for 1-8% of the mass of a raw material into a screw extruder for mixing melt extrusion, and feeding the material into a hardening and tempering device, wherein the melt viscosity of the melt extruded from the screw extruder is 0.40-0.50dl / g; the melt viscosity of the melt discharged from the hardening and tempering device is 0.620-0.685dl / g. Due to adoption of a proper amount of the ethylene glycol, the melt viscosity can be improved, meanwhile, the problems that a filter is short in cycle and a vacuum system is large in maintenance workload can be effectively solved, the production cost can be lowered, and meanwhile, the additional value of a product can be increased.

Owner:NINGBO DAFA CHEM FIBER

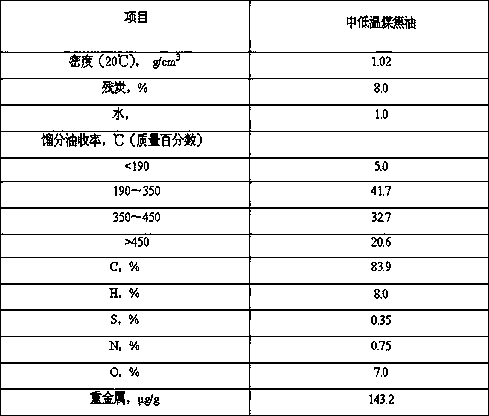

Coal tar full-fraction fluidized bed-fixed bed combined treatment process

ActiveCN111378490AIncrease temperatureLow viscosityTreatment with hydrotreatment processesNaphthaFluid phase

The invention discloses a coal tar full-fraction fluidized bed-fixed bed combined treatment process. The combined treatment process comprises the following steps: feeding a full-fraction coal tar rawmaterial and an auxiliary agent into a pretreatment tank for mixing; carrying out liquid-solid separation after mixing treatment; a liquid-phase material obtained after separation enters a fluidized bed hydrogenation reaction unit for a hydrogenation reaction; feeding the obtained reaction outflow into a separation tank to be subjected to gas-liquid separation, thus forming a gas-phase material and a liquid-phase material after separation, and then separating the liquid-phase material into a first liquid-phase material and a second liquid-phase material, returning the first liquid-phase material to the pretreatment tank; feeding the second liquid-phase material to a fixed bed hydrogenation reaction unit for hydrogenation reaction; and fractionating the reaction outflow to prepare naphtha,diesel oil and hydrogenated tail oil. The process provided by the invention can realize efficient utilization and long-period operation of coal tar resources.

Owner:CHINA PETROLEUM & CHEM CORP +1

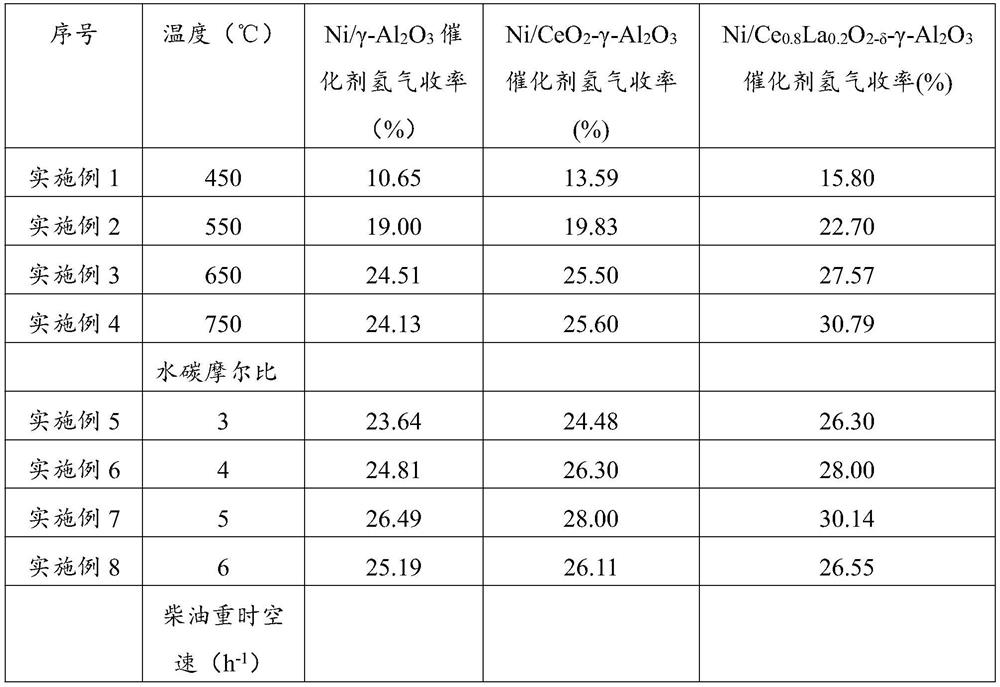

Nickel-based oxygen vacancy carrier catalyst as well as preparation method and application thereof

ActiveCN111604045AImprove catalytic stabilitySolving activityHydrogenHydrogen/synthetic gas productionCatalytic reformingPtru catalyst

The invention provides a nickel-based oxygen vacancy carrier catalyst as well as a preparation method and application thereof, and belongs to the field of catalytic reforming and diesel hydrogen production. With the catalyst provided by the invention adopted, the problems of low activity, easy coking and poor sulfur resistance of a diesel reforming catalyst can be solved. Cerium dioxide is used asan oxygen carrier; heterovalent metal La is doped in the CeO2 to reduce oxygen vacancy generation energy; the enhancement of the oxygen storage and release capacity of the carrier can inhibit side reactions so as to improve the activity of a main reaction. Diesel oil H / C is low, a large amount of carbon deposits are likely to occur during reforming; when coking occurs, the oxygen vacancy carriercan release more oxygen to oxidize the carbon deposits, so that coking inactivation of the catalyst is avoided. Ni particles are smaller in size and more uniform in distribution, so that the catalyticactivity of the catalyst is improved, and the catalyst can still keep excellent reforming performance after part of active metal sulfur is poisoned; the oxide of lanthanum is mainly distributed on asurface phase, so that high-temperature stability of the catalyst can be improved, and high-temperature sintering of the catalyst carrier is avoided.

Owner:TSINGHUA UNIV

Method for preparing polyester spinning melt by eliminating polyurethane in polyester textiles through alcoholysis

The invention relates to a waste polyester high-value circulation reutilization technology, in particular to a method for preparing polyester spinning melt by eliminating polyurethane in polyester textiles through alcoholysis. The method for preparing polyester spinning melt by eliminating polyurethane in polyester textiles alcoholysis is characterized in that the polyurethane exists in the polyester textile raw materials; alcohol accounting for 1 to 8 percent of the mass of the raw materials is added into the raw materials; blending and melting extrusion are performed after the materials enter a screw extruding machine; the melting viscosity of the melt discharged from the screw extruding machine is 0.40 to 0.50dl / g; then, the materials enter a tempering and viscosity regulating device; the melting viscosity of the melt discharged from the tempering and viscosity regulating device is 0.635 dl / g to 0.685dl / g. By using the alcoholysis mode, the influence and series of problems on polyester melt viscosity, flowing performance, fiber saturation performance, traction performance and easy blockage of vacuum pipelines and shell-and-tube heat exchangers caused by the existence of spandex (polyurethane) can be reduced.

Owner:NINGBO DAFA CHEM FIBER

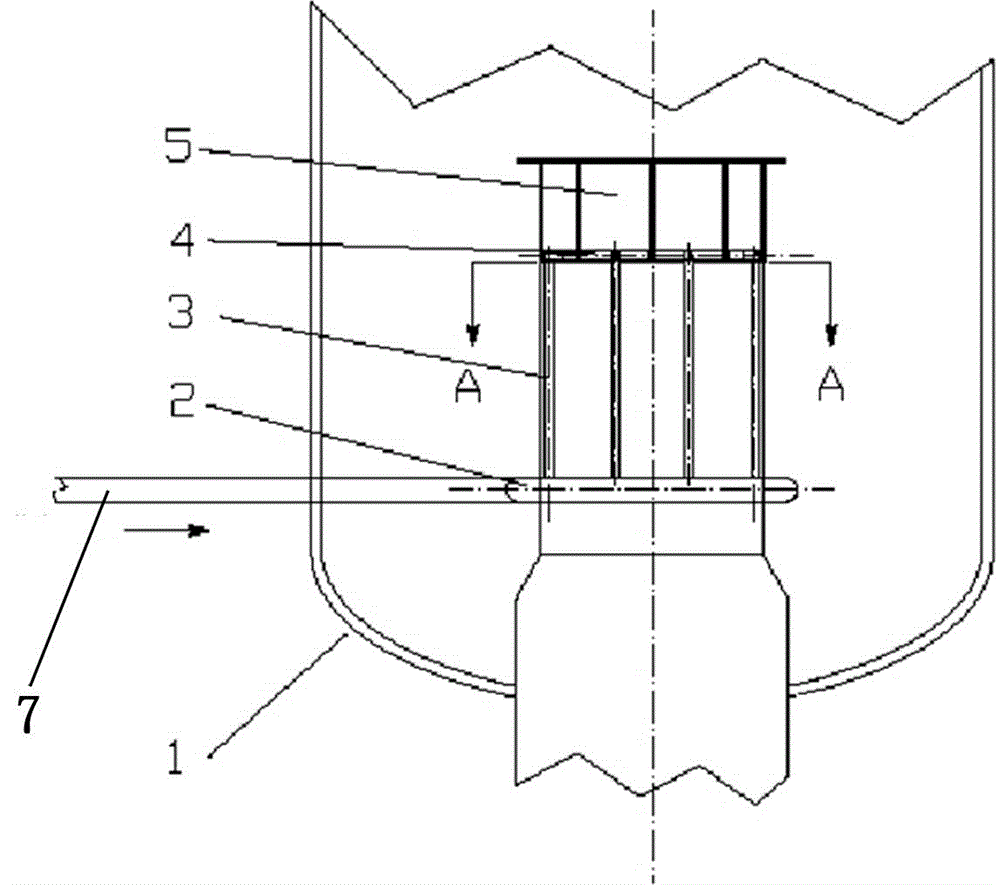

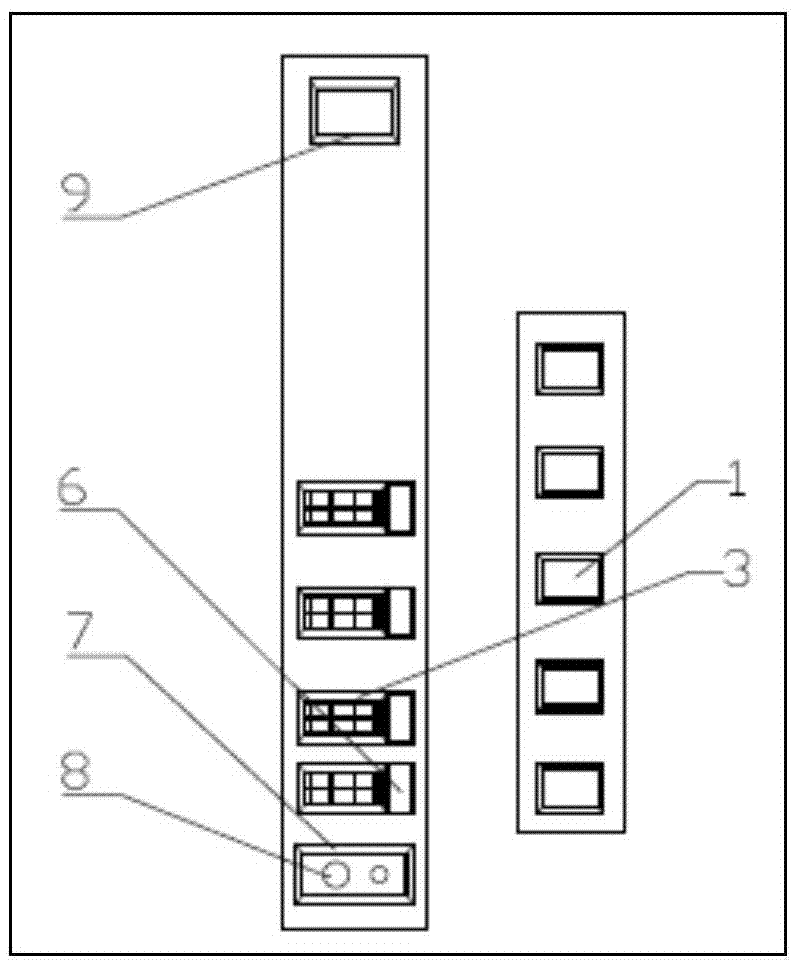

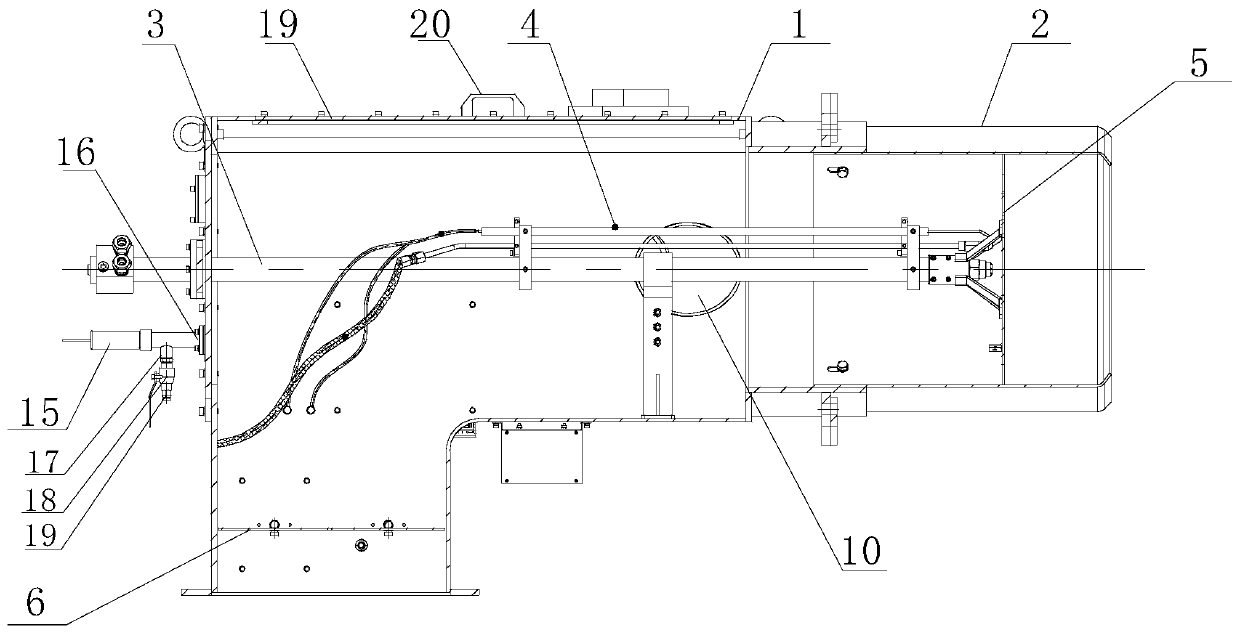

Laser detection type combustion chamber temperature detection device

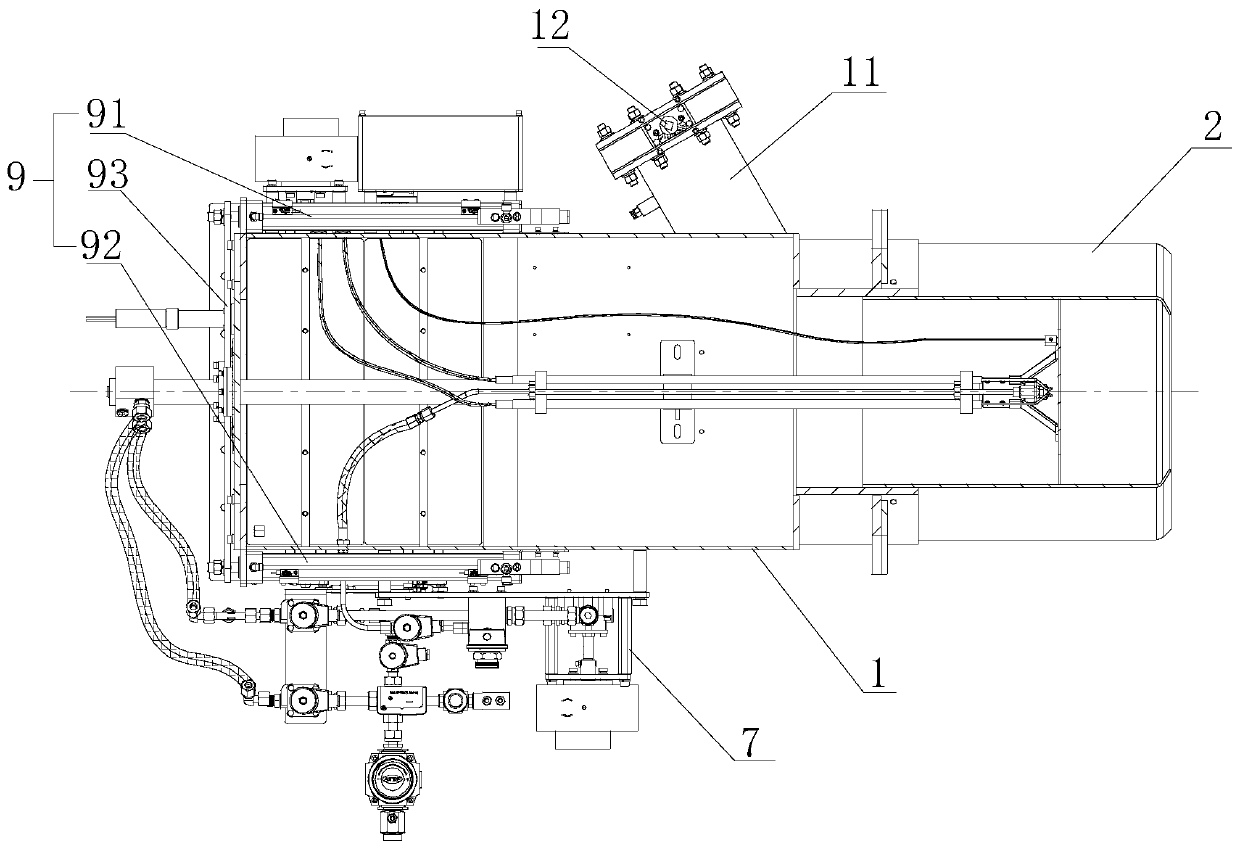

PendingCN108225574AAccurately obtain combustion parametersReal-time monitoring of temperature field distribution parametersSensing radiation from gases/flamesCombustion chamberEngineering

The invention discloses a laser detection type combustion chamber temperature detection device, which comprises a supporting frame, a decoking device, a soot blowing and cooling device and a laser detection device. The supporting frame comprises a seamless steel pipe; one end of the decoking device is arranged in the seamless steel pipe and capable of axially and freely sliding; the decoking device is provided with a forked head portion which extends out of the front end of the supporting frame during decoking; the soot blowing and cooling device and the laser detection device are sequentiallyfixed to the rear end of the supporting frame; one end of the soot blowing and cooling device is communicated with the seamless steel pipe while the other end is sealed through a windproof filter, and the soot blowing and cooling device is provided with an air inlet. During laser detection, laser emitted by the laser detection device sequentially penetrates the soot blowing and cooling device andthe supporting frame to enter a to-be-detected combustion chamber or sequentially penetrates the supporting frame and the soot blowing and cooling device to be received by the laser detection device.By arrangement of the supporting frame, the decoking device and the soot blowing and cooling device, problems of high temperature, high dust and proneness to coking of a viewport in implementation ofa TDLAS (tunable diode laser absorption spectroscopy) system is effectively solved.

Owner:NANJING SCIYON AUTOMATION GRP

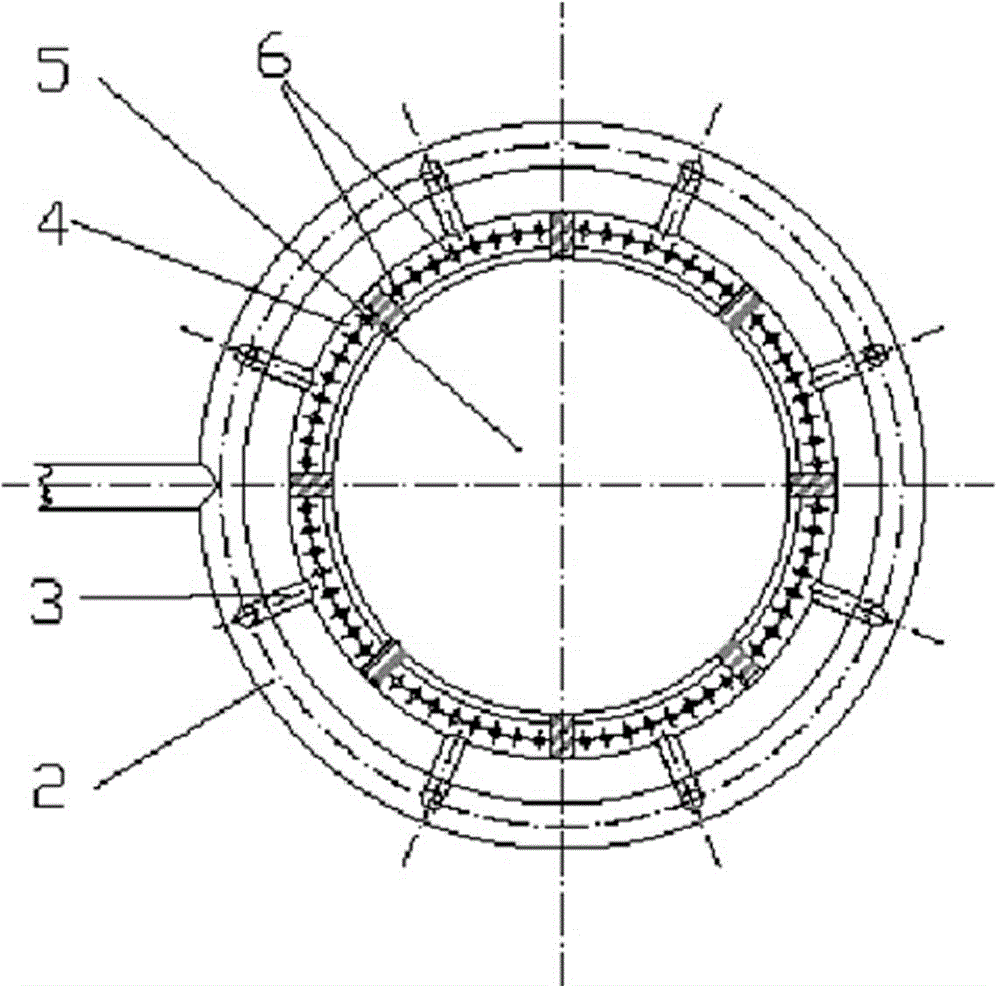

Anti-coking device for high-temperature pyrolysis gas inlet of oil gas quench cooler

The anti-coking device at the high-temperature pyrolysis gas inlet of the oil-gas quencher, the anti-coking device is a hollow air intake pipe, and its technical key points are: an anti-coking steam ring pipe is arranged concentrically at the oil and gas outlet of the air intake pipe, and steam holes are arranged on the anti-coking steam ring pipe , from the oil and gas outlet, the distribution pipe and the distribution ring pipe are arranged sequentially from top to bottom, the anti-coking steam ring pipe and the distribution ring pipe are connected through the distribution pipe, and the distribution ring pipe is provided with a steam inlet. The advantages of the present invention: After the existing quenching equipment is transformed, the problem of easy coking at the inlet of the quenching equipment is solved, and the effect is remarkable; the partial pressure of hydrocarbons is reduced, and the yield is improved; no regular shutdown and maintenance is required, the production cycle is prolonged, and the production rate is improved. Improve production efficiency, reduce production and maintenance costs.

Owner:SHENYANG PARAFFIN CHEM

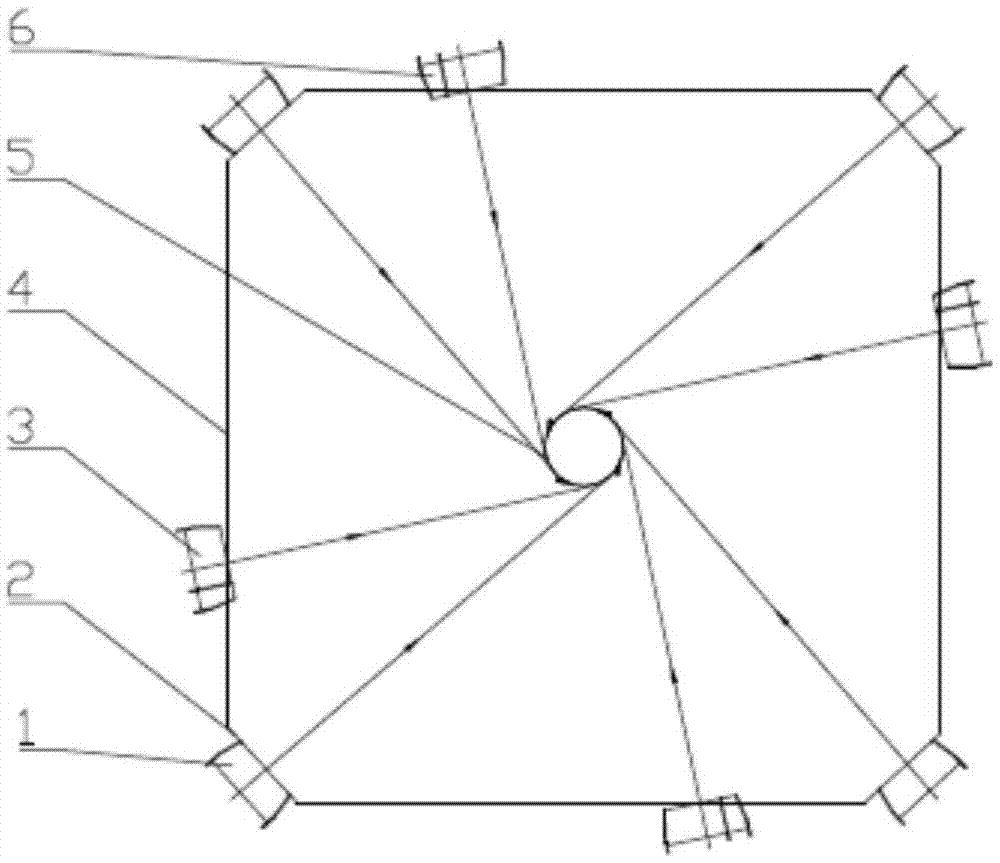

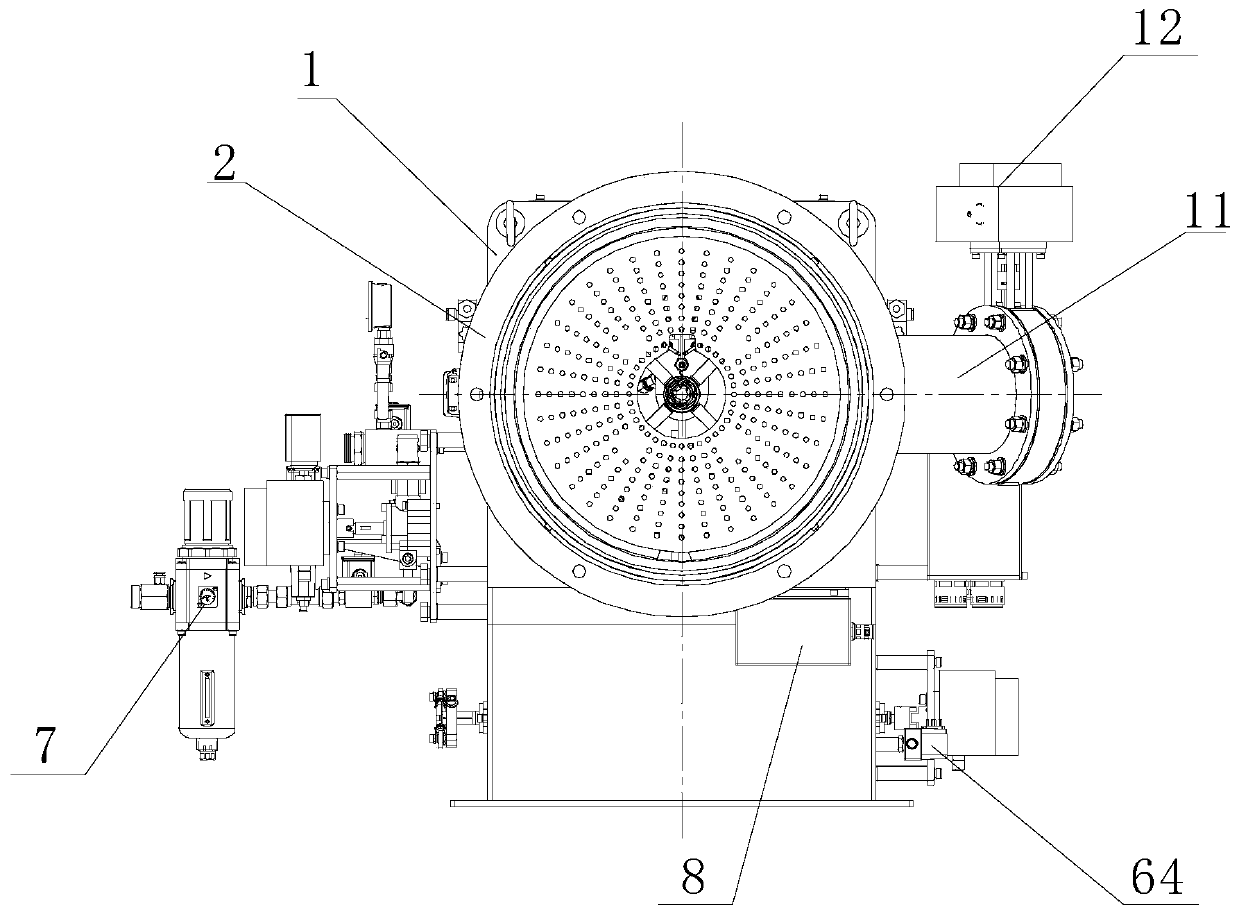

Flow-equalizing multi-angle tangential pulverized coal decoupling combustion device and combustion method

ActiveCN107228357ASuppress generationReduce dependenceCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustionHearth

The invention discloses a flow-equalizing multi-angle tangential pulverized coal decoupling combustion device and a combustion method. The device comprises a multi-angle tangential combustion hearth, wherein the multi-angle tangential combustion hearth comprises a hearth angle wall and hearth side walls; and a plurality of rows of primary air spraying holes, ignition secondary air spraying holes and over-fire air spraying holes, which are formed in the height direction, are formed in the wall of the multi-angle tangential combustion hearth. The invention further discloses a method for performing combustion by utilizing the combustion device. The multi-angle tangential pulverized coal decoupling combustion device provided by the invention can realize multi-scale NOx emission reduction according to the pulverized coal combustion characteristics and the NOx transformation rule, and improves the defects of the conventional multi-angle tangential pulverized coal decoupling combustion device.

Owner:SHANXI SANHESHENG IND TECH +1

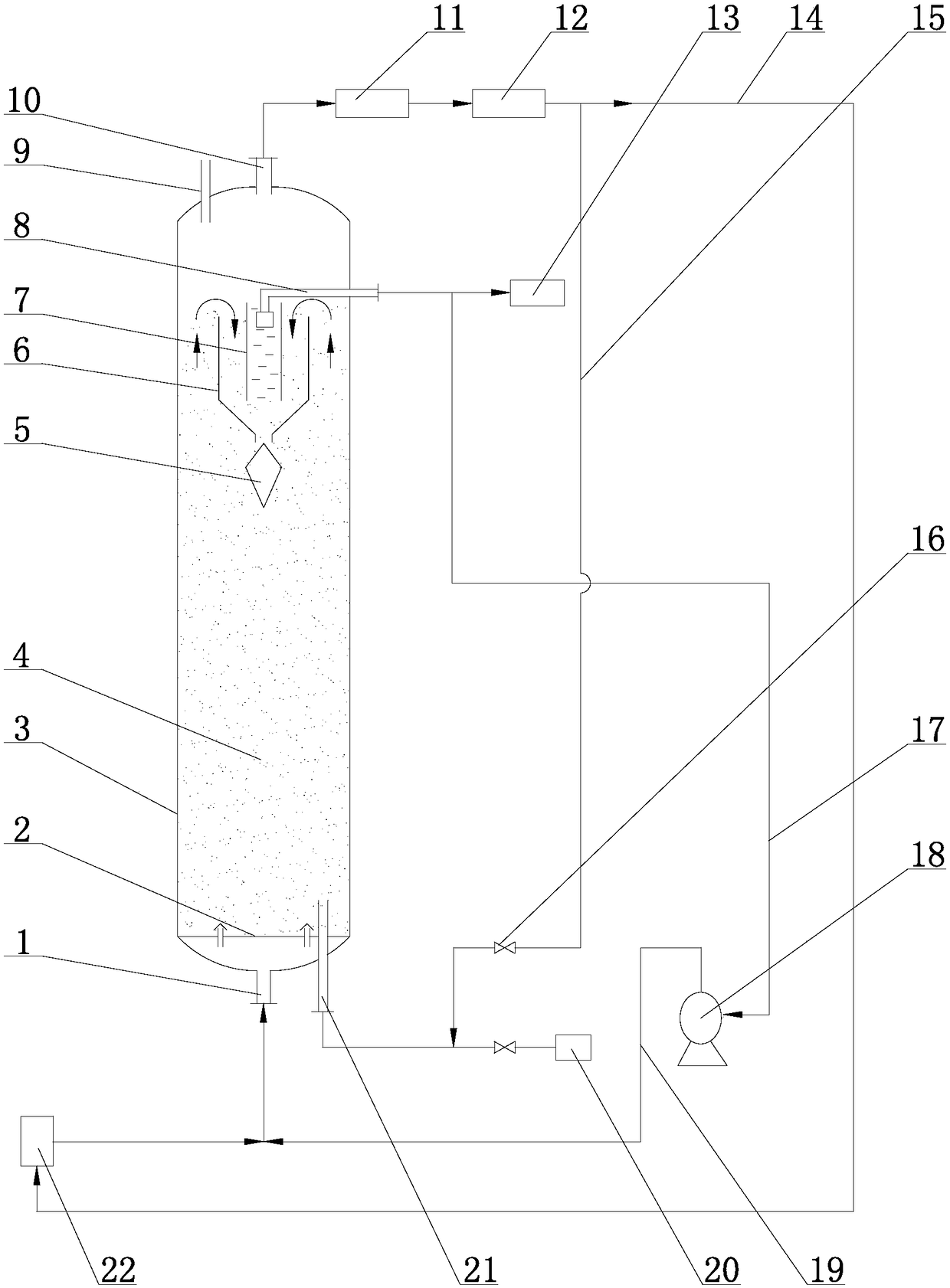

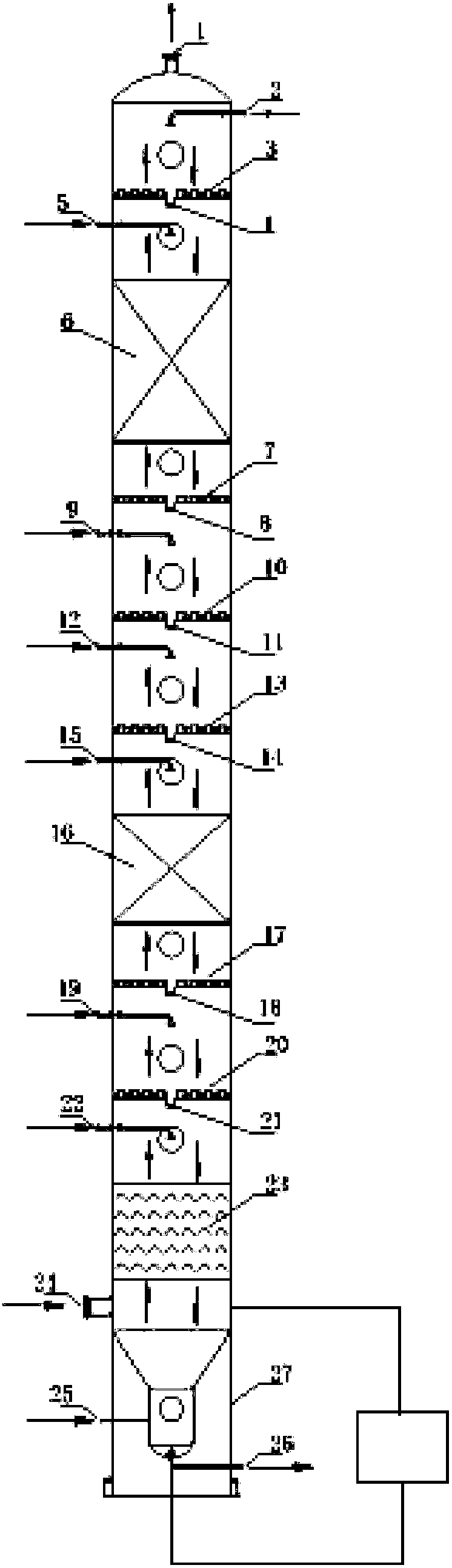

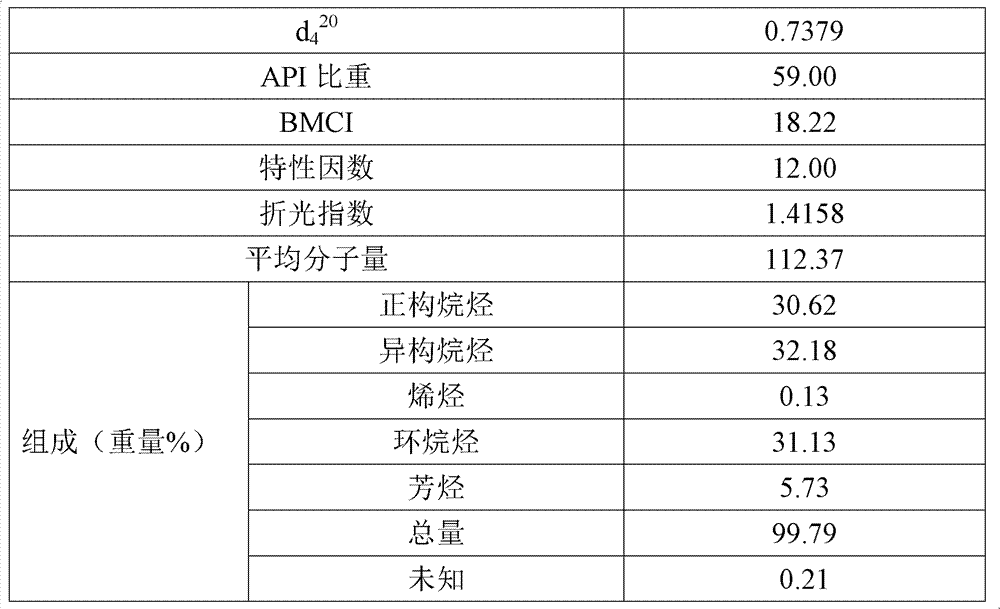

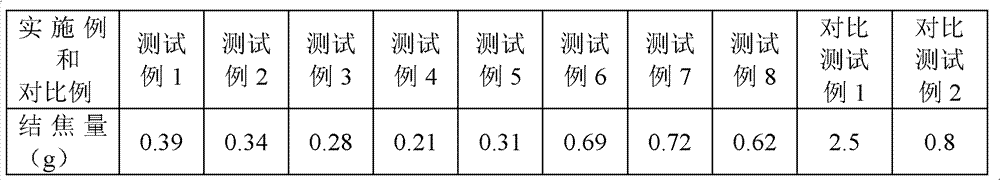

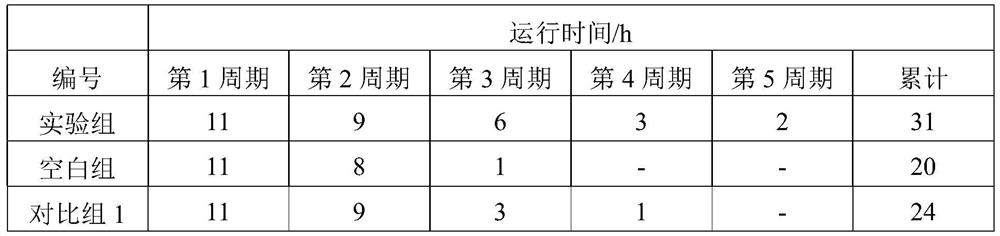

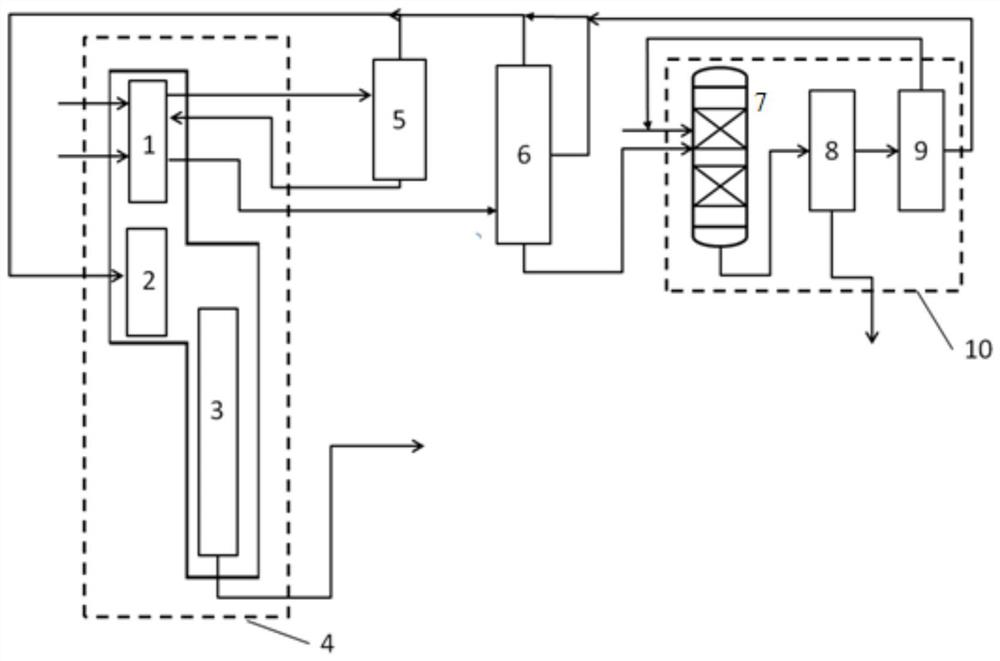

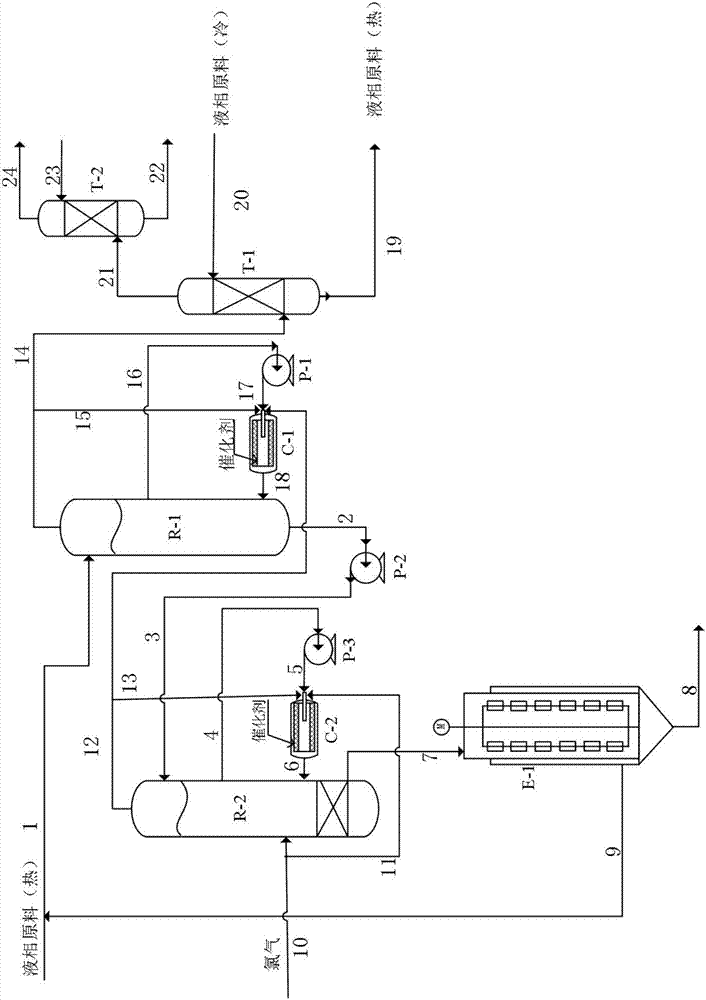

Boiling bed hydrogenation reaction system and boiling bed hydrogenation process method

PendingCN108144556ASolve easy cokingEasy to operateHydrocarbon oil crackingHydrocarbon oils refiningHydrogenation reactionHydrogenation process

The invention belongs to the technical field of hydrogenation, and particularly relates to a boiling bed hydrogenation reaction system and a boiling bed hydrogenation process method. On one hand, theproblem of coking of parts of pipelines caused by intermittent operation of a catalyst discharge system can be effectively solved. On the other hand, the use ratio of a reactor can be further increased (namely, reserve of catalysts in the reactor is improved), hydrogenation reaction effects are further improved, operating stability of the system is improved, and particularly, stable boiling stateof the catalysts can be maintained in start, in stop and under unusual service conditions.

Owner:上海竣铭化工工程设计有限公司

Low-rank pulverized coal gas generating process used for blast furnace injection

InactiveCN106244751AImprove efficiencyReduce pollutionBlast furnace detailsGas emission reductionCombustionWater vapor

The invention discloses a low-order pulverized coal gas-making process for blast furnace injection. Oxygen and water vapor are mixed at high temperature to form a gasification agent, and the gasification agent is passed into pulverized coal to react to form high-temperature coal-made gas. The dust in the high-temperature coal-to-gas is purified and cooled, and then desulfurized. The gas is compressed and stored in the gas storage tank. The gas in the gas storage tank is led to each blast furnace tuyere through the pipeline for injection. The low-order pulverized coal gas production process used in blast furnace injection in the present invention first generates coal gas through the reaction of clean coal powder, and then utilizes it for blast furnace injection. The process of producing coal gas burns clean, effectively alleviating energy pollution, and the preparation process Simple and efficient, strong operability, high purity of the gas produced and low pollution; the injection of clean gas not only improves the efficiency of the blast furnace, but also solves the problem of energy imbalance, reduces the cost of blast furnace ironmaking, and solves the problem of blast furnace injection Coal powder is easy to coke and the combustion efficiency is low, which solves the problem of high cost of natural gas, solves the problem of poor atomization caused by heavy oil injection, and prevents the formation of a large amount of soot at high temperatures.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

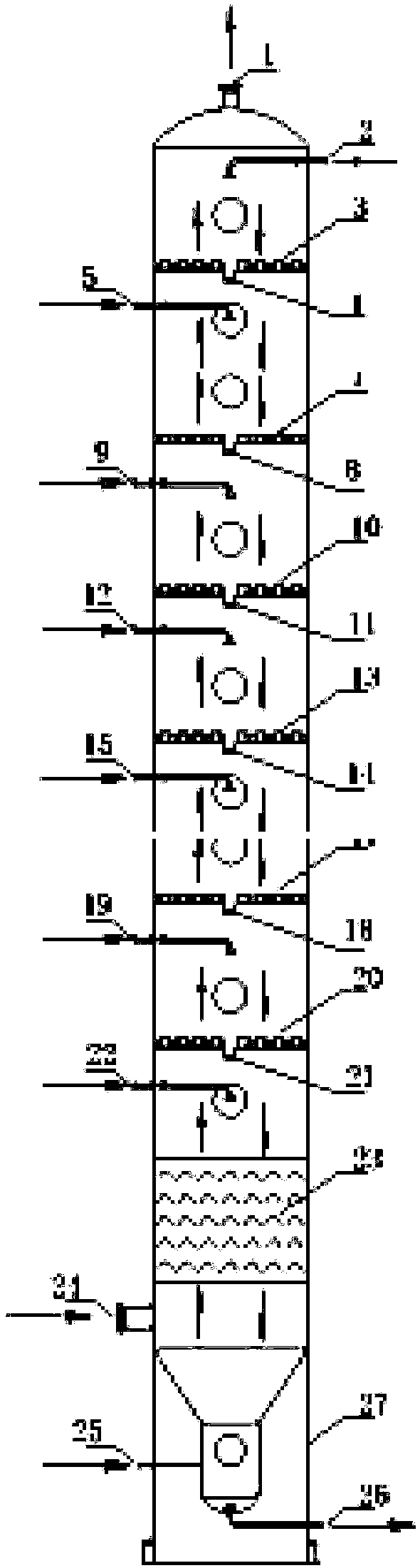

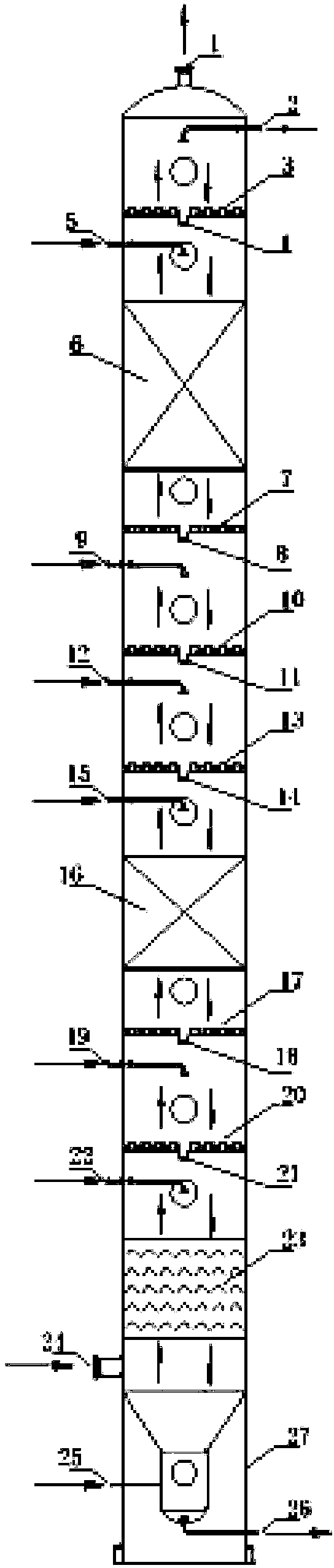

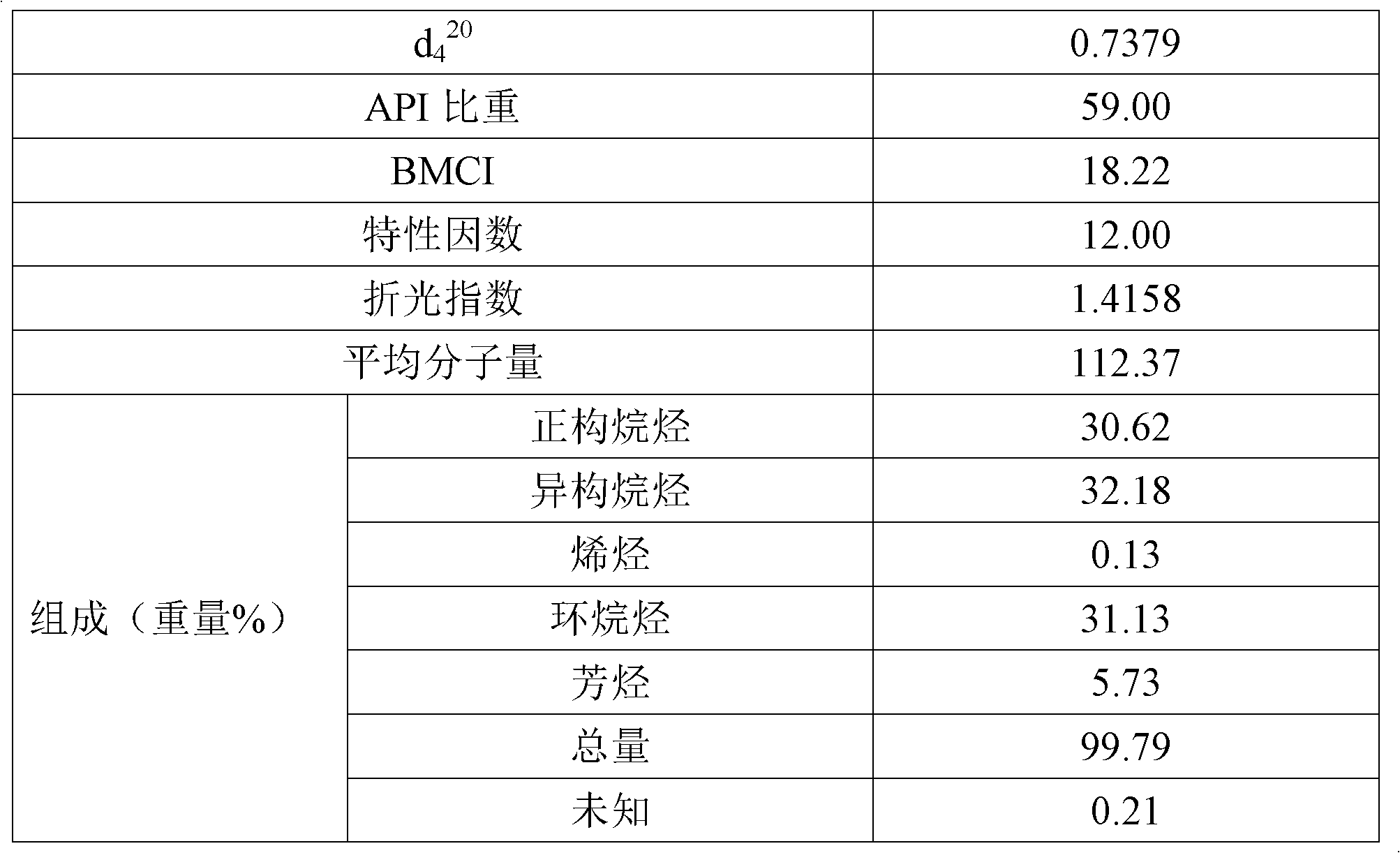

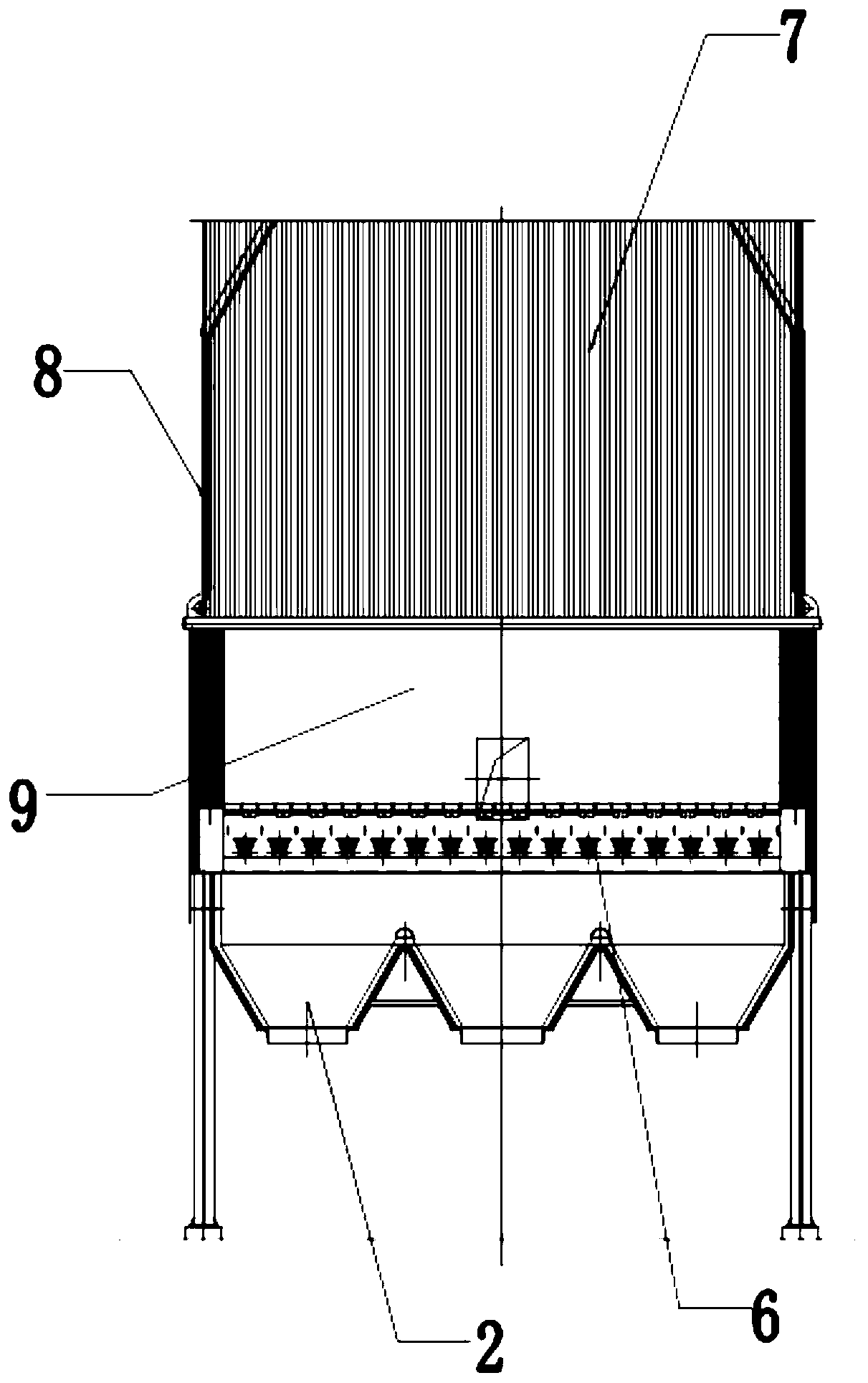

Vacuum tower for waste lubricating oil pretreatment

PendingCN108251152ASolve easy cokingAchieve rectification effectLubricating oils distillationHydrocarbon oils treatmentSprayerFractionation

The invention provides a vacuum tower for waste lubricating oil pretreatment. The vacuum tower is of a cylinder vertical structure; a tower tray is not arranged in the vacuum tower; a tower skirt, a feeding port, a baffle, an over-vaporized oil production section, a distillate oil production section, a diesel production section and a gas outlet are formed in the vacuum tower; two packing sectionscan be arranged among the diesel production section, the distillate oil production section and the over-vaporized oil production section according to the difficulty of separation of distillate oil ineach of the production sections; further, backflow spray distributors are respectively arranged on the three oil production sections and the packing sections. According to the vacuum tower in the scheme of the invention, the tower tray and fillers are directly replaced by utilizing a sprayer, the pressure drop is reduced in a manner of spray fractionation, the separation effect is good, and the process is simple, convenient and practical; moreover, according to the fraction separation difficulty, whether the fillers are provided or not can be freely selected, the heat and mass transfer efficiency is enhanced, and flexible and variable effects are realized, Importantly, the technical scheme of the invention solves the problem of influence on continuous production due to coking in all positions in the vacuum tower.

Owner:深圳至诚环境科技有限公司

Method for producing olefin

ActiveCN102899065ASolve easy cokingOvercoming pollutionThermal non-catalytic crackingWater vaporAlkene

he invention provides a method for producing olefin. The method comprises step of placing cracking raw materials in a cracking furnace tube for cracking, so as to obtain the olefin. The cracking furnace tube comprises a cracking furnace tube matrix, and an inert coating attached to an inner wall of the cracking furnace tube matrix. The inert coating can prevent contact between coke and cracking furnace tube matrix, but does not react with the cracking raw materials and / or cracking products; the inert coating has a porous structure with average pore radius of 0.5-15nm, and specific surface area from 1m<2> / g to less than 150m<2> / g; the inert coating can also catalyze reaction between coke and water vapor; or the inert coating surface is attached by an active catalytic layer capable of catalyzing reaction between coke and water vapor; or the inert coating can catalyze reaction between coke and water vapor, and is also attached by an active catalytic layer capable of catalyzing reaction between coke and water vapor. The method for producing olefin provided by the invention has simple operation and good anti-coking performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

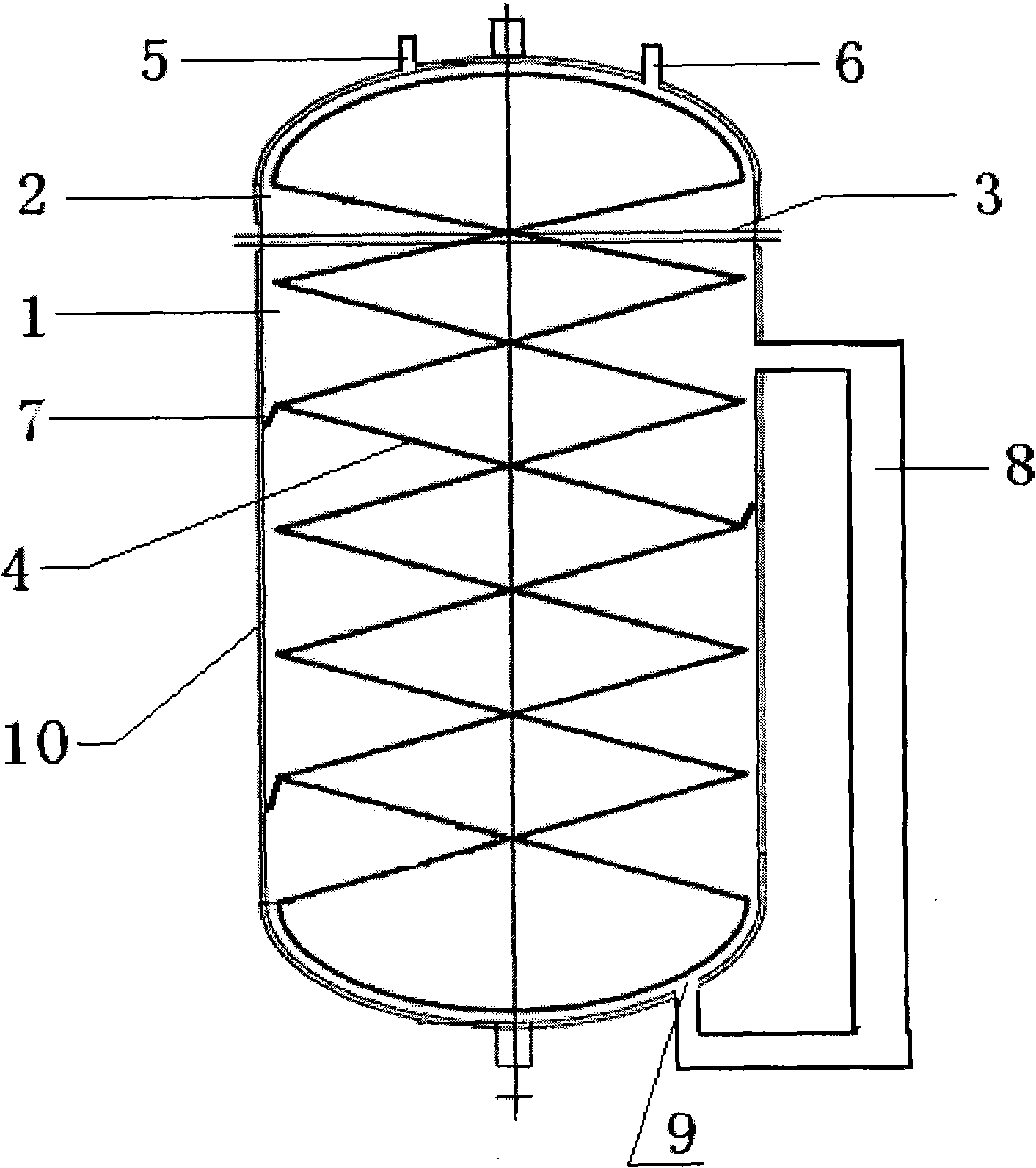

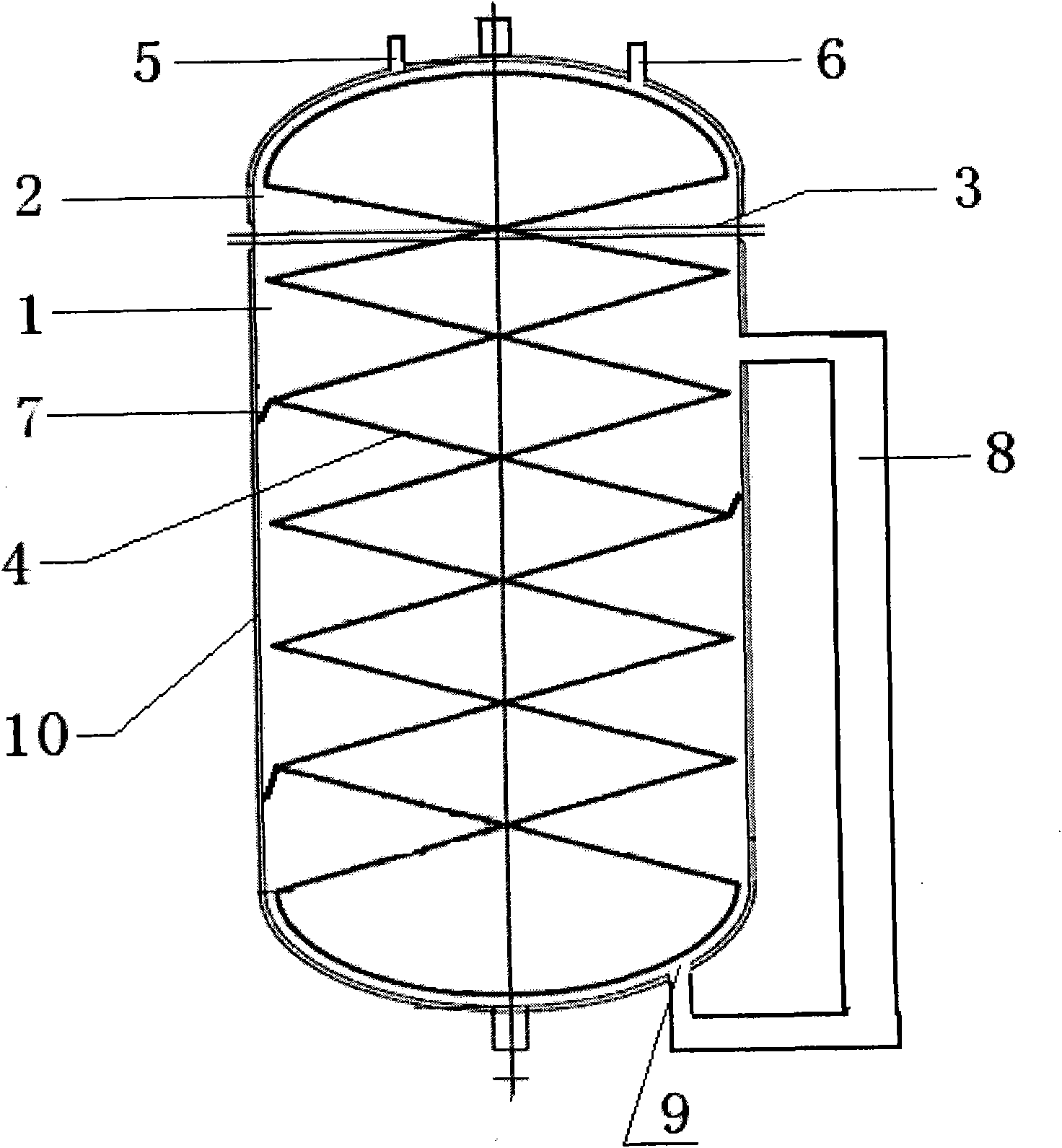

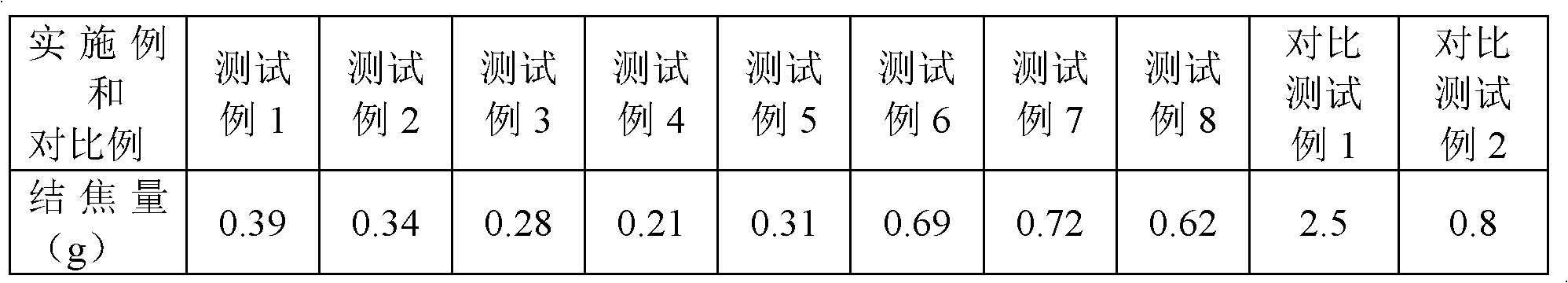

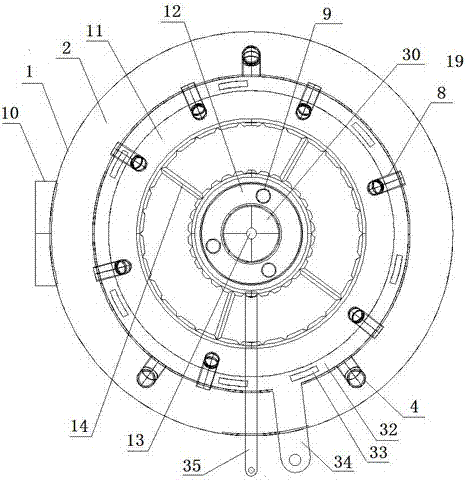

Polyacrylonitrile precursor and polymerization reaction kettle serving as production equipment thereof

InactiveCN102041575ASolve for uniformitySolve easy cokingMonocomponent synthetic polymer artificial filamentSolventPolyacrylonitrile

The invention relates to a polyacrylonitrile precursor and a polymerization reaction kettle serving as production equipment thereof. The formula of the polyacrylonitrile precursor mainly comprises monomers AN, MA and IA, dimethylsulfoxide (DMSO) serving as a solvent, and azodiisobutyronitrile (AIBN) serving as an initiator; and if the total content of the mixed liquid of AN, MA and IA is 1, the content of the DMSO is 30-50% by weight, and the content of the AIBN is 6.5-9.5% by weight. The reaction kettle serving as the production equipment of polyacrylonitrile precursor provided by the invention comprises a kettle body and a kettle cover, wherein the kettle body and the kettle cover are connected through a flange; stirrers are arranged in the kettle body; a liquid inlet and a liquid outlet are arranged on the kettle cover; each stirrer is a ribbon stirrer; and two or more ribbon stirrers are arranged. The invention has the advantages that the conversion rate is obviously improved, the monomer recovery is easy, and fiber with a dense structure is easily obtained in spinning, thereby being beneficial to the improvement of the soft scientific performance of the finally obtained fiber; and moreover, the problems of non-uniform stirring, easy coking, low conversion rate, unstable reaction and the like in the production of the polyacrylonitrile precursor can be effectively solved.

Owner:HENGSHEN

Method for producing olefin

ActiveCN102898265BSolve easy cokingOvercoming pollutionHydrocarbon purification/separationHydrocarbonsCarbon layerMetallurgy

The invention provides a method for producing olefin. The method comprises step of placing cracking raw materials in a cracking furnace tube for conducting cracking under cracking conditions, so as to obtain the cracking product olefin. The cracking furnace tube comprises a cracking furnace tube matrix, an adhesive layer attached to an inner wall of the cracking furnace tube matrix, and an anti-coking and anti-permeability carbon layer attached to the adhesive layer surface; the adhesive layer is a coating capable of bonding the cracking furnace tube matrix and the anti-coking and anti-permeability carbon layer, and preventing the coke from contacting with the cracking furnace tube matrix; the anti-coking and anti-permeability carbon layer is a coating, which can prevent the coke from contacting with the cracking furnace tube matrix, but does not react with cracking raw materials and / or cracking products; the adhesive layer and the anti-coking and anti-permeability carbon layer have a porous structure; and the average pore radius of the pore structure of the adhesive layer is less than that of the pore structure of the anti-coking and anti-permeability carbon layer. The method for producing olefin provided by the invention has simple operation and good anti-coking performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

An ultrasonic quenching device capable of on-line decoking and its application

ActiveCN111073678BEfficient and uniform conductionImprove heat transfer efficiencyThermal non-catalytic crackingHollow article cleaningPetrochemicalUltrasonic technology

The invention belongs to the technical field of petrochemical cracking, in particular relates to an ultrasonic quenching device capable of online decoking, and further discloses a cracking quenching process and an online decoking process performed by the ultrasonic quenching device. The ultrasonic quenching device of the present invention combines ultrasonic technology with quenching technology to form a combination device of ultrasonic and quenching device, which not only has the function of ordinary quenching cooler, but also uses ultrasonic technology to solve the problem of easy coking at the entrance of quenching equipment, and breaks through traditional quenching In order to avoid the disadvantages of only transporting gaseous materials, the hot water is introduced into the tube side of the quencher, and the ultrasonic distributor is used to efficiently transmit the ultrasonic wave to the coke layer of the tube side of the quencher. The hot water weakens the van der Waals force of the coke layer. The coke layer is gradually decomposed into particles and falls off, realizing online decoking treatment. It can be widely used in thermal cracking process of petrochemical industry.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing olefin

ActiveCN102899065BSolve easy cokingOvercoming pollutionThermal non-catalytic crackingCoated surfaceCoke

Owner:CHINA PETROLEUM & CHEM CORP +1

Waste incinerator and construction method thereof

ActiveCN109855102AContain the risk of collapseDoes not affect combustionLinings repairFurnace coolingCombustionEngineering

The invention relates to the technical field of waste incineration power generation, and discloses a waste incinerator. The waste incinerator comprises a drying area, a main combustion area and a burnout area, wherein the main combustion area comprises a hearth, the hearth comprises a rear wall and two side walls which are connected with one another; the rear wall and the two side walls are all heat insulation furnace walls, new water cooling walls covered with the heat insulation furnace walls are arranged on the inner side walls of the heat insulation furnace walls; and the invention furtherdiscloses a construction method of the waste incinerator. According to the waste incinerator and the construction method, the problems that the furnace wall near the main combustion area of an existing waste incinerator is easy to coke is effectively solved.

Owner:广州广重企业集团有限公司

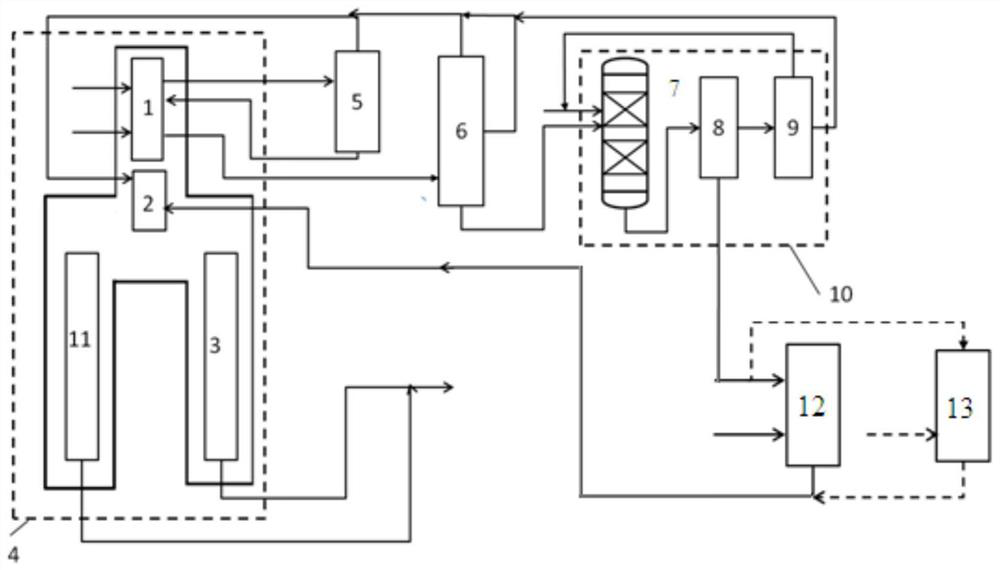

A method and system for preparing low-carbon olefins

ActiveCN112708459BSolve easy cokingHigh yieldTreatment with hydrotreatment processesHydrocarbon by hydrocarbon crackingFluid phaseDistillation

The invention relates to a method and system for preparing low-carbon olefins. The method is carried out as follows: the crude oil is sent to the first tube group of the convection section of the cracking furnace for preheating, and then vapor-liquid separation is performed to form a first vapor phase and a first liquid phase. phase; the first liquid phase is sent to the first tube group of the convection section for preheating, and the preheated first liquid phase is distilled to form a tower top fraction, a middle distillate and a tower bottom fraction; the tower bottom fraction is subjected to hydroprocessing , to obtain circulating hydrogen, light components after hydrogenation and heavy components after hydrogenation; mix the top distillate with the middle distillate, mix with the first vapor phase, and light components after hydrogenation, and send them to the cracking furnace for cracking to obtain a low carbon olefins. The present invention adopts the combination of cracking furnace, vapor-liquid separation unit, distillation unit and hydroprocessing unit, which can effectively solve the problems that the heavy cracking raw material cannot be fully gasified in the convection section and is easy to coke in the radiation section and the quenching section.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and system for preparing low-carbon olefin from crude oil

ActiveCN112708455ASolve the problem of insufficient gasificationHigh yieldTreatment with plural serial stages onlyEthylene productionChemistryVapor phase

The invention relates to a method and system for preparing low-carbon olefin from crude oil, and the method comprises the following steps: feeding crude oil into a first pipe group of a convection section of a cracking furnace for preheating, and then carrying out vaporization treatment to form a first vapor phase and a first liquid phase; feeding the first liquid phase into the first pipe group of the convection section of the cracking furnace, conducting preheating, and then conducting distilling to form a tower top fraction, a middle fraction and a tower bottom fraction; mixing the tower top fraction, the middle fraction and the first steam phase, feeding a formed mixture into a second pipe group of the convection section of the cracking furnace, conducting heating to a crossing temperature, and feeding the mixture into a radiation section for cracking to obtain cracking gas; and carrying out deep catalytic cracking on the tower bottom fraction to obtain deep catalytic cracking gas, and separating the deep catalytic cracking gas from the cracking gas to obtain the low-carbon olefin. The cracking furnace is matched with a vaporization treatment unit, a distillation unit and a deep catalytic cracking unit, so that the problems that a heavy cracking raw material cannot be fully gasified in a convection section and is easy to coke in a radiation section and a quenching part can be effectively solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

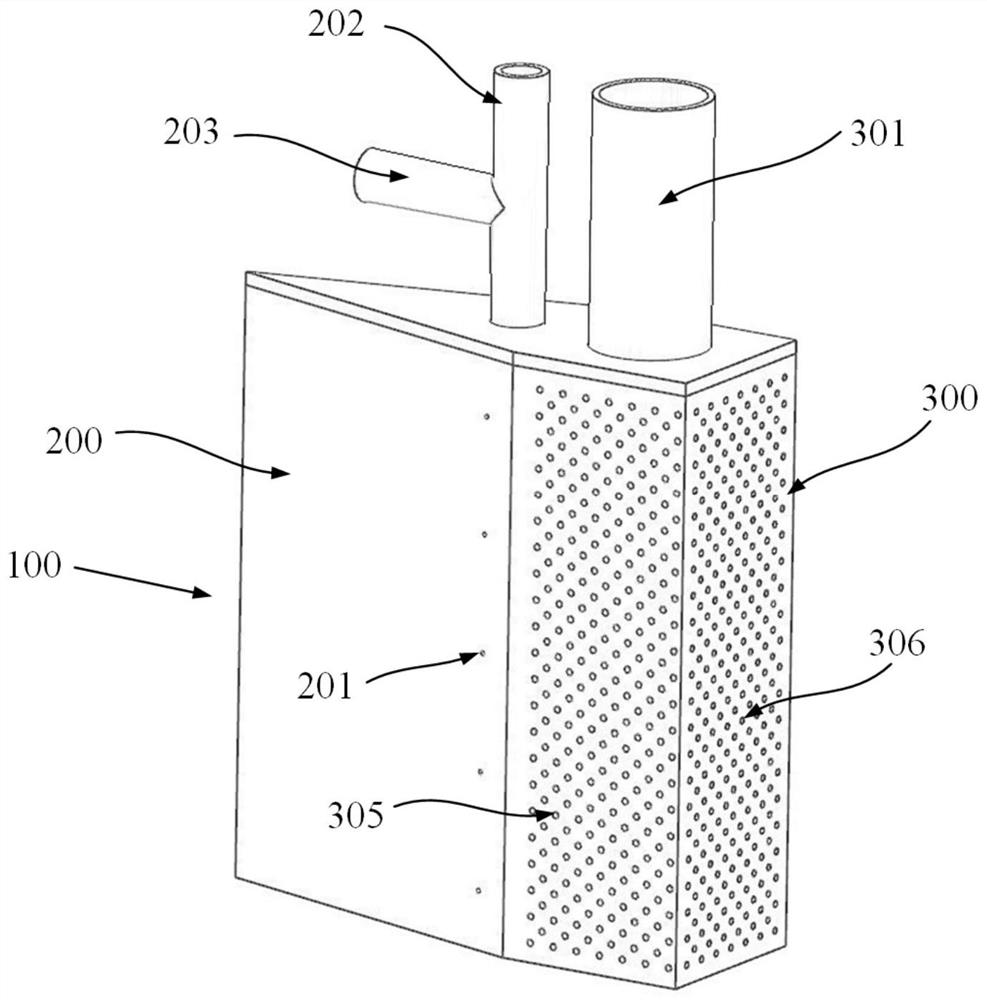

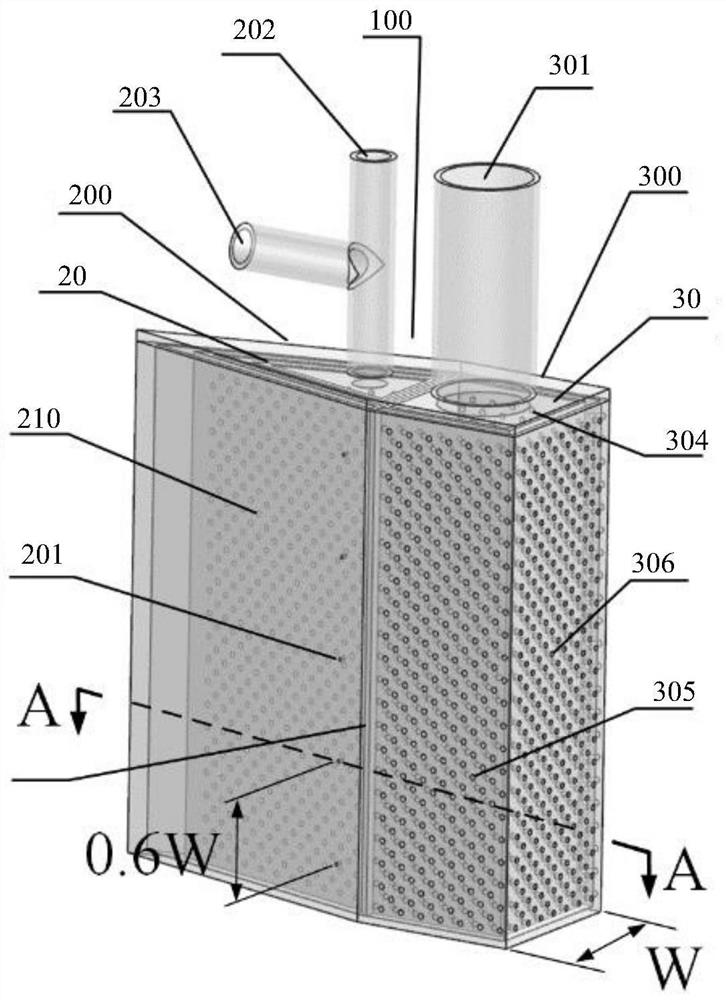

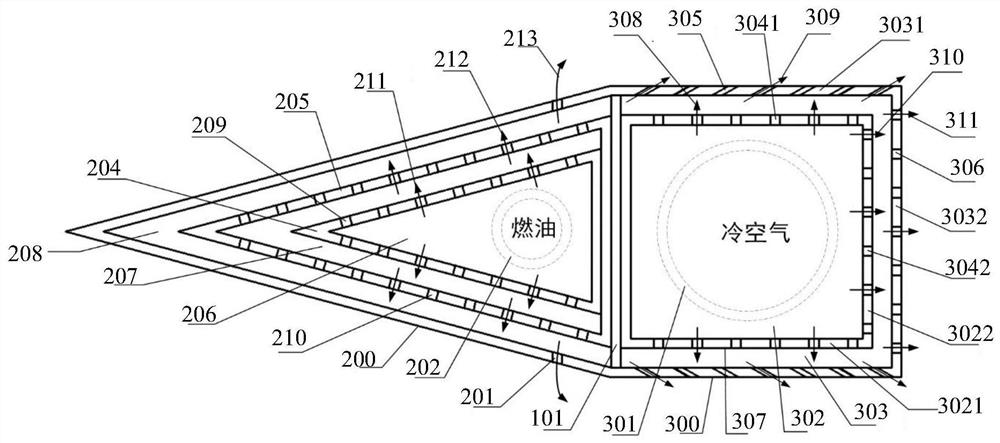

Nozzle stem, fuel nozzle and aero-engine gas turbine

ActiveCN104713128BSolve easy cokingReduce temperature differenceContinuous combustion chamberAviationEngineering

The invention discloses a nozzle rod part, a fuel nozzle and an aero-engine gas turbine, relates to the technical field of aero-engines, and is used for solving the problems of easy coking of fuel of the nozzle rod part and short service life of the fuel nozzle in a working state in a fuel supply scheme of using a main fuel way as a discontinuous working fuel way and using a secondary fuel way as a continuous working fuel way in the prior art. The nozzle rod part comprises a rod body, a main fuel way and a secondary fuel way. The secondary fuel way is arranged at the periphery of the main fuel way; a fluid in the main fuel way and a fluid in the secondary fuel way can exchange heat; the fluid entering from a fluid inlet of the main fuel way can flow out through a fluid outlet of the main fuel way; and the fluid entering from a fuel inlet of the secondary fuel way can at least experience once of the process of returning to a position near the fluid inlet of the main fuel way from a position near the fluid outlet of the main fuel way in the secondary fuel way, and then flows out by the fuel outlet of the secondary fuel way. The nozzle rod part can prevent the fuel coking problem, and can prolong the service life of the fuel nozzle.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

High Efficiency Cokeless Briquette Boiler

A high-efficiency coke-free briquette boiler, including a furnace body, a furnace, a smoke chamber, a high-level water tank, a preheater and a dust collector. Including the outer furnace body, outer water jacket and inner smoke chamber; the furnace includes the combustion zone and the air chamber; the high-level water tank is respectively connected with the outer water jacket and the preheater; the preheater is connected with the water inlet pipe, and the preheater is connected with the inner and lower water jacket Connected; the inner and lower large water jackets are connected with the outer water jacket; the outer water jacket is connected with the outlet pipe; a water level gauge and a water level controller are installed in the high water tank, which are respectively connected with the outer water jacket and the preheater. The present invention utilizes the design features of the water-cooled wall tube and the air chamber, so that there is sufficient air circulation in the furnace, the briquettes are fully burned, and a large amount of nitrogen oxides cannot be formed, which reduces the discharge of nitrogen oxides, reduces urban pollution, and The flame in the combustion area is scattered, and it also solves the problem of easy coking in traditional small hand-burning furnaces. It is an environmentally friendly, high-efficiency and energy-saving new boiler.

Owner:杨飞

Method for preparing polyester spinning melt by removing polyurethane contained in waste polyester textile through alcoholysis of ethylene glycol

The invention relates to a waste polyester high-value circulation reutilization technique, in particular to a method for preparing a polyester spinning melt by removing polyurethane contained in a waste polyester textile through alcoholysis of ethylene glycol. According to the method for preparing the polyester spinning melt by removing the polyurethane contained in the waste polyester textile through the alcoholysis of the ethylene glycol, a waste polyester textile raw material contains the polyurethane, a raw material, in which ethylene glycol with 1% to 8% of the raw material mass is added, is fed to a screw extruder to be blended, melt and extruded, and the melt viscosity of melt from the screw extruder is 0.40 to 0.50 d1 / g; and then the material enters a hardening, tempering and viscosity regulation device, and the melt viscosity of the melt body discharged from the hardening, tempering and viscosity regulation device is 0.635 to 0.685 d1 / g. Due to an alcoholysis manner, the influences on the viscosity, flowing property, fiber saturation property and drafting property of a polyester melt body, and series problems that vacuum pipes and tubular heat exchangers are easy to block due to the existence of spandex (polyurethane) are reduced.

Owner:NINGBO DAFA CHEM FIBER

A method and system for preparing light olefins from crude oil

ActiveCN112708455BSolve easy cokingHigh yieldTreatment with plural serial stages onlyEthylene productionFluid phaseDistillation

The invention relates to a method and system for preparing low-carbon olefins from crude oil. The method is carried out as follows: the crude oil is sent to the first tube group in the convection section of the cracking furnace for preheating, and then vaporized to form the first vapor phase and the second steam phase. One liquid phase; the first liquid phase is sent to the first tube group of the convection section of the cracking furnace to be preheated and then distilled to form an overhead fraction, a middle fraction and a bottom fraction; the overhead fraction, the middle fraction and the first After the steam phase is mixed, it is sent to the second tube group of the convection section of the cracking furnace, and after being heated to the crossing temperature, it is sent to the radiation section for cracking to obtain cracked gas; the bottom fraction is subjected to deep catalytic cracking to obtain deep catalytic cracking gas, which is then combined with the The cracked gas is separated to obtain light olefins. The invention adopts cracking furnace to cooperate with vaporization treatment unit, distillation unit and deep catalytic cracking unit, which can effectively solve the problems that heavy cracking raw materials cannot be fully gasified in the convection section and are easy to coke in the radiation section and the quenching section.

Owner:CHINA PETROLEUM & CHEM CORP +1

A garbage incinerator and its construction method

ActiveCN109855102BContain the risk of collapseDoes not affect combustionLinings repairFurnace coolingThermodynamicsCombustion

The invention relates to the technical field of waste incineration power generation, and discloses a waste incinerator. The waste incinerator comprises a drying area, a main combustion area and a burnout area, wherein the main combustion area comprises a hearth, the hearth comprises a rear wall and two side walls which are connected with one another; the rear wall and the two side walls are all heat insulation furnace walls, new water cooling walls covered with the heat insulation furnace walls are arranged on the inner side walls of the heat insulation furnace walls; and the invention furtherdiscloses a construction method of the waste incinerator. According to the waste incinerator and the construction method, the problems that the furnace wall near the main combustion area of an existing waste incinerator is easy to coke is effectively solved.

Owner:广州广重企业集团有限公司

Fuel oil burner for incinerator

PendingCN110762521ASolve easy cokingSolve the problem of being easily burned outBurnersFuel oilAir door

The invention relates to a fuel oil burner for an incinerator. The fuel oil burner comprises a burner shell, a flame tube, an oil gun assembly, an ignition needle assembly, a diffusion disc, an air door adjusting mechanism, an oil circuit module and an ignition transformer, wherein an openable and closable cooling air inlet is arranged on one side of the front end of the burner shell; the diffusion disc is fixedly arranged at the front end of the oil gun assembly and forms a whole with the oil gun assembly; and the fuel oil burner further comprises an oil gun assembly advancing and retreatingdriving mechanism, and the oil gun assembly advancing and retreating driving mechanism is connected with the oil gun assembly and then drives the whole oil gun assembly to advance and retreat so as todrive the diffusion disc to move between the flame tube and the cooling air inlet. The fuel oil burner has the beneficial effects that the problems in the prior art that an oil nozzle on the oil gunassembly is prone to coking and the diffusion disc is prone to being burned out are effectively solved, and therefore the service life of the fuel oil burner is ensured and the cost for enterprises issaved.

Owner:上海迎韦热能设备有限公司

Oil-gas composite cooling type flame stabilizer and combustion chamber

ActiveCN113898973AShorten the lengthEliminates the problem of easy coking and the need for thermal protectionContinuous combustion chamberCold airCombustion chamber

The invention discloses an oil-gas composite cooling type flame stabilizer and a combustion chamber. The flame stabilizer comprises a flame stabilizer main body, wherein the flame stabilizer main body is divided into a V-shaped section and a straight section by a partition plate; an inner cavity of the V-shaped section is divided into a plurality of layers of oil cooling cavities which are in communication with one another from inside to outside; an inner cavity of the straight section is in communication with a cooling gas guide pipe, and a plurality of through holes used for sending out gas sent by the cooling gas guide pipe are formed in the outer wall of the straight section; and fuel oil passes through the oil cooling cavity and then is vertically injected into the high-temperature main flow through fuel oil injection holes. Cold air enters an air cooling cavity through the cooling gas guide pipe, then part of the cold air forms an air film on the side wall face through air film holes, the rest of the cold air enters the near-wall area of the rear end face of the stabilizer through cold air jet holes to form cold air vortexes, the wall temperature of the straight section of the stabilizer can be reduced, and the oxygen content and combustion efficiency in the wake area of the stabilizer can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Process and device for producing tetrachloro-2-cyanopyridine with liquid chromatography

The invention relates to a process for producing tetrachloro-2-cyanopyridine. The process comprises steps as follows: liquid 2-cyanopyridine is preheated, flows into a gas-liquid reinforcement pre-reactor and pre-reacts with chlorine under the action of a pre-reaction catalyst; after the reaction, a gas-phase material is washed and flows into an absorption device to be absorbed; a liquid-phase material after pre-reaction enters a gas-liquid reinforcement main reactor and has a chlorination reaction with the chlorine under the action of a main reaction catalyst; the liquid-phase material discharged from the main reactor is introduced into an evaporator for separation, and finally a tetrachloro-2-cyanopyridine solid is obtained. The process has the advantages that the production flow of tetrachloro-2-cyanopyridine is shortened, and safety and operability of the production process are improved; the utilization rate of the chlorine is increased, and the exhaust gas treatment load is reduced; the chlorination reaction temperature is reduced, the problem that the catalyst is prone to coking is solved, and the service life of the catalyst is prolonged; the yield and content of the product are increased, the difficulty of product purification is reduced, the reaction temperature is low, energy consumption is small; the process is green and environment-friendly.

Owner:NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com