Method for preparing polyester spinning melt by removing polyurethane contained in waste polyester textile through alcoholysis of ethylene glycol

A technology of polyester spinning and waste polyester, which is applied in the field of high-value recycling of waste polyester, can solve the problems of poor post-drawing performance of vacuum pipes, poor melt flow performance, and large melt viscosity degradation, etc., to achieve Effects of improved melt flow properties, improved lipophilic properties, and improved fiber spinnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

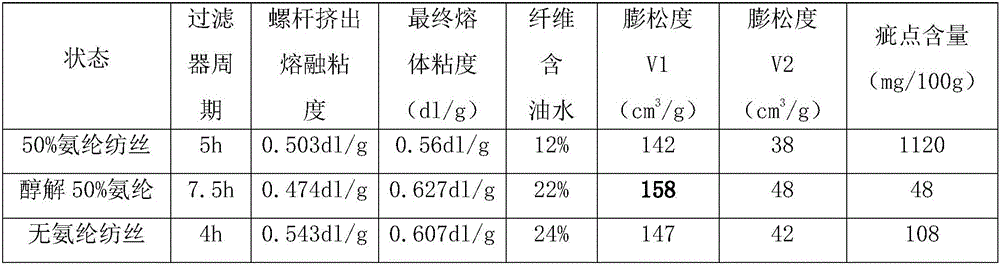

Embodiment 1

[0030]Mix the waste polyester textile foam containing spandex (accounting for 10% to 15% of the mass ratio of the foam) in the conventional waste polyester textile foam according to the addition ratio of 50%, and then according to the foam material impurity content, color, After the viscosity difference is compounded, it is spin-dried for 9 hours under certain vacuum (≤-0.96MPa) and temperature (145°C±5°C) conditions, and finally 110PPm of water is put into the spinning silo. Adjust the speed of the ethylene glycol pump so that the mass fraction of ethylene glycol measured is 3% of the foam material, the feed rate of the screw is 1t / h, and the temperature from the first to the tenth area of the screw is 278°C, 280°C, and 285°C. , 290°C, 295°C, 290°C, 290°C, 288°C, 288°C, 286°C, the filter temperature is 288°C, and the residence time of the melt in the screw, filter and pipeline is 15min. It takes 70 minutes to enter the liquid-phase tempering and viscosity-adjusting device. ...

Embodiment 2

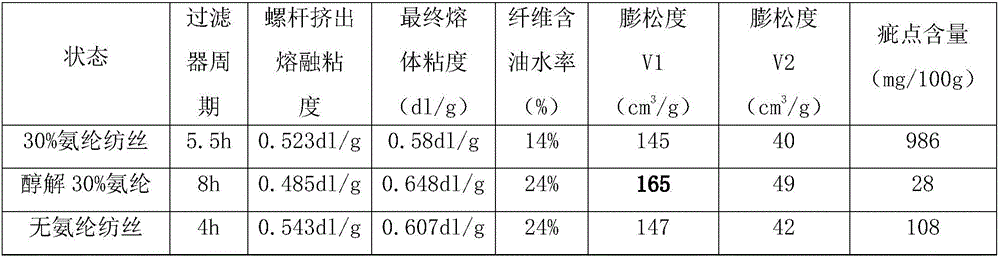

[0034] Mix the waste polyester textile foam containing spandex (accounting for 10% to 15% of the mass ratio of the foam) in the conventional waste polyester textile foam according to the addition ratio of 30%, and then according to the impurity content, color, After the viscosity difference is compounded, it is spin-dried for 9 hours under certain vacuum (≤-0.96MPa) and temperature (145°C±5°C) conditions, and finally 100PPm of water is put into the spinning silo. Adjust the speed of the ethylene glycol pump so that the mass fraction of ethylene glycol measured is 4% of the foam material, the feed rate of the screw is 1t / h, and the temperatures in the first to tenth areas of the screw are 278°C, 280°C, and 285°C in sequence , 290°C, 295°C, 290°C, 290°C, 288°C, 288°C, 286°C, the filter temperature is 288°C, and the residence time of the melt in the screw, filter and pipeline is 16min. It takes 75 minutes to enter the liquid-phase tempering and viscosity-adjusting device. The vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com