Double-cylinder articulated multi-rope winding type hoist

A hoist and articulated technology, applied in elevators, lifting equipment in mines, transportation and packaging, etc., can solve the problems of inconvenient manufacture and use of large-diameter steel wire ropes, increase mine construction costs, and increase the width of shafts, etc. The driving effect is safe and reliable, reducing the cost of mine construction and increasing the effect of lifting load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

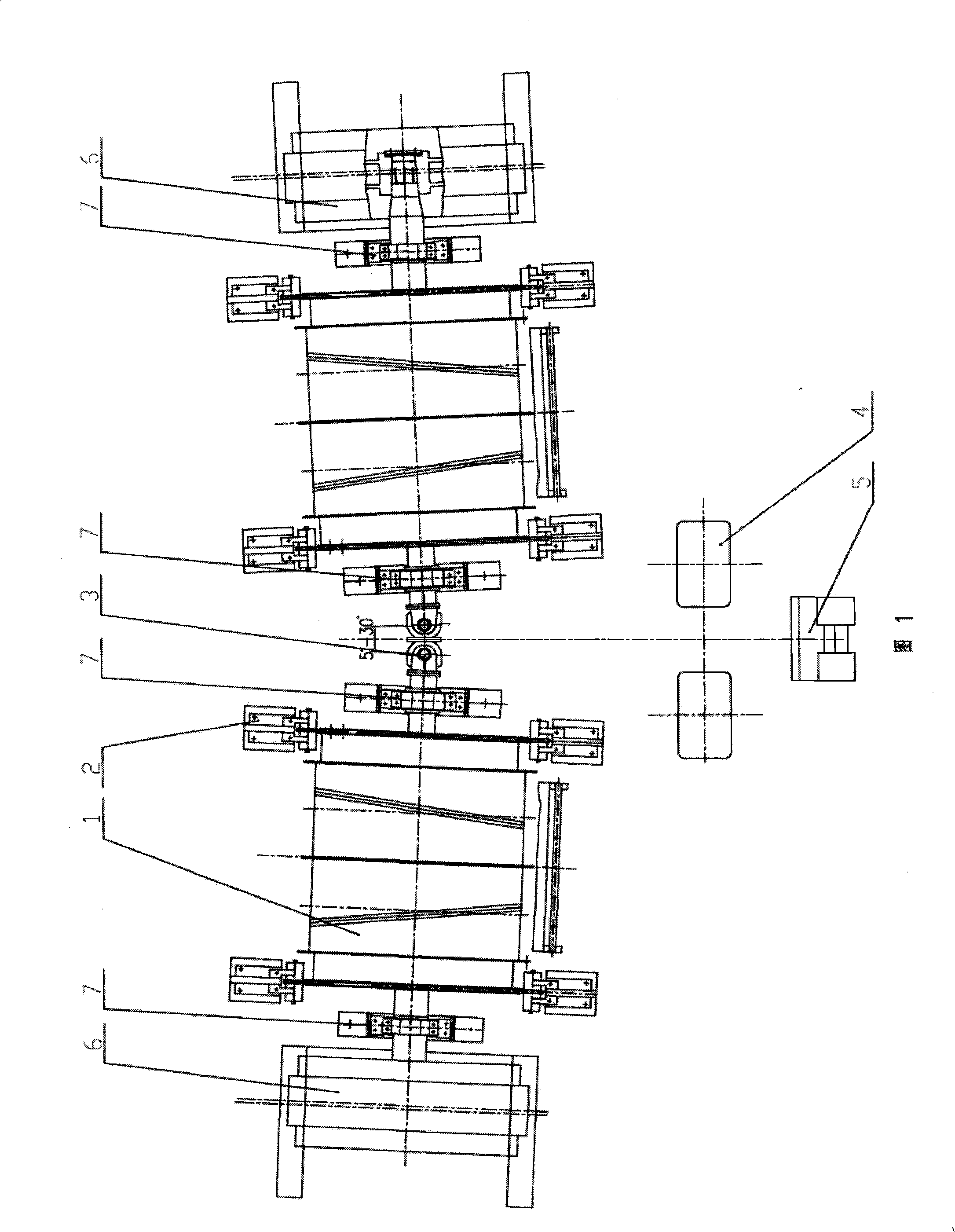

[0030] As shown in Figure 1: the double-barrel articulated multi-rope winding hoist of the present invention is mainly composed of a main shaft device (1), a disc brake (2), a universal coupling (3), a hydraulic station (4), an operating It consists of a table (5) and a motor (6). The main shaft device (1) is installed on four rolling bearing housings (7) and respectively fixed. The main shaft device (1) is hinged by a universal coupling (3) and the other It is connected with the motor (6) for synchronous direct drive. Both ends of the assembled brake disc (1.1) of the main shaft device (1) are equipped with symmetrical disc brakes (2), and the disc brakes (2) are controlled by the hydraulic station. (4) Braking pressure is provided, and the operation commands of the two motors (6) and the hydraulic station (4) are controlled by the console (5).

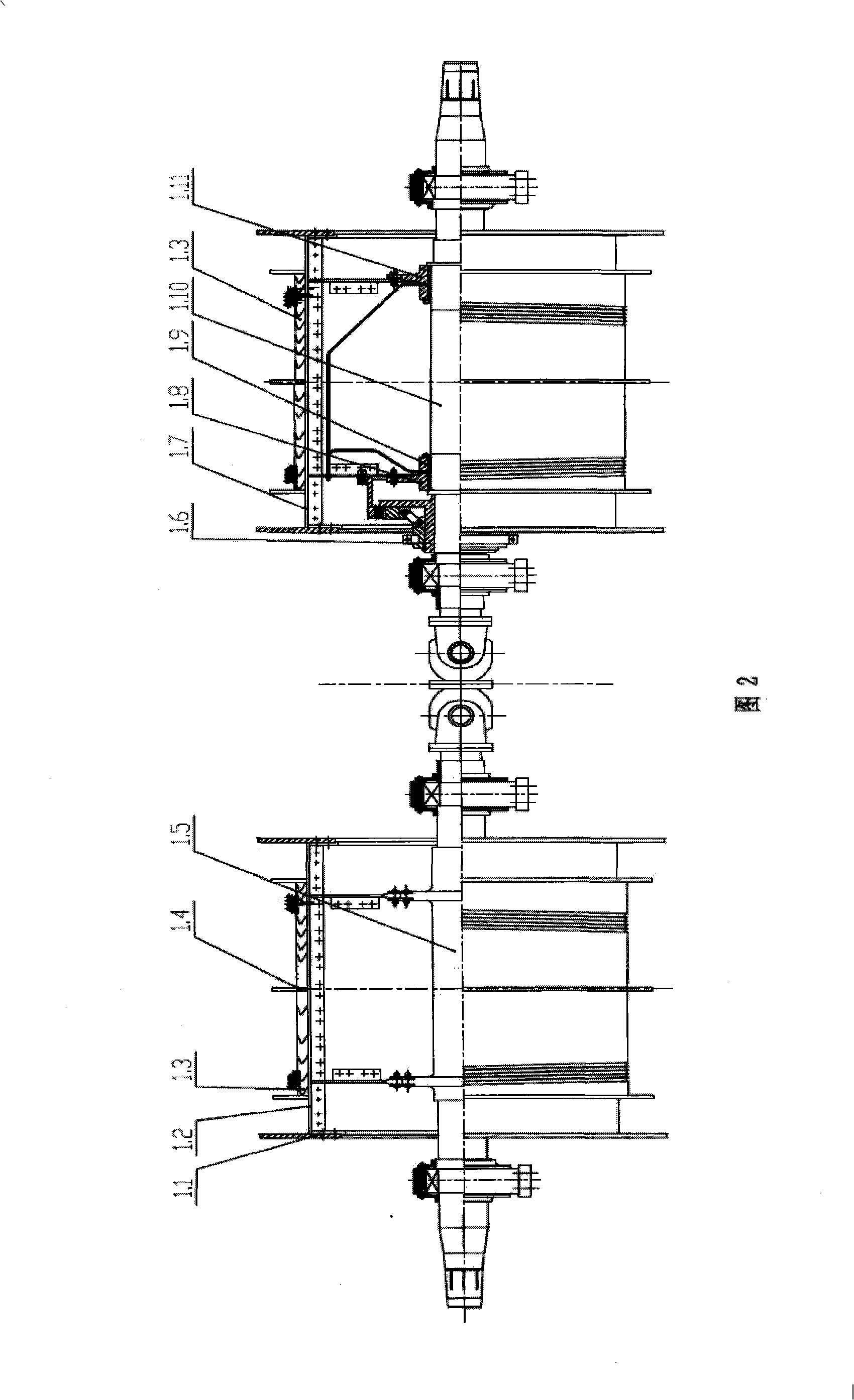

[0031] In the double-tube articulated multi-rope winding hoist of the present invention, the main shaft device (1) consists of an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com