Patents

Literature

107results about How to "Reduce motor power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

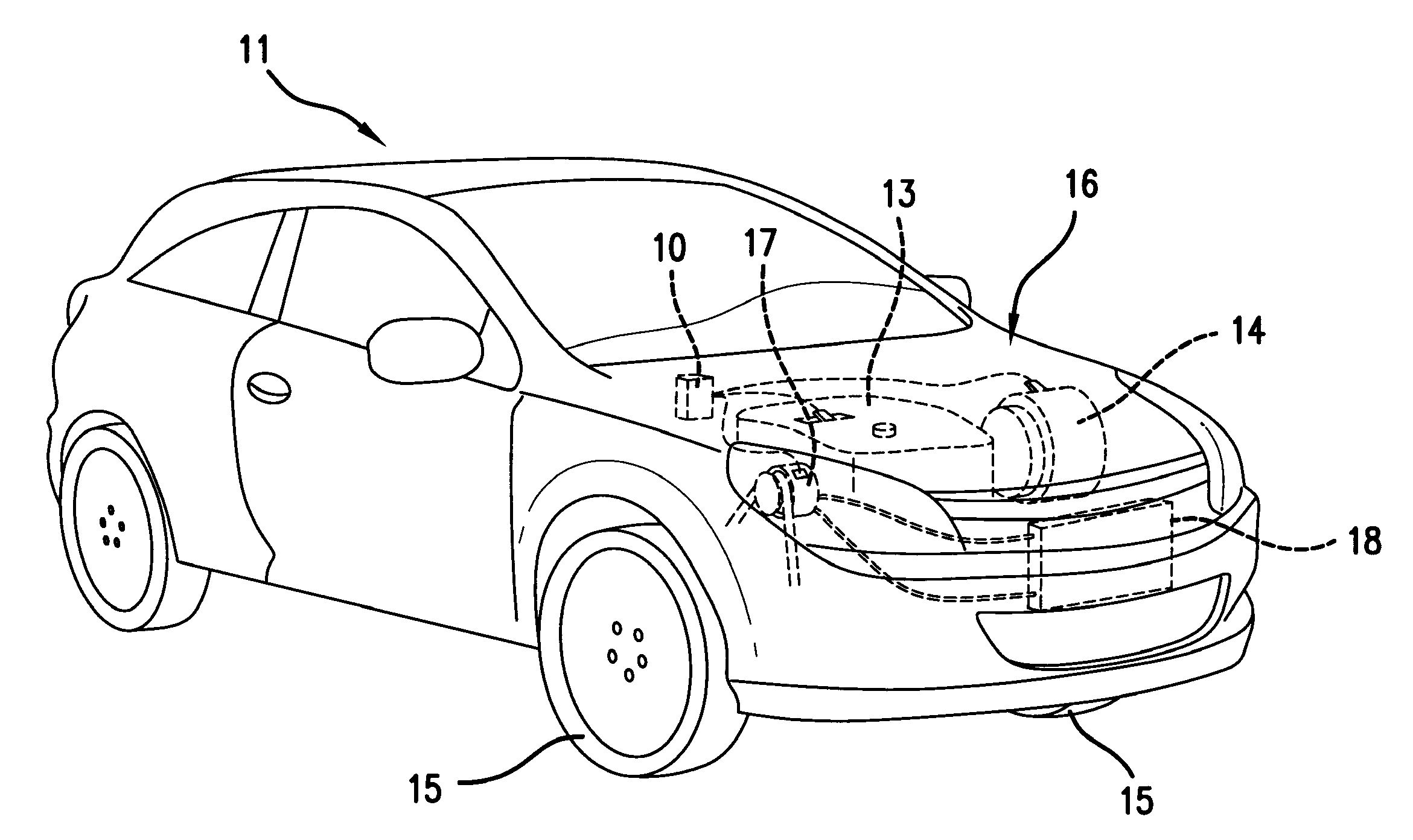

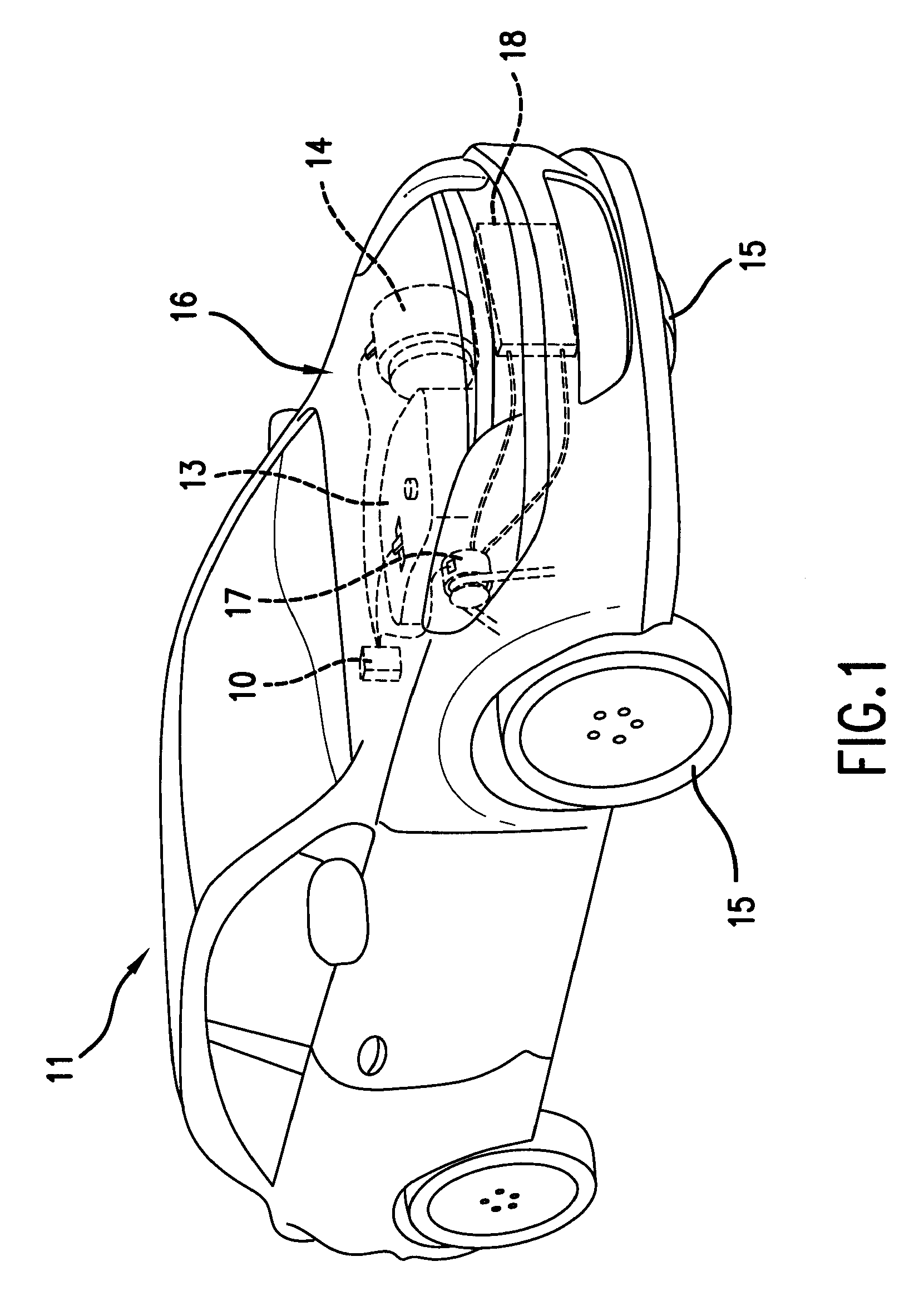

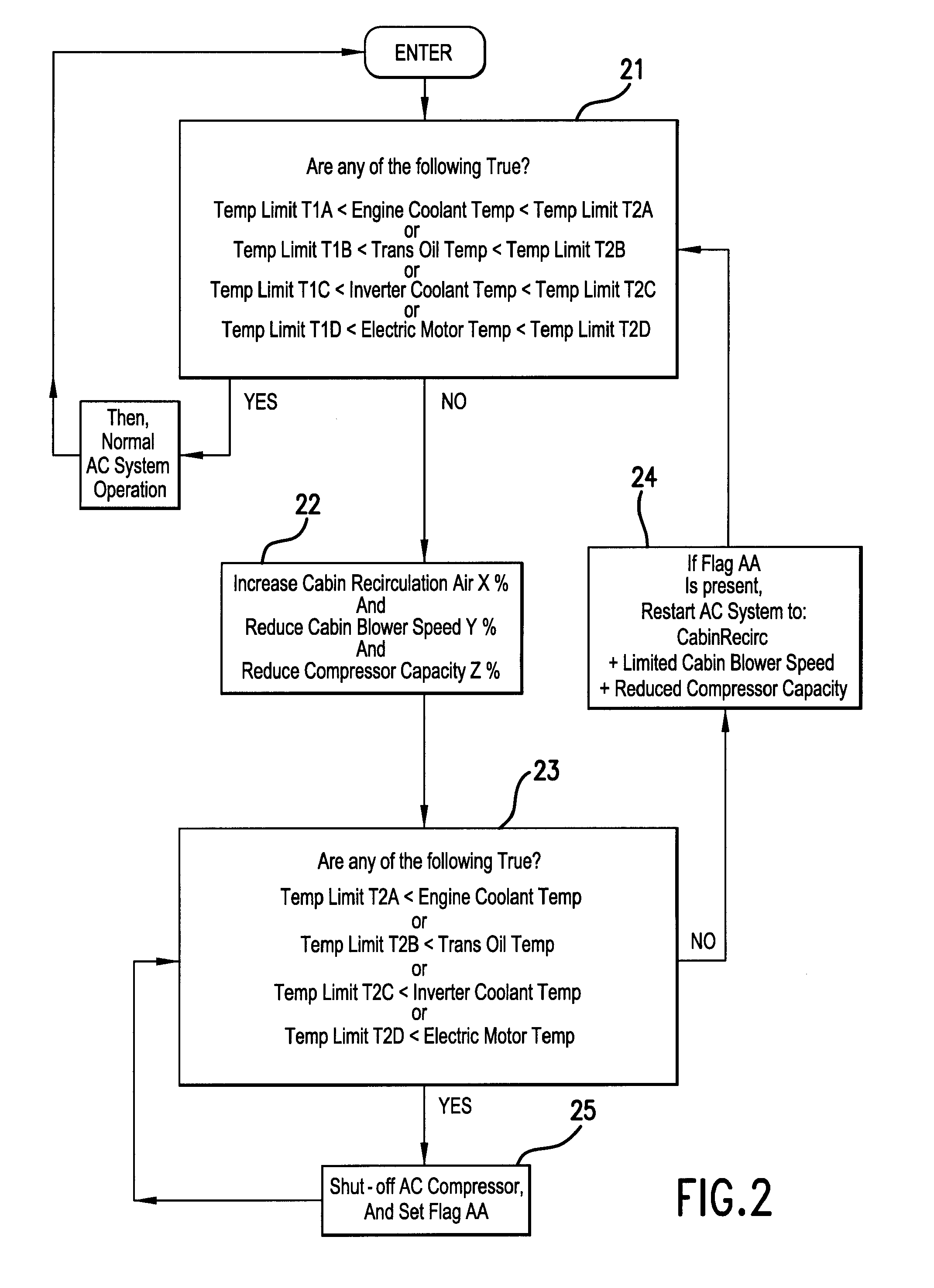

Methods of Optimizing Vehicular Air Conditioning Control Systems

InactiveUS20080034767A1Reduction in propulsion cooling system sizeReduce heat loadCompression machines with non-reversible cycleVehicle heating/cooling devicesElectric driveOperating temperature

Air conditioning system controls are optimized for an air conditioning system having a compressor in IC engine vehicles and in hybrid or fuel cell vehicles having electric drive motors by first determining the operating temperature of at least one of the following vehicle components: engine coolant and transmission oil for all types of vehicles, and for hybrid or fuel cell vehicles also determining the operating temperature of inverter coolant and the electric drive motors. At least one operating temperature is then compared to lower and upper temperature limits. If the operating temperature is outside of the temperature limits air conditioner heat load is reduced by at least one of the following steps: increasing cabin air recirculation, reducing cabin blower speed and reducing air conditioner compressor capacity. Subsequent to reducing air conditioner heat load, selected operating temperature or temperatures are monitored to determine if the operating temperature exceeds the upper temperature limit or limits. If the operating temperature or temperatures exceed the upper limit or limits the compressor is shut off.

Owner:GM GLOBAL TECH OPERATIONS LLC

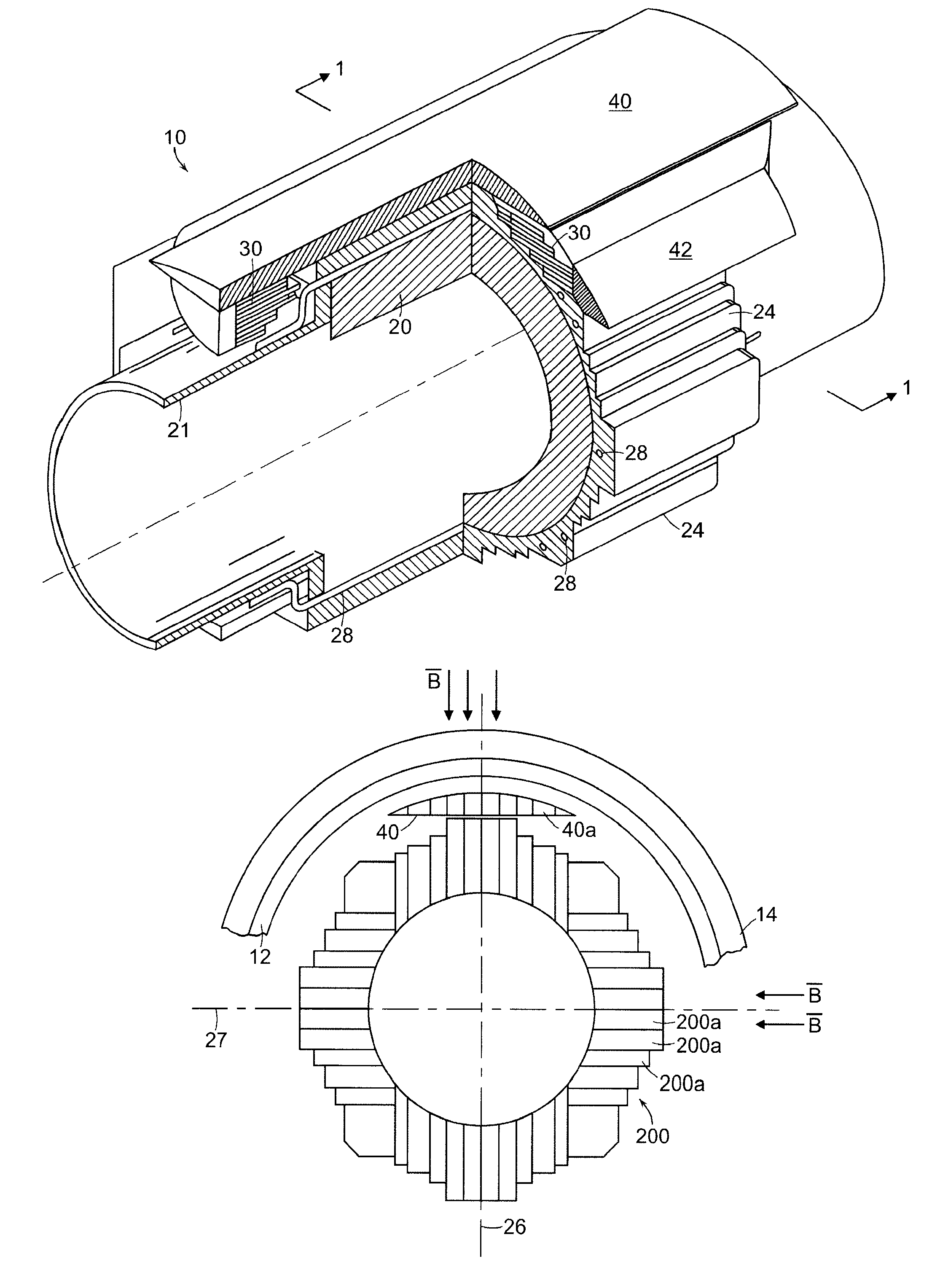

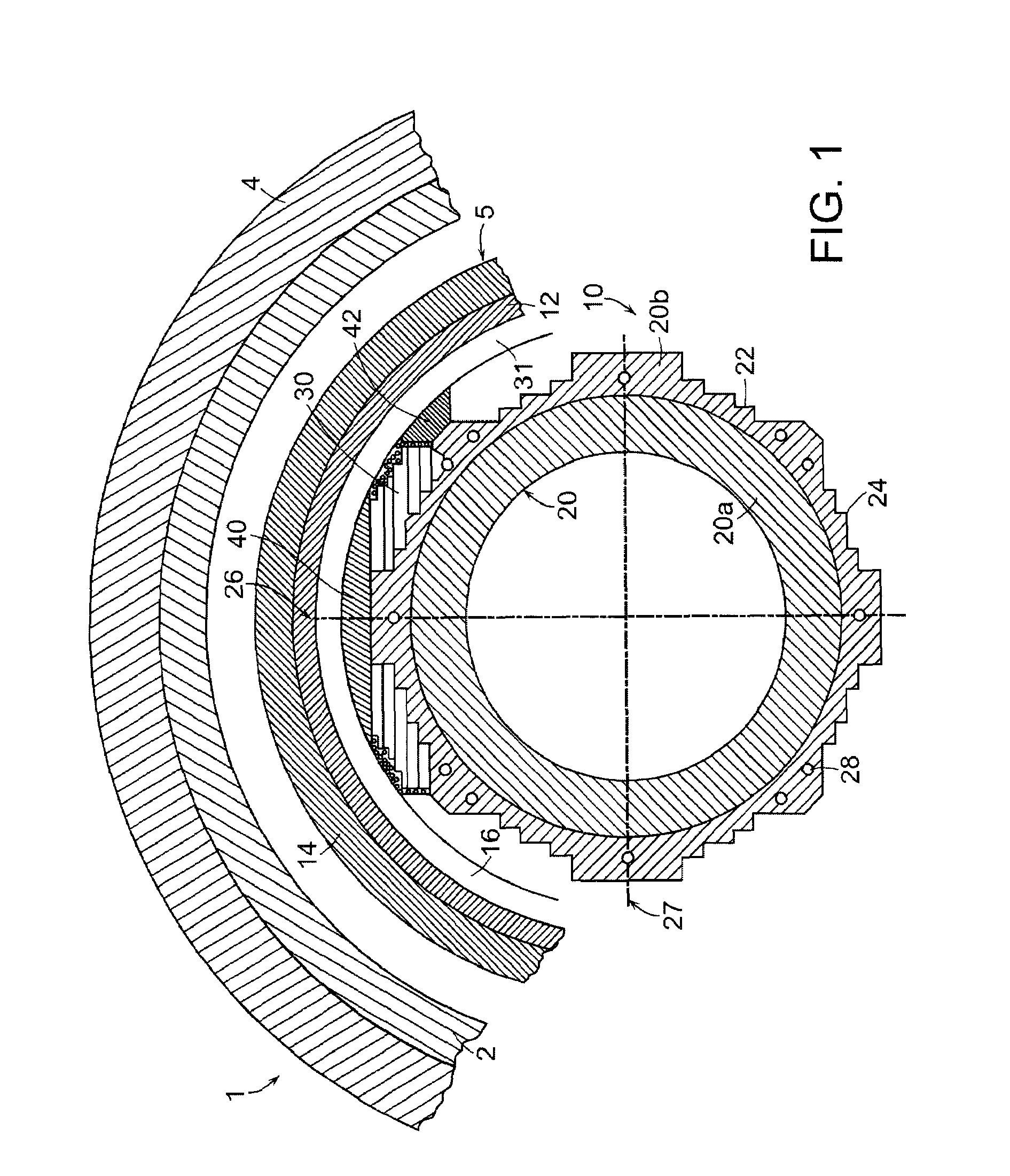

Superconducting electric motor

InactiveUS7453174B1Reduce motor powerGuaranteed uptimeWindingsMagnetic circuit rotating partsSynchronous motorInduction motor

A superconducting motor which operates in a synchronous mode of operation, can also be operated in an induction mode in the event that the superconducting components of the motor lose their superconducting properties (e.g., due to cooling system failure). The superconducting electric motor includes a rotor assembly having at least one superconducting winding which, in operation, generates a flux path within the rotor assembly, and a support member which supports the at least one superconducting winding. The rotor assembly is configured to operate in a synchronous mode of operation at temperatures in which the superconducting winding exhibits superconducting characteristics and in a steady-state induction mode of operation at temperatures in which the superconducting winding exhibits non-superconducting characteristics.

Owner:AMERICAN SUPERCONDUCTOR

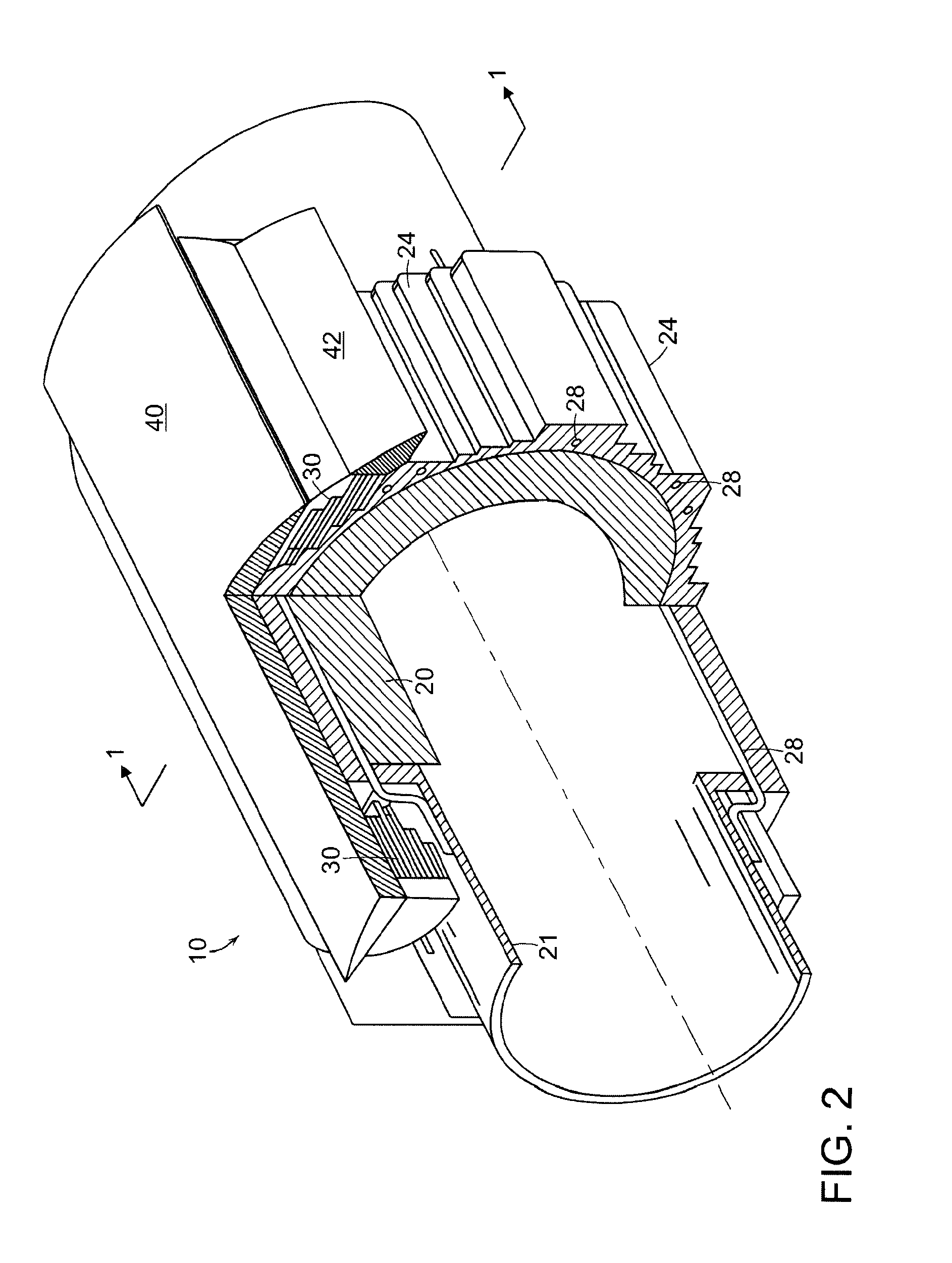

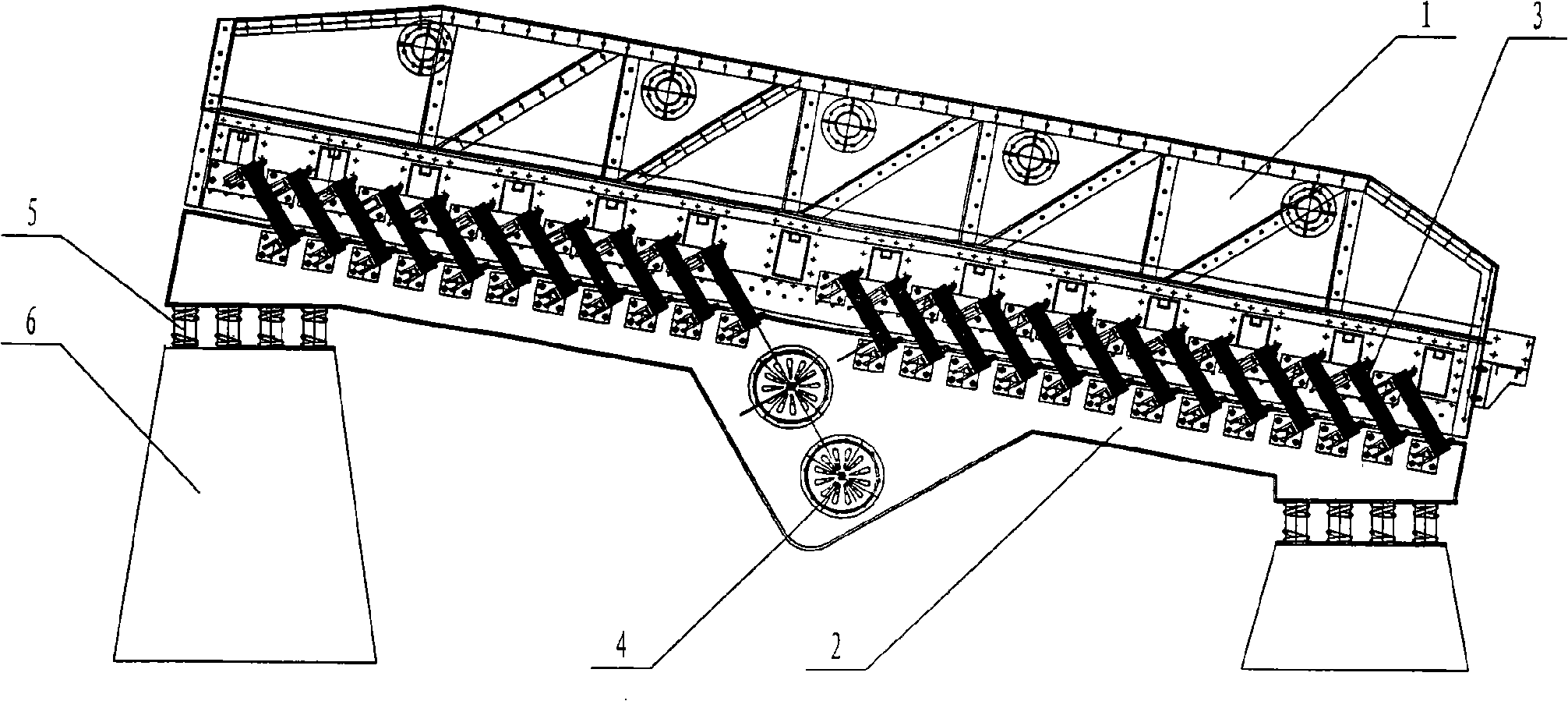

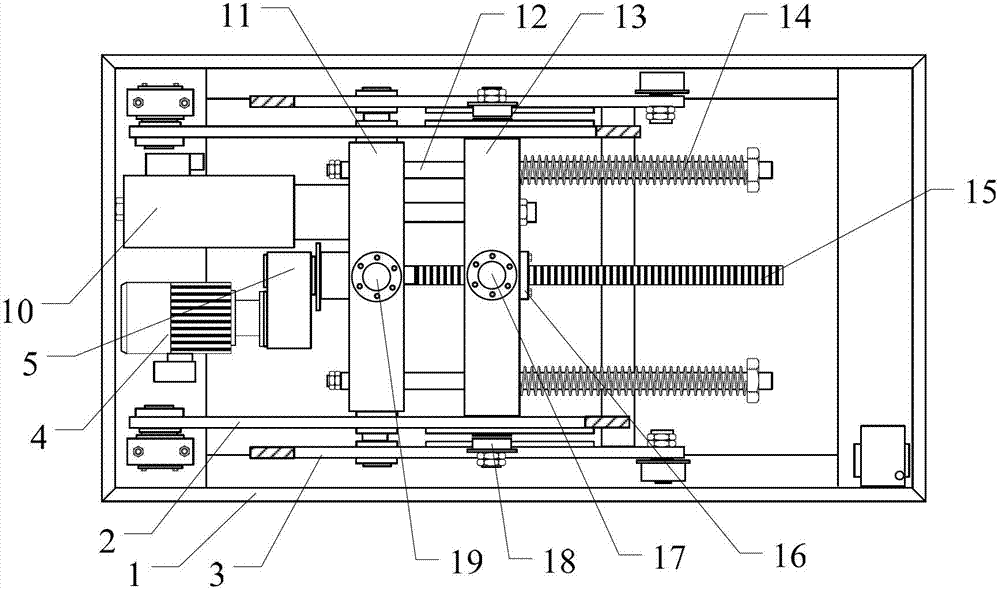

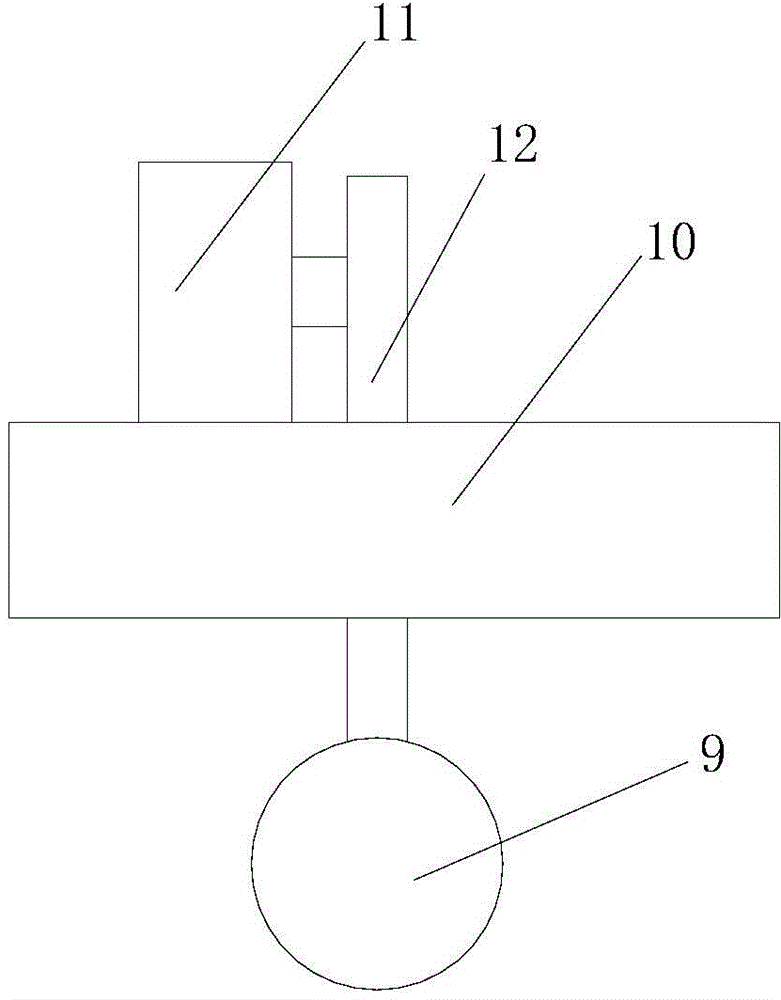

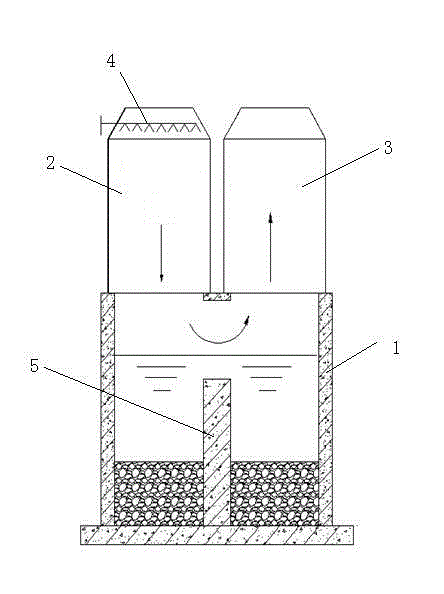

Anti-resonance vibrating sifter

The present invention relates to an anti-resonance vibration sieve, which belongs to the technical field of vibration machinery. The anti-resonance vibration sieve comprises a sieve box as an upper plasmid, an excitation body as a lower plasmid, a master vibration spring, a vibration generator, an isolation spring, a base, a motor, etc. The sieve box upper plasmid is a working part of the anti-resonance vibration sieve, and the excitation body lower plasmid is a driving part. The excitation body is equipped with the vibration generator. The sieve box and the excitation body are connected by the master vibration spring. The excitation body is located on the base by the isolation spring. The motor is arranged at a motor frame and is connected with the vibration generator by a transmission shaft. The anti-resonance vibration sieve has the advantages that the sieve box of the anti-resonance vibration sieve is provided with the vibration generator, the mass of vibration can be totally reduced by 20 percent to 30 percent, so that the excitation force is reduced, and the motor power is also reduced, thereby being good for saving energy; the master vibration spring is distributed along the direction of a lateral board of the sieve box, and the sieve box bears force uniformly, thereby being good for prolonging the service life of the sieve; the vibration generator is arranged at the lower plasmid, the lower plasmid almost does not vibrate, and the requirement on rigidity and strength can be ensured easily. The noise of the whole machine is reduced obviously.

Owner:NORTHEASTERN UNIV

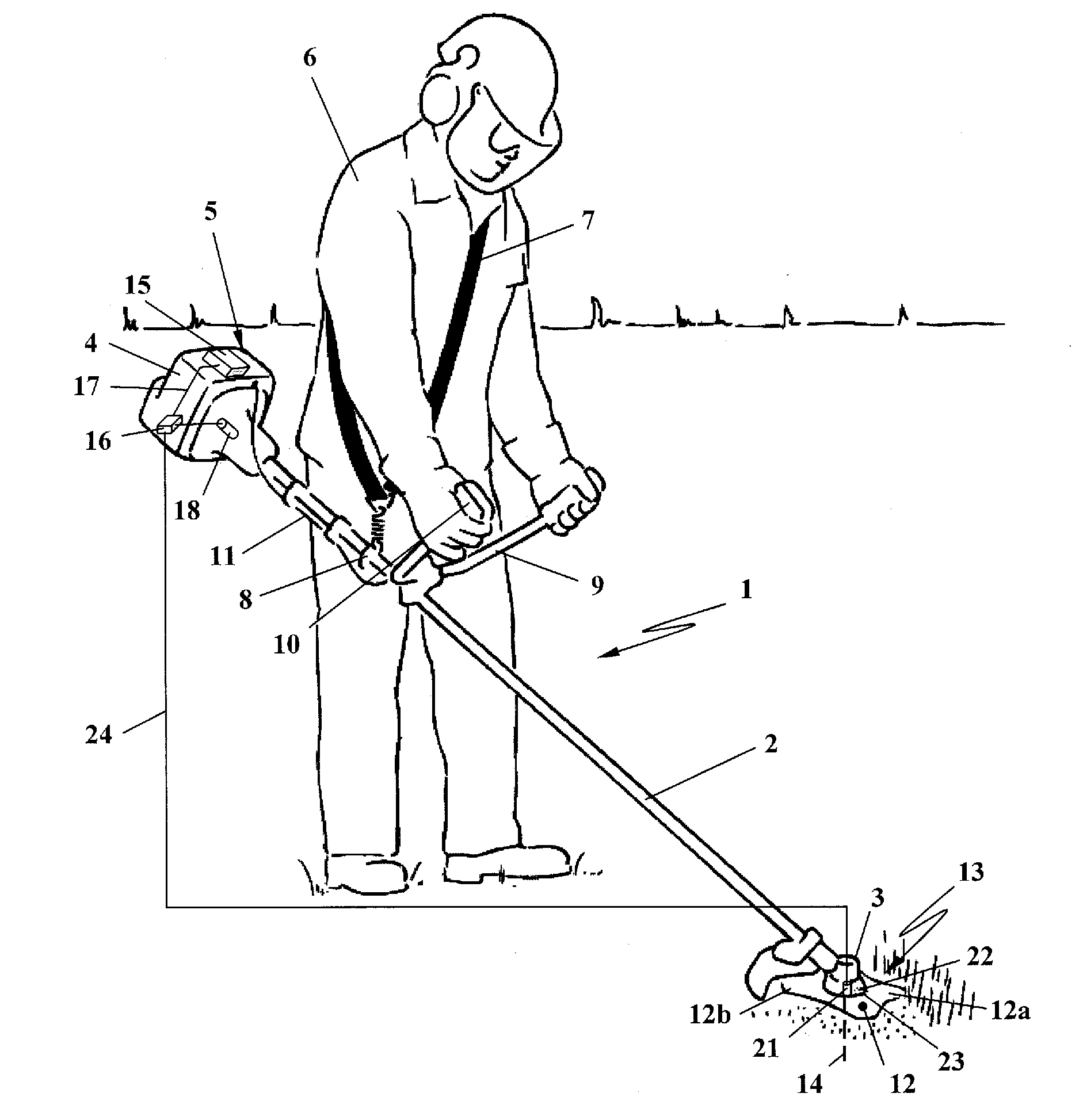

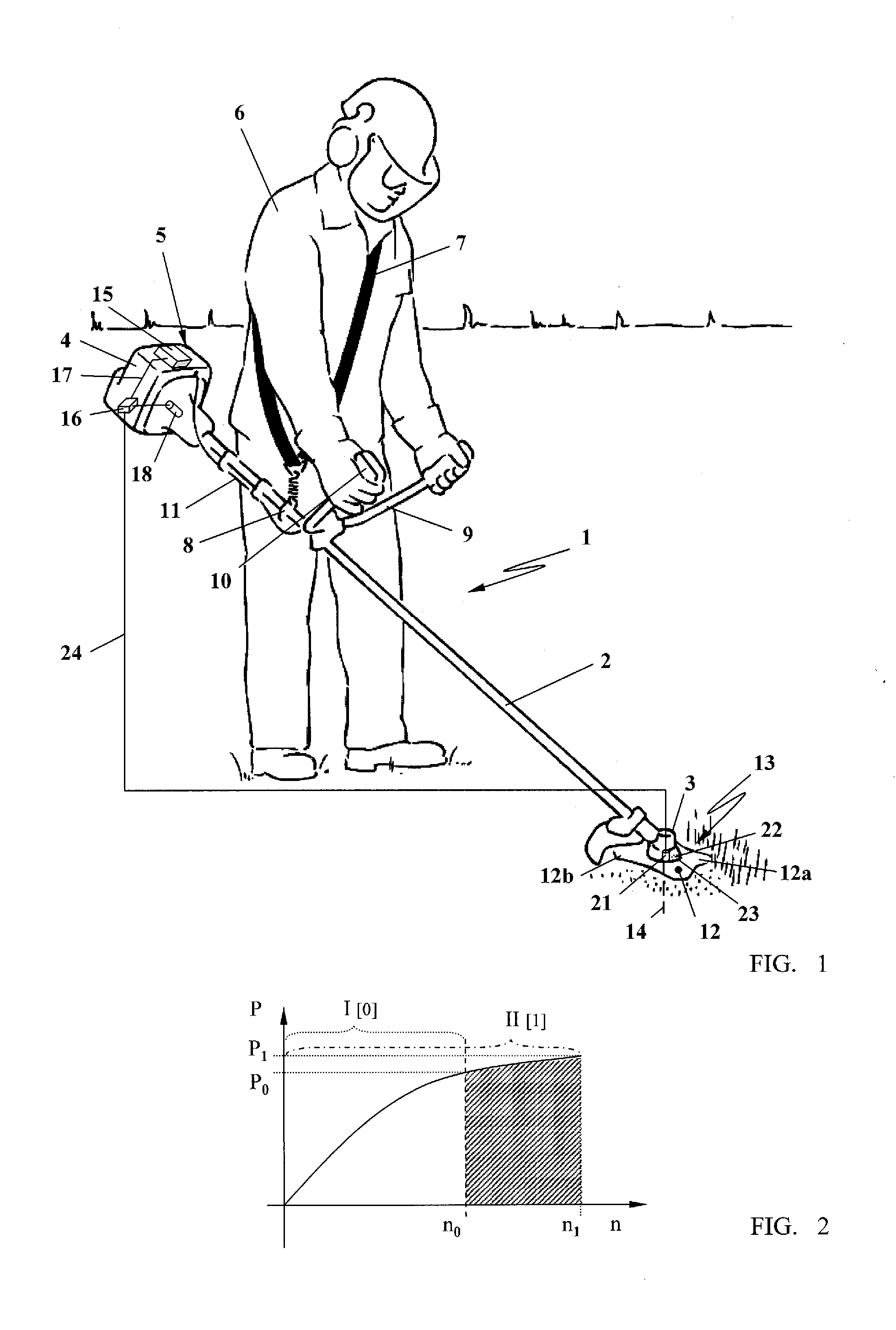

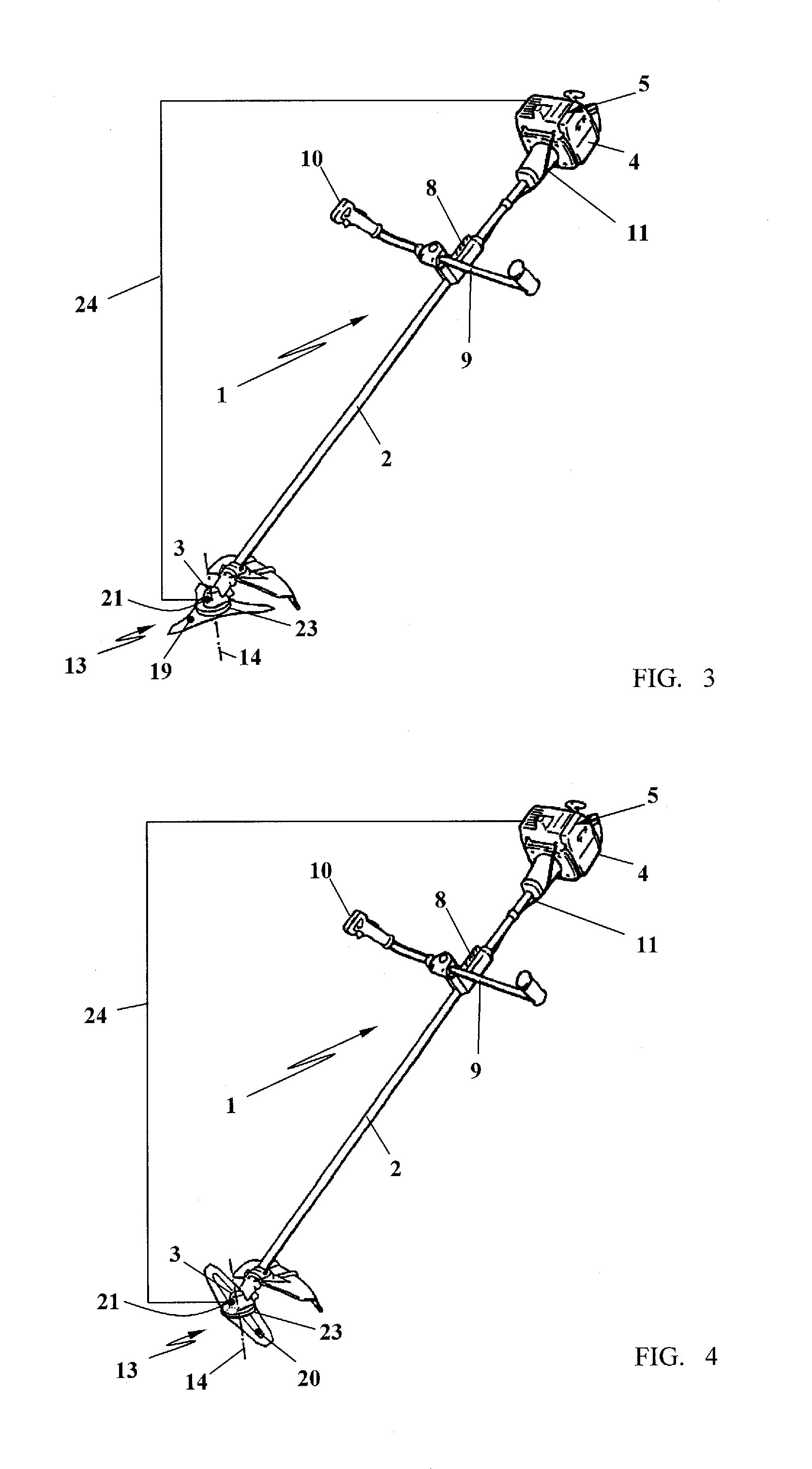

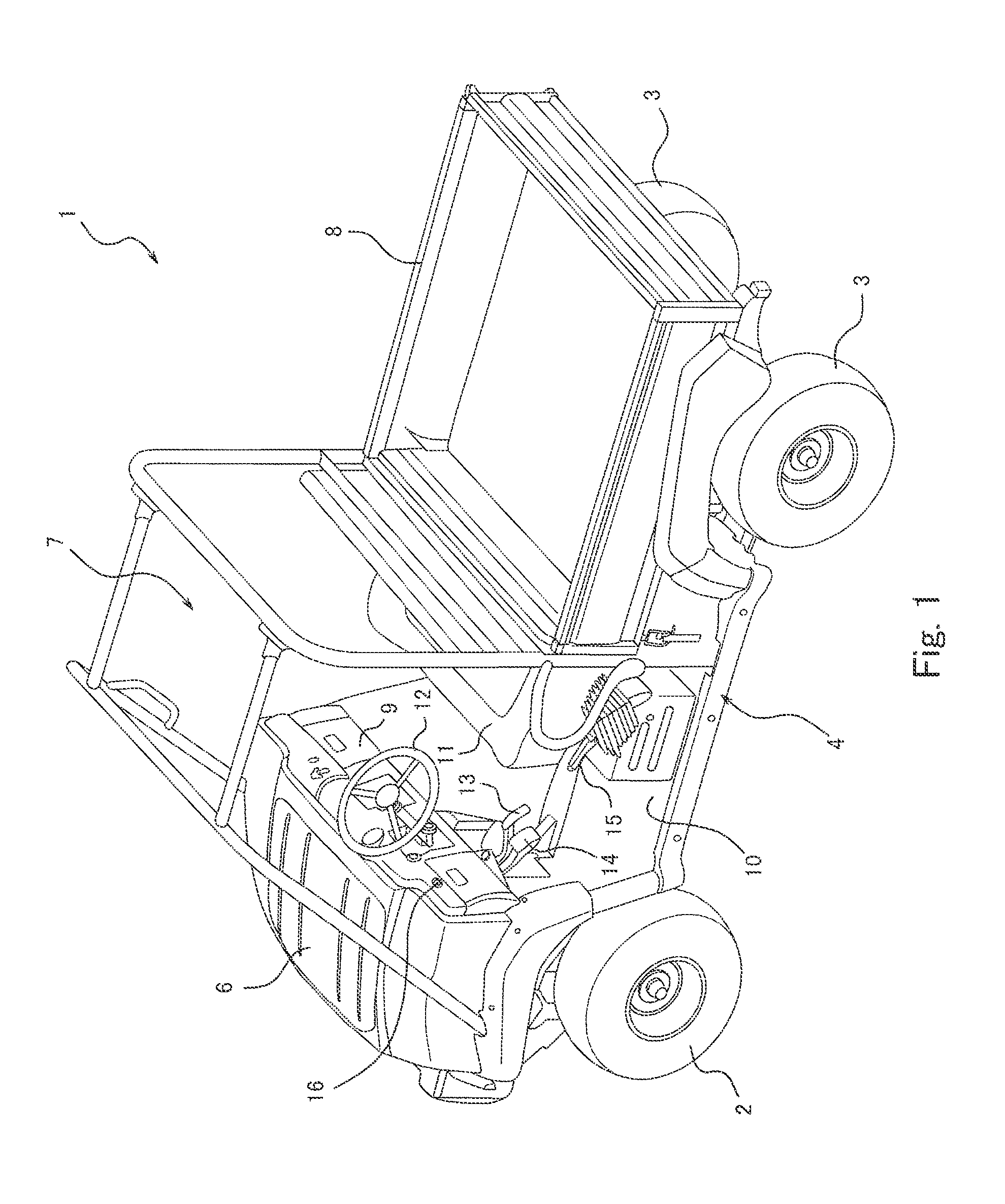

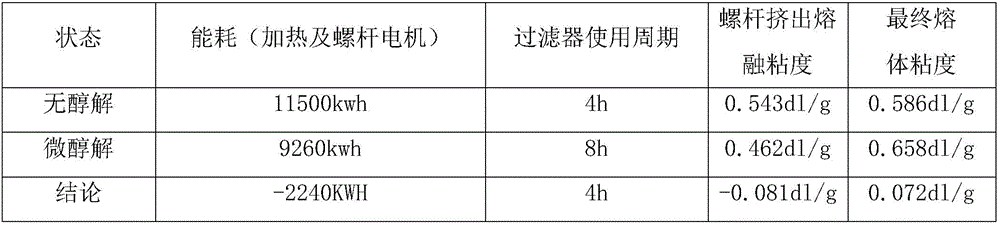

Handheld Work Apparatus with Switchable Power

ActiveUS20120138322A1Operational safety is enhancedReduce speedMetal sawing accessoriesDerricks/mastsHand heldOperation mode

The invention relates to a portable, handheld work apparatus such as a trimmer, a cut-off machine, a chain saw or the like, having a motor (5, 33) to drive a rotating, exchangeable work tool (13). A control unit (15) serves to control the operation of the motor (5, 33). The control unit (15) determines the rotational speed (n) and / or the power (P) of the motor (5, 33). According to the invention, the motor (5, 33) can be operated in a first operating mode (I) with reduced rotational speed (n0) and / or power (P0) and in at least a second operating mode (II) with an increased rotational speed (n1) and / or power (P1). In dependence on a release signal, the control uses exclusively the first operating mode (I) for a limited operation and the second operating mode (II) for an expanded operation.

Owner:ANDREAS STIHL AG & CO KG

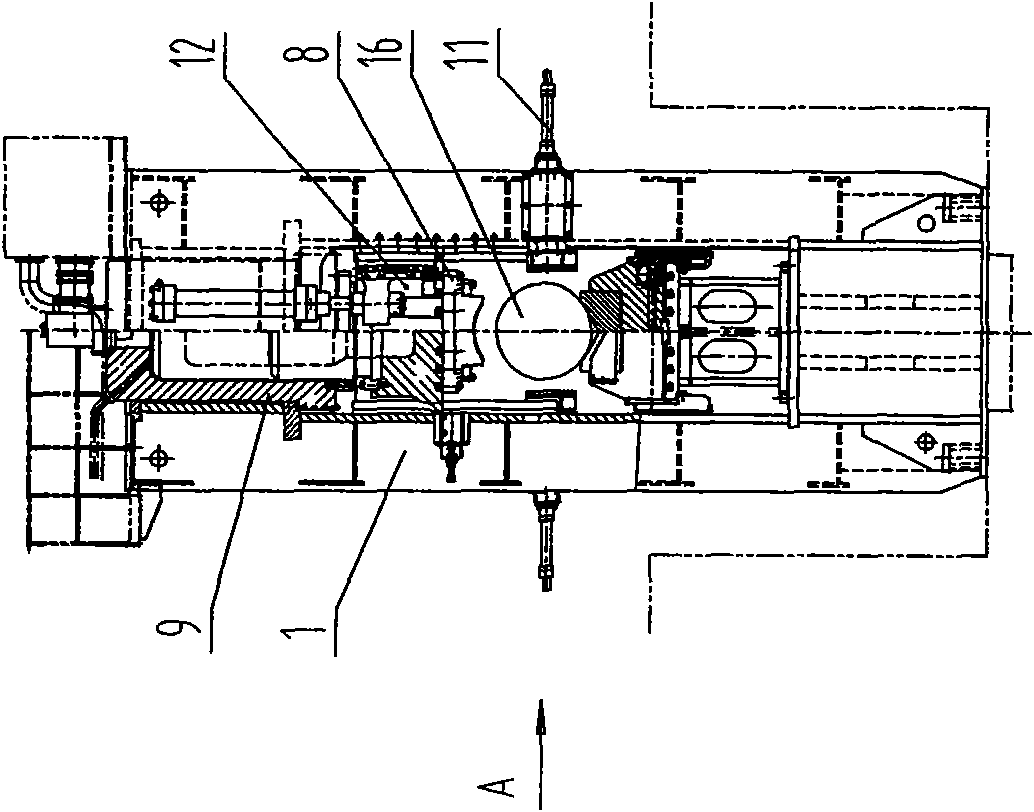

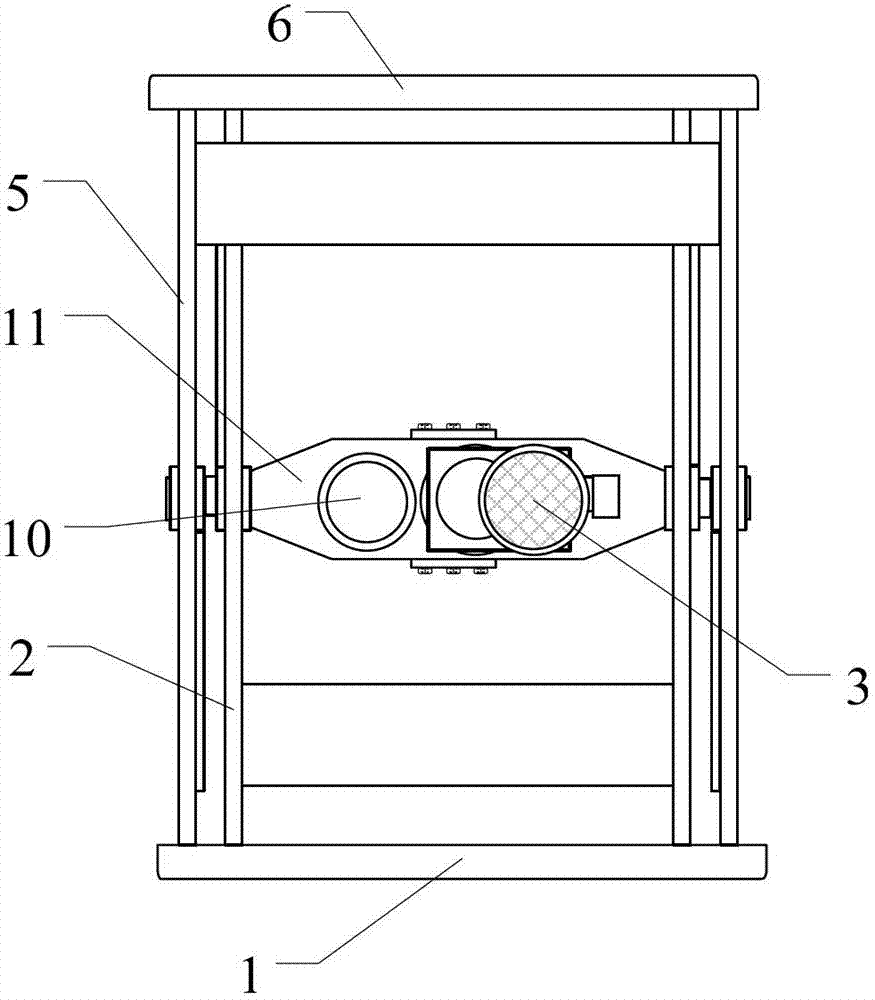

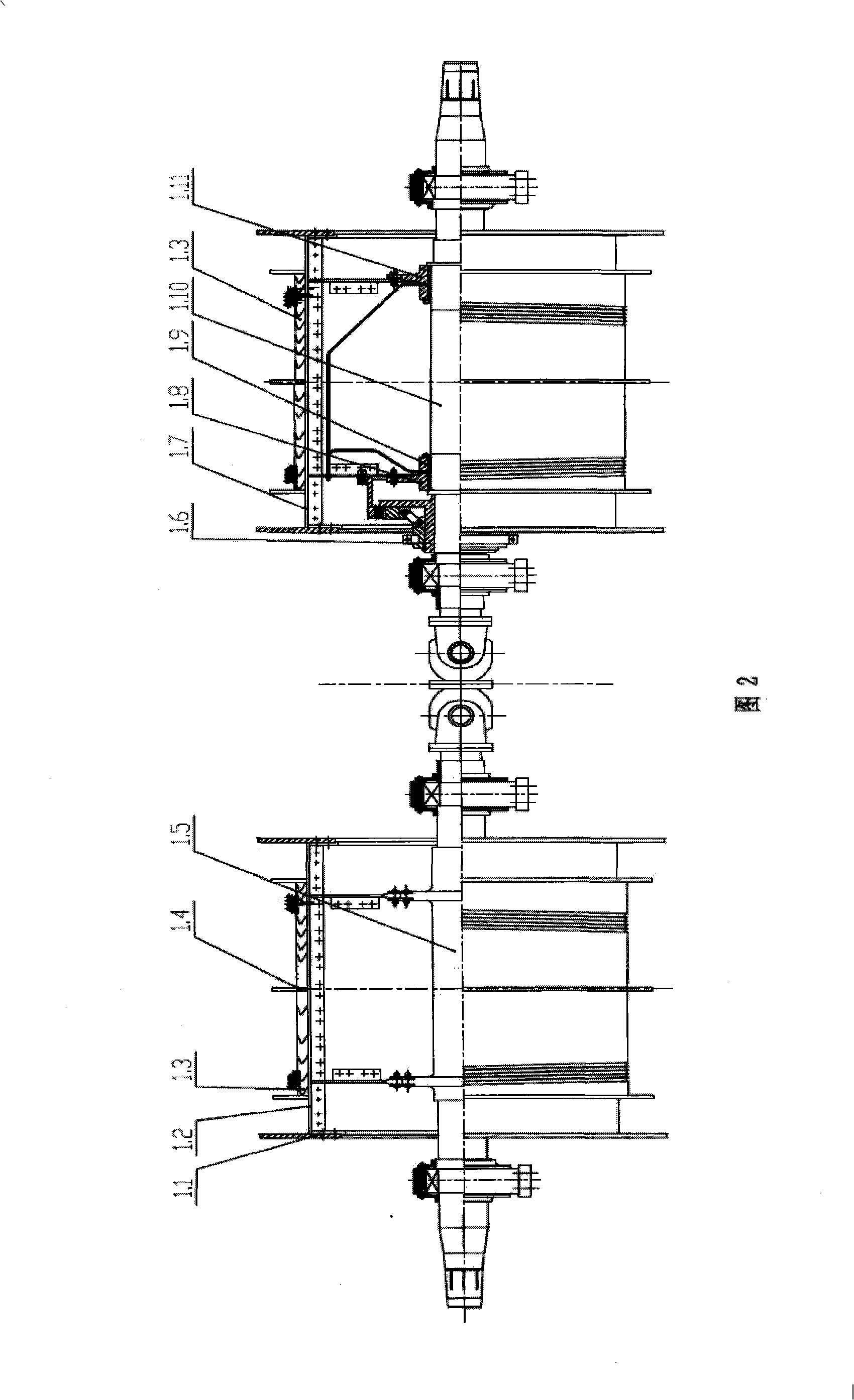

Vertical hydraulic straightening machine

The invention discloses a vertical hydraulic straightening machine and relates to the vertical hydraulic straightening machine with a fixed pressing machine and a movable workbench. The vertical hydraulic straightening machine comprises a rack, the workbench which is mounted at the lower part of the rack and can move on a base, a left slewing mechanism and a right slewing mechanism which are arranged on the upper surface of the workbench, a main cylinder, a pullback cylinder and a portable beam which are mounted on the rack, a press head fixed on the portable beam and two V-shaped supports which are arranged on the upper surface of the workbench. The vertical hydraulic straightening machine is characterized in that four plunger cylinders and four wheels are respectively arranged on the lower surface of the workbench which is positioned at two ends of the workbench, a driving transmission mechanism and a driven transmission mechanism are respectively mounted at two ends of the workbench, and material supporting devices are symmetrically arranged on two sides of the rack and in the positions which are vertical to the length direction of a work piece. The vertical hydraulic straightening machine can solve the problems that the friction resistance between a plate of the workbench and the base is large, the deformation of the work piece is irregular, the center of gravity is unstable, and a steel pipe can lodge during straightening.

Owner:TAIYUAN HEAVY IND

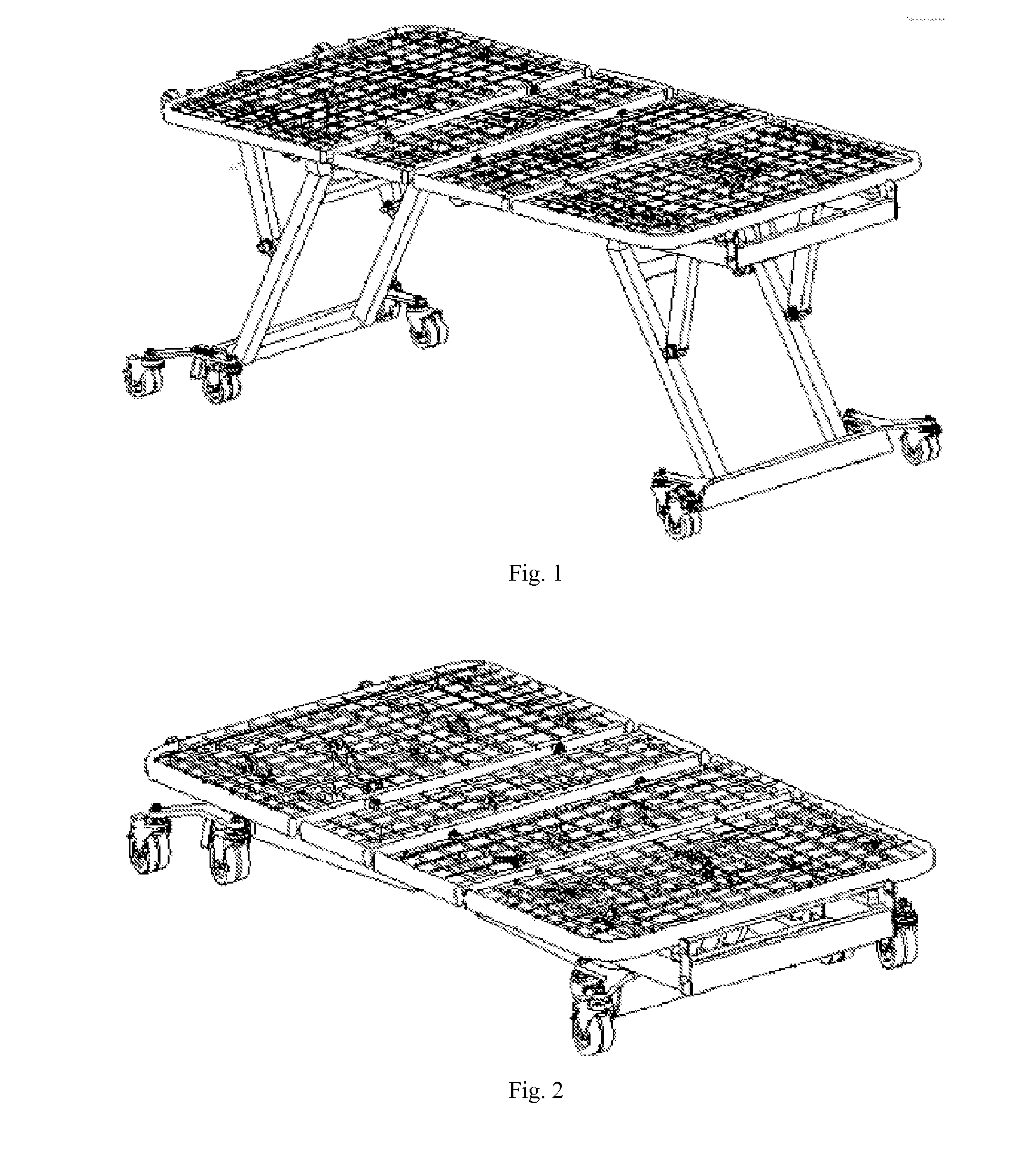

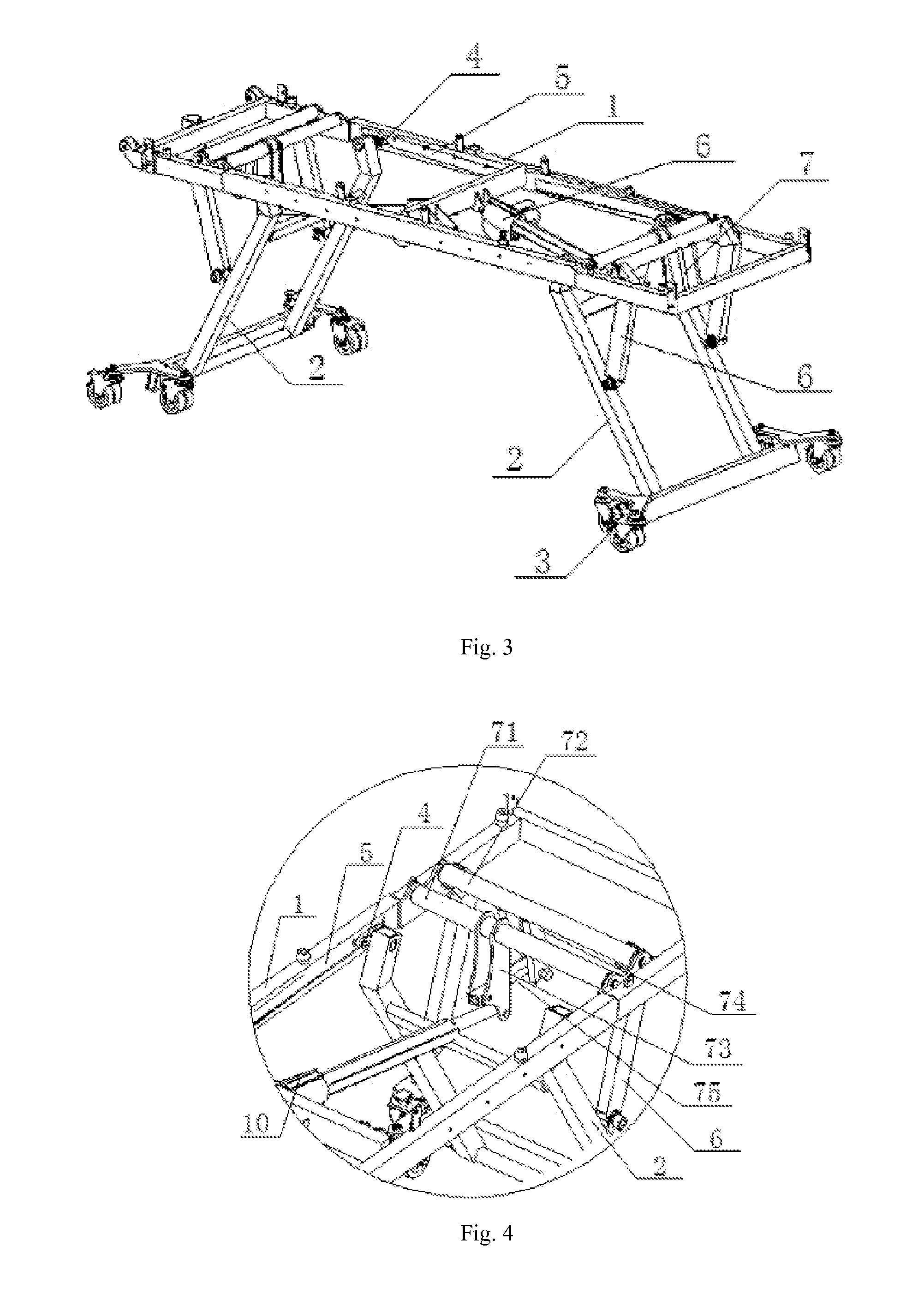

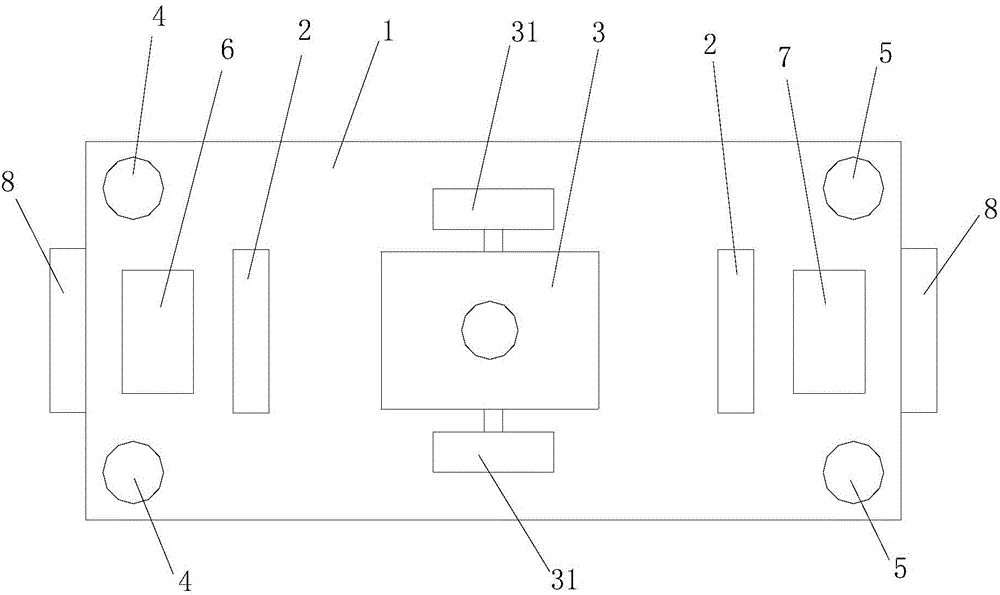

Liftable Hospital Bed

ActiveUS20150033472A1Little powerLow production costOperating tablesStretcherEngineeringHospital bed

Disclosed is a liftable hospital bed, comprising a bedplate base frame (1) symmetrical about a transverse central plane and a longitudinal central plane, wherein two ends of the bedplate base frame (1) are provided with bed leg rods (2), the lower end of the bed leg rods (2) being hinged to a first roller device (3) in contact with the ground and the upper end of the bed leg rods (2) being connected to a second roller device (4), the second roller device (4) being slidable in tracks (5) on the bedplate base frame (1) and the tracks (5) being parallel to a longitudinal axis of the bedplate base frame (1); connecting rods (6) are hinged to the bed leg rods (2); and a turnover mechanism is further provided for changing included angles between the bed leg rods (2) and the bedplate base frame (1) to lift the bedplate base frame (1), the turnover mechanism comprises the connecting rods (6) and a thrust mechanism, end portions of the thrust mechanism drive the connecting rods (6) to rotate via a hinged four-rod mechanism (7), and the connecting rods (6) drive the bed leg rods (2) to turn over relative to the bedplate base frame (1), so that the lifting of the hospital bed is realized.

Owner:NINGBO KANGMAILONG MEDICAL APP

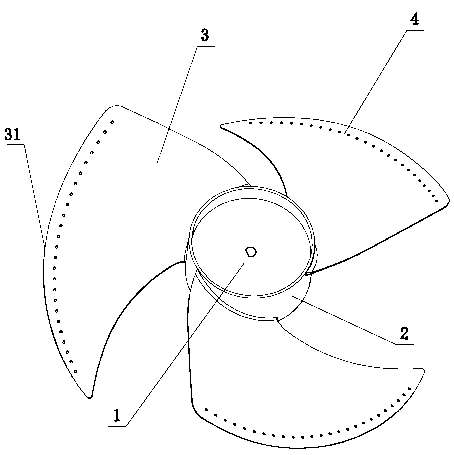

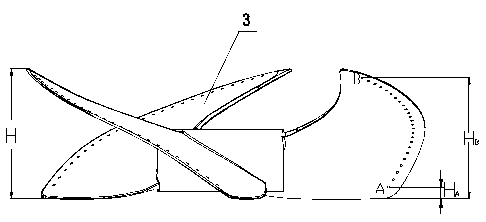

Axial flow rotor blade

The invention discloses an axial flow rotor blade. The axial flow rotor blade comprises at least two vanes (3) arranged on a hub (2), wherein each vane (3) is provided with a hole area with a plurality of through holes (4). The vanes (3) are distributed on the hub (2) by taking a rotation central axis as a center at equal or unequal intervals; and the area of a vane outer edge (31) of each vane (3) is the hole area. When the axial flow rotor blade rotates, the hole structure of the adjacent area of each vane outer edge ensures that air on the pressure surface of each vane flows into a suction surface through the through holes, so that kinetic energy of air on the suction surface of each vane is increased, and the growth of a boundary layer is inhibited; eddy noise is effectively reduced, and the voice is more soft and comfortable; and meanwhile, by the hole structure of the adjacent area of each vane outer edge, the weight of the rotor blade and the load of a motor are reduced, and the cost of the rotor blade and the powder of the motor are reduced. The axial flow rotor blade is particularly suitable for an air conditioner outdoor unit.

Owner:MIDEA GRP CO LTD

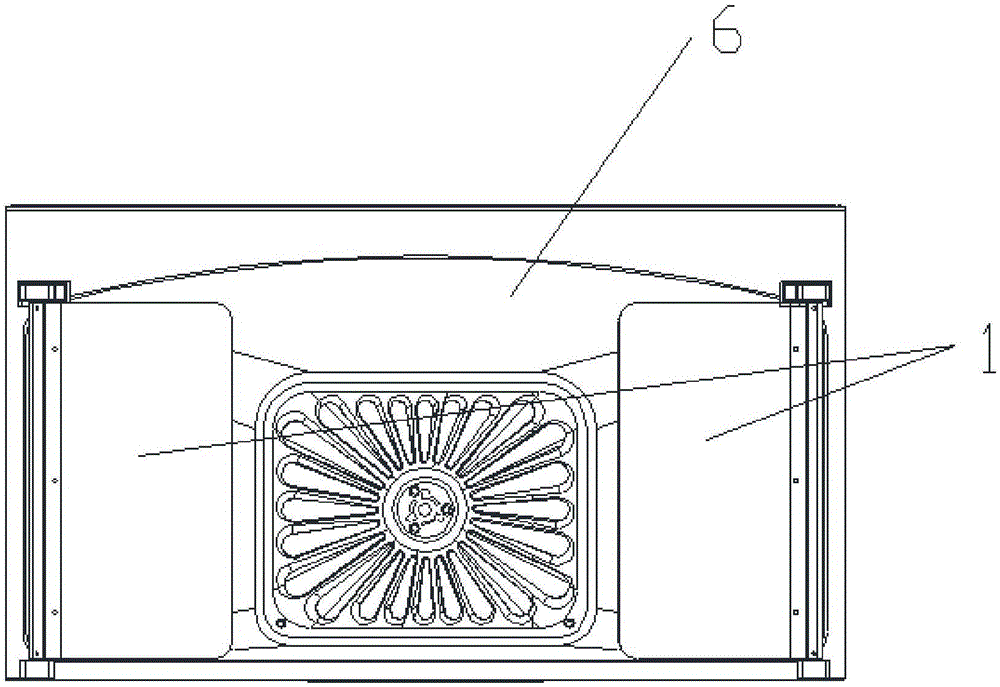

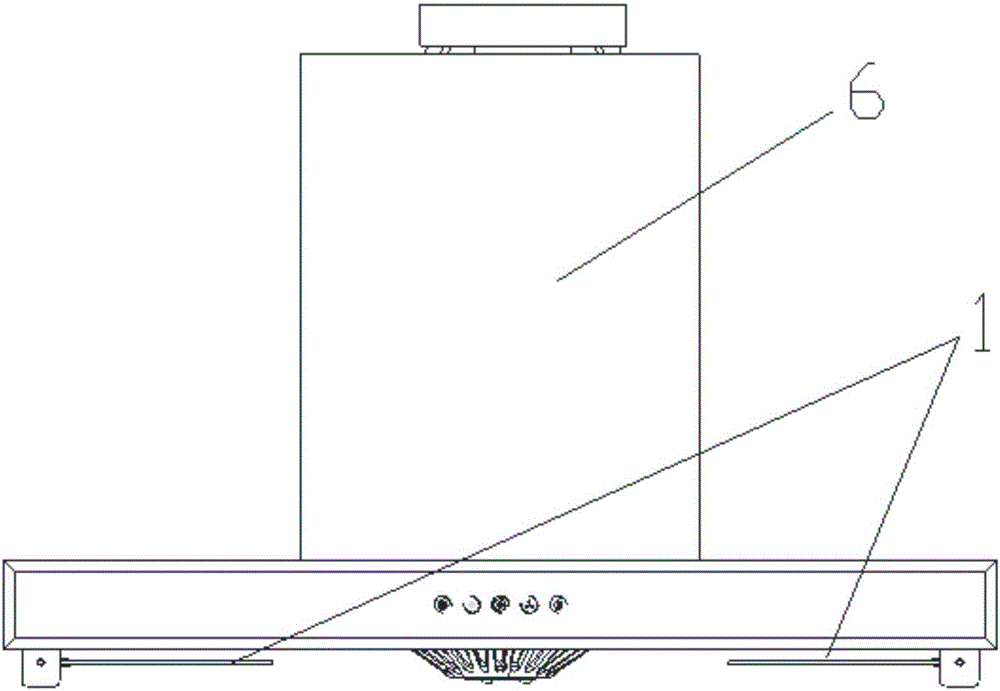

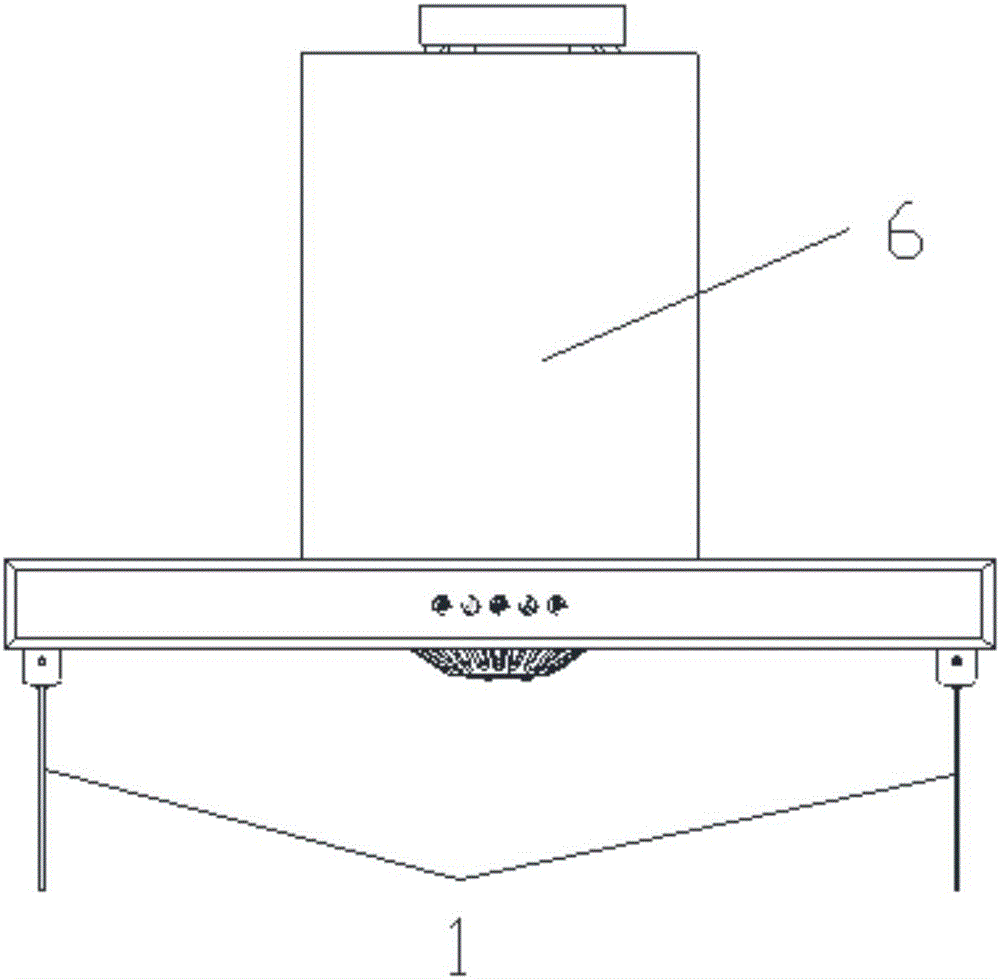

Novel extractor hood with intelligent overturning smoke barriers

PendingCN106765398AExpand the smoke collection areaImprove smoke exhaust effectDomestic stoves or rangesLighting and heating apparatusSynchronous motorDrive shaft

The invention relates to a novel extractor hood with intelligent overturning smoke barriers. The novel extractor hood comprises an extractor hood main body and reversible smoke barrier assemblies. The reversible smoke barrier assemblies are located at the two sides below the extractor hood main body. Each reversible smoke barrier assembly is composed of one smoke barrier, a rotating shaft, a motor fixing rack, a synchronous motor, a drive gear assembly, rotating shaft mounting bases and a motor control system. Each smoke barrier is fixedly connected with the corresponding rotating shaft. The two ends of each rotating shaft are connected to the corresponding rotating shaft mounting bases. The rotating shaft mounting bases are fixed below the extractor hood main body. One end of each rotating shaft is engaged with the corresponding drive gear assembly, and each drive gear assembly is fixedly connected with a drive shaft of the corresponding synchronous motor. Each synchronous motor is fixed to the corresponding motor fixing rack. The motor fixing racks are fixed to the extractor hood main body. By means of the novel extractor hood with the intelligent overturning smoke barriers, the smoke gathering region of the extractor hood is effectively widened, smoke exhaust capacity of the extractor hood is improved, motor power of the extractor hood can be lowered, and energy consumption is reduced.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

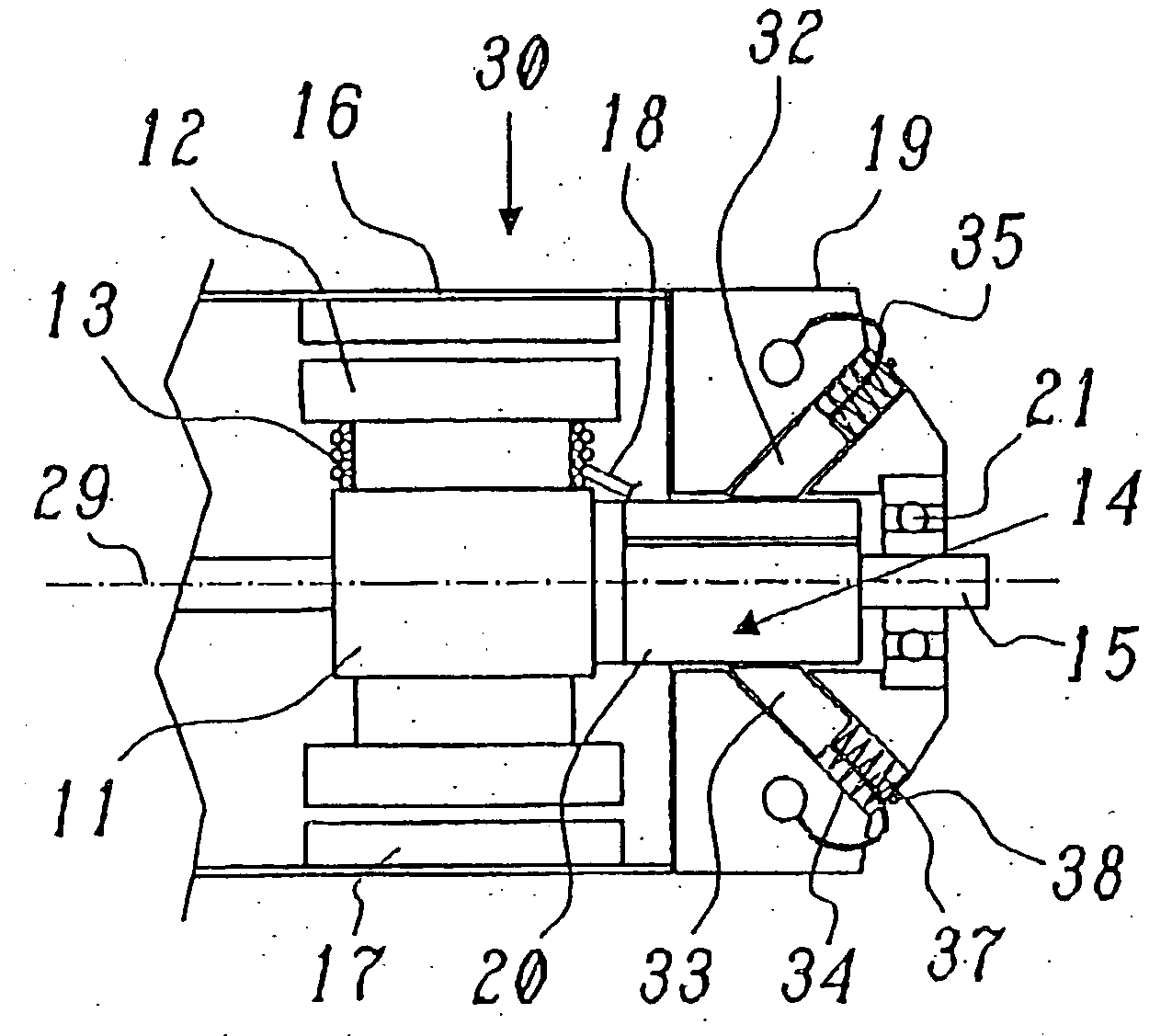

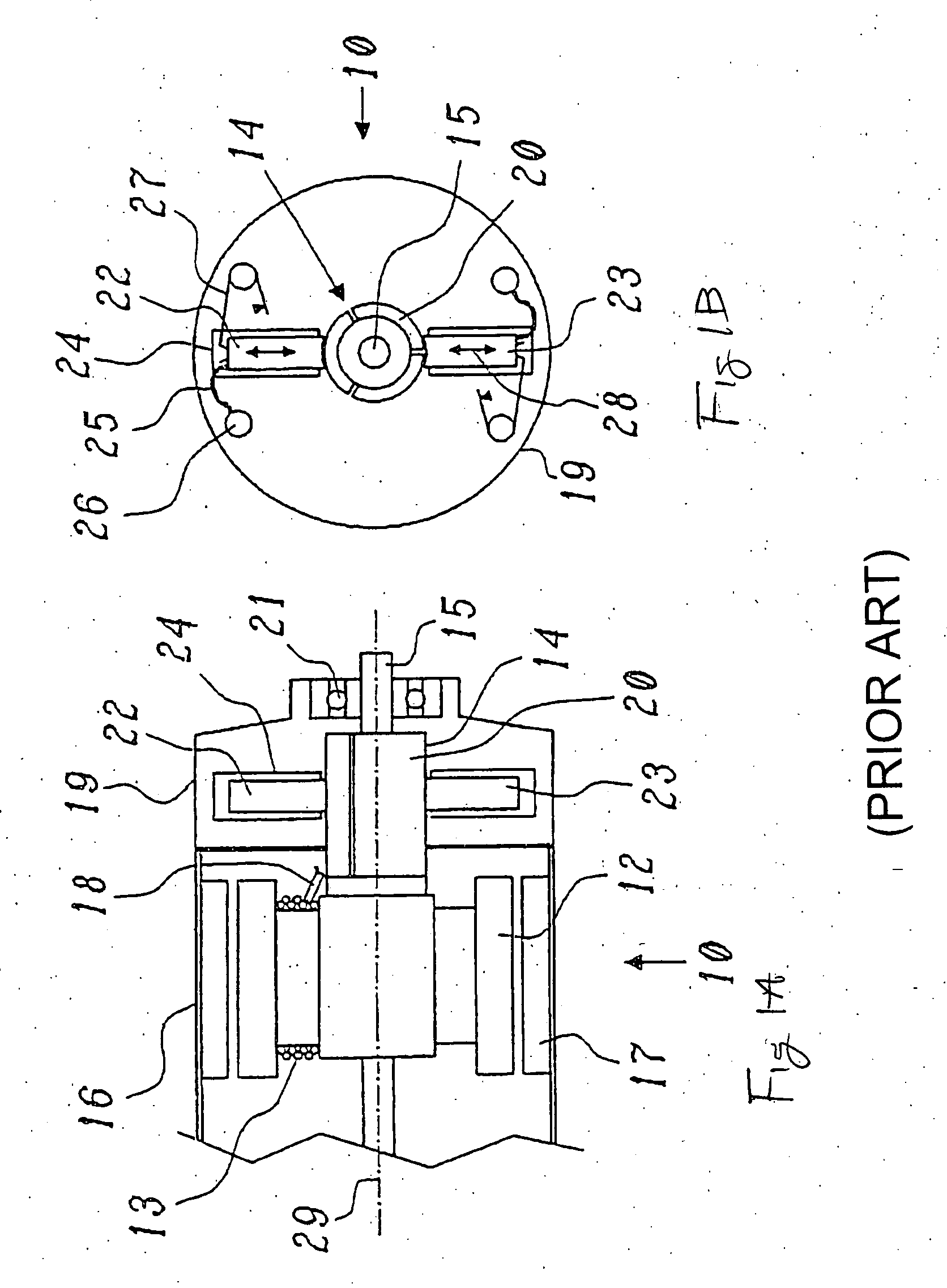

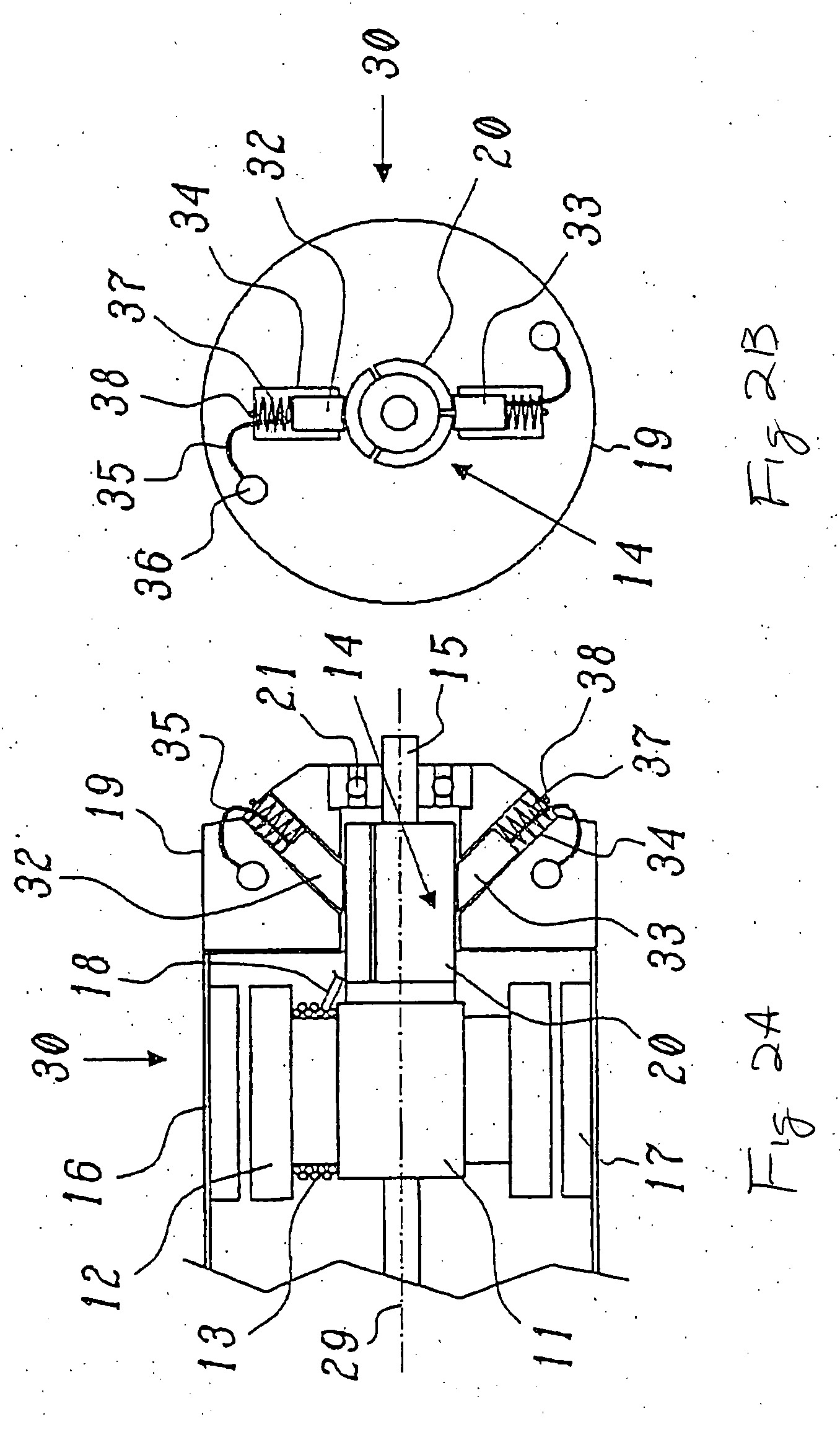

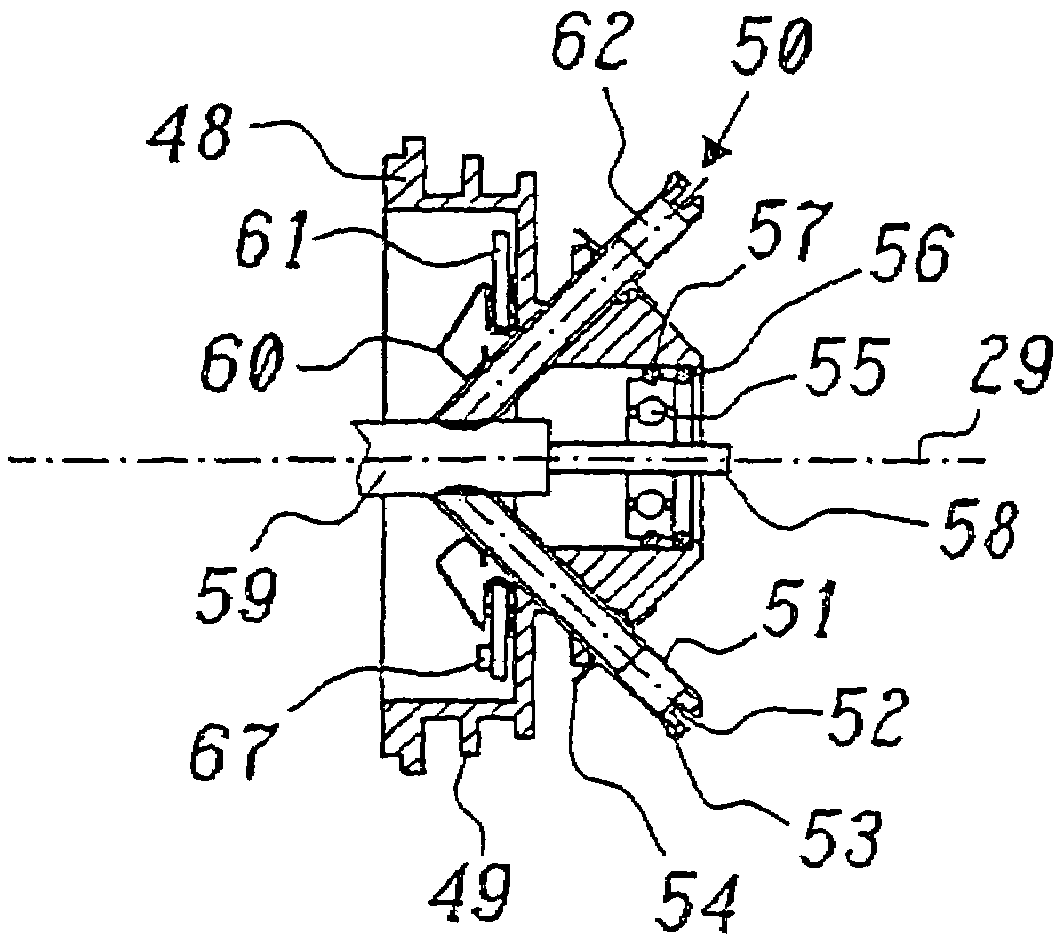

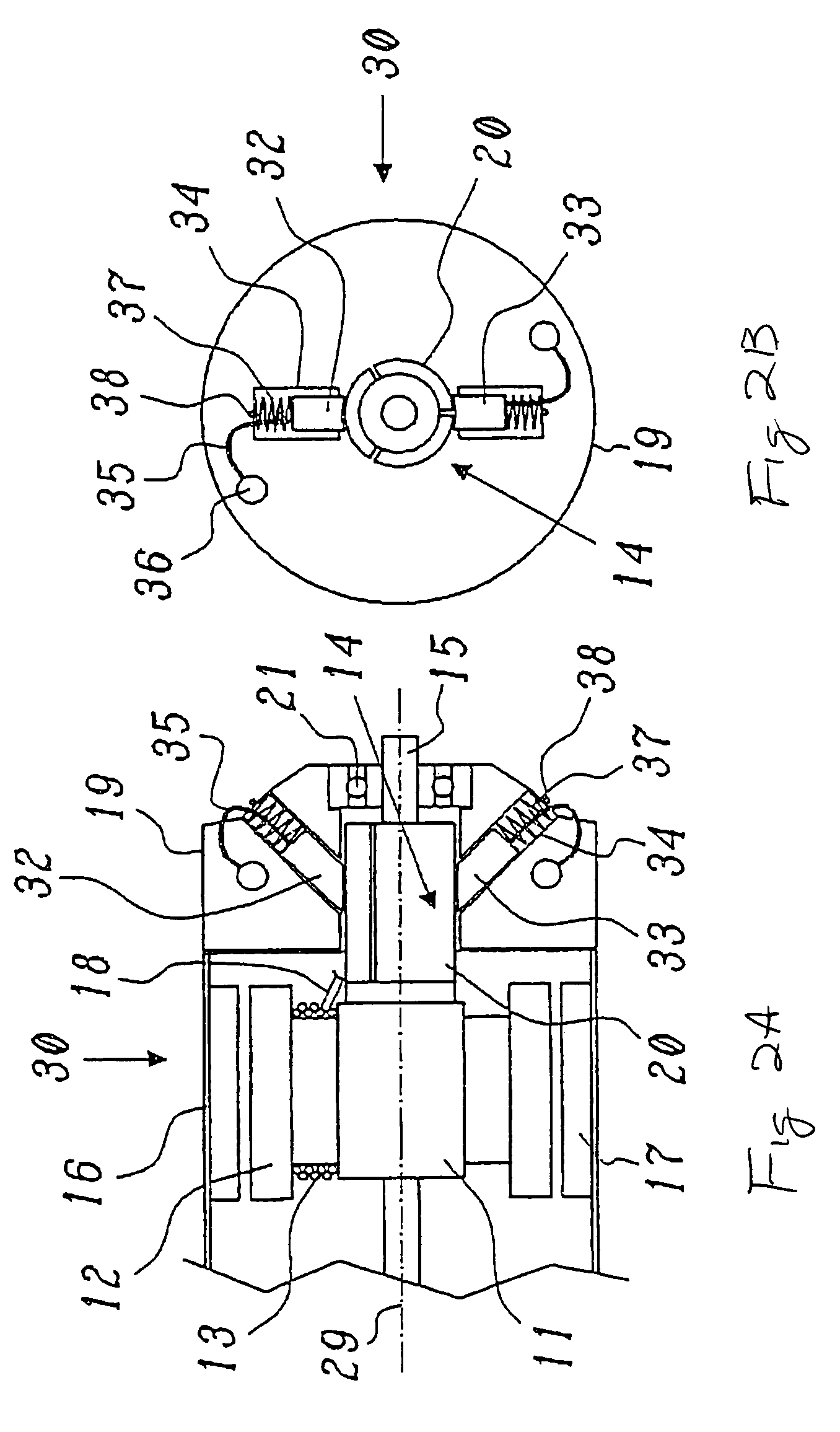

High-power direct current engine comprising a collector and carbon brushes for a racing car serving as prototype

InactiveUS20050029895A1Reduce electric resistanceReduce total motor powerRotary current collectorToysMechanical engineeringDirect current

A DC motor includes a rotor which is mounted in a housing so that it can rotate about an axis. The rotor includes at least one winding to which direct current is applied from the outside in alternating directions via a commutator, which is arranged on the rotor. Brushes are seated on the commutator and are mounted whereupon they can move relative to the commutator while being pushed by spring pressure onto the commutator.

Owner:TEAM ORION EURO

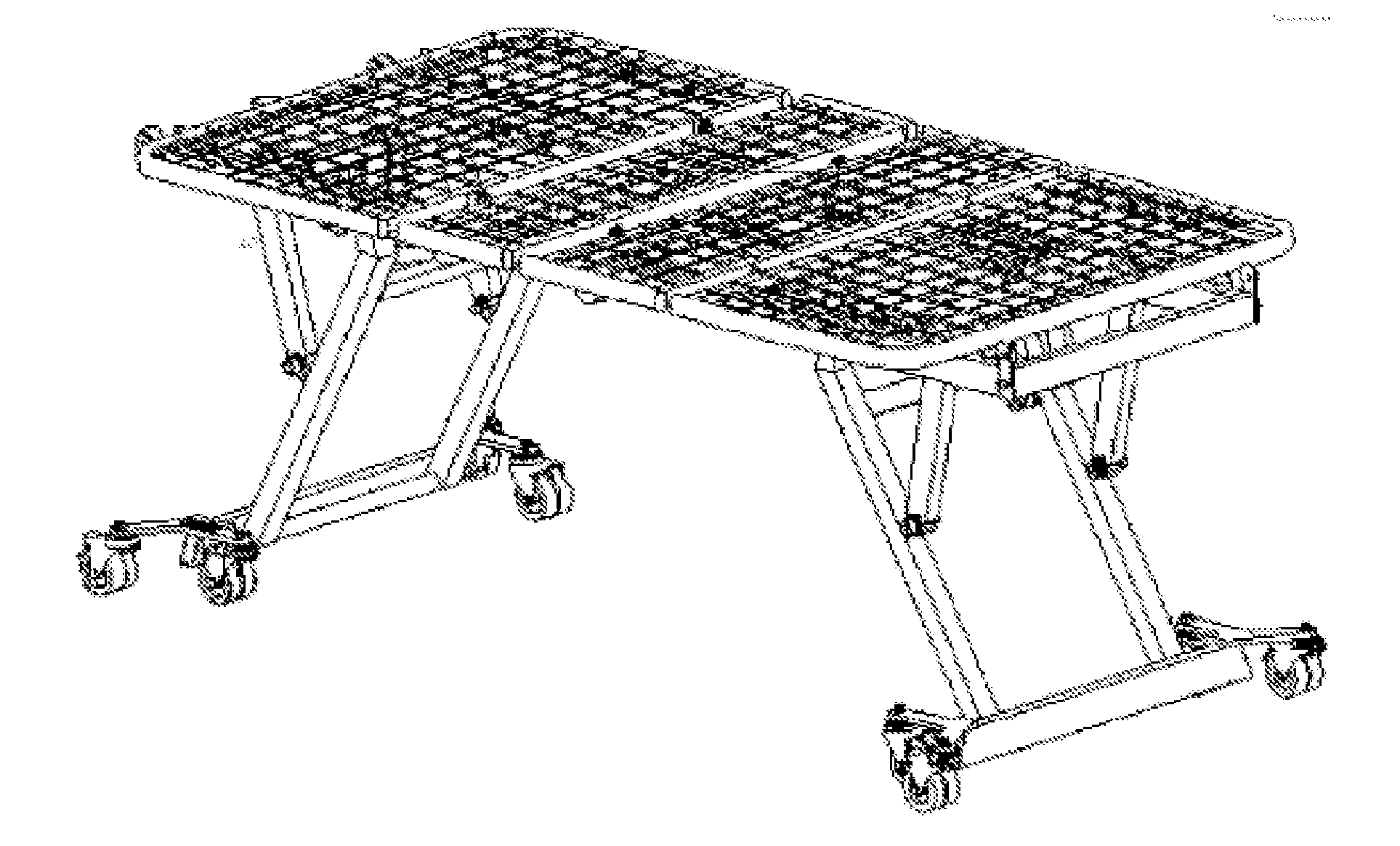

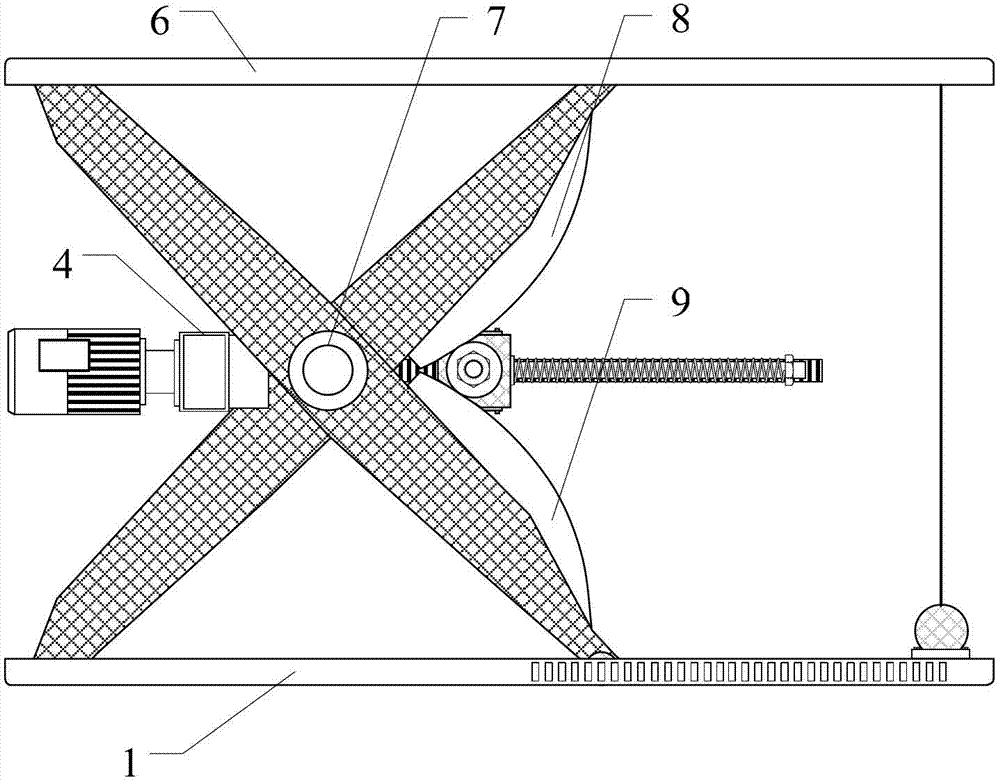

Electric lifting table with spring balanced design

ActiveCN102765677AReduce motor powerImprove overall efficiencyLifting framesElectric machineryEngineering

The invention relates to an electric lifting table with a spring balanced design. The electric lifting table comprises a base, an upper tabletop, scissor mechanisms, a lead screw transmission mechanism and an assorted electronic control system, and the lead screw transmission mechanism is arranged between the two scissor mechanisms and comprises a motor, a gearbox, a middle box, a push box, a lead screw, a stroke guide rod and a brake hydraulic cylinder. The electric lifting table is characterized in that a compressed balance spring is arranged on the stroke guide rod. A lead screw transmission mechanism of an existing electric lifting table is reasonably modified, counterweight balance is realized by the compressed balance spring arranged on the stroke guide rod, the balance spring assists the motor to lift up a heavy object when the lifting table ascends, and gravitational potential energy is converted into elastic potential energy to be stored by the balance spring when the lifting table descends, so that purposes of reducing power of the motor and improving integral efficiency are realized.

Owner:MIRACLE AUTOMATION ENG CO LTD

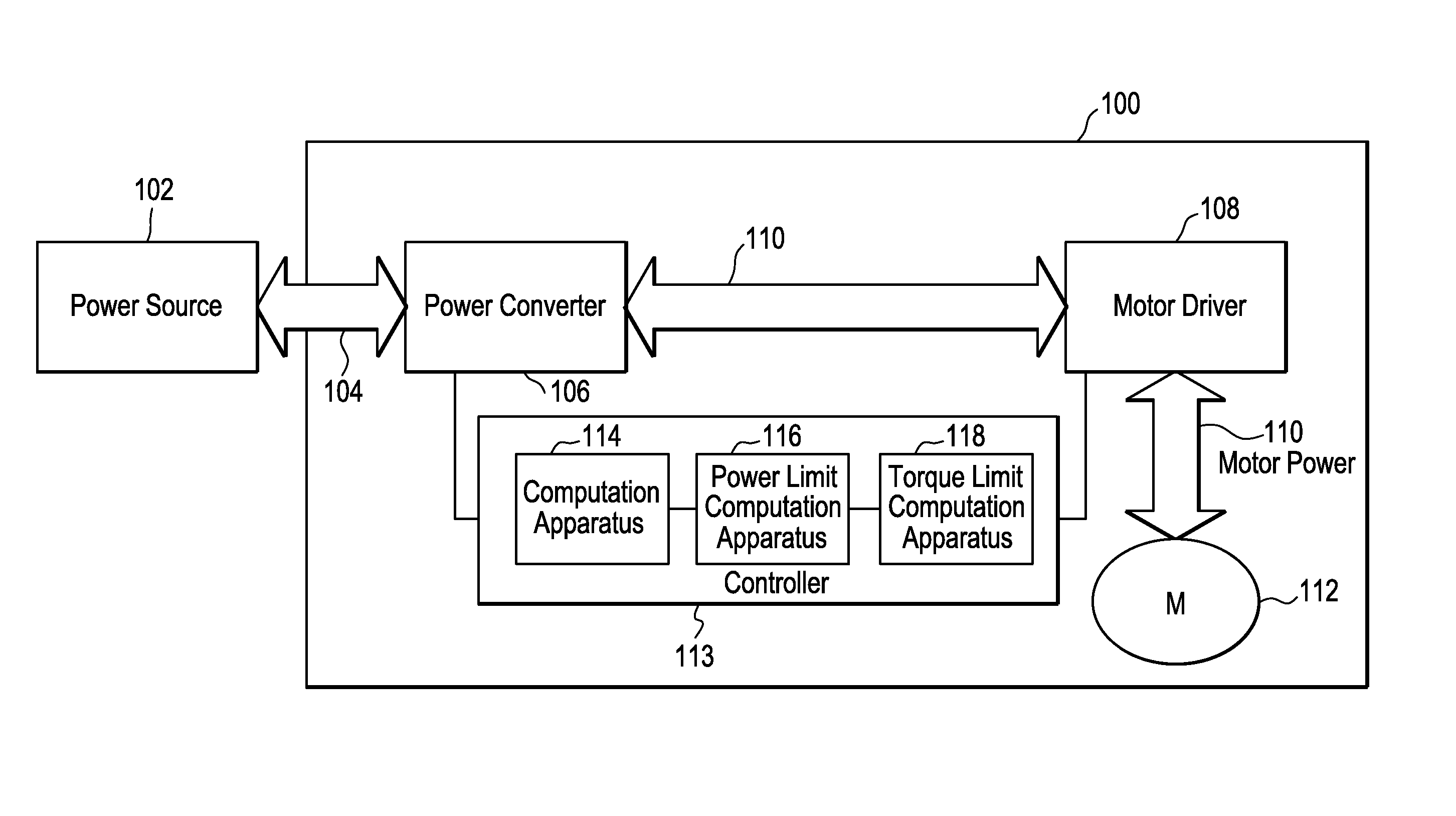

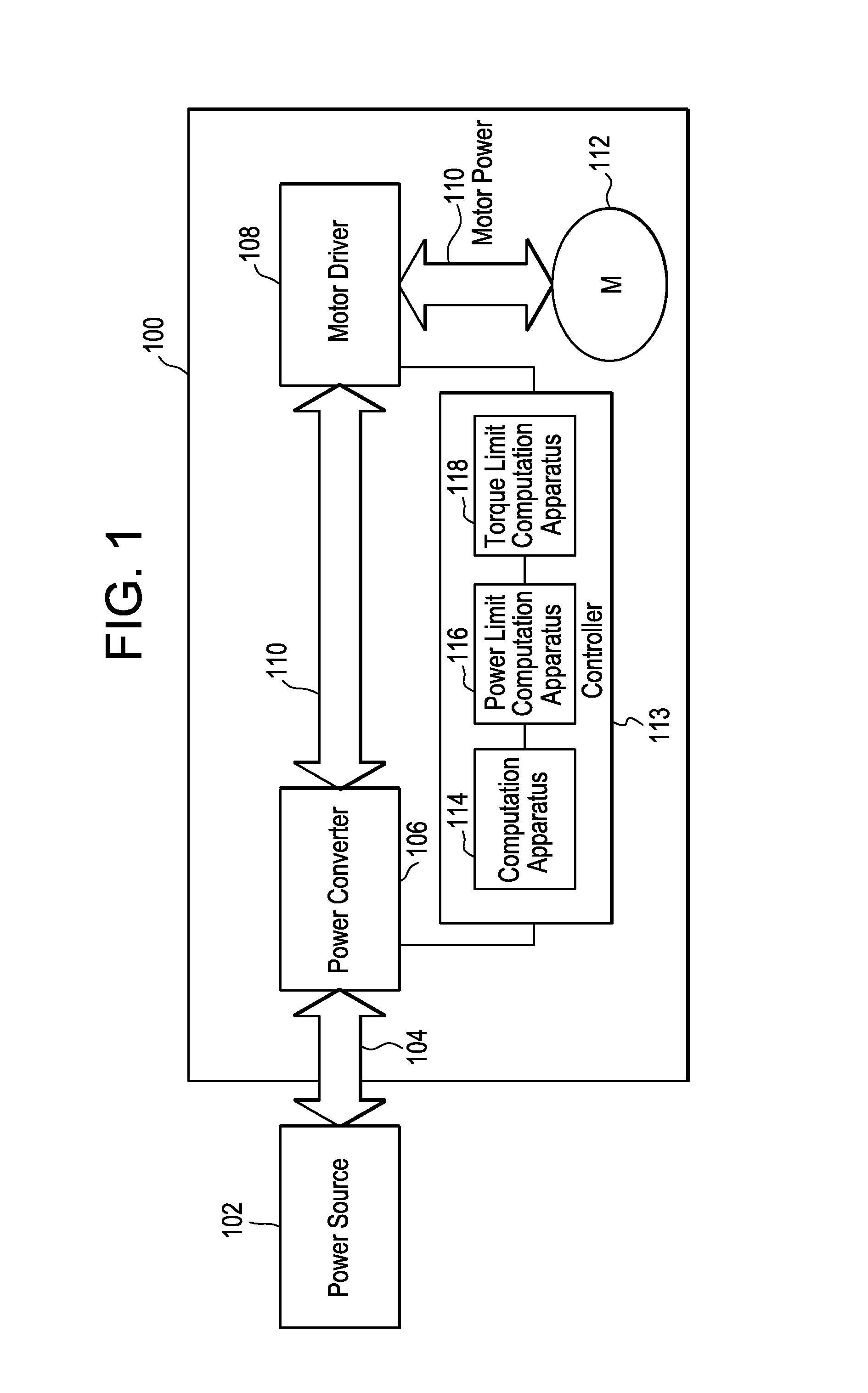

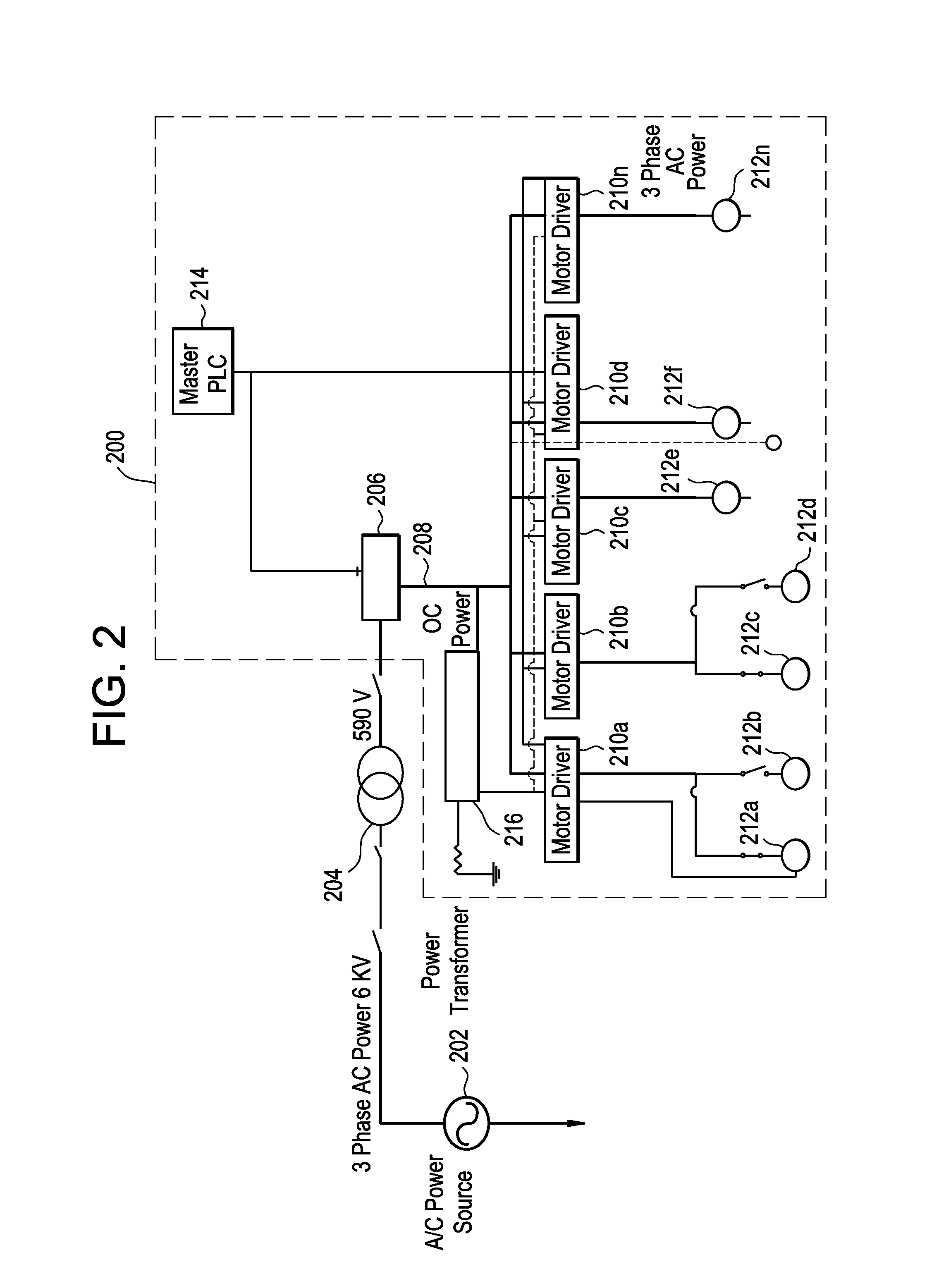

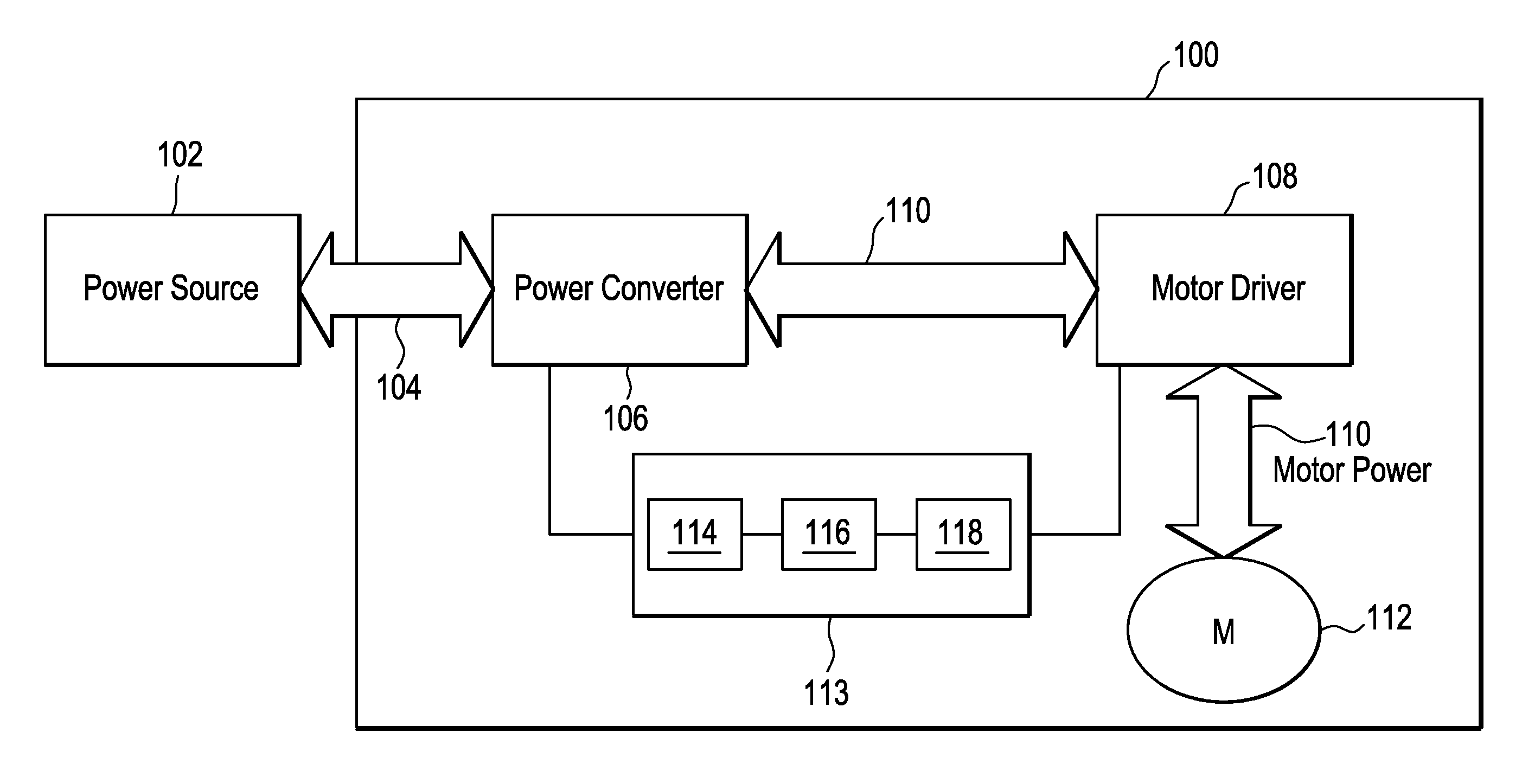

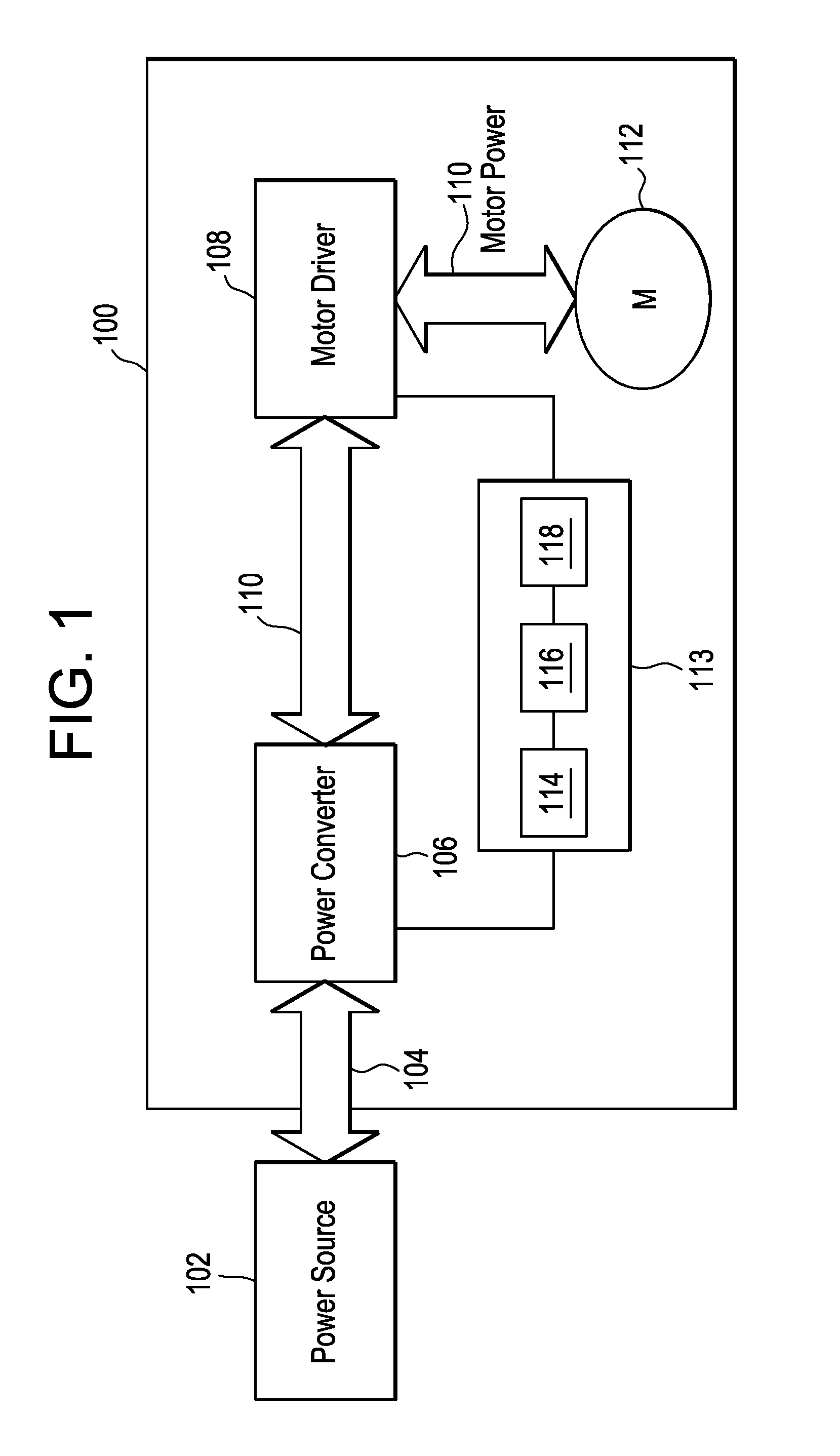

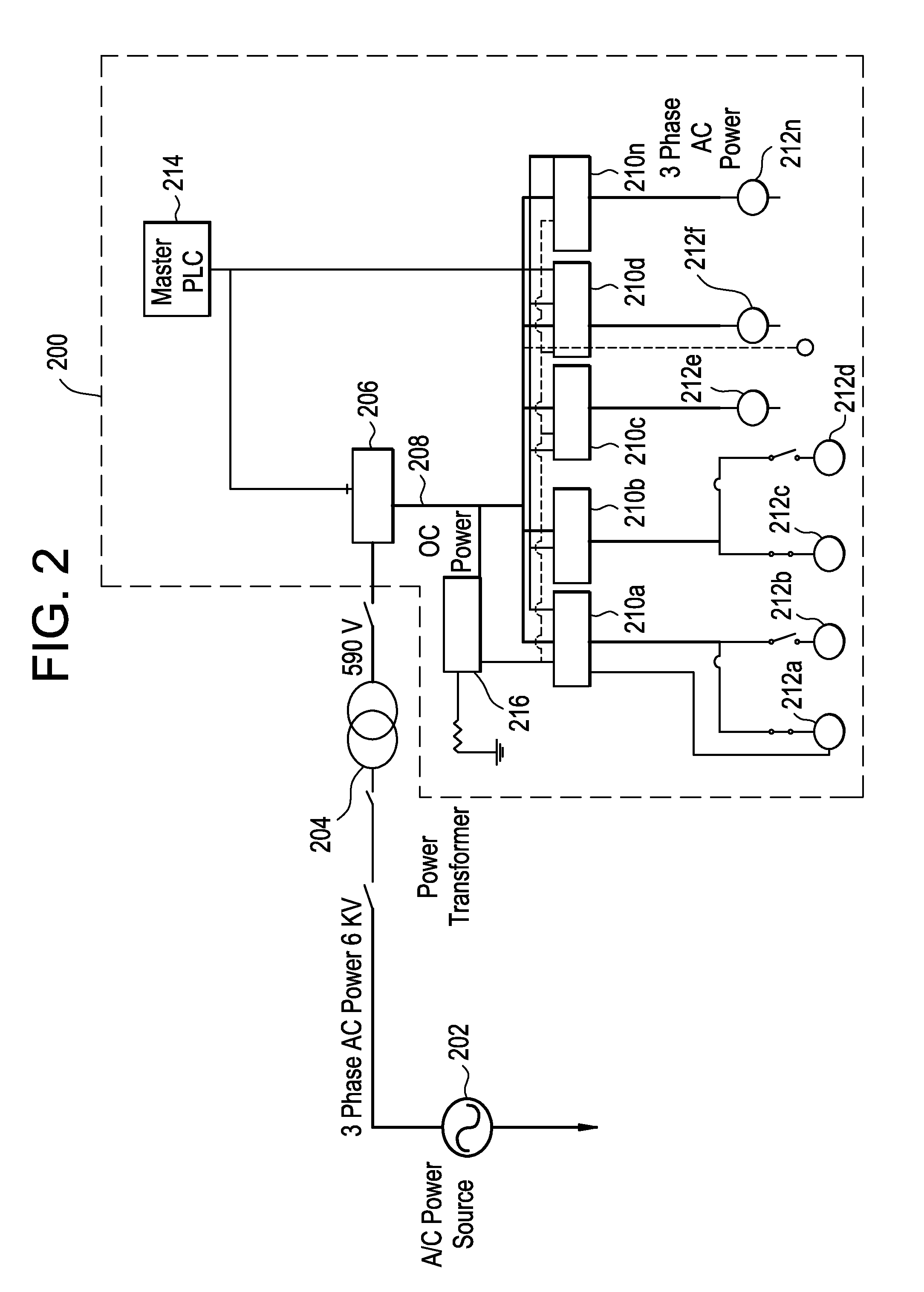

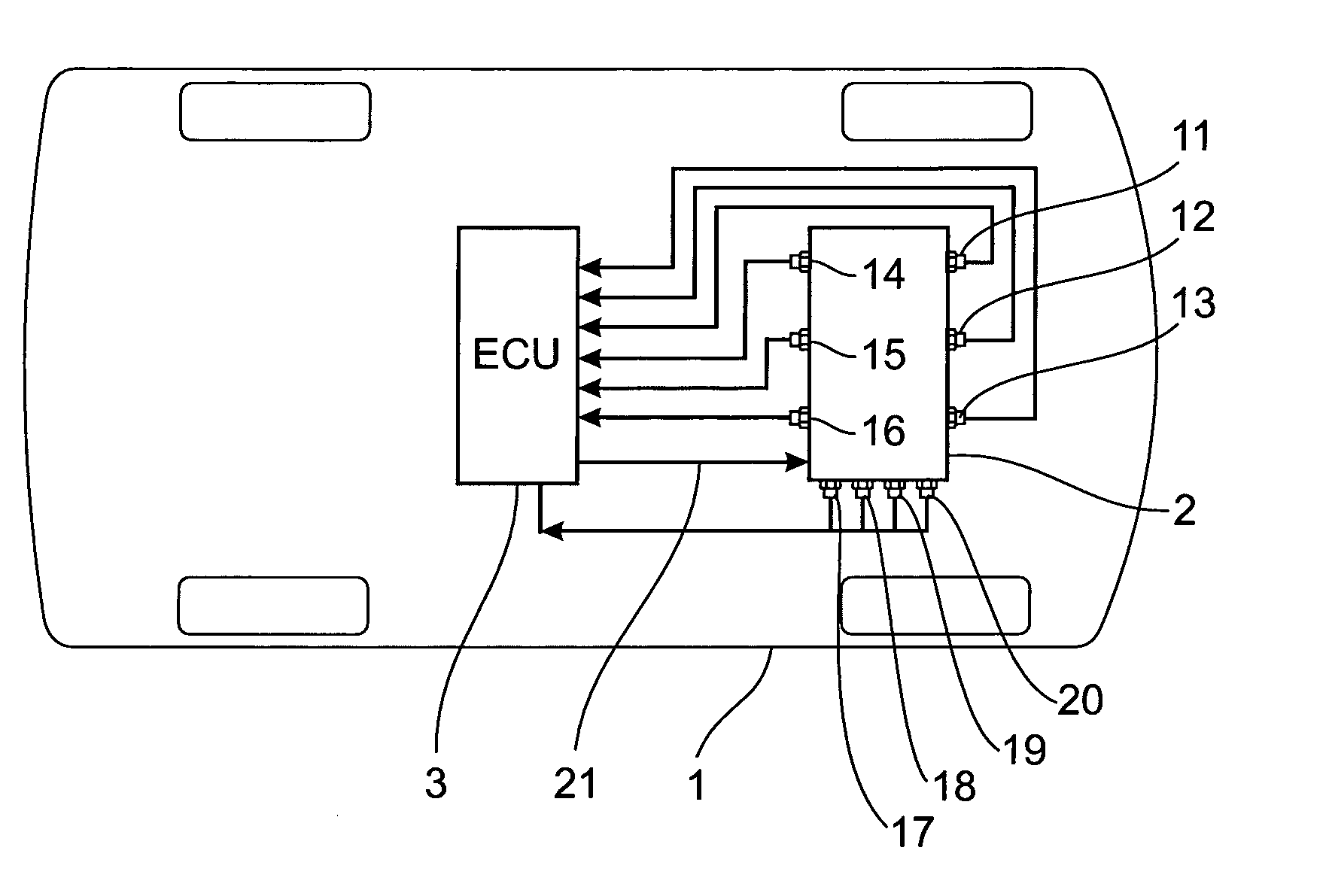

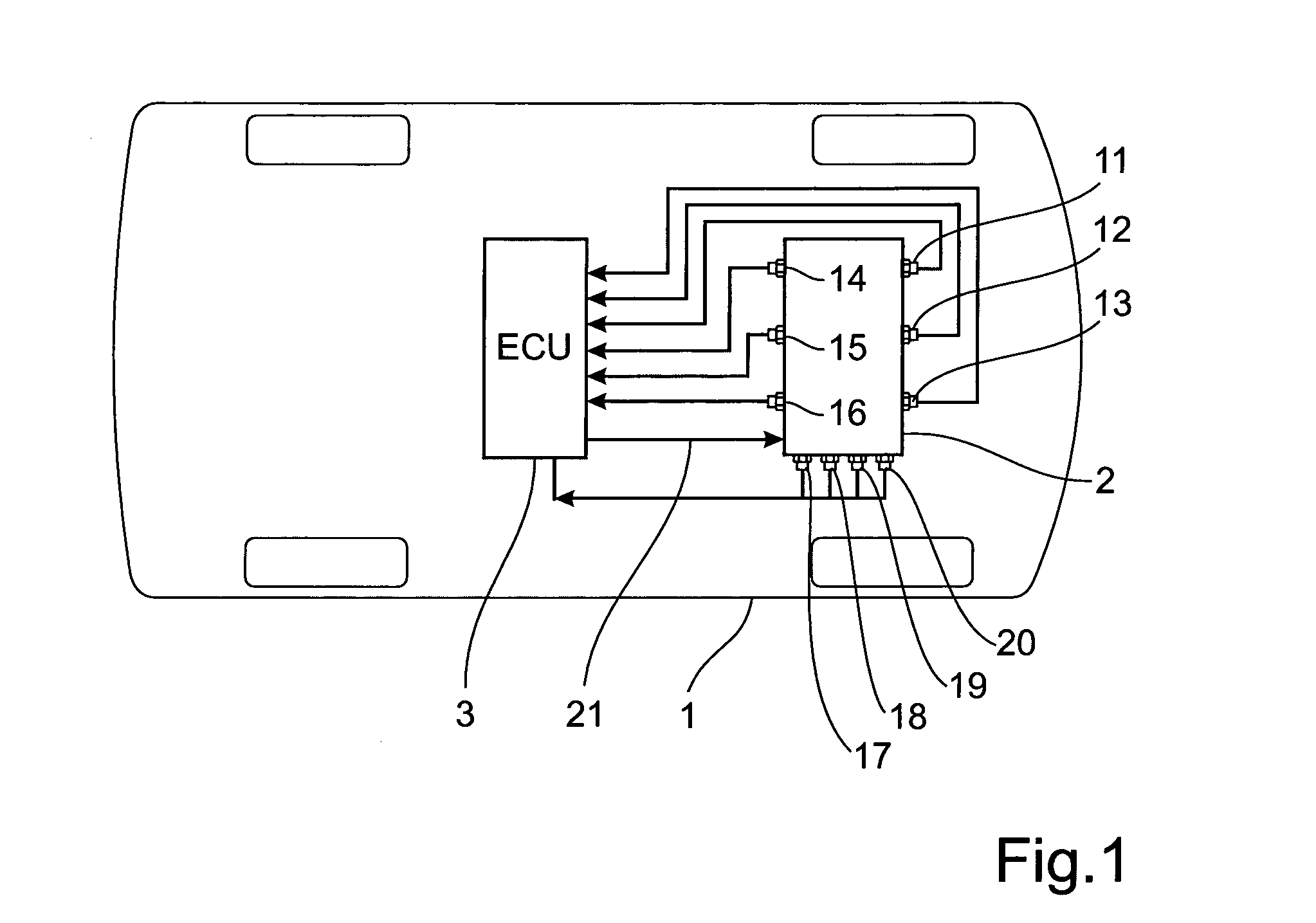

Power control on a multi-motion electric drive system

ActiveUS8415909B2Reduce motor powerLimited motor powerDC motor speed/torque controlElectric motor controlMotor driveControl system

A motor control system for controlling two or more motor groups includes a power converter that receives power from a power source and converts the power to an intermediate power and an intermediate power link coupled to the power converter. The motor control system also includes at least one motor driver coupled to the intermediate power link configured to provide power to one or more motors and a controller coupled to the power converter and the at least one motor driver. The controller is configured to cause the at least one motor driver to limit the amount of power delivered to the one or more motors based on the amount of power that the power converter can produce.

Owner:GENERAL ELECTRIC CO

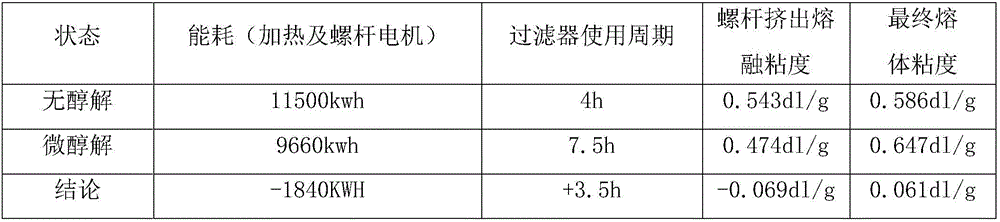

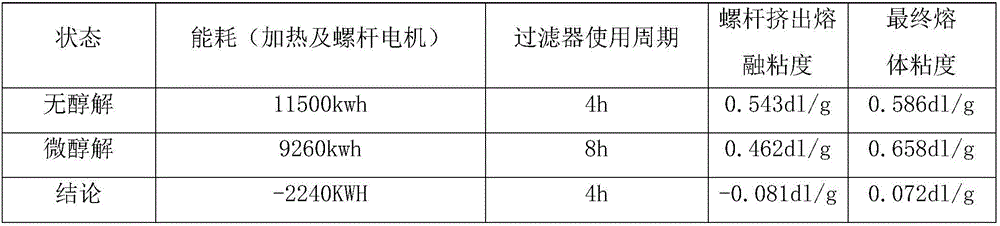

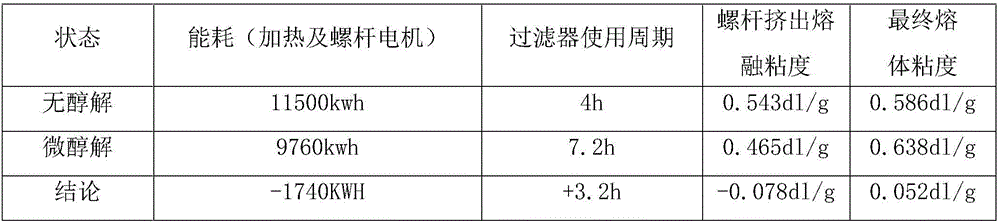

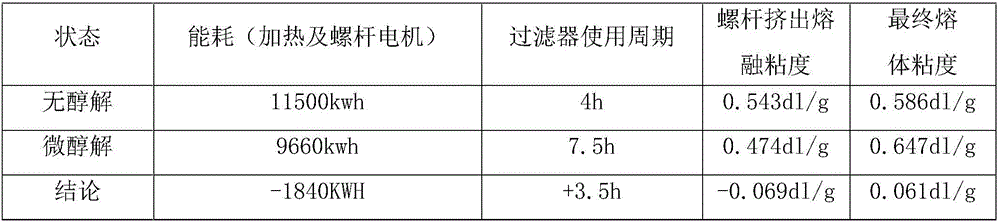

Method for preparing high-quality fusant from waste polyester textiles

InactiveCN106283226ARapid alcoholysisHigh intrinsic viscositySpinning solution de-aeratingFilament forming substance formingPolyesterPolymer science

The invention relates to high-value cycling and reusing techniques of waste polyester and particularly relates to a method for preparing a high-quality fusant from waste polyester textiles. The method comprises the following steps: adding 1-8% of alcohol into the raw material according to the mass of the raw material, and carrying out blending and melt extrusion by virtue of a screw extruder, wherein the melt viscosity of the fusant from the screw extruder is 0.40dl / g-0.50dl / g; and then adding the material into a tempering and viscosity-regulating device, wherein the melt viscosity of the fusant from the tempering and viscosity-regulating device is 0.620dl / g-0.685dl / g. According to the method, by adding a proper amount of glycol, the melt viscosity is increased, meanwhile, the problems that the cycle of a filter is short, and the maintenance quantity of a vacuum system is great are further effectively solved, the production cost is lowered, and the additional value of products is further increased.

Owner:NINGBO DAFA CHEM FIBER

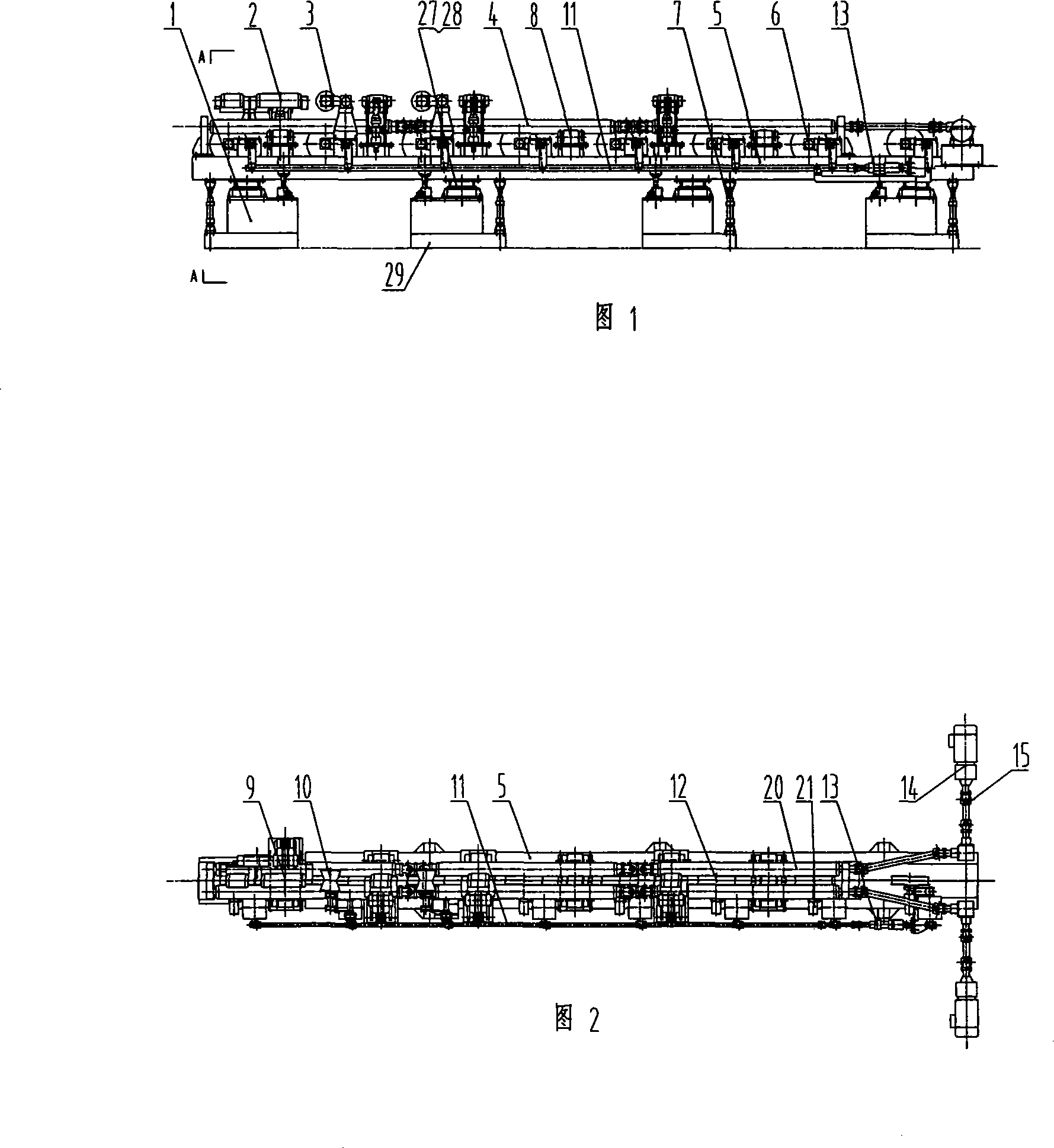

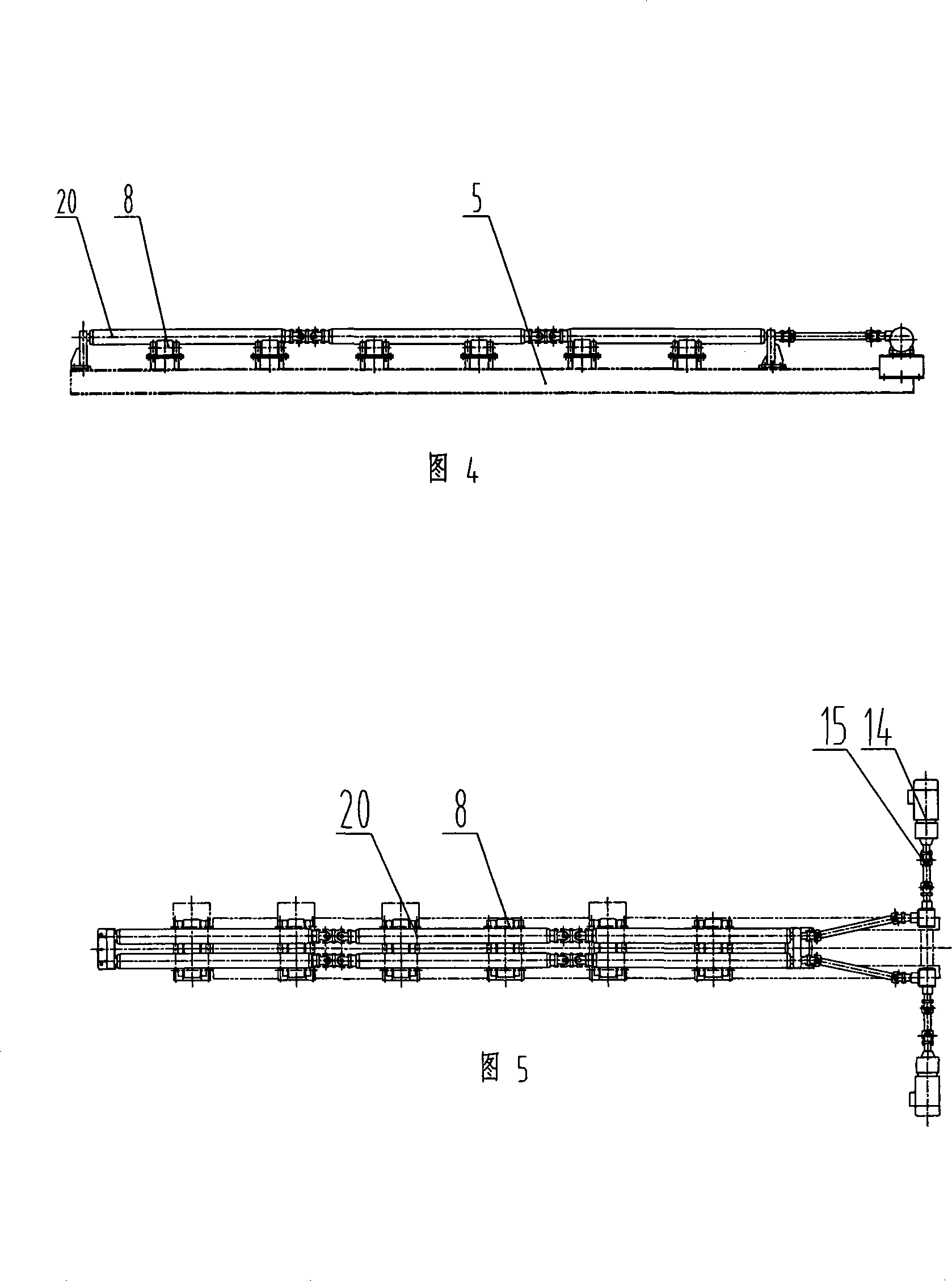

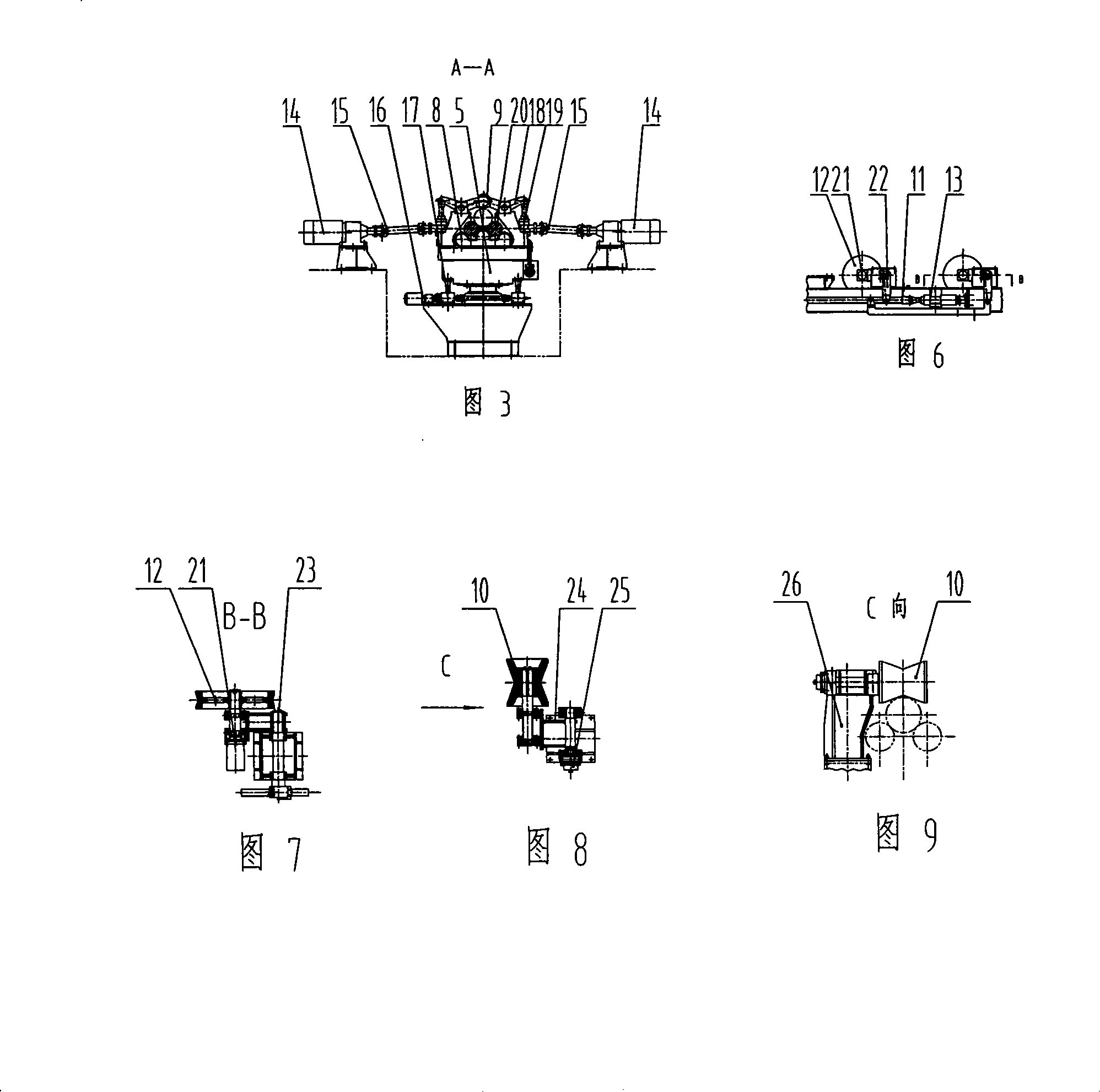

Long guide roller outlet table for tube rolling machine

InactiveCN101234400AExtend your lifeReduce motor powerGuiding/positioning/aligning arrangementsMetal rolling arrangementsWorking environmentReducer

The invention provides a long guide roll typed outlet platform used in a tube mill, relating to an outlet platform of a hot tube mill. The outlet platform of the traditional tube mill adopts three rolls holding unit to limit the waggle of a steel tube; as the volume of the three rolls holding unit is large, only the centralized drive of a single motor can be adopted, therefore, the weight of an outlet platform device and the motor power are great; in addition, as a high-temperature pierced billet runs through the middle of a reducer, the working environment is bad, thereby reducing the service life of the reducer and limiting the diameter size of the pierced billet. The invention is formed by a lifting base, an upper press roll, a V-shaped press roll, two sets of long guide rolls provided with transmissions, a lifting beam and a lifting live-roller table, wherein, the lower part of the lifting beam is provided with a lifting base device, while the upper part is provided with a long guide roll device with a backup roll driven by the motor, an upper press roll device and a V-shaped press roll device, and the middle of the two long guide rolls is provided with a lifting live-roller table device. The outlet platform has the advantages of compact structure, low cost, major-diameter and high-strength steel tube rolling applicability, etc.

Owner:TAIYUAN HEAVY IND

Singe-driving and double-direction type AGV

The invention relates to the technical field of automatic guided vehicles, in particular to a single-driving and double-direction type AGV. The single-driving and double-direction type AGV comprises a vehicle body, a navigation sensor, a controller, a driving assembly, a first universal wheel set and a second universal wheel set, the navigation sensor and the controller are arranged on the vehicle body, the driving assembly is arranged below the vehicle body, and the first universal wheel set and the second universal wheel set are arranged at the bottom of the vehicle body in a front-and-back opposite mode. The driving assembly is connected with the controller. The single-driving and double-direction type AGV further comprises a directional wheel arranged at the bottom of the vehicle body and a switching mechanism connected with the directional wheel. The switching mechanism is connected with the controller, and the switching mechanism is used for folding or expanding the directional wheel and expands the directional wheel to the rear end of the vehicle body according to the moving direction of the single-drive and double-direction type AGV. According to the single-driving and double-direction type AGV, due to the fact that the directional wheel and the switching mechanism are arranged on the vehicle body, the directional wheel can be expanded to the rear end of the vehicle body according to the moving direction of the AGV, and therefore the AGV can walk stably, the power consumption of a motor is reduced, and the production cost is reduced.

Owner:SUZHOU AGV ROBOT CO LTD

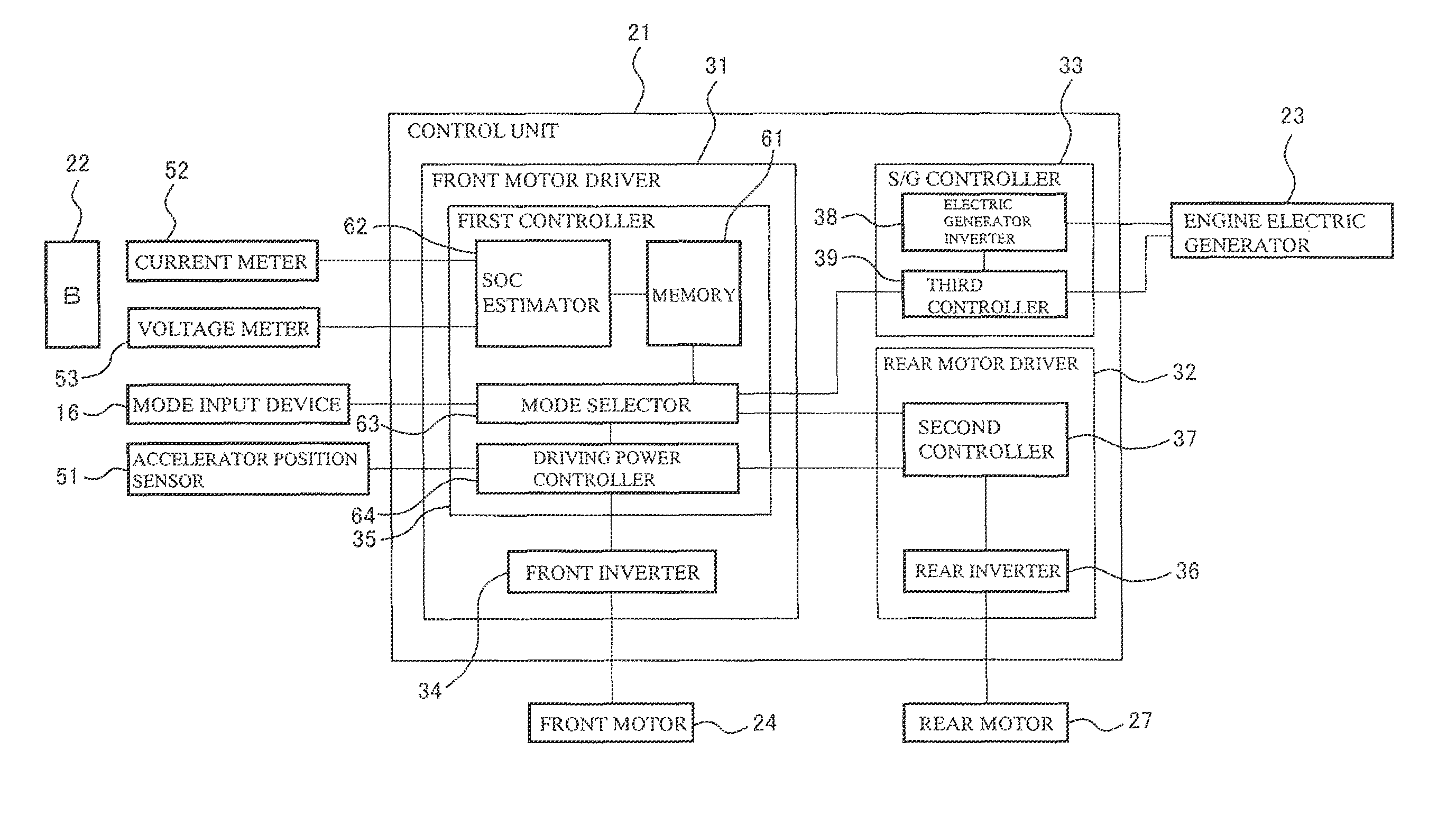

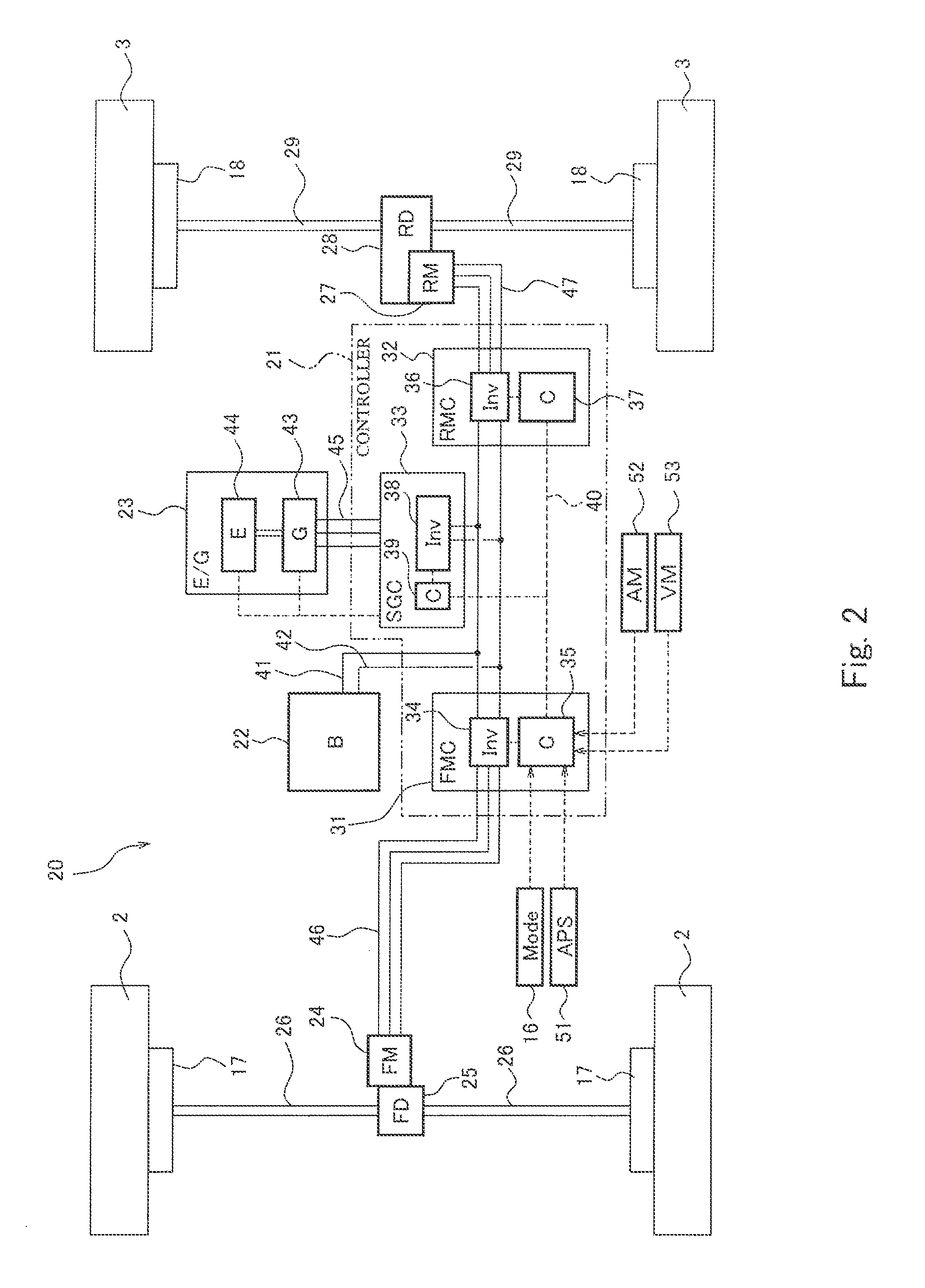

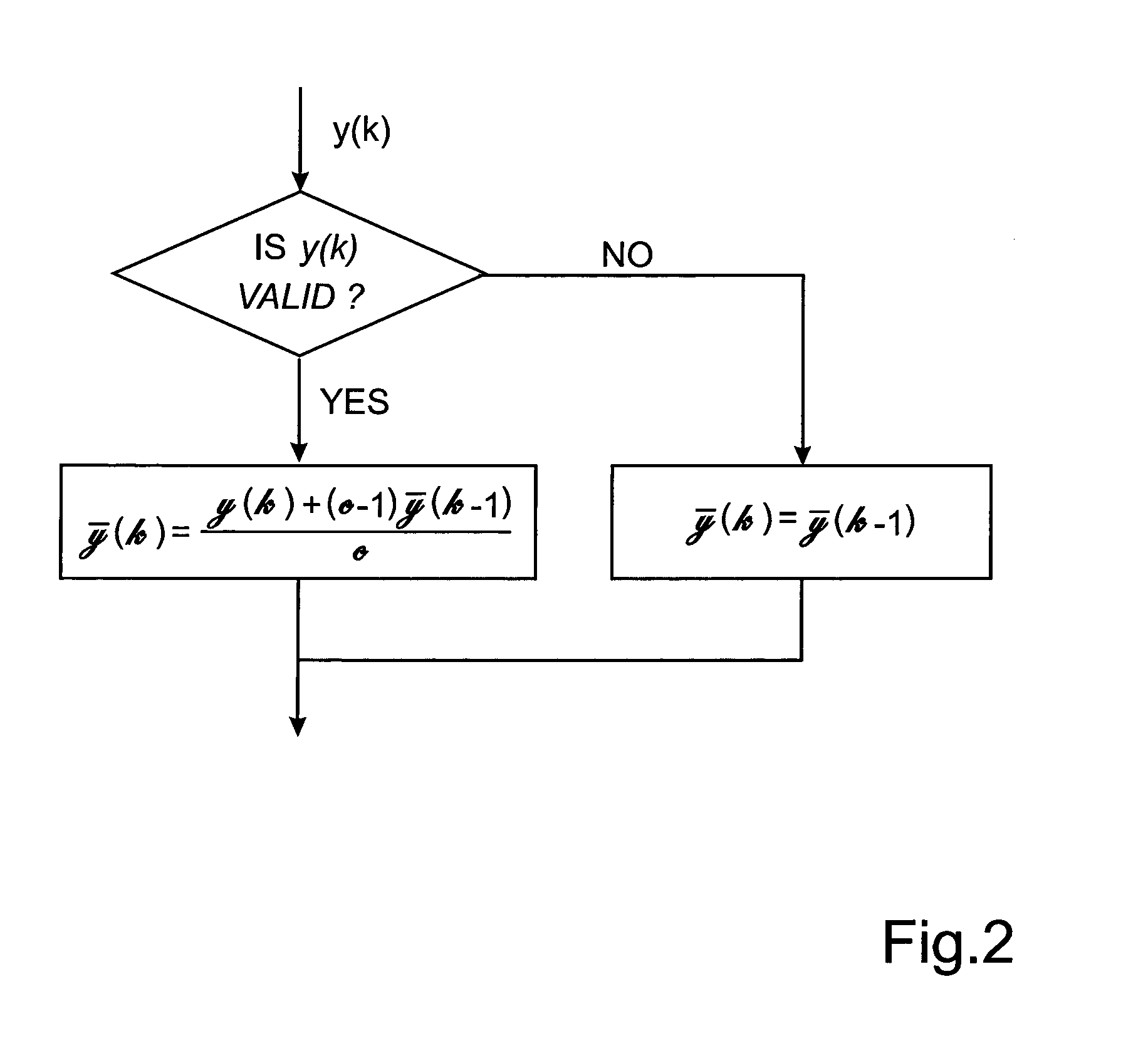

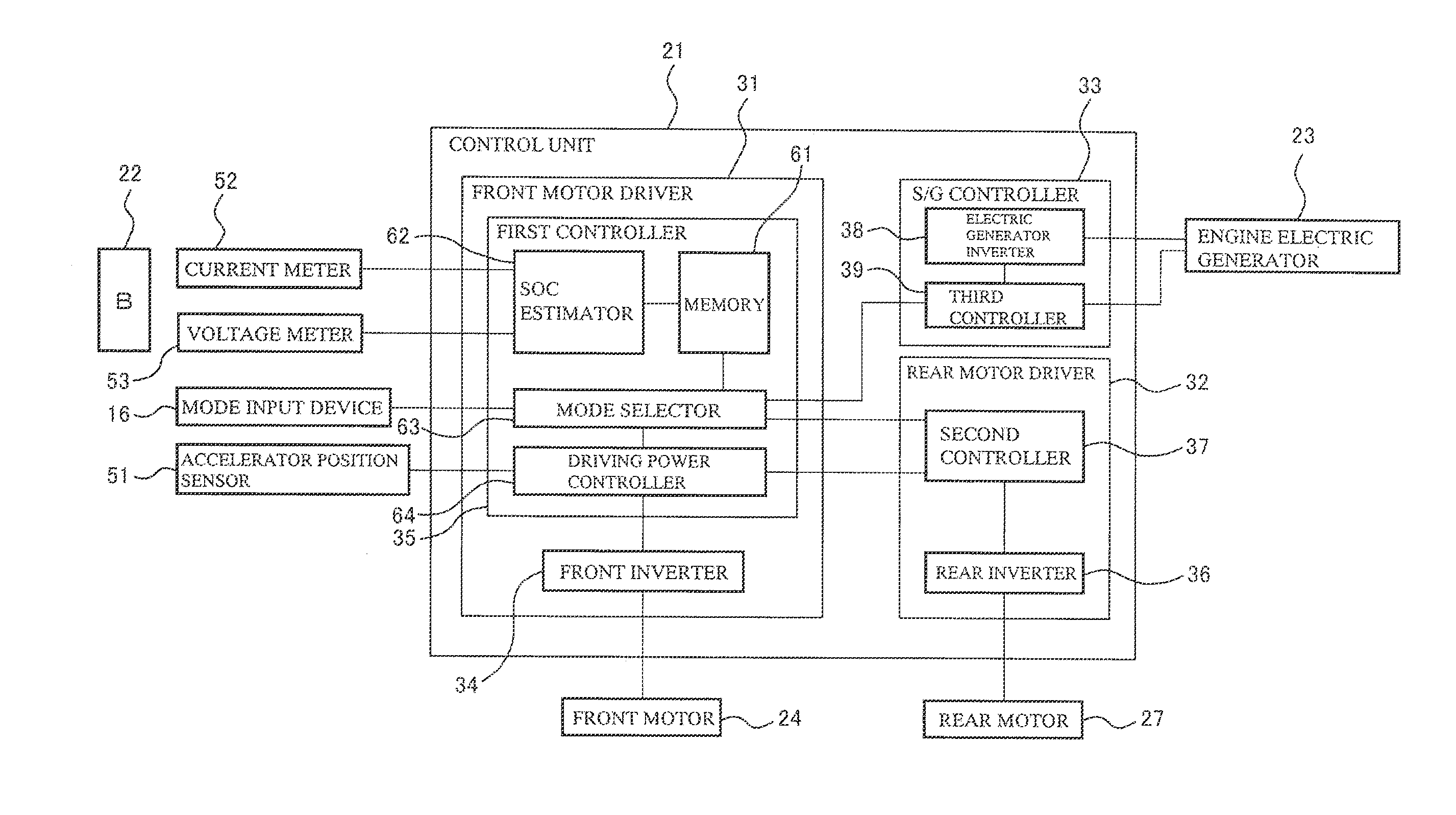

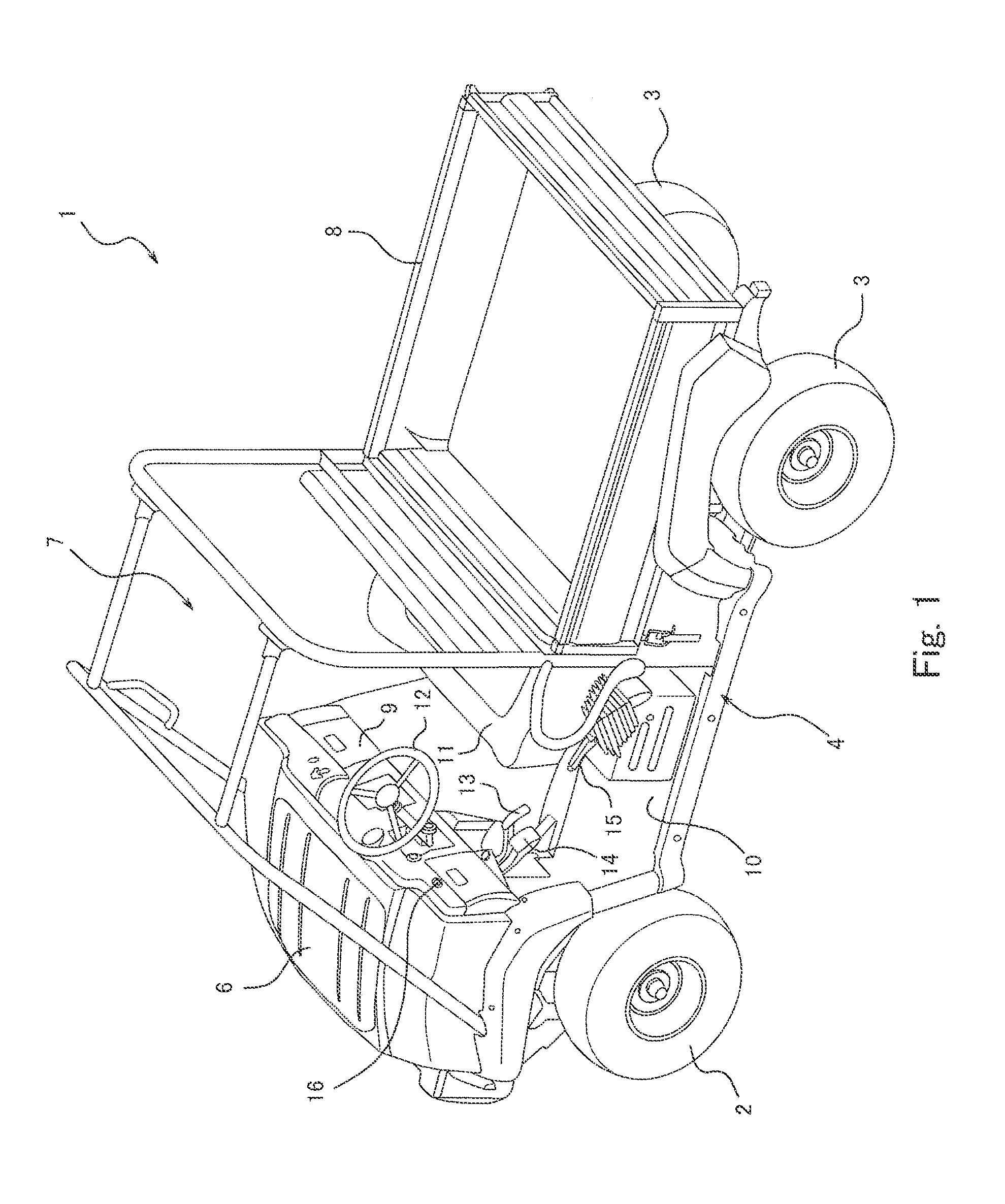

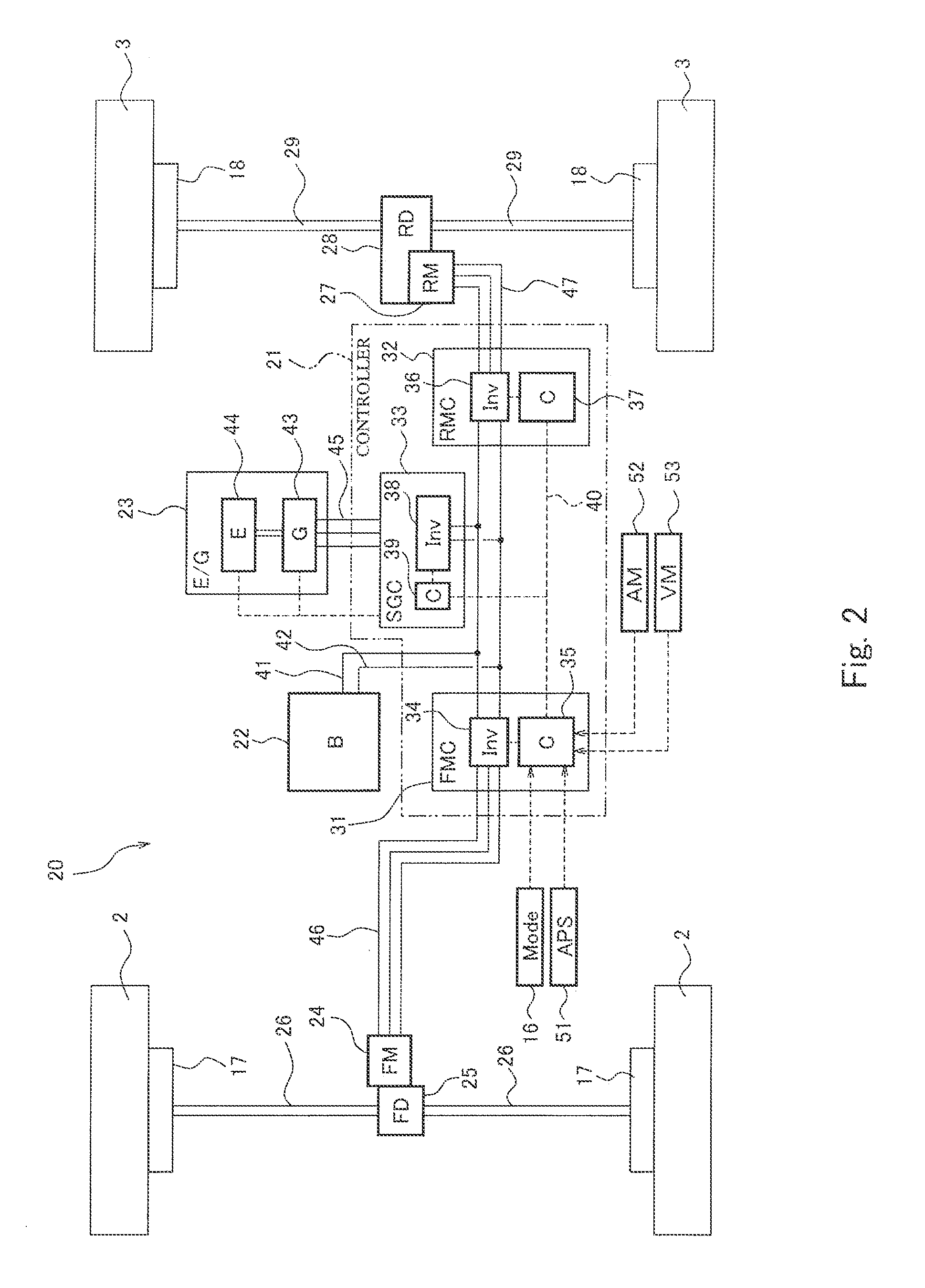

Drive control system in series-hybrid vehicle

ActiveUS8948943B2Reduce motor powerAvoid dischargeHybrid vehiclesSteering initiationsControl systemElectrical battery

Owner:KAWASAKI MOTORS LTD

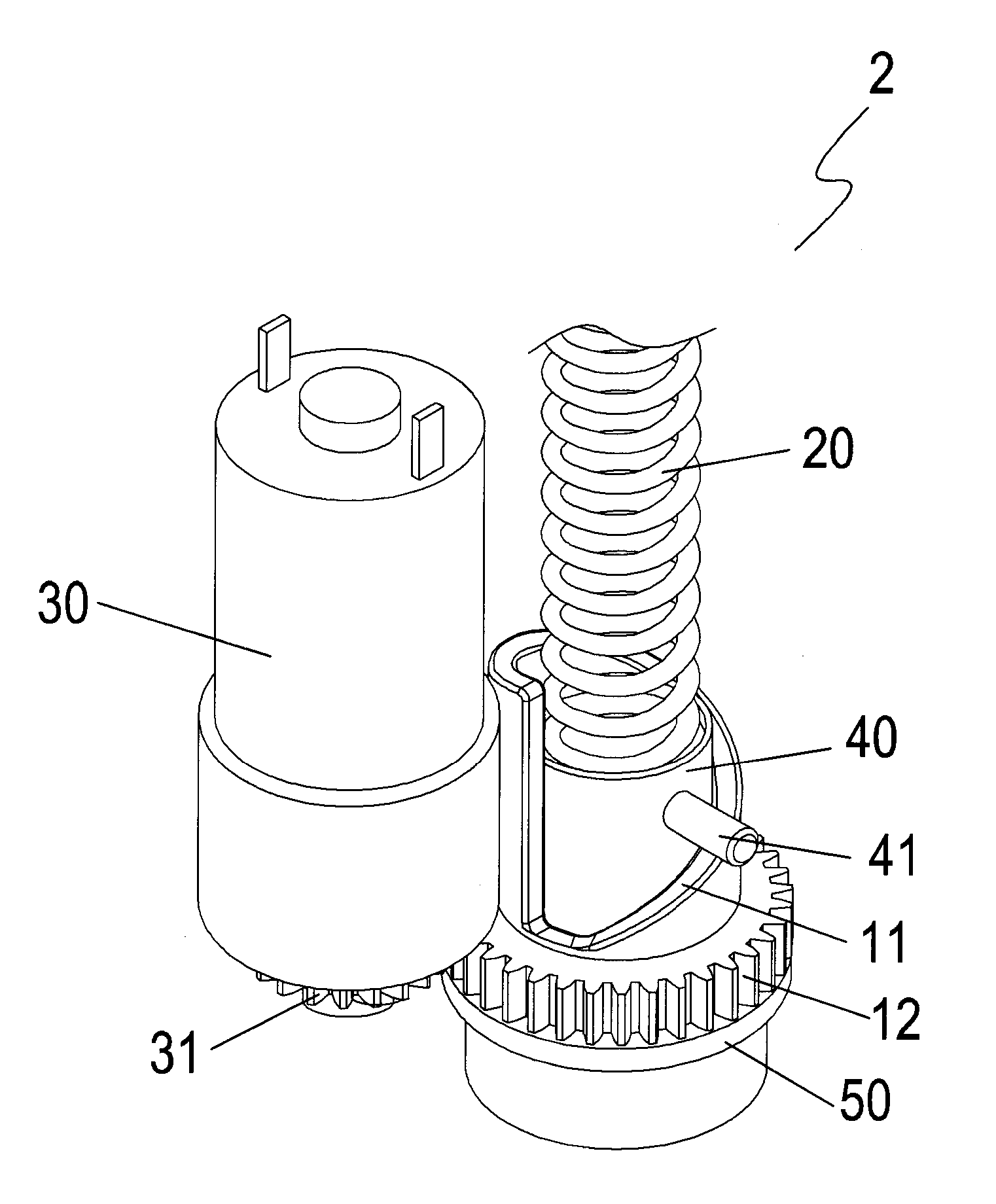

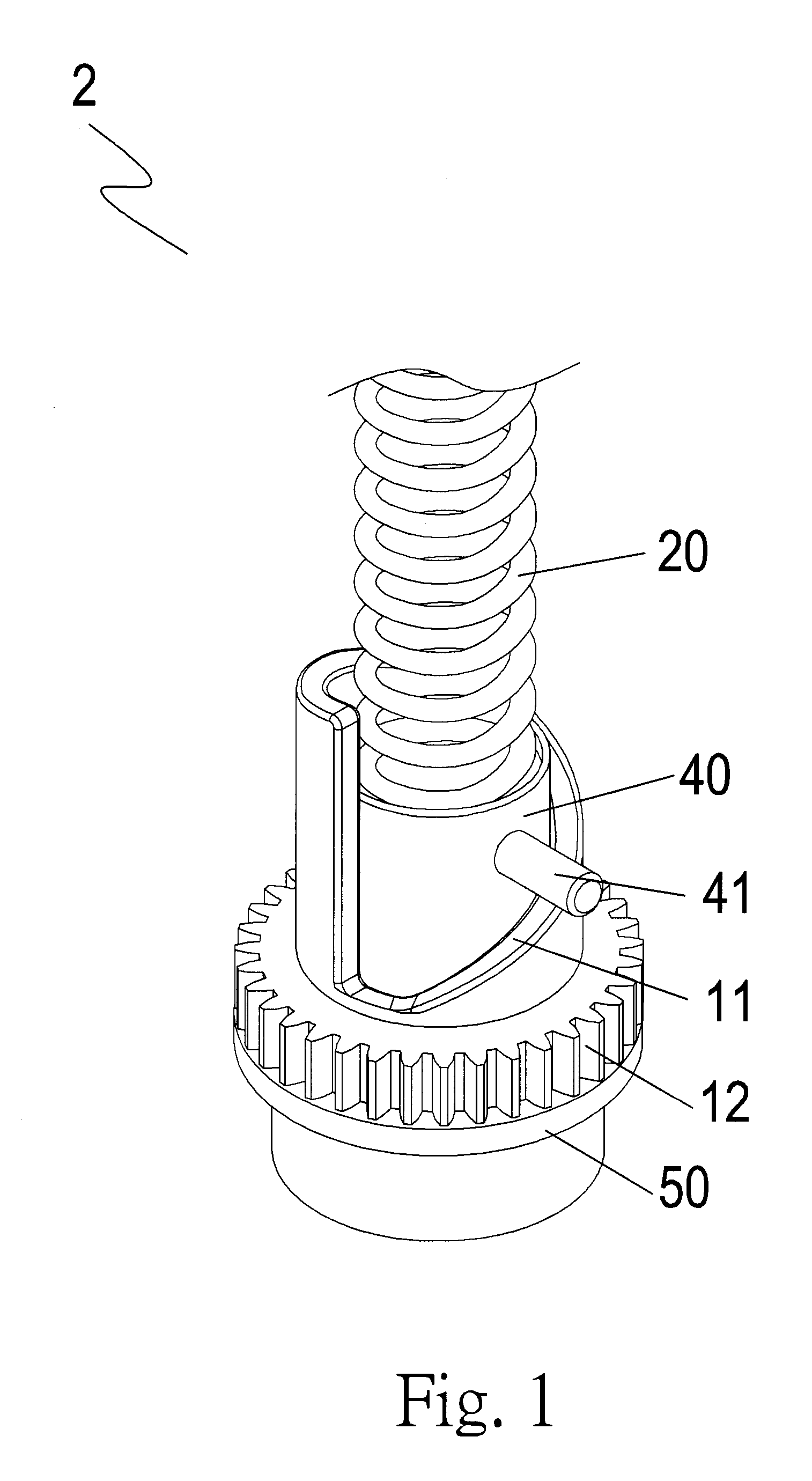

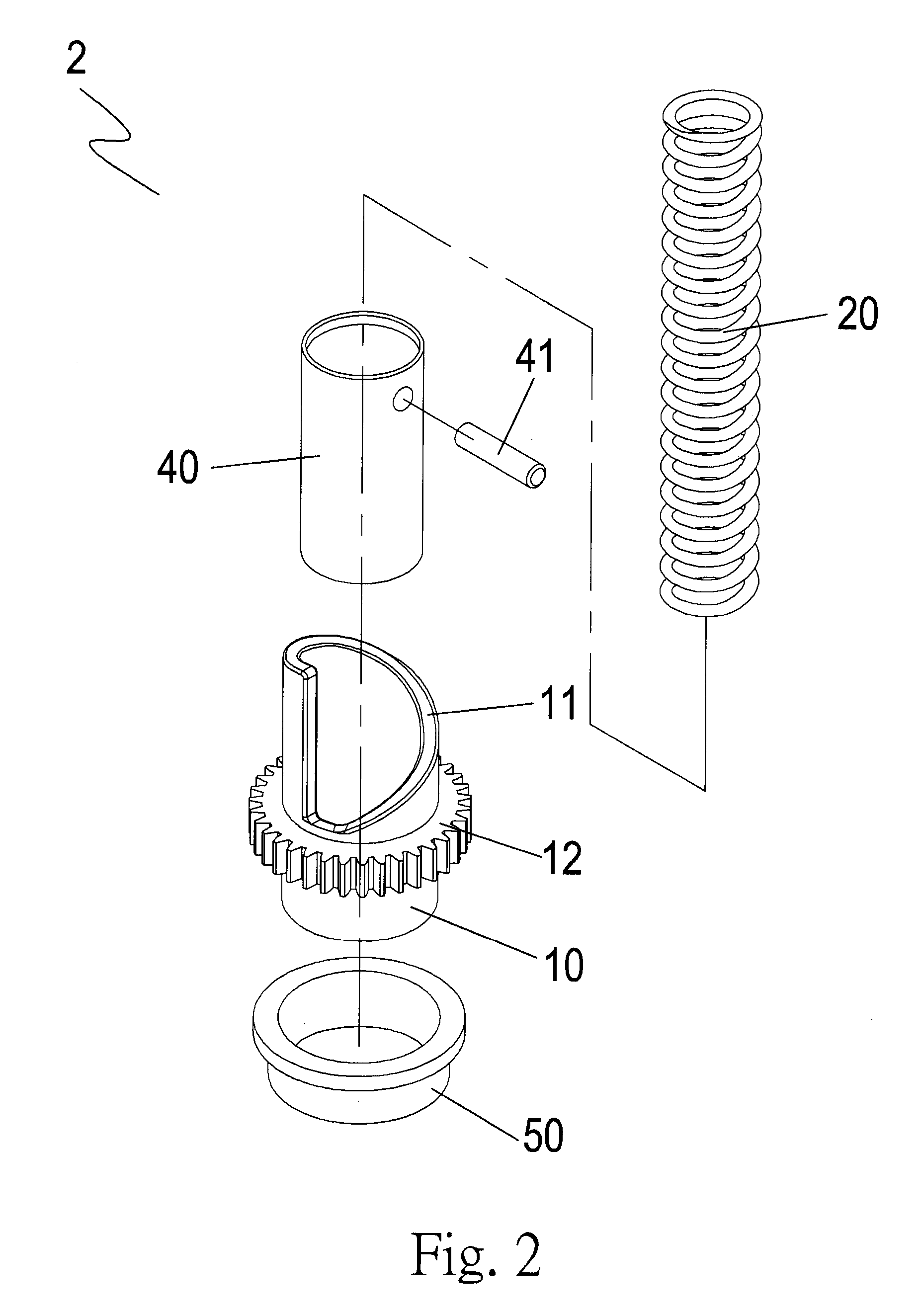

Power beating device

ActiveUS7757922B2Improve power efficiencyReduce weightStapling toolsNailing toolsActuatorControl theory

A power beating device using includes a driving unit and an actuator. The driving unit has a spring for storing and releasing energy so as to drive an impact unit. The driving unit has at least one driving surface. The actuator serves for actuating the driving surface so that the impact unit is lifted with the driving unit. Deformation of the spring will store energy. When the impact unit is lifted to a predetermined height, it will rest and then the spring will release energy to drive the impact unit to have the effect of beating.

Owner:JELLEY TECH

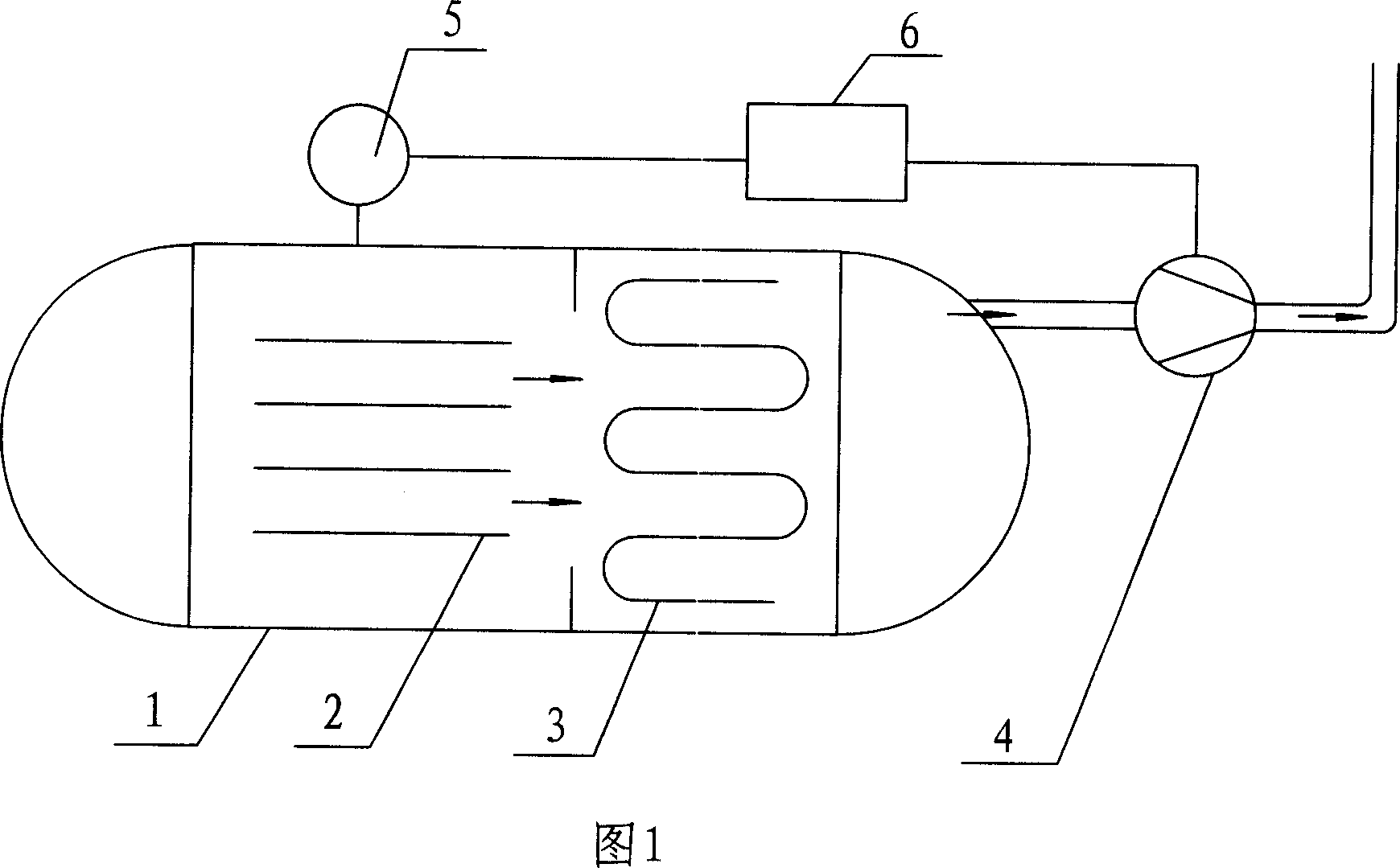

Vacuum freeze drier

InactiveCN101046350AReduce the impact of water capture performanceReduce operating energy consumptionDrying solid materials without heatFrequency changerElectricity

The vacuum freeze drier includes one drying bin, heating shelves inside the drying bin, one water vapor condenser for condensing water vapor from the heated material, and one vacuum pump for vacuumizing. It features that the vacuum freeze drier includes also one vacuum gauge to sense the vacuum degree inside the drying bin, and one frequency converter to receive the output signal of the vacuum gauge and to output variable frequency, with the frequency converter being connected electrically to the vacuum pump. The present invention has the advantages of no aeration to the drying bin during drying, no contamination of the inflated air on the dried material, varying frequency of the vacuum pump motor, and lowered power consumption.

Owner:SHUNDE POLYTECHNIC

Power control on a multi-motion electric drive system

ActiveUS20110260667A1Reduce motor powerLimited motor powerDC motor speed/torque controlElectric motor controlMotor driveControl system

A motor control system for controlling two or more motor groups includes a power converter that receives power from a power source and converts the power to an intermediate power and an intermediate power link coupled to the power converter. The motor control system also includes at least one motor driver coupled to the intermediate power link configured to provide power to one or more motors and a controller coupled to the power converter and the at least one motor driver. The controller is configured to cause the at least one motor driver to limit the amount of power delivered to the one or more motors based on the amount of power that the power converter can produce.

Owner:GENERAL ELECTRIC CO

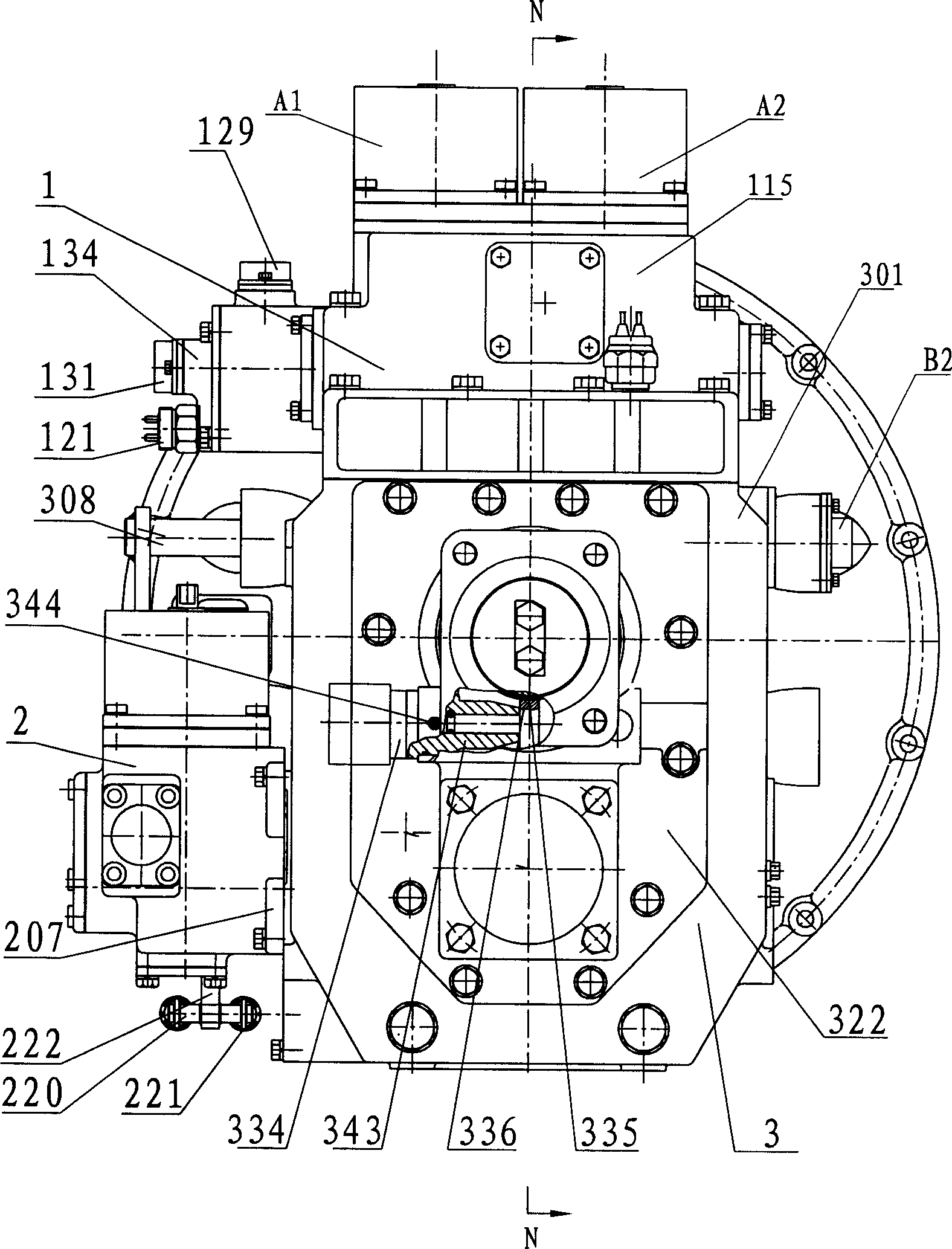

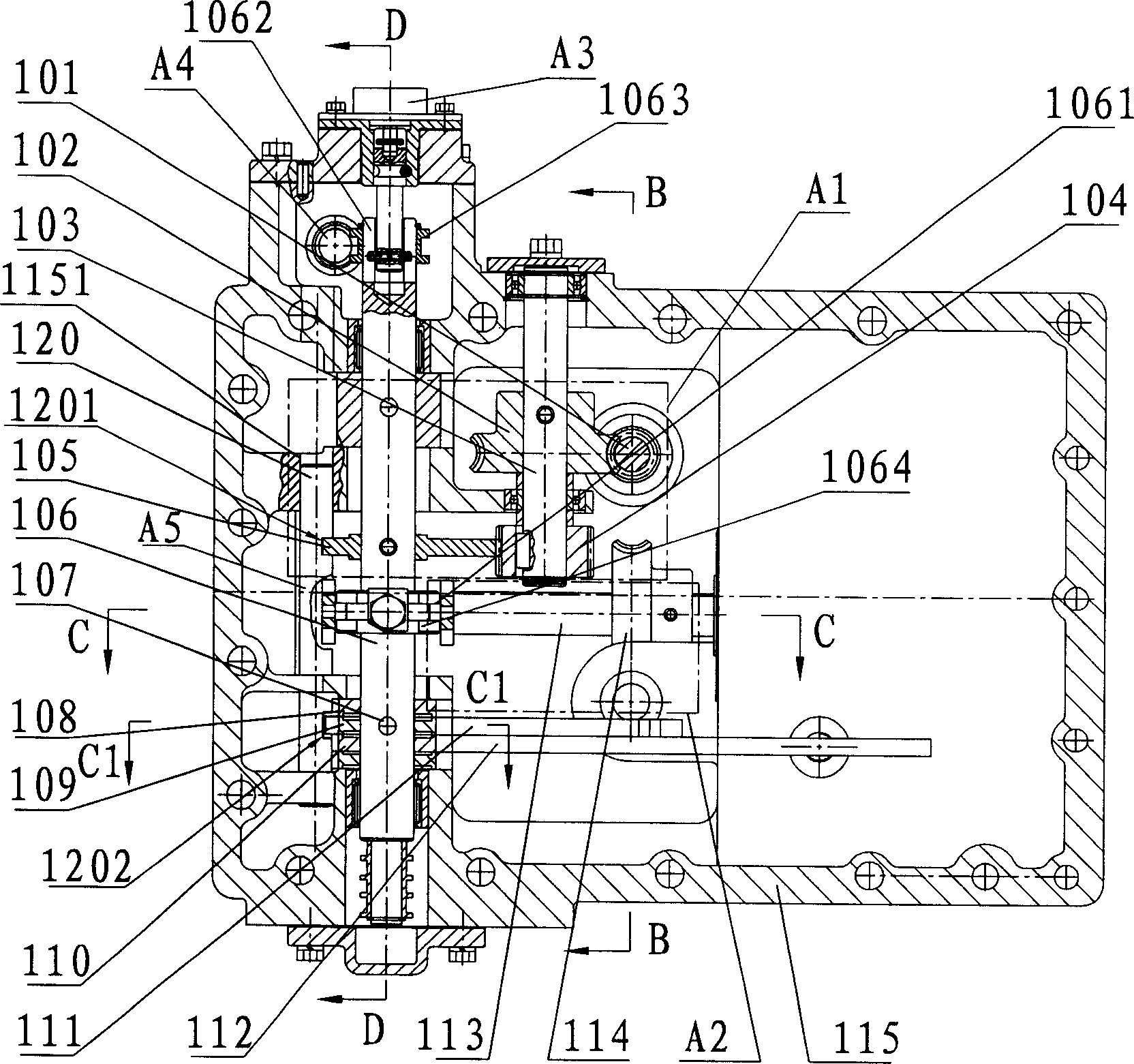

Mechanical automatic speed transmission

InactiveCN1851289ASimple structureEasy maintenanceToothed gearingsGearing controlJoystickDriver/operator

The invention relates to mechanism automatic transmission. It includes variable speed drive, gearshift actuator, and clutch actuator. The gearshift actuator includes electric machine control and gear worm driving joy stick swing and moving driving mechanism, swing and moving place detection mechanism, and gear place mutual interlocking gear. The cluth actuator includes clutch pusher driving mechanism and place detection mechanism. The invention has the advantages of simple structure, low manufacture difficulty, high working efficiency, and reliable operation.

Owner:ZHONGNAN TRANSMISSION MACHINERY FACTORY CHANGSHAAVIATION IND

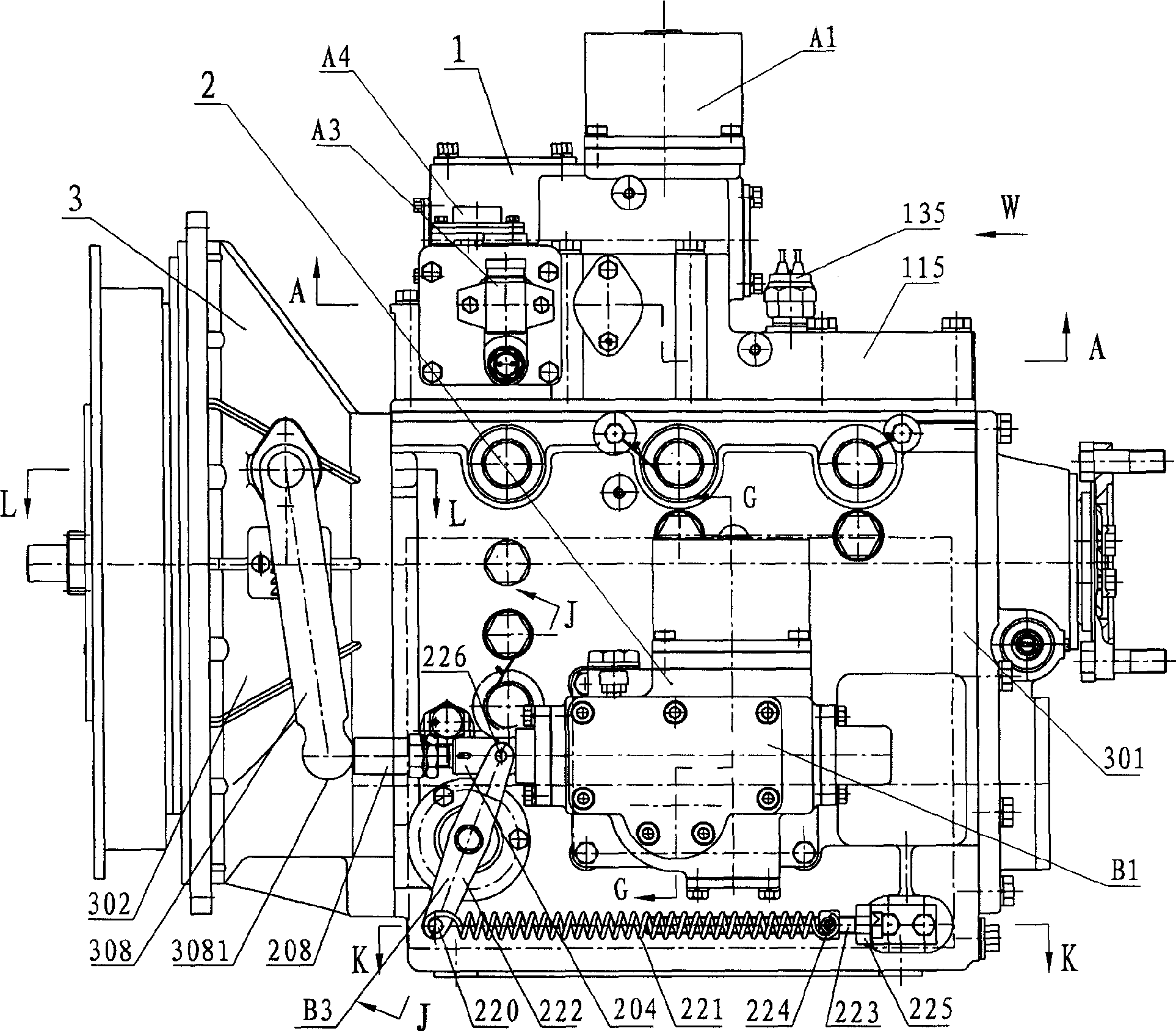

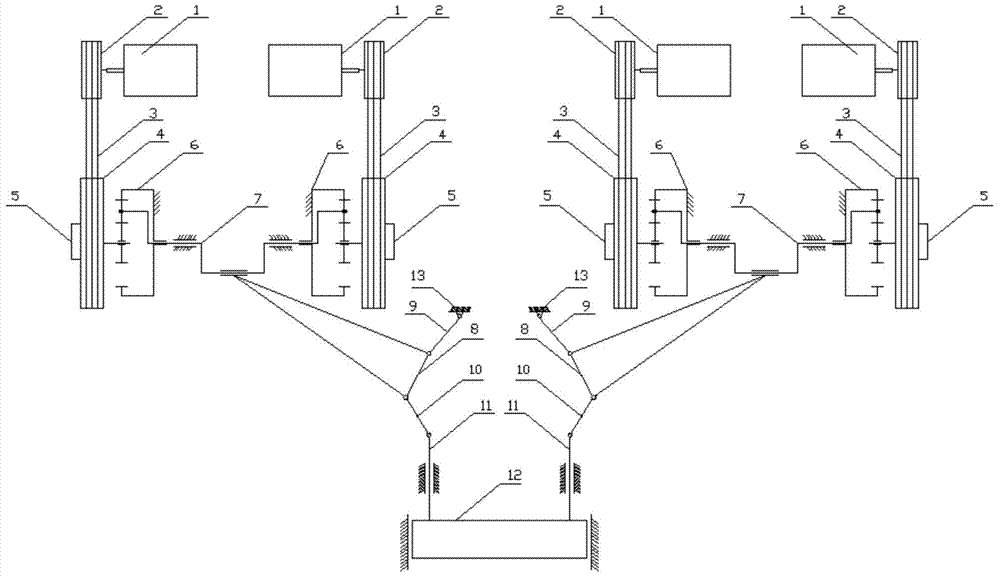

Drive system applicable to large-tonnage servo direct-driven hot die forging press

Disclosed is a drive system applicable to a large-tonnage servo direct-driven hot die forging press. The drive system comprises four sets of drive mechanisms and two sets of actuating mechanisms. The drive mechanisms are in multilateral layout, each set of the drive mechanism comprises a servo motor, an output shaft of each servo motor is connected with a large belt wheel through a small belt wheel and a drive belt, the outer side of each large belt wheel is connected with a brake, and the inner side of each large belt wheel is connected with an input shaft of a planetary gear reducer. Two sets of toggle link mechanisms are adopted as the actuating mechanisms, each set of toggle link mechanism is composed of a crank, a triangular connecting link, an upper toggle link and a lower toggle link which are connected, output ends of the four planetary gear reducers are connected with two ends of the two cranks respectively, one end of each triangular connecting link is directly sleeved on the corresponding crank, the upper end of each triangular connecting link is connected onto an upper crossbeam of the hot die forging press through the corresponding upper toggle link, and the lower end of each triangular connecting link is connected with a slider through the corresponding lower toggle link and a guide plunger type connecting link. By the drive system, torque needed for forging can be lowered remarkably, the requirement on motor power is lowered, and bearing capacity and working efficiency of the hot die forging press are improved.

Owner:XI AN JIAOTONG UNIV

Automatic grain sampler

InactiveCN102305726AGuaranteed uptimeAvoid out of syncWithdrawing sample devicesMotor driveDrive shaft

The invention discloses an automatic grain sampler. The automatic grain sampler comprises a longitudinal traveling cart which is arranged on longitudinal traveling tracks, two transverse traveling trolleys which are arranged on transverse traveling tracks of the longitudinal traveling cart, and fiche chain transmission lifting mechanisms which are arranged on the transverse traveling trolleys. The automatic grain sampler is characterized in that: a longitudinal traveling cart reducing motor drives a driving shaft of the cart by a chain wheel, and traveling wheels of the cart which are positioned at both ends of the driving shaft and a driven shaft of the cart are arranged on the longitudinal traveling tracks; the two transverse traveling trolleys have the same structure, a driving sprocket of a transverse traveling reducing motor shaft of one trolley is connected with a driven sprocket of a transverse traveling reducing motor shaft of the other trolley through a trolley chain, and moving rollers of the trolleys are arranged on the transverse traveling tracks; and driving sprockets of fiche lifting reducing motor shafts of the fiche chain transmission lifting mechanisms are connected with driven sprockets of sprocket adjustment shafts of the trolleys through fiche chains, and the fiche chains are fixedly connected with fiches. The automatic grain sampler has the advantages of simple structure, high manufacturing and assembly processability, low cost, high performance-price ratio and the like, and can be operated stably.

Owner:吉林三豪自动化机械有限责任公司

Wet-type desulfurizing deduster downstream spraying structure

InactiveCN102743942AReduce motor powerSmall running resistanceCombination devicesUsing liquid separation agentEngineeringMotor power

The invention discloses a wet-type desulfurizing deduster downstream spraying structure, which is characterized by comprising a base cylinder (1), which is provided with a desulfurizer cylinder (2) and a dehydrator cylinder (3). The upper port diameters of the desulfurizer cylinder (2) and the dehydrator cylinder (3) are both smaller than the lower port diameters. A spraying pipe (4) is disposed at the upper port of the desulfurizer cylinder (2). While meeting the desulfurization effect requirement, the spraying structure disclosed in the invention can reduce the equipment running resistance by 400-500Pa and greatly reduce the motor power of a fan, thus really reaching the effects of high efficiency and energy saving. The running mode is safe and reliable, the equipment resistance is small. Simultaneously, a lot of energy can be saved, and the running cost is low.

Owner:无锡翱翔环保机械有限公司

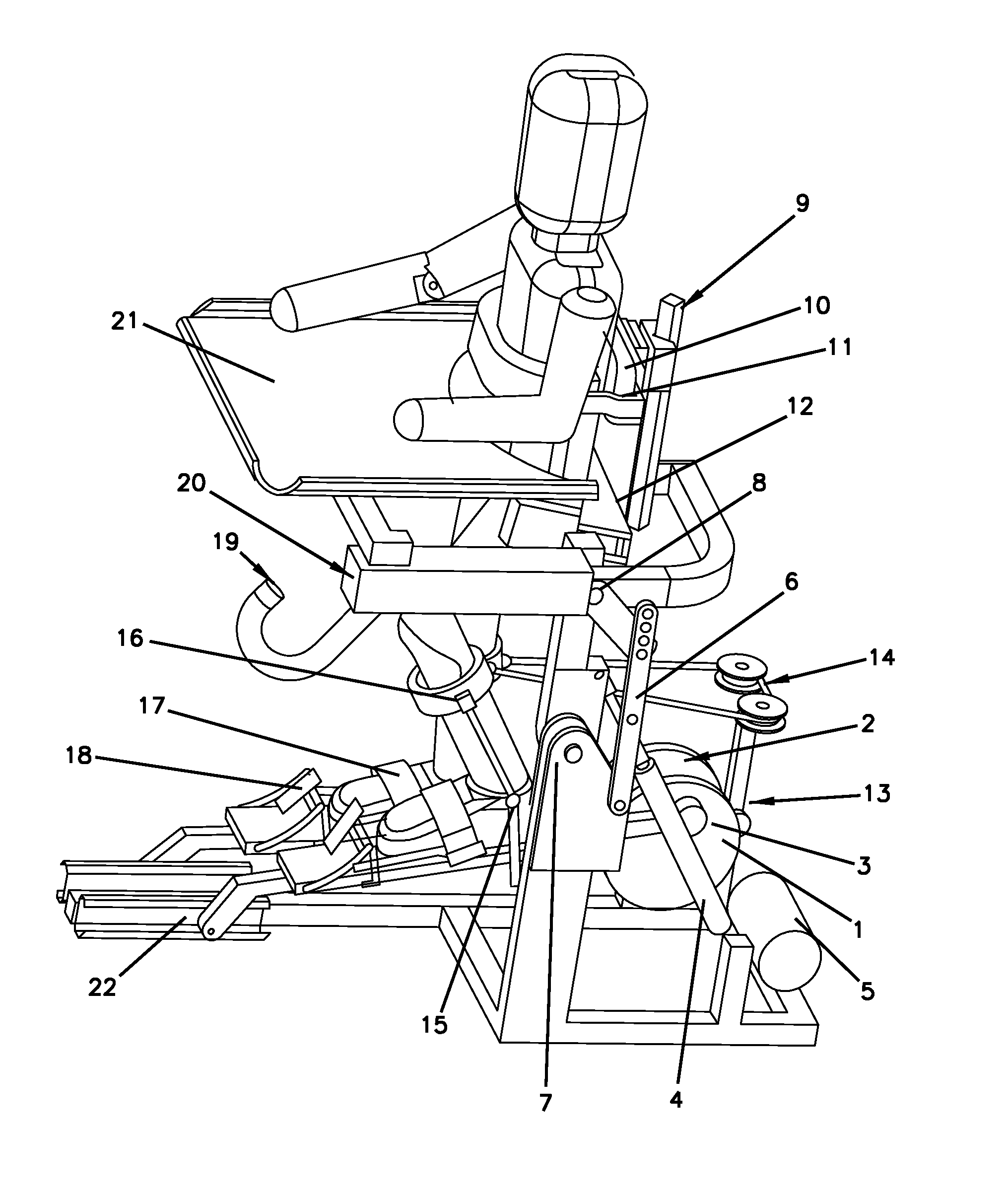

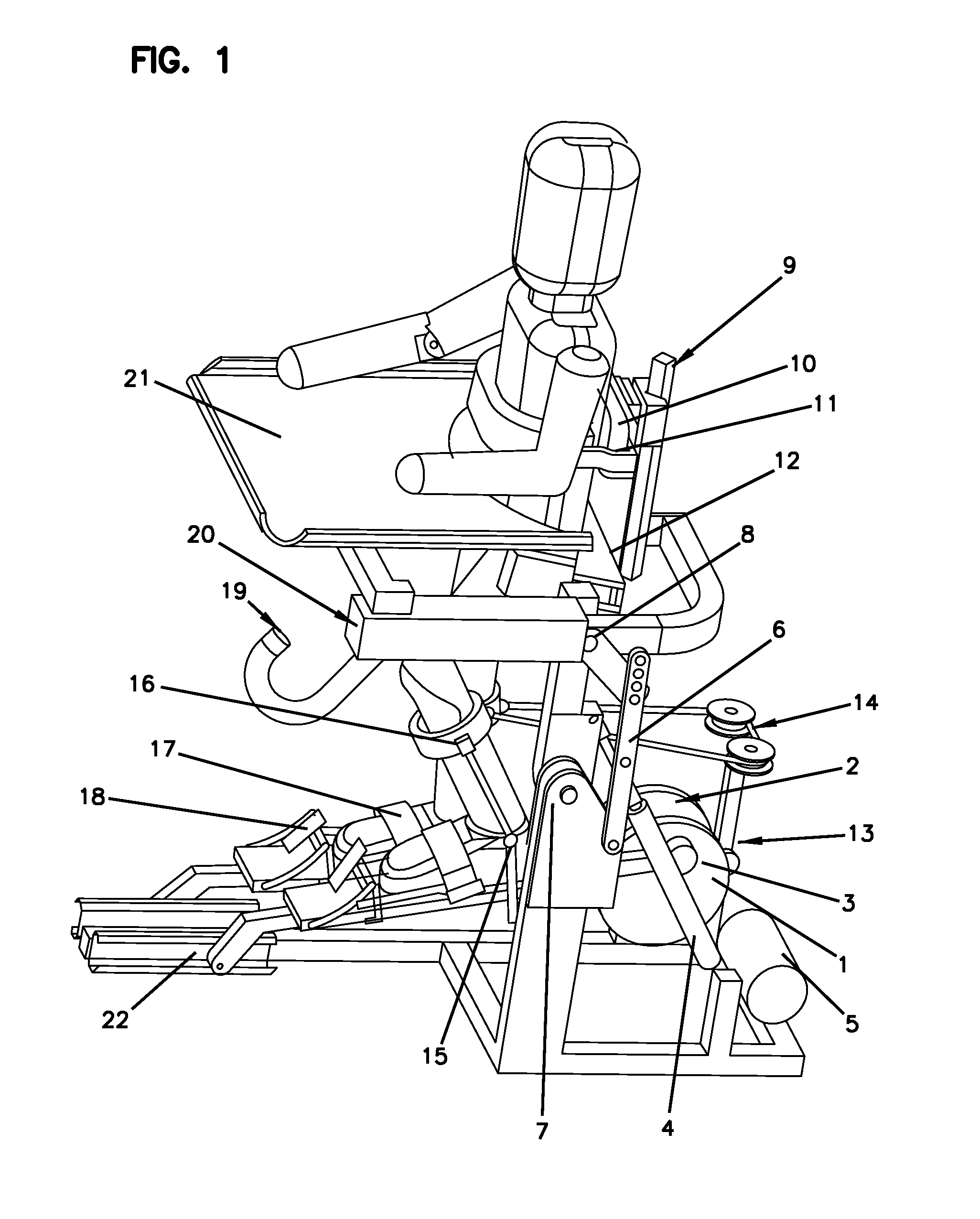

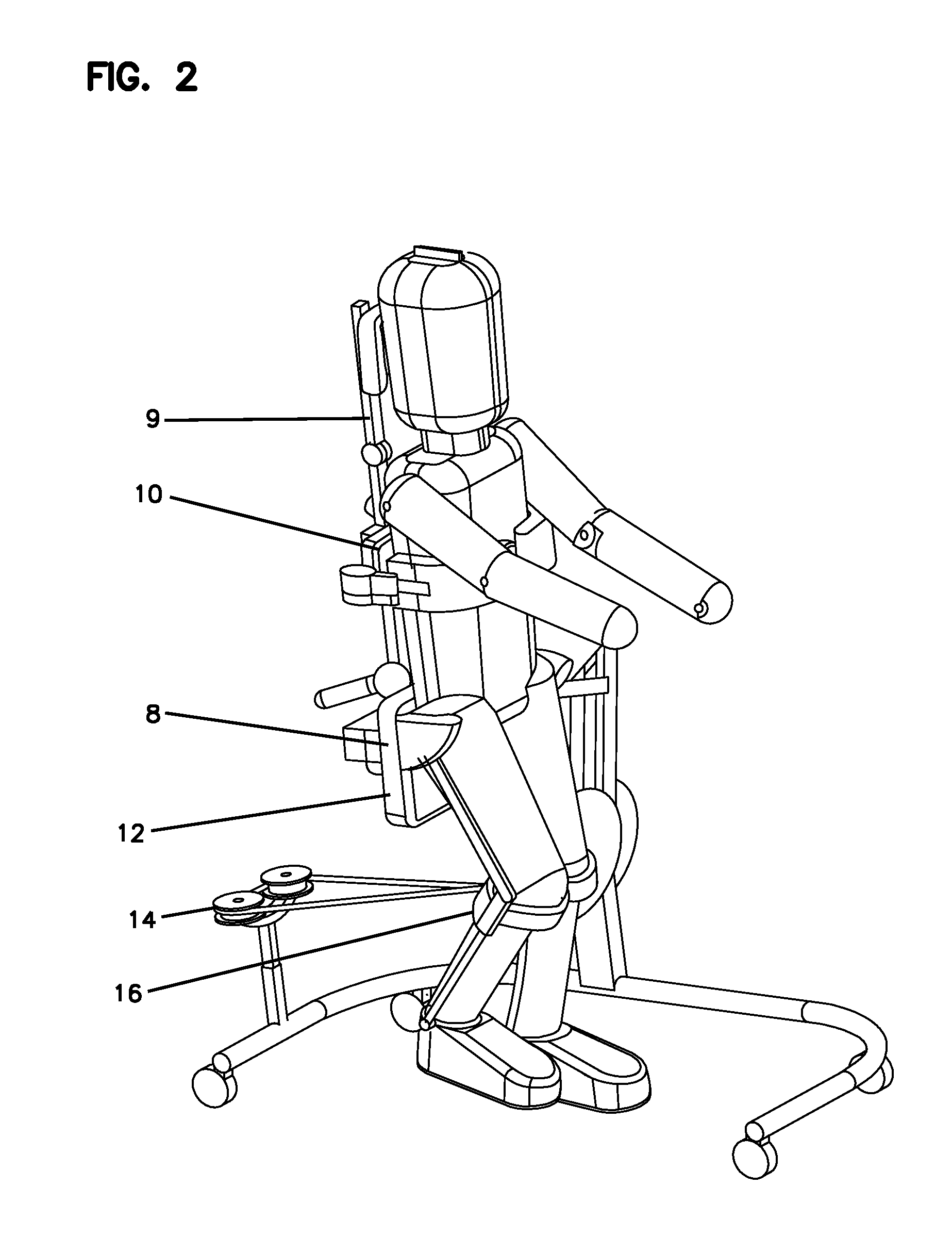

Training apparatus for the disabled

Owner:MADE FOR MOVEMENT GRP

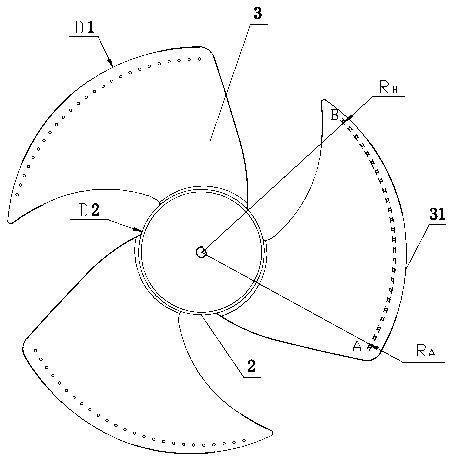

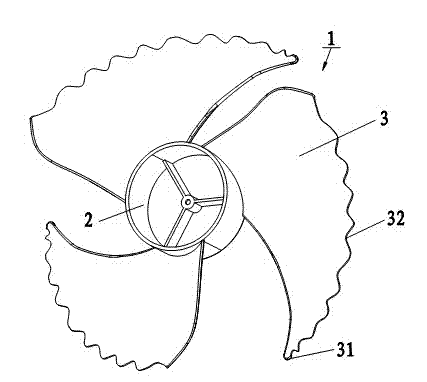

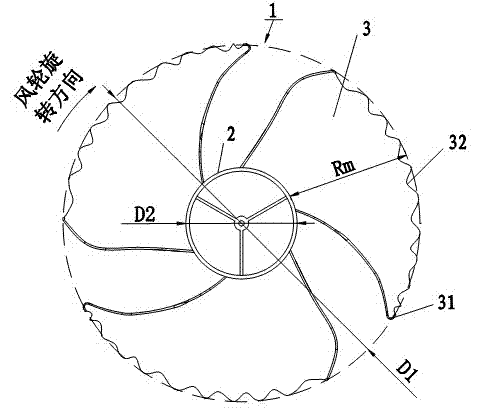

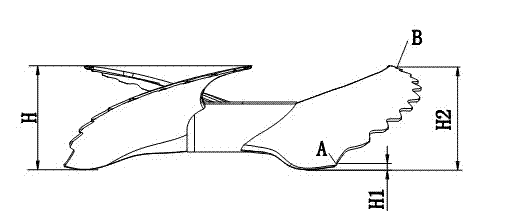

Axial flow wind wheel

ActiveCN102374194AReduce eddy current noiseSuppression of eddy current noisePump componentsPumpsWave shapeEngineering

The invention relates to an axial flow wind wheel, which comprises more than two blades arranged on a hub, wherein the blades are distributed on the hub at equal intervals or unequal intervals by taking the rotating central axis of the wind wheel as the center. The axial flow wind wheel is characterized in that: the outer edge shape of each blade is in a wave-shaped space curve. When the axial flow wind wheel rotates, gas of the pressure surfaces of the blades flows into the suction surface in different degrees through the wave-shaped outer edges of the blades due to the wave shapes of the outer edges of the blades, so that the pressure distribution of the blades is changed, the kinetic energy of the gas on the suction surface is increased, low-energy fluid can be prevented from accumulating at the annular walls of the blades, large eddy turbulence is destructed, blade tip vortex and trailing edge falloff are effectively refined, the energy strength of the vortex is reduced, and the vortex noise of the wind wheel is restricted, therefore the noise of the wind wheel is effectively reduced, the acoustic quality is softer and more comfortable, meanwhile, the wind wheel weight and the motor load are lightened by wave shapes of the outer edges of the blades, and the wind wheel cost and the motor power are reduced. The invention is especially suitable for an outdoor unit of an air-conditioner.

Owner:MIDEA GRP CO LTD

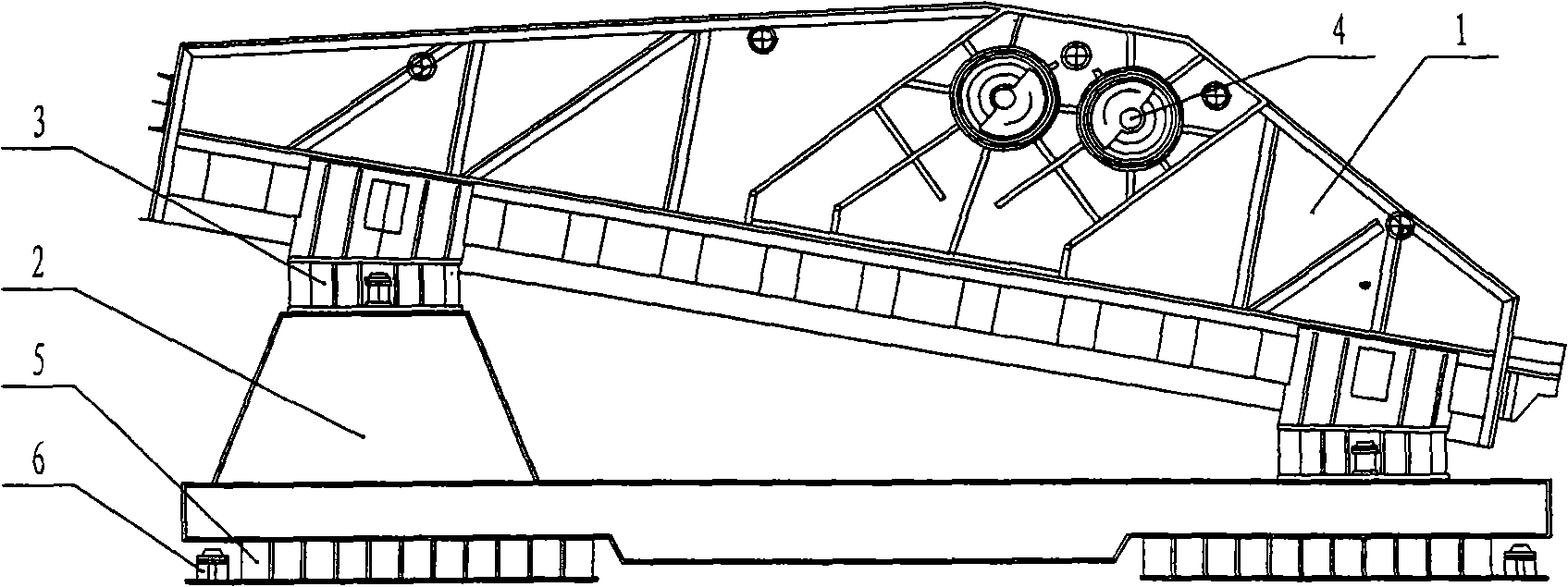

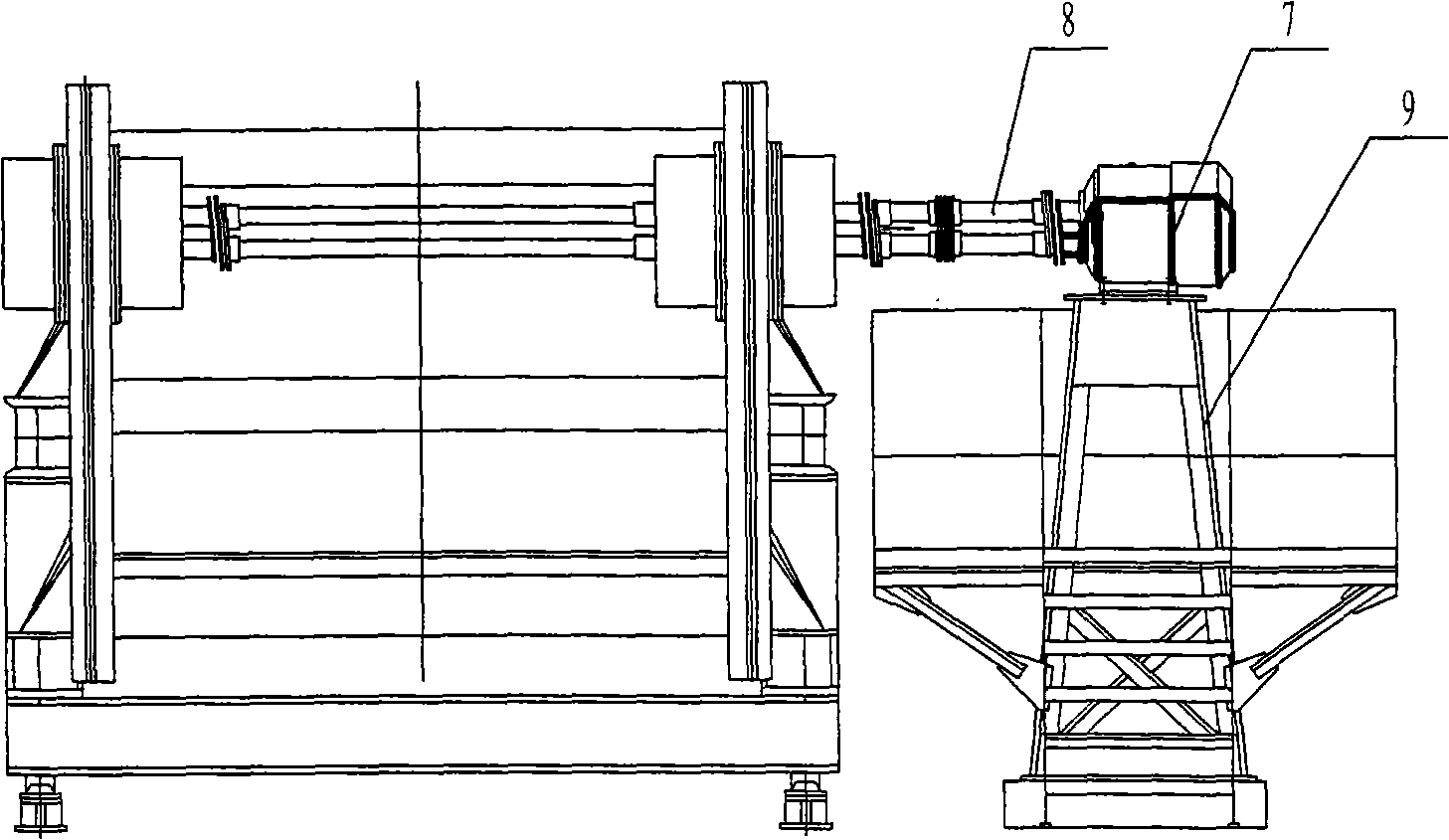

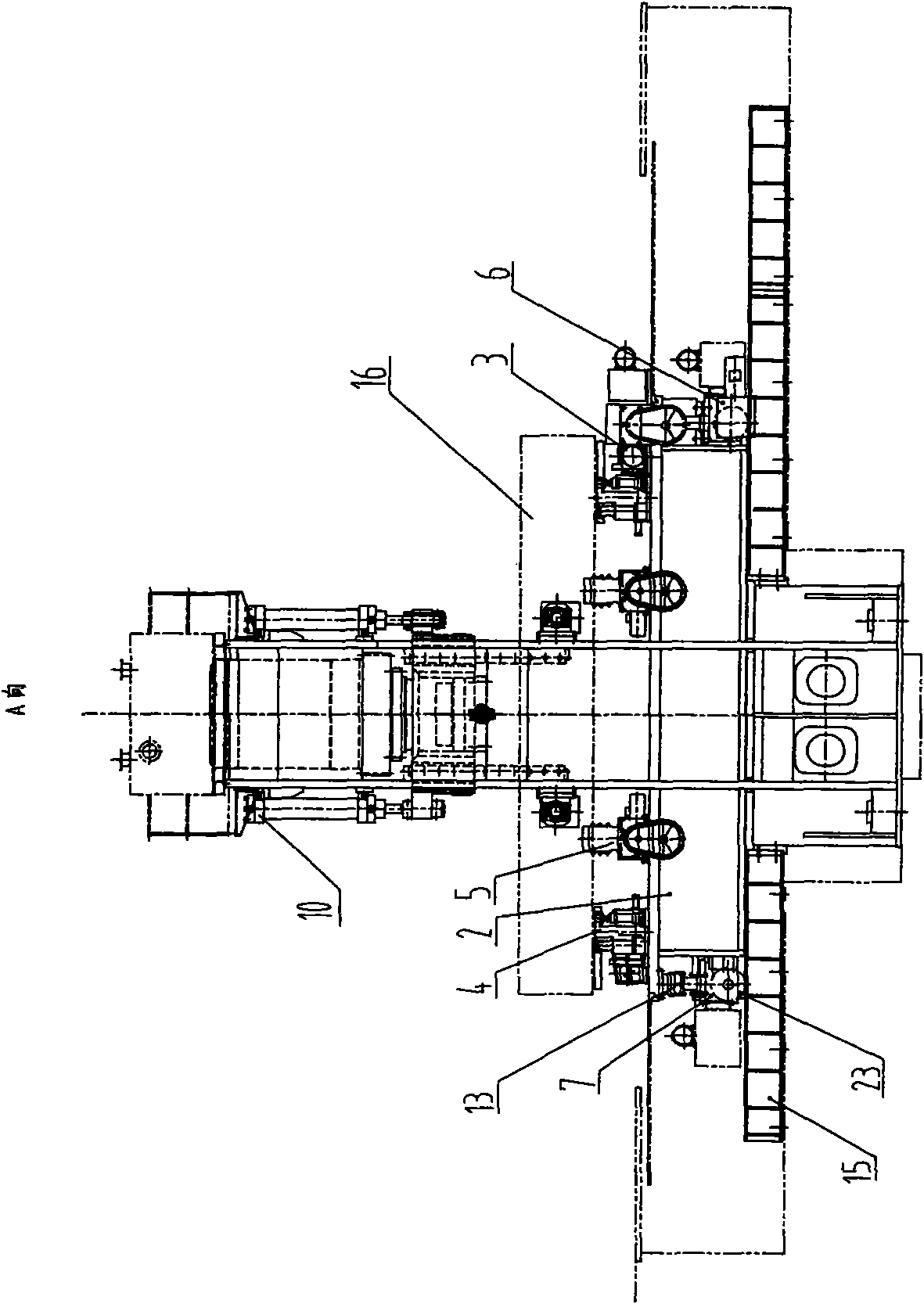

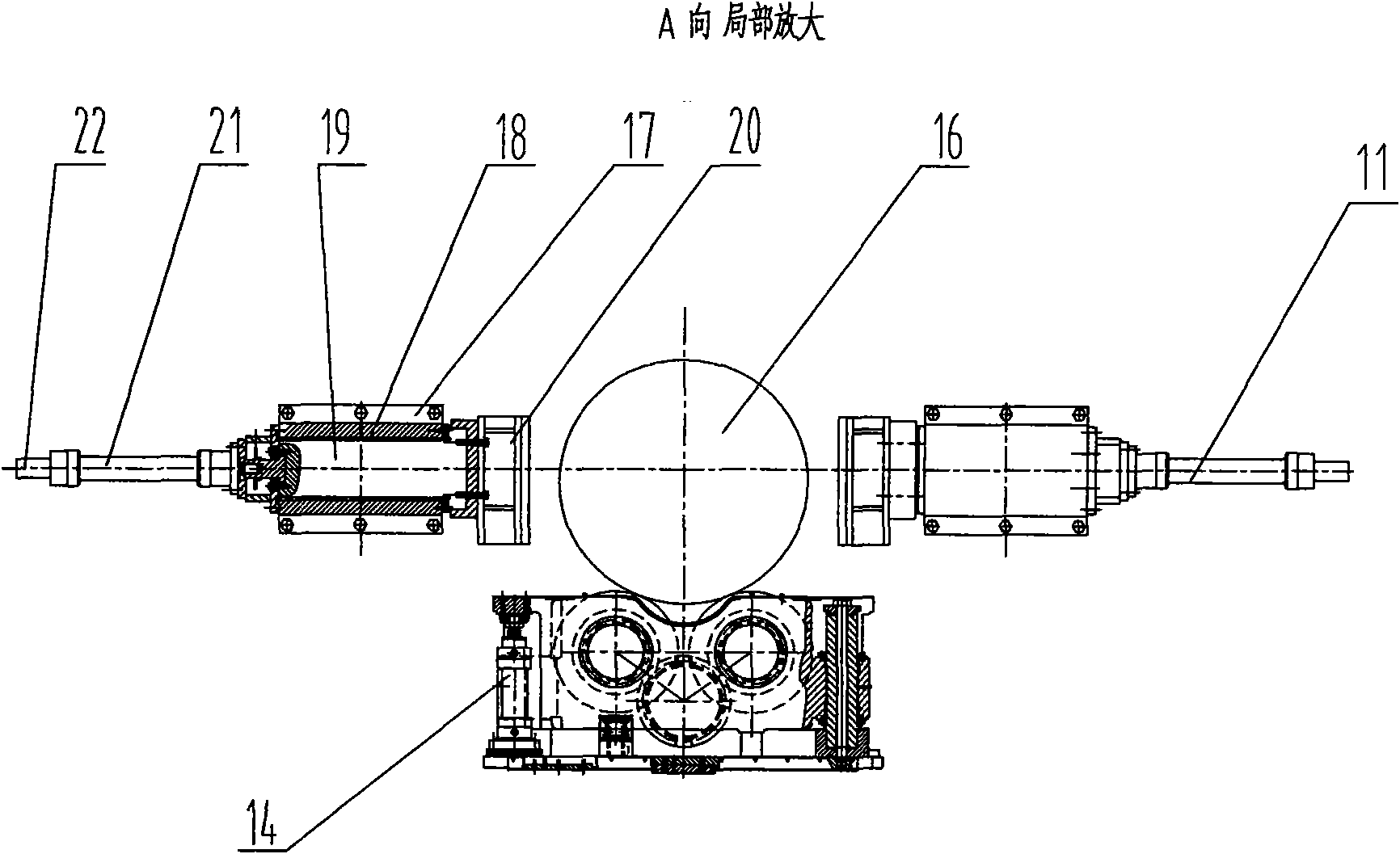

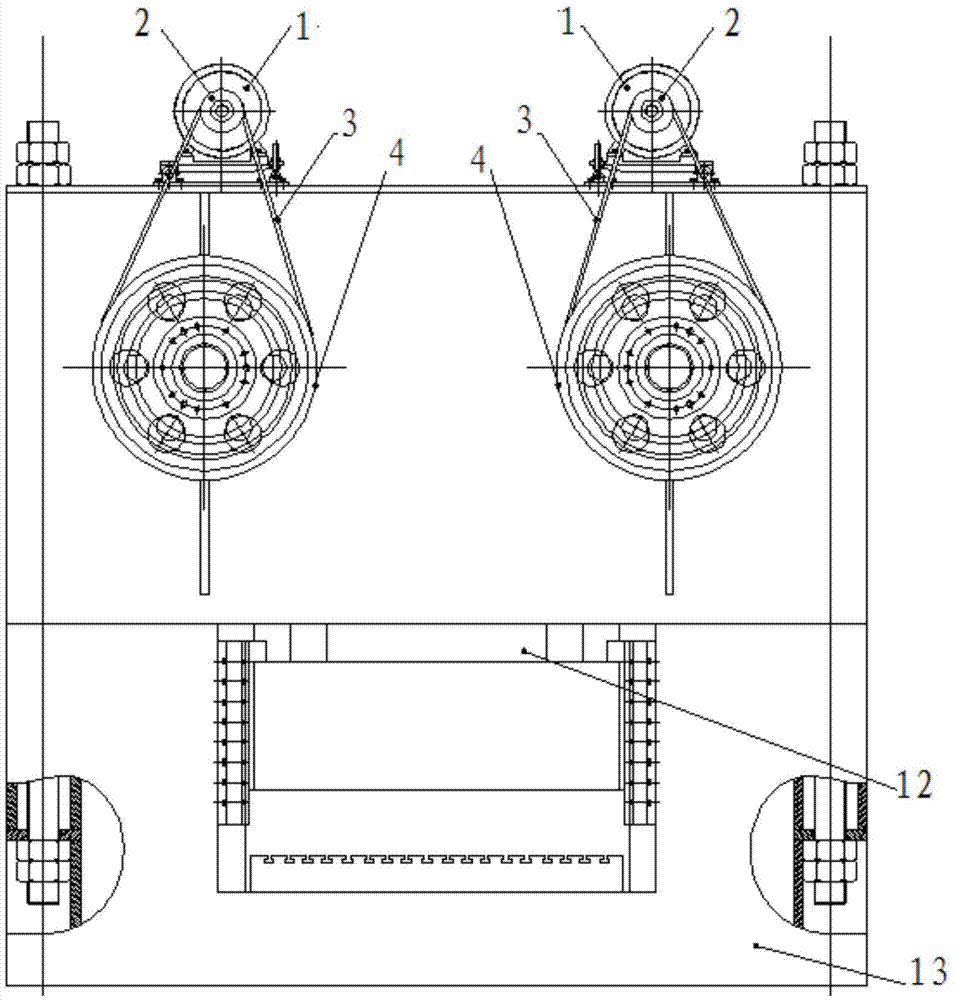

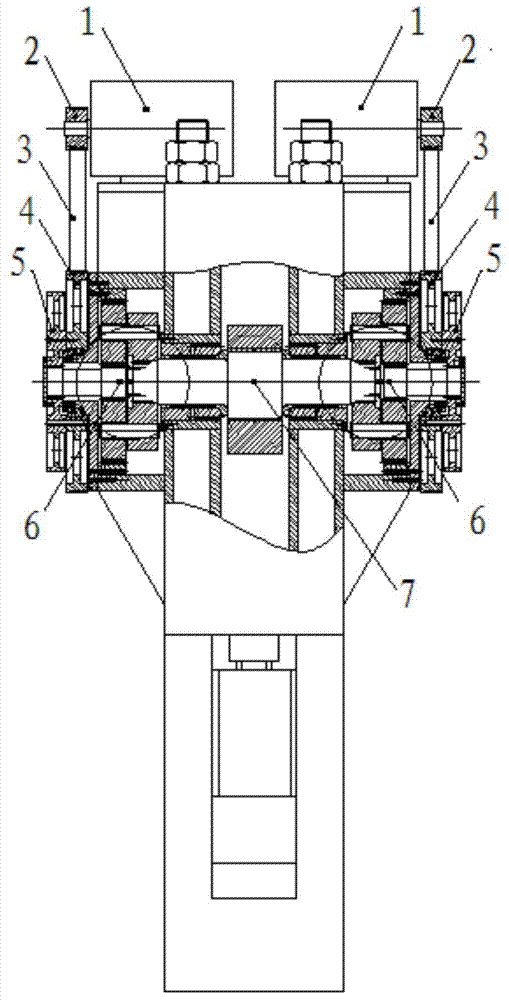

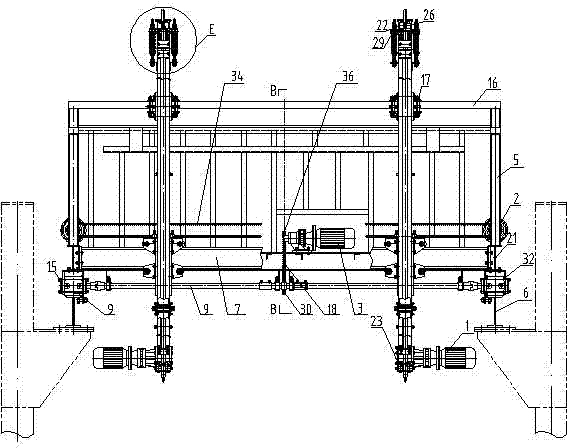

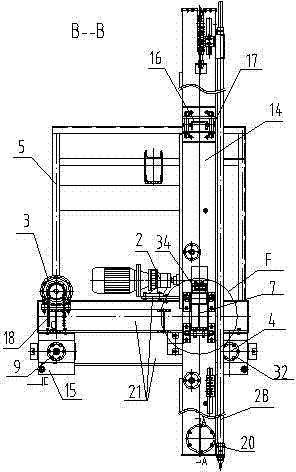

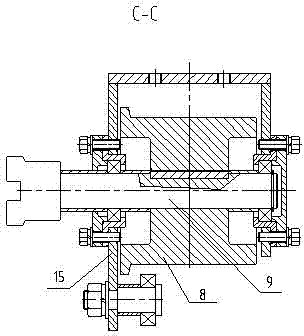

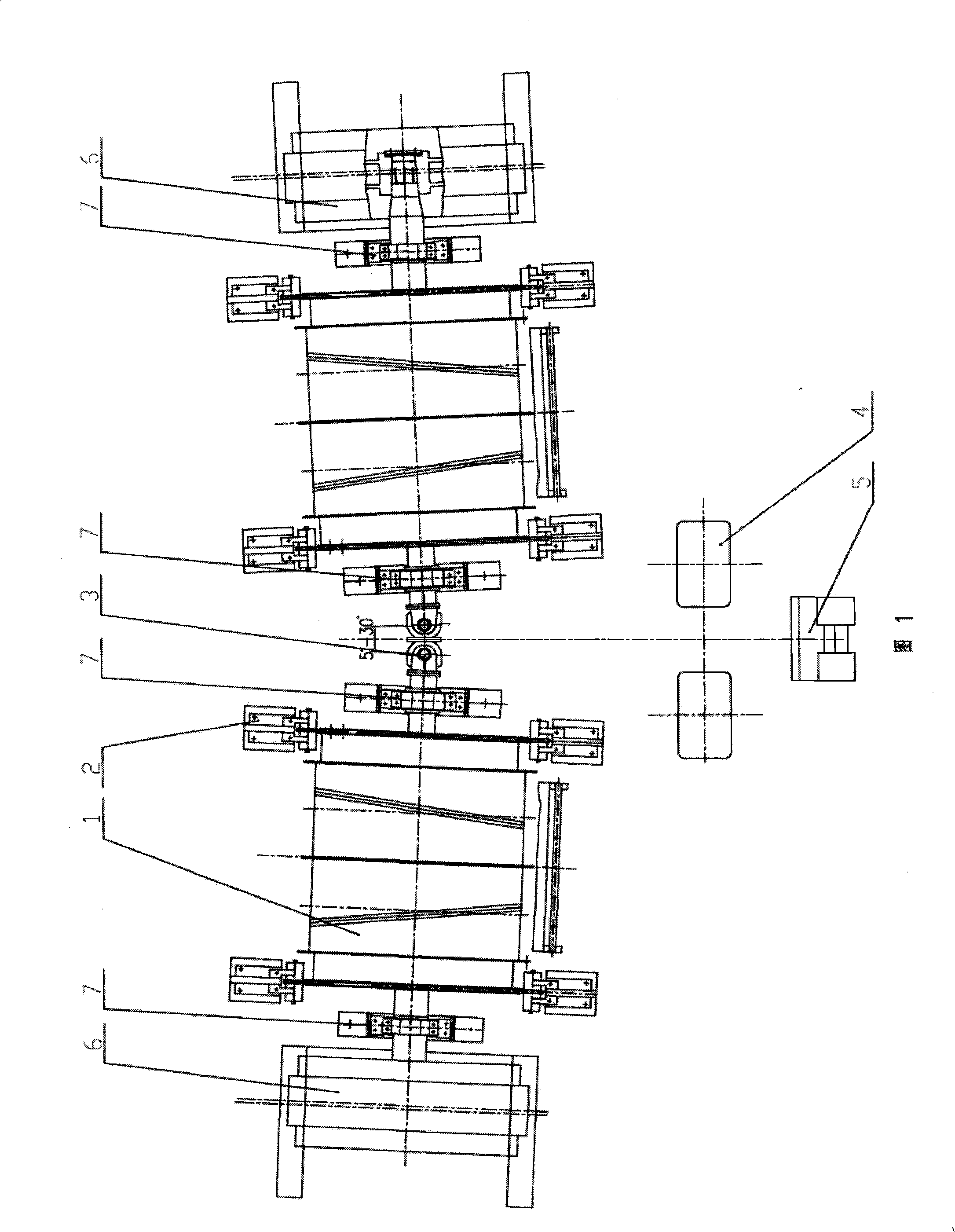

Double-cylinder articulated multi-rope winding type hoist

ActiveCN101407299ASmall diameterIncrease the lifting loadElevatorsMine liftsCouplingElectric machinery

The invention discloses a dual-drum articulated multirope winding hoisting machine, which mainly consists of a main shaft unit 1, a disc brake 2, a universal coupling 3, a hydraulic station 4, an operation desk 5 and motors 6. The main shaft unit is arranged on and respectively fixed with a bearing support 7, and articulated by the universal coupling, other ends thereof are linked with the motor for carrying out synchronous direct connection drag, the two ends of an assembled braking disc 1.1 are provided with the symmetrical disc brake, the hydraulic station is used for providing brake pressure, and the two motors and the hydraulic station are controlled by the operation desk. The main shaft unit consists of the assembled braking disc, a fixed wound roll 1.2, a plastic lining board 1.3, a rope-retaining board 1.4, the main shaft 1.5 of the fixed wound roll, a rope-adjusting clutch 1.6, a nomadic wound roll 1.7, a left hub 1.8, two halves of brasses 1.9, the main shaft 1.10 of the nomadic wound roll and a right hub 1.11, wherein, the main shafts of the fixed wound roll and the nomadic wound roll are not in the same center line and have an included angle of 5 to 10 degrees. When in working, a container is lifted by two cable wires, thus effectively meeting the lifting needs.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Method for determining fuel blend in a dual fuel mixture

ActiveUS20160047325A1Optimal engine operationGuaranteed uptimeElectrical controlInternal combustion piston enginesInternal combustion engineSystem identification

A method is provided for determining fuel blend in a dual fuel mixture including a first and a second fuel in an internal combustion engine. The method includes the steps of measuring multiple engine parameters using sensors during transient cycle operation for a predetermined range of engine loads and fuel blends; using system identification of transient time series of the measurements to determine one or more relevant engine parameters; determining a model for estimation of the fuel blend based on said one or more engine parameters; using the model fur determining a current fuel blend during transient operation using current measured values of the one or more engine parameters, and using the calculated current fuel blend for controlling the amount of dual fuel mixture injected into each cylinder of the internal combustion engine. A vehicle and a computer program product using the method are also provided.

Owner:VOLVO LASTVAGNAR AB

Drive Control System In Series-Hybrid Vehicle

ActiveUS20130173098A1Reduce motor powerAvoid dischargeDigital data processing detailsPlural diverse prime-mover propulsion mountingElectric power systemElectrical battery

A drive control system in a series-hybrid utility vehicle comprises a motor for driving a wheel; a battery; an engine electric generator for generating the electric power charged into the battery; and a controller configured to estimate an SOC value of the battery, and control the motor and the engine electric generator in accordance with an HV mode or an EV mode; wherein when the estimated SOC value is less than a predetermined low threshold, the controller stops electric power supply from the battery to the motor; and when the estimated SOC value is less than a predetermined medium threshold greater than the predetermined low threshold, the controller sets the HV mode, and controls the motor and the engine electric generator such that a driving power of the motor is suppressed in a state where the motor is supplied with the electric power from the battery.

Owner:KAWASAKI MOTORS LTD

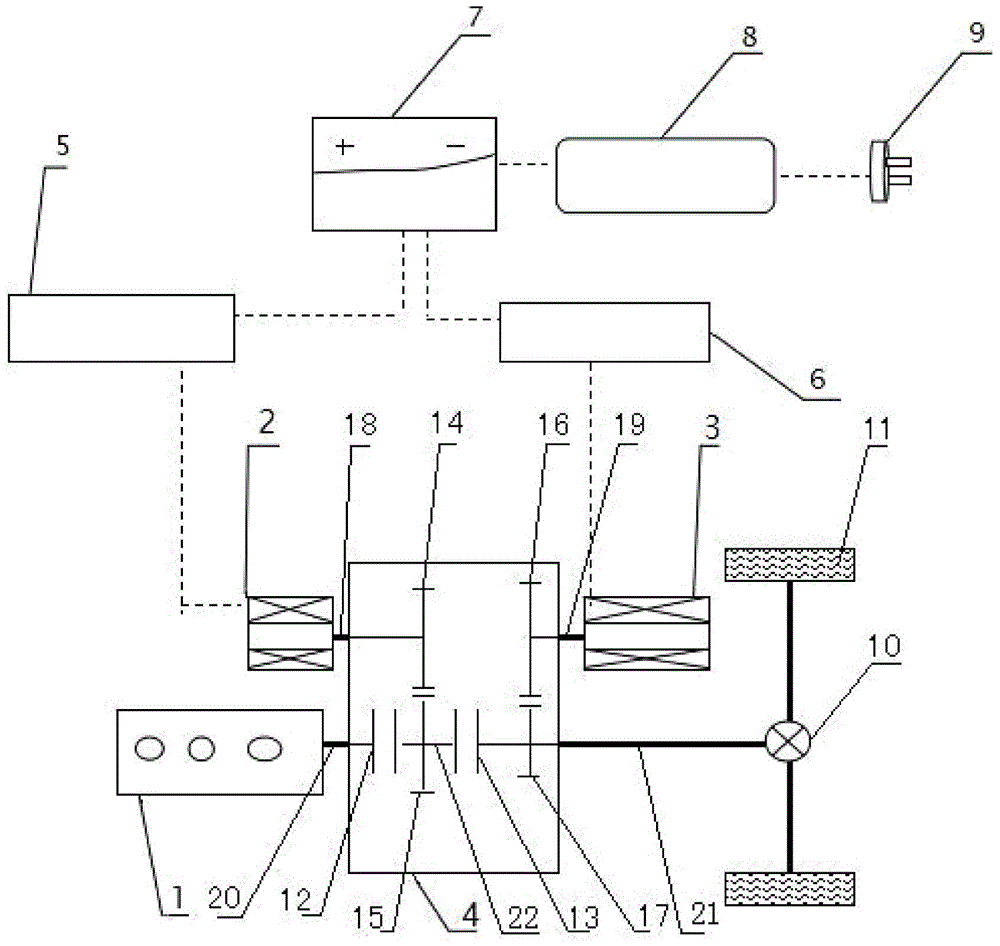

Multi-power input hybrid power driving device

InactiveCN104786820ASimple structureSmall footprintGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingElectric machineDrive motor

The invention relates to a multi-power input hybrid power driving device, and belongs to the technical field of hybrid electric vehicles. The multi-power input hybrid power driving device comprises a first input shaft, a second input shaft, a third input shaft, an intermediate shaft, an output shaft, an engine, an electric generator and a drive motor; the power output end of the engine is connected with the third input shaft, the power output end of the electric generator is connected with the first input shaft, and the power output end of the drive motor is connected with the second input shaft; the first input shaft is provided with a first driving gear, the second input shaft is provided with a second driving gear, the intermediate shaft is provided with a first driven gear, the output shaft is provided with a second driven gear, the first driving gear is meshed with the first driven gear, and the second driving gear is meshed with the second driven gear; a clutch is arranged between the third input shaft and the intermediate shaft, and a power interruption device is arranged between the intermediate shaft and the output shaft. The multi-power input hybrid power driving device can achieve multiple driving modes, and the control is easy.

Owner:DONGFENG MOTOR CORP HUBEI

Method for preparing high-quality melt through alcoholysis of waste polyester textile with ethylene glycol

InactiveCN106279757ARapid alcoholysisHigh intrinsic viscosityArtificial thread manufacturing machinesPlastic recyclingPolyesterPolymer science

The invention relates to a waste polyester high-value circulation reuse technique, and in particular to a method for preparing a high-quality melt through alcoholysis of a waste polyester textile with ethylene glycol. The method for preparing the high-quality melt through alcoholysis of the waste polyester textile with ethylene glycol comprises the following steps: adding ethylene glycol which accounts for 1-8% of the mass of a raw material into a screw extruder for mixing melt extrusion, and feeding the material into a hardening and tempering device, wherein the melt viscosity of the melt extruded from the screw extruder is 0.40-0.50dl / g; the melt viscosity of the melt discharged from the hardening and tempering device is 0.620-0.685dl / g. Due to adoption of a proper amount of the ethylene glycol, the melt viscosity can be improved, meanwhile, the problems that a filter is short in cycle and a vacuum system is large in maintenance workload can be effectively solved, the production cost can be lowered, and meanwhile, the additional value of a product can be increased.

Owner:NINGBO DAFA CHEM FIBER

High-power direct current engine comprising a collector and carbon brushes for a racing car serving as prototype

InactiveUS7218027B2Reduce motor powerReduce total powerRotary current collectorToysEngineeringMechanical engineering

A DC motor includes a rotor which is mounted in a housing so that it can rotate about an axis. The rotor includes at least one winding to which direct current is applied from the outside in alternating directions via a commutator, which is arranged on the rotor. Brushes are seated on the commutator and are mounted whereupon they can move relative to the commutator while being pushed by spring pressure onto the commutator.

Owner:TEAM ORION EURO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com