Method for improving purity of nickel-based superalloy

A nickel-based high-temperature alloy, purity technology, applied in the field of alloy smelting, can solve the problems of increasing oxide inclusion content, affecting purity, cumbersome process, etc., to achieve the effect of improving comprehensive performance and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

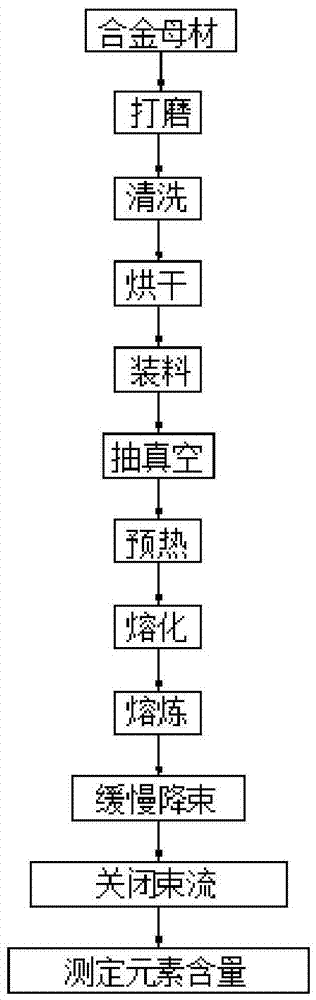

[0022] 1. Pretreatment of nickel-based superalloys

[0023] 1. Select a commercially available nickel-based superalloy Inconel 718 alloy block material, and cut it into a circular nickel-based alloy block with a size of Φ100mm×8mm by wire electric discharge cutting.

[0024] 2. First, take a small part of the raw material for component testing;

[0025] 3. Use sandpaper to polish the surface of the nickel-based alloy block to remove the oxide layer and impurity-enriched areas on the surface to ensure the purity of the alloy before smelting. When the surface of the sample is polished until it is clean and bright, the sequence of using sandpaper is: 200#, 600#, 1000#, 1500#. Then place it in deionized water to wash and dry, the drying time is 5 hours, and the drying temperature is 50 degrees.

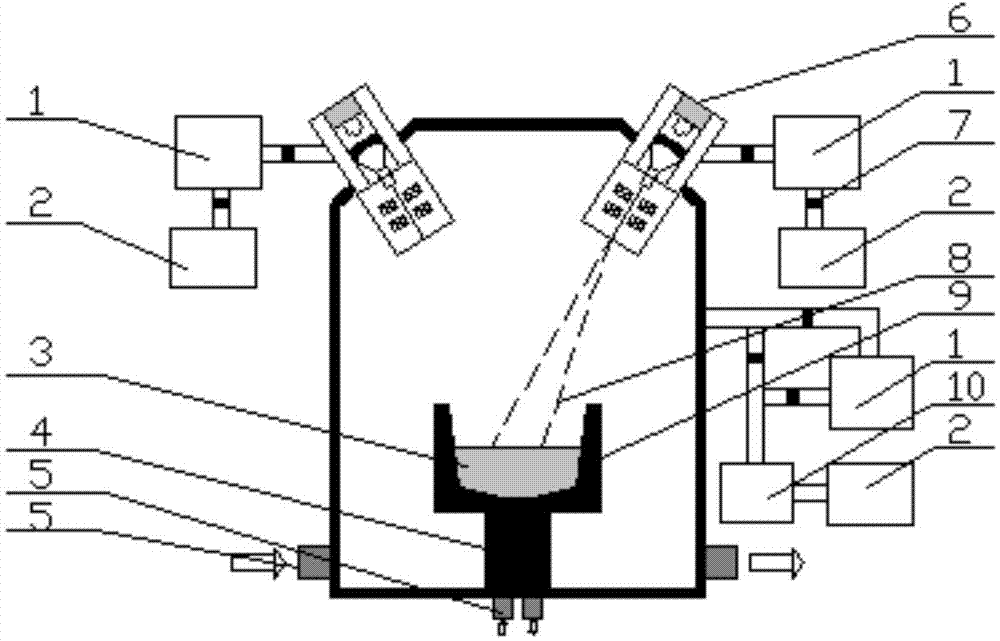

[0026] 2. Electron beam remelting technology removes impurity element atoms

[0027] 1. Place the round piece of nickel-based alloy stably in the water-cooled copper crucible of the el...

Embodiment 2

[0033] 1. Pretreatment of nickel-based superalloys

[0034] 1. Select a commercially available nickel-based superalloy Inconel 718 alloy block material, and cut it into a circular nickel-based alloy block with a size of Φ100mm×8mm by wire electric discharge cutting.

[0035] 2. First, take a small part of the raw material for component testing;

[0036] 3. Use sandpaper to polish the surface of the nickel-based alloy block to remove the oxide layer and impurity-enriched areas on the surface to ensure the purity of the alloy before smelting. When the surface of the sample is polished until it is clean and bright, the sequence of using sandpaper is: 200#, 600#, 1000#, 1500#. Then wash and dry in deionized water, the drying time is 4 hours, and the drying temperature is 65 degrees.

[0037] 2. Electron beam remelting technology removes impurity element atoms

[0038] 1. Place the round piece of nickel-based alloy stably in the water-cooled copper crucible of the electron beam ...

Embodiment 3

[0044] 1. Pretreatment of nickel-based superalloys

[0045] 1. Select a commercially available nickel-based superalloy Inconel 718 alloy block material, and cut it into a circular nickel-based alloy block with a size of Φ100mm×8mm by wire electric discharge cutting.

[0046] 2. First, take a small part of the raw material for component testing;

[0047] 3. Use sandpaper to polish the surface of the nickel-based alloy block to remove the oxide layer and impurity-enriched areas on the surface to ensure the purity of the alloy before smelting. When the surface of the sample is polished until it is clean and bright, the sequence of using sandpaper is: 200#, 600#, 1000#, 1500#. Then place it in deionized water to wash and dry, the drying time is 3 hours, and the drying temperature is 80 degrees.

[0048] 2. Electron beam remelting technology removes impurity element atoms

[0049] 1. Place the round piece of nickel-based alloy stably in the water-cooled copper crucible of the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com