Patents

Literature

107results about How to "Take full advantage of performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

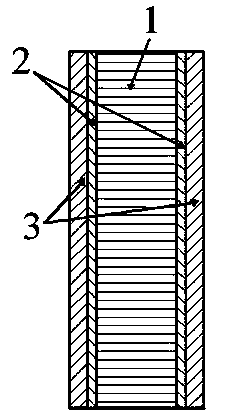

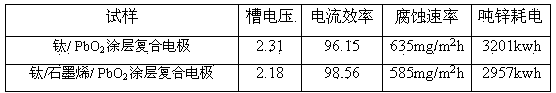

Titanium/graphene/oxide combined electrode

ActiveCN103526235APerfect quantum tunnelingImprove conductivityElectrodesCharge carrier mobilityTitanium

The invention relates to a titanium / graphene / oxide combined electrode, which belongs to the technical field of electroplating. The combined electrode is such structured that graphene and an oxide coating are successively coated on a matrix, wherein the oxide coating is an oxide of Mn, Pb or La, and the matrix is a titanium or titanium alloy plate or screen plate. A plurality of layers of graphene are coated on the matrix, each layer being 0.4 to 1.0 mm thick. The thickness of the oxide coating is 150 mu m to 700 mu m. The titanium or titanium alloy plate is 0.5 to 10 mm thick, and the mesh diameter of the screen plate is 0.1 to 5 mm. According to the invention, overall performance of the electrode is improved by using a stable lattice structure and high carrier mobility of graphene, advantages of each layer of graphene are performed, so the electrode has the advantages of high strength, good conductivity, high corrosion resistance, a long service life and the like.

Owner:KUNMING UNIV OF SCI & TECH

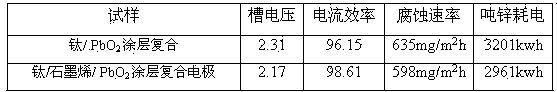

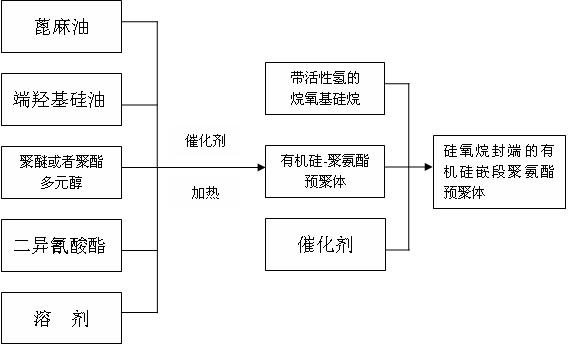

Preparation method for siloxane-terminated organosilicon block polyurethane prepolymer

ActiveCN102633983ATake full advantage of performanceGood adhesionPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention discloses a preparation method for siloxane-terminated organosilicon block polyurethane prepolymer. The method includes the following steps: polyester polyol or polyether polyol, hydroxy-terminated silicone oil, castor oil and the like are dripped into aromatic or aliphatic diisocyanate, so that organosilicon block polyurethane prepolymer is obtained; and afterwards, under organic tin catalyst, siloxane with activated hydrogen is added into the organosilicon block polyurethane prepolymer to react, so that the stable siloxane-terminated organosilicon block polyurethane prepolymer is obtained. The cured film of the prepolymer prepared by the method has the advantages of high elasticity, low-temperature flexibility, high water resistance, high adhesive force, high wear resistance and high aging resistance. The siloxane-terminated organosilicon block polyurethane prepolymer can be widely applied in sealing or coating materials for environment protection, buildings, electronics and other industries and other fields.

Owner:INST OF APPLIED CHEM JIANGXI ACAD OF SCI

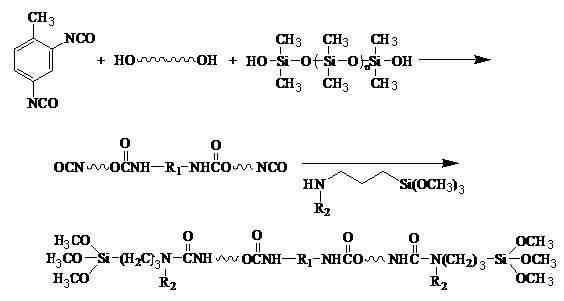

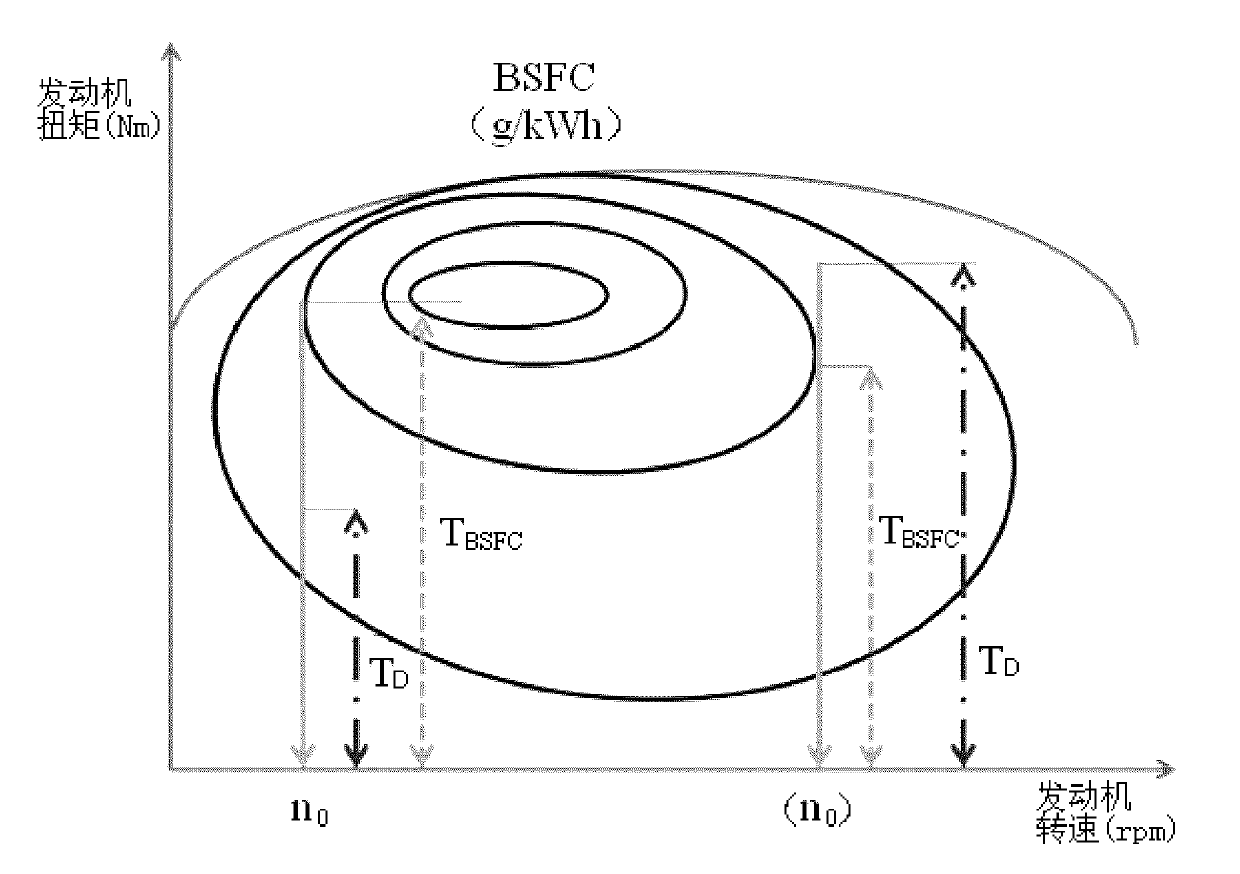

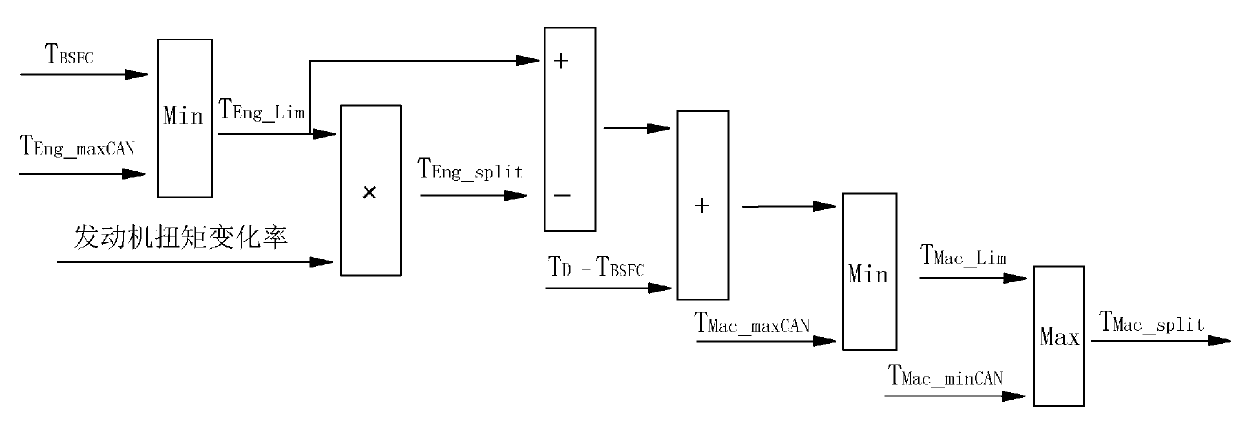

Hybrid electric vehicle engine based on energy optimization and distribution method of motor torque

ActiveCN103863311ATake full advantage of performanceAvoid consumptionHybrid vehiclesPlural diverse prime-mover propulsion mountingPower batteryElectrical battery

The invention relates to a hybrid electric vehicle engine based on energy optimization and a distribution method of a motor torque, wherein the distribution method comprises the following steps: an off-line specific fuel consumption Map graph under all conditions is provided, so that the engine and the motor together take part in a requirement torque in response to driving; the motor and the engine will work in harmony under the same rotating speed so that their operating efficiency is optimized; a present state of charge (SOC) for a vehicle-mounted power battery, the engine torque and the motor torque are distributed according to the following situations; when SOC is more than a first preset value, the engine and the motor enter into a first distribution mode; when SOC is less than a second preset value, the engine and the motor enter into a second distribution mode, otherwise they keep a present operating status. The method is characterized in that performance advantages of the motor and the engine can be fully achieved, so that the system is always operated in a high-efficiency region, the energy consumption cost of the vehicle is reduced, the harmful gas is greatly reduced in emission, and it is beneficial to energy saving and environmental protection.

Owner:SAIC MOTOR

Casting method of magnesium alloy casting

InactiveCN103231016AGuaranteed decompositionGuaranteed fillingFoundry mouldsFoundry coresInterfacial reactionCasting mold

The invention provides a casting method of a magnesium alloy casting. With the method, advantages of different casting methods are utilized, and defects of the methods are overcome. With a special shell preparation method and a method for preventing magnesium alloy-casting mold interfacial reaction, a unique casting technology suitable for thin-wall complex magnesium alloy part production is formed. The method has important significance for developing magnesium alloy performance advantages and satisfying automotive magnesium alloy application requirements.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

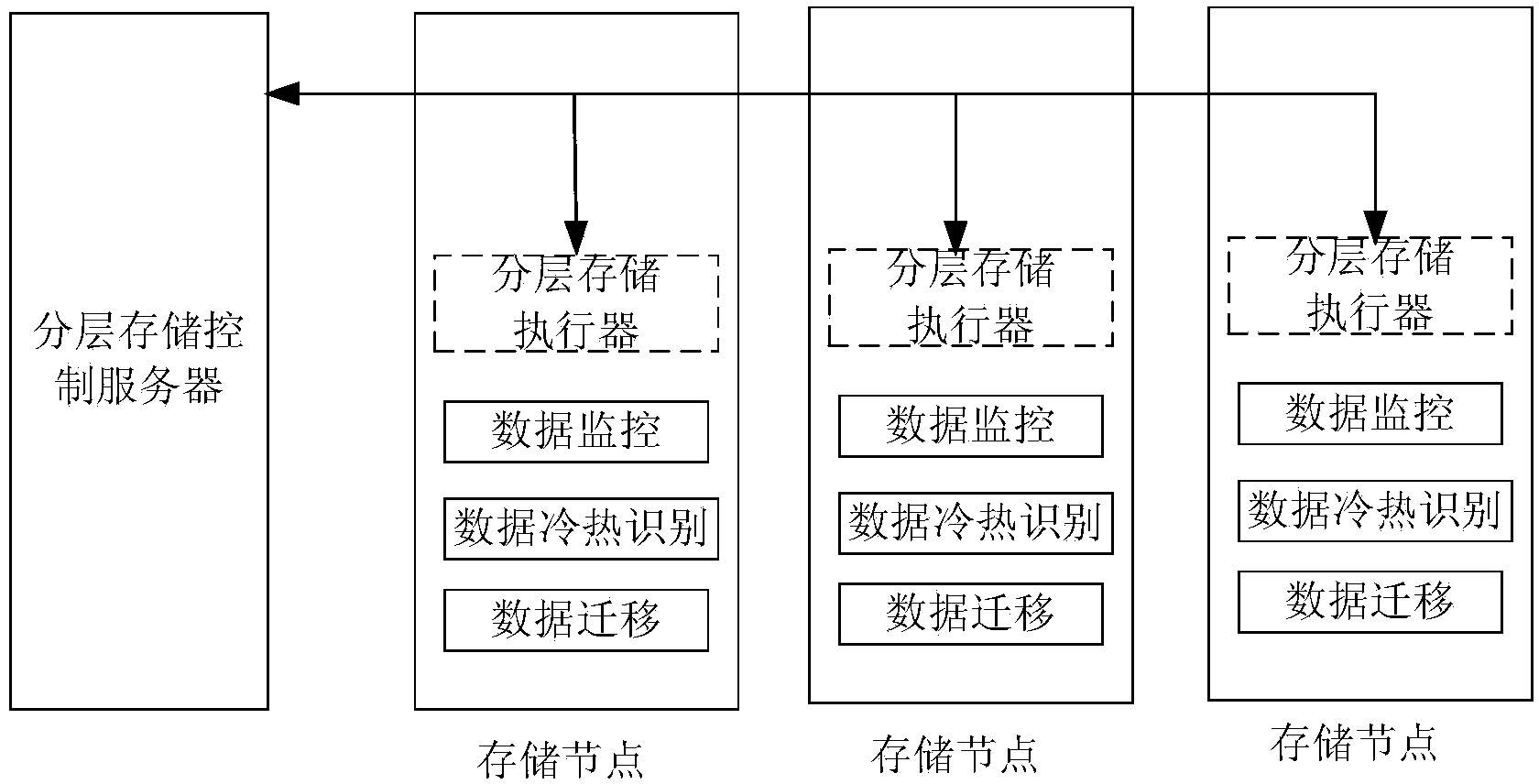

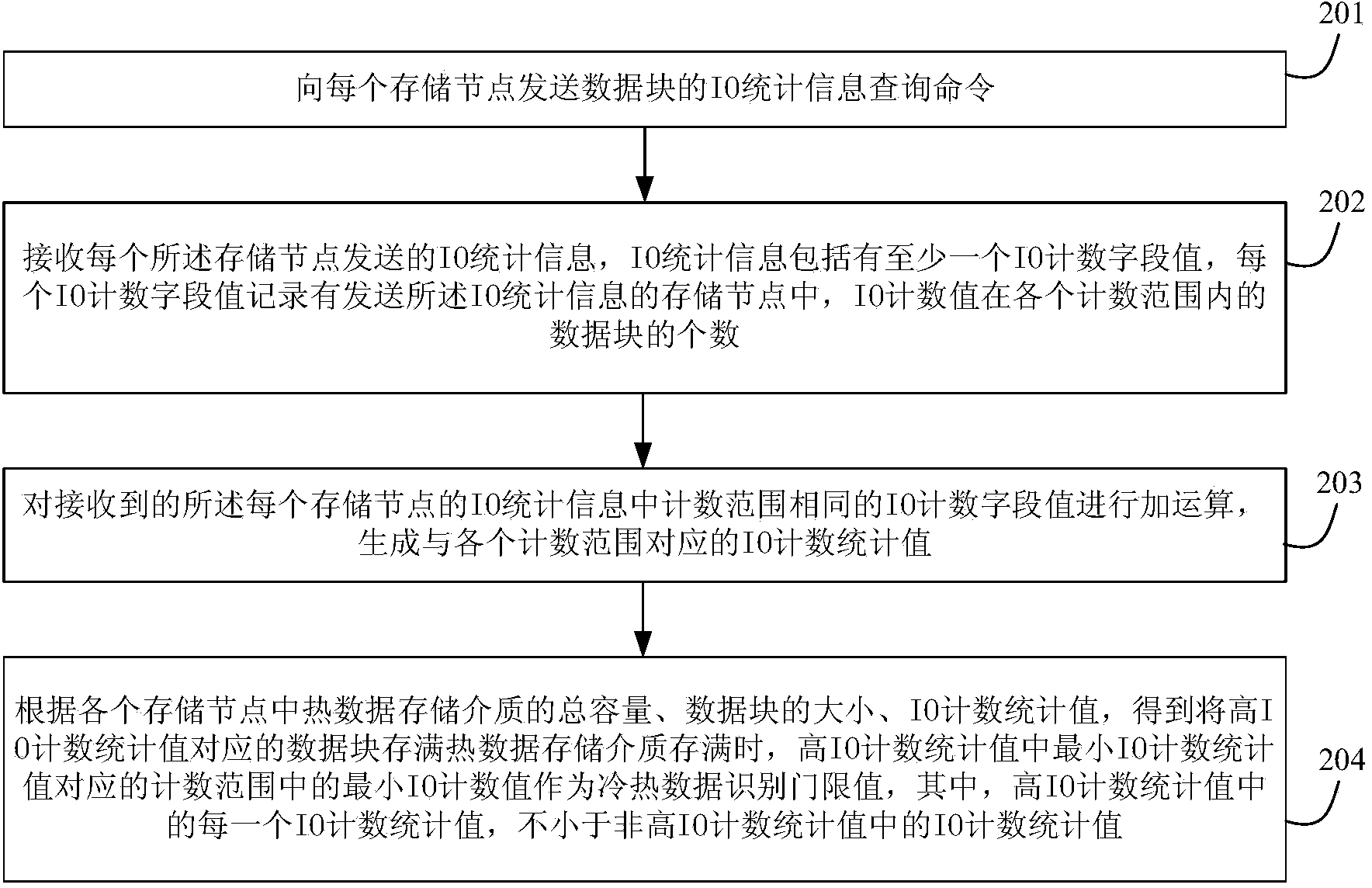

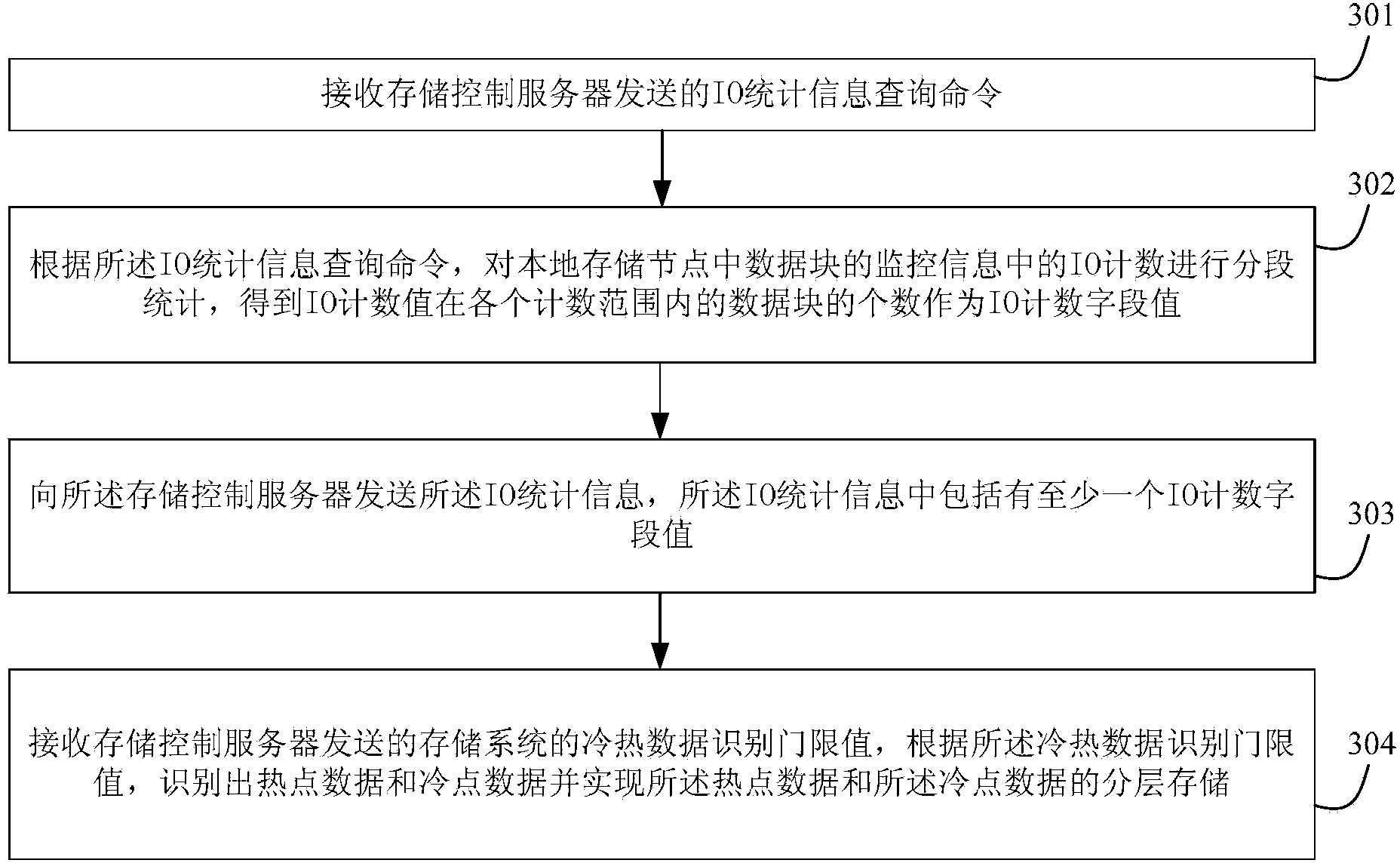

Cold and hot data identification threshold value calculation method, device and system

ActiveCN103631538AImplement data migrationTake full advantage of performanceInput/output to record carriersNumeric ValueBand counts

The invention relates to a cold and hot data identification threshold value calculation method, device and system. The method comprises the following steps of transmitting a data block IO (input / output) statistical information query command to each storage node; receiving IO statistical information from each storage node; performing addition operation on IO count field values in the same count ranges in the IO statistical information received from each storage node, generating an IO count statistical value corresponding to each count range, and obtaining a minimum IO count value in the count range corresponding to a minimum IO count statistical value in high IO count statistical values when data blocks corresponding to the high IO count statistical values are filled with hot data storage media as a cold and hot data identification threshold value according to the overall capacity of the hot data storage media, the sizes of the data blocks and the IO count statistical values in each storage node. According to the method, the device and the system, each storage node in a storage system can independently finish the hierarchical data storage of the whole storage system in a coordination way.

Owner:HUAWEI TECH CO LTD

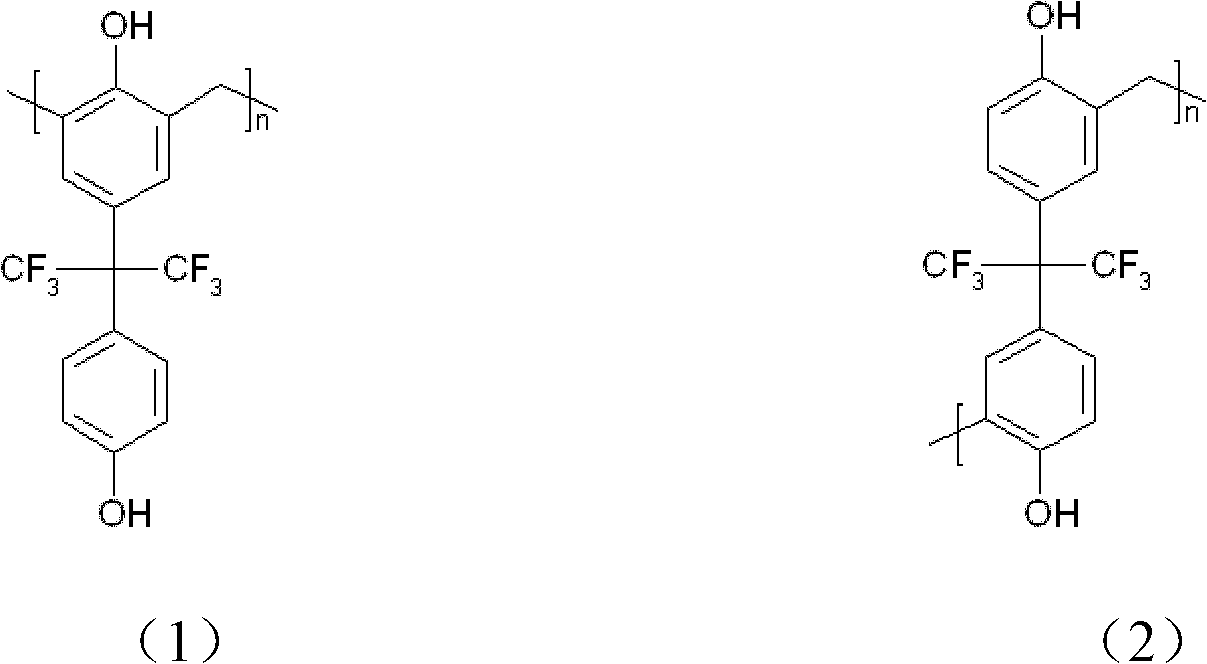

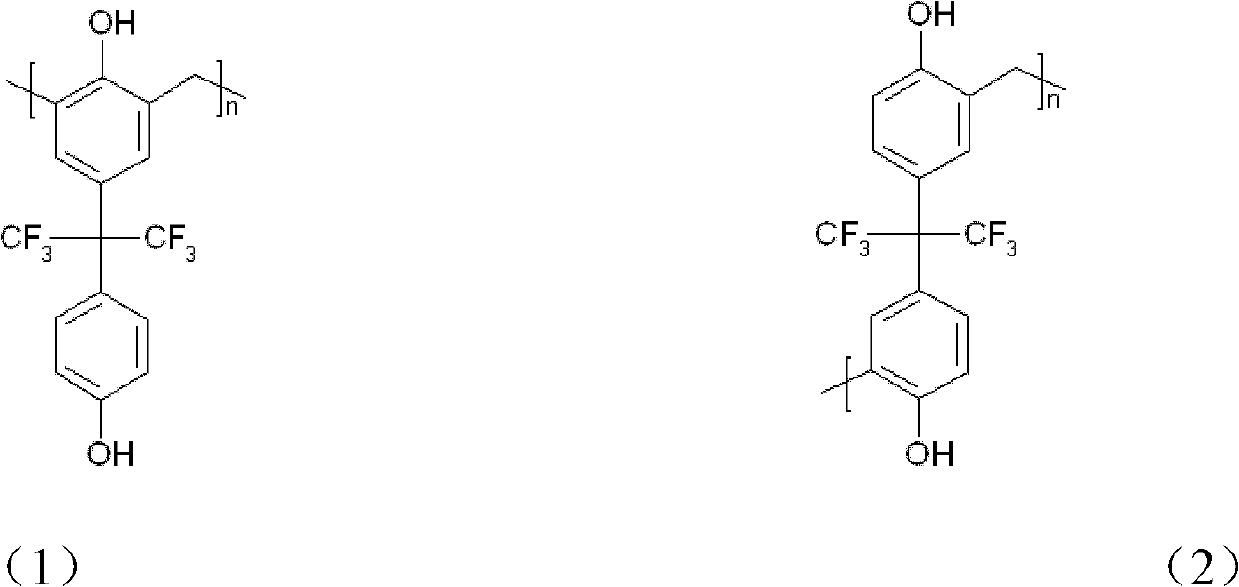

Fluorine-containing novolac resin and preparation method and application of fluorine-containing novolac resin

The invention discloses a fluorine-containing novolac resin, a preparation method of the fluorine-containing novolac resin and application of the fluorine-containing novolac resin, serving as a curing agent. The preparation method of the fluorine-containing novolac resin comprises the following step of performing a reaction of hexafluoro bisphenol A and solid paraformaldehyde by using organic acid as a catalyst to obtain the fluorine-containing novolac resin. The fluorine-containing novolac resin can be used as the curing agent to be cured with epoxide resin. High-content fluorine is induced into the curing agent, so that the comprehensive performance of an epoxide resin cured product is greatly promoted. A production process is controlled by adopting an acid catalysis method and a method of feeding paraformaldehyde serving as the raw material in batch. In the production process, the three wastes are not discharged, wherein a reaction solvent can be recycled. The production process is environmental-friendly. The structure of the fluorine-containing novolac resin is shown in the following formula (1) or (2).

Owner:ETERNAL CHEM (CHINA) CO LTD +1

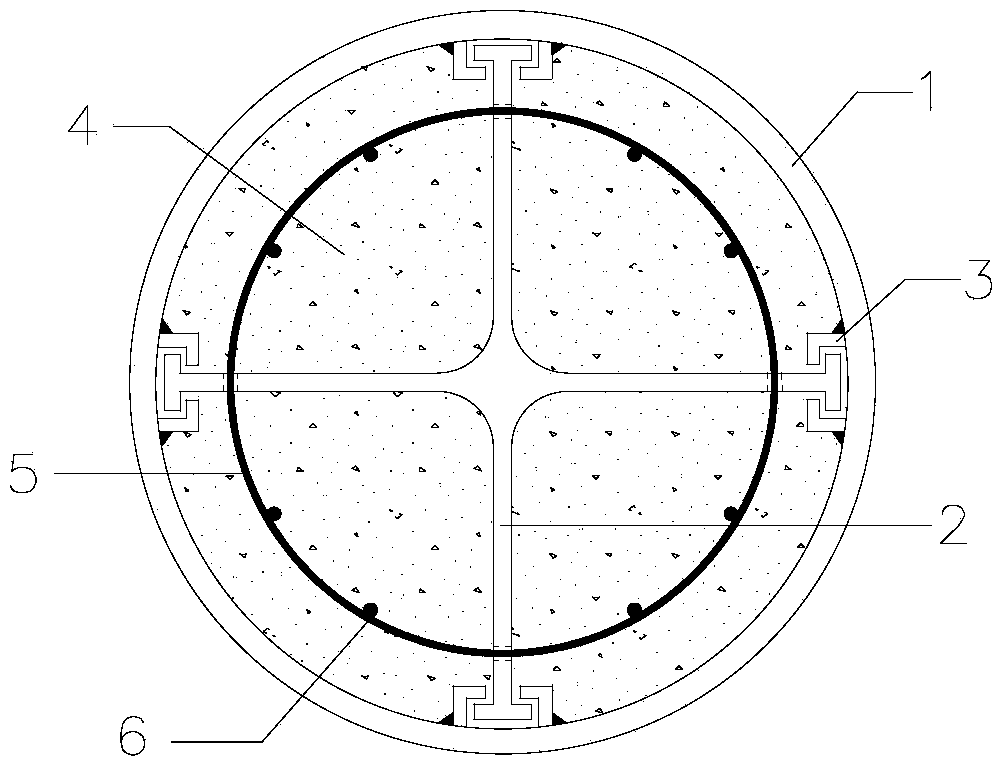

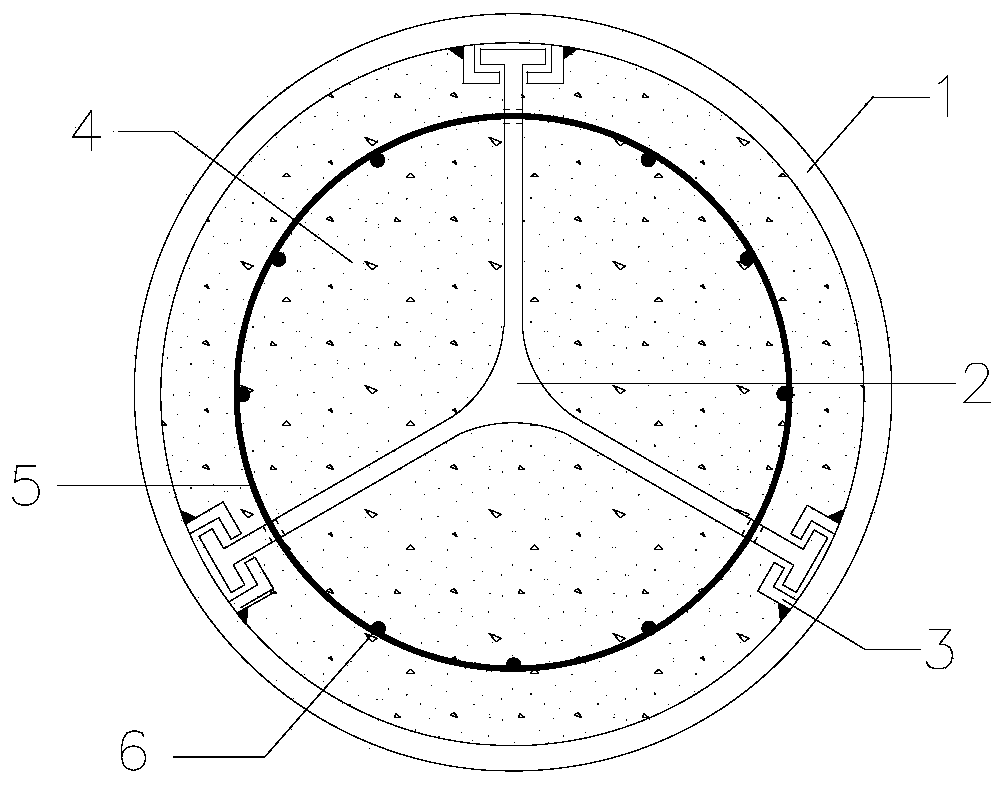

Fiber reinforce plastic (FRP) reinforced concrete-filled steel tube combination column

ActiveCN103899040AEnhanced binding effectDelayed bucklingStrutsBuilding reinforcementsFiberReinforced concrete

The invention aims at providing a fiber reinforce plastic (FRP) reinforced concrete-filled steel tube combination column which comprises a steel tube, a hoop rib, an FRP reinforced rib and a longitudinal reinforcement, wherein the hoop rib and the FRP reinforced rib are arranged in the steel tube; the inner wall of the steel tube is provided with fixed angle iron; the end part of the FRP reinforced rib is fixed on the angle iron; the FRP reinforced rib is provided with a hole, and the hoop rib passes through the hole in the FRP reinforced rib; the longitudinal reinforcement is fixed on the hoop rib; the steel tube is filled with concrete. An FRP reinforced rib plate internally provided with the hoop rib and the longitudinal reinforcement is arranged in the FRP reinforced concrete-filled steel tube combination column, and the concrete can be separated again, so that the restraint effect of the concrete is improved, the bearing capacity of the concrete is improved, and the tube wall on the stressed side is effectively prevented from being bended. By adopting a structure of enabling reinforced concrete, the FRP reinforced rib and the steel tube to cooperative work, the FRP reinforced concrete-filled steel tube combination column is simple in structure and convenient to construct, and has the characteristics of being light in weight, high in carrying capacity and good in ductility and shock resistance.

Owner:HARBIN ENG UNIV

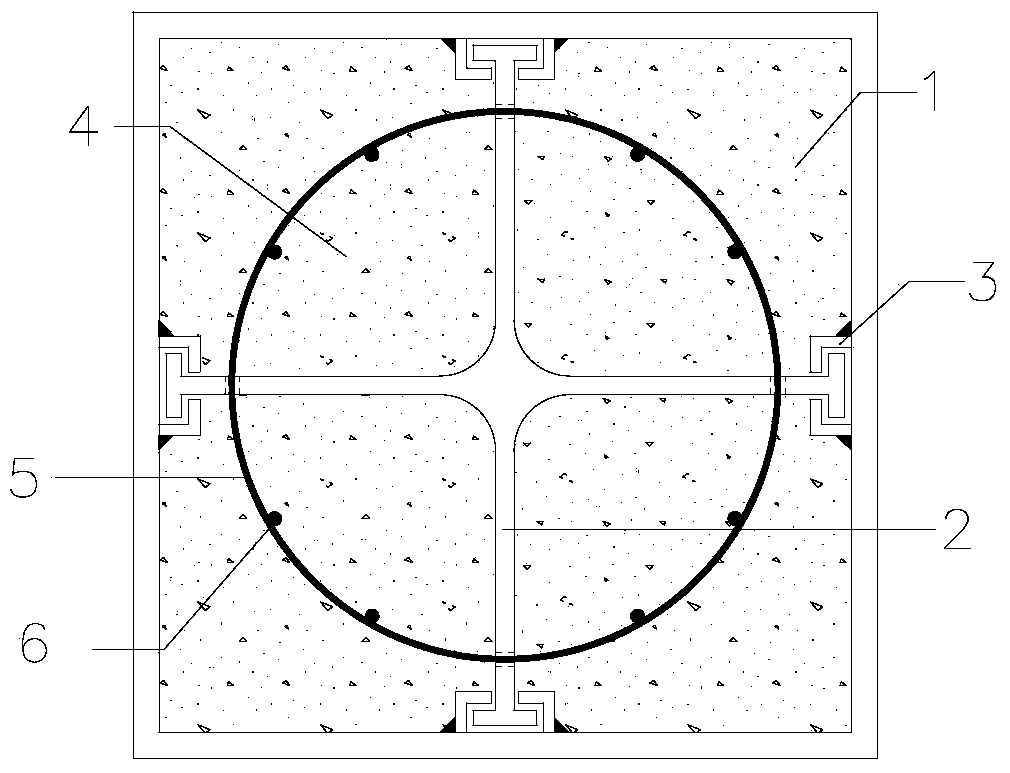

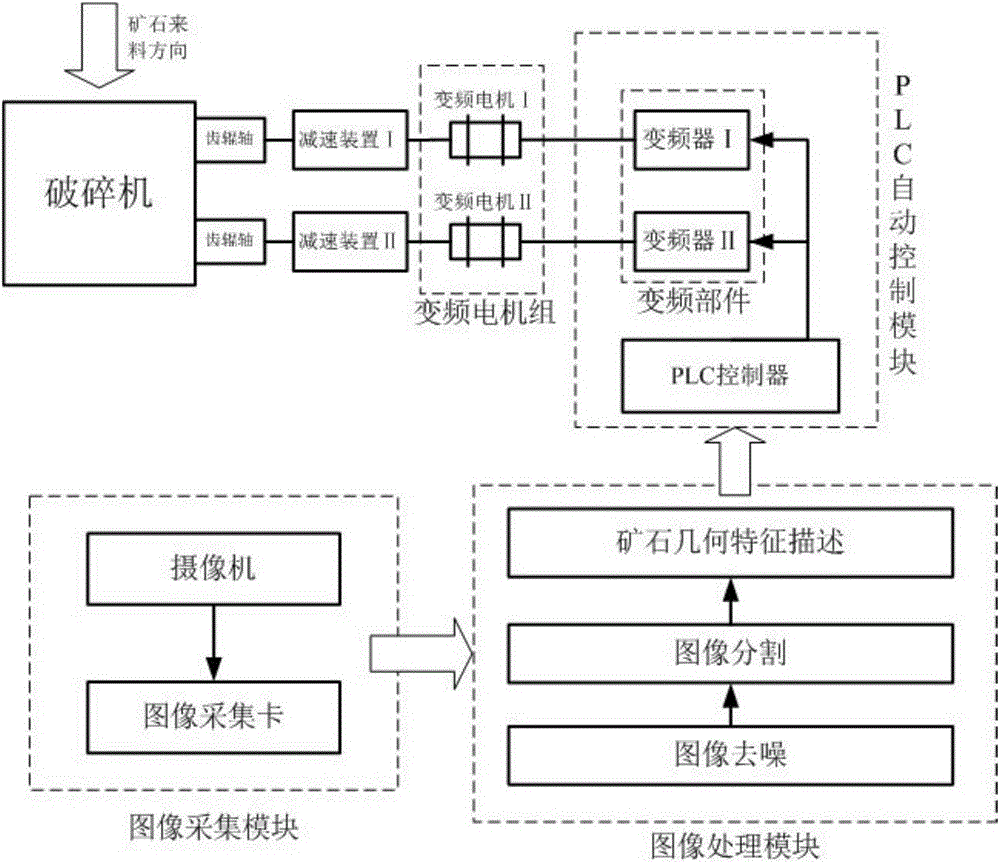

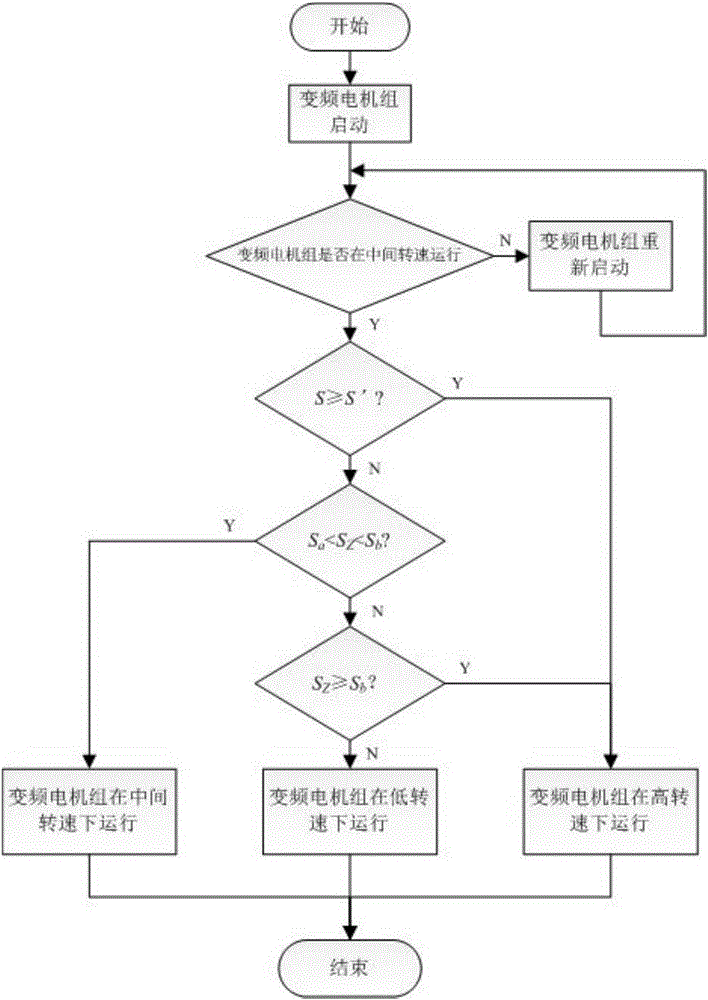

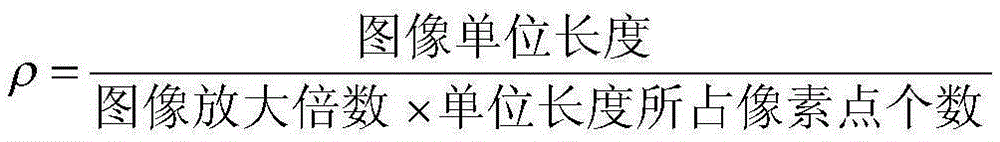

Automatic speed adjustment control system of toothed roll crusher and control method

InactiveCN105251563ATake full advantage of performanceAvoid wastingGrain treatmentsAutomatic controlCrusher

The invention discloses an automatic speed adjustment control system of a toothed roll crusher and a control method. An image collecting module carries out image pre-treatment on ore pictures. The planar projection area S of a single ore body and the overall planar projection area SZ of the whole stack of ore are obtained through an image processing module. A programmable logic controller (PLC) automatic control module is used for controlling the rotation speed of a motor. The geometric shape of the ore and the coverage rate of coming materials are judged through an image recognition method and then compared with preset parameters in a PLC so that the rotation speed of the motor can be automatically controlled. Therefore the toothed roll crusher can operate reasonably under different work conditions, the resource waste and use failures caused by underload and overload are effectively avoided, the repairing workloads of equipment are reduced, the economic benefits are improved, and the performance advantages of the crusher are brought into full play. The PLC is used for automatically controlling the rotation speed of the motor through programming, the original electromechanical system of the crusher is not changed, the automation degree is high, and the method is simple and reliable.

Owner:CHINA UNIV OF MINING & TECH +1

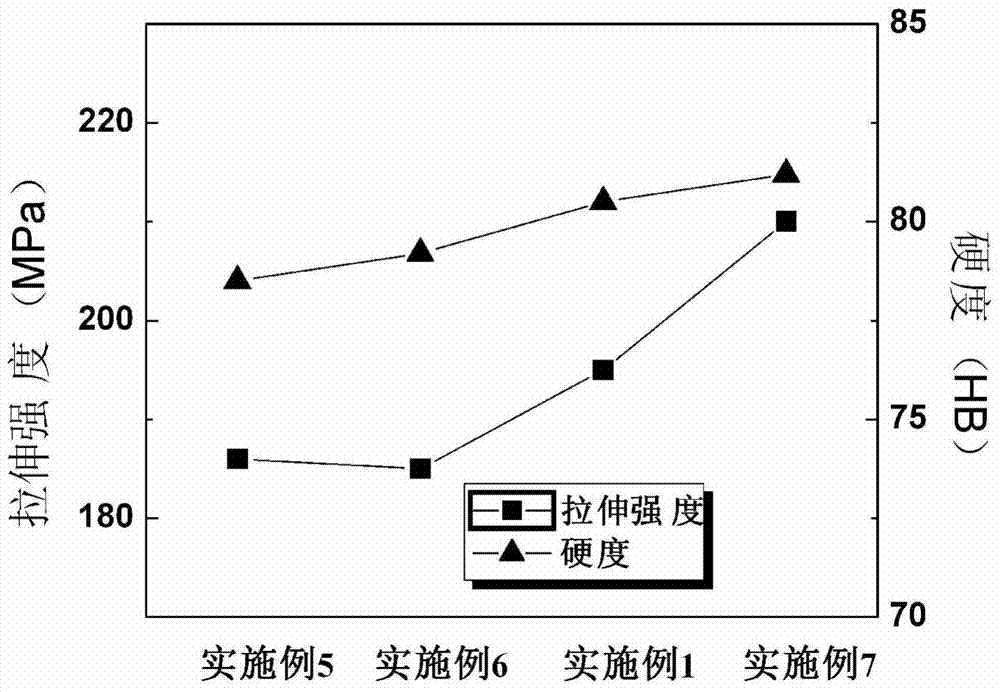

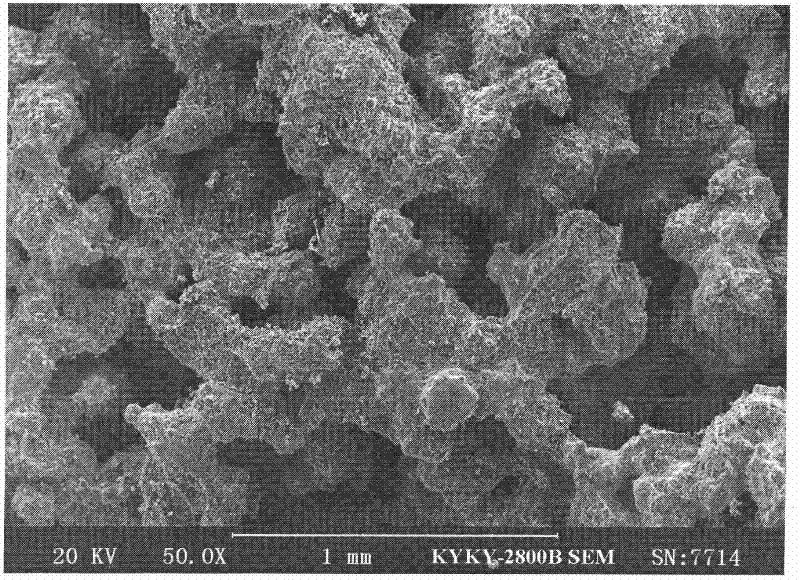

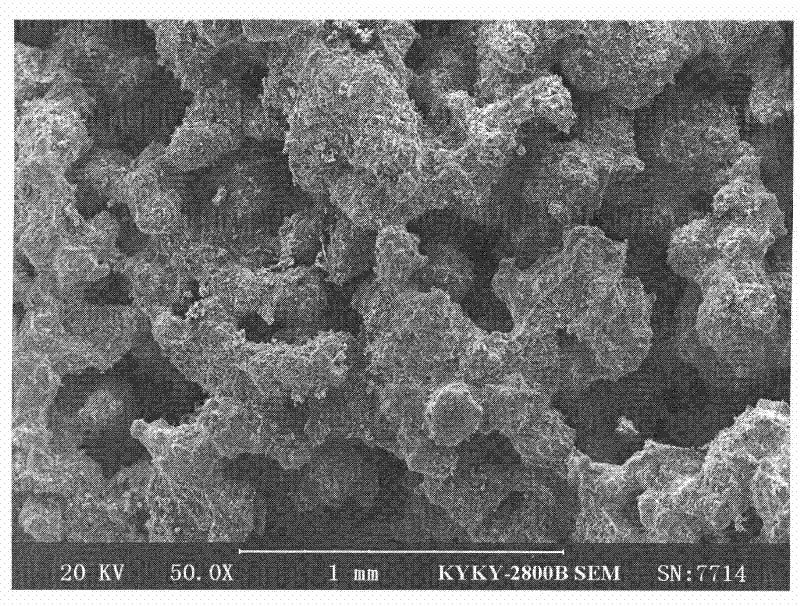

Nanocarbon reinforced copper-based composite material for maglev trains, and preparation method thereof

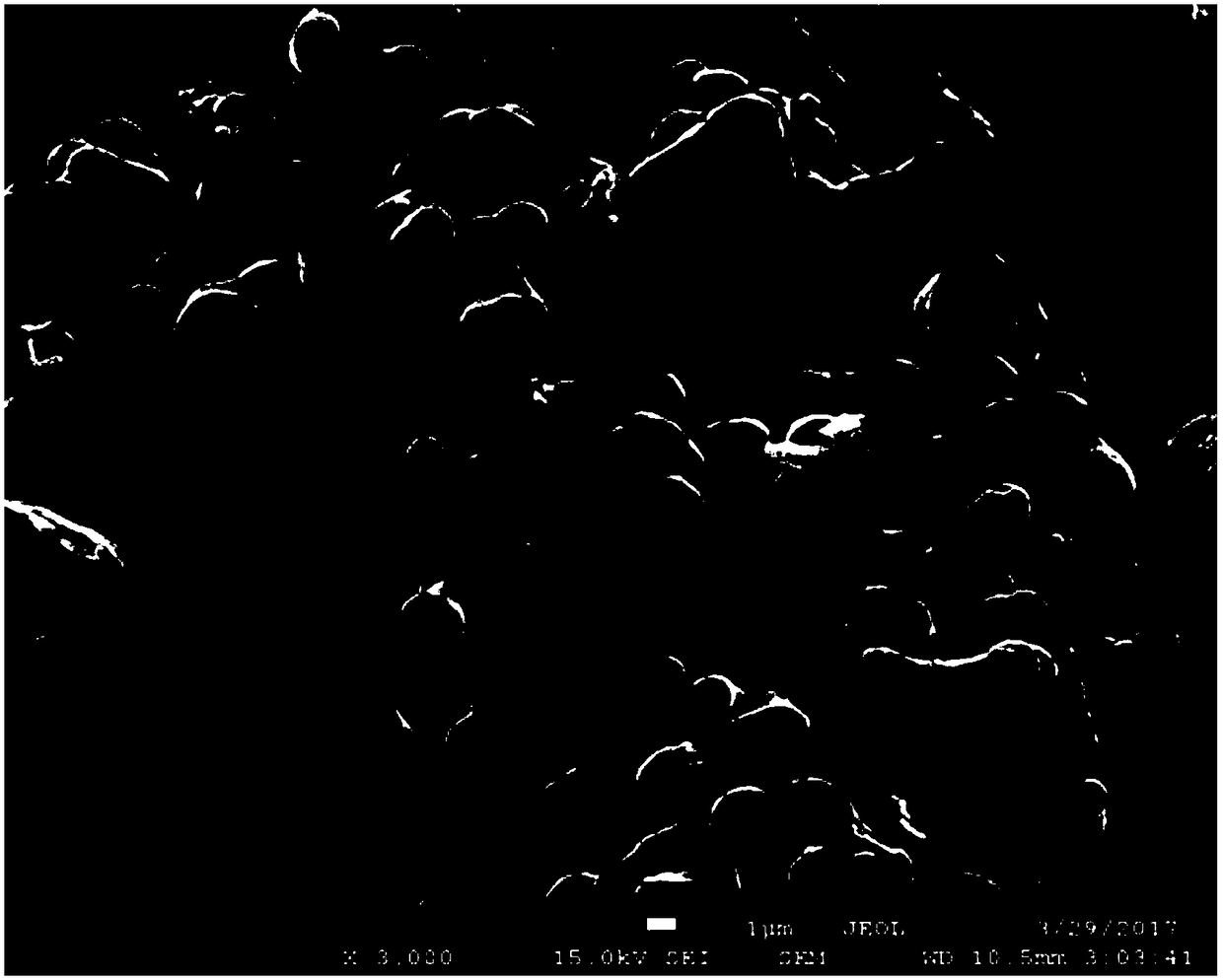

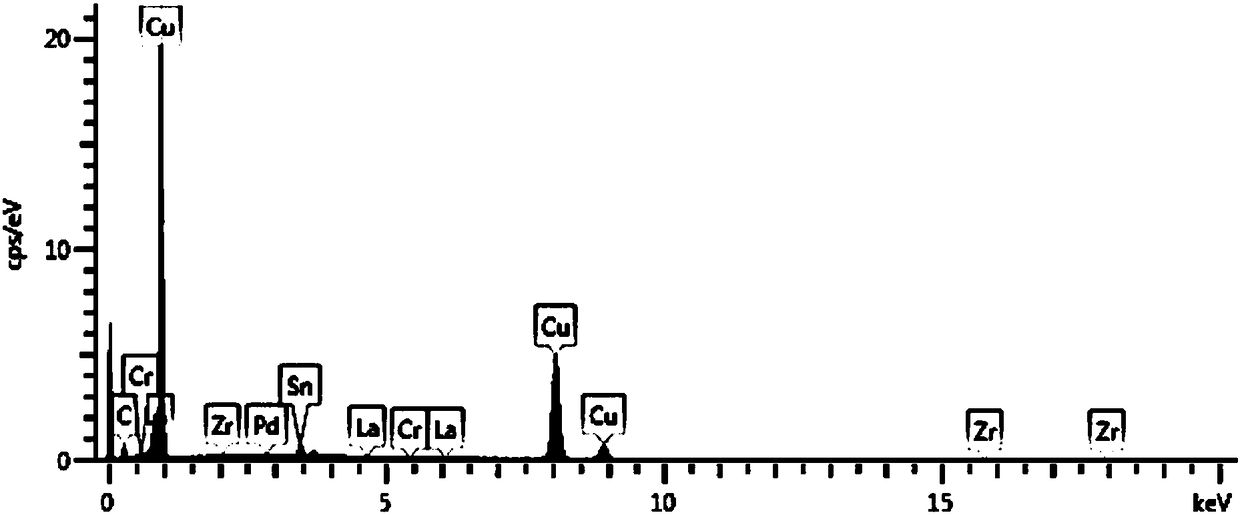

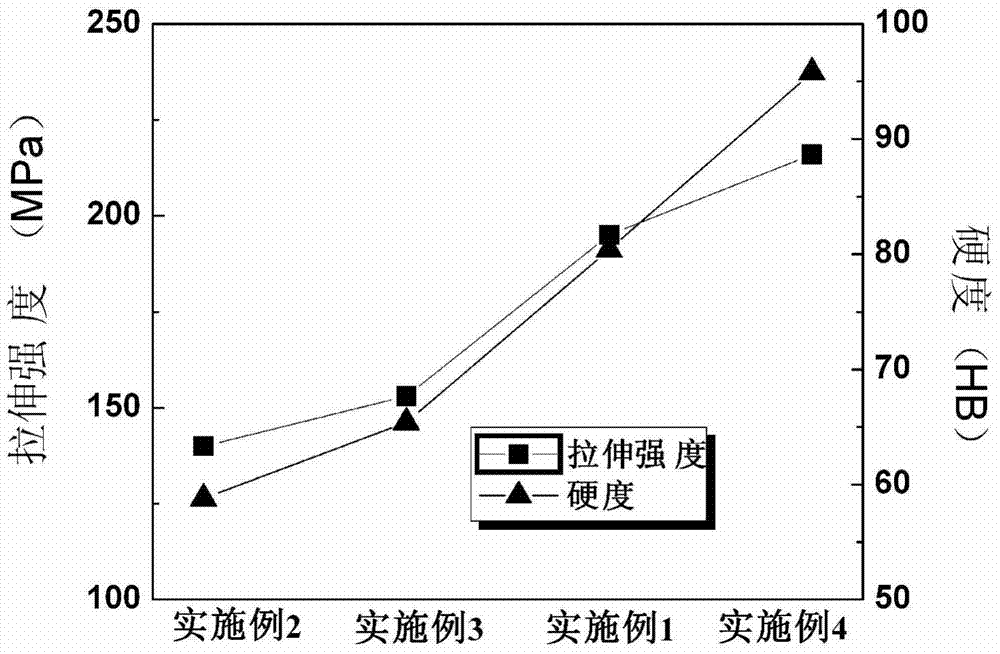

The invention discloses a nanocarbon reinforced copper-based composite material for maglev trains. The nanocarbon reinforced copper-based composite material is characterized in that the nanocarbon reinforced copper-based composite material comprises 0.1-5% of surface-modified carbon nanotubes, 0.1-5% of surface modified graphene, 2-10% of graphite powder, 1-4% of chromium powder, 1-8% of lead powder, 2-10% of tin powder, 0.1-1% of zirconium powder, 0.01-0.5% of lanthanum powder, and the balance of copper powder, wherein the surface-modified carbon nanotubes are carbon nanotubes obtained by modifying carbon nanotubes with an aqueous solution of gallic acid, and the surface-modified graphene is graphene modified with an aqueous solution of rutin. A copper-based composite material has low impurity content, and maintains the structure of an added reinforcing phase component complete, and various added components have a co-reinforcing effect, and significantly improve the strength, the hardness and the current-carrying friction and wear properties of the copper-based composite material. The invention also discloses a preparation method of the copper-based composite material. The methodhas the advantages of simple process, easiness in production, and broad application prospect.

Owner:SOUTHWEST JIAOTONG UNIV

Ordered carbon nano-tube reinforced aluminum matrix composite material and preparation method thereof

ActiveCN103757569ATake full advantage of performanceSignificant mechanical enhancementCarbon nanotubeThin membrane

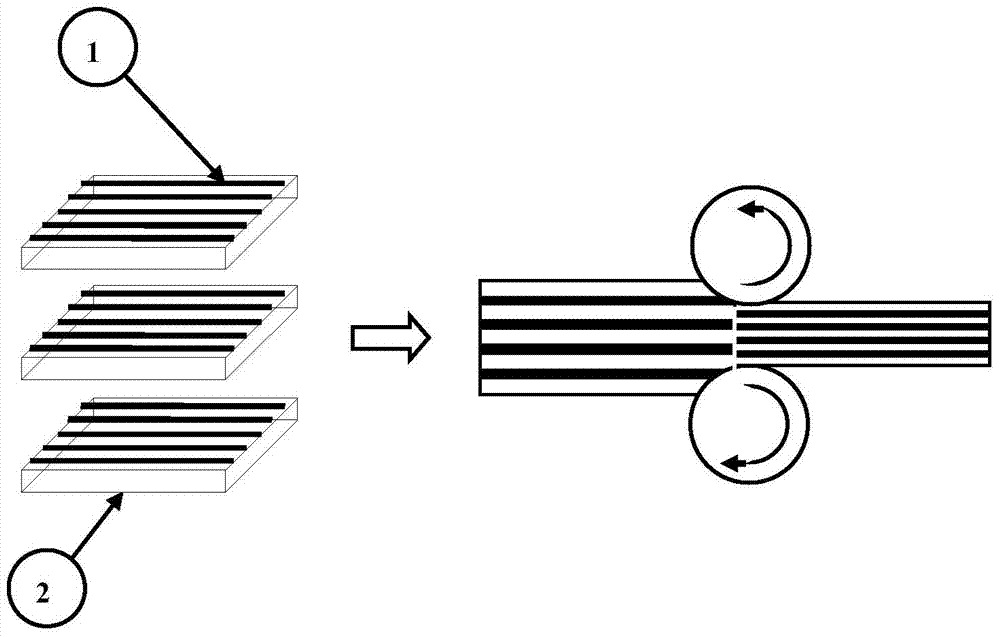

The present invention discloses an ordered carbon nano-tube reinforced aluminum matrix composite material and a preparation method thereof. The composite material comprises aluminum or an alloy thereof adopted as a matrix material and carbon nano-tubes orderedly dispersed in the matrix material. The method comprises: carrying out cross-lamination on plural ordered carbon nano-tube thin film layers and plural aluminum layers or aluminum alloy layers, and carrying out hot rolling to form the ordered carbon nano-tube reinforced aluminum matrix composite material, wherein the ordered carbon nano-tube thin film layer is formed by the plural orderly-dispersed carbon nano-tubes. According to the present invention, the ordered carbon nano-tube thin film such as the superaligned nano-tube thin film and the like is adopted to carry out lamination and hot rolling with the aluminum foil to prepare the composite material so as to achieve orientation distribution of the carbon nano-tubes in the aluminum matrix, completely provide excellent mechanical property and functional characteristics of the carbon nano-tubes, achieve mechanical enhancement and function modification on the aluminum matrix composite material, combine with the hot rolling molding, and provide important practical application prospects.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Surface modified carbon fiber reinforced high-resistance and high-tensile-strength cement-based 3D (three-dimensional) printing base material and preparation method thereof

ActiveCN108529984AHigh tensile strengthGood synergyAdditive manufacturing apparatusCarbon fibersPolymer science

A surface modified carbon fiber reinforced high-resistance and high-tensile-strength cement-based 3D printing base material and a preparation method thereof belong to the technical field of building materials. The surface modified carbon fiber reinforced high-resistance and high-tensile-strength cement-based 3D printing base material is composed of, by weight part, 10-70 parts of surface modifiedcarbon fiber, 500-1500 parts of cement, 0-2000 parts of aggregate, 50-500 parts of mineral additives and 10-50 parts of chemical additives. The preparation method of the surface modified carbon fiberreinforced high-resistance and high-tensile-strength cement-based 3D printing base material specifically comprises the steps of preparation of nano-silica modifier; surface modification of carbon fiber, and preparation of the 3D printing base material. The surface modified carbon fiber reinforced high-resistance and high-tensile-strength cement-based 3D printing base material has the advantage that, through modification treatment of growing SiO2 on the surface of the carbon fiber, a layer of inactive but highly pozzolan-hydration active nano SiO2 can be formed on the surface of the carbon fiber and subjected to secondary hydration with a cement hydration product of Ca(OH)2 to produce calcium silicate hydrate C-S-H to improve interfacial weak areas, thereby further improving cooperativity and interfacial bonding strength between the carbon fiber and a cement base, giving full play to performance advantages of materials and achieving a tensile strength higher than 30 MPa.

Owner:HARBIN INST OF TECH

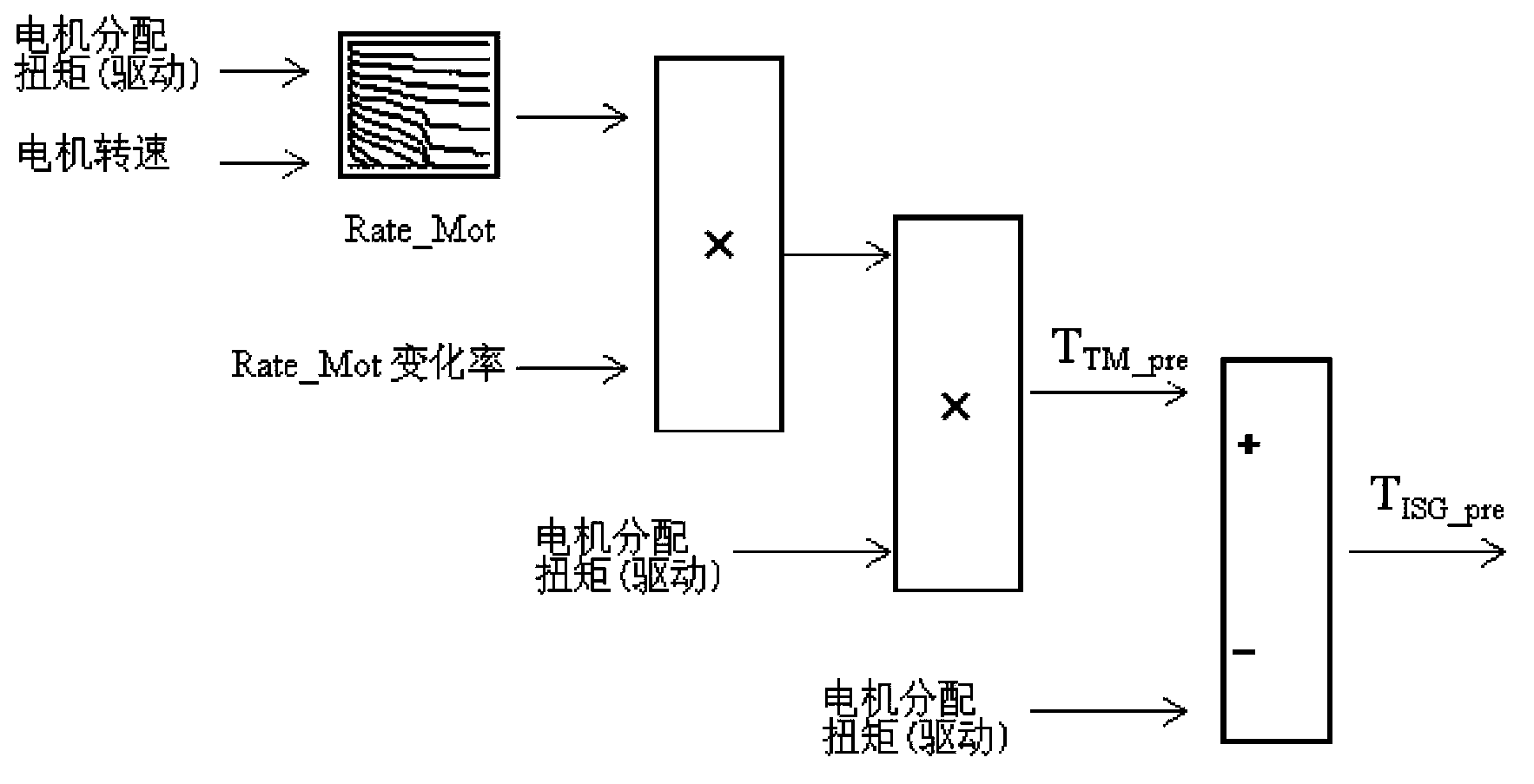

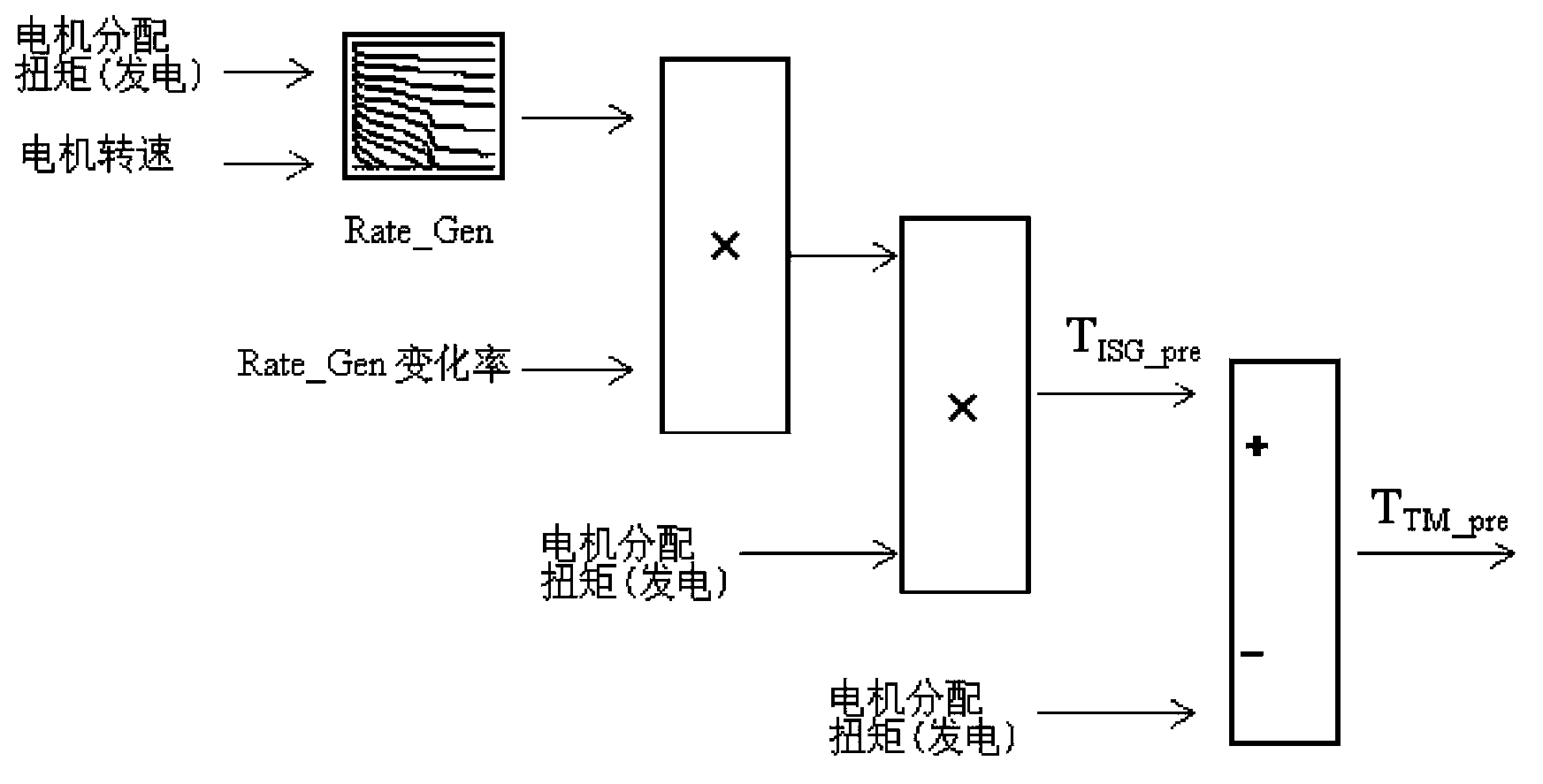

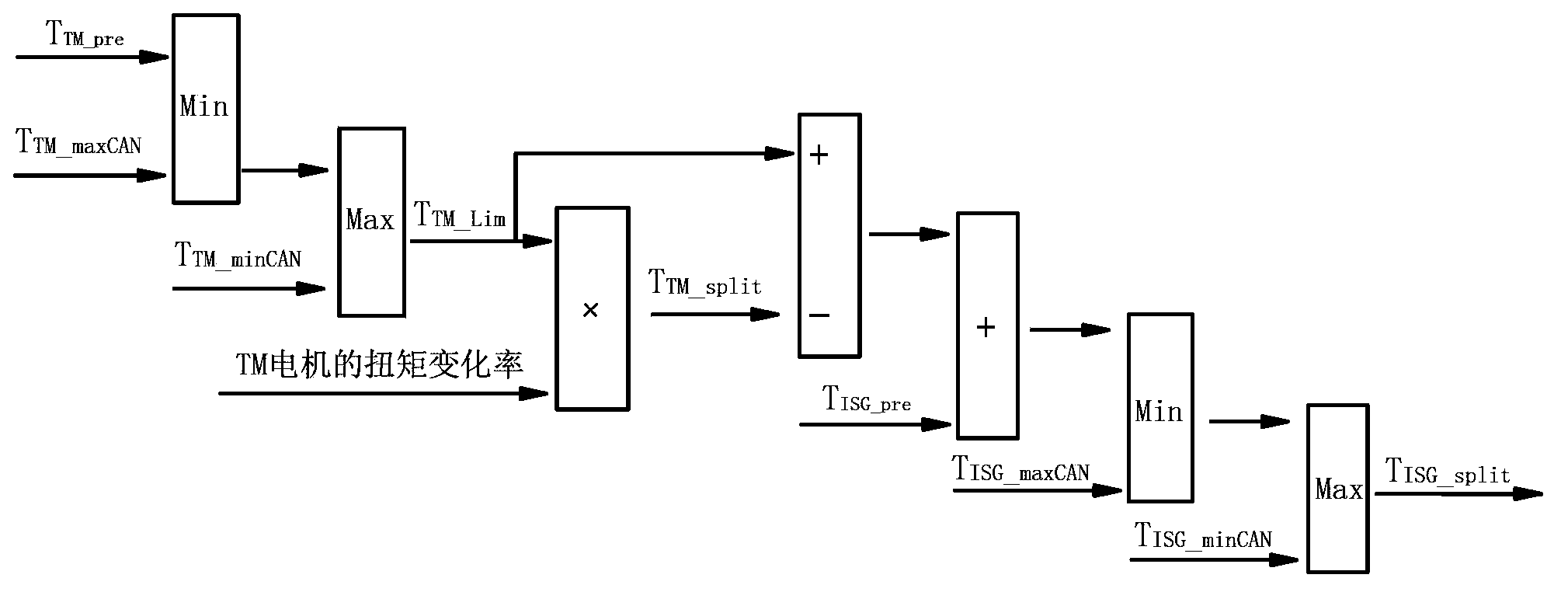

Torque distributing and controlling method based on efficiency optimization for double motors in hybrid power system

ActiveCN104129388ATake full advantage of performanceReasonable distributionHybrid vehiclesSpeed controllerElectricityElectric machine

The invention relates to a torque distributing and controlling method based on efficiency optimization for double motors in a hybrid power system. The hybrid power system supports the double motors (namely a TM motor and an ISG motor) to simultaneously carry out driving work and electricity generating work. The method comprises the steps: providing an all-condition efficiency graph about the driving and the electricity generating of the TM motor and the ISG motor under the all working condition; calculating the optimized distribution of the driving torque and the optimized distribution of the electricity generating torque between the double motors; associating each of Rate_Mot and Rate_Gen, which are obtained under the condition of different rotating speeds, with the rotating speed and the torque T distributed into the TM motor and the ISG motor to obtain an off-line computation table; and distributing the torque between the double motors. Through the adoption of the method disclosed by the invention, the torque can be reasonably and efficiently distributed between the double motors, the respective performance advantage can be fully taken, the work efficiency of the system is obviously improved, the energy consumption cost of a vehicle is reduced, and therefore, the goals of energy conservation and environmental protection can be realized.

Owner:SAIC MOTOR

Manufacturing method for precisely cast titanium alloy impeller

InactiveCN103509974ASimple processTissue uniformity is easy to controlMolten spray coatingImpellerTitanium

The invention discloses a manufacturing method for a precisely cast titanium alloy impeller. The manufacturing method is characterized in that alloy comprises the following components in percentage by mass: 4-5% of Al, 0.7-0.8% of Ni, 0.5-0.6% of Nb, 0.5-0.7% of V, 0.3-0.4% of Cr, 0.1-0.2% of Si, 0.07-0.09% of In, 0.03-0.04% of Cu, 0.03-0.04% of Pr, 0.01-0.02% of Y, 0.75-0.8% of Mn, 0.5-0.7% of Mo, 0.7-0.9% of Sn and the balance of titanium and inevitable nonmetal impurities. The strength of a titanium alloy plate is higher than 1200 MPa.

Owner:SUZHOU CHENGTENG ELECTRONICS TECH

Preparation method for titanium alloy-hydroxyapatite salt biological ceramic porous material

PendingCN108950305ATake full advantage of performanceOvercome the performance mismatchAdditive manufacturing apparatusTransportation and packagingBiological propertyBone tissue

The invention discloses a preparation method for a titanium alloy-hydroxyapatite salt biological ceramic porous material. The preparation method for the titanium alloy-hydroxyapatite salt biological ceramic porous material has the characteristics that the 3D printing technology is applied, and by means of the manner that the proportion value of hydroxyapatite salt powder to titanium alloy matrix powder of all fusion covering layers is dynamically adjusted, the titanium alloy-hydroxyapatite salt biological ceramic porous material with titanium alloy being a central layer and titanium alloy-hydroxyapatite salt being a transition layer is prepared. According to the preparation method for the titanium alloy-hydroxyapatite salt biological ceramic porous material, because the performance advantages of various materials are sufficiently utilized and the internal stress is further reduced, excellent mechanical and biological properties are exhibited, therefore, the preparation method for the titanium alloy-hydroxyapatite salt biological ceramic porous material is suitable for the field of bone tissue replacing or implant repairing.

Owner:SHANDONG JIANZHU UNIV

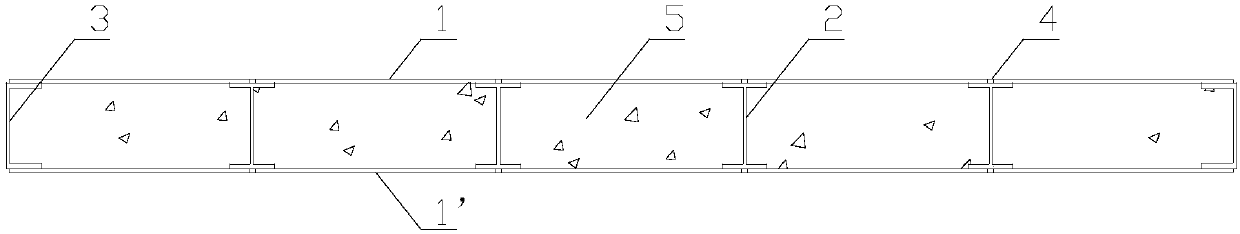

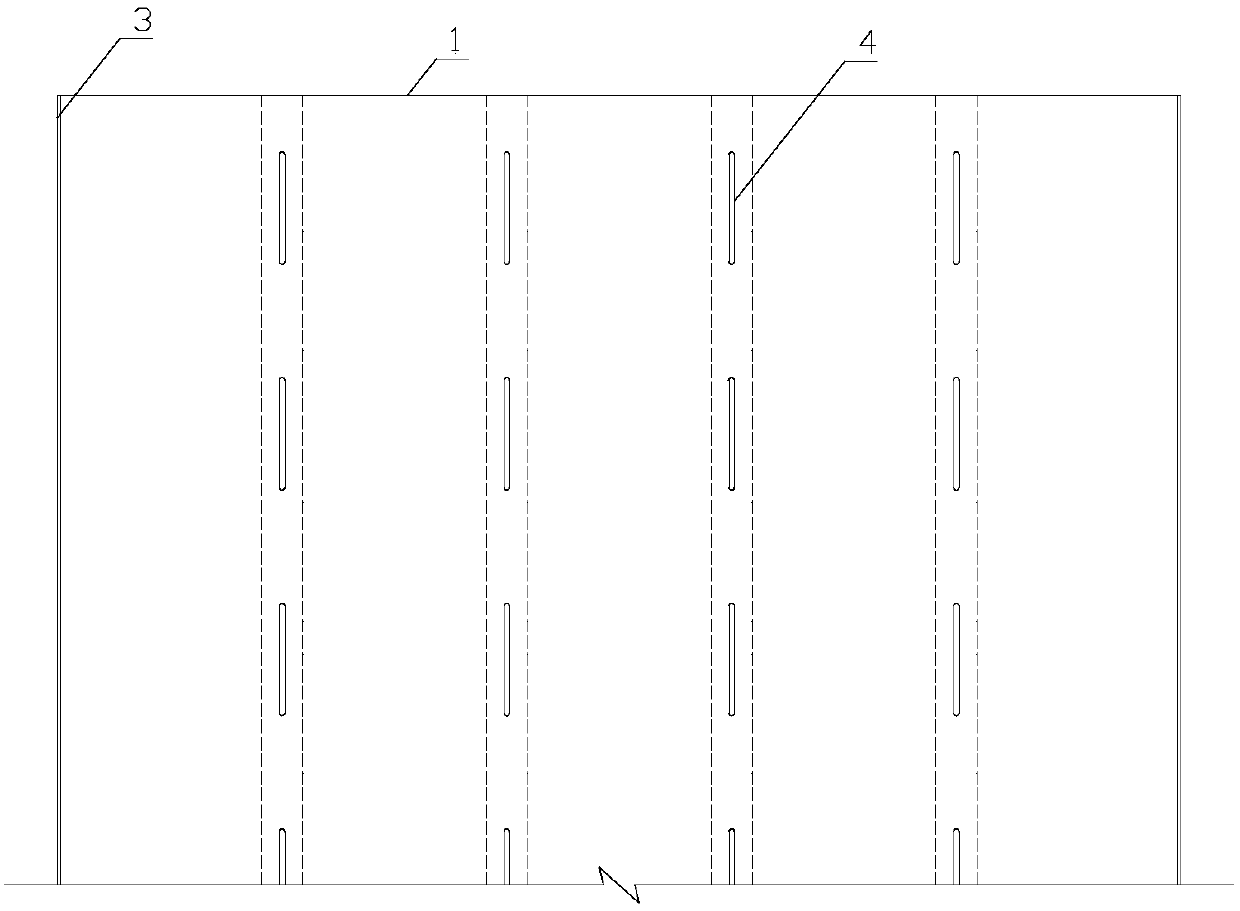

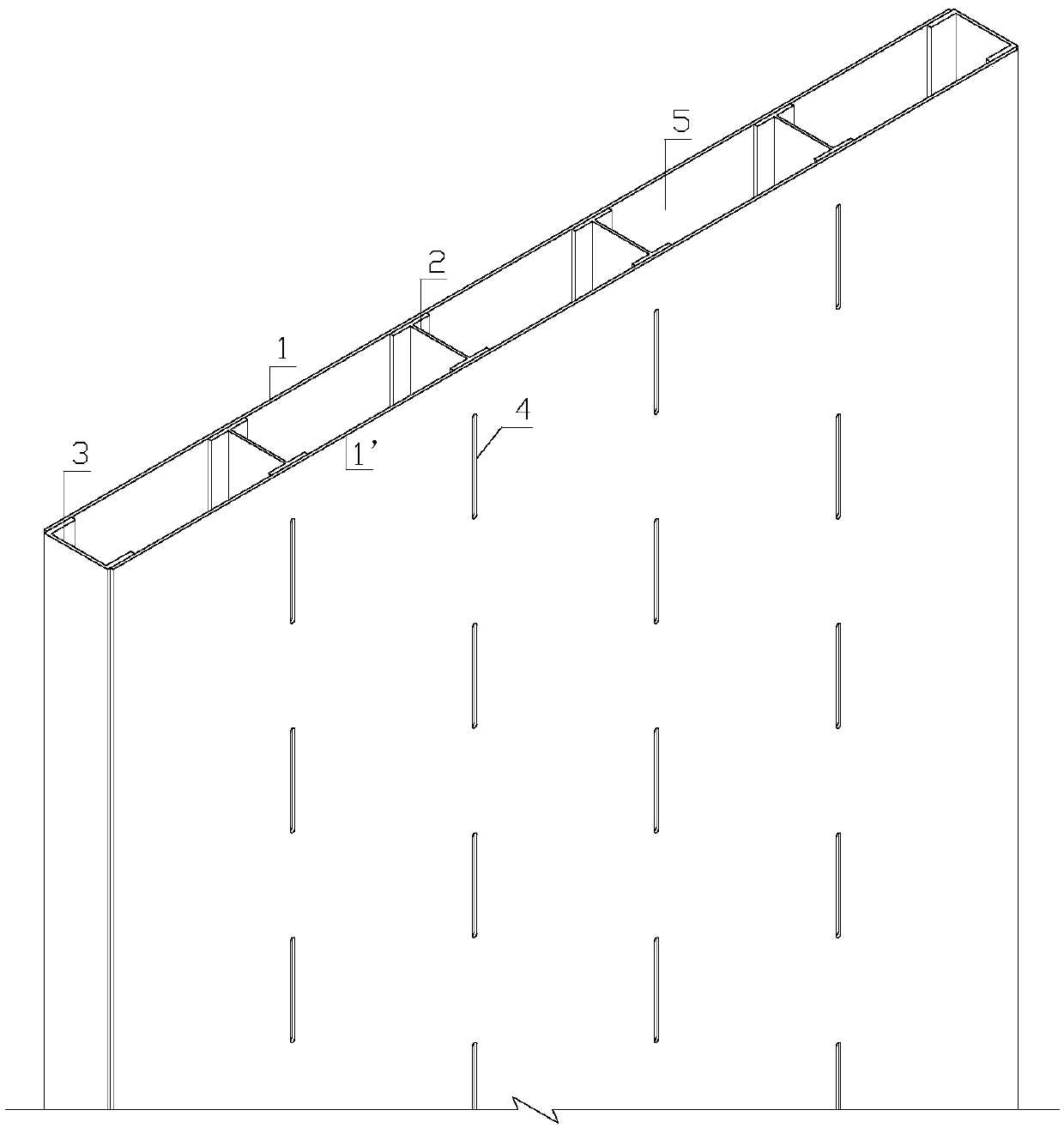

Fabricated shear wall structure in combination of steel plates and section steel

PendingCN109610697AFlexible building layoutHigh degree of industrializationWallsProtective buildings/sheltersSteel platesInternal cavity

The invention relates to a fabricated shear wall structure in combination of steel plates and section steel. According to the fabricated shear wall structure, a plurality of long holes are formed in the two oppositely arranged steel plates correspondingly; a plurality of internal section steel are arranged between the two side steel plates; the steel plates and the internal section steel are connected and fixed through the long holes; edge section steel are arranged at the two ends of the two side steel plates correspondingly, and a plurality of internal cavities are formed; and then concreteis poured into the cavities to finally form the fabricated shear wall structure. According to the fabricated shear wall structure in combination of the steel plates and the section steel, building layout is flexible, the degree of industrialization of steel structure manufacturing is high, design is simple, the steel quantity is economical, components are simple to manufacture, and construction isconvenient and quick; and the fabricated shear wall structure can give full play to the performance advantages of steel products and the concrete, and has the characteristics of environmental protection and high anti-seismic performance.

Owner:CUBIC DIGITAL TECH CO LTD

High-strength titanium alloy plate and manufacturing method thereof

Owner:南通波斯佳织造科技有限公司

Preparing method for titanium alloy panel

InactiveCN105349808ATake full advantage of performanceHigh strengthIngot castingNon-metallic inclusions

The invention relates to a preparing method for a titanium alloy panel. An alloy comprises, by mass percentage, 4%-5% of Al, 1%-2% of Ni, 0.7%-0.8% of Cu, 0.5%-0.7% of V, 0.1%-0.2% of Bi, 0.1%-0.2% of Si, 0.07%-0.09% of In, 0.05%-0.06% of Ni, 0.03%-0.04% of Pd, 0.03%-0.04% of Pr, 0.01%-0.02% of Y and the balance titanium and titanium non-metallic inclusion; and the titanium alloy panel is obtained through ingot casting, annealing treatment, forging, hot rolling, cold rolling, quenching treatment and heat preservation. The intensity of the titanium alloy panel reaches more than 1200 MPa.

Owner:WUXI QINGYANG MACHINERY MFG

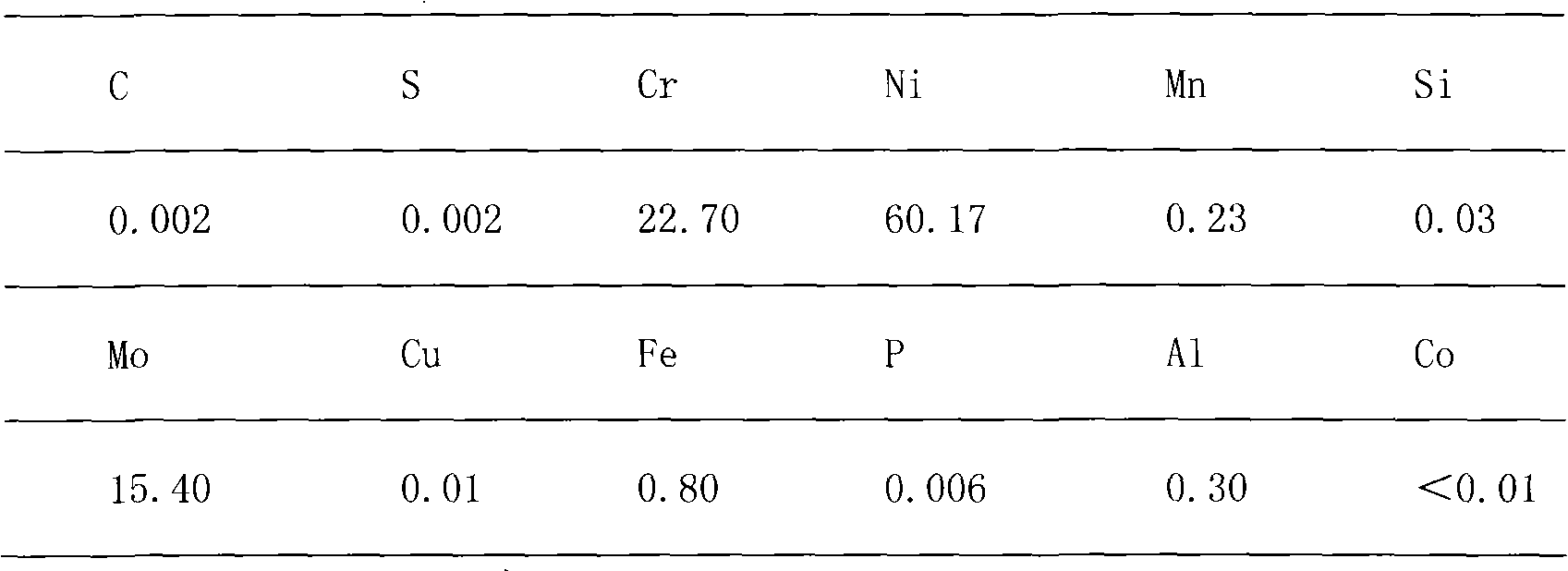

Ultra-low carbon Ni-Cr-Mo5923hMo steel alloy explosion welding high corrosion resistance composite material

ActiveCN101293305AEliminate the detonatorEliminate both sidesNon-electric welding apparatusCrack resistanceStress corrosion cracking

The invention relates to a novel compound material which is formed by an explosion welding technique and a common low alloy steel Q345B as well as by adopting the ultra-low-carbon Ni-Cr-Mo 5923hMo alloy steel as a high anti-corrosion layer. The manufacture method of the invention includes the techniques of surface pre-treatment, explosion welding compounding and annealing for removing a stress. The structure of the invention is that the common low alloy steel is combined with the metallurgy of a 5923hMo anti-corrosion steel multiple layer on the common low alloy steel. The compound material of the invention has the advantages that the multiple layer has excellent anti-corrosion property to most corrosion properties and extremely excellent properties of pit corrosion resistance, crevice corrosion resistance and stress corrosion cracking resistance caused by chlorides; while a basic layer plate has excellent mechanical property to fully play the excellent physical and chemical properties of two metals. The novel compound material can not have the phenomena of cracking or separation on the interface between the basic layer and the composite layer after being processed by the hot and cold techniques such as annealing, leveling and cutting, etc. Analyzed by a physical test and a chemical test, the property index of the novel compound material is completely in accordance with the standard of JB4748-2002 and can meet the property requirements of a device to special materials under execrable working conditions.

Owner:JIANGSU RUNBANG NEW MATERIAL GRP CO LTD

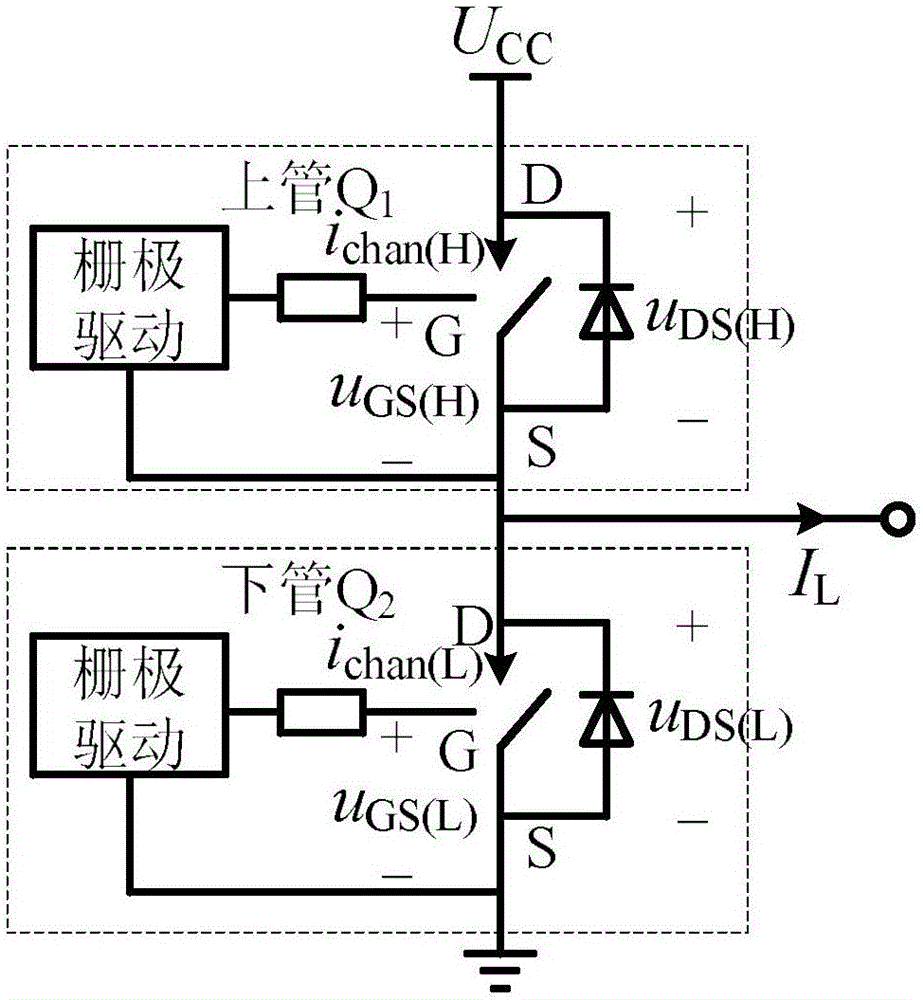

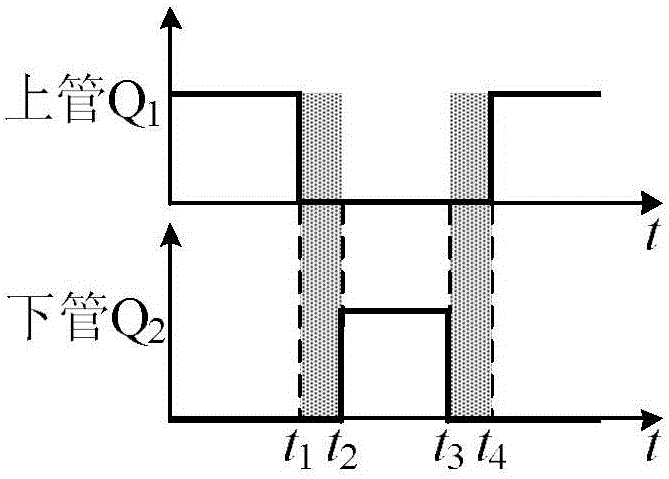

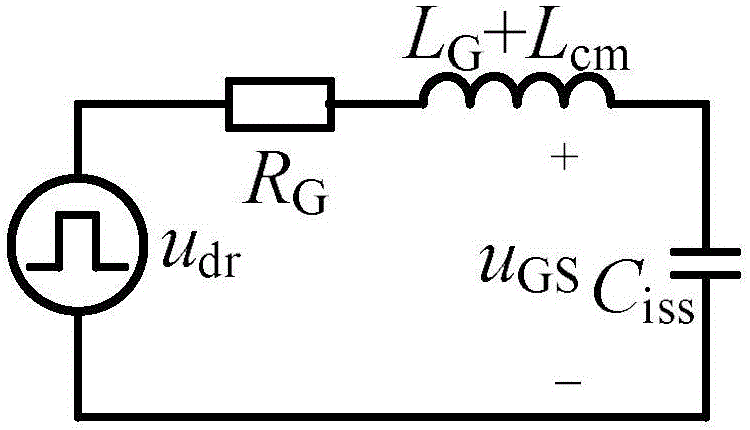

Dead-time optimization control method suitable for SiC-based bridge arm power circuit

InactiveCN106160447AReduce lossImprove work efficiencyEfficient power electronics conversionPower conversion systemsPower circuitsPower consumption

The invention discloses a dead-time optimization control method suitable for a SiC-based bridge arm power circuit. The time for reducing grid voltage to reach threshold voltage, channel current reduction time and drain-source voltage rising time are comprehensively compared, and maximum dead time is preset; the time for reducing grid voltage to reach threshold voltage can be calculated according to a grid drive equivalent circuit; the channel current reduction time is selected in an offline state and under heavy-load and high-temperature conditions; the grid-source voltage reduction edge and the drain-source voltage reduction edge of a switch tube are detected by adopting upper and lower tube auxiliary circuits through edge detector, and their difference is the drain-source voltage rising time. By comparing these times, an optimal dead time is output, the optimal dead time consumed after a turning-off signal of the switch tube is output is the turning-on signal output moment of the corresponding switch tube. On the premise that the working reliability of a system is ensured, the power consumption caused by dead time reduction is effectively reduced, and the working efficiency of a convertor is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

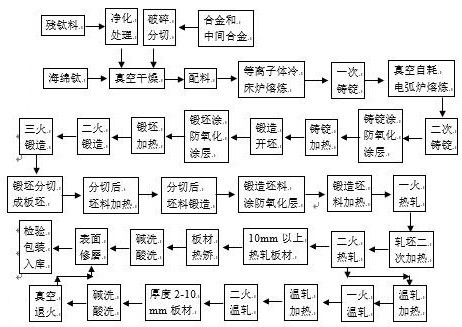

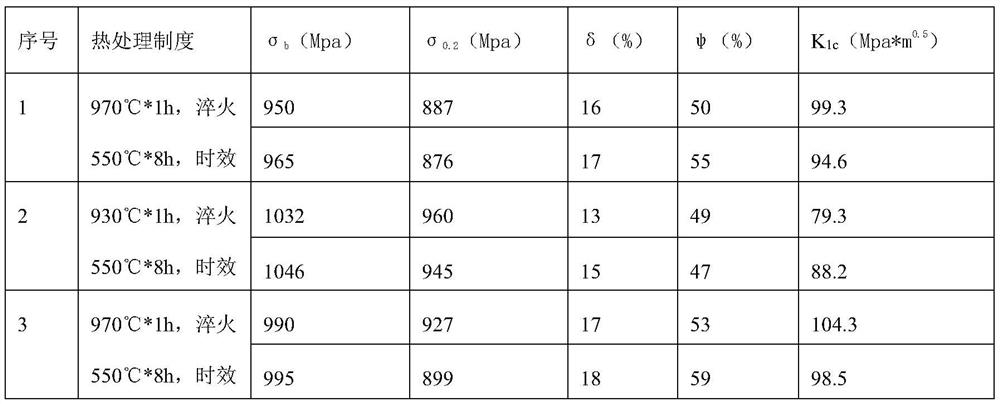

Preparation method of titanium alloy plate

The invention discloses a preparation method of a titanium alloy plate. A TC4 casting blank is prepared by adopting a plasma-vacuum consumable arc combined process; the first heating number finish forging temperature is 880 DEG C, and the deformation is 60-75%; the second heating number finish forging temperature is 850 DEG C, and the deformation is 25-65%; and the third heating number final heating temperature is 800 DEG C, and the deformation is 45-75%. A 20mm finished plate is rolled, the pass deformation is 4-6mm, and reversing rolling is carried out when the deformation is 50%; and when a 2-10 mm plate strip is rolled, hot rolling is conducted firstly, then warm rolling is conducted, the rolling temperature of the first heating number is 960-1050 DEG C, the rolling temperature of the second heating number is 950-1000 DEG C, and the warm rolling technology is adopted in the third heating number and the fourth heating number. The annealing temperature is 600-650 DEG C, and the heat preservation time is 5-10 hours. According to the preparation method, high-temperature melting, dissolving, flotation and sedimentation are adopted to remove inclusions, and a partial pressure principle is utilized to remove gas, so that burning loss of low-melting-point alloy element aluminum is reduced, an electrode preparation process is omitted, and a production process is simplified; titanium residues can be directly utilized, so that the ingot casting cost is reduced; and a product has a uniform fine grain structure, and the preparation method has the advantages of being wide in machining temperature range, good in strength, plasticity and fracture toughness matching property.

Owner:XINJIANG UNIVERSITY

Method for preparing aluminum-titanium alloy impeller

ActiveCN104745871ATake full advantage of performanceHigh strengthMolten spray coatingTitaniumTitanium alloy

The invention discloses a method for preparing an Al-Ti alloy impeller. The method is characterized in that the alloy comprises the following components by mass percent: 7% to 8% of Al, 0.7% to 0.8% of Ni, 0.7% to 0.8% of Co, 0.8% to 0.9% of V, 0.3% to 0.4% of Cr, 0.3% to 0.4% of Sn, 0.07% to 0.09% of Fe, 0.03% to 0.04% of Cu, 0.05% to 0.06% of Pr, 0.01% to 0.02% of Ce, 0.5% to 0.6% of Mg, 0.5% to 0.7% of Mo, 0.7% to 0.9% of Si and the balance of Ti and inevitable nonmetallic inclusions. The strength of a Ti alloy board can reach more than 1200MPa.

Owner:TONGSHAN COUNTY FENGHUA IND & TRADE

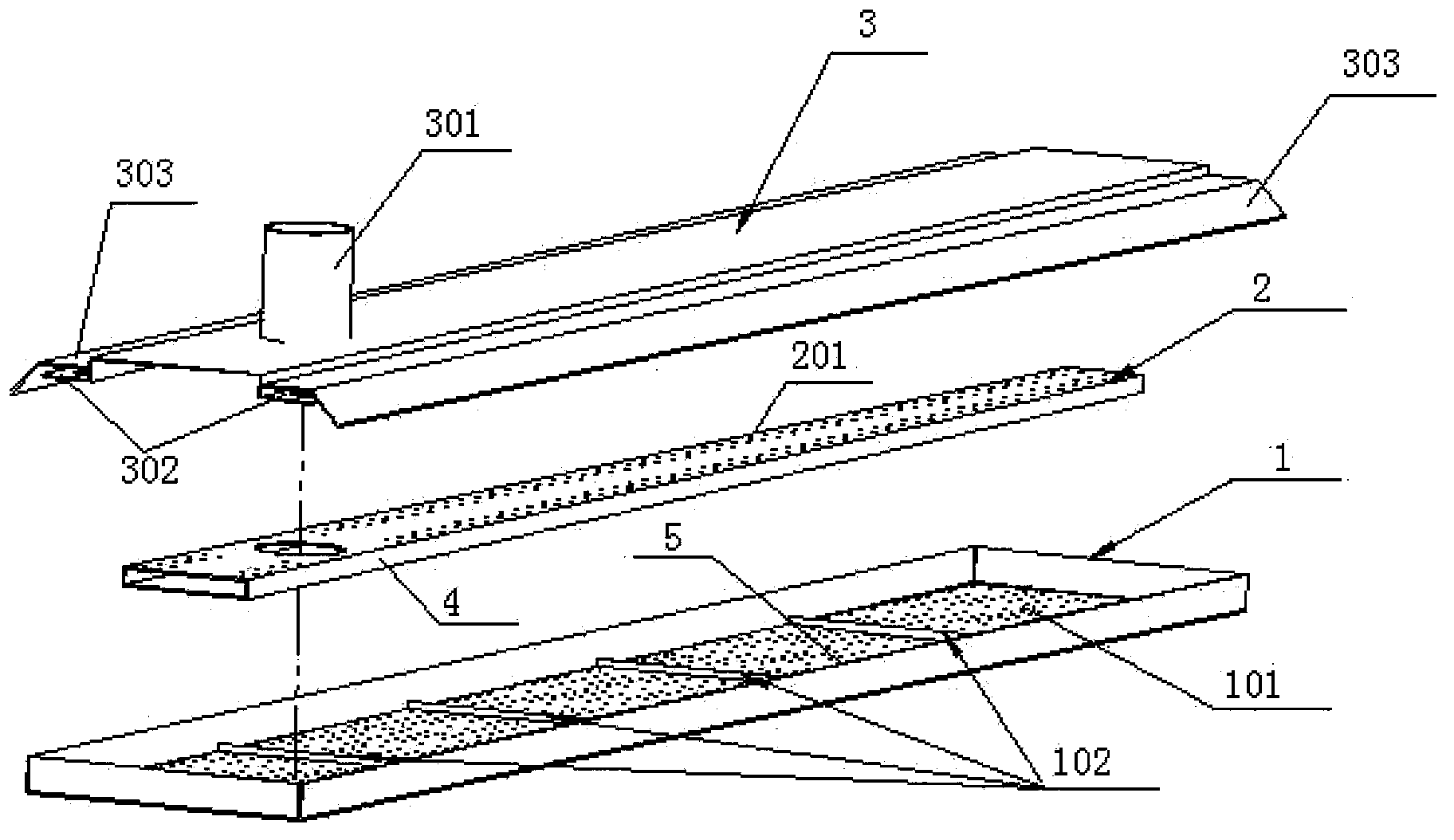

Distributor applied to falling film type evaporator

InactiveCN103851839APrevent splash leaksTake full advantage of performanceEvaporators/condensersFluid circulation arrangementEngineeringDistributor

The invention discloses a distributor applied to a falling film type evaporator. The distributor comprises a baffle plate, a pressure box and a gravity box, wherein first through holes are uniformly and closely distributed in the bottom of the gravity box, the bottom of the gravity box are provided with a plurality of clapboards in the width direction, the pressure box is contained in the gravity box, an interval exists between the circumference of the pressure box and the circumference of the gravity box, second through holes are closely distributed in the top of the pressure box, the baffle plate is arranged above the pressure box, the two sides of the baffle plate are fixed on the gravity box, pore plates are arranged on the edges of the baffle plate and are provided with cover plates, intervals are reserved between the pore plates and the cover plates to form ventilation slots, and an inlet tube is arranged on the baffle plate and is communicated with the pressure box. According to the distributor applied to the falling film type evaporator, which is disclosed by the invention, the pressure potential energy and the gravity potential energy are mutually matched to distribute coolant working mediums, so that the reliability is high, the uniformity is good, the fluid distribution is uniform, the coolant working mediums are prevented from splashing and leaking, and the pressure loss is small; the distributor is matched with the falling film type evaporator, so as to be capable of fully exerting the performance advantages of the falling film type evaporator and to have good manufacturability.

Owner:MCQUAY AIR CONDITIONING & REFRIGERATION WUHAN

Method for preparing titanium alloy blade by investment casting method

InactiveCN103469009ATake full advantage of performanceHigh strengthBlade accessoriesMachines/enginesInvestment castingMetal impurities

Owner:SUZHOU CHENGTENG ELECTRONICS TECH

Method for preparing aluminium-titanium alloy blade

ActiveCN103555998ATake full advantage of performanceHigh strengthMolten spray coatingTitaniumTitanium alloy

The invention discloses a method for preparing an aluminium-titanium alloy blade. The aluminium-titanium alloy is characterized by comprising the following components in percentage by mass: 11-12% of Al, 3-4% of Sn, 0.8-0.9% of Fe, 0.1-0.2% of Si, 0.1-0.2% of Cr, 0.3-0.4% of Ca, 0.5-0.6% of Bi, 0.05-0.07% of In, 0.03-0.04% of Cu, 0.01-0.02% of La, 0.03-0.04% of Y, 0.01-0.03% of Mn, 0.05-0.06% of V and the balance of titanium and inevitable nonmetal inclusions, and the strength of a titanium alloy plate is more than 1200MPa.

Owner:泊头市瑞恒机械有限责任公司

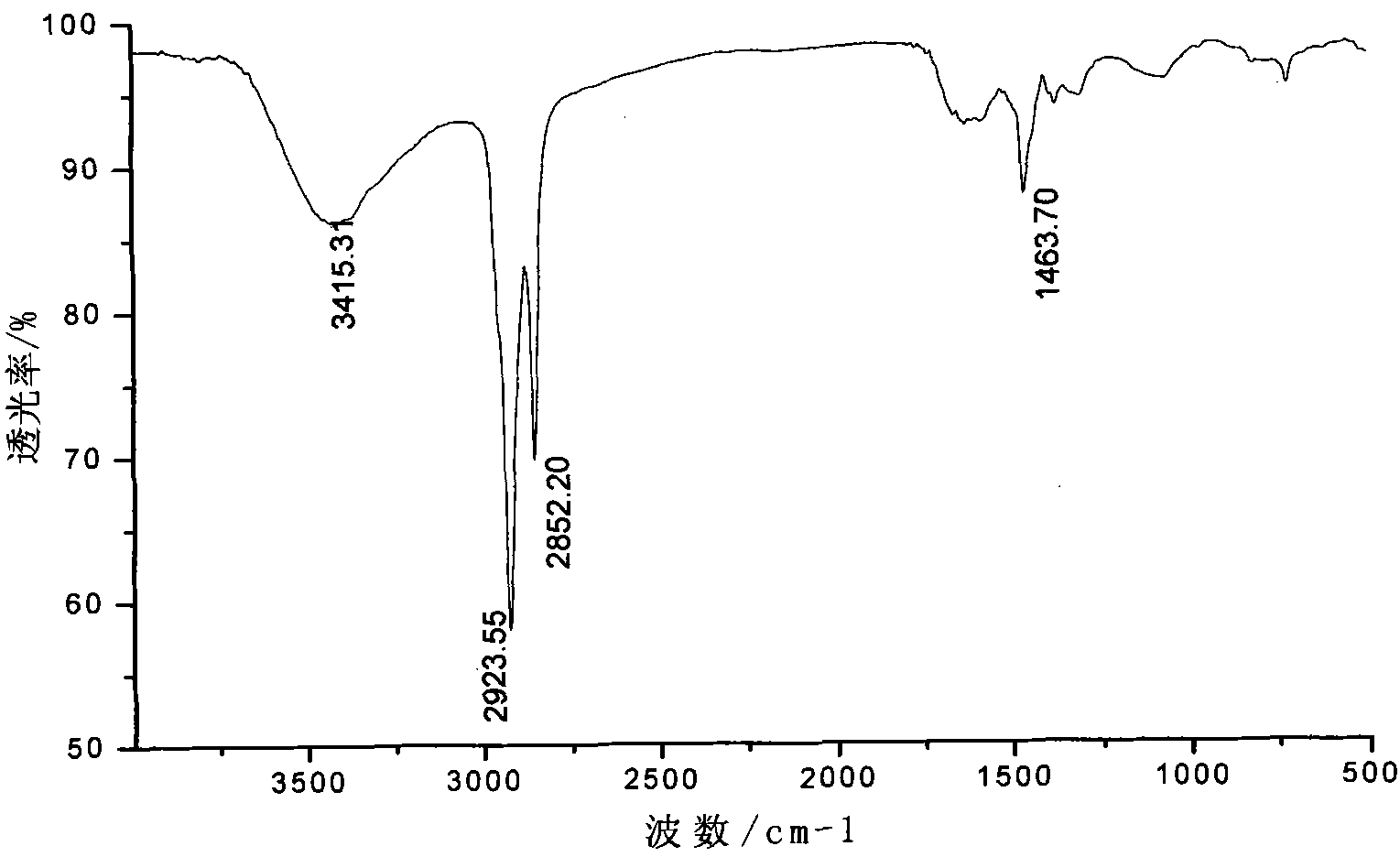

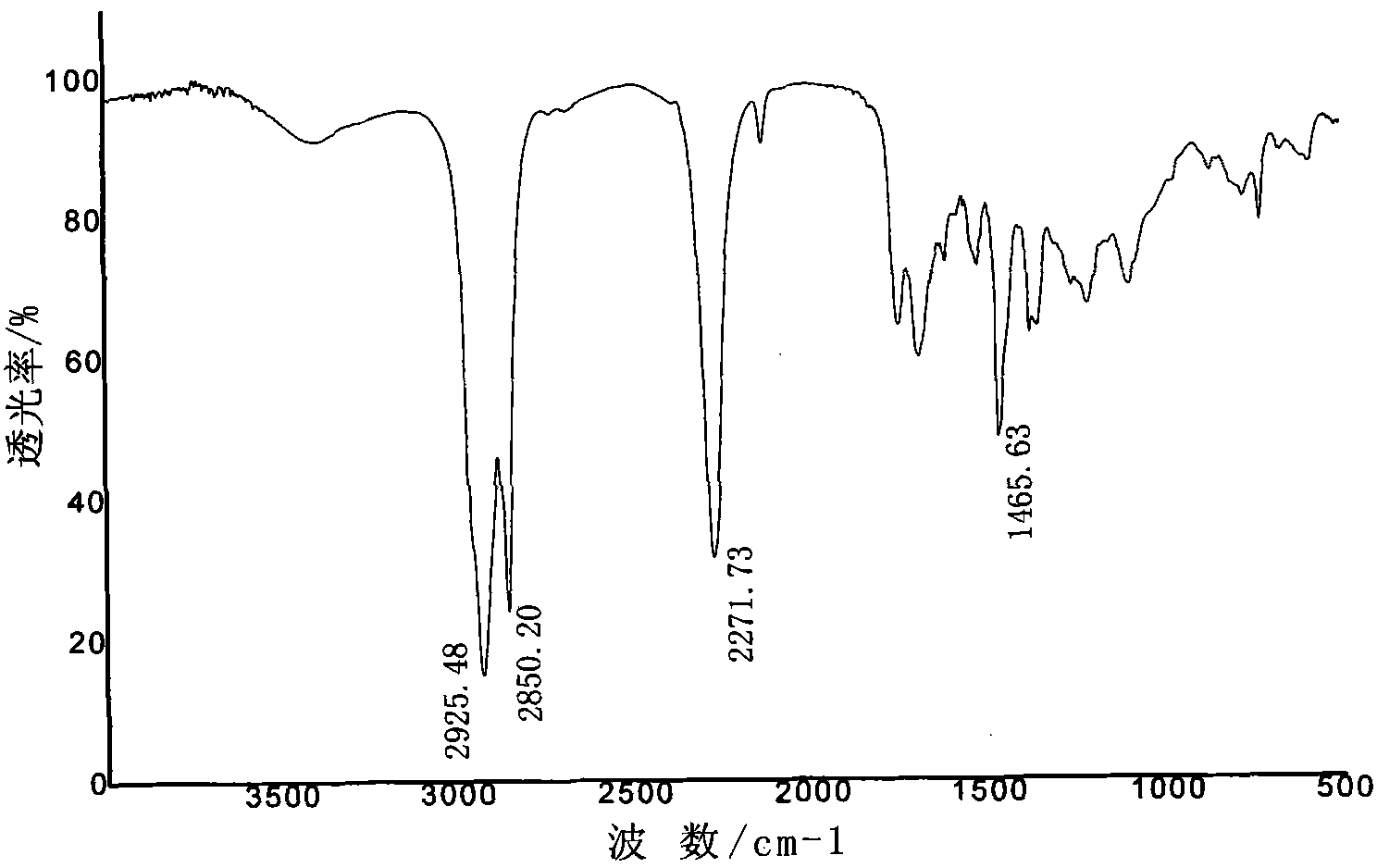

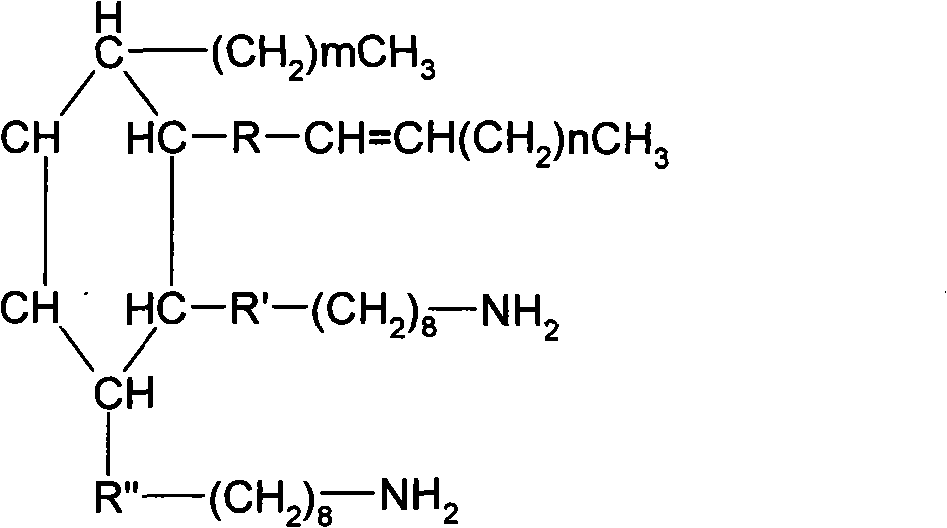

Dimeric fatty acid diamine, preparation method and method for preparing dimeric fatty acid diisocyanate

InactiveCN101844988AHigh reaction yieldMild reaction conditionsIsocyanic acid derivatives preparationOrganic compound preparationIce waterEther

The invention discloses a dimeric fatty acid diamine and a preparation method thereof. The invention adopts the dipoly fatty acid diamine as a raw material and provides a method for preparing dimeric fatty acid diisocyanate. The preparation method comprises the steps: by weight, mixing 30-80 parts of ether reaction medium, 4 parts of metal hydride reducing agent and 5 parts of dimeric fatty acid diamide under ice-water bath, carrying out temperature rising, backflow and reaction for 12-50 hours on the obtained reaction mixture, then carrying out treatment of extraction, washing, drying and decoloring and preparing and obtaining the dimeric fatty acid diamine which can be used for carrying out condensation with triphosgene directly and preparing the dimeric fatty acid diisocyanate. The invention prepares the dimeric fatty acid diamine by the reduction of dimeric amide, and has high reaction yield and pure products. The method for directly preparing DDI has mild reaction conditions in the preparation process, simple and feasible technique and easy implementation, and the synthetic method of the products is suitable for industrial production.

Owner:湖南省方正达电子科技有限公司

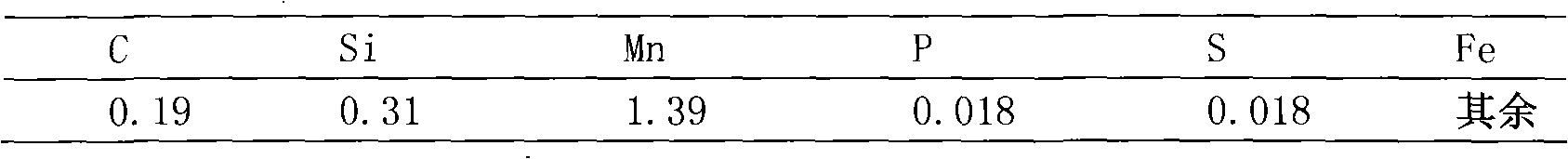

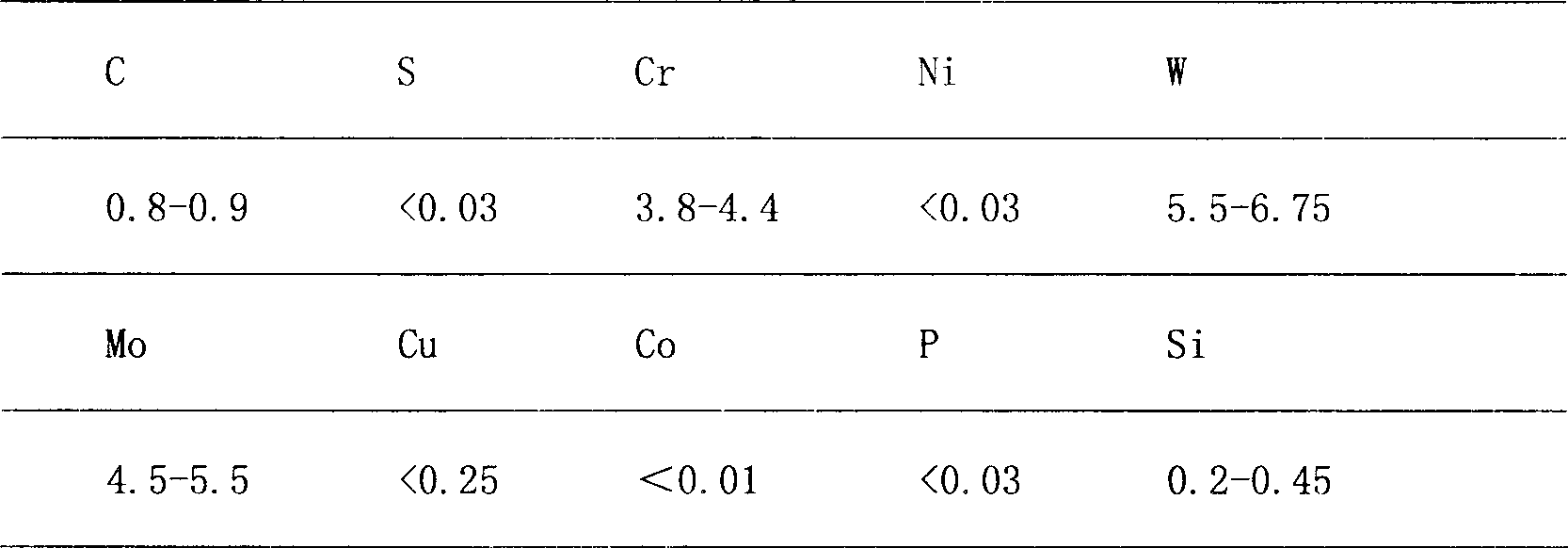

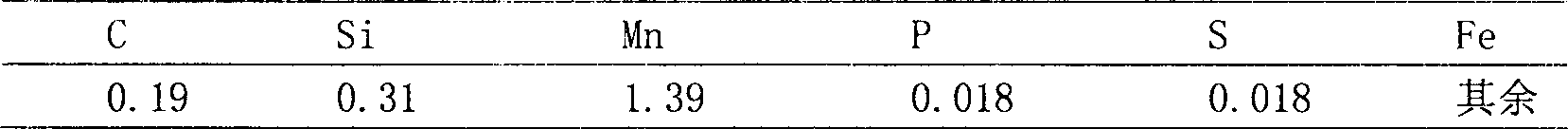

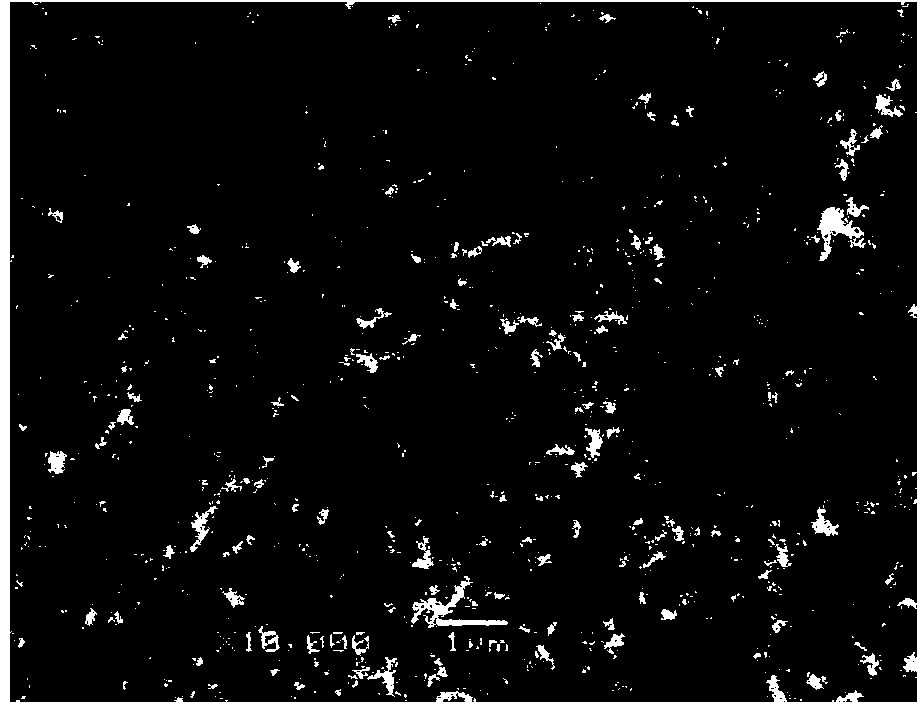

W6Mo5Cr4V2/Q345 explosive welding composite material

InactiveCN103009702AHigh bonding strengthInvariant physicsExplosivesMetal layered productsMetallic materialsMechanical property

The invention discloses a novel composite material which takes W6Mo5Cr4V2 high-speed steel as a high wear-resistance, high hardness and high strength covering layer, and adopts Q345 and an explosive welding process. The unique production process comprises the following steps of: selecting researched main body explosive RB53 and denotation explosive cyclonite; overlapping three layers of explosive at a denotation point and peripheral parts, wherein the total thickness is increased by 10-15mm compared with that of other areas; and carrying out a secondary sectional annealing thermal treatment process. The composite material provided by the invention has the advantages that the covering layer has the complete advantages of the high-speed steel W6Mo5Cr4V2, and the substrate layer Q345 has a good mechanical property, so that the perfect combination of the two metal materials of different properties is realized, the property advantages of one single material is brought into full play, and particularly the composite material has wide application prospect in fields requiring cost conservation and producing knives, dies and the like of irregular structures.

Owner:JIANGSU RUNBANG NEW MATERIAL GRP CO LTD

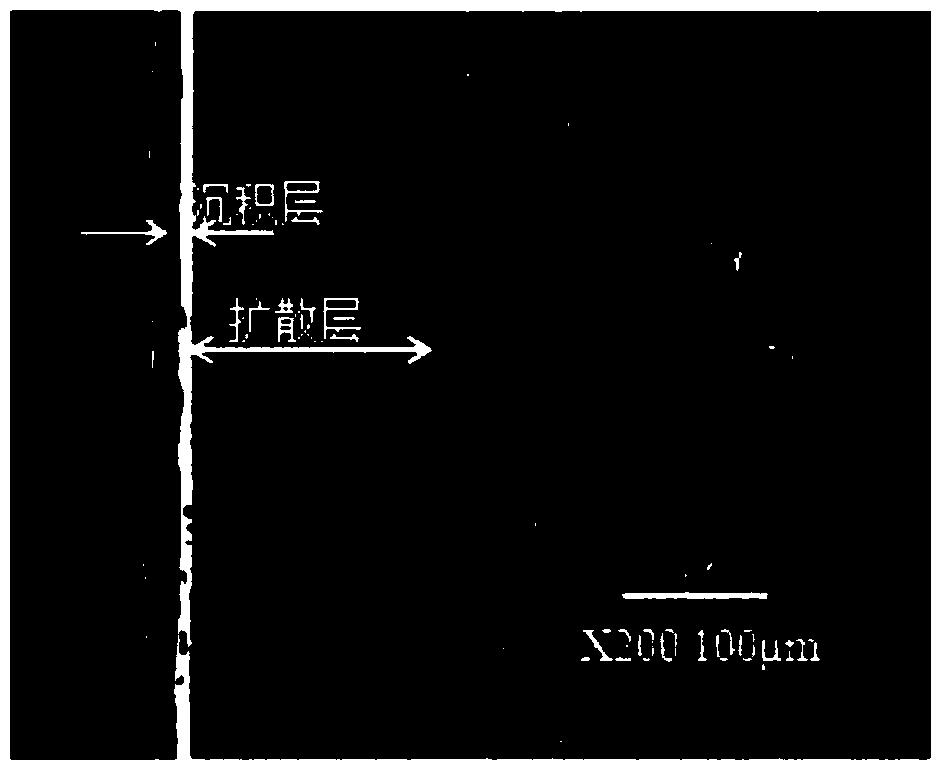

Fe-Al-Nb alloy coating and preparation method thereof

ActiveCN104070725ASolve the problem of cracking and even peelingTake full advantage of performanceHot-dipping/immersion processesSolid state diffusion coatingFragilityAlloy coating

The invention discloses a Fe-Al-Nb alloy coating which comprises three parts such as a base body layer, a sedimentary layer and a diffusion layer, wherein the base body layer is made of ordinary carbon steel; the sedimentary layer comprises 99.5 weight percent of Nb, and 5 weight percent of AlNb2, Fe7Nb6, Fe2Al5 and Fe3Al; the diffusion layer comprises 25 to 34 weight percent of Al, 65 to 73 weight percent of Fe and 1.0 to 2.0 weight percent of Nb; the thickness of the Fe-Al-Nb alloy coating is 150 to 200 <Mu>m; the ordinary carbon steel is 45 steel or Q235 steel. According to the invention, not only can the strength and high-temperature corrosion resistance of an Fe-Al based coating improved, but also the tenacity of the Fe-Al based coating is improved, so as to effectively reduce the ambient temperature fragility of the Fe-Al based coating.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Porous NiAl/Al2TiO5 composite material and preparation method thereof

ActiveCN102212735ATake full advantage of performanceSmall coefficient of thermal expansionCatalyst carriersExhaust apparatusSelf-propagating high-temperature synthesisThermal expansion

The invention discloses a porous NiAl / Al2TiO5 composite material and a preparation method thereof. Industrially pure Ni, Al, TiO2 and Al2O3 powder are used as raw materials of the composite material. The preparation method comprises the following steps of: performing high-temperature sintering reaction (TiO2+Al2O3=Al2TiO5) to synthesize Al2TiO5, mixing the crushed Al2TiO5 and Ni and Al powder, adding C powder serving as a pore forming agent and a heat generating agent, uniformly mixing the raw materials, pressing the mixture into a blank, and performing self-propagating high-temperature synthesis reaction to generate the porous composite material consisting a NiAl phase and a Al2TiO5 phase. The adjustable ranges of the strength, the porosity and the thermal expansion coefficient of the porous composite material are large; and the production process is simple, the yield is high, and the porous composite material can be used as a carrier and a filter in catalysis and environmental purification.

Owner:SHANDONG UNIV OF SCI & TECH

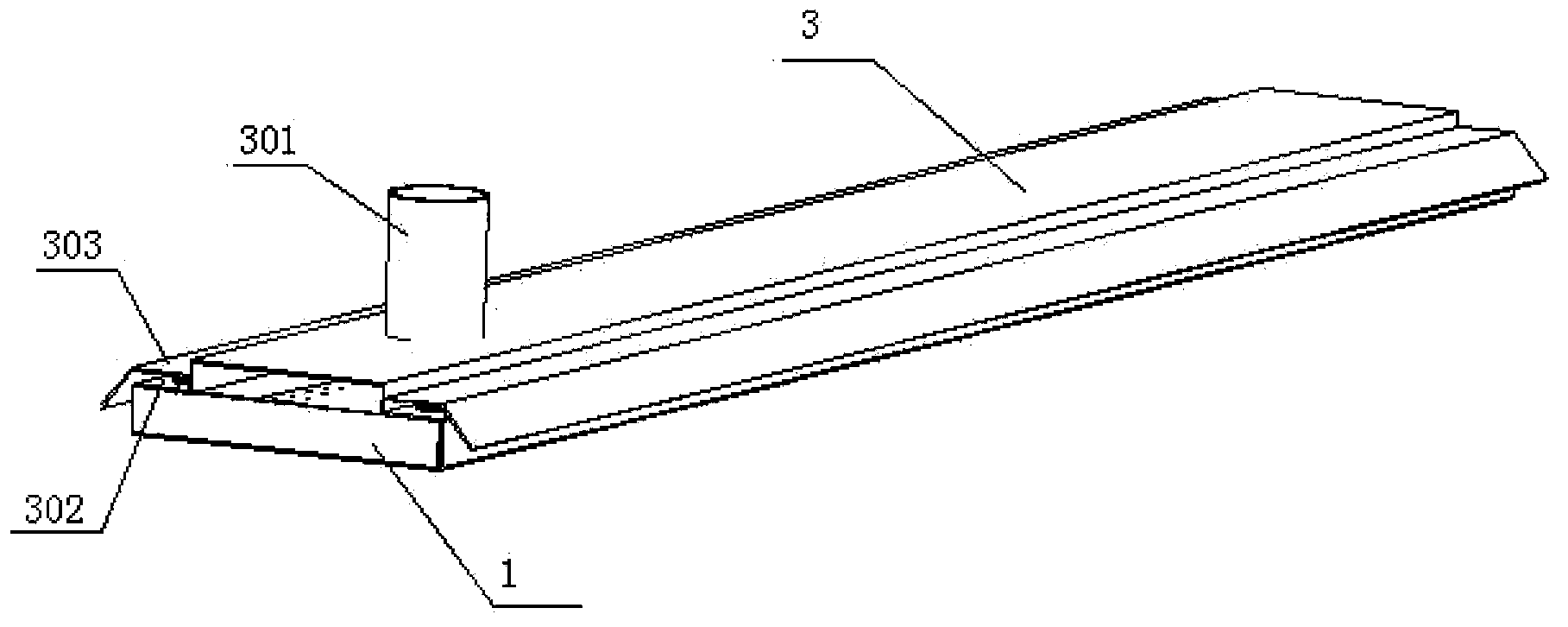

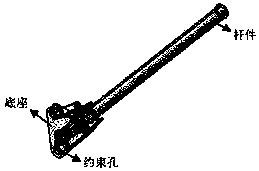

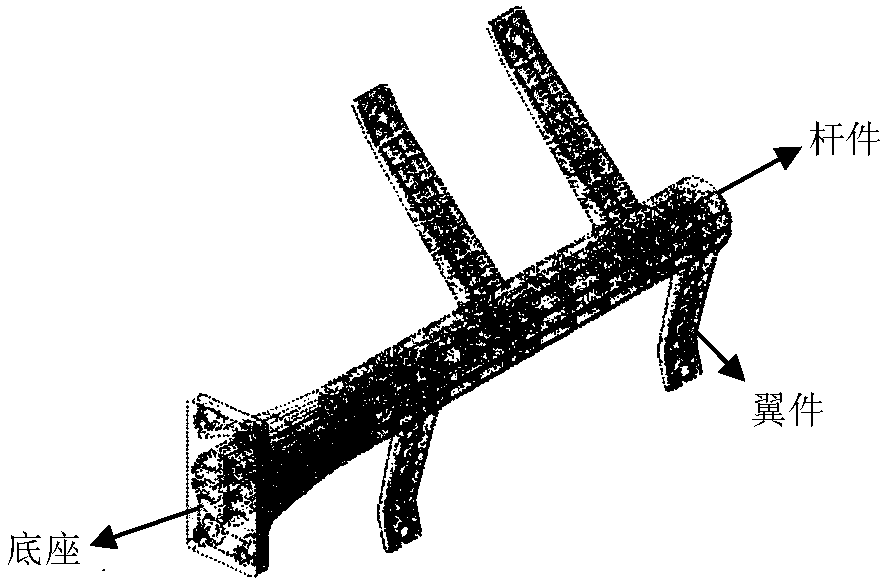

Cantilever beam supporting device and preparation method thereof

InactiveCN107867336ATake full advantage of performanceLightweight effect is goodSuperstructure subunitsSteps arrangementVehicle frameCar manufacturing

The invention belongs to the field of automobile manufacturing, and particularly provides a cantilever beam supporting device and a preparation method thereof. The cantilever beam supporting device comprises a base and a rod piece connected with the base, wherein the base and the rod piece are made of fiber-reinforced resin-based composite materials. The cantilever beam supporting device has the characteristic of lightweight so that the weight of a vehicle can be reduced, and the energy-saving and emission-reducing effects can be achieved. Meanwhile, the cantilever beam supporting device can effectively reduce the resonance effect of the cantilever beam supporting device and a vehicle frame, breaking can be prevented, quality risks are avoided, and the preparation method is simple and feasible.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

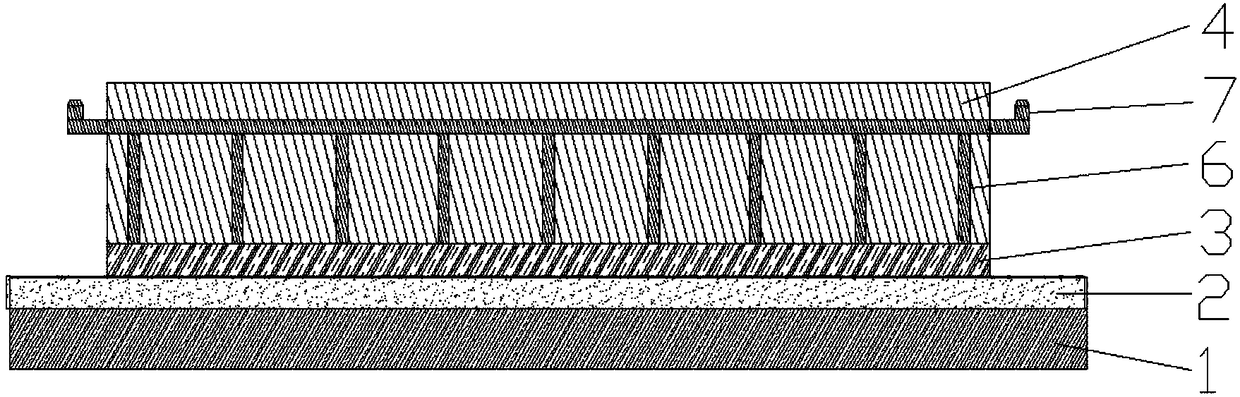

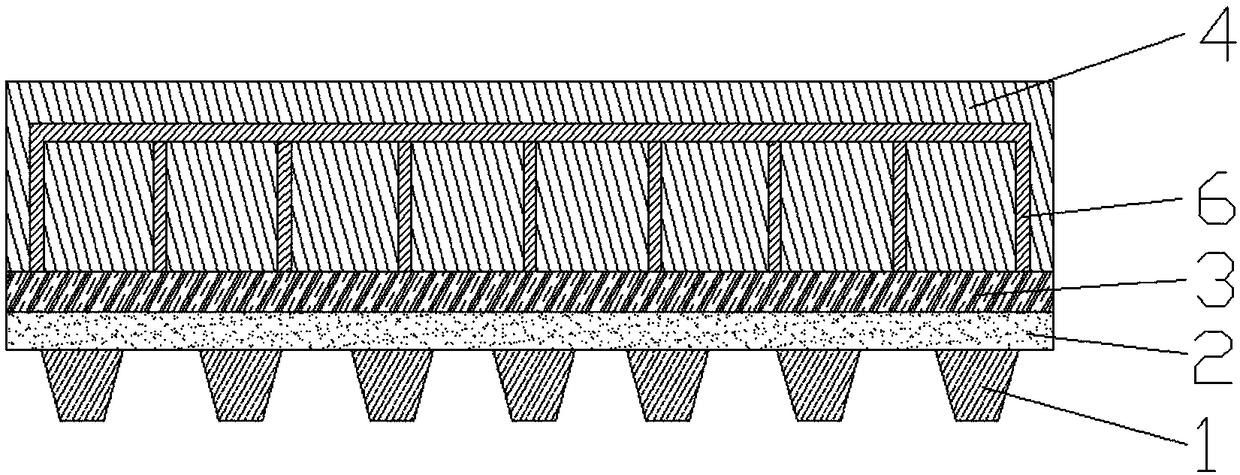

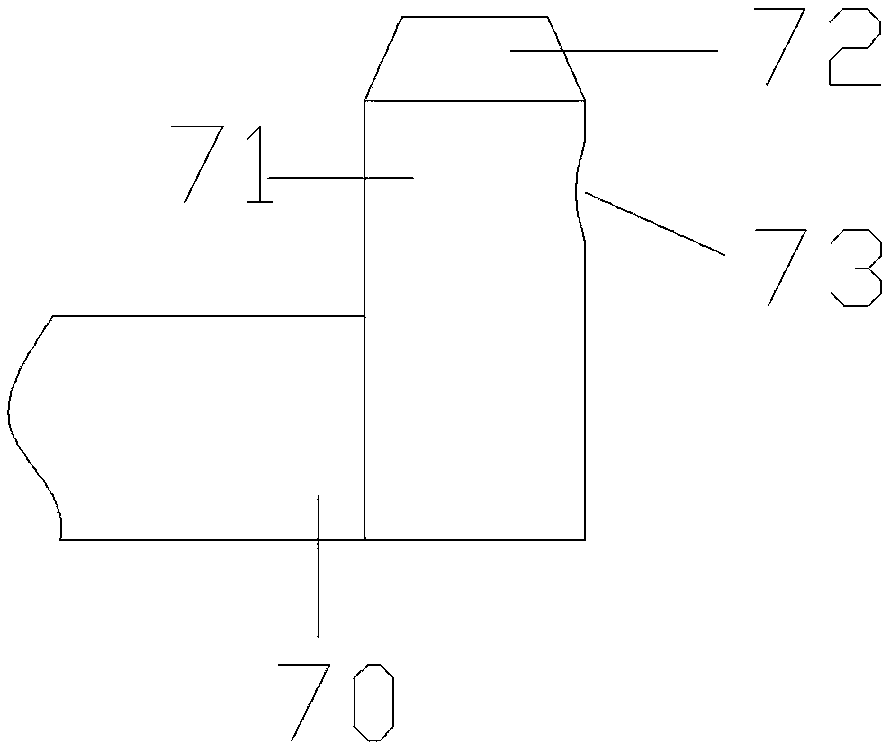

Assembly type steel bridge super-tough durability prefabricated pavement layer structure

PendingCN108589528AShorten construction period on siteUltra-tough durability achievedBridge structural detailsBridge deckResin bonding

The invention discloses an assembly type steel bridge super-tough durability prefabricated pavement layer structure. The structure comprises a steel bridge precast beam section, a steel bridge deck slab, a pavement section bonding layer, a prefabricated pavement layer and a splicing piece used for splicing the pavement layer structure, all of which are sequentially arranged from bottom to top. Theinside of the prefabricated pavement layer is paved with a reinforcing mesh frame, and protruding connecting pieces extending out of the prefabricated pavement layer along the side portions are arranged on the side portions of the reinforcing mesh frame. The two ends of the steel bridge precast beam section extend out of the prefabricated pavement layer to form assembly splicing sections. The splicing piece is arranged between the assembly splicing sections of two adjacent pavement layer structures to form a splicing space. The splicing piece is used for connecting the protruding connecting pieces on the adjacent to-be-spliced pavement layer structures. By the adoption of the assembly type steel bridge super-tough durability prefabricated pavement layer structure, a super-tough resin bonding layer and super-tough resin concrete serve as pavement layer structure materials, and super-tough durability of the pavement layer can be achieved.

Owner:NANJING ROAD KEEPER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com