Method for preparing high-quality melt through alcoholysis of waste polyester textile with ethylene glycol

A technology of waste polyester and ethylene glycol, which is used in the preparation of spinning solutions, textiles and papermaking, single-component polyester rayon, etc., can solve the problems of product quality impact, increased production cost, and limited viscosity increase. , to solve the easy blockage of the pipeline, improve the flow performance, and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

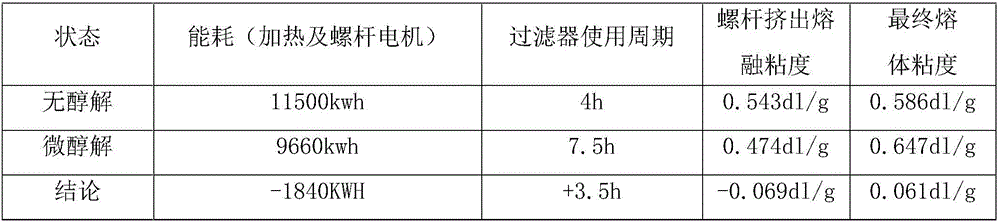

Embodiment 1

[0028] After compounding the foam material according to the impurity content, color, viscosity difference, etc., it is rotated and dried for 9 hours under a certain vacuum (≤-0.96MPa) and temperature (145°C±5°C), and finally 90PPm of water is put into the spinning silo. Adjust the speed of the ethylene glycol pump so that the mass fraction of ethylene glycol measured is 4% of the foam material, the feed rate of the screw is 1t / h, and the temperature from the first to the tenth zone of the screw is 280°C, 285°C, and 295°C in sequence , 295°C, 295°C, 290°C, 290°C, 285°C, 285°C, 285°C, the filter temperature is 285°C, and the residence time of the melt in the screw, filter and pipeline is 16min. It takes 75 minutes to enter the liquid-phase tempering and viscosity-adjusting device. The vacuum degree of the vertical kettle and the horizontal kettle are 200Pa~185Pa and 100Pa~60Pa respectively, and the temperature of the kettle is 285°C. Continuously run for 48 hours in the case of ...

Embodiment 2

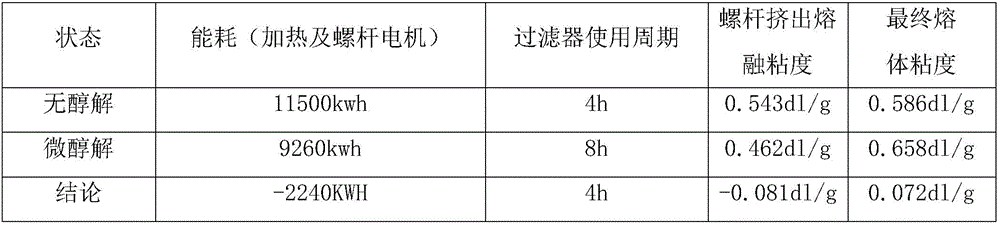

[0032]After compounding the foam material according to the impurity content, color, viscosity difference, etc., it is rotated and dried for 8.5 hours under a certain vacuum (≤-0.96MPa) and temperature (145°C±5°C), and 105PPm is put into the spinning silo. Adjust the speed of the ethylene glycol pump so that the mass fraction of ethylene glycol measured is 5% of the foam material, the feed rate of the screw is 0.8t / h, and the temperature from the first to the tenth area of the screw is 280°C, 285°C, and 295°C. ℃, 295℃, 295℃, 290℃, 290℃, 285℃, 280℃, 280℃, the filter temperature is 285℃, and the residence time of the melt in the screw, filter and pipeline is 20min. It takes 90 minutes to enter the liquid-phase tempering and viscosity-adjusting device. The vacuum degree of the vertical kettle and the horizontal kettle are 200Pa~185Pa and 100Pa~60Pa respectively, and the temperature of the kettle is 280°C. Continuously run for 48 hours under the condition of similar raw materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com