Type 1-3 polymer/cement based piezoelectric composite material and preparation method thereof

A piezoelectric composite material and polymer technology, which is applied in the field of 1-3 type polymer/cement-based piezoelectric composite material and its preparation, can solve the problem of interfacial adhesion, restrict the intelligent development of civil engineering structures, and improve temperature Moisture-induced deformation coordination problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

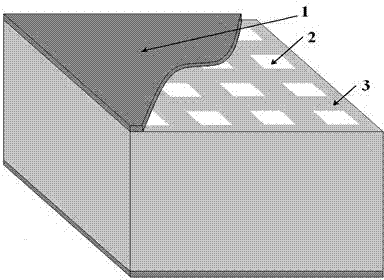

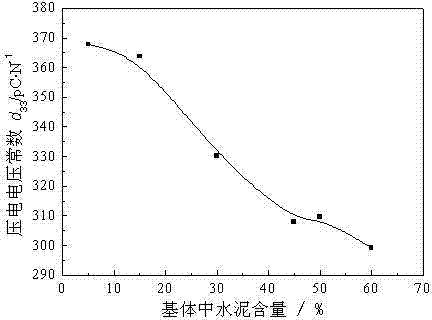

[0074] A 1-3 polymer / cement-based piezoelectric composite material, using a mixture of E-55 epoxy resin and Portland cement as the matrix, and using niobium lithium zirconium titanate piezoelectric ceramics as the functional body. The body is cut into multiple rows of vertical columns, and the matrix is filled around and inside the functional body by casting; wherein the mass ratio of polymer to cement is 0.3:1, and the volume ratio of piezoelectric ceramic to matrix is 4 :5. It is prepared as follows:

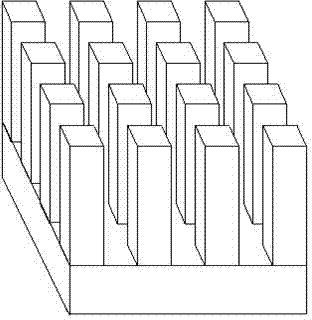

[0075] (1) Take a piezoelectric ceramic block, first cut a series of grooves on it horizontally, and then cut a series of grooves in the direction perpendicular to it, so that a series of vertical columns are formed on the piezoelectric ceramic block. Keep the volume ratio of the piezoelectric ceramic to the substrate 4:5, and the cross-sectional area of the vertical column is 1 mm×1 mm;

[0076] (2) After cutting, clean the cut ceramic block repeatedly with acetone to remo...

Embodiment 2

[0083] A 1-3 polymer / cement-based piezoelectric composite material, using a mixture of 731 epoxy resin and ferro-aluminate cement as a matrix, and using niobium-magnesium-zirconium-zirconate-titanate piezoelectric ceramic as a functional body. Cut into multiple rows of vertical columns, the substrate is filled on the functional body by casting. Specifically, the substrate is cast in the interval between the vertical columns of the functional body and on the surrounding walls of the ceramic block, so that the functional body and the substrate cross Mix together; wherein the mass ratio of polymer to cement is 0.5:1, and the volume ratio of piezoelectric ceramic to matrix is 3:5. The preparation is as in Example 1.

[0084] The properties of the resulting composite material are:

[0085]

Embodiment 3

[0087] A 1-3 polymer / cement-based piezoelectric composite material, using a mixture of AG80 epoxy resin and aluminate cement as the matrix, and lead zirconate titanate piezoelectric ceramic as the functional body, which is cut into Multiple rows of vertical columns, the base body is filled on the functional body by casting, specifically, the base body is cast in the interval between the vertical columns of the functional body and on the surrounding walls of the ceramic block, so that the functional body and the base body are cross-mixed ; Among them, the mass ratio of polymer to cement is 0.15:1, and the volume ratio of piezoelectric ceramic to matrix is 1:5. The preparation is as in Example 1.

[0088] The properties of the resulting composite material are:

[0089]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com