Centrifugal fan with vane guide grooves for noise reduction

A technology of centrifugal fan and diversion groove, which is applied to components, mechanical equipment, machines/engines, etc. of pumping devices used for elastic fluids, and can solve problems such as difficulty in reducing fan noise and complex eddy current parameters, and achieve noise reduction effects Good, area and intensity reduction, eddy current noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

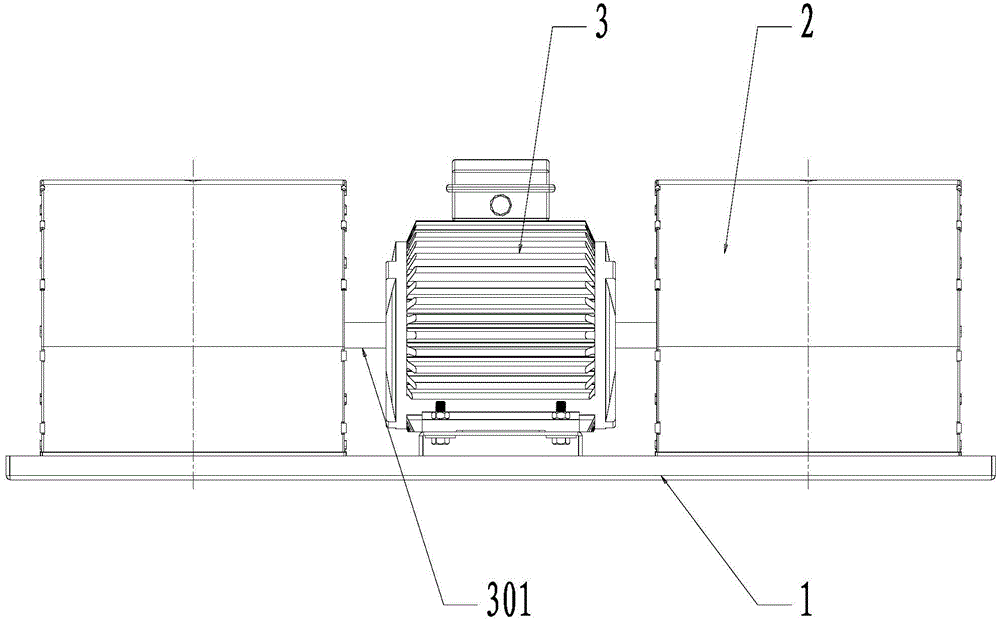

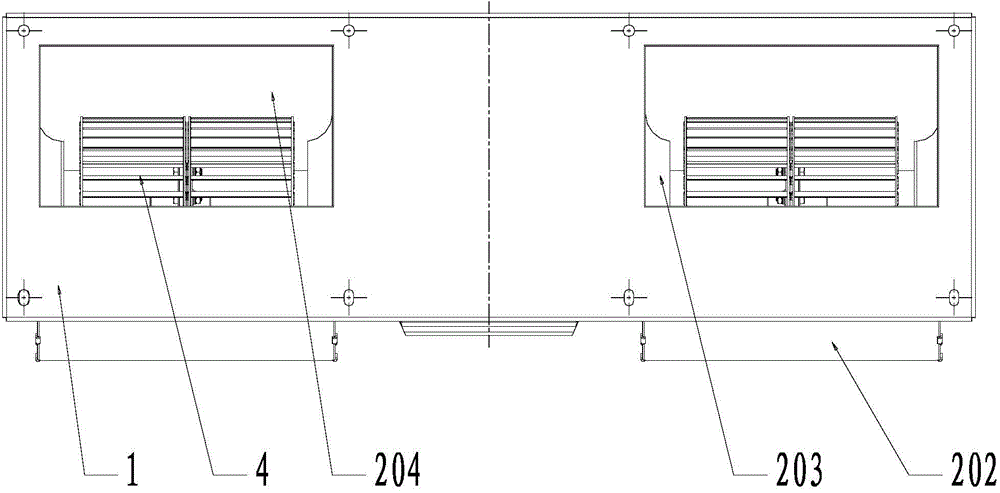

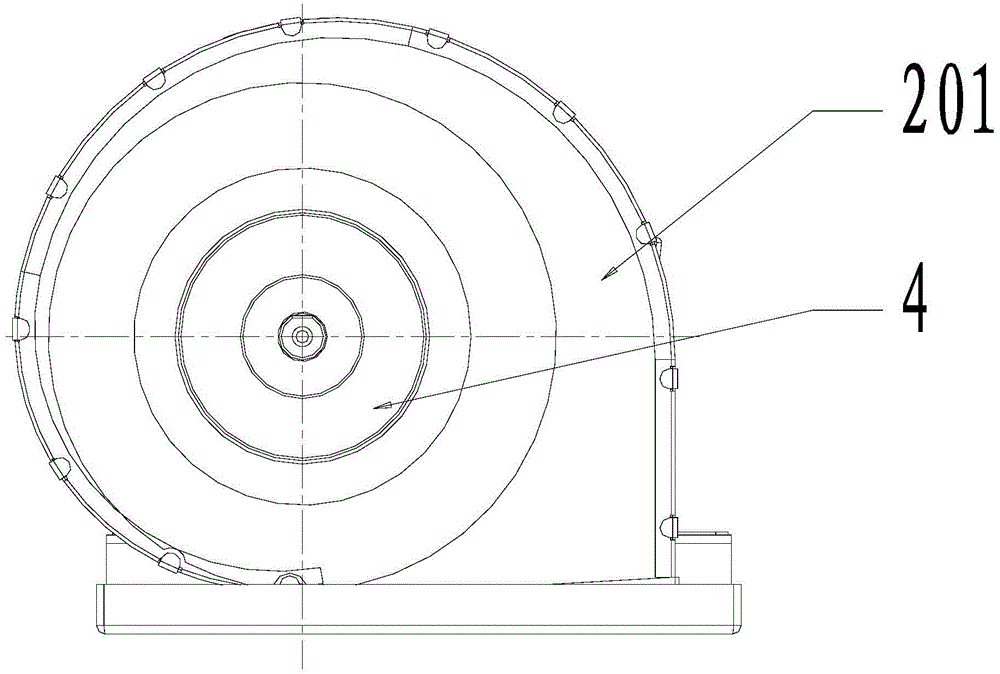

[0027] like Figure 1 to Figure 4 As shown, a centrifugal fan with blade guide grooves for noise reduction, including a base 1, a volute 2, a motor 3 and a wind wheel 4, the motor 3 is a double-extended shaft four-pole motor, and its two transmission shafts 301 are respectively fixed The wind wheel 4 in the volute 2, the volute 2 and the motor 3 are fixed on the base 1, and the installation angle A of the blade 410 of the wind wheel 4 is 30°-40°, such as Image 6 As shown, the blade 410 includes a main body 411 and mounting parts 412 arranged at both ends of the main body 411. The main body 411 is made of a rectangular raw material with one long side as the center line, and the two wide sides are reversely rotated. The length of the wide side is 90-100mm, and the length of the wide side is 18-24mm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com