Electric lifting table with spring balanced design

A spring balance, lifting platform technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of wasting energy, reducing system efficiency, and the inability to realize the lifting platform of the counterweight system, so as to improve the overall efficiency and reduce the motor power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific drawings and embodiments.

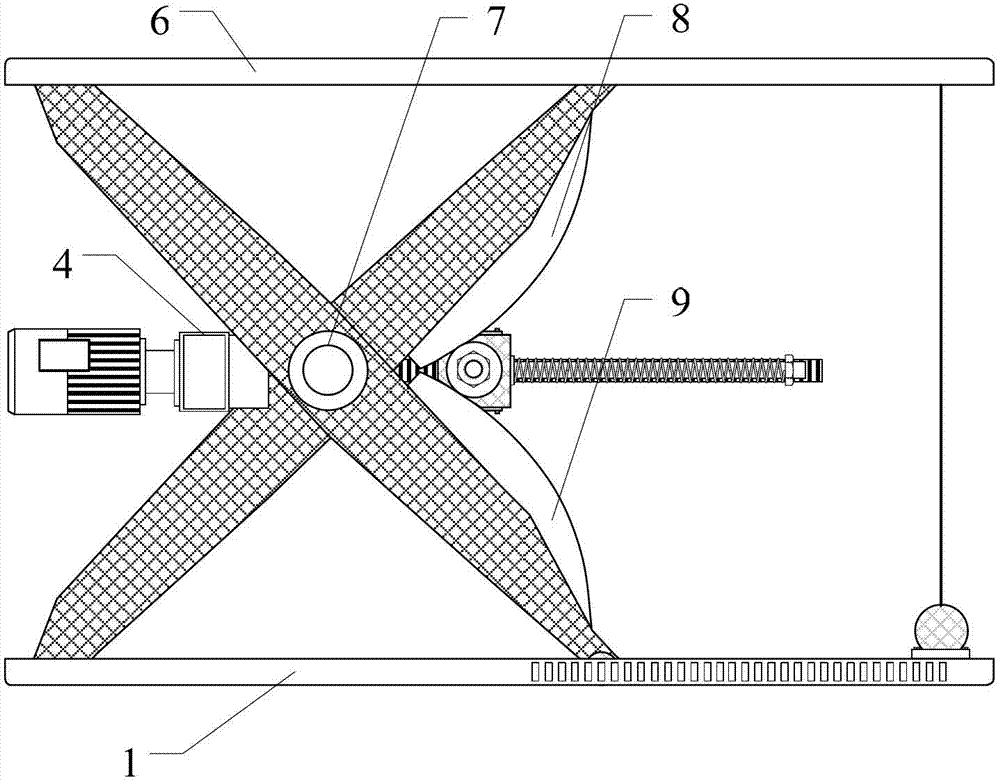

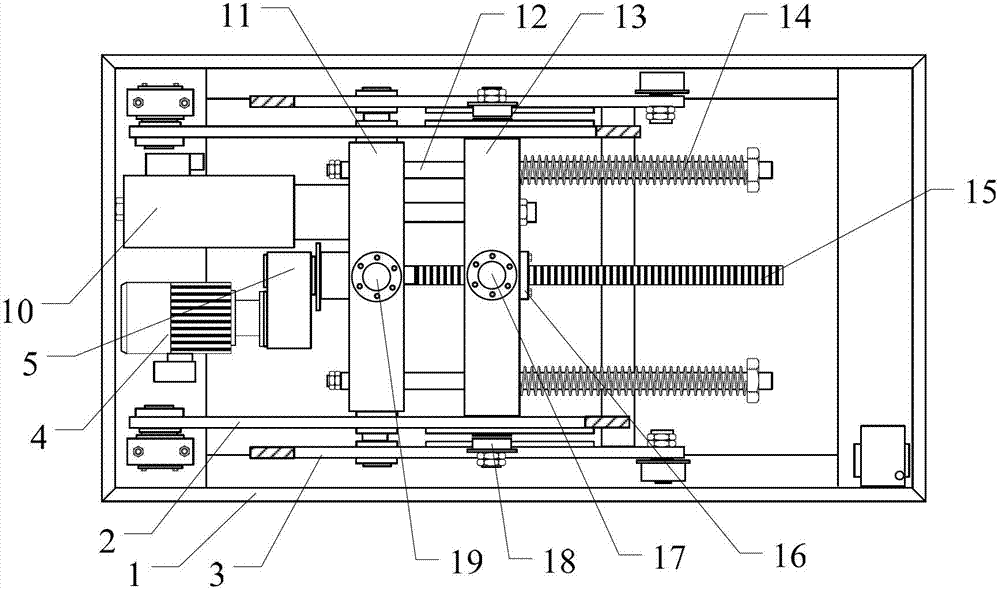

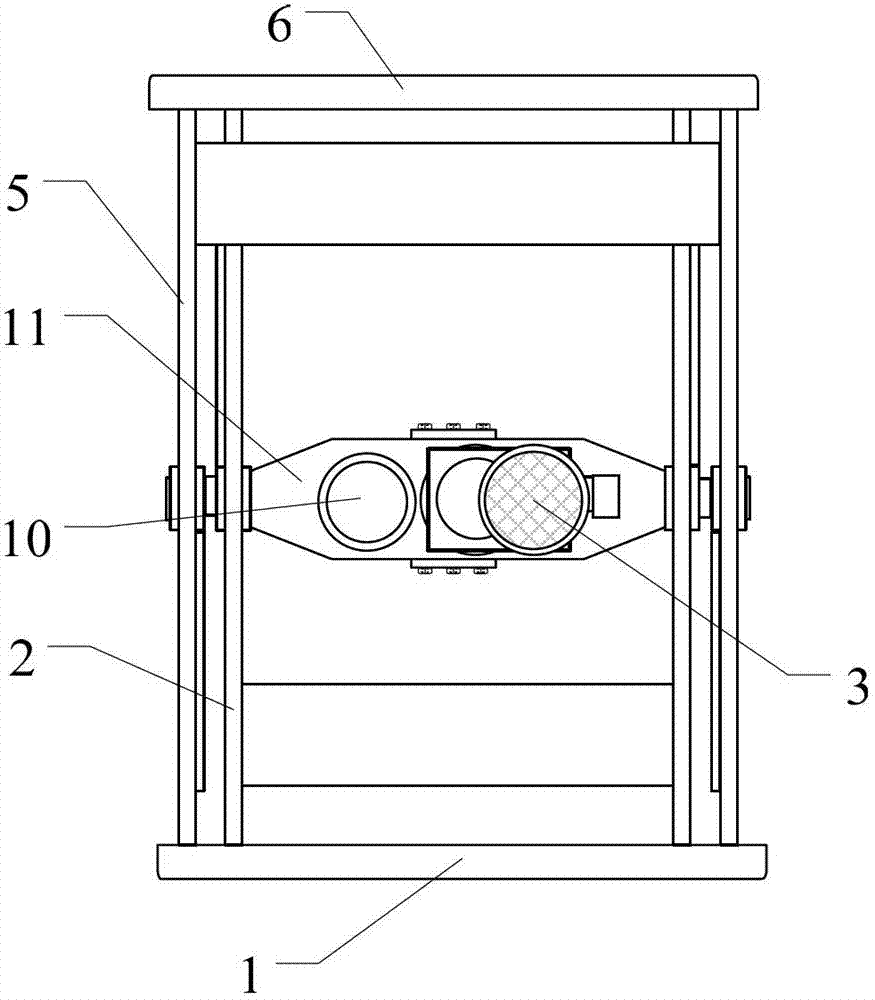

[0014] Such as Figure 1~Figure 3 As shown, the electric lifting platform of the present invention is mainly composed of a base 1, an upper table 6, a scissors mechanism, a screw drive mechanism and a supporting electric control system; the scissors mechanism has two groups, and the two groups of scissors mechanisms Symmetrically arranged on both sides of the electric lifting platform; each set of scissors mechanism is composed of an inner scissors arm 2 and an outer scissors arm 5, and the inner scissors arm 2 and the outer scissors arm 5 are mutually connected by a pin 7 in the middle. Hinged: the lower end of the inner scissor arm 2 is hinged with the base 1, the upper end of the inner scissor arm 2 is supported on the upper table 6 by supporting wheels, and the upper cam plate 8 is installed above the hinge of the inner scissor arm 2; the outer scissor arm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com