Vacuum freeze drier

A technology of freezing equipment and vacuum drying, which is applied in the direction of drying solid materials, lighting and heating equipment, and drying solid materials without heating. The effect of power drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

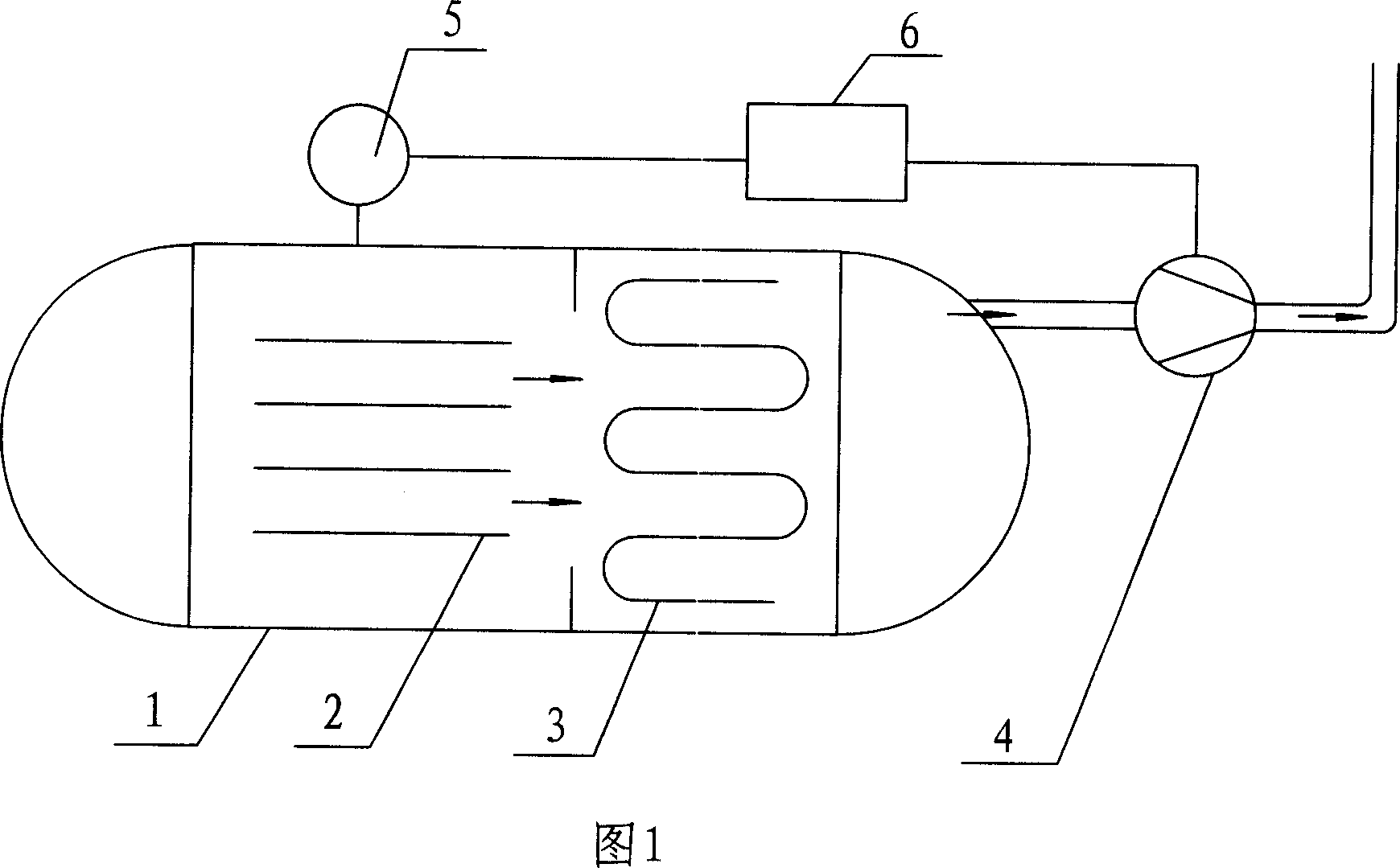

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0011] As shown in Figure 1, it includes a drying chamber body 1, a heating shelf 2 located in the drying chamber body, a water vapor condenser 3 for condensing sublimated water vapor in the heated material, and a vacuum sensor for inductive drying chamber body 1. A gauge 5, a vacuum pump 4 for vacuuming and a frequency converter 6 for receiving the signal output by the vacuum gauge and performing frequency conversion; the frequency converter is electrically connected to the vacuum pump 4. The steam condenser 3 can be placed in the drying chamber body 1, or can be set separately. Adopt one vacuum pump 4 in the present embodiment, it also can be to adopt multiple vacuum pump groups.

[0012] When working, when the frozen material is put into the drying chamber 1, the vacuum pump 4 is started to vacuumize the drying chamber 1. When the vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com