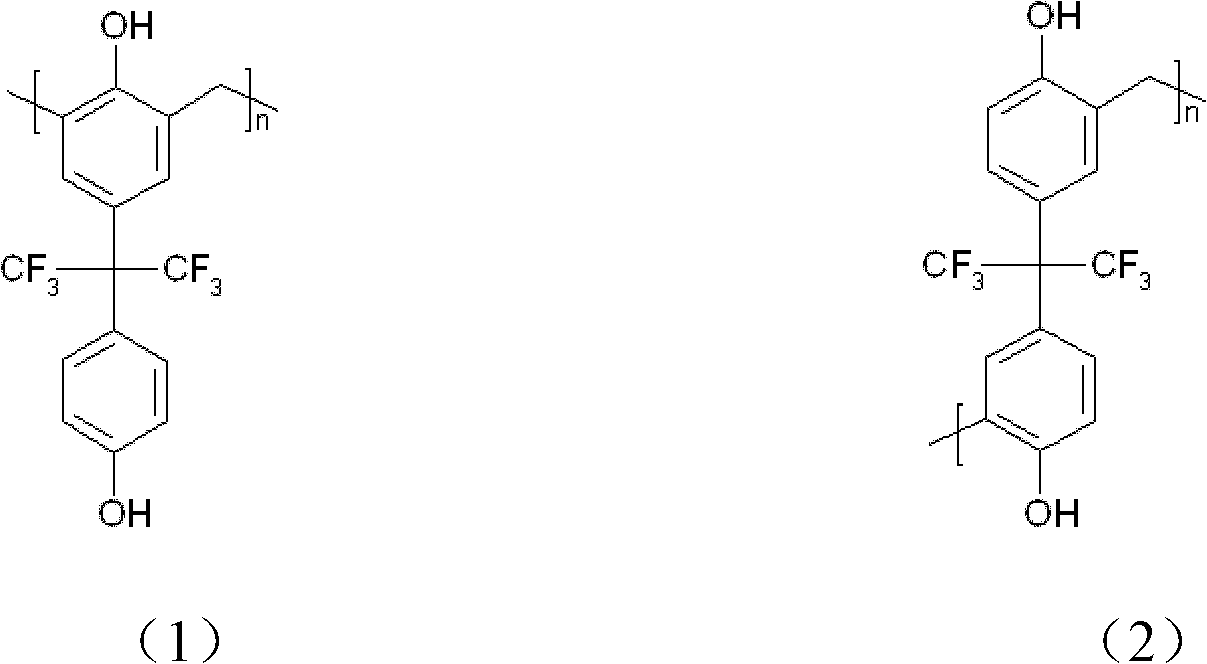

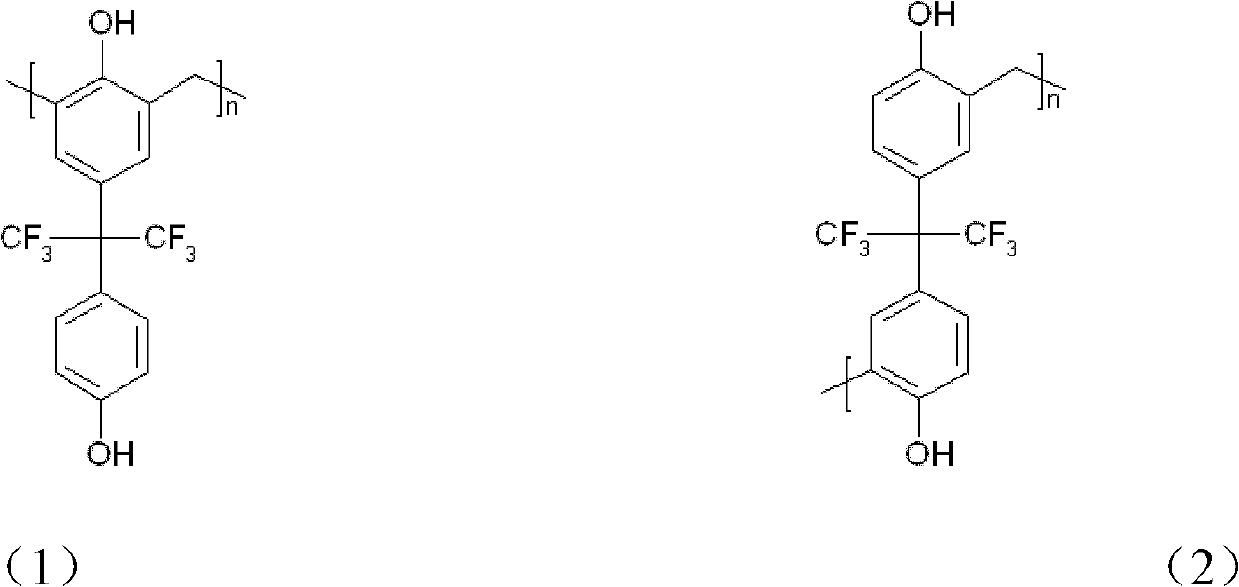

Fluorine-containing novolac resin and preparation method and application of fluorine-containing novolac resin

A technology of novolac resin and hexafluorobisphenol, which is applied in the field of low-molecular-weight fluorine-containing phenolic resin and its preparation, can solve the problems of low fluorine element content and insufficient improvement of comprehensive performance, and achieve comprehensive performance improvement, free The effect of low phenol residue and no three-hazard discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Add 350ml of n-butanol and 336g of hexafluorobisphenol A into a 500ml reaction kettle equipped with a thermometer, a stirrer and a reflux condenser, and stir at 60°C to fully dissolve the hexafluorobisphenol A. Then 5 g of oxalic acid was added and the temperature was raised to 80°C. Add a total of 60g of paraformaldehyde in batches, about 10g for the first feeding, and about 8g for each subsequent feeding. Control the feeding time within 45 minutes. After feeding, the temperature was raised to 95°C, and the reaction was stirred vigorously for about 5 hours. Raise the temperature to 160°C, distill under reduced pressure at a vacuum of -0.8 MPa, condense and recover the solvent through a condenser tube, and finally obtain a black viscous product, namely 345 g of fluorine-containing novolak resin.

[0037] The properties of the obtained fluorine-containing phenolic resin are: softening point 50°C (test standard: GB / T1633-2000), hydroxyl equivalent 137g / mol (test method:...

Embodiment 2

[0039] Add 300ml of toluene and 50ml of methyl ethyl ketone into a 500ml reaction kettle equipped with a thermometer, agitator and reflux condenser, add 380g of hexafluorobisphenol A and 7.6g of benzoic acid at the same time, stir at 50°C to fully dissolve and then heat up to 75°C . Then 50 g of paraformaldehyde was dissolved in methanol at a ratio of 1:6, and added to the hexafluorobisphenol A solution at a rate of 1 drop per second. After all the paraformaldehyde solution was dropped, the reaction temperature was raised to 95° C., and the reaction was stirred vigorously for about 7 hours. Finally, vacuum distillation was performed at 180° C. to distill off the solvent and unreacted substances to obtain about 403 g of fluorine-containing novolak resin.

[0040] The properties of the fluorine-containing phenolic resin are: softening point 60°C (test standard: GB / T 1633-2000), hydroxyl equivalent 145g / mol (test method: acetyl chloride titration hydroxyl value), and its average...

Embodiment 3

[0042] Add 400ml of benzene, 500g of hexafluorobisphenol A and 4g of salicylic acid into a 500ml reaction kettle equipped with a thermometer, stirrer and reflux condenser, stir at 60°C to fully dissolve and then heat up to 75°C. Then 49g of paraformaldehyde was added into the hexafluorobisphenol A solution three times. After the feeding was completed, the reaction temperature was raised to 95° C., and the reaction was vigorously stirred for about 7 hours. Finally, distill under reduced pressure at 200° C. to distill off the solvent and unreacted substances to obtain about 460 g of fluorine-containing novolak resin.

[0043] The properties of the fluorine-containing phenolic resin are: softening point 90°C (test standard: GB / T 1633-2000), hydroxyl equivalent 182g / mol (test method: acetyl chloride titration hydroxyl value), and its average molecular weight measured by GPC is 3100.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Hydroxyl equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com