Flow-equalizing multi-angle tangential pulverized coal decoupling combustion device and combustion method

A combustion device and angle cutting technology, which are applied in the combustion method, combustion using multiple fuels, combustion using lump fuel and powder fuel, etc., can solve the problems of unfavorable reducing atmosphere, unfavorable stable combustion, and reduction of furnace utilization, etc. Avoid local peroxidation and high temperature environment, improve the ability to prevent coking of furnace walls, and increase the effect of short-range lateral rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The following are examples of the present invention, which are only used to explain the present invention rather than limit it.

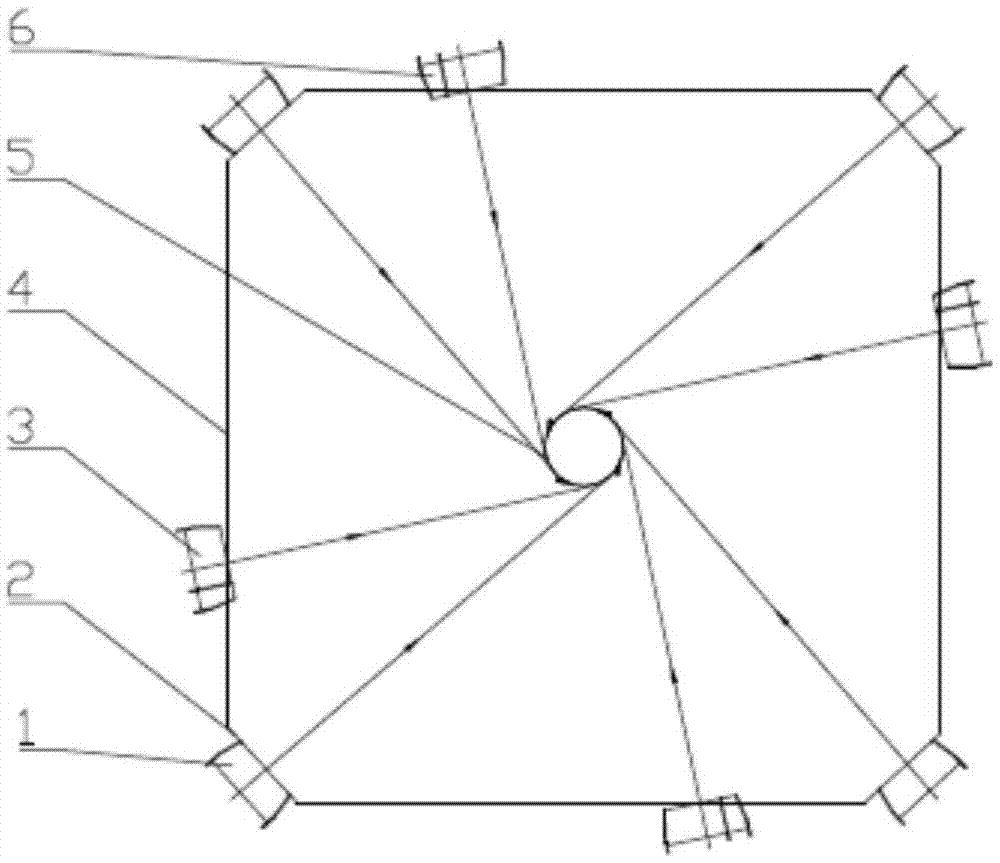

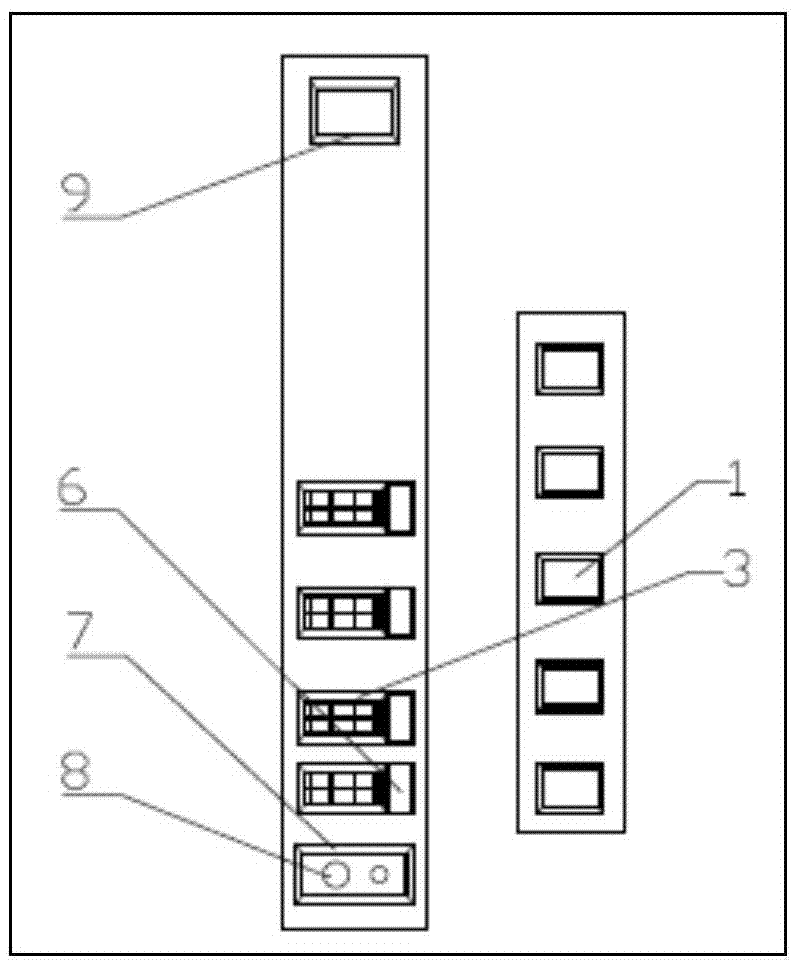

[0057] The present invention proposes an even-flow multi-angle tangentially circular pulverized coal decoupling combustion device, which includes a multi-angle tangentially circular combustion furnace. A row of primary air nozzles 3, ignition secondary air nozzles 7 and overburning air nozzles 9 arranged along the height direction.

[0058] The aspect ratio of the primary air nozzles 3 is 1.5 to 3; the primary air nozzles 3 are arranged in a centralized manner, no secondary air nozzles are set between the primary air nozzles, and the center distance between the primary air nozzles is 1.5 of the height of the nozzles. ~ 3 times, the distance between the bottom two primary air nozzles is determined according to the type of coal, and the center distance between the bottom primary air nozzles of coal that is not easy to catch fire is less than 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com