Coal tar full-fraction fluidized bed-fixed bed combined treatment process

A treatment process, coal tar technology, applied in the field of coal chemical industry, can solve the problems of increased investment, insufficient and efficient utilization of coal tar, increased management costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

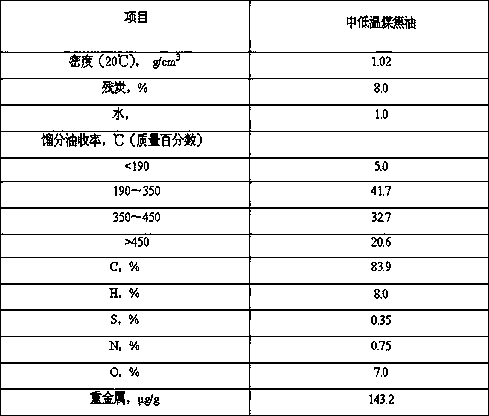

Embodiment 1

[0042] Using the medium and low temperature coal tar in Table 1 as raw material, adopt the fluidized bed-fixed bed treatment process in the patent of the present invention, first use a centrifuge to carry out centrifugal desolidification treatment on the whole fraction coal tar raw material (the raw material temperature is 95 °C, and the centrifuge speed is 3500r / min, centrifugation time is 15min), the coal tar raw material and additives obtained after desolidification treatment are mixed into the pretreatment tank for advanced pretreatment, and the mixing ratio of coal tar raw material and additives is 45:1 (mass ratio) , the liquid phase mixture after solid-liquid separation is hydrogenated in an ebullating bed reactor in the presence of hydrogen and a hydrogenation catalyst. The reaction conditions of the ebullating bed hydrogenation reactor are: reaction temperature 380 ° C, reaction pressure 16 MPa , volumetric space velocity 0.5h -1 , the volume ratio of hydrogen to oil ...

Embodiment 2

[0044] Using the medium and low temperature coal tar in Table 1 as the raw material, adopt the fluidized bed-fixed bed treatment process in the patent of the present invention, first use a centrifuge to carry out centrifugal desolidification treatment on the whole fraction coal tar raw material (the raw material temperature is 105 °C, and the centrifuge speed is 4000r / min, centrifugation time is 20min), the coal tar raw material and additives obtained after desolidification treatment are mixed into the pretreatment tank for advanced pretreatment, and the mixing ratio of coal tar raw material and additives is 35:1 (mass ratio) , the liquid phase mixture after solid-liquid separation is hydrogenated in an ebullating bed reactor in the presence of hydrogen and a hydrogenation catalyst. The reaction conditions of the ebullating bed hydrogenation reactor are: reaction temperature 390 ° C, reaction pressure 16.5 Mpa, volumetric space velocity 0.55h -1 , the volume ratio of hydrogen ...

Embodiment 3

[0046] Using the medium and low temperature coal tar in Table 1 as the raw material, adopt the fluidized bed-fixed bed treatment process in the patent of the present invention, first use a centrifuge to carry out centrifugal desolidification treatment on the whole fraction coal tar raw material (the raw material temperature is 110°C, and the centrifuge speed is 4200r / min, centrifugation time is 20min), the coal tar raw material and additives obtained after desolidification treatment are mixed into the pretreatment tank for advanced pretreatment, and the mixing ratio of coal tar raw material and additives is 25:1 (mass ratio) , the liquid phase mixture after solid-liquid separation is hydrogenated in an ebullating bed reactor in the presence of hydrogen and a hydrogenation catalyst. The reaction conditions of the ebullating bed hydrogenation reactor are: reaction temperature 395 ° C, reaction pressure 16.5 Mpa, volumetric space velocity 0.4h -1 , the volume ratio of hydrogen to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com