Patents

Literature

79results about How to "Reduce eddy current noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Axial flow rotor blade

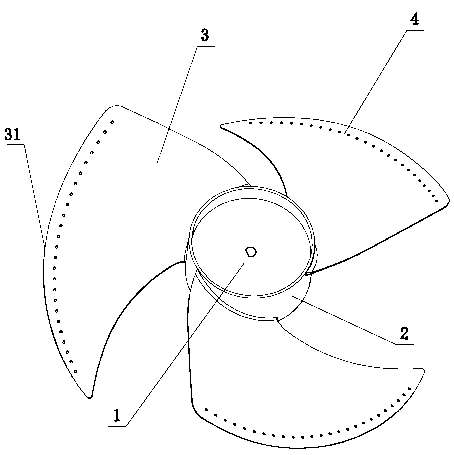

The invention discloses an axial flow rotor blade. The axial flow rotor blade comprises at least two vanes (3) arranged on a hub (2), wherein each vane (3) is provided with a hole area with a plurality of through holes (4). The vanes (3) are distributed on the hub (2) by taking a rotation central axis as a center at equal or unequal intervals; and the area of a vane outer edge (31) of each vane (3) is the hole area. When the axial flow rotor blade rotates, the hole structure of the adjacent area of each vane outer edge ensures that air on the pressure surface of each vane flows into a suction surface through the through holes, so that kinetic energy of air on the suction surface of each vane is increased, and the growth of a boundary layer is inhibited; eddy noise is effectively reduced, and the voice is more soft and comfortable; and meanwhile, by the hole structure of the adjacent area of each vane outer edge, the weight of the rotor blade and the load of a motor are reduced, and the cost of the rotor blade and the powder of the motor are reduced. The axial flow rotor blade is particularly suitable for an air conditioner outdoor unit.

Owner:MIDEA GRP CO LTD

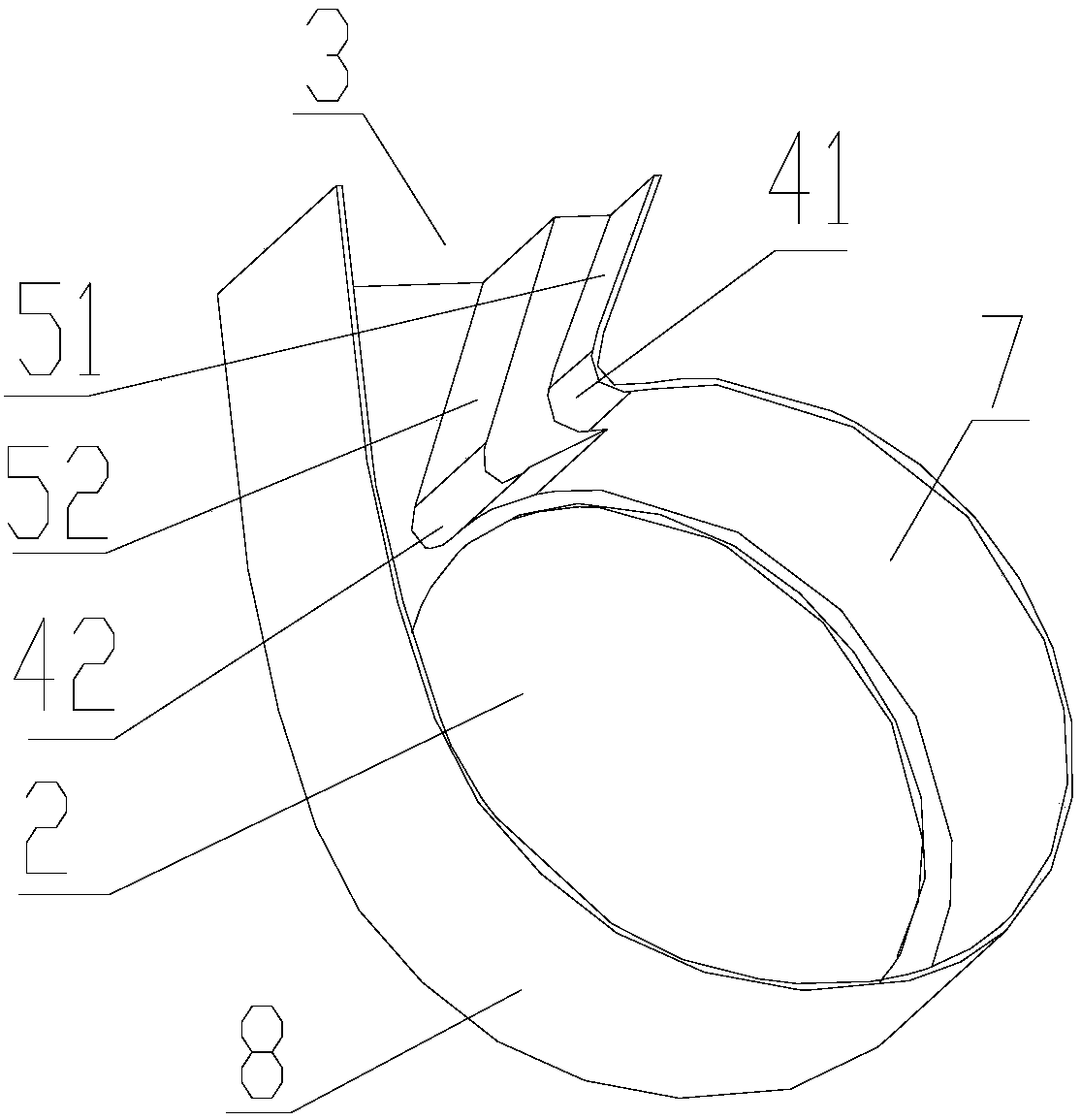

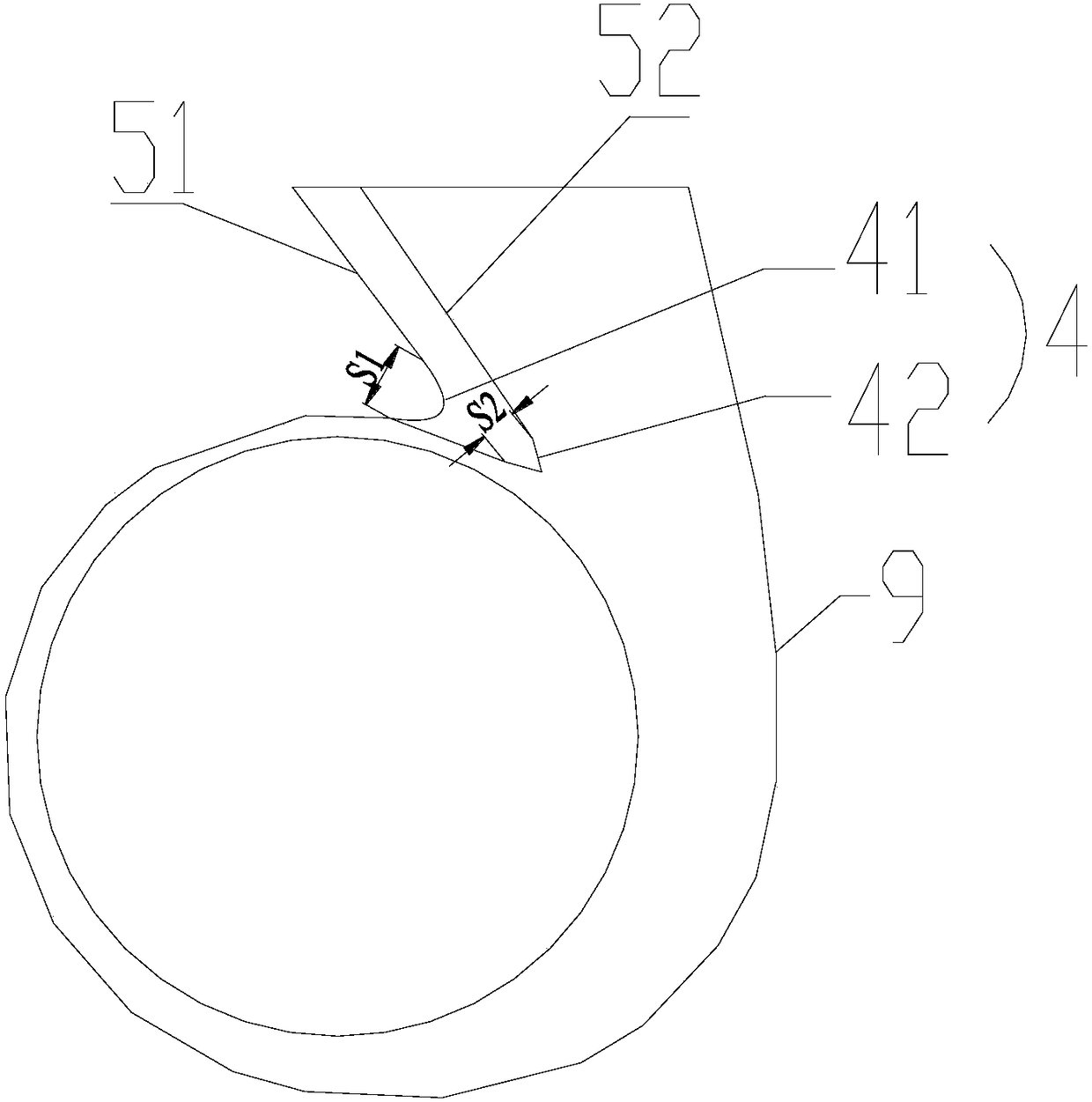

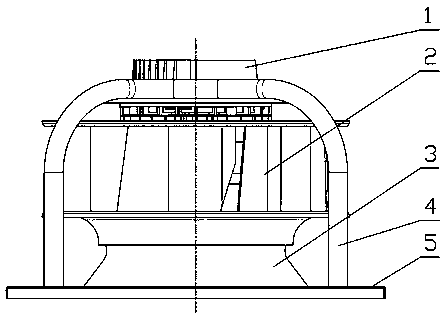

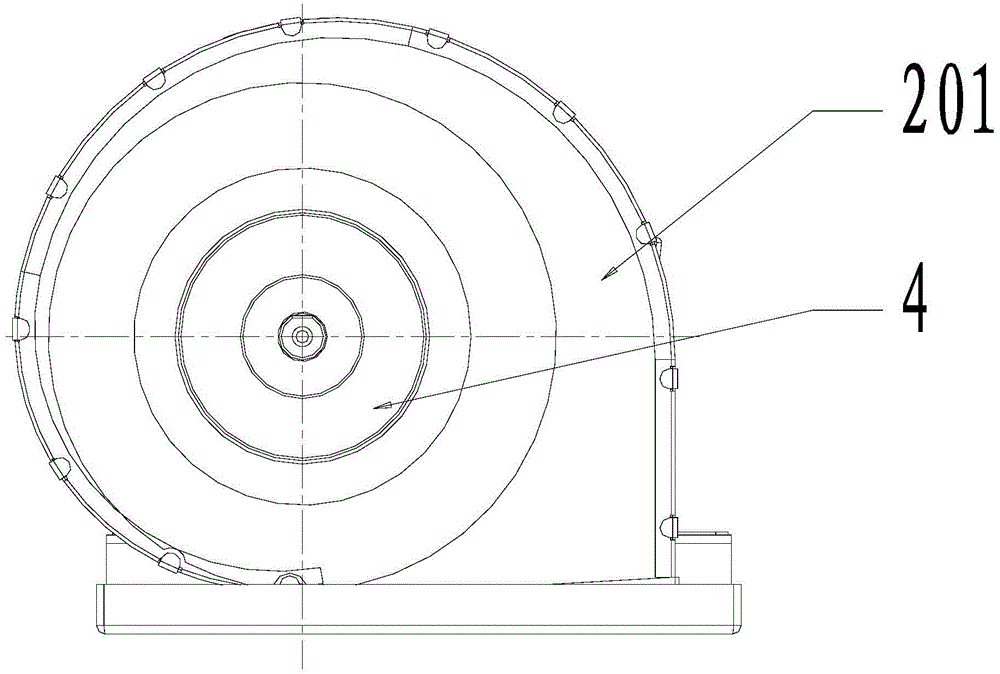

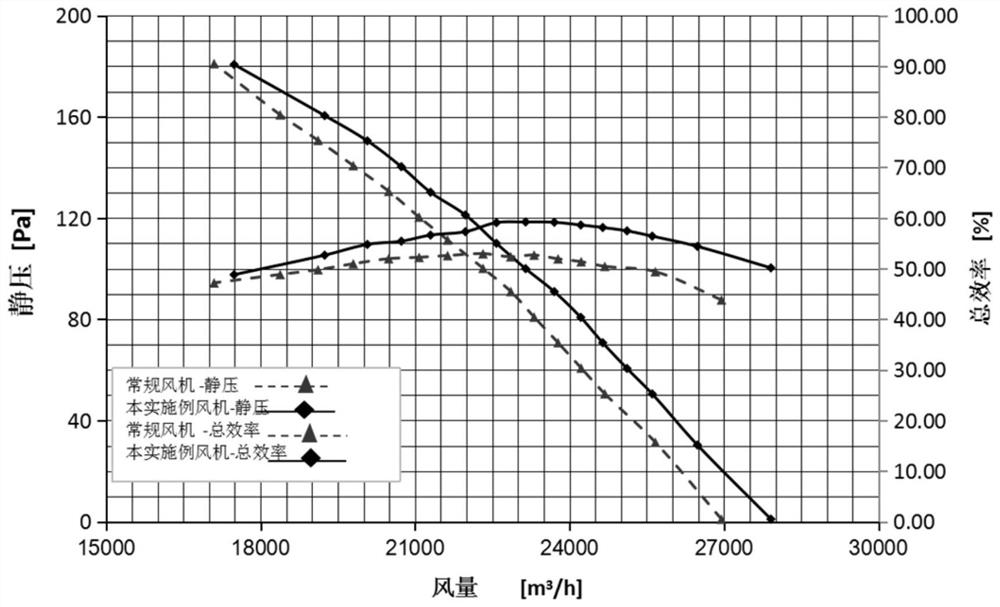

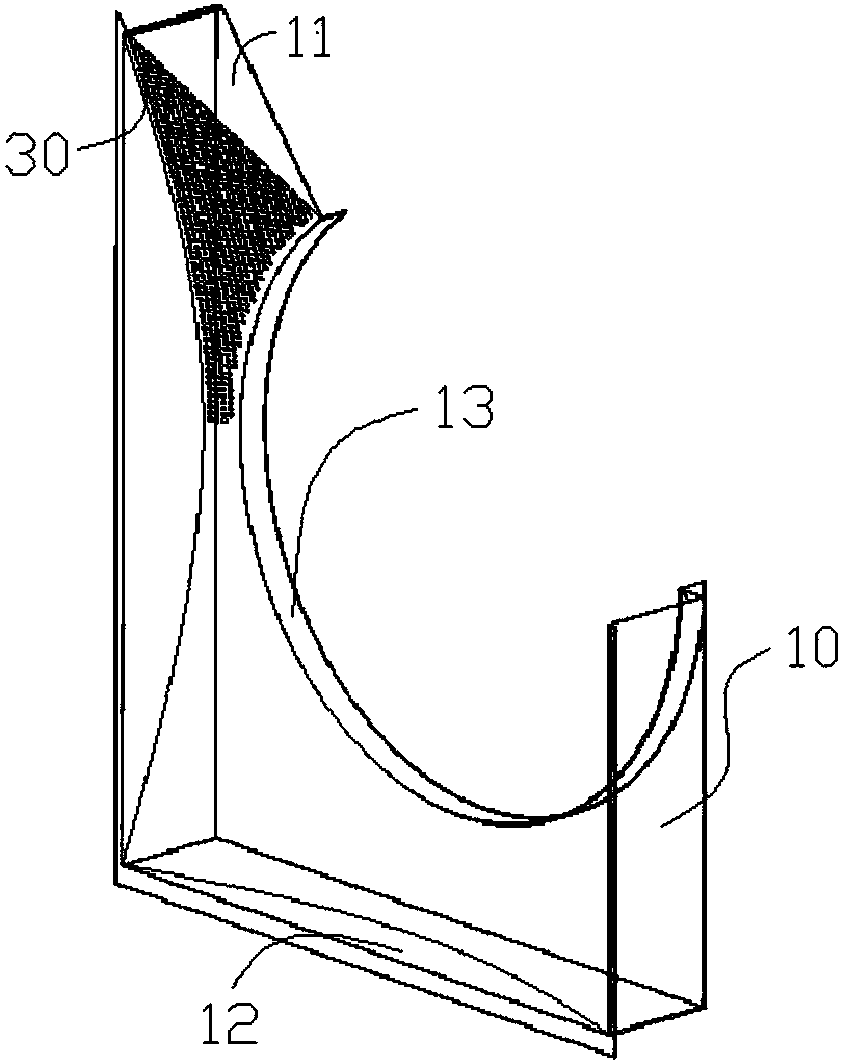

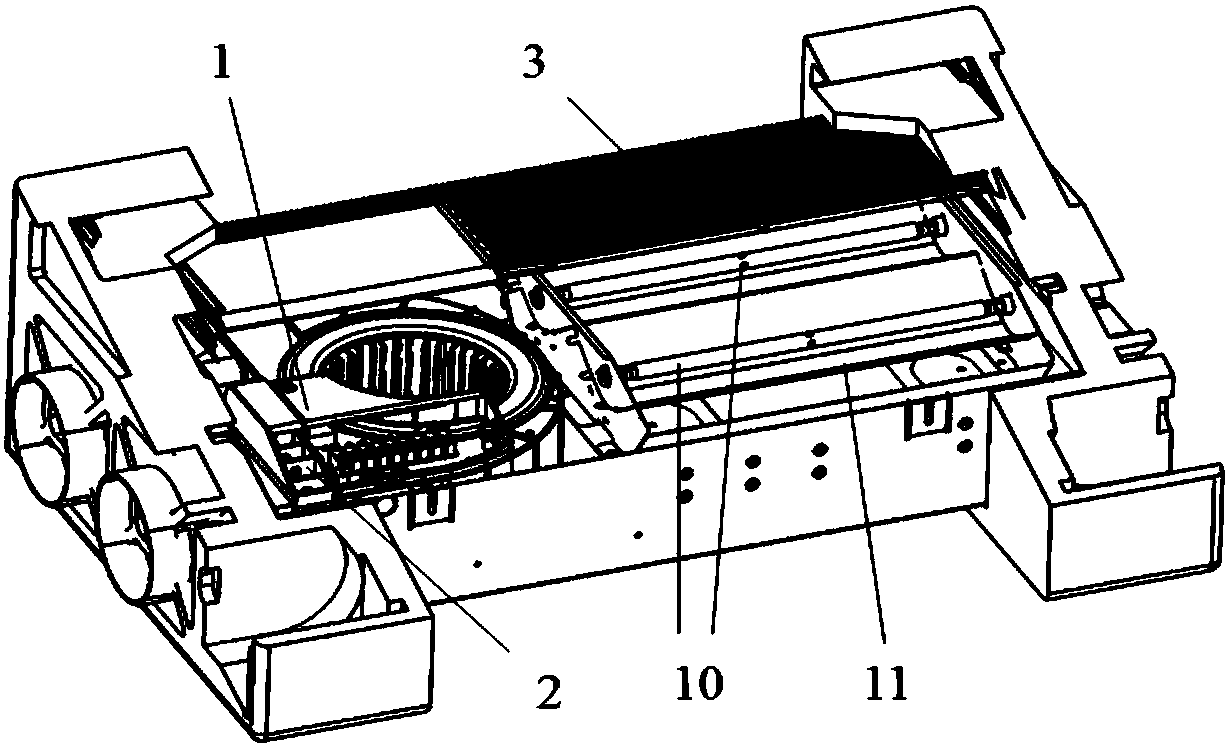

Stepped volute structure, centrifugal fan and air blowing device

PendingCN108443226AEfficient separationReduce eddy current noisePump componentsPumpsAir volumeEddy current

The invention provides a stepped volute structure, a centrifugal fan and an air blowing device. In the stepped volute structure, a plurality of volute tongues and volute volute-tongue side wall surfaces are arranged in a stepped mode and extend in the thickness direction from an air inlet to a shell. The distances from the volute volute-tongue side wall surfaces to a front blade disc are graduallyincreased, so that on the height volute section nearby the front blade disc, the overall width of a volute diffusion section is reduced, namely the volute tongues and the volute volute-tongue side wall surfaces are closer to a volute throat side wall surface. Since high-speed airflow impact is close to the volute-tongue side wall surfaces, the situation that a negative pressure area is generatedlike a traditional centrifugal volute is avoided, generation of whirling airflow is restrained, and thus an eddy current whirling area of a diffusion section of the traditional centrifugal volute is eliminated. After the whirling airflow area on the height volute section nearby the front blade disc is cut off, the disturbance of the whirling airflow on normal acting and air exhausting of the volute is eliminated, and thus the air volume is increased; and meanwhile eddy current noise disappears accordingly, and thus noise is reduced.

Owner:GREE ELECTRIC APPLIANCES INC

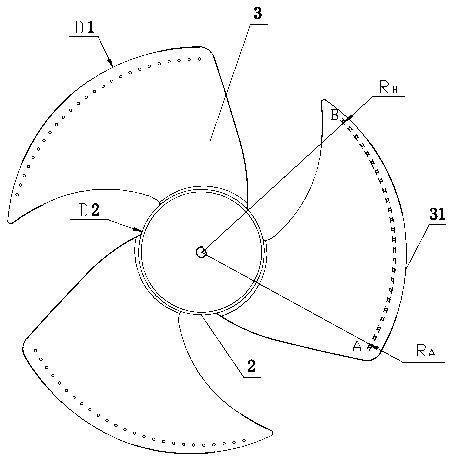

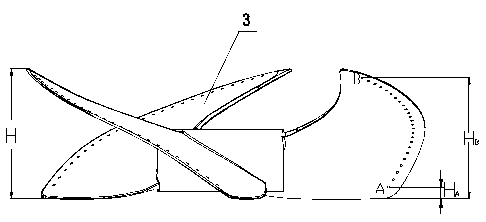

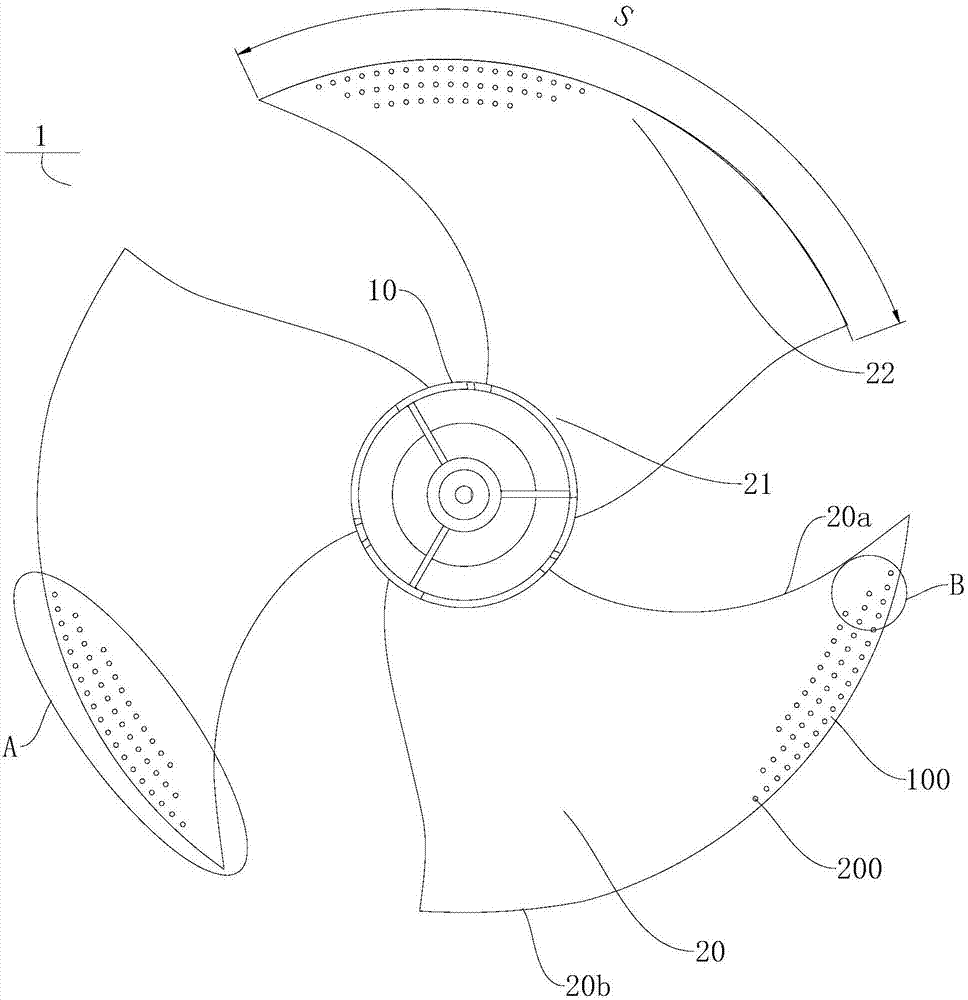

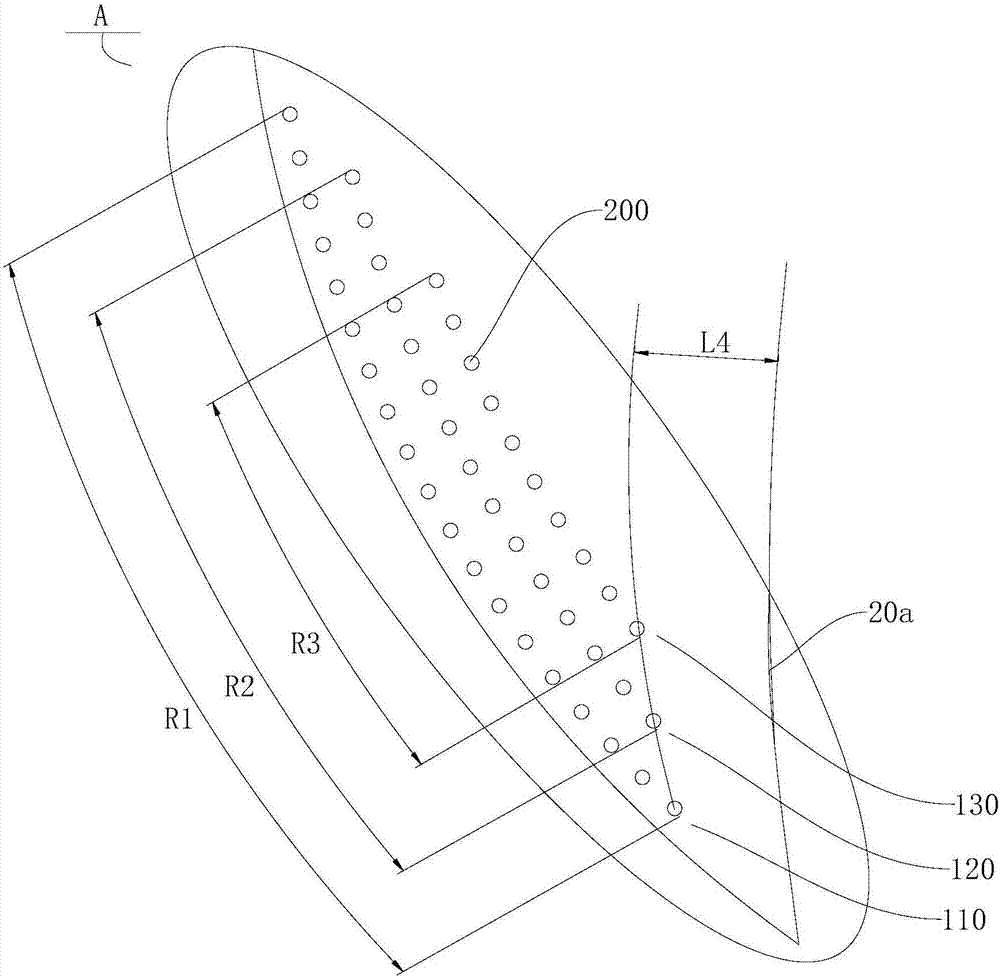

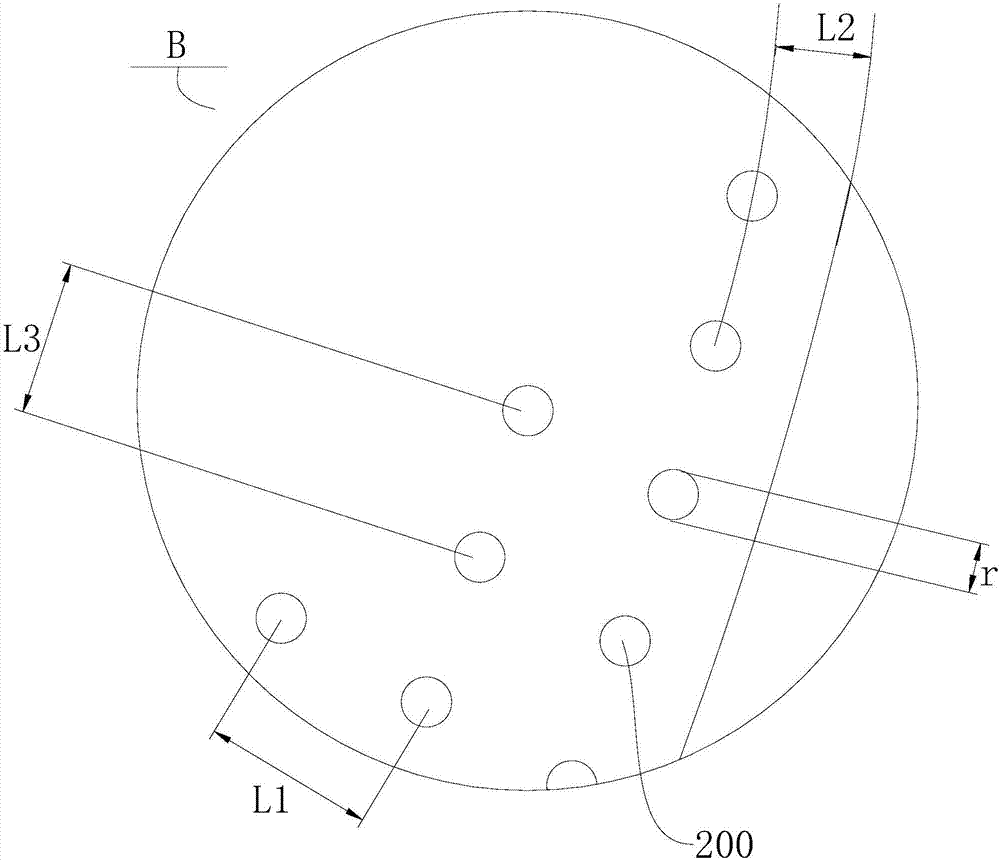

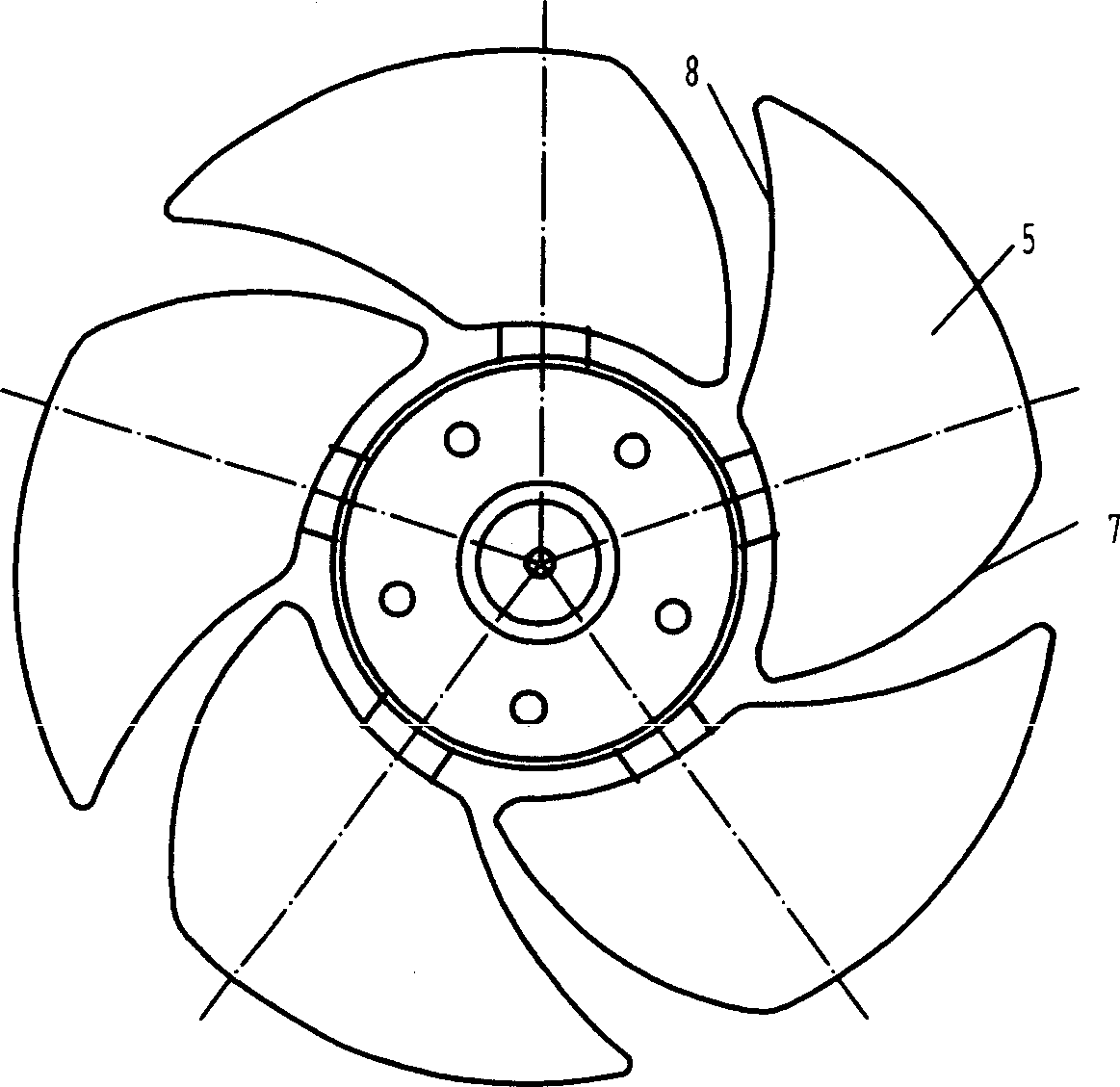

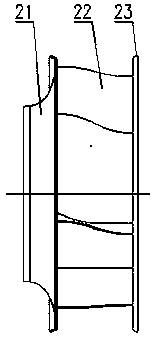

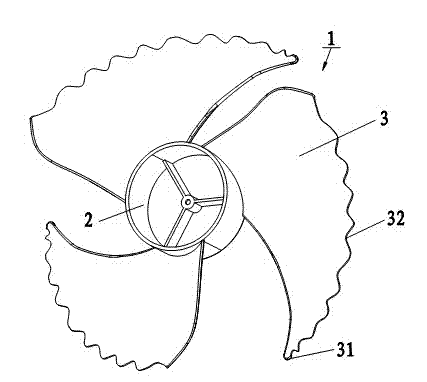

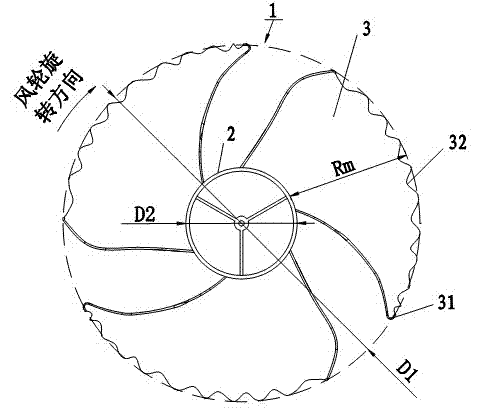

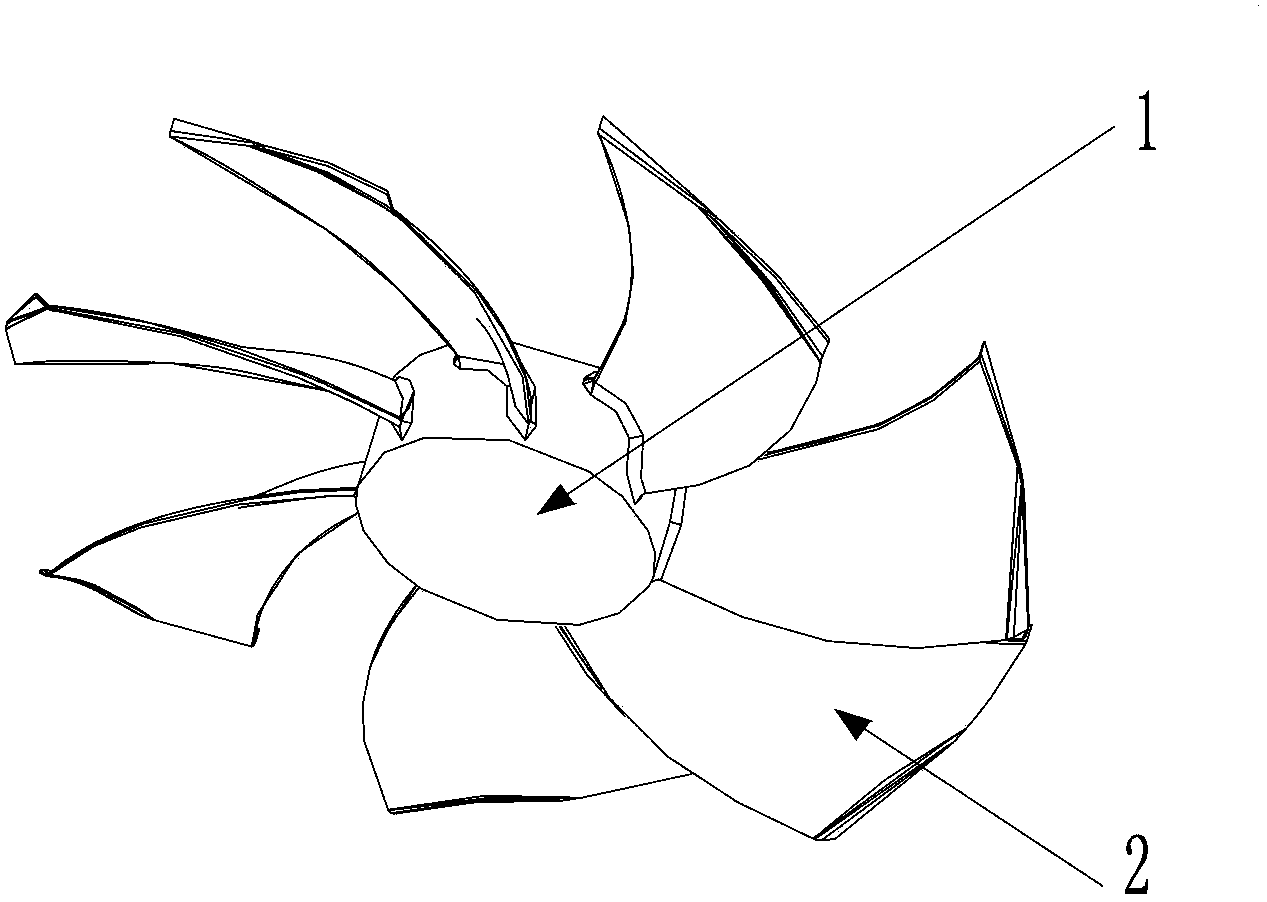

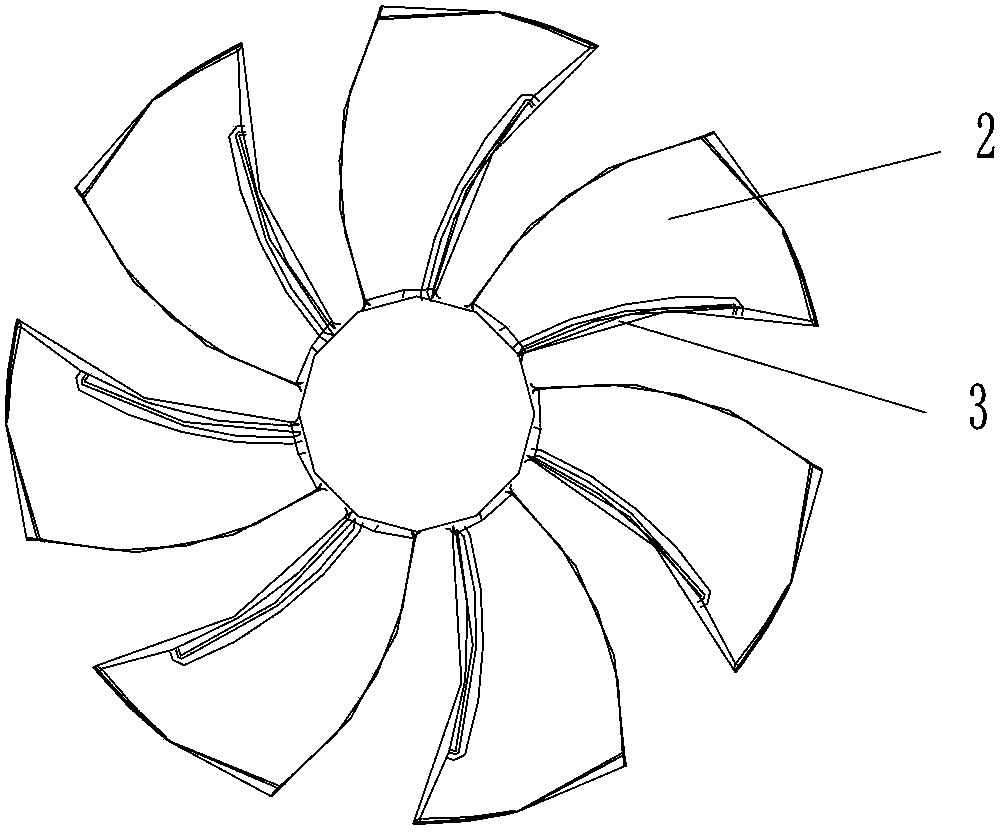

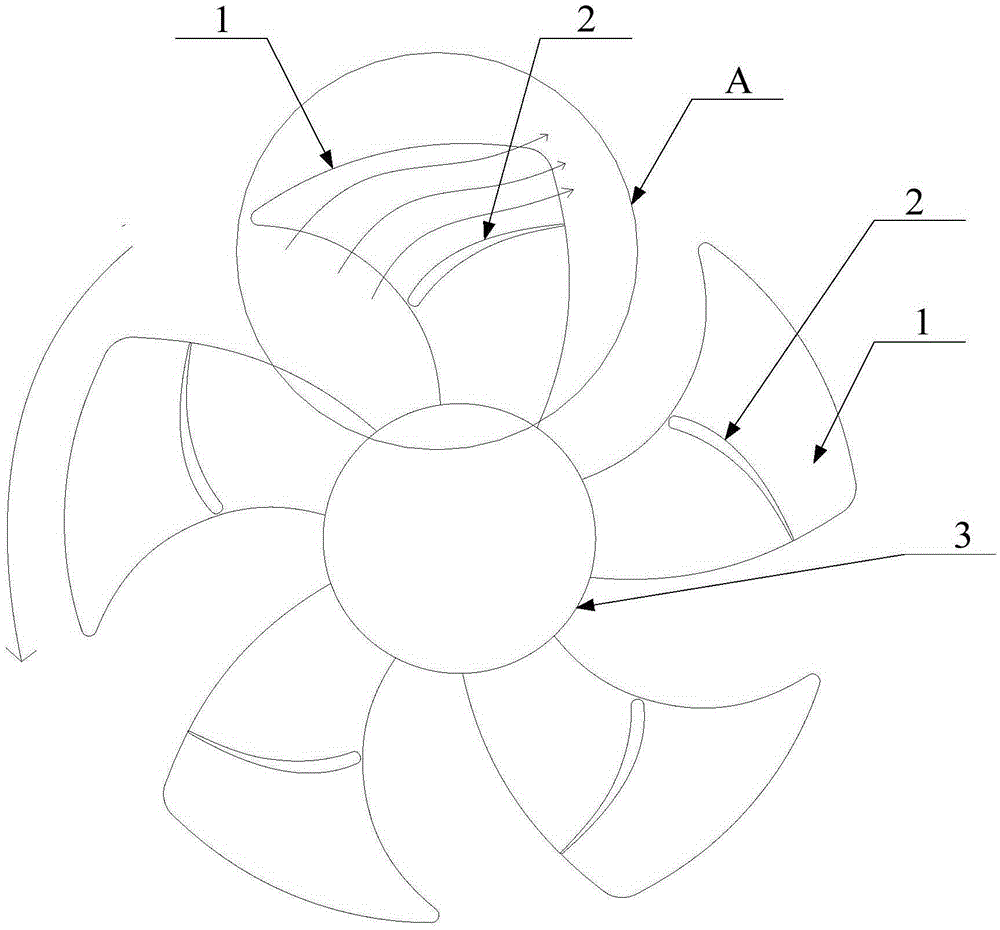

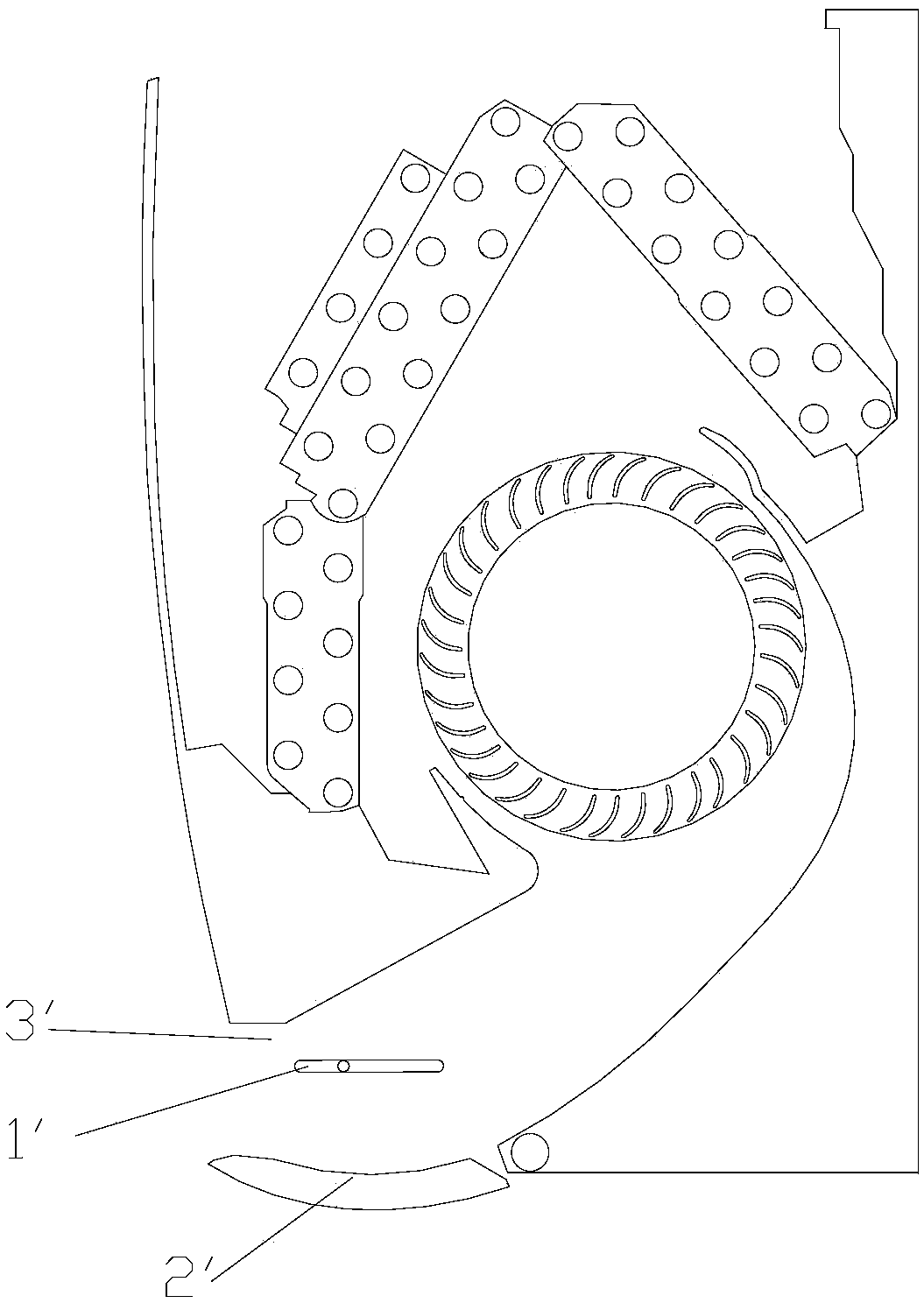

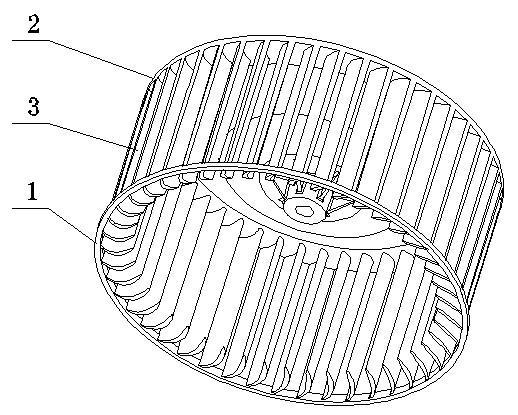

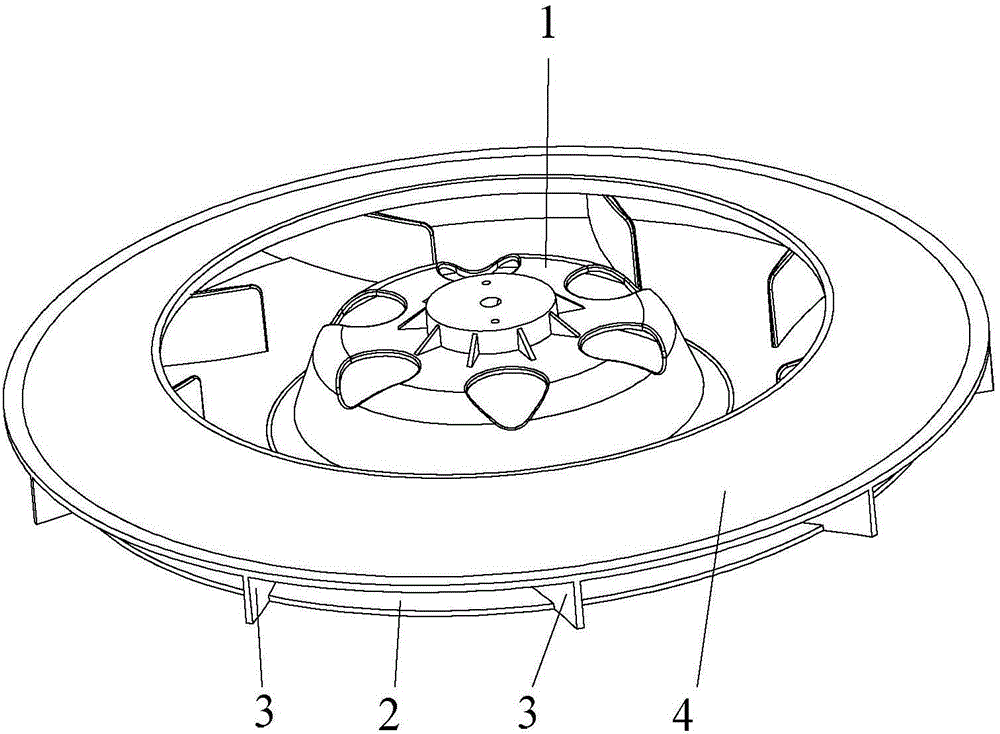

An axial flow wind wheel and an air conditioner with the same

ActiveCN107313979AReduce eddy current noiseReduce blade weightPump componentsPumpsAirflowEngineering

The invention provides an axial flow wind wheel and an air conditioner with the same. The axial flow wind wheel comprises a hub and a plurality of blades distributed in the circumferential direction of the hub in a spaced manner; each blade is connected with the hub; the position close to the outer edge of each blade is provided with multiple hole groups, which are distributed in the radial direction of the hub in a spaced manner; each hole group comprises a plurality of mutually-spaced through holes; the through holes are arranged in the circumferential direction of the hub. The axial flow wind wheel has the advantages that the outer edge positions of the blades are provided with the multiple hole groups, so that part of air flow of a pressure surface of each blade can flow to a suction surface via the hole groups directly, air flow flowing from the outer edge of the pressure surface of each blade to the suction surface is reduced, leaking vortexes generated at the outer edges of the suction surfaces can be reduced and eddy current noise of the axial flow wind wheel can be reduced; with the hole groups, the weight of the blades can be reduced, so that the front edge resistance of the blades can be reduced and the motor power of an air conditioner can be reduced.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

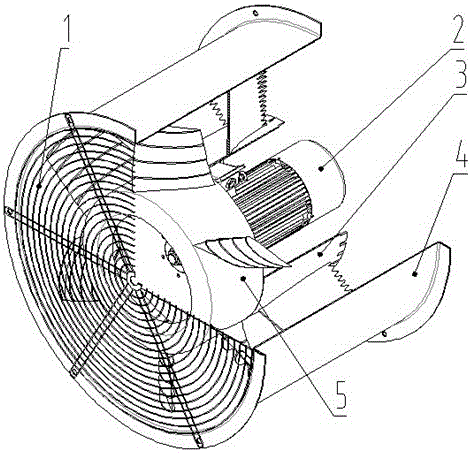

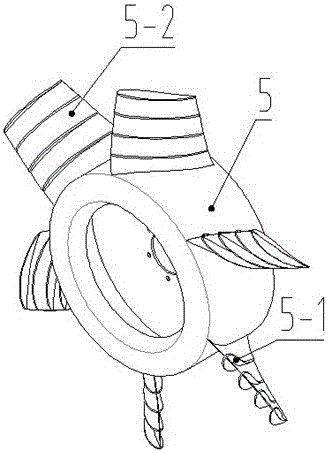

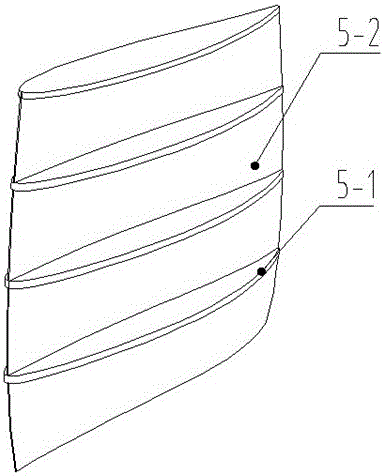

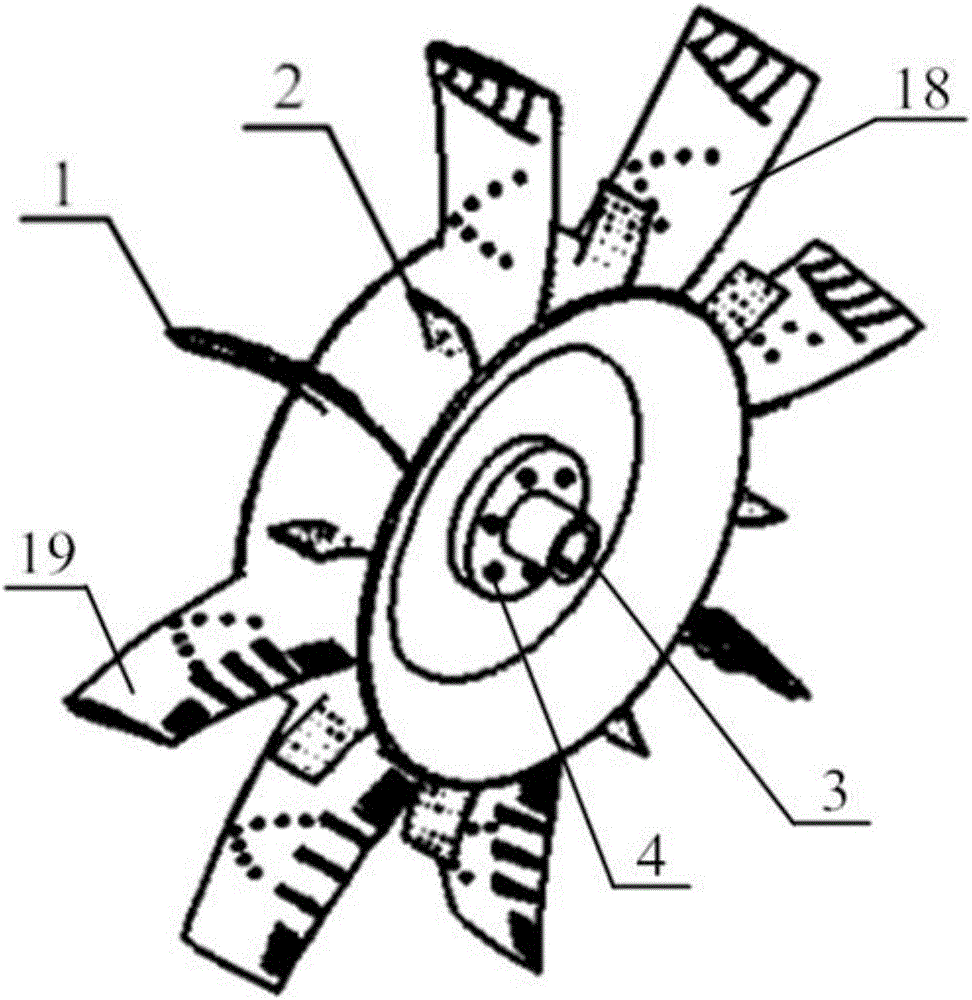

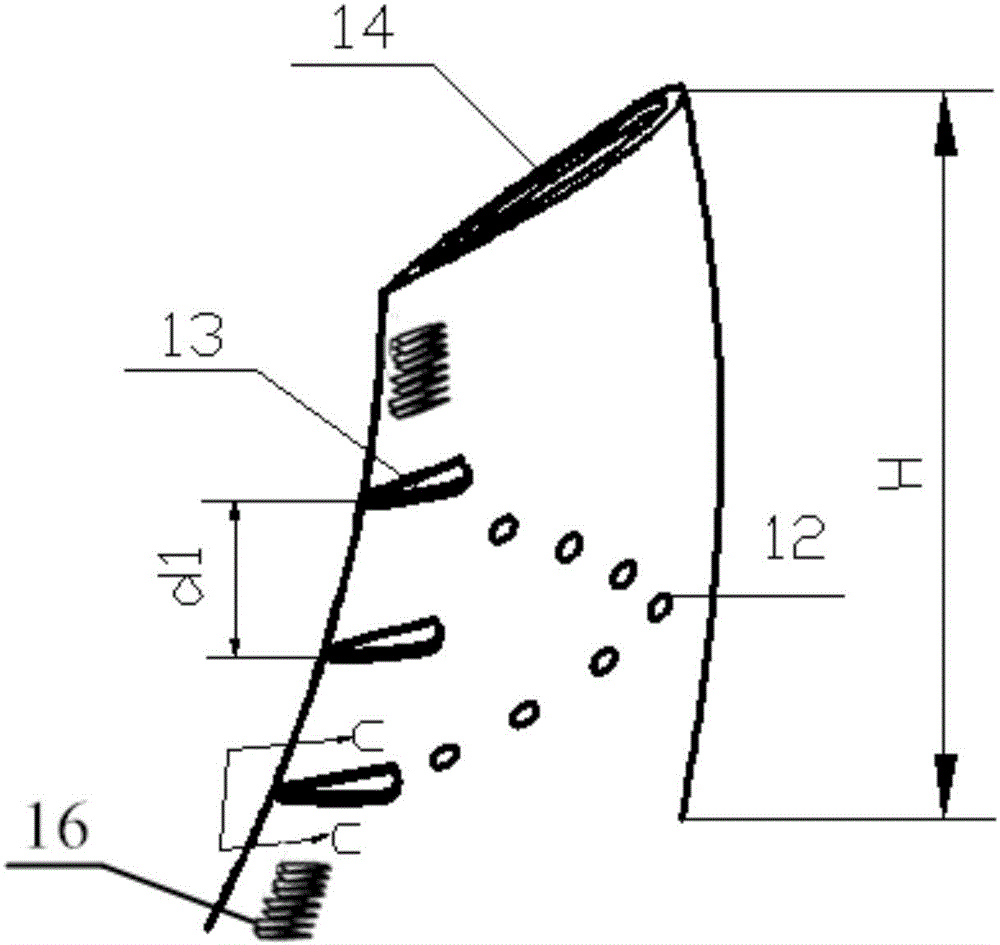

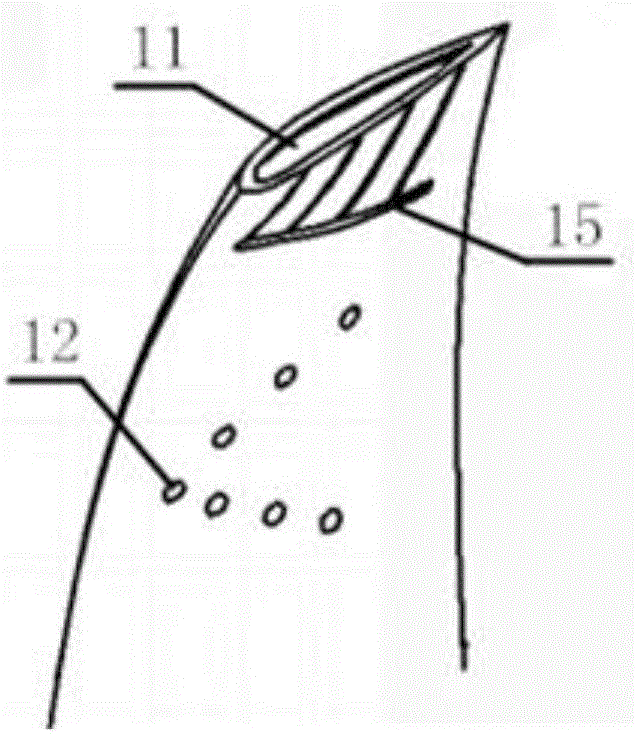

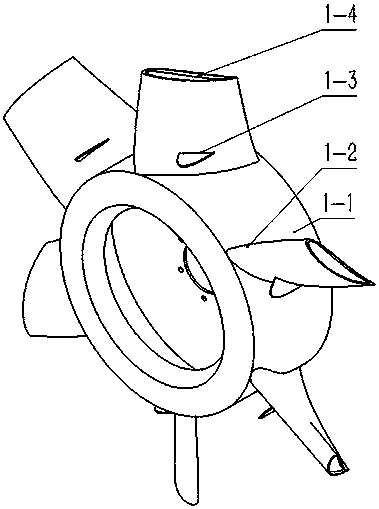

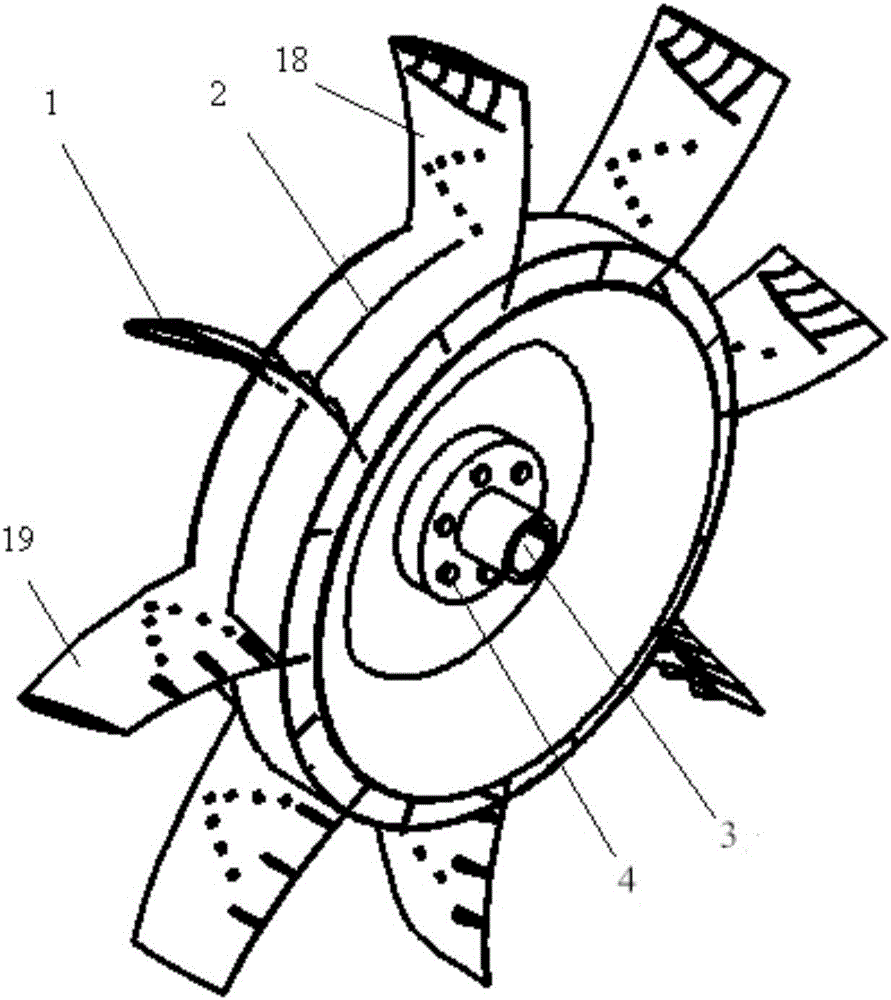

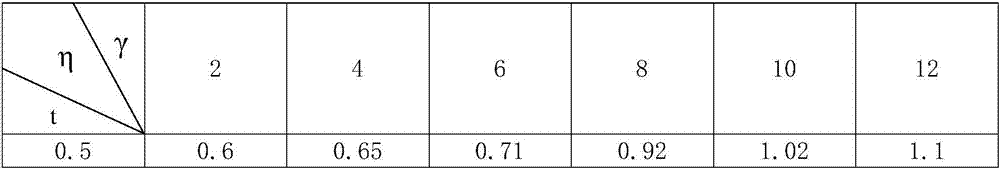

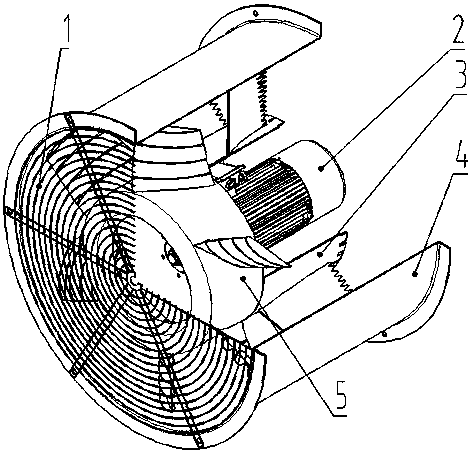

Axial flow fan comprising blades with wing-type guide plates and guide blades with bionic tail edges

ActiveCN105736425APrevent creeping flowImprove efficiencyPump componentsPump installationsImpellerEngineering

The invention discloses an axial flow fan comprising blades with wing-type guide plates and guide blades with bionic tail edges. The axial flow fan is characterized in that four guide plates are uniformly added on every impeller blade and are disposed at the positions as high as 25%, 50% and 75% of the height of every blade and the blade top respectively. The wing-type guide plates are obtained by keeping mean camber lines of the blades, where the guide plates are disposed, unchanged and superposing NACA four-figure wing-type thickness distribution. With the aid of the wing-type guide plates, fluid in an impeller can flow more steadily, and boundary layers are thinner, so that fan efficiency is improved, and leakage loss and vortex noise can be reduced. The guide plates at the blade tops are large in area to form complicated vortexes in blade top gaps, so that blade top leakage flow can be improved effectively. Based on three improvements, the axial flow fan is higher in efficiency and lower in noise, thereby being energy saving and environment friendly.

Owner:嘉兴芸诗娇电子商务有限公司

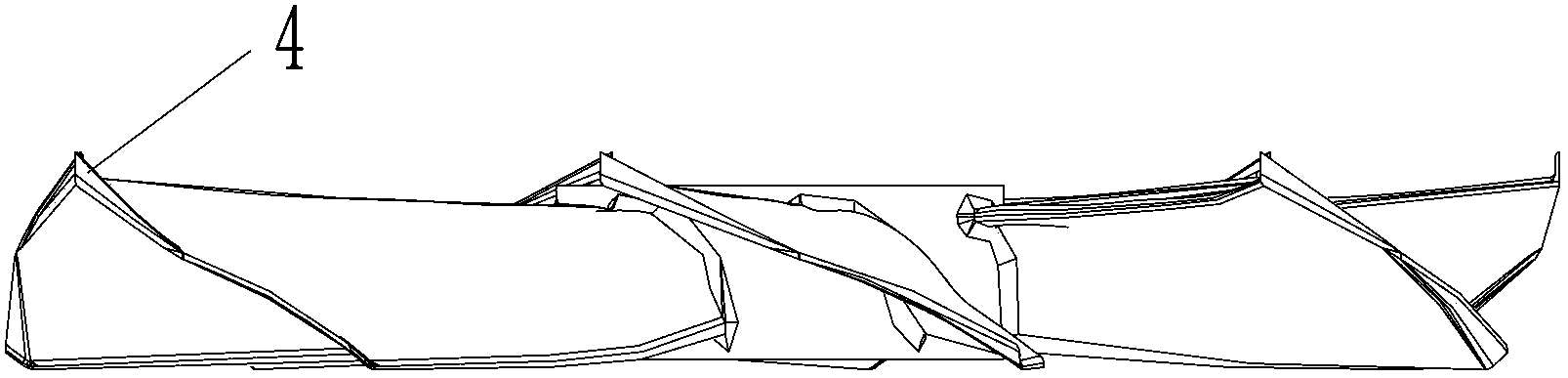

Axial flow fan ternary impeller with vein-shaped structure and nonuniform empennage

The invention discloses an axial flow fan ternary impeller with a vein-shaped structure and a nonuniform empennage. The axial flow fan ternary impeller comprises a hub, and a connecting piece for a shaft sleeve fixed on the hub. The axial flow fan ternary impeller further comprises twisted blades and splitter blades fixedly connected to the hub; the twisted blades include suction surfaces and pressure surfaces; wing-shaped grooves are formed in the tops of the twisted blades; vein-shaped grooves are formed in the upper half parts of the pressure surfaces of the twisted blades; the wing-shaped grooves are communicated with the vein-shaped grooves through exhaust ports; winglet projections and dense winglets are arranged at the tail parts of the suction furnaces of the twisted blades; the dense winglets are arranged on two sides of the winglet projections; parabola small holes are formed in the twisted blades; the splitter blades are arranged between two adjacent twisted blades; and the heights of the splitter blades are smaller than the heights of the twisted blades by one half.

Owner:杭州宏德智能装备科技有限公司

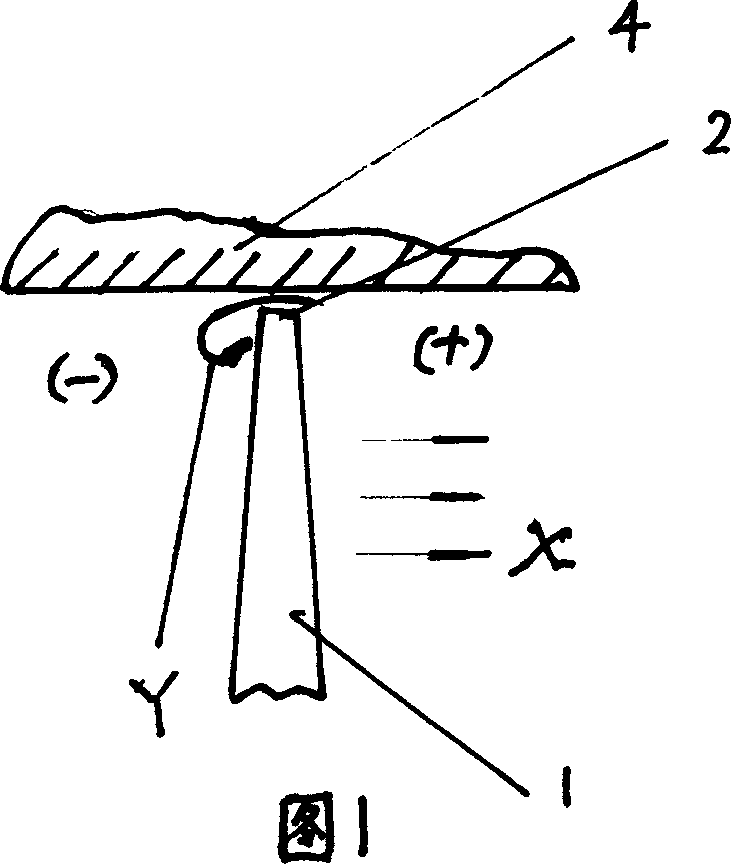

Low-noise strong blast volume axial-flow fan

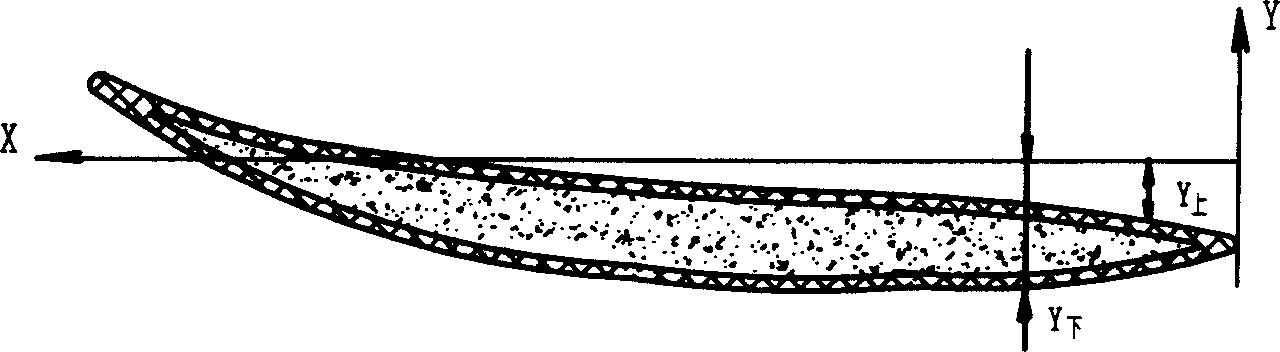

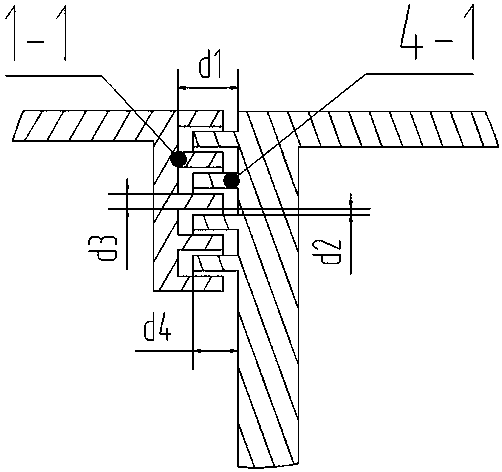

InactiveCN1598325AIncrease stiffnessHigh strengthPump componentsPump installationsLow noiseLeading edge

The invention relates to a pumping current blower fan with low noise and high wind rate, which belongs to non-positive-displace pump technical field. The shape of fan blade is back-swept, and its sectional plane is airfoil. The especial is that central axis is the center of rotation of the vane, it is cut by different radius cylinder face, geometry of the vane is fixed on by the numerical value of the chord An which is from the vane leading edge to its slurry radix axle wire, chord is spread by the sectional plane, X and Y in the sectional plane airfoil developed pattern. The advantage of the invention is big air output, low noise, high static pressure, and light weight.

Owner:BAODING BAOLING TRANSFORMER

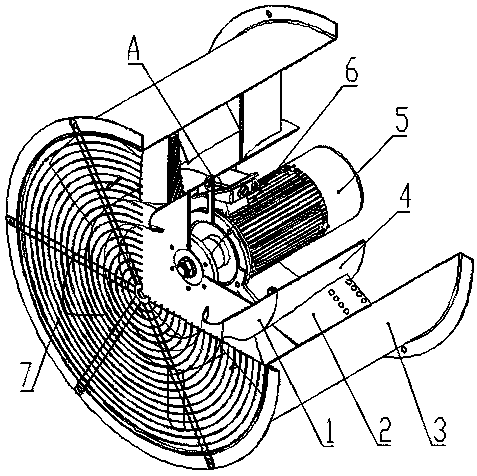

Axial flow blower

PendingCN107061329AImprove efficiencyReduce sizePump componentsPump installationsImpellerEngineering

The invention discloses an axial flow blower, which comprises a net cover, an impeller, a guide vane, an inner cylinder, an outer cylinder, a motor and a shaft sleeve. The net cover is fixed on the outer cylinder, is of a concentric structure and is formed by weaving iron wires; the impeller comprises a wheel hub and vanes, and the vanes are airfoil vanes which are designed through a constant circulation isolated airfoil method; a fin-shaped vortex breaking structure is arranged on a part, close to the root, of the suction surface of each vane; the top parts of the vanes are machined into an airfoil groove structure; and a labyrinth seal structure is formed in a gap between the wheel hub of the impeller and the inner cylinder. The shark fin-like vortex breaking plate is additionally arranged on the part, close to the root, of the suction surface of each vane of the impeller of the axial flow blower, the airfoil groove is formed in the top of each vane of the axial flow blower, and the labyrinth seal structure is formed in the gap between the wheel hub of the impeller and the inner cylinder, and different positions of the axial flower blower are improved, so that the efficiency of the axial flow blower is relatively high, the noise is relatively low, and the energy conservation and environment protection are achieved preferably.

Owner:ZHEJIANG SCI-TECH UNIV

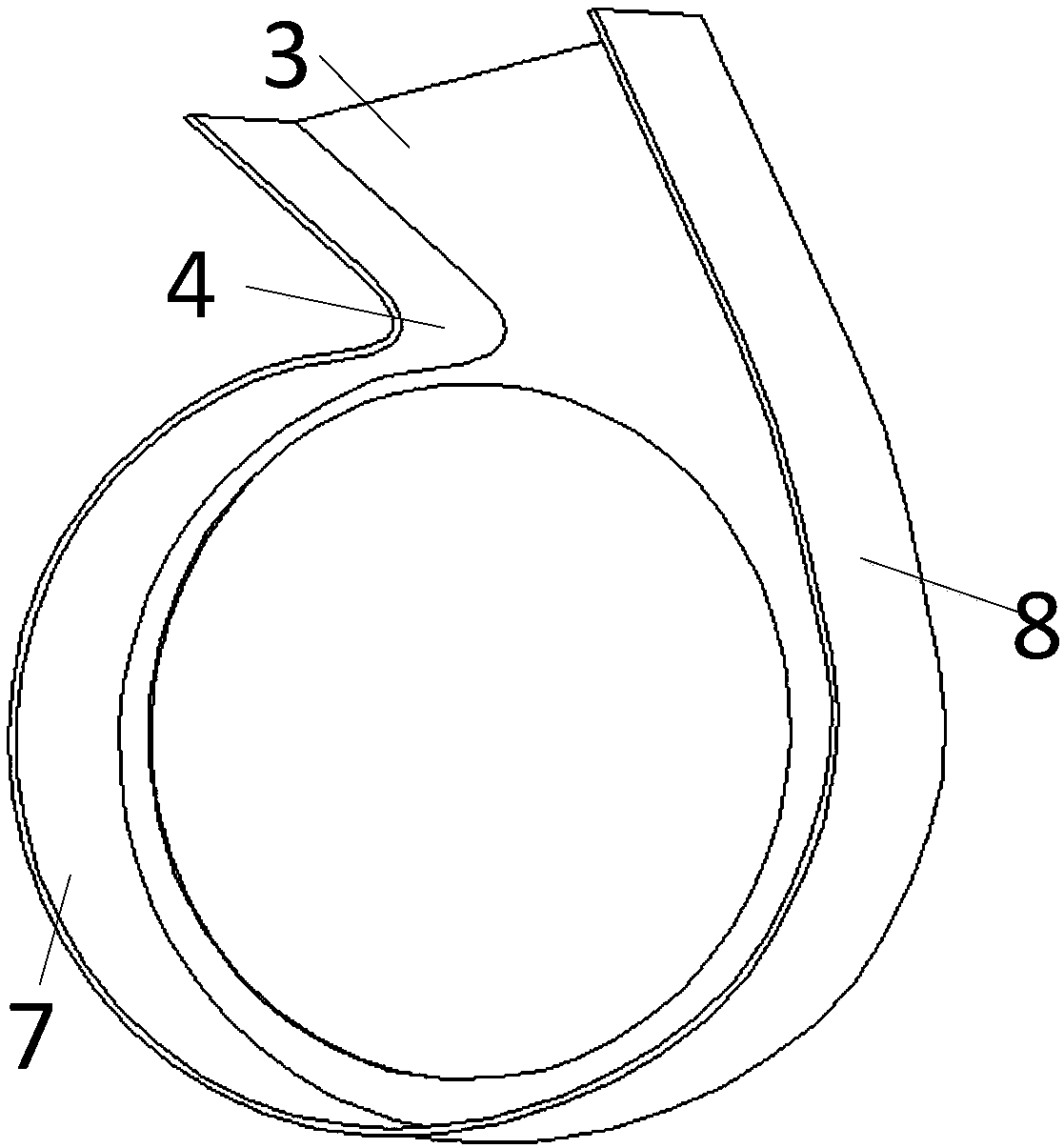

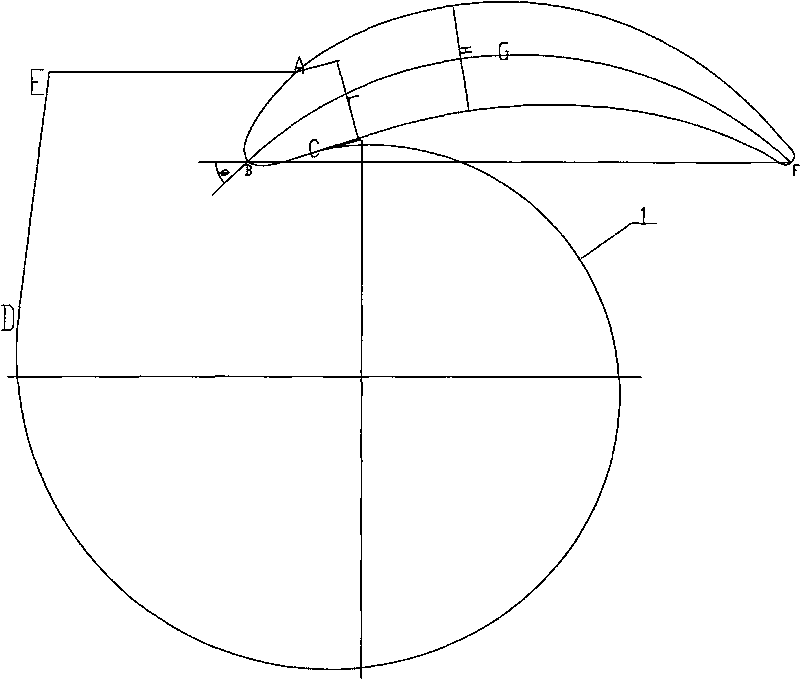

Centrifugal blower volute of range hood

The invention relates to a centrifugal blower volute of a range hood. A molded line of the volute (1) consists of a first curve AB, a second curve BC, a log spiral CD and a straight line DE which are in smooth transition connection with each other, and the first curve AB and the second curve BC which form a volute tongue are front edge parts of a wing profile molded line, wherein the first curve AB is the front edge part of a wing profile upper airfoil molded line BAF, the second curve BC is the front edge part of a wing profile lower airfoil molded line BCF, and the upper airfoil molded line BAF and the lower airfoil molded line BCF form the wing profile molded line. The centrifugal blower volute uses the wing profile front edge parts with good streamline forms as the molded lines of the centrifugal blower volute tongue. The volute adopting the wing profile volute tongue can greatly reduce the probability of generating flow separations and back flows at the volute tongue and reduce impact losses, and is favorable for improving the wind quantity, the wind pressure and the efficiency of a centrifugal blower and reducing aerodynamic noises.

Owner:MIDEA GRP CO LTD

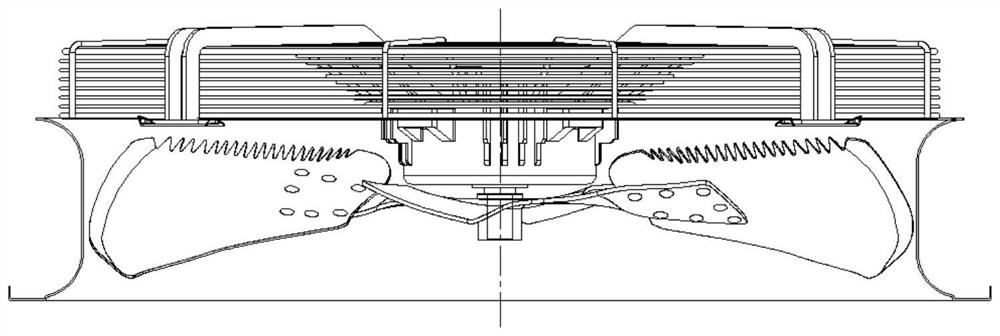

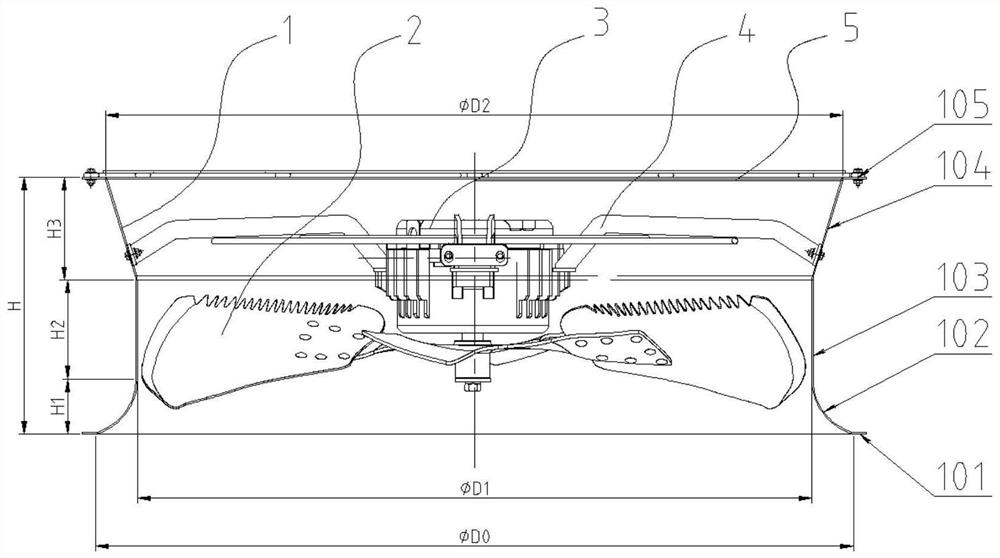

Non-volute backward centrifugal ventilator

PendingCN109441876AIncrease air volumeIncrease pressurePump componentsPump installationsImpellerAir volume

The invention discloses a non-volute backward centrifugal ventilator. The non-volute backward centrifugal ventilator comprises a motor, a vane wheel, an air inlet, a bracket and a panel, wherein one end of the bracket is fixedly connected with the panel; the other end of the bracket is fixedly connected with one end of the motor; the vane wheel comprises a rear disk, blades and a front disk, wherein the blades are arranged between the rear disk and the front disk of the vane wheel; and the rear disk, the blades and the front disk of the vane wheel are fixedly connected; the rear disk of the vane wheel is fixedly connected with the other end of the motor; the front disk of the vane wheel cooperates with a sleeving opening of the air inlet; the cooperating section of the front disk of the vane wheel and the air inlet is an arc-shaped section; the curve convex point of the arc-shaped section faces one side of the outer diameter; the facing direction of the curve convex point of the arc-shaped section is opposite to that of the curve convex point of a main body molded line of the front disk of the vane wheel, and the curve convex point of the arc-shaped section and the curve convex point of the main body molded line form a hump-shaped curve. Through the adoption of the non-volute backward centrifugal ventilator disclosed by the invention, inlet air current flow loss is reduced, thewind capacity of the ventilator is improved, and inlet vortex noise is reduced.

Owner:浙江科贸智能机电股份有限公司

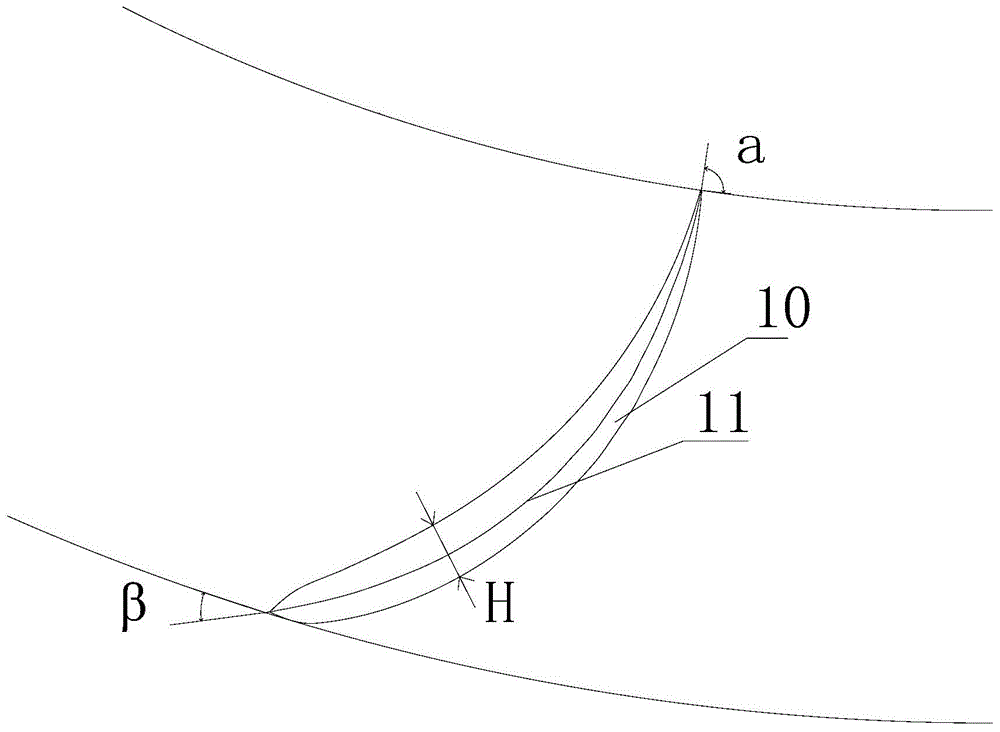

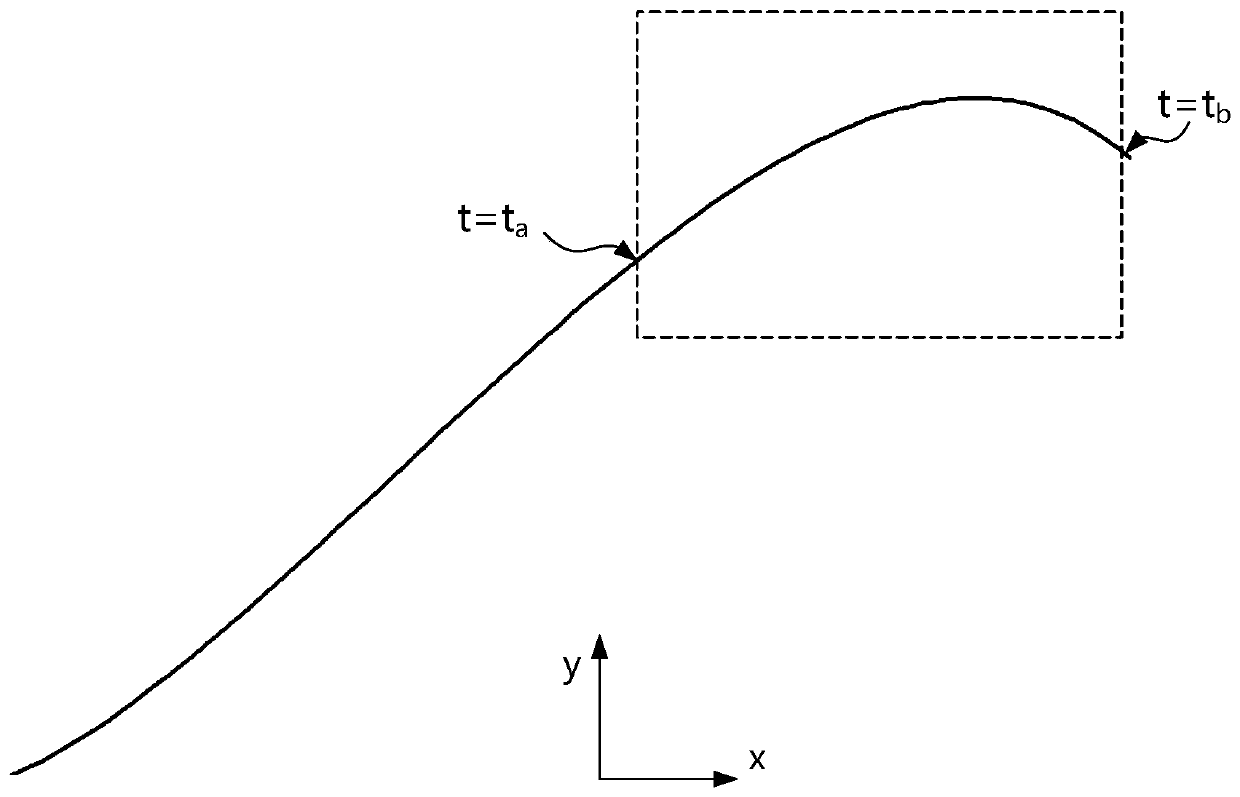

Wind wheel blade, cross-flow wind wheel and design method of wind wheel blade

ActiveCN104564804AImprove energy conversion efficiencyEffective peak controlPump componentsPumpsEngineeringPeak value

The invention provides a wind wheel blade, a cross-flow wind wheel and a design method of the wind wheel blade. The section curve of the upper surface / the lower surface of the wind wheel blade is provided with a curvature gradual-changing section. According to the technical scheme, since the adoption of the surface provided with the curvature gradual-changing section, the cross-flow wind wheel blade is more advantageous in aerodynamics. Therefore, the efficiency of a ventilation wheel is improved, the total value of noise is reduced, the peak value of the blade passing frequency (BPF) during rotation and the flow separation of the vortex flow can be effectively controlled, and the noise of the vortex flow and loss can be reduced.

Owner:GREE ELECTRIC APPLIANCES INC

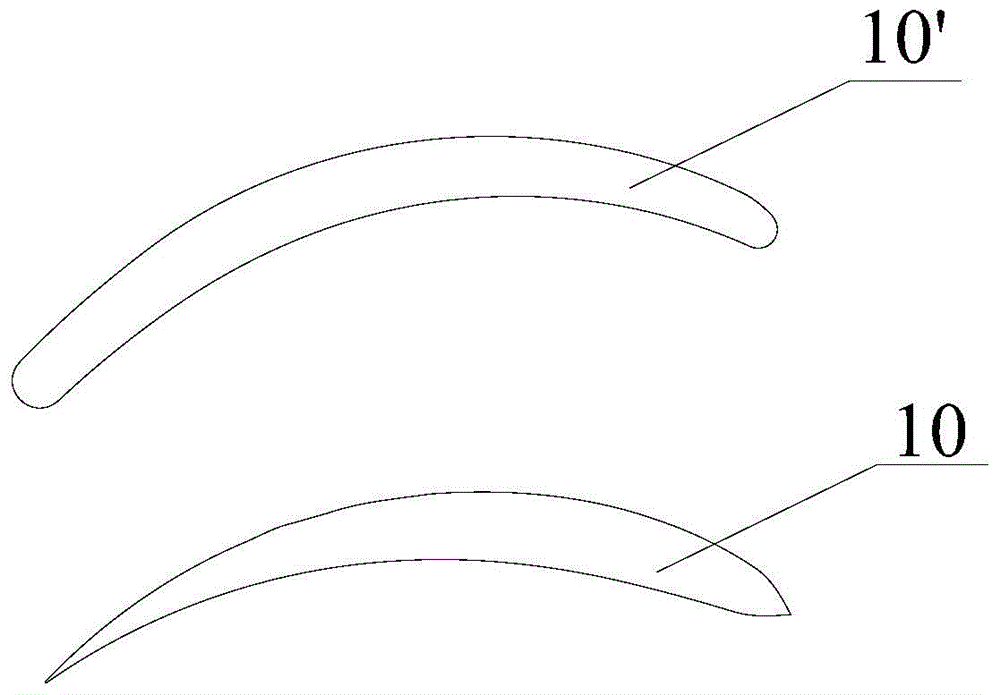

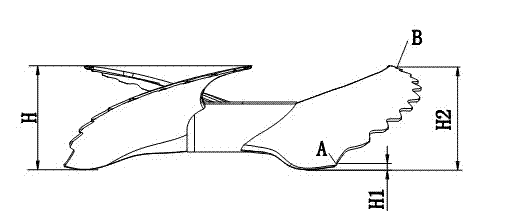

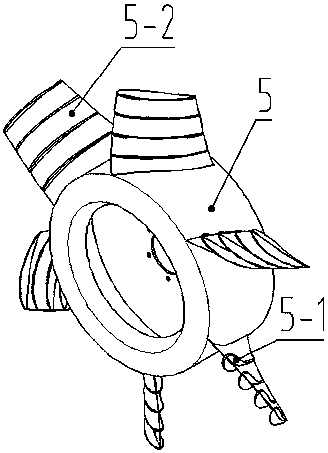

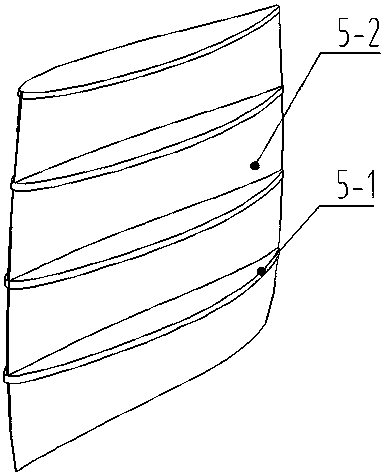

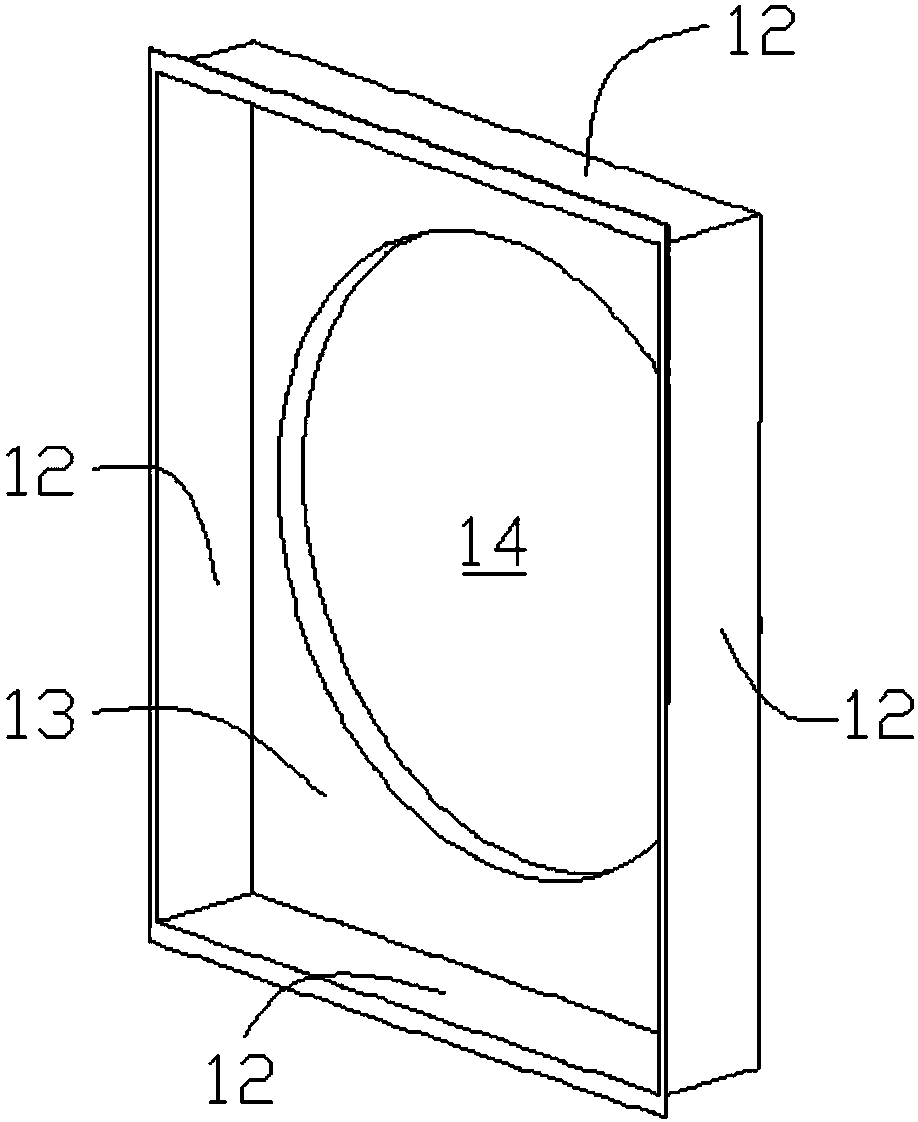

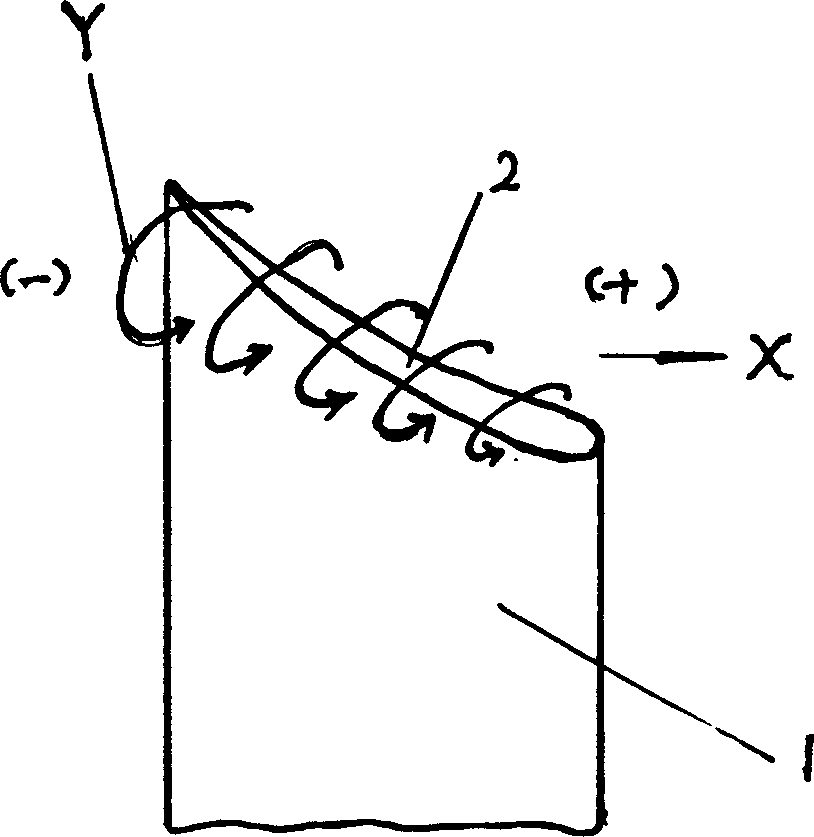

Axial flow wind wheel

ActiveCN102374194AReduce eddy current noiseSuppression of eddy current noisePump componentsPumpsWave shapeEngineering

The invention relates to an axial flow wind wheel, which comprises more than two blades arranged on a hub, wherein the blades are distributed on the hub at equal intervals or unequal intervals by taking the rotating central axis of the wind wheel as the center. The axial flow wind wheel is characterized in that: the outer edge shape of each blade is in a wave-shaped space curve. When the axial flow wind wheel rotates, gas of the pressure surfaces of the blades flows into the suction surface in different degrees through the wave-shaped outer edges of the blades due to the wave shapes of the outer edges of the blades, so that the pressure distribution of the blades is changed, the kinetic energy of the gas on the suction surface is increased, low-energy fluid can be prevented from accumulating at the annular walls of the blades, large eddy turbulence is destructed, blade tip vortex and trailing edge falloff are effectively refined, the energy strength of the vortex is reduced, and the vortex noise of the wind wheel is restricted, therefore the noise of the wind wheel is effectively reduced, the acoustic quality is softer and more comfortable, meanwhile, the wind wheel weight and the motor load are lightened by wave shapes of the outer edges of the blades, and the wind wheel cost and the motor power are reduced. The invention is especially suitable for an outdoor unit of an air-conditioner.

Owner:MIDEA GRP CO LTD

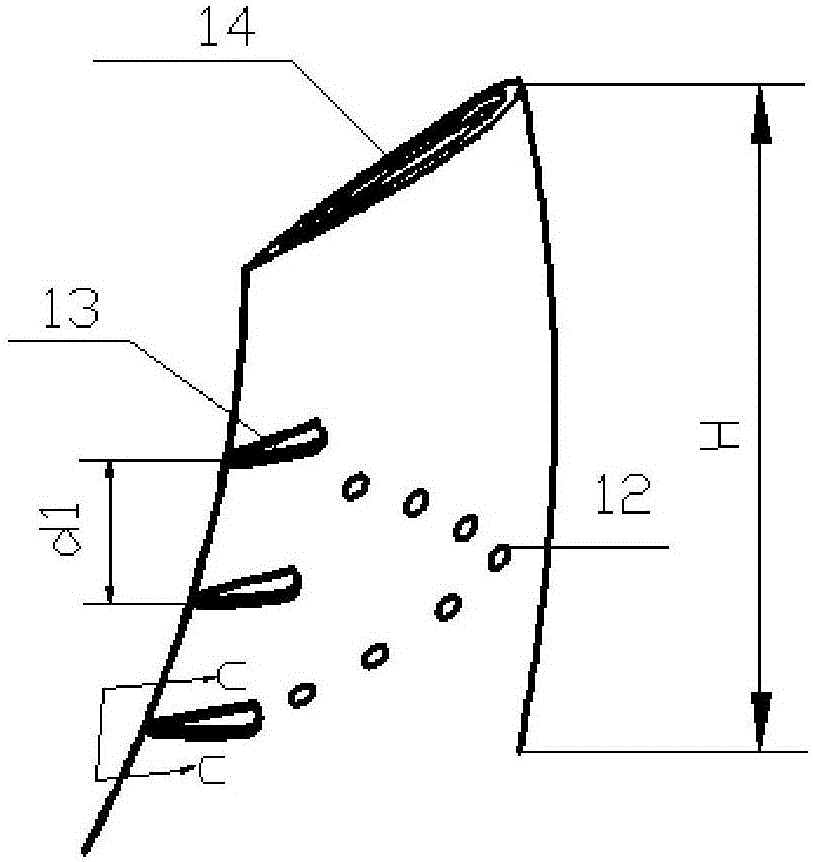

Axle-flow fan blade

The invention discloses an axle-flow fan blade comprising a hub and blades connected to the hub. Each blade is of a pressure face on the outlet side and a suction face on the intake side, multiple fold sections are arranged at the outer edges, extending outwards, of the blades, and the fold sections extend to the suction faces from the pressure faces. The multiple fold sections are arranged at the outer edges of the blades, the front edges of the blades are provided with recesses, the mode of air flowing through the outer edges and the front edges of the blades is changed, 'drain' of air at the outer edges of the blade is reduced, the drop mode of vortexes at the front edges of the blades can be improved, the efficiency of the fan is improved, and vortex noises (broad-band noises) of the fan blade are reduced..

Owner:GREE ELECTRIC APPLIANCES INC

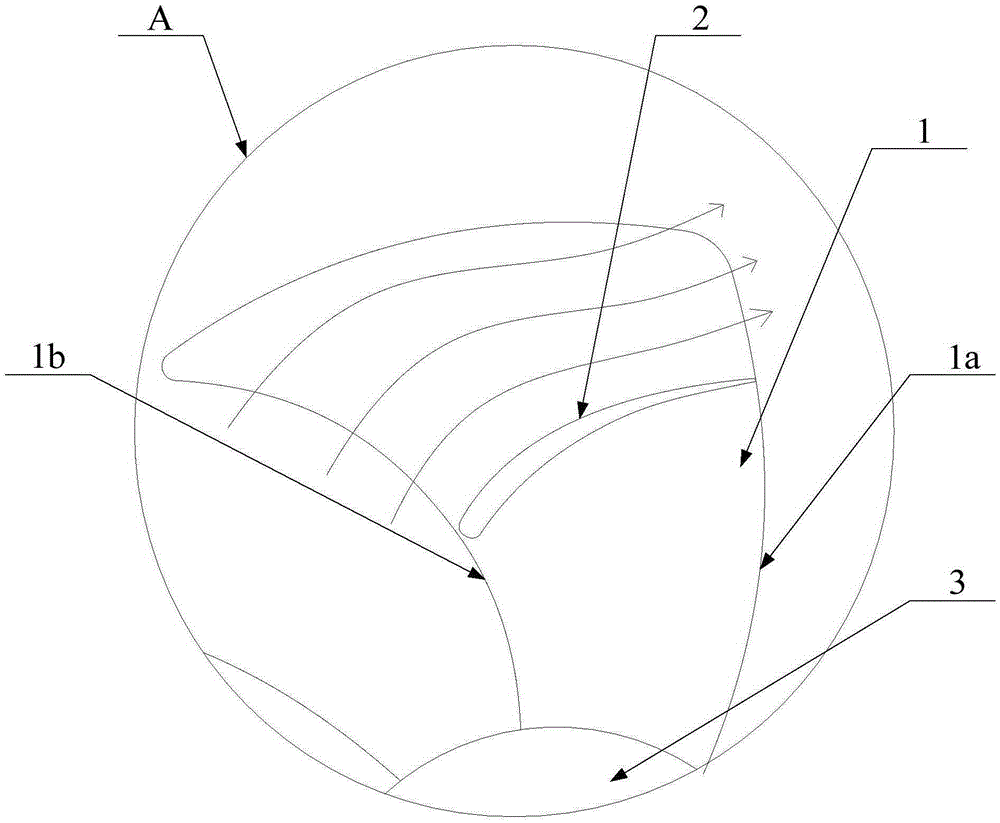

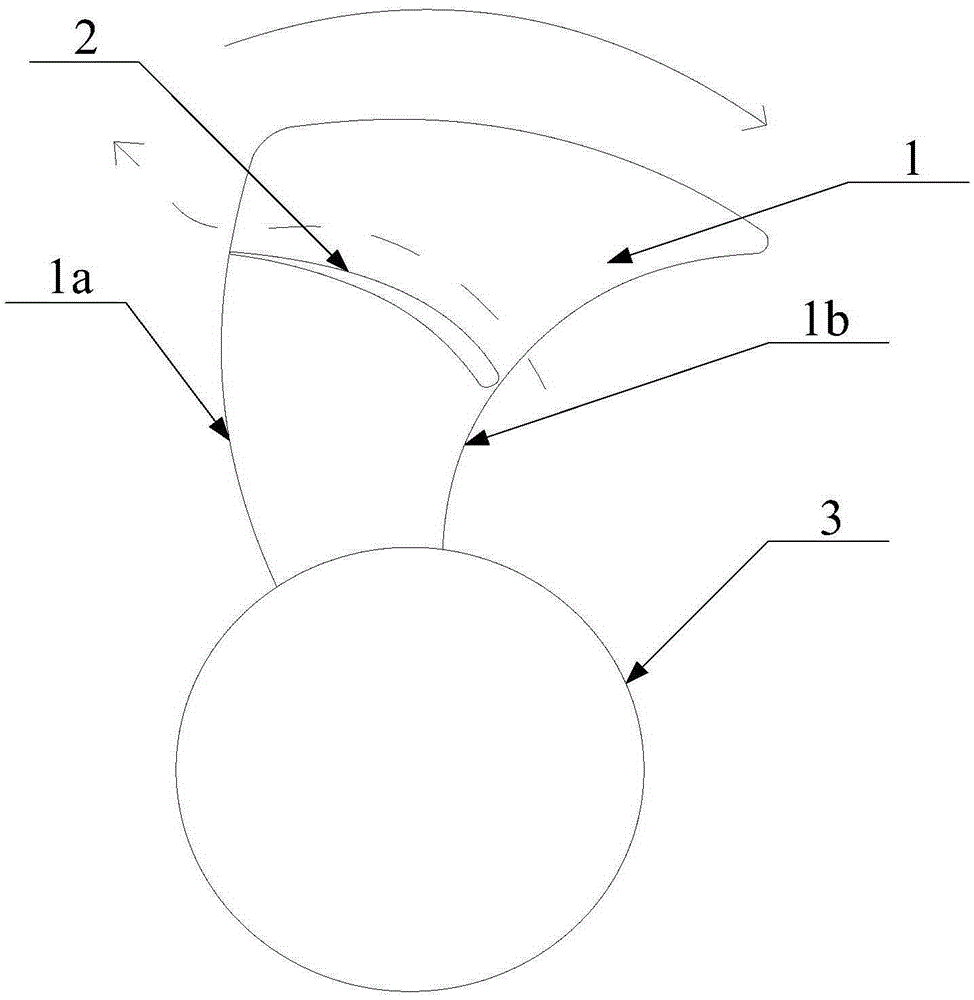

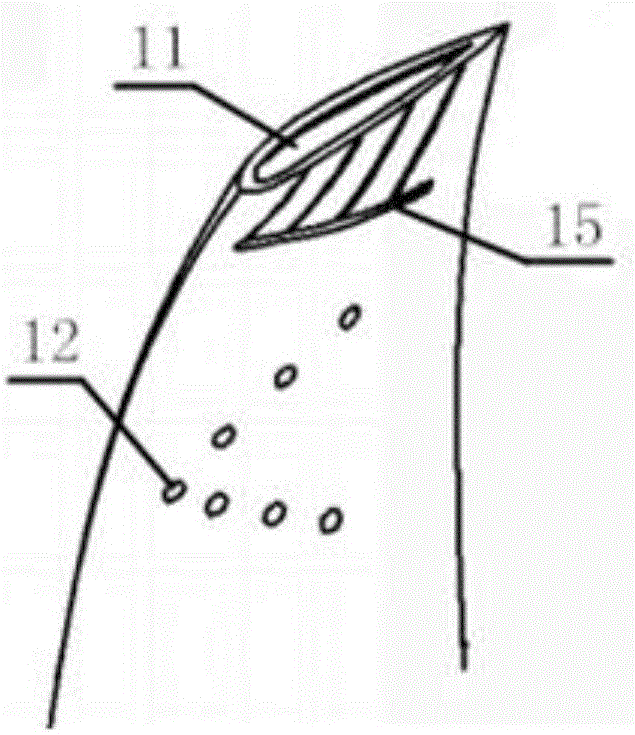

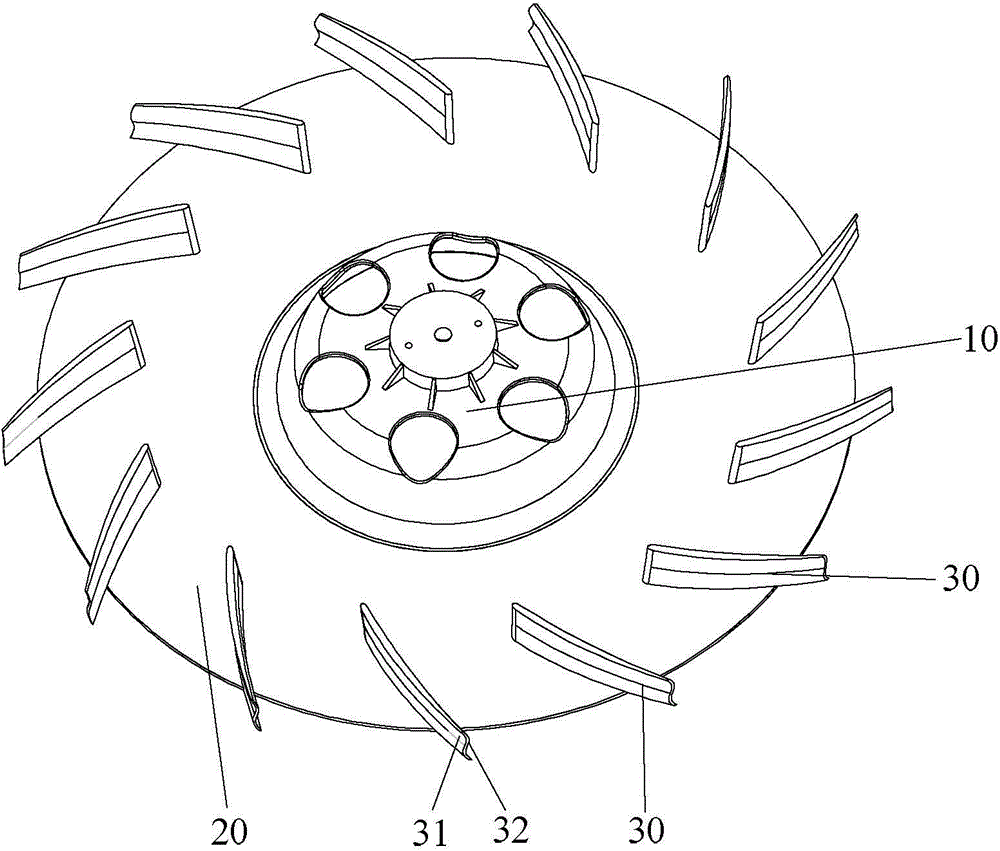

Fan, axial flow blade and vane for axial flow blade

InactiveCN105402160AReduce noiseImproved gas flow characteristicsPump componentsPumpsEngineeringMechanical engineering

The invention discloses a fan, an axial flow blade and a vane for the axial flow blade. According to the vane for the axial flow blade disclosed by the invention, the two sides of the vane are arranged in the rotation direction of the vane and are defined as a first side and a second side respectively; the two ends of the vane are a free end and a connecting end for being connected with a hub of the axial flow blade respectively; an aerofoil guide vane is fixed to the suction surface of the vane and extends from the first side to the second side along an arc line; the end part, arranged on the first side, of the aerofoil guide vane is the first end; the end part, arranged on the second side, of the aerofoil guide vane is the second end; the extension direction, from the first end to the second end, of the aerofoil guide vane is the same as the rotation direction of the vane; and the distance from the second end to the free end is larger than that from the first end to the free end. With the structural design, the vane for the axial flow blade can effectively reduce noise produced during rotation of the axial flow blade and increase the air supply volume of the fan.

Owner:GREE ELECTRIC APPLIANCES INC

Axial flow fan three-dimensional impeller with leaf vein structures and seagull-shaped splitter blades

Owner:ZHEJIANG SCI-TECH UNIV

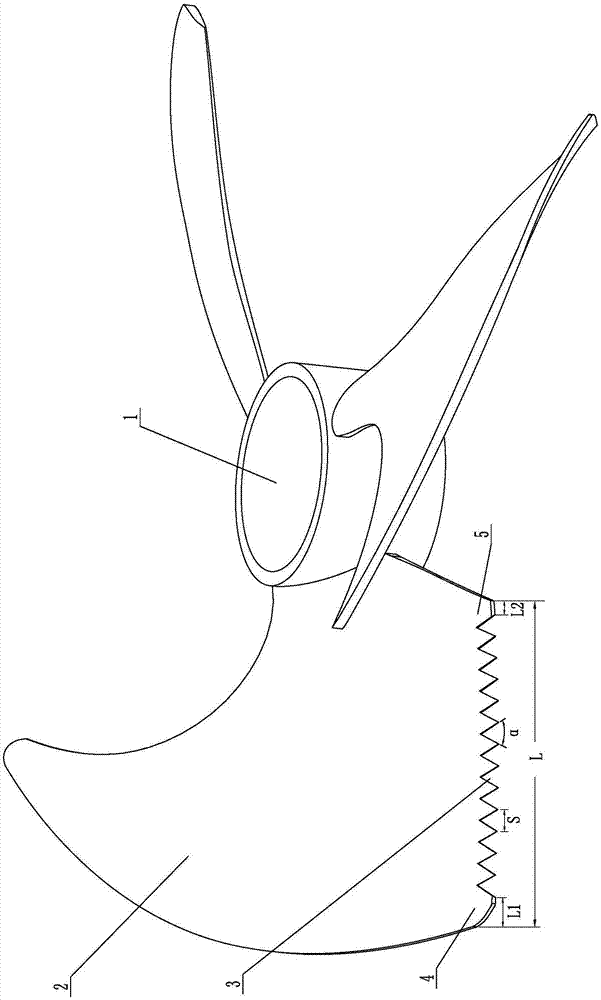

Zigzag noise reduction axial flow blade

PendingCN107489646AImprove noise reductionReduce eddy current noisePump componentsPumpsEngineeringNoise reduction

The invention relates to a zigzag noise reduction axial flow blade. The zigzag noise reduction axial flow blade comprises a center shaft sleeve (1) and a plurality of blade bodies (2) evenly distributed on the outer circumferential wall of the center shaft sleeve (1) in the circumferential direction. The zigzag noise reduction axial flow blade is characterized in that a row of zigzag grooves (3) are formed in the tail edge of each blade body (2); and at least quarter of all the zigzag grooves (3) are equal in the groove opening width and groove depth. The zigzag noise reduction axial flow blade has the advantages of the good noise reduction effect and high universality.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

Air conditioner

ActiveCN104807110AIncrease arcReduce eddy current noiseDucting arrangementsLighting and heating apparatusEngineeringRadian

The invention provides an air conditioner. The air conditioner comprises a bottom case and noise reducing mechanisms, wherein air ducts are arranged on the bottom case and are provided with air duct wall surfaces; each noise reducing mechanism is used for increasing the radian of the air duct wall surface at an air outlet of a corresponding air duct, and is movably arranged on the bottom case. According to the air conditioner, the noise reducing mechanisms are arranged, so that air is smoothly guided by improving the radian of the air duct wall surface at the air outlet of each air duct, the fact that wind generates vortex at each air duct wall surface is effectively avoided, vortex noise of the air conditioner is reduced, and the use comfort of the air conditioner is ensured. Particularly, when a wind shield shields each air outlet, wind cannot be blown out of the air outlets, so that wind blown to a connection part between each wind shield and a corresponding air duct wall surface generates the vortex noise at the connection part; by improving the radians of the air duct wall surfaces at the air outlets of the air ducts, the wind guiding function of each air duct wall surface can be improved, so that the problem that vortex noise generates under a working situation is solved.

Owner:GREE ELECTRIC APPLIANCES INC

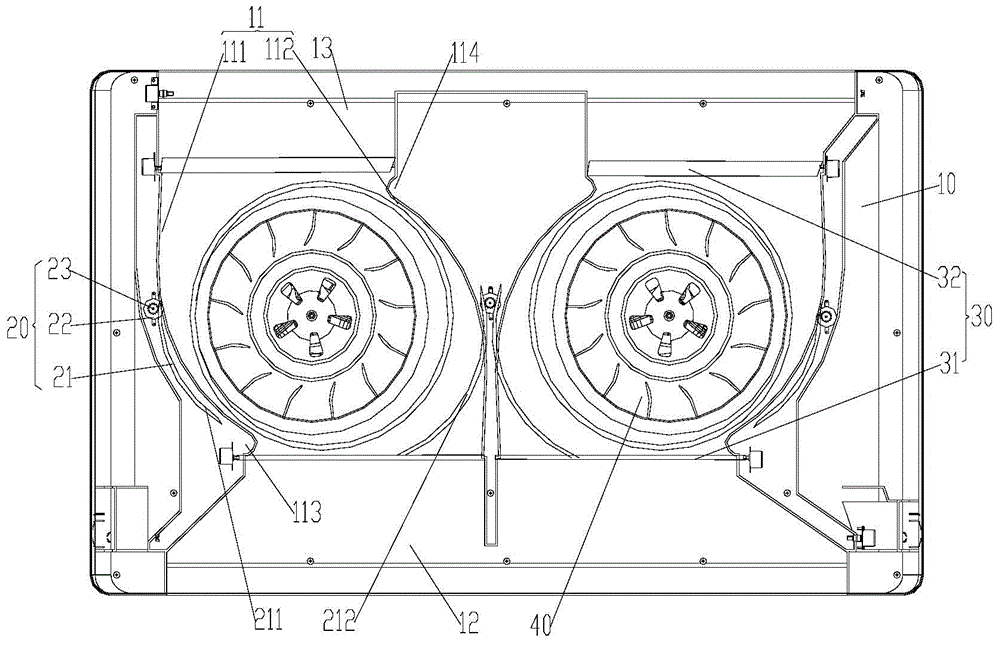

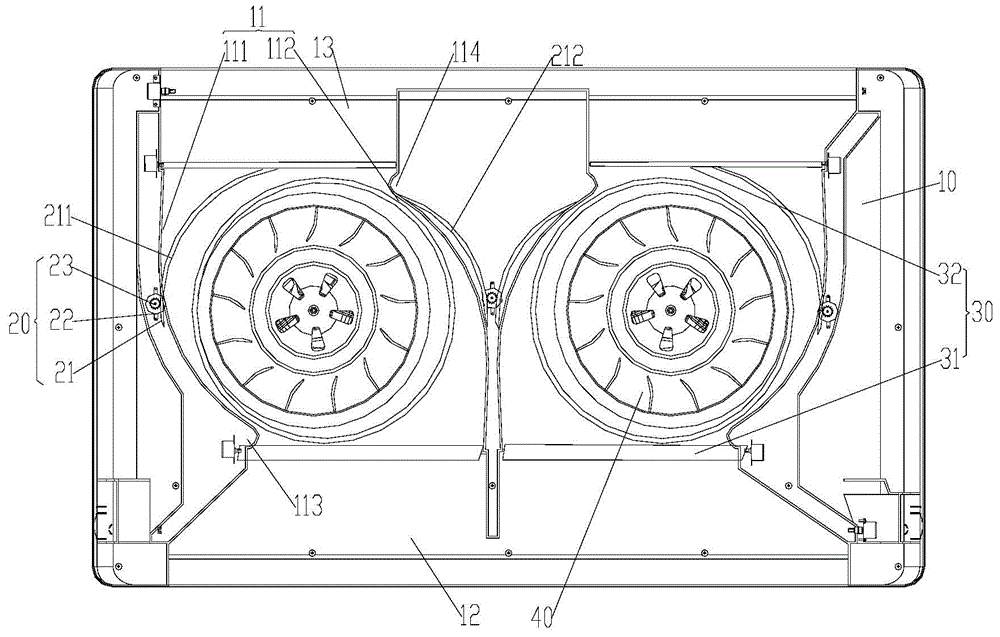

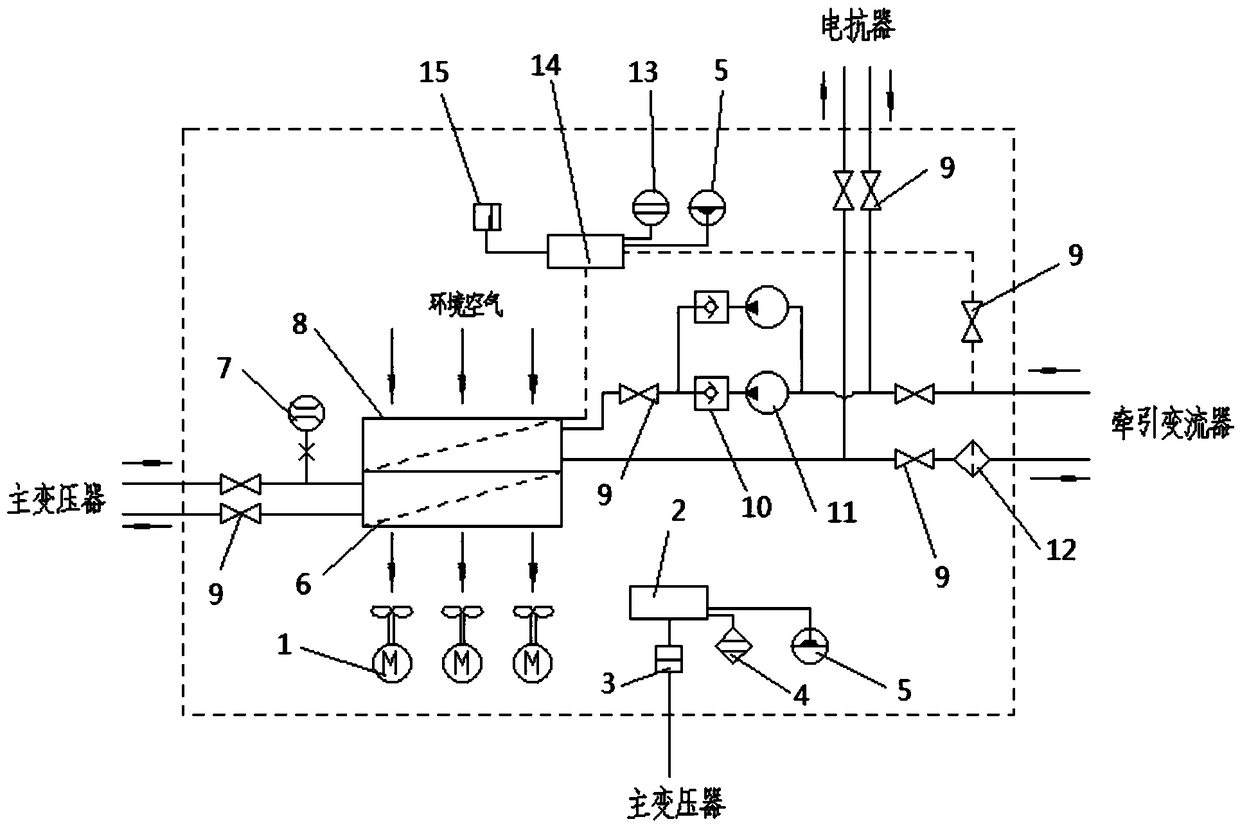

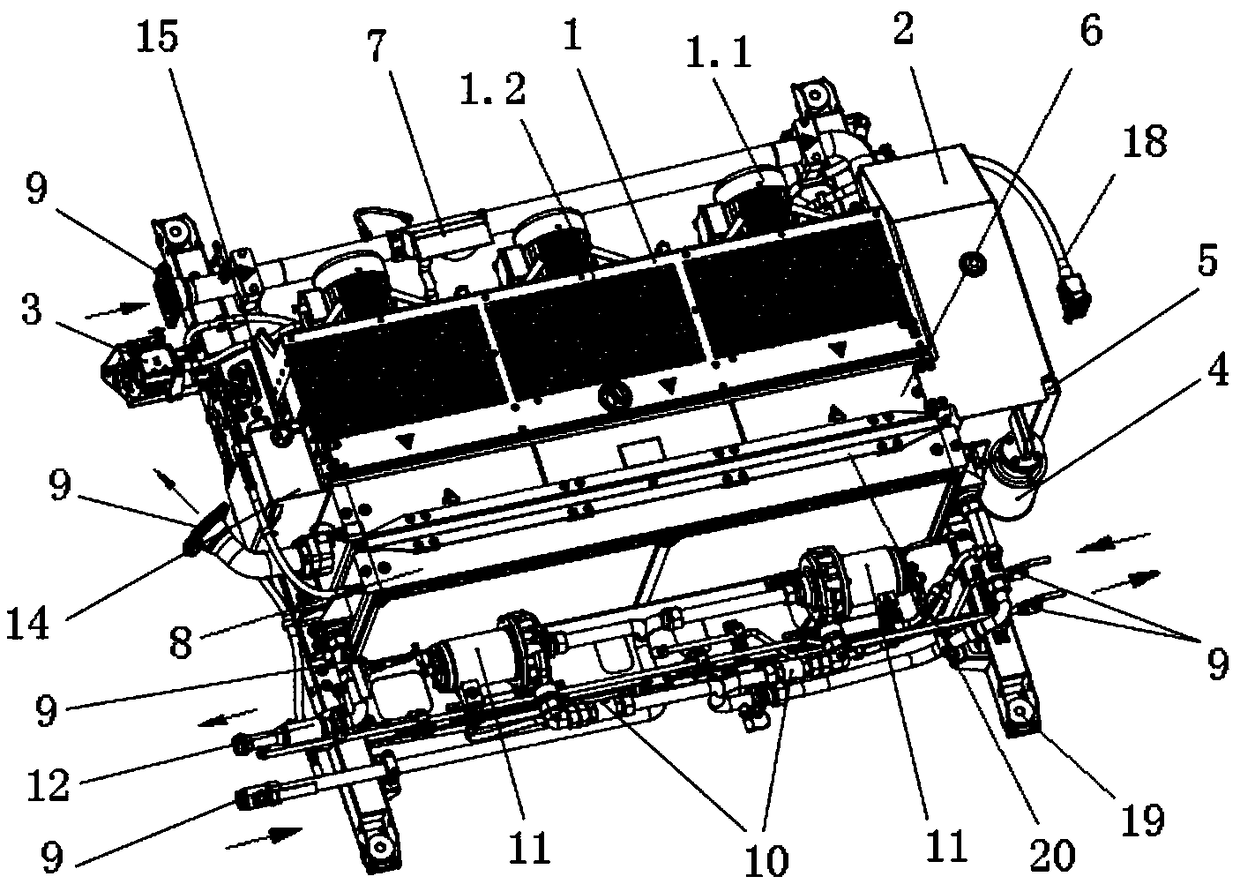

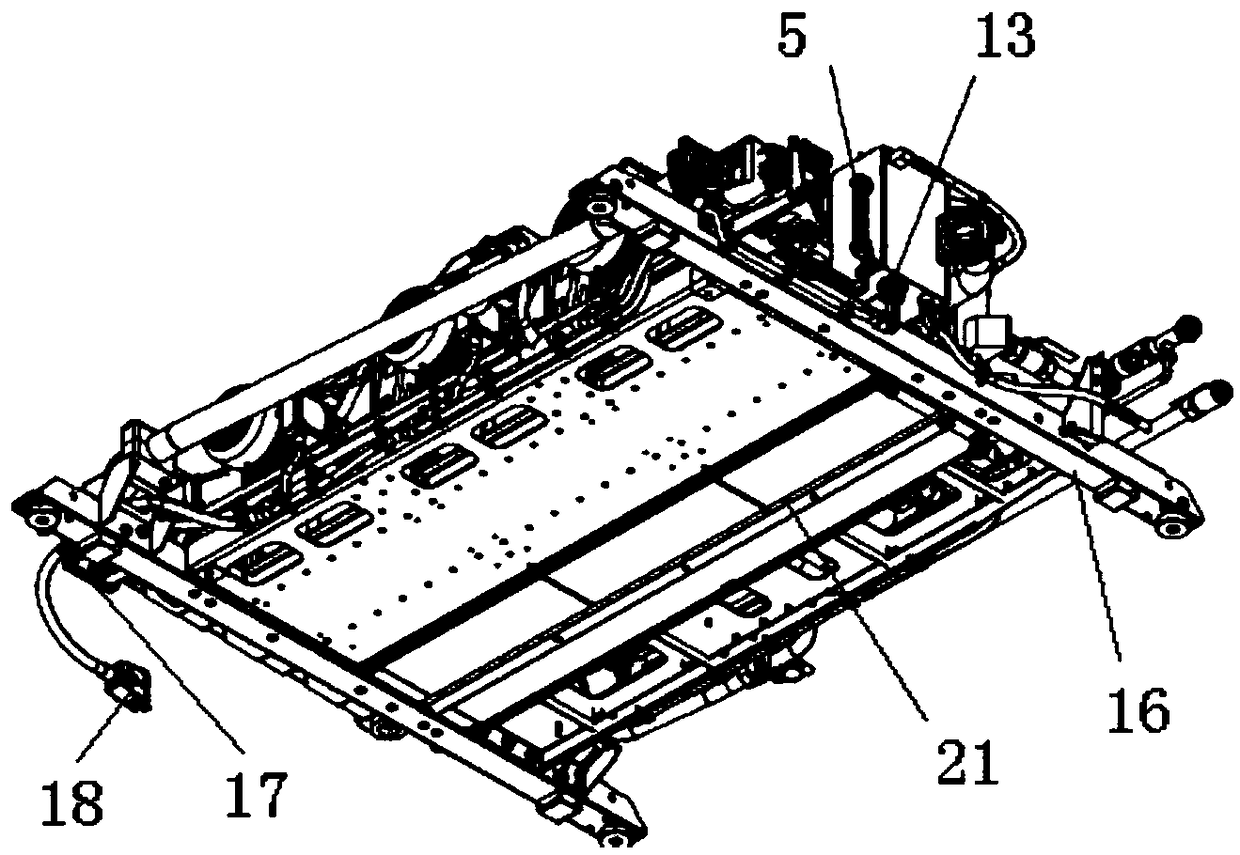

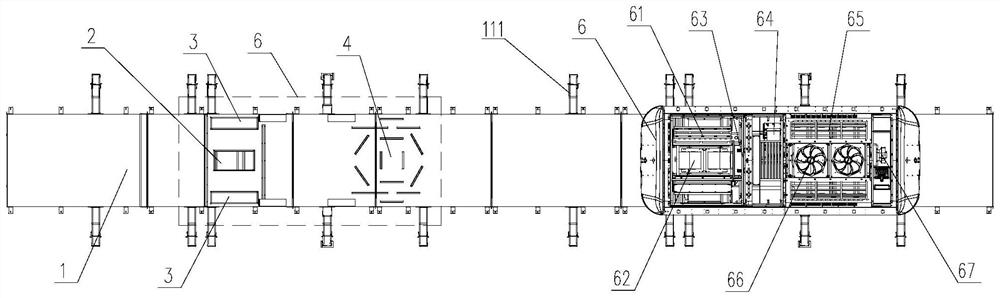

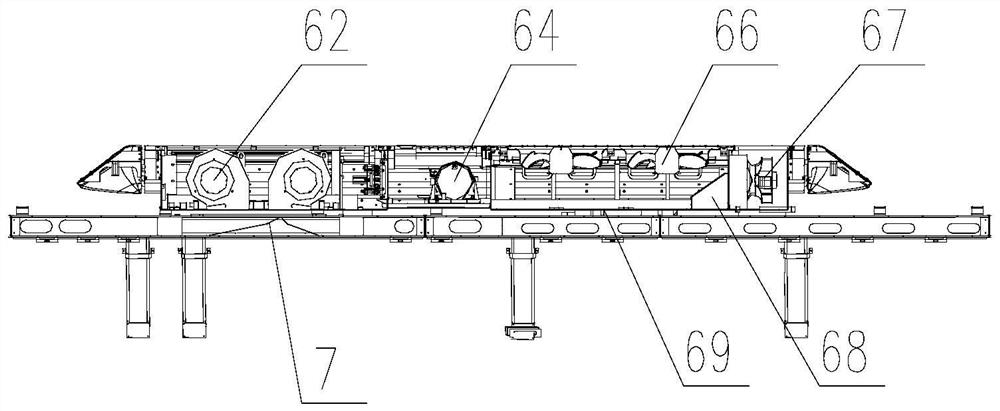

Cooling device

PendingCN109413969AFix things that don't workGuaranteed uptimeTransformers/inductances coolingCooling/ventilation/heating modificationsExpansion tankCavitation

The invention provides a cooling device. The cooling device comprises a water cooling circuit, an oil cooling circuit and an air cooling device, wherein the water cooling circuit is used for cooling an electric reactor and a traction converter; the oil cooling circuit is used for cooling a main transformer; and the air cooling device is used for cooling the cooling mediums in the water cooling circuit and the oil cooling circuit. The cooling device has the benefits that the condition that the cooling device cannot be operated normally as any one of a fan and a water pump breaks down due to single design of the fan and the water pump is effectively solved; the noise is effectively reduced, the comfort of a train is ensured and the service life of the motor is prolonged through improving thecooling fan; cooling oil can be effectively prevented from entering a dryer to disturb the normal work of the dryer through improving the structure of an expansion oil tank and the mounting manner ofthe dryer; and the expansion water tank is a single cavity structure so that the structure is simpler and more reliable and cavitation can be effectively prevented.

Owner:HUNAN LIANCHENG TRACK EQUIP CO LTD

Novel centrifugal fan

The invention provides a novel centrifugal fan and belongs to the technical field of fans. The novel centrifugal fan solves the problems of proneness to dust accumulation and short service life of existing centrifugal fans, and comprises a frame, a volute casing and a motor. The volute casing which is provided with an air inlet and an air outlet is arranged at the frame, the motor is disposed on the frame, the air inlet is positioned on the side of the volute casing, and an impeller driven by the motor is arranged in the volute casing. One side, positioned at the air inlet, of the impeller is ratchet-shaped. A conical rectifying barrel is arranged at the air inlet. The novel centrifugal fan has the advantages of long service life, high pneumatic performance and efficiency and the like.

Owner:ZHEJIANG XINGYI VENTILATOR ELECTRICAL APPLIANCE

Air conditioner air-out structure and air conditioner

InactiveCN108386988AReduce turbulenceReduce or eliminate eddy currentsLighting and heating apparatusNoise suppressionEngineering

The invention provides an air conditioner air-out structure and an air conditioner. The air conditioner air-out structure comprises an air-out port (1), a first air guiding plate (2) and a second airguiding plate (3), and when the air-out port (1) is closed, the first air guiding plate (2) is located on the inner side of the second air guiding plate (3); the first air guiding plate (2) comprisesa first plate body (4) and a second plate body (5), in the air-out direction, the first plate body (4) is located on the downstream side, and the second plate body (5) is located on the upstream side;a preset included angle is formed between the first plate body (4) and the second plate body (5), the first plate body (4) is a straight plate, and the second plate body (5) is a straight plate or anarc plate; or the first plate body (4) is an arc plate, and the second plate body (5) is a straight plate. According to the air conditioner air-out structure, the air-out property of the air conditioner can be adjusted, and air-out noise of the air conditioner is reduced.

Owner:GREE ELECTRIC APPLIANCES INC

An axial flow fan with blades with airfoil deflectors and guide vanes with bionic trailing edges

ActiveCN105736425BPrevent creeping flowImprove efficiencyPump componentsPump installationsImpellerEngineering

The invention discloses an axial flow fan with airfoil deflectors on the blades and bionic trailing edges on the guide vanes. Four deflectors are evenly added to the impeller blades of the axial flow fan, and the relative height of the blades is The positions are respectively at 25%, 50%, 75% and leaf top. The airfoil deflector is obtained by keeping the center arc of the blade at each deflector position unchanged, and then superimposing the NACA four-digit airfoil thickness distribution. The airfoil deflector can make the fluid flow in the impeller more stable, the boundary layer is thinner, the fan efficiency is improved, the leakage loss is reduced and the eddy current noise is reduced. The deflector at the tip of the blade can effectively improve the leakage flow at the tip of the blade due to its large area and forms a complex vortex in the gap of the tip of the blade. Through three modifications of this type of fan, the efficiency of the fan can be improved and the noise of the fan can be reduced, so as to achieve the purpose of energy saving and environmental protection.

Owner:嘉兴芸诗娇电子商务有限公司

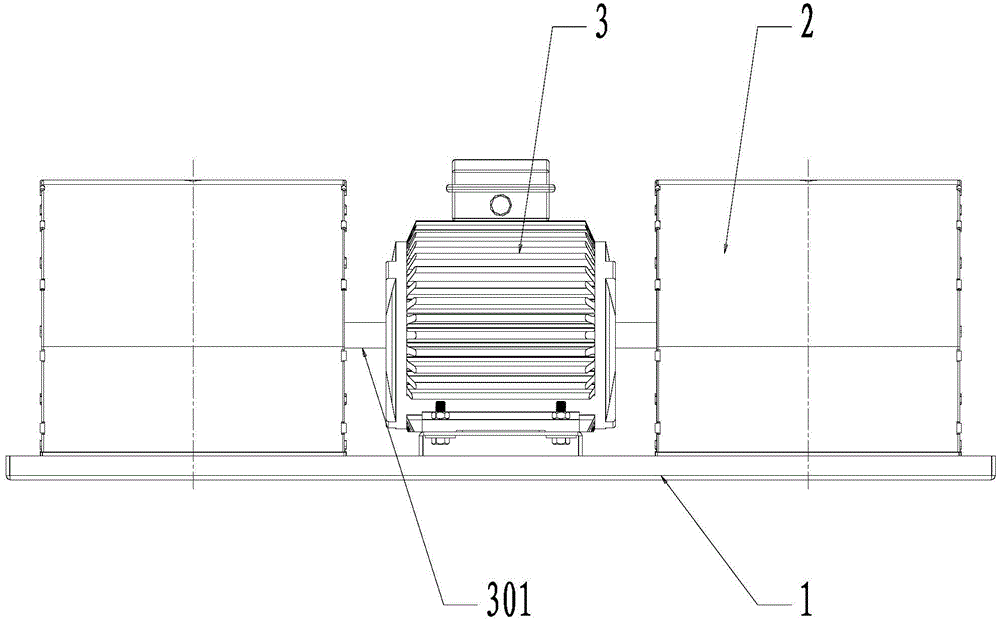

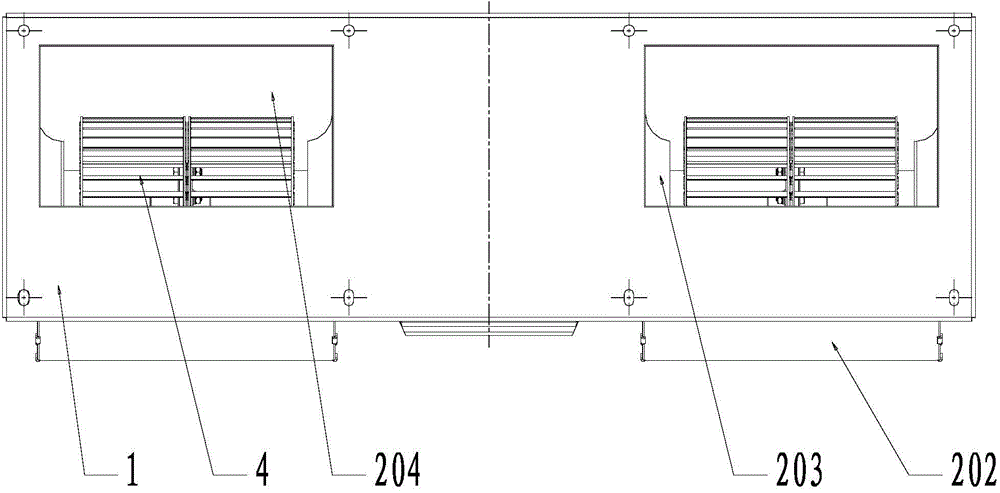

Centrifugal fan with vane guide grooves for noise reduction

InactiveCN104533832AImprove overall performanceReduced areaPump componentsPump installationsDrive shaftEngineering

The invention relates to the technical field of air supplying equipment, and specifically relates to a centrifugal fan with vane guide grooves for noise reduction. The centrifugal fan comprises a base, a volute, a motor and wind wheels. The motor is a double-extension-shaft quadrupole motor. Two transmission shafts of the motor are respectively fixed to the wind wheels in the volute. The volute and the motor are fixed on the base. Each vane of each wind wheel includes a main body and mounting portions arranged at two ends of the main body. The main body of the vane is made of a rectangular raw material in a manner that by the long side of the rectangular raw material is used as a central line and the two wide sides are rotated in opposite directions. A plurality of guide grooves are arranged on one side or both sides of the vane. By adopting the above structure, the guide grooves are arranged on the side faces of the vanes, where the air flow passes, of the centrifugal fan, so that the wind can be more concentrated, the area and strength of air escaping from the vortex in the vane channel are both reduced, the vortex noise is decreased, the noise reduction effect is optimized and the overall characteristic effect of the fan is optimized.

Owner:FOSHAN HECAI TECH SERVICE

Air conditioner axial flow fan and air duct

PendingCN111649005AReduce noiseReduced stabilityPump componentsPump installationsMechanical engineeringMechanics

The invention discloses an air duct of an air conditioner axial flow fan. The air duct comprises an inlet diversion segment, a straight segment and a diffusion segment. Air flow enters through the inlet diversion segment, flows in the axial direction and is output of the diffusion segment. The inlet diversion segment, the straight segment and the diffusion segment are integrally prepared. The inlet diversion segment is a hollow and smooth conical arc-shaped circular truncated cone body. The diameter of the inner wall of the inlet diversion segment successively decreases in the axial directionwith an air inlet as the start. The straight segment is a hollow cylinder with all the cross sections equal. The cross sectional area of the diffusion segment successively increases in the axial direction with the an air outlet of the straight segment as the start. The sum of the axial height of the inlet diversion segment and the axial height of the straight segment is larger than the axial height of the diffusion segment. With the air conditioner axial flow fan with the air duct, the noise of the flow fan can be obviously reduced, the performance and the efficiency of the flow fan can be improved, the integrated making technology of the air duct is simple, and the flow fan is easy and convenient to install and maintain.

Owner:浙江科贸实业有限公司

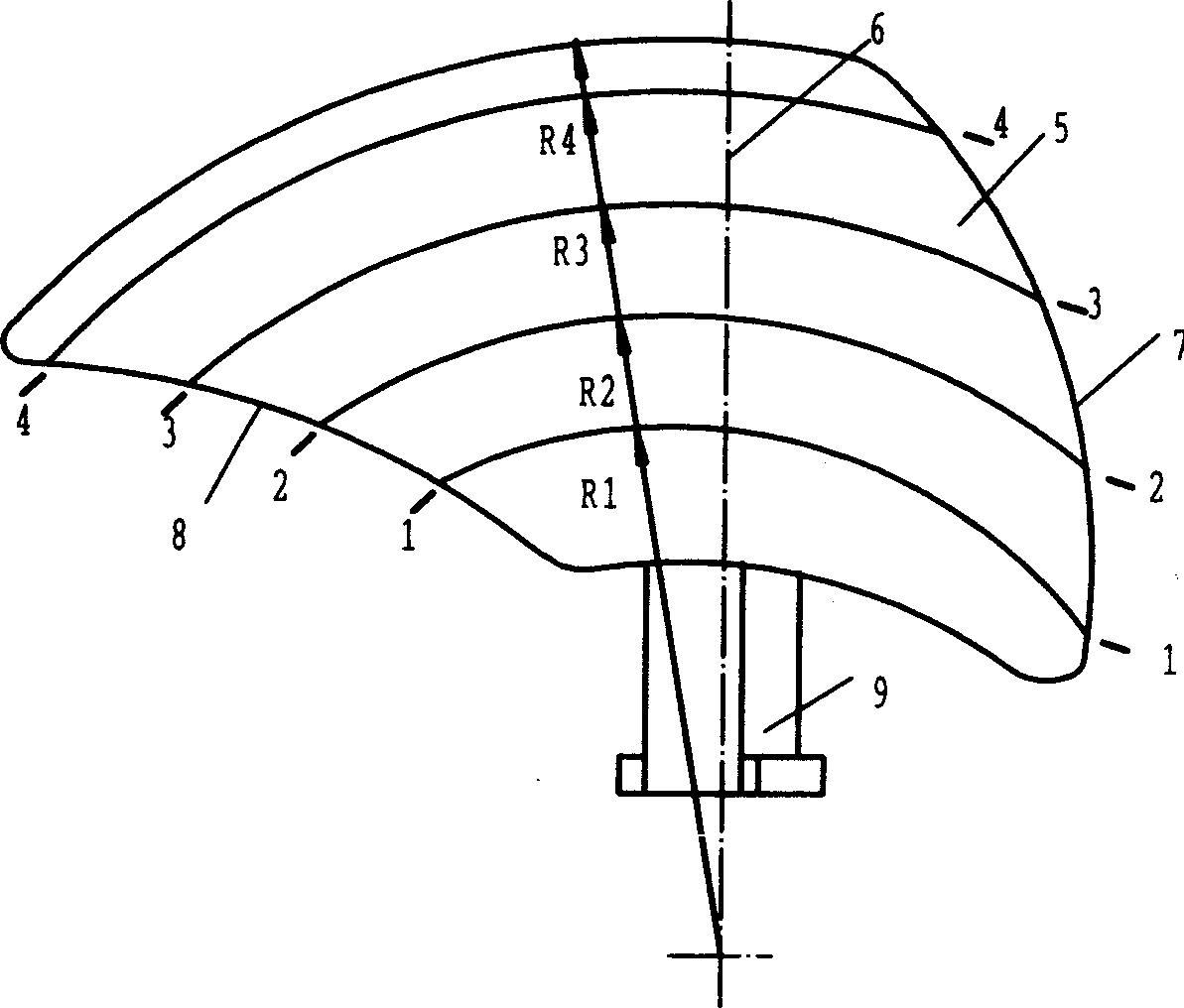

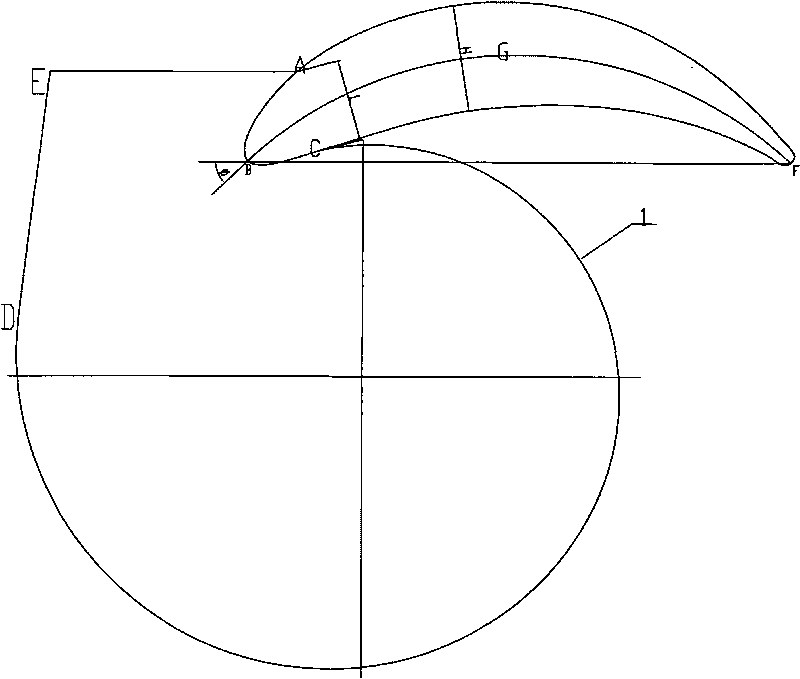

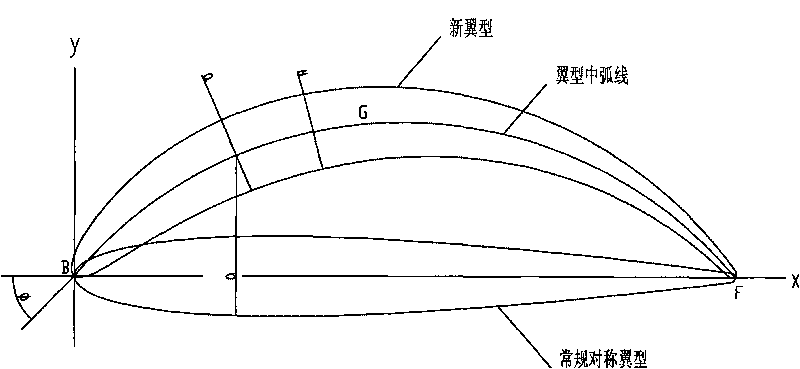

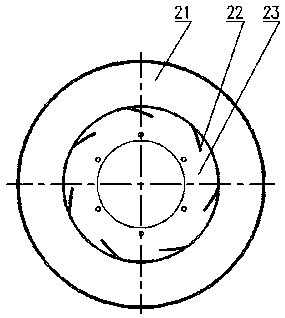

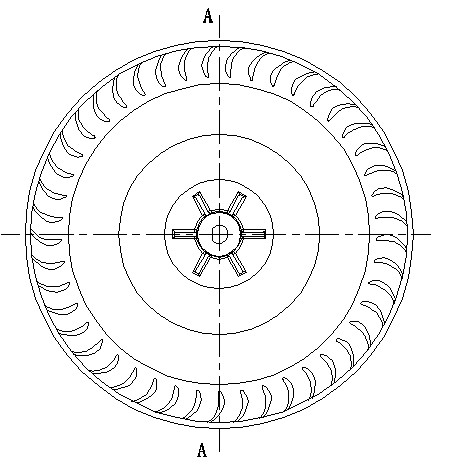

Centrifugal fan impeller for range hood

The invention relates to a centrifugal impeller for a range hood. The centrifugal fan impeller comprises an end ring, a wheel disc and a plurality of blades; an outer edge part of one end of each blade is connected with an inner edge part of the end ring, and the other end face of each blade is connected with an outer edge part of the wheel disc; the centrifugal fan impeller is characterized in that: the cross section of each blade has an airfoil shape; a method for superposing the conventional symmetrical airfoil thickness on a central arched curve is adopted by a generation method for an airfoil molded line, and the central arched line of an airfoil consists of two sections of arcs BE and EF which are tangent to each other. A tangent point E of the arcs BE and EF is the maximum bending position of the airfoil. A projection point of E on a straight line BF where the chord length is is D point, the length of a segment BD is a, the length of the chord BF of the airfoil is c, the maximum bending of the airfoil structure is h, h / c is the maximum relative bending, the maximum thickness of the airfoil structure is L, and L / c is the maximum relative thickness of the airfoil structure. The centrifugal impeller can prevent flow separation in a blade channel or reduce the flow separation degree, the eddy current in the blade channel is reduced, flow loss in the blade channel is reduced, and the inlet loss and noise can be reduced.

Owner:MIDEA GRP CO LTD

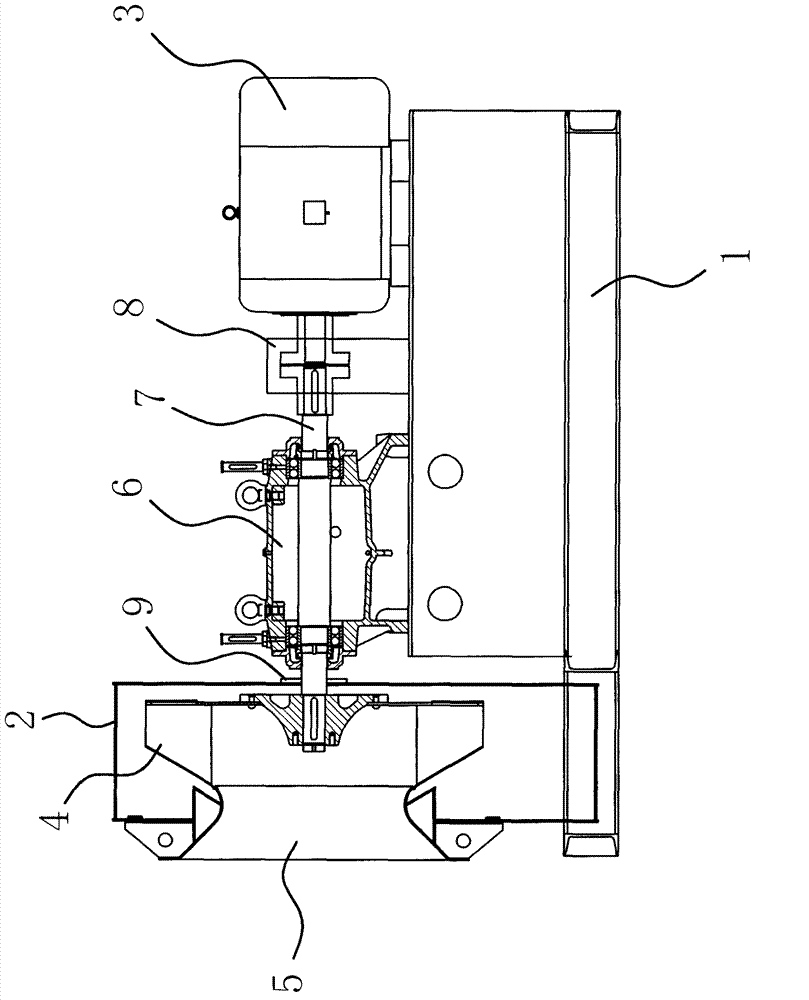

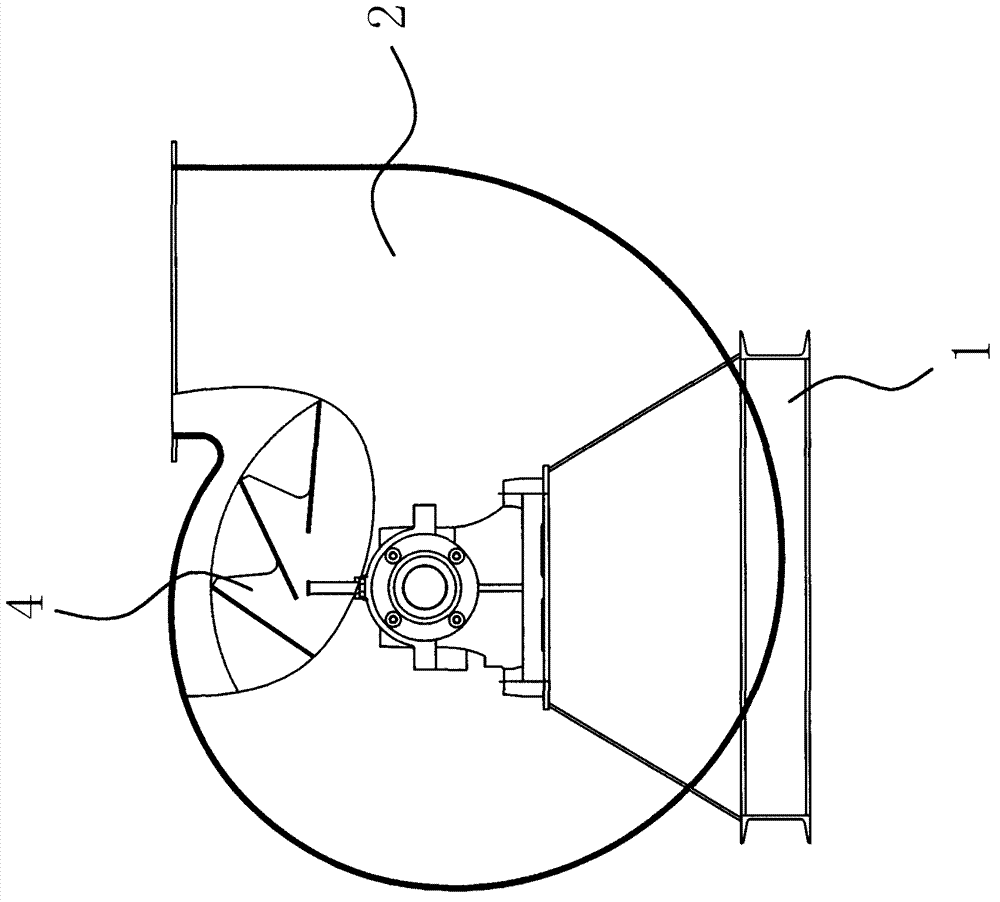

Air guide cover, engine and power equipment

PendingCN108035791AReduce resistanceReduce energy consumptionPump componentsPumpsAbsorption capacitySound energy

The invention discloses an air guide cover, an engine and power equipment. The air guide cover comprises a shell and further comprises a liner plate arranged in the shell. A cavity is formed by the liner plate and the shell. A through hole is formed in the liner plate. The cavity communicates with the internal space of the shell through the through hole. Noise generated when a fan of the air guidecover operates is transmitted into the cavity through the through hole, air in the through hole can generate violent vibration and friction to convert sound energy into heat energy, and thus a resonant noise absorption effect is achieved; the uniformity of air flow in the air guide cover can be improved to avoid vortexes, so that airflow resistance and energy consumption during operation of the fan are reduced, the cooling efficiency of a radiator is improved, and air power noise is lowered. Meanwhile, the cavity is filled with sound absorption materials, and the cavity and the sound adsorption materials are combined to form a combined resonant sound absorption structure, so that the sound absorption frequency bandwidth and the sound absorption capacity are improved, and air power noise is further lowered.

Owner:SANY AUTOMOBILE MFG CO LTD

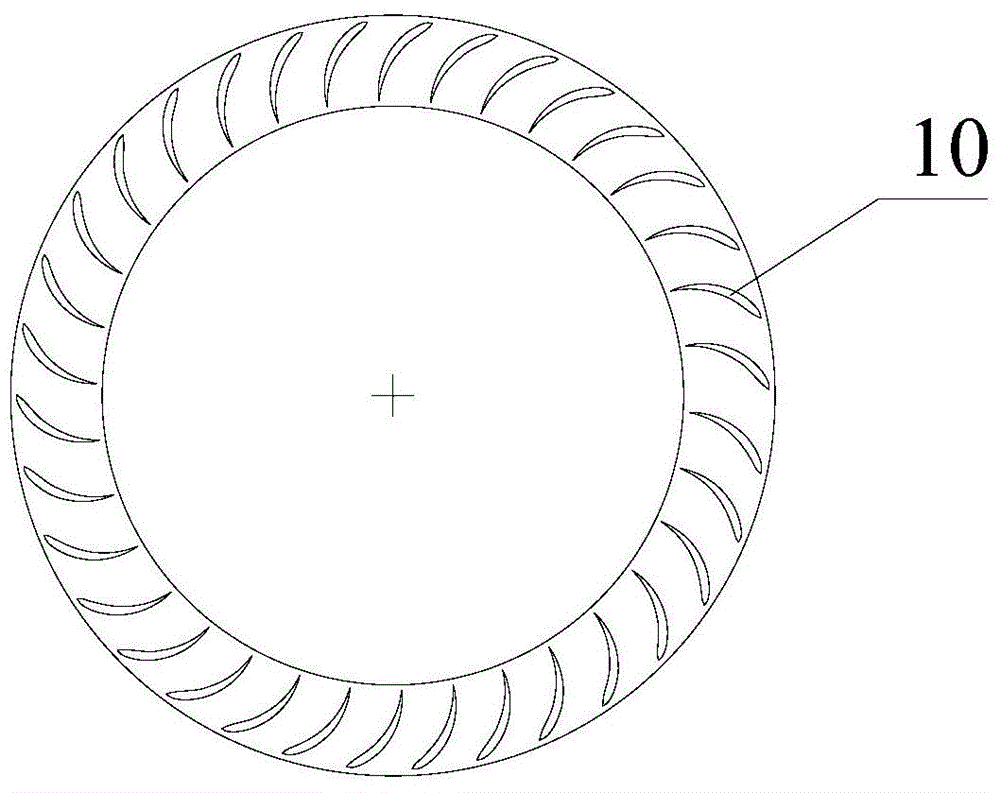

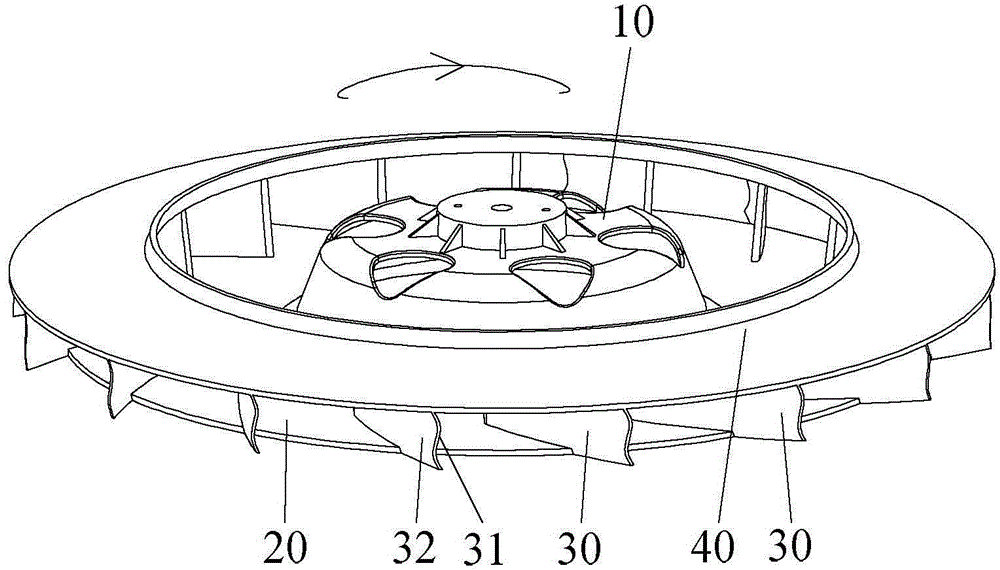

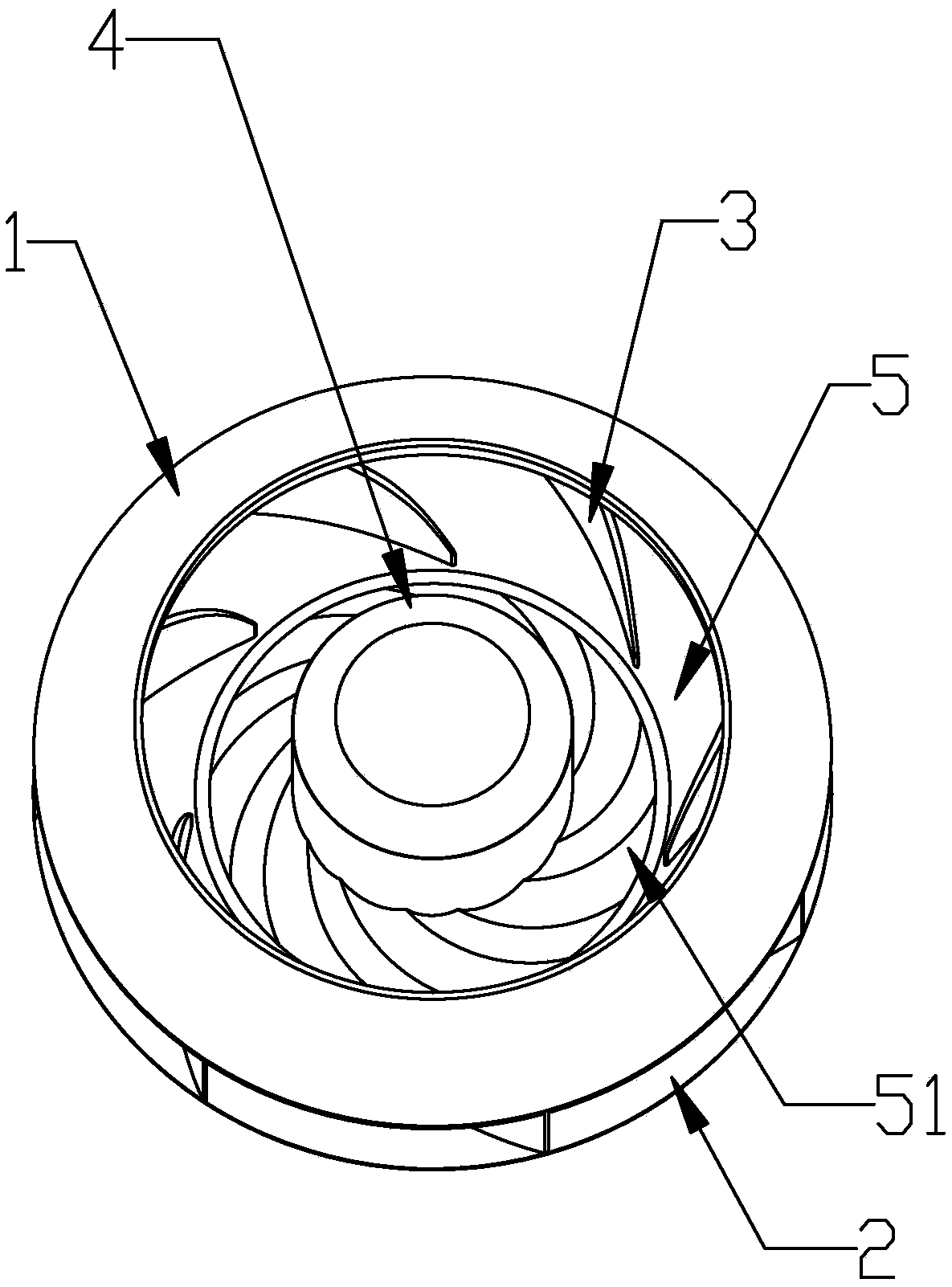

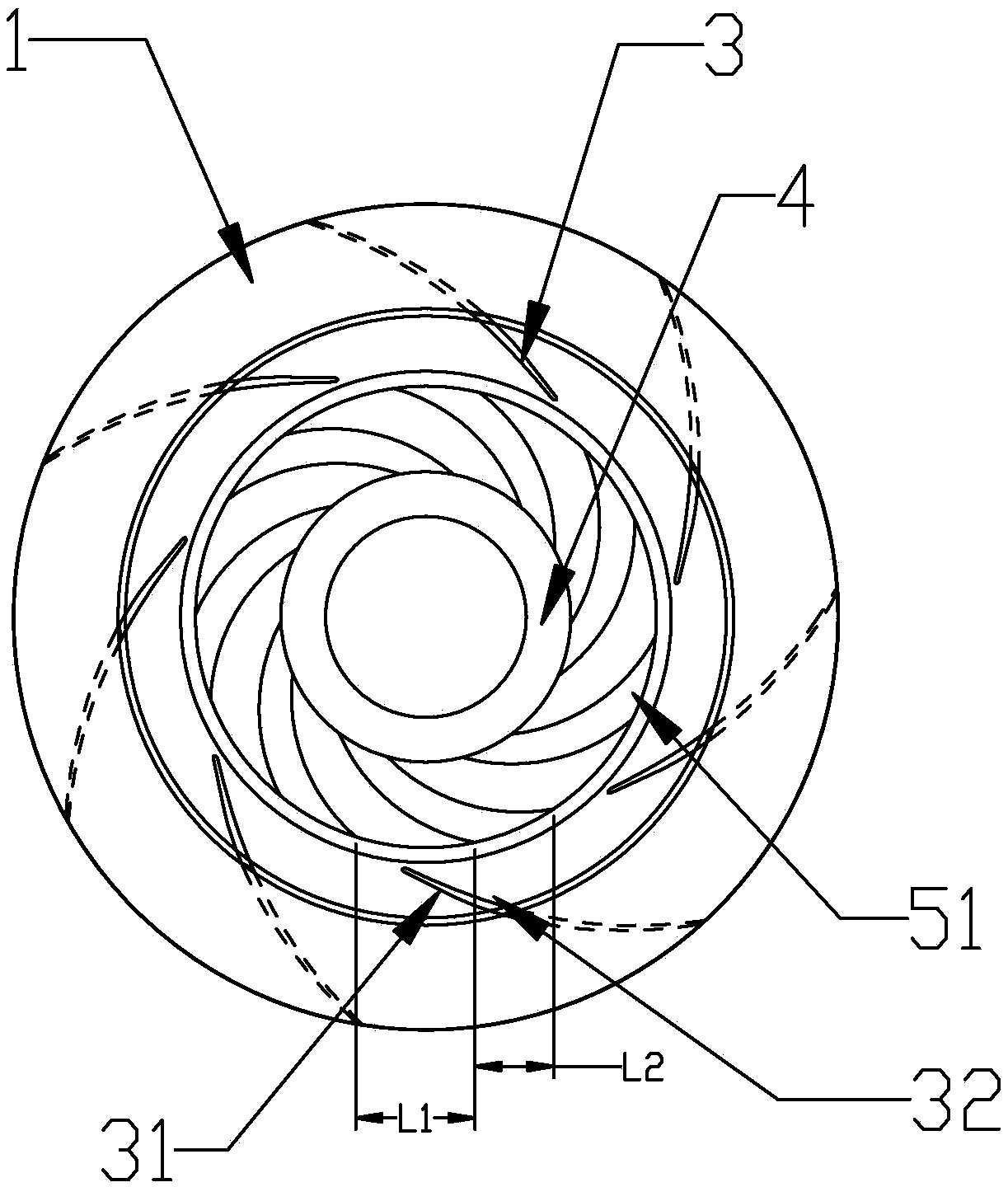

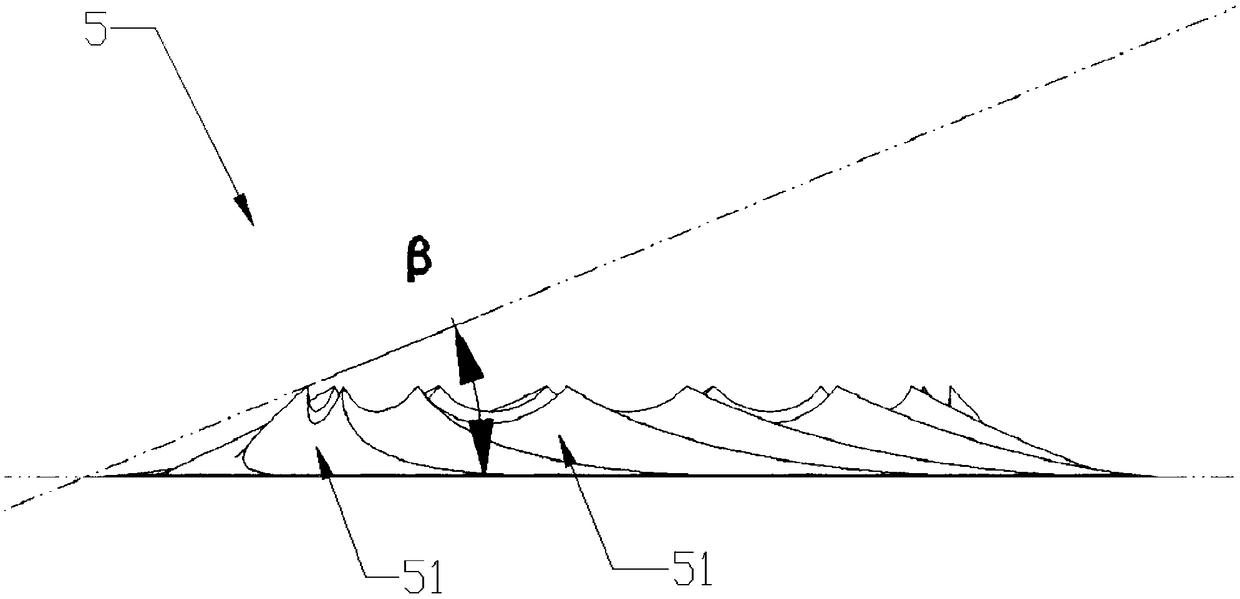

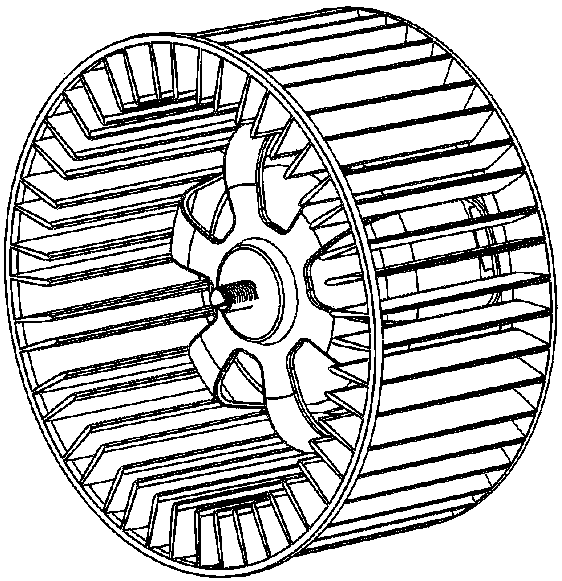

Centrifugal fan and air conditioner with same

ActiveCN104154035AGuaranteed uptimeReduce rotational noisePump componentsPumpsConvex structureCentrifugal fan

The invention provides a centrifugal fan and an air conditioner with the centrifugal fan. The centrifugal fan comprises a hub (10), a base plate (20) and multiple vanes (30), wherein the base plate (20) is arranged on the hub (10) in a sleeved mode, and the multiple vanes (30) are arranged on the base plate (20) and are located on the outer side of the hub (10) in the circumferential direction. Each vane (30) comprises an edge section which is far away from the hub (10) and extends out of the base plate (20), wherein the edge section comprises a first surface (31) and a second surface (32) which is opposite to the first surface (31), a backpressure surface is formed by the first surface (31), a pressure surface is formed by the second surface (32), and the first surface (31) is provided with a first concave-convex structure used for weakening an eddy. By the adoption of the centrifugal fan, the problem that in the prior art, a centrifugal fan is high in noise is solved.

Owner:GREE ELECTRIC APPLIANCES INC

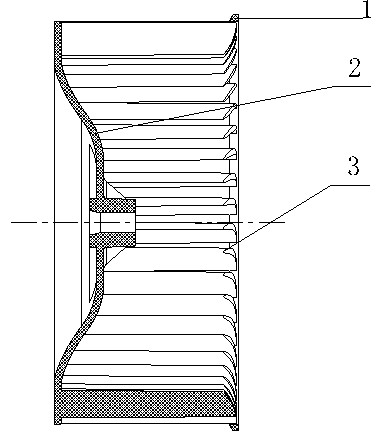

Centrifugal wind wheel with flow guide device

The invention discloses a centrifugal wind wheel with a flow guide device. The centrifugal wind wheel comprises a motor, a front wind wheel plate, a rear wind wheel plate, the flow guide device and aplurality of blades. The flow guide device is disposed between the motor and the blades and provided with a plurality of flow guide passages, a blade flow passage of one blade corresponds to one or more flow guide passages, and the flow guide device can be integrally formed with the rear wind wheel plate or separately mounted on the same. With the aid of the flow guide device, airflow of the rearwind wheel plate can flow into the blades along the blade flow passages when the wind wheel rotates. The centrifugal wind wheel with the flow guide device has the advantages that eddy at the joint ofthe motor and the rear wind wheel plate can be reduced, airflow at the inlets of blades can be smoother, and eddy separation on the blade suction surfaces can be reduced, so that the working efficiency of the wind wheel is effectively improved and wind wheel eddy noise is lowered.

Owner:FANS TECH ELECTRIC CO LTD

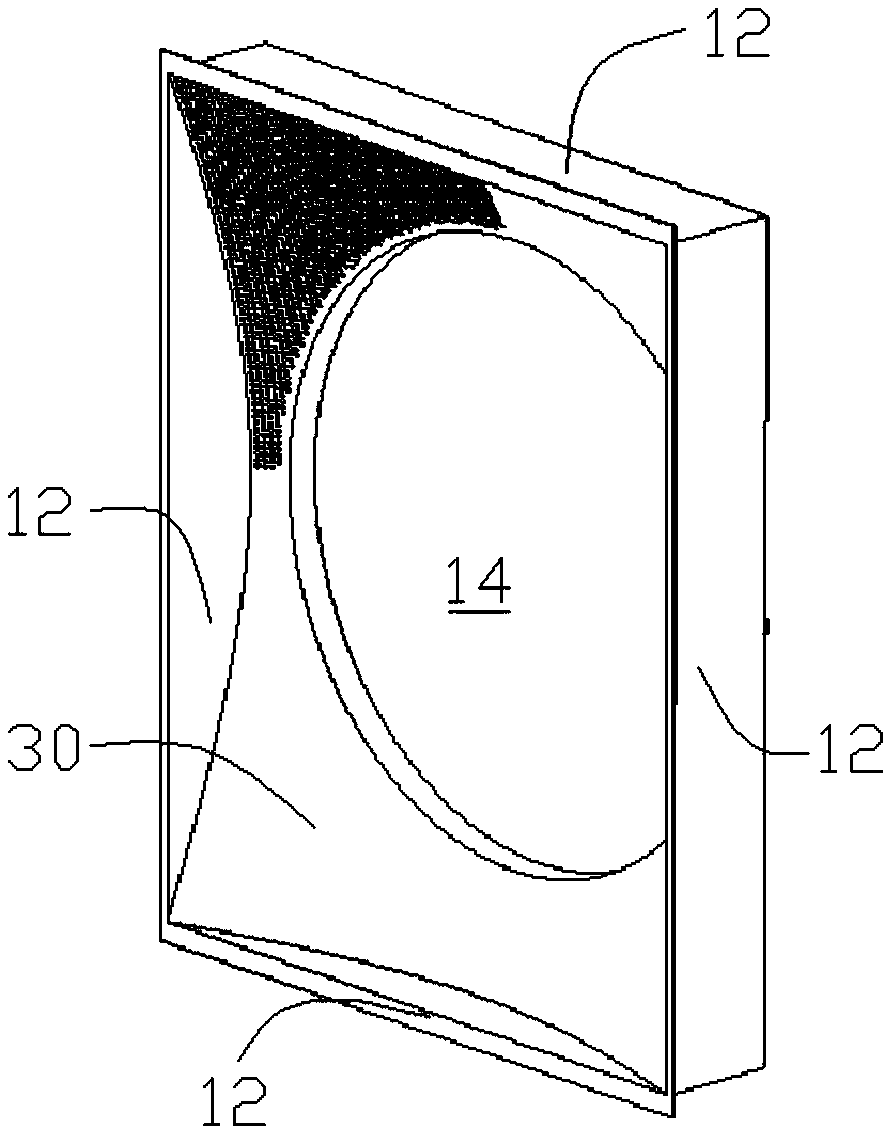

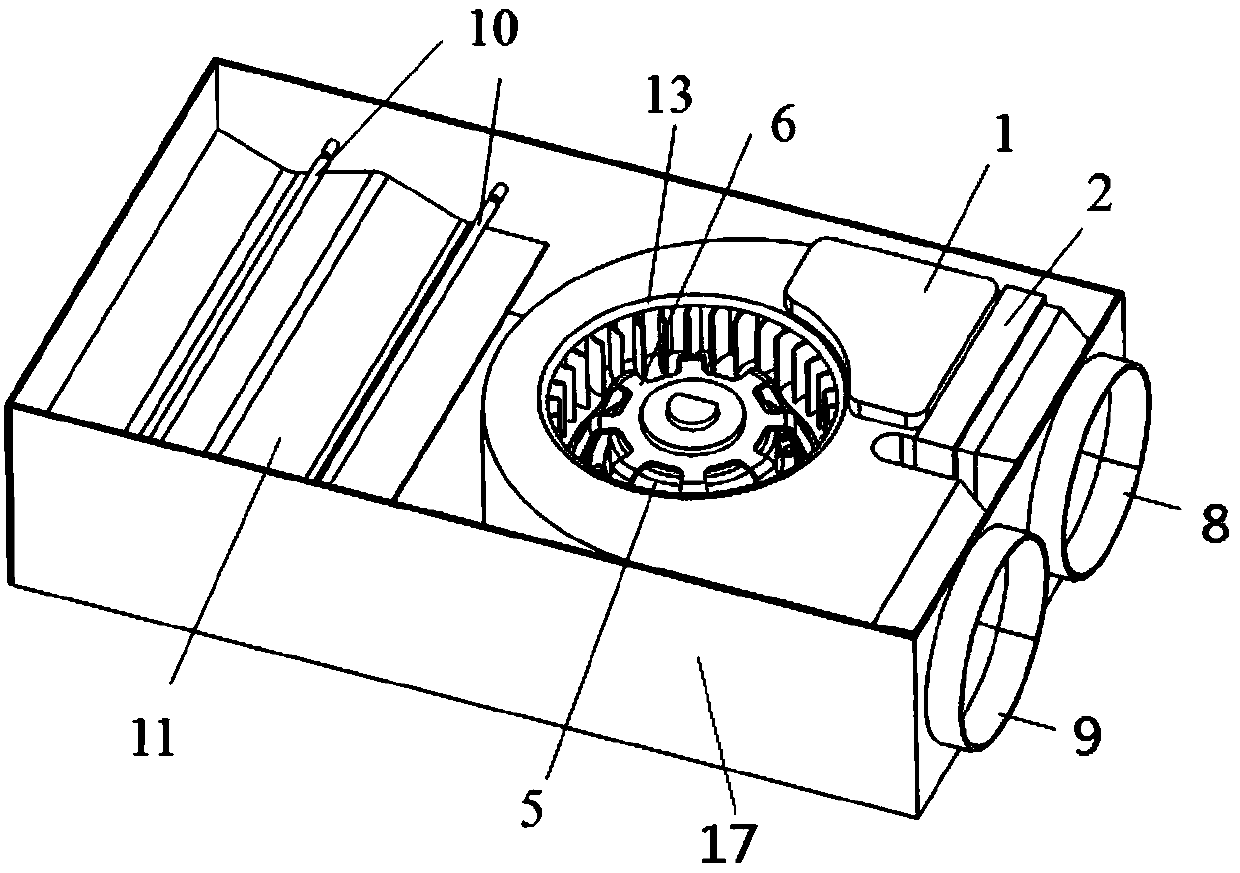

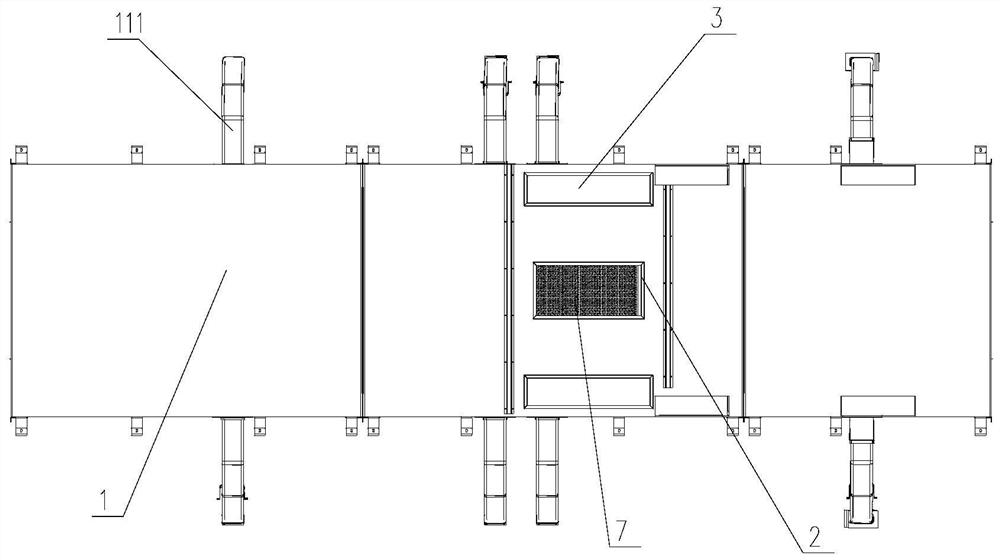

Double-face-air-incoming bidirectional multi-blade centrifugal fan type air exchange device and working method thereof

ActiveCN108374795AIncrease air volumeReduce eddy current noisePump componentsPump installationsGratingEngineering

The invention discloses a double-face-air-incoming bidirectional multi-blade centrifugal fan type air exchange device and a working method thereof. The air exchange device comprises a box shell, a reflecting panel, a double-face-air-incoming multi-blade centrifugal fan and two gold pipes, the reflecting panel, the double-face-air-incoming multi-blade centrifugal fan and the gold pipes are arrangedin the box shell, the reflecting panel and the gold pipes are positioned on the left side of the box shell, the centrifugal fan is positioned on the right side of the box shell, the end of the reflecting panel is fixed on the inner wall of the left side of the box shell, the reflecting panel is positioned at 1 / 2 height of the box shell, an air incoming grating is arranged on the upper surface ofthe box shell and directly faces the reflecting panel, the gold pipes are positioned on the reflecting panel, one side, close to the centrifugal fan, of the reflecting panel is of a flat plate structure, and the other side of the reflecting panel is of a wavy structure. The air exchange device and the working method are large in air quantity, high in pressure coefficient and low in noise.

Owner:浙江名流科技有限公司

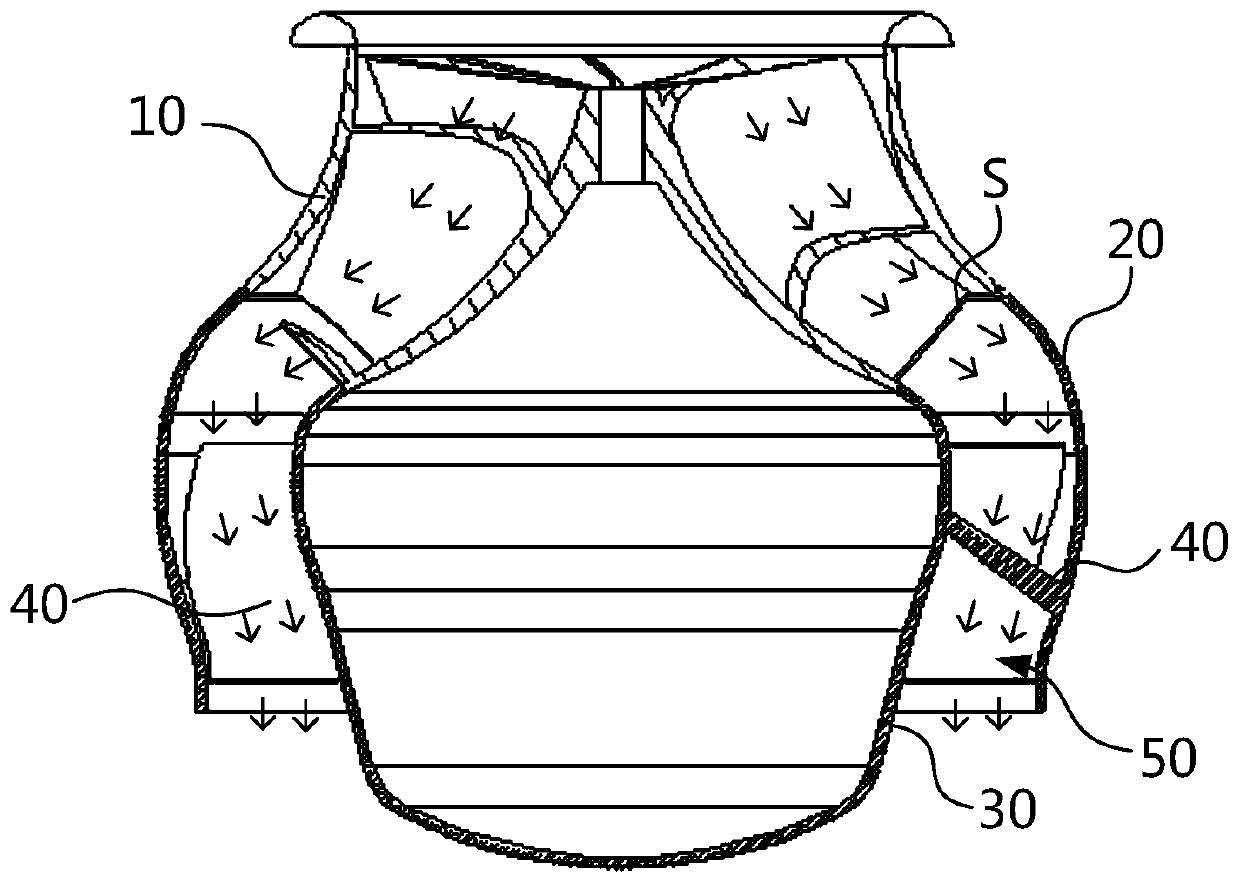

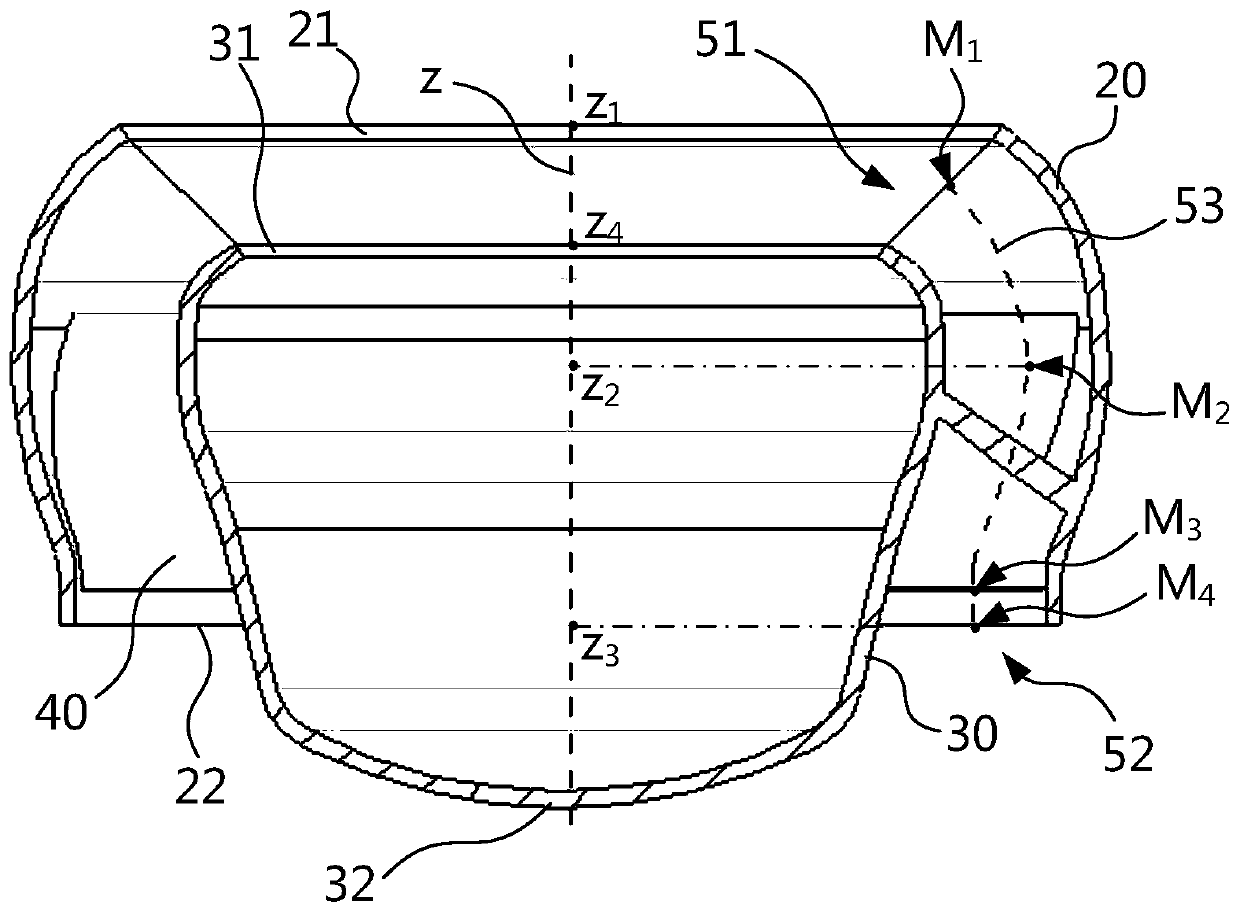

Racemization structure, mixed flow fan assembly and air conditioner

PendingCN111156203AEliminate peripheral velocityAvoid separationPump componentsPumpsMixed flowEngineering

The invention relates to a racemization structure, a mixed flow fan assembly and an air conditioner. The racemization structure comprises a racemization wheel cover (20), a racemization wheel hub (30), and racemization blades (40), wherein a through inner cavity is formed in the racemization wheel cover (20); the racemization wheel hub (30) is located in the inner cavity of the racemization wheelcover (20); the racemization blades (40) are connected between the cavity wall of the inner cavity and the outer wall of the racemization wheel hub (30); the intersection interfaces of the racemization blades (40) and the racemization wheel hub (30) are blade root sections (41); the intersection interfaces of the racemization blades (40) and the racemization wheel cover (20) are blade outer edge sections (42); the projections of contour lines of at least one of the blade root sections (41) and the blade outer edge sections (42) on a longitudinal section passing through an axis of the racemization structure each comprise a drag line; and a first included angle between a tangent of the portion, corresponding to a front edge (43) of the corresponding racemization blade (40), of each drag lineand the axis is greater than a second included angle between the tangent of the portion, corresponding to a tail edge (44) of the corresponding racemization blade (40), of the drag line and the axis.According to the racemization structure, the mixed flow fan assembly and the air conditioner, air supply performance can be improved.

Owner:GREE ELECTRIC APPLIANCES INC

Low-noise air conditioner air duct of railway passenger car

PendingCN113928358AReduce resistanceReduce pressure headRailway heating/coolingSound producing devicesLow noiseRailway passenger car

The invention discloses a low-noise air conditioner air duct of a railway passenger car. The low-noise air conditioner air duct comprises an air conditioner return air inlet (3), an air conditioner air supply outlet (2), an air supply channel and an air return channel (11), the air conditioner air supply outlet is connected with the air supply channel, a silencer (7) is arranged in the air supply channel below the air conditioner air supply outlet, and the silencer comprises a left arc plate (701) and a right arc plate (702); the adjacent sides of the left arc plate and the right arc plate are connected into a whole, and the opposite sides of the left arc plate and the right arc plate extend towards one end of the air supply channel in an arc shape. The two ends of the left arc plate and the two ends of the right arc plate are sealed through reinforcing rib plates (704) correspondingly, so that a sound absorption cavity is defined by the left arc plate, the right arc plate, the air supply channel bottom plate and the reinforcing rib plates at the two ends. Sound absorption micropores (03) are evenly distributed in the left arc plate and the right arc plate respectively, and the sound absorption cavity is filled with sound absorption cotton used for absorbing noise of the air conditioning unit. The low-noise air conditioner air duct is convenient to process, and the riding comfort of passengers in the passenger compartment is greatly improved.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

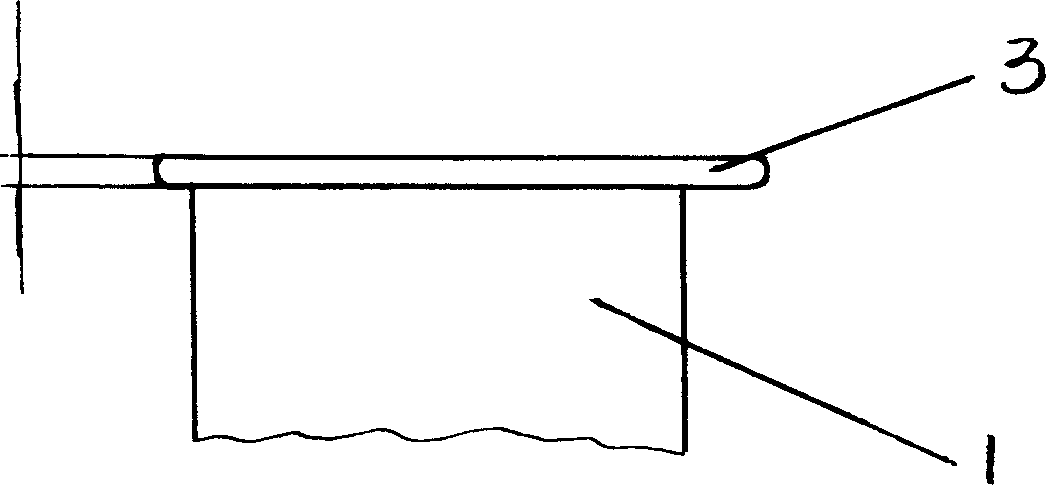

Vane blade tip structure of vane type machine

InactiveCN1414249ASuppression of eddy current noiseReduce eddy current noisePump componentsPumpsPulp and paper industry

The present invention relates to a blade apex structure of blade type machine, it is characterized by that a certain width is added on the circumferential direction of blade apex rotation along the blade to form blade apex secondary blade, and large quantity of concave depressions are set up on relative surface of blade apex secondary blade and blade type machine shell inner wall and further optimize the width, thickness and shape of blade apex secondary blade, thereby achieves the aim of effectively inhibit the vortex noise of blade type machine.

Owner:王晓强

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com