Patents

Literature

68results about How to "Shorten construction period on site" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

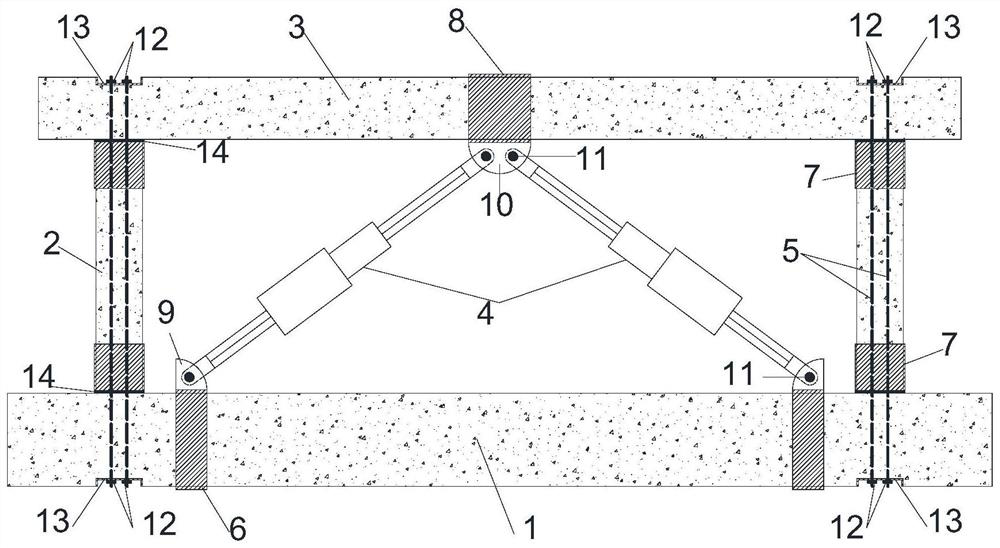

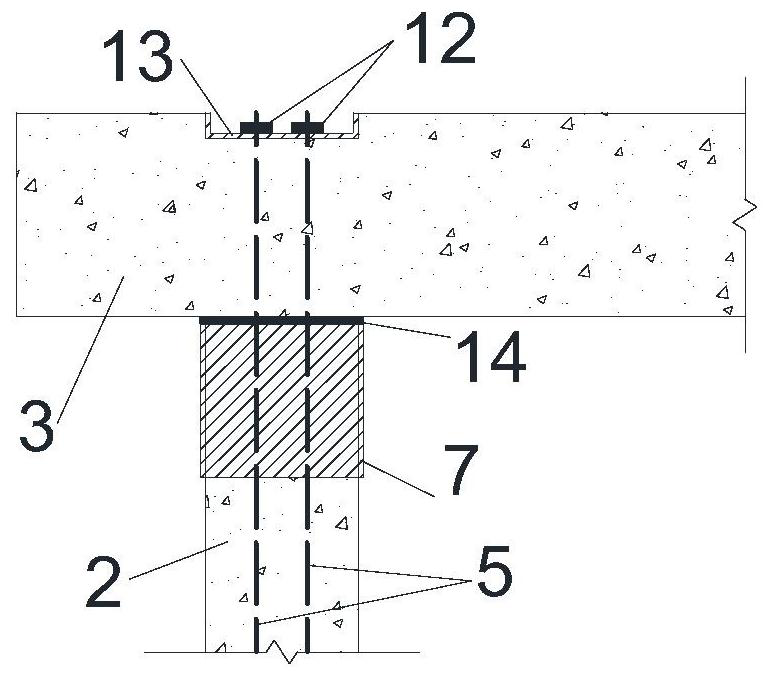

Full-prefabricated assembling dual-layer framework pier structure system of which functions can be recovered after earthquake

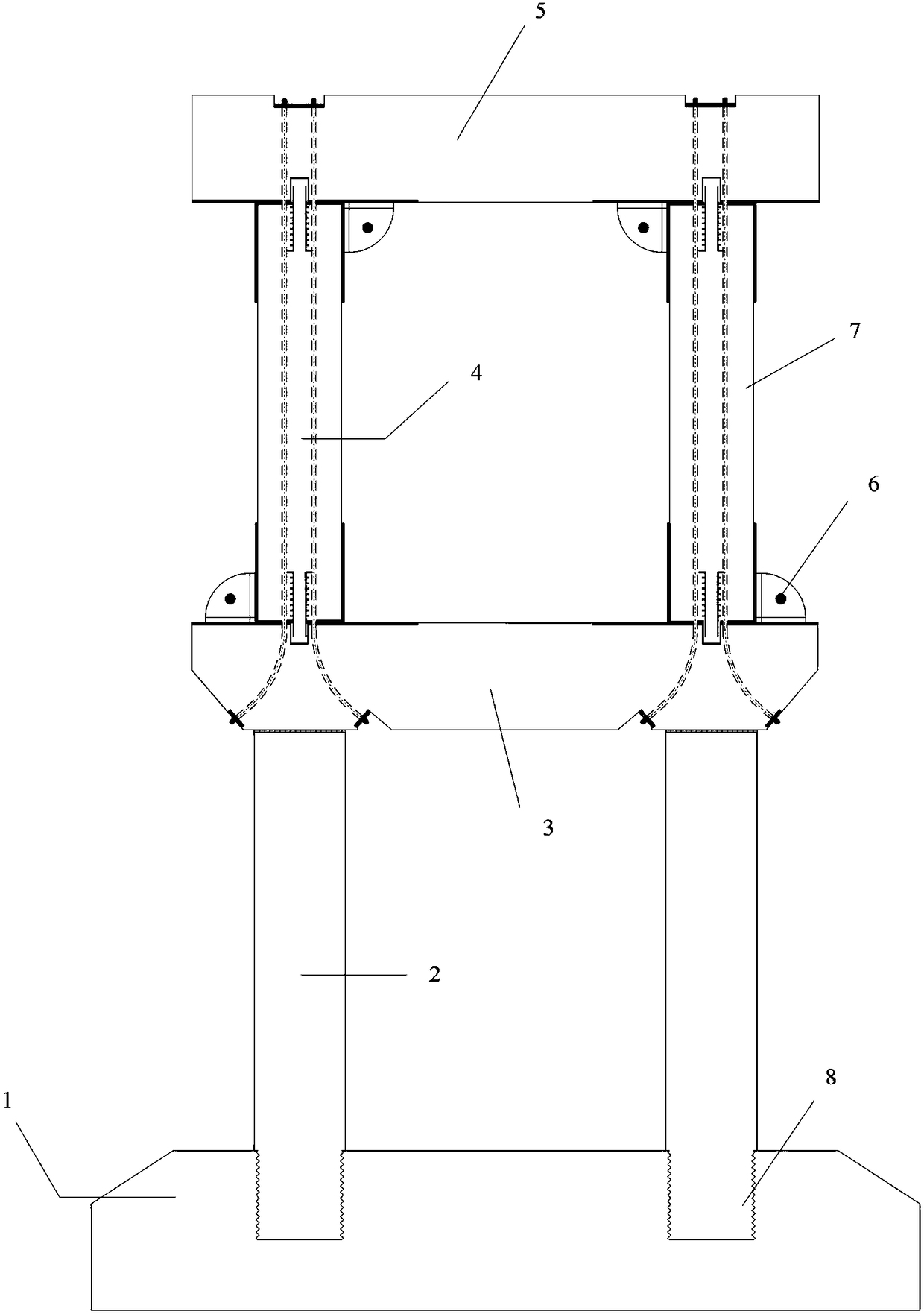

The invention discloses a full-prefabricated assembling dual-layer framework pier structure system of which functions can be recovered after an earthquake. The structure system is composed of a prefabricated bearing platform, prefabricated lower-layer pier studs, a prefabricated lower-layer cross beam, prefabricated upper-layer pier studs, a prefabricated upper-layer cross beam, a friction energy-dissipation damper, unbonded tendons and steel pin bolts. The prefabricated upper-layer pier studs are connected with the prefabricated upper-layer cross beam and the prefabricated lower-layer cross beam through the unbonded tendons, and with the assistance of the friction damper, a self-restoration swing energy-dissipation system is formed. The prefabricated lower-layer pier studs are connected with the prefabricated lower-layer cross beam and the bearing platform through a grouting sleeve and in an insertion mode respectively to form an equivalent cast-in-situ system. Under a small earthquake effect, the upper layer dissipates energy through self-restoration swing, and the lower-layer structure is in an elastic period. The lower-layer structure generates limited plastic damage to dissipate the earthquake energy while the upper-layer structure generates swing to dissipate the energy. After the earthquake, the upper-layer structure can be restored by itself, the lower-layer structure can be quickly repaired, and the structure system can quickly recover the recovery function.

Owner:BEIJING UNIV OF TECH

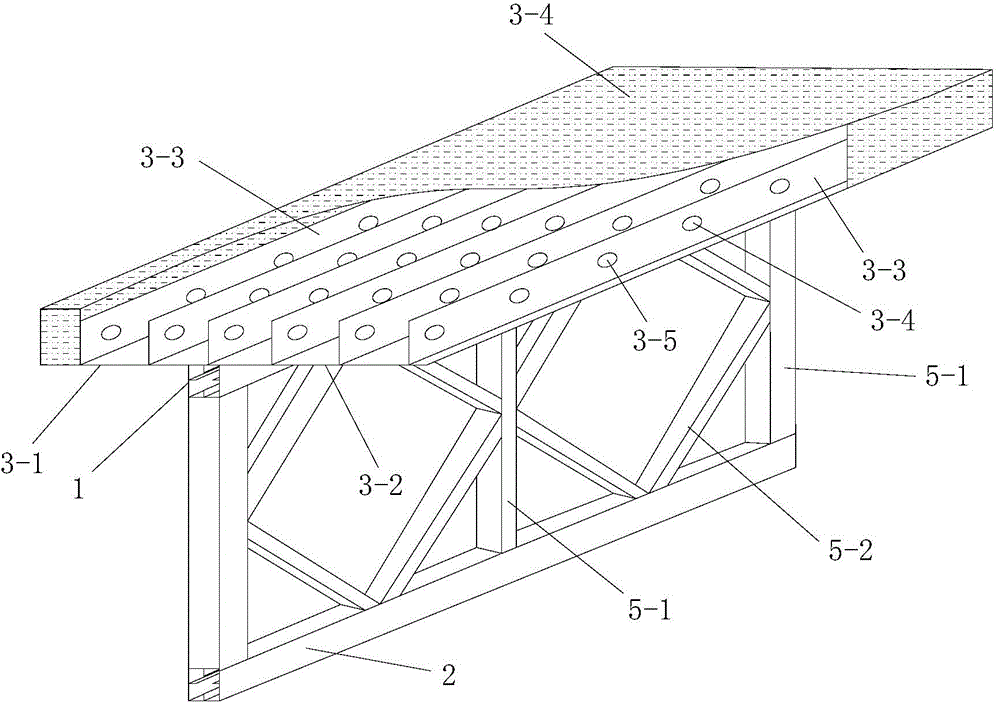

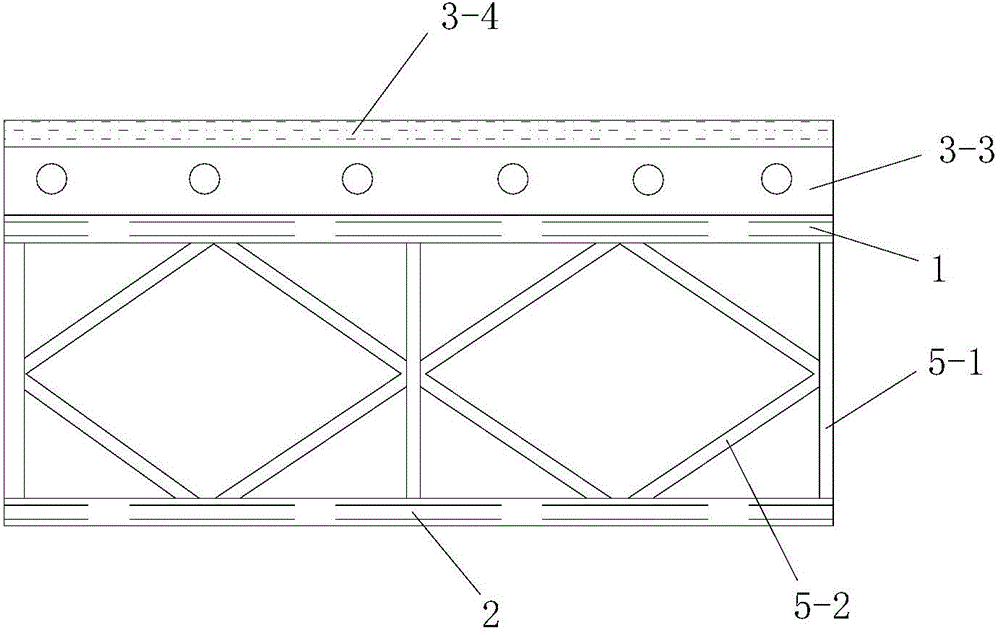

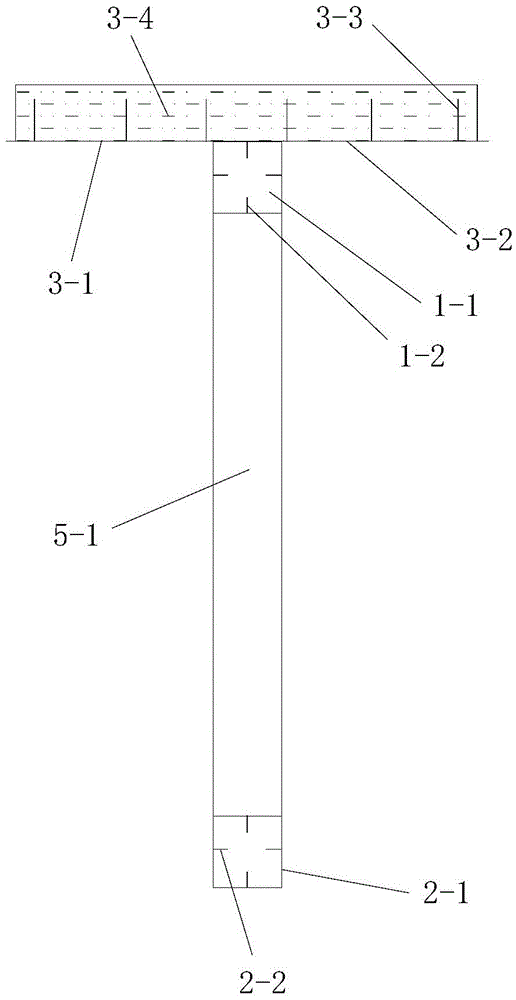

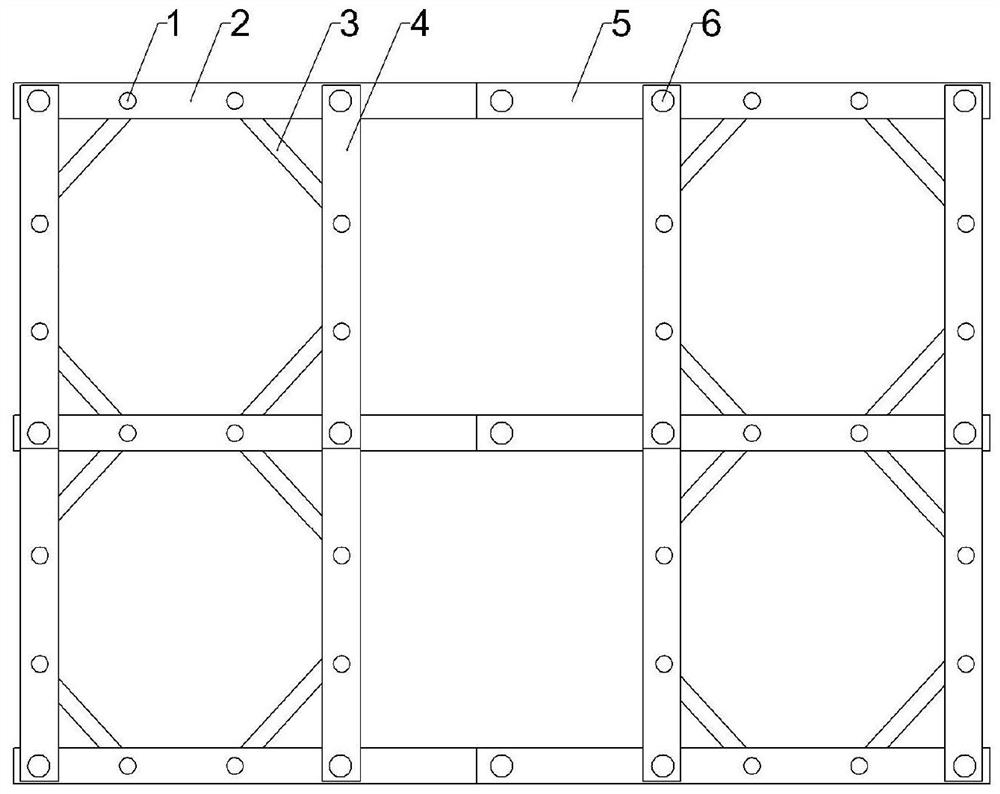

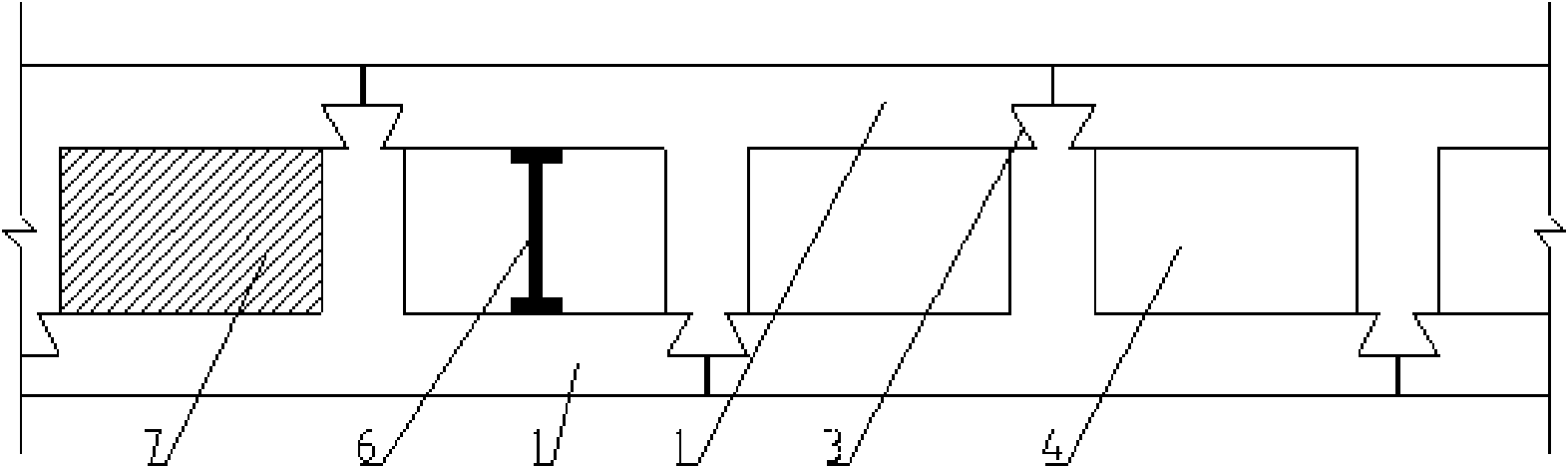

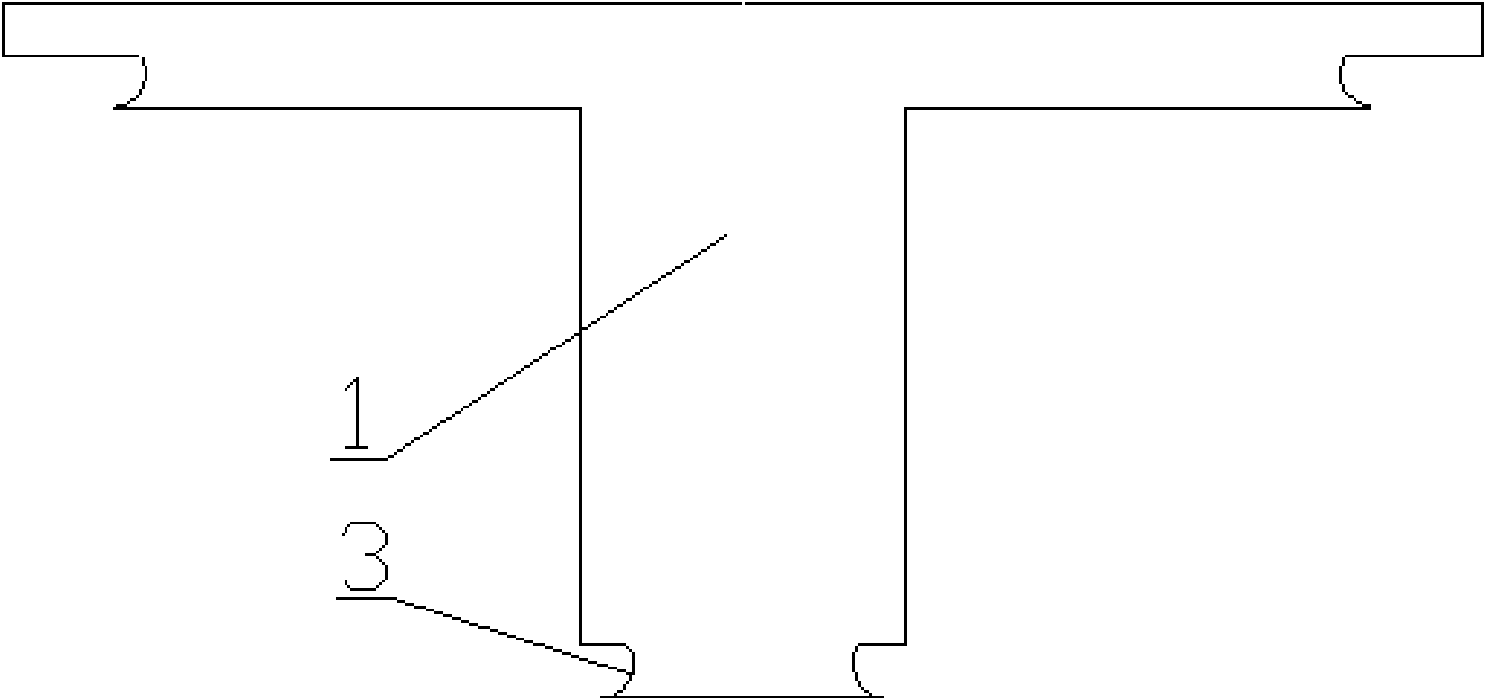

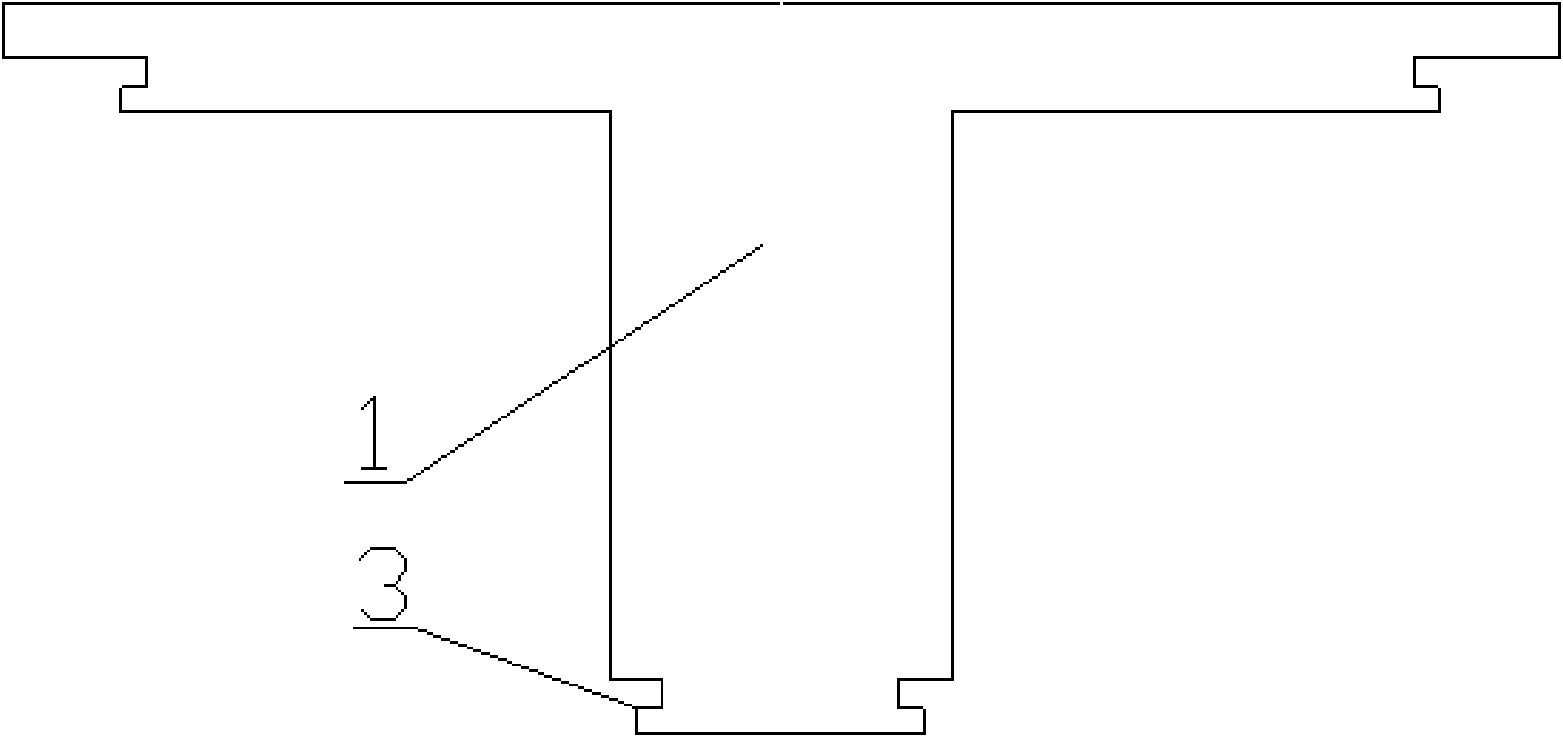

T-shaped plate girder segment prefabricating unit based on steel truss and combined bridge deck slab

InactiveCN104088221ASimple structureReasonable designBridge structural detailsSheet steelBridge deck

The invention discloses a T-shaped plate girder segment prefabricating unit based on a steel truss and a combined bridge deck slab. The T-shaped plate girder segment prefabricating unit comprises a lower force bearing structure and the combined bridge deck slab arranged on the lower force bearing structure, and the combined bridge deck slab and the lower force bearing structure are both arranged in the longitudinal bridge direction; the lower force bearing structure is a planar truss composed of an upper chord rod, a lower chord rod and a web rod, the upper chord rod comprises a first rectangular steel tube, and the lower chord rod comprises a second rectangular steel tube; the combined bridge deck slab comprises a bottom supporting steel plate, a plurality of upper longitudinal ribs arranged on the bottom supporting steel plate, and a concrete bridge deck slab arranged on the bottom supporting steel plate in a pouring mode, the upper longitudinal ribs are arranged in the concrete bridge deck slab in a pouring mode, and the upper longitudinal ribs are long-strip-shaped steel plates with the middles provided with a plurality of through holes; the bottom supporting steel plate is a rectangular supporting steel plate formed by connecting a left extension steel plate, a right extension steel plate and a first rectangular steel tube. The T-shaped plate girder segment prefabricating unit is simple in structure, reasonable in design, easy and convenient to construct, good in overall mechanical property and capable of improving the structure accuracy and construction convenience of a steel and concrete combined bridge.

Owner:CHANGAN UNIV

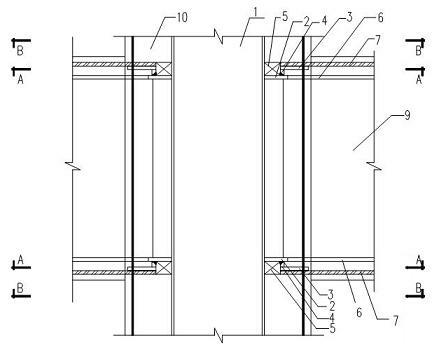

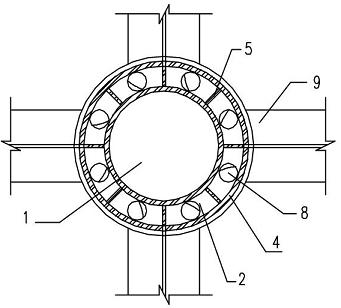

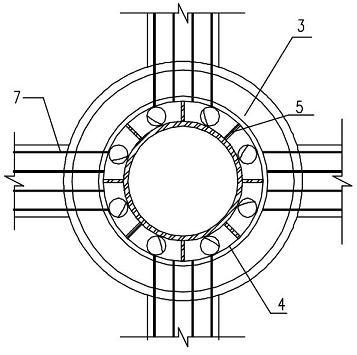

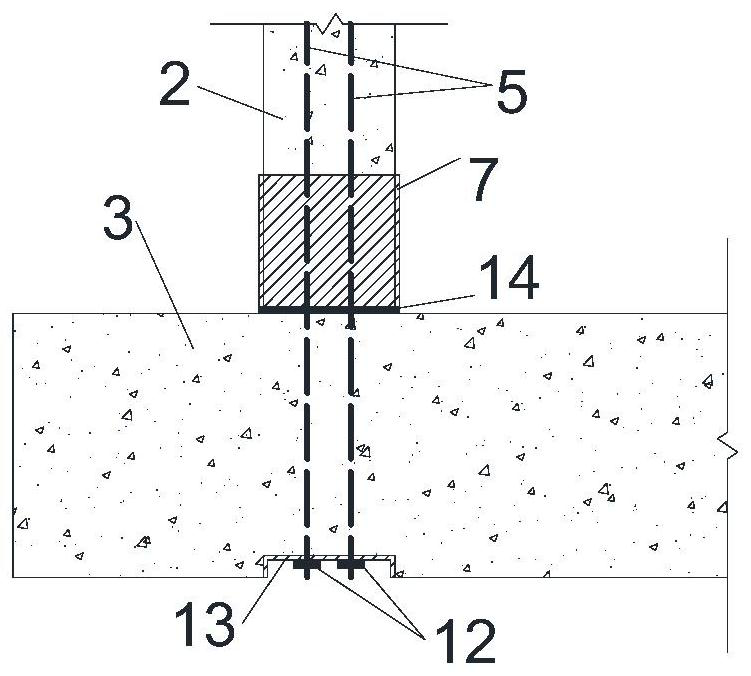

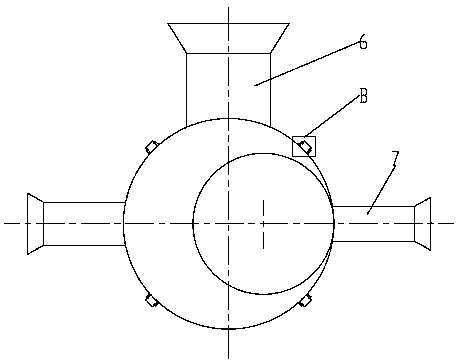

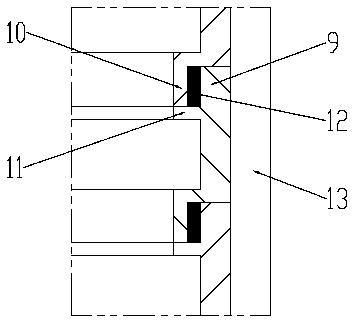

Connecting joint of steel pipe concrete column and profile steel concrete beam

ActiveCN102619286AGuaranteed longitudinal reinforcement anchorageShorten the lengthBuilding constructionsPunchingConcrete beams

The invention discloses a connecting joint of a steel pipe concrete column and a profile steel concrete beam. The intersection between a steel pipe in the steel pipe concrete column and a flange girth of the profile steel concrete beam is provided with a pair of large and small annular plates of different diameters; the horizontal and vertical positions of the two annular plates are staggered away from each other; the small annular plate is welded with a steel beam flange girth in the profile steel concrete beam; the large annular plate is welded with a longitudinal bar in the profile steel concrete beam; a steel pipe is arranged between the annular plates for welding the large and small annular plates into a whole; and the steel pipe of the steel pipe concrete column and the steel pipe for connecting the two annular plates are connected into a whole through a vertical rib. The connecting joint of the steel pipe concrete column and the profile steel concrete beam disclosed by the invention has the advantages that: 1, a large quantity of steel bar holes are not required to be formed on a steel pipe in a steel pipe concrete column; 2, damages to the section of a profile steel concrete column caused by steel pipe punching are avoided; and 3, convenience is brought to construction casting and compacting of concrete.

Owner:CHINA NERIN ENG

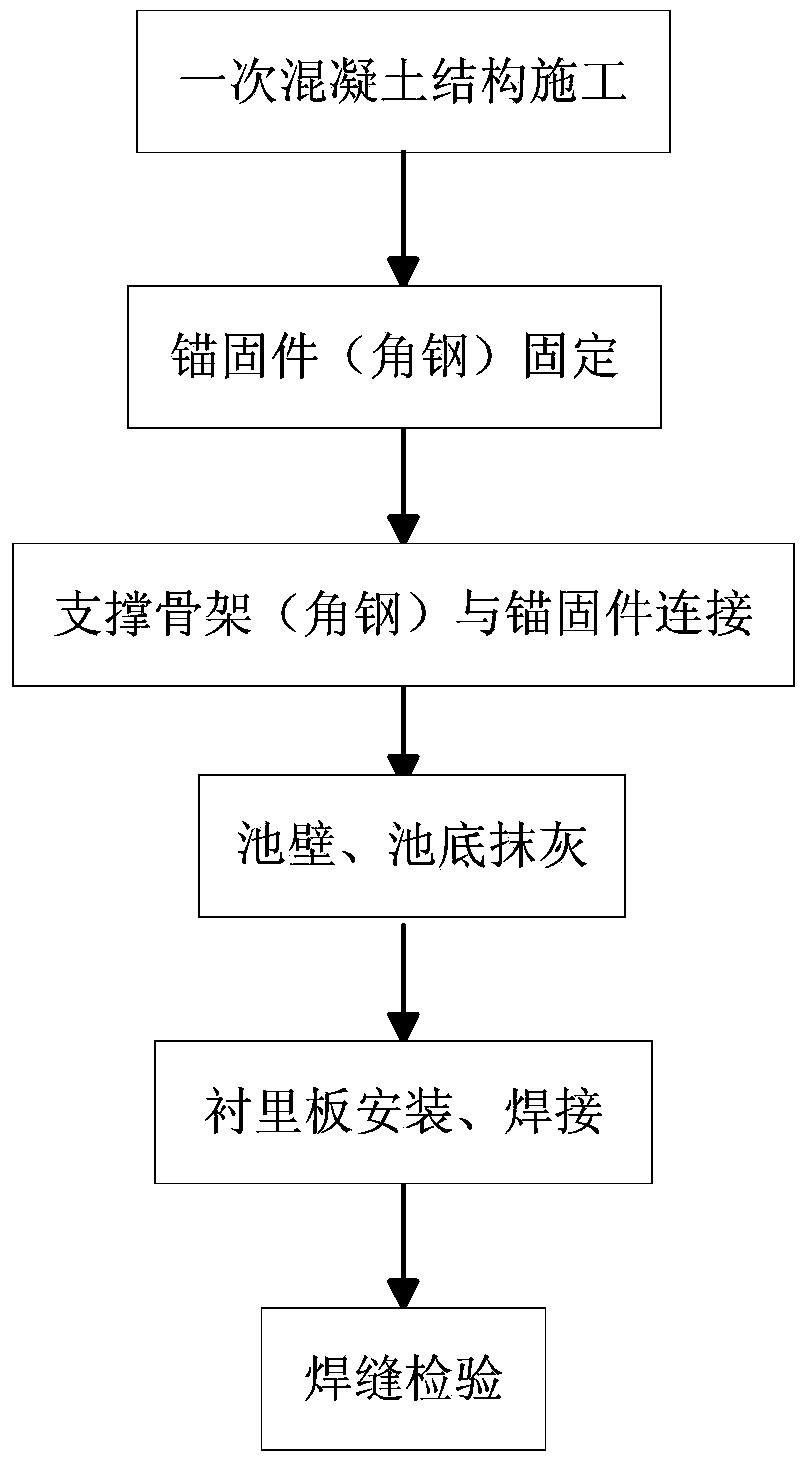

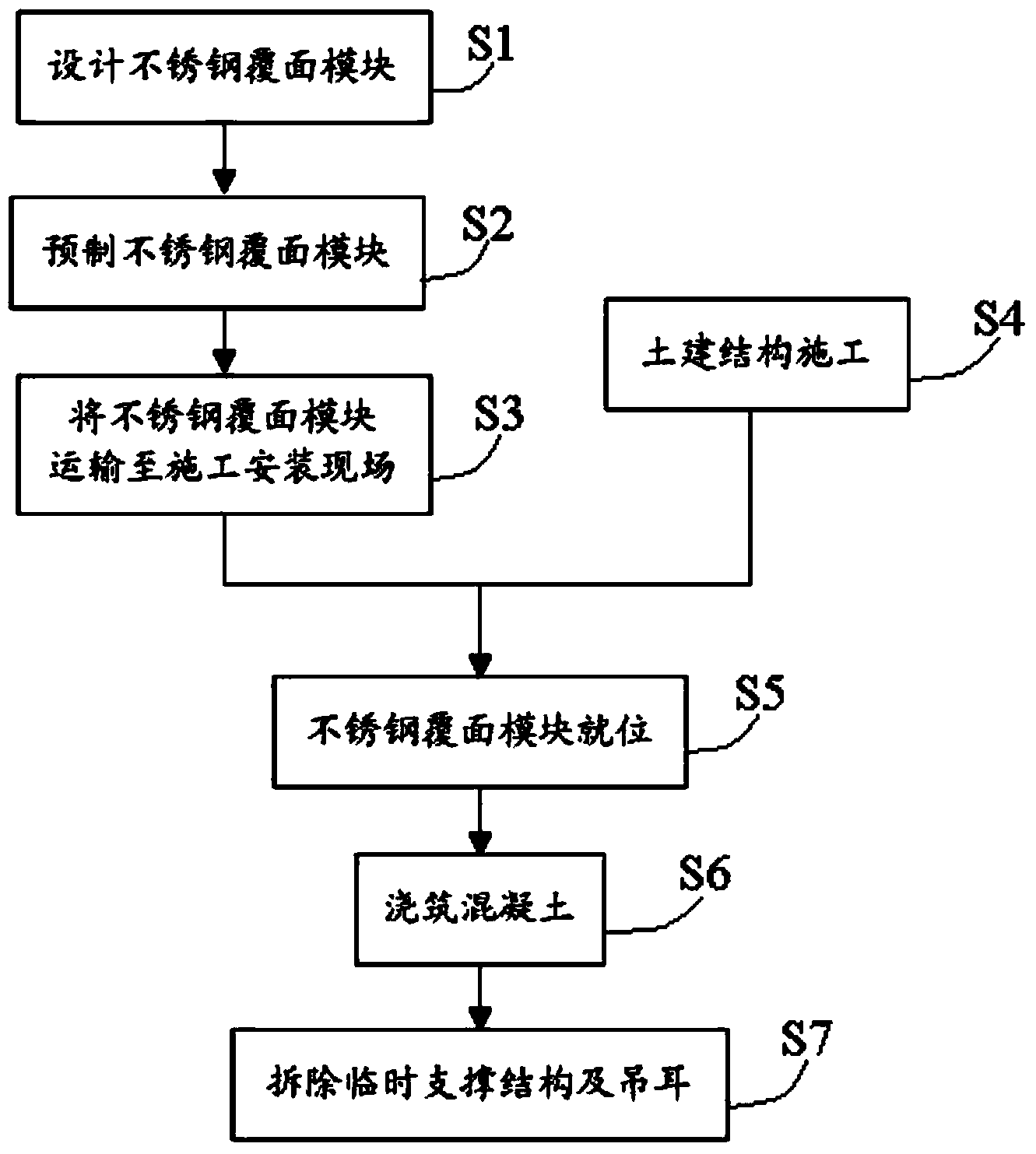

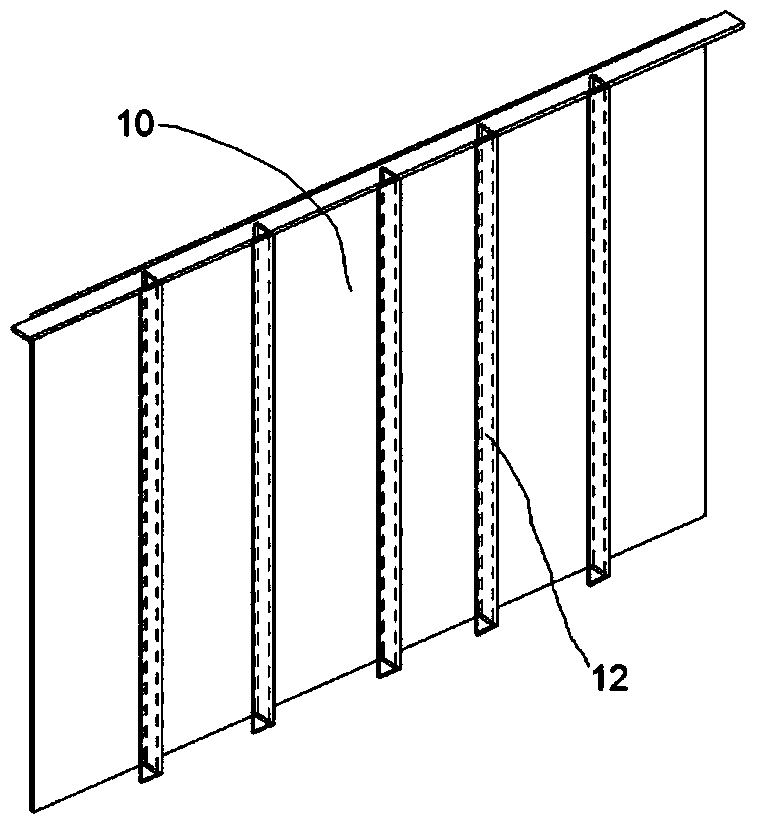

Modular building method of nuclear power plant stainless steel cladding surface

InactiveCN104234436AImprove construction efficiencyImprove welding qualityBuilding material handlingIndustrial buildingsNuclear plantEngineering structures

The invention discloses a modular building method of a nuclear power plant stainless steel cladding surface. The method comprises the following steps of (1) designing and prefabricating a stainless steel cladding surface module; (2) transporting the stainless steel cladding surface module to a construction mounting field; (3) constructing a civil engineering structure at a positioning place of the stainless steel cladding surface module, wherein the step (1) and the step (2) are parallel steps and are performed at the same time; (4) placing the stainless steel cladding surface module to the civil engineering structure; (5) casting concrete to the surrounding of the stainless steel cladding surface module, so that the stainless steel cladding surface module is mounted. Compared with the prior art, the method has the advantages that due to the fact that the stainless steel cladding surface is made into the module structure, the step of constructing the civil engineering structure and prefabricating the stainless steel cladding surface module can be constructed at the same time, the shortening of the construction period of the whole cladding surface field is facilitated, and the construction efficiency and the welding quality of the stainless steel cladding surface can also be improved.

Owner:中广核工程有限公司 +1

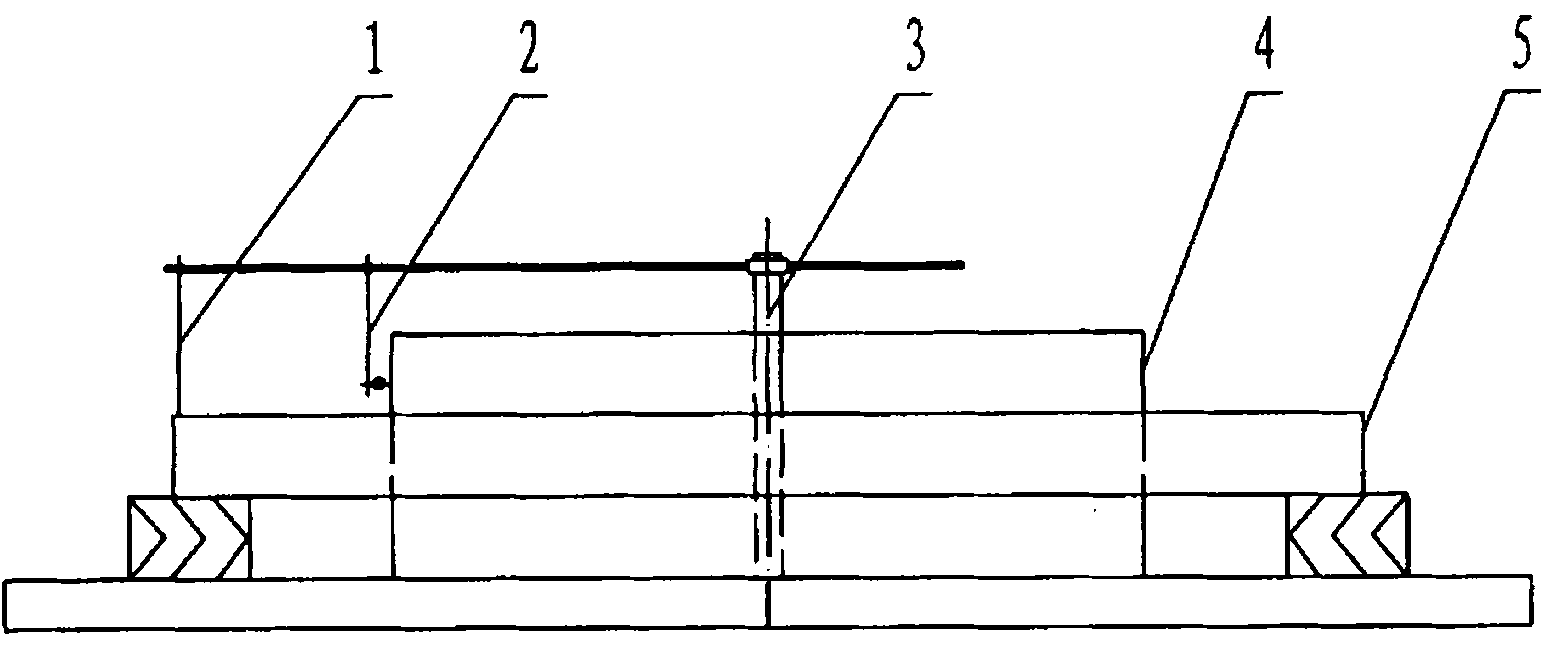

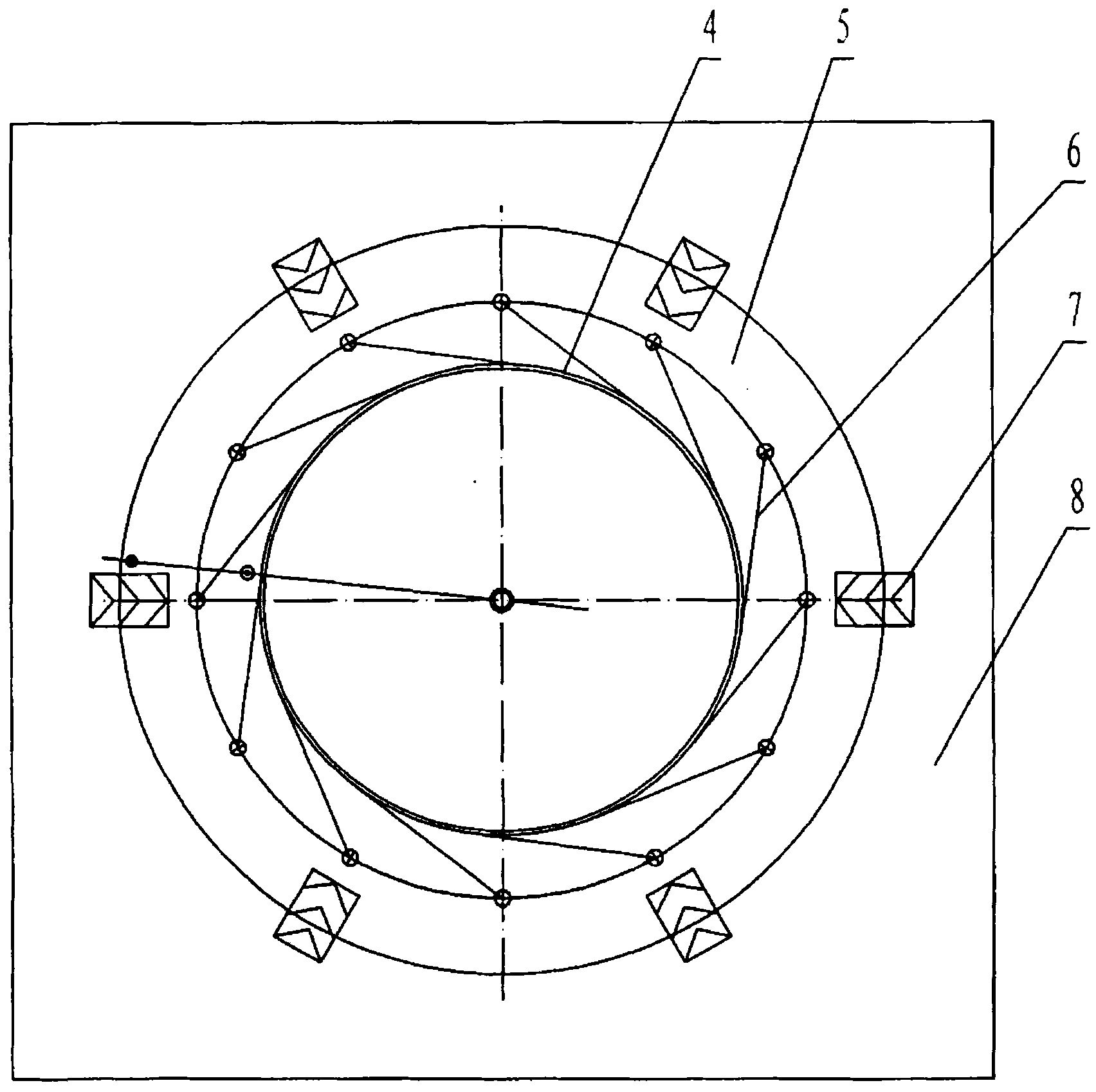

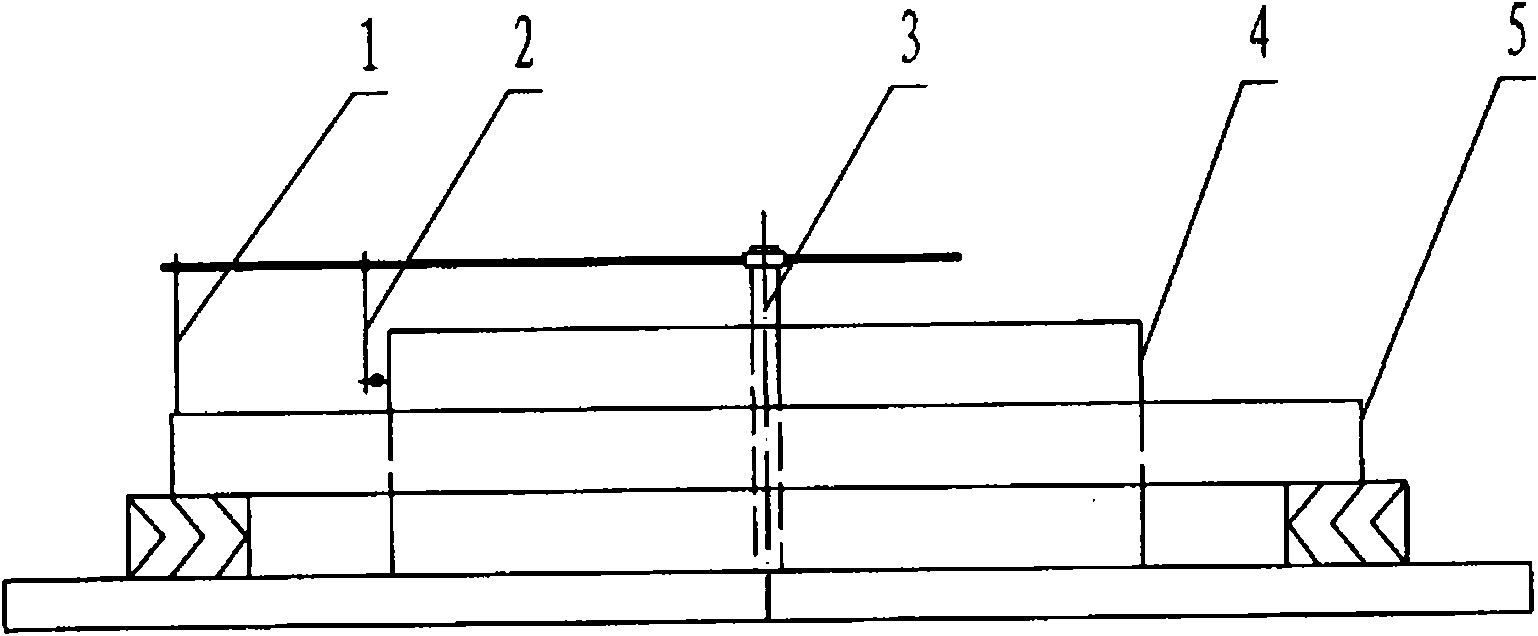

Installation method of big gear ring of rotary kiln

InactiveCN101846450AImprove installation accuracyShorten construction period on siteRotary drum furnacesBuilding materialTransmission system

The invention discloses an installation method of a big gear ring of a rotary kiln, which relates to rotary kiln installation, big gear ring replacement or installation method after turn-over repair in aluminum oxide, building material, nonferrous metal and metallurgical industries. The invention is characterized in that the installation process comprises the steps of preassembling the big gear ring and a lower shell ring thereof, aligning and installing integrally after connecting the big gear ring and the lower shell ring into a whole body. In the method, a large-tonnage jack-up plate rotary kiln body mechanism does not need to be arranged, and barrel and gear ring deflection alignment is carried out directly via an auxiliary transmission system. The invention shortens construction period, increases the installation accuracy of the large ring gear, improves the working environment for constructors and relieves labor intensity.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

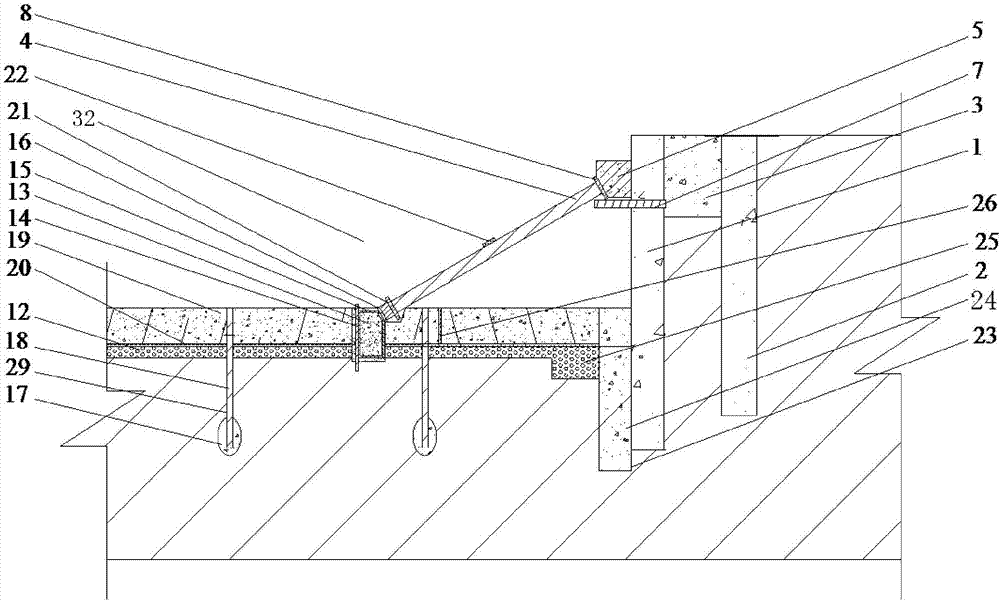

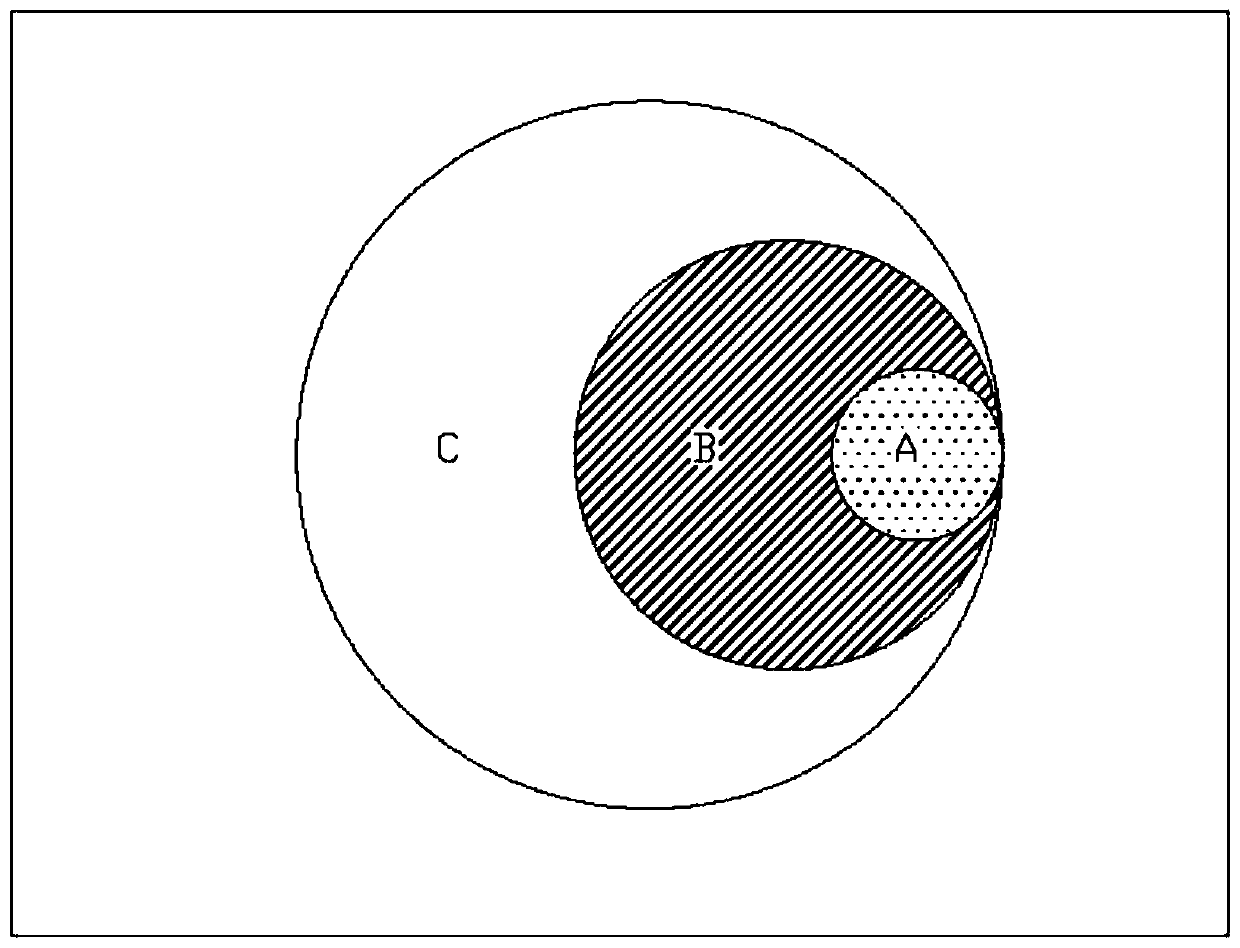

Post-arranged inner supporting structure for partitioned excavation of super-large deep foundation pit and construction method

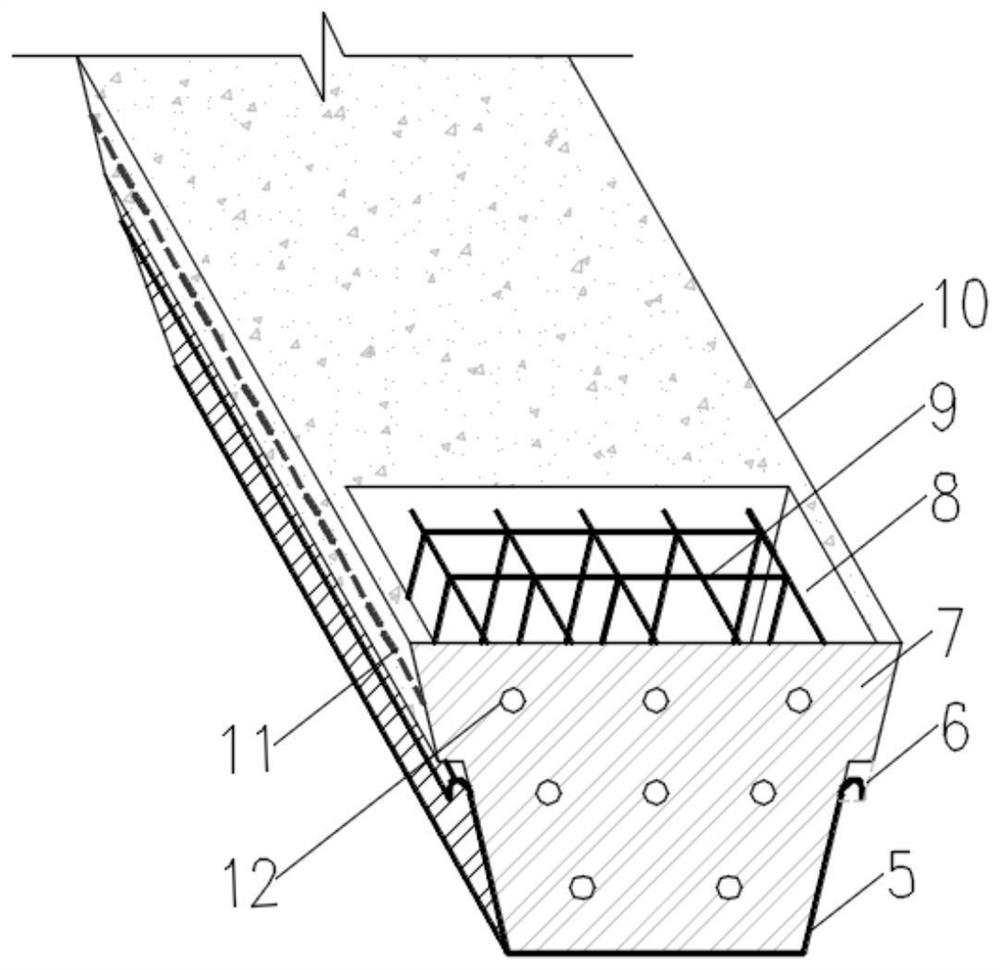

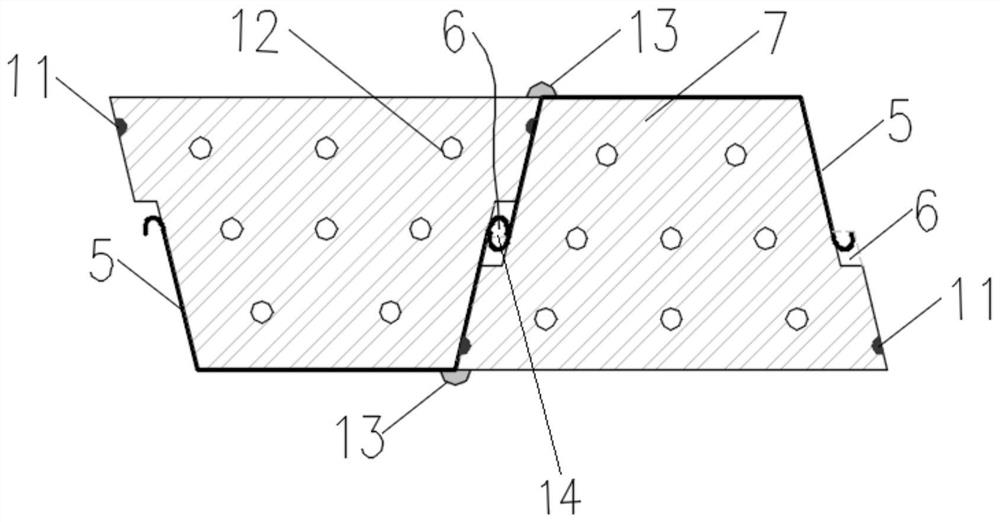

InactiveCN107246015AGive full play to self-stabilization abilityImprove stress propertiesExcavationsSupporting systemSoil horizon

The invention relates to a post-arranged inner supporting structure for partitioned excavation of a super-large deep foundation pit and a construction method. The method is characterized in that an outer support pile, an inner support pile and a pile top solidified soil layer are arranged on the outer side wall of the foundation pit firstly, and lower top beam positioning bar bodies and upper top beam positioning bar bodies are implanted in the inner support pile; then step-slope excavation is conducted on soil in the middle of the foundation pit from the middle to the two sides of the foundation pit, and a pit bottom drainage layer, a geogrid layer, a post-cast strip ground beam, anti-floating anchors and a solidified cement soil layer are arranged in the positions, at the bottom of the foundation pit, of the excavated area; and a post-arranged inner support is arranged between an adjustable bracket on the post-cast strip ground beam, and a pile top beam, then soil below the post-arranged inner support is excavated, pit bottom reinforcing piles, a pit bottom drainage layer, pit bottom drainage ditches and a solidified cement soil layer are arranged at the pit bottom below the post-arranged inner support, and finally, the post-arranged inner support is removed. The force-bearing behavior of a foundation pit supporting system can be improved, in addition, the excavation rate of the foundation pit can be increased, and the amount of materials for foundation pit supporting can be decreased.

Owner:ZHONGDA CONSTR

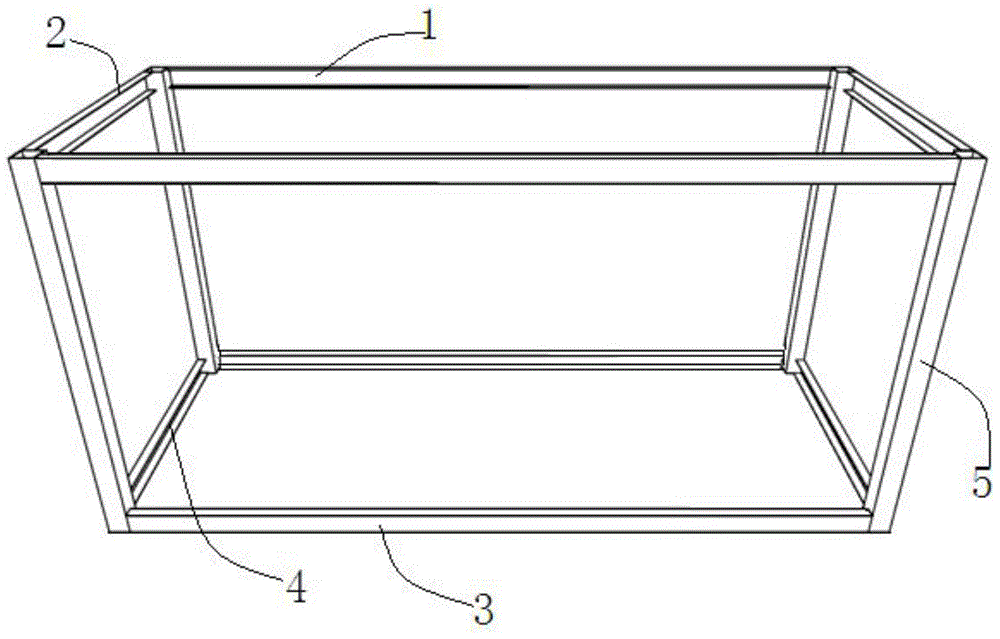

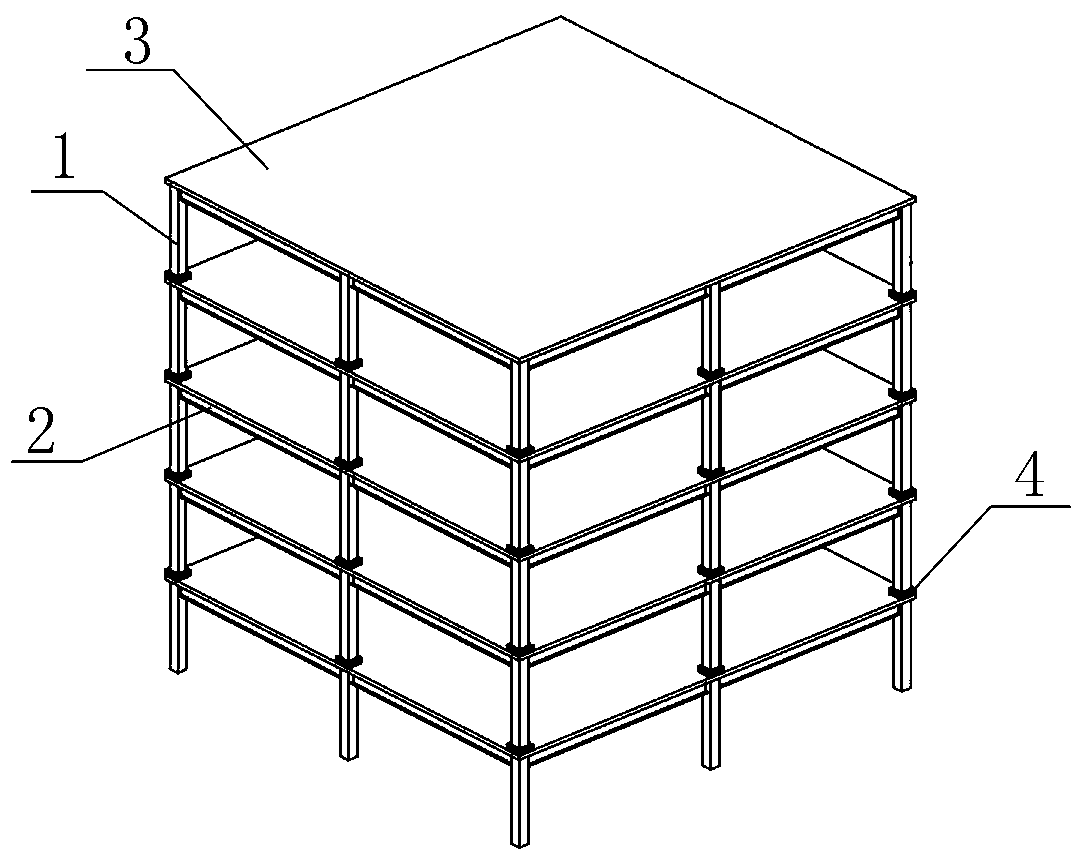

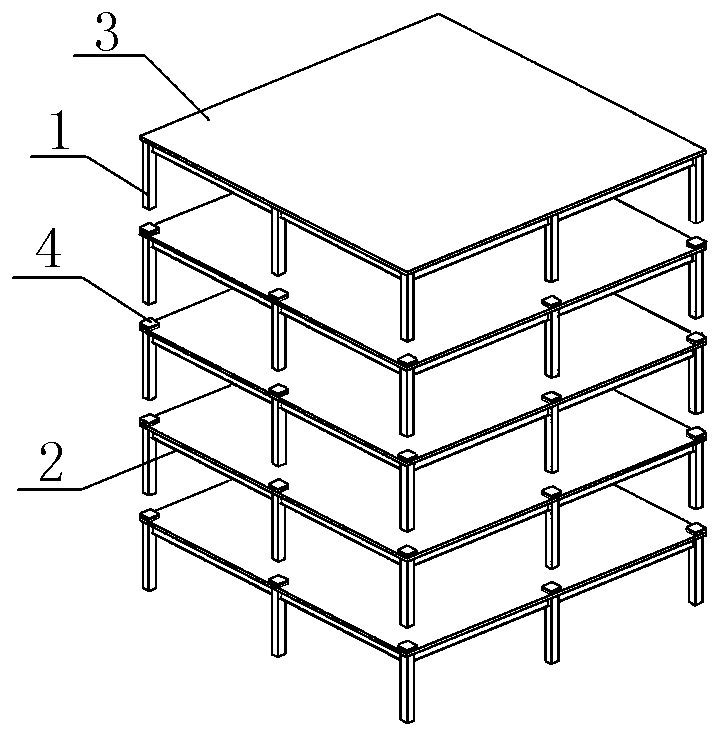

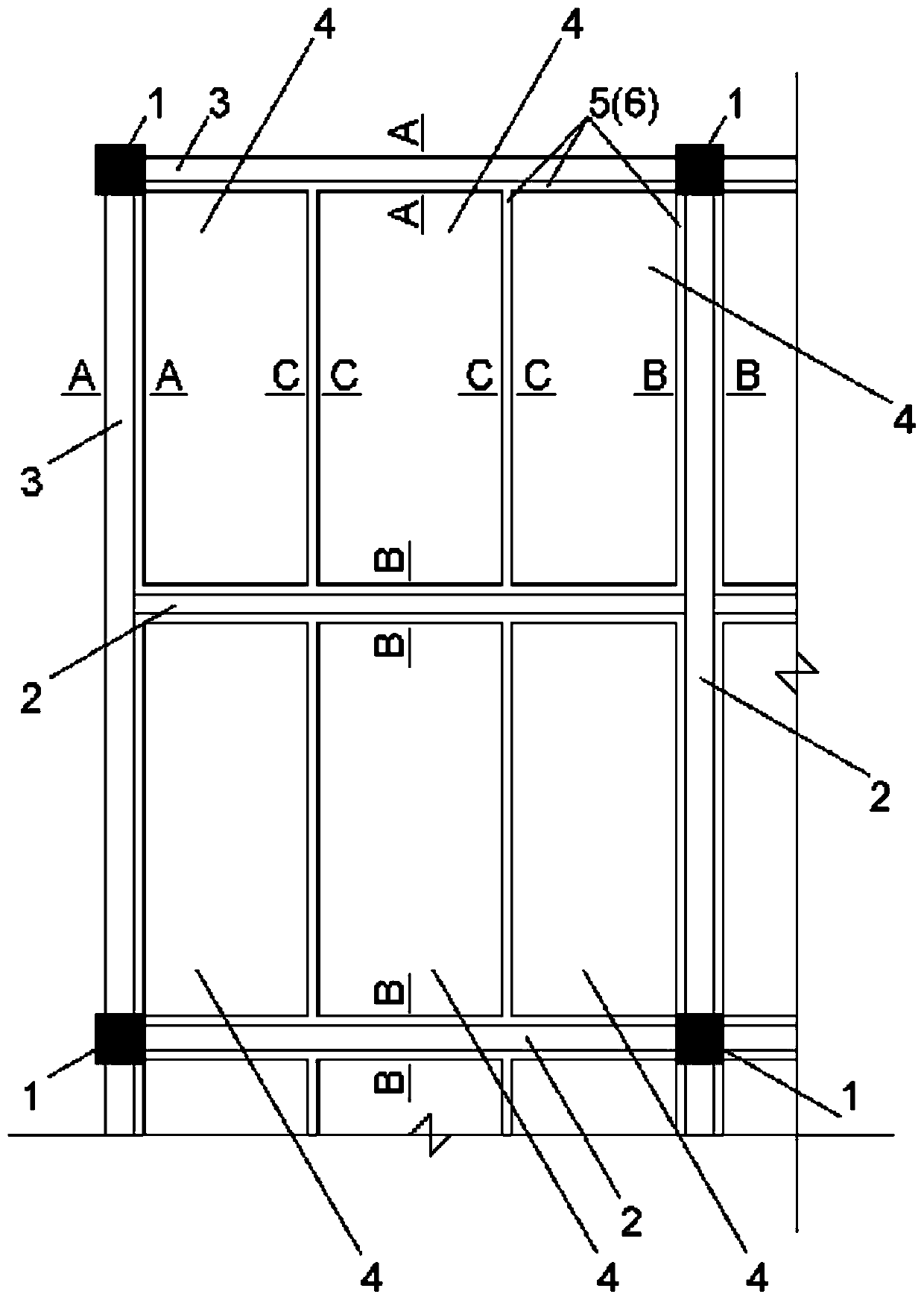

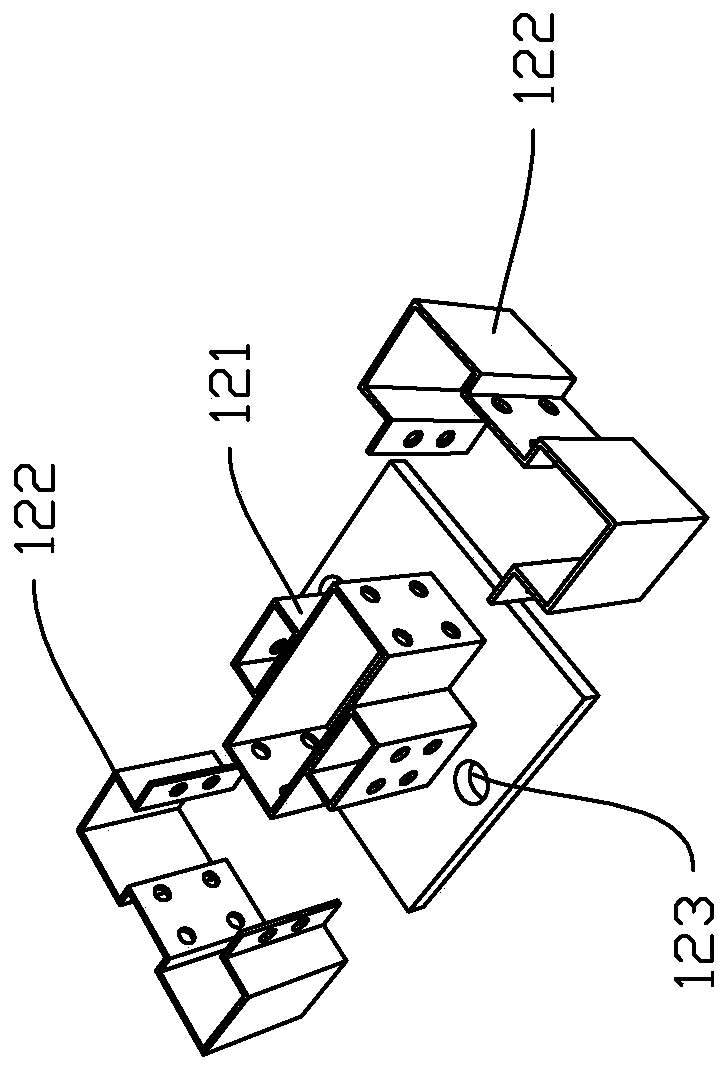

Column bearing type cellular building module, and cellular modularization building and building method thereof

InactiveCN104532951AImprove integrityImprove stabilityBuilding constructionsArchitectural engineeringModularity

The invention provides a column bearing type cellular building module, and a cellular modularization building and a building method thereof. The column bearing type cellular building module comprises two top girders, two top beams, two bottom girders, two bottom beams and a frame box formed by welding four support columns, wherein the top girders, the top beams, the bottom girders and the bottom beams are all formed through cold bending and thin wall channel steel, and the support columns are manufactured through clod bending or hot rolling square steel tubes. The column bearing type cellular building module is high in integrality and stability. The cellular modularization building is composed of a plurality of the column bearing type cellular building modules which are overlapped, and each two adjacent column bearing type cellular building modules are connected through bolts. The cellular modularization building is short in site construction period, small in labor demand and small in influence on environment. The invention further provides the building method of the cellular modularization building.

Owner:TONGJI UNIV

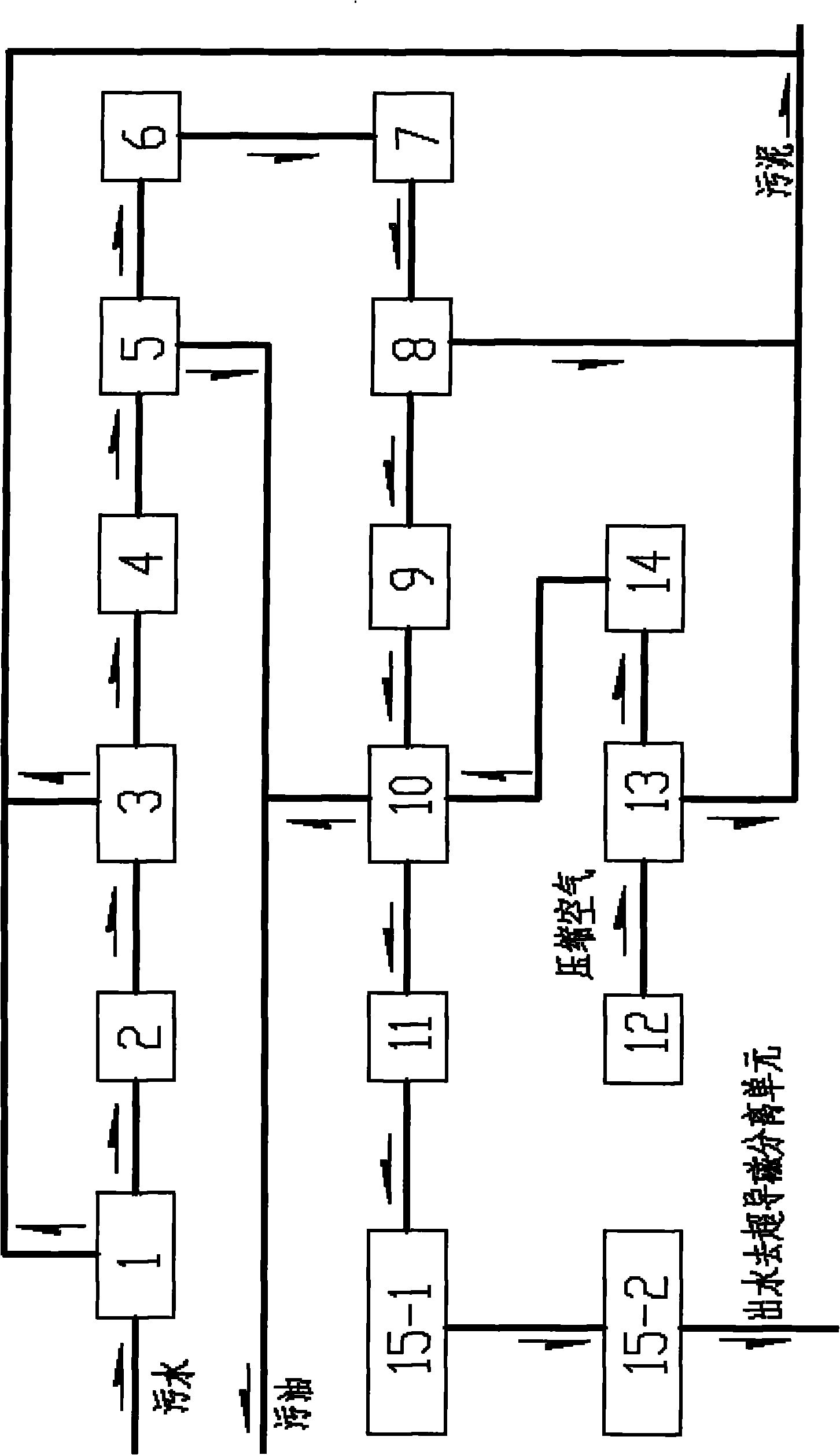

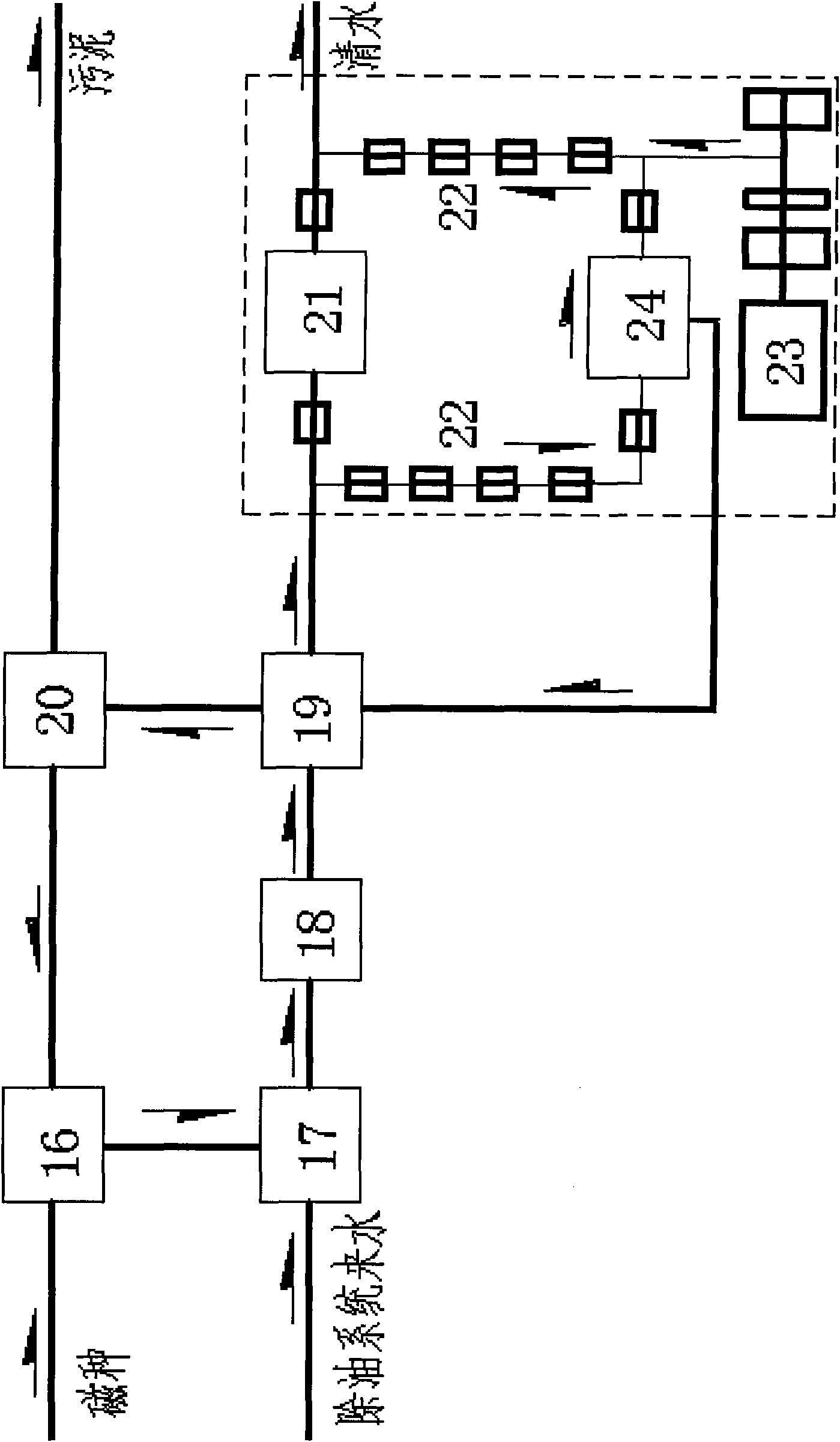

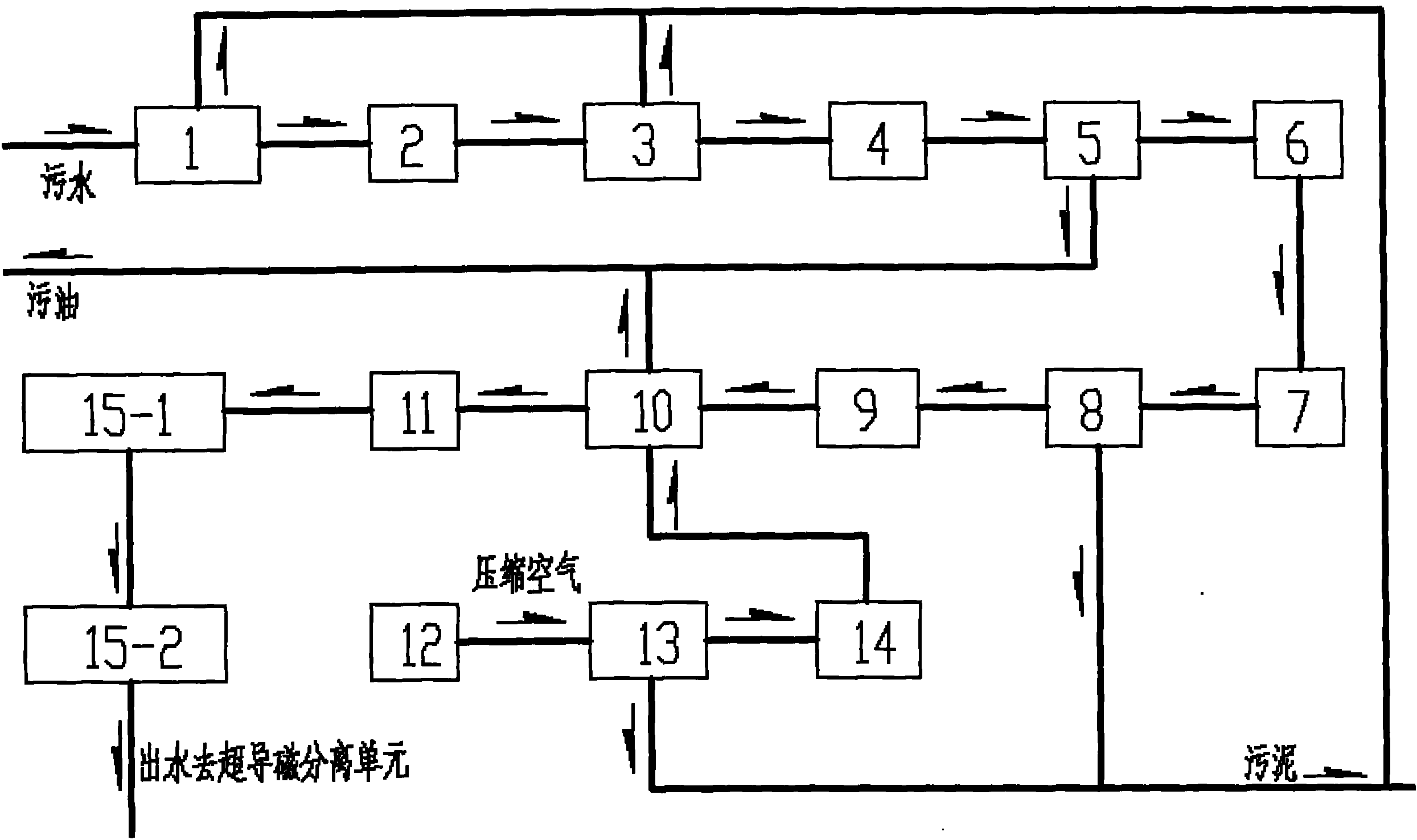

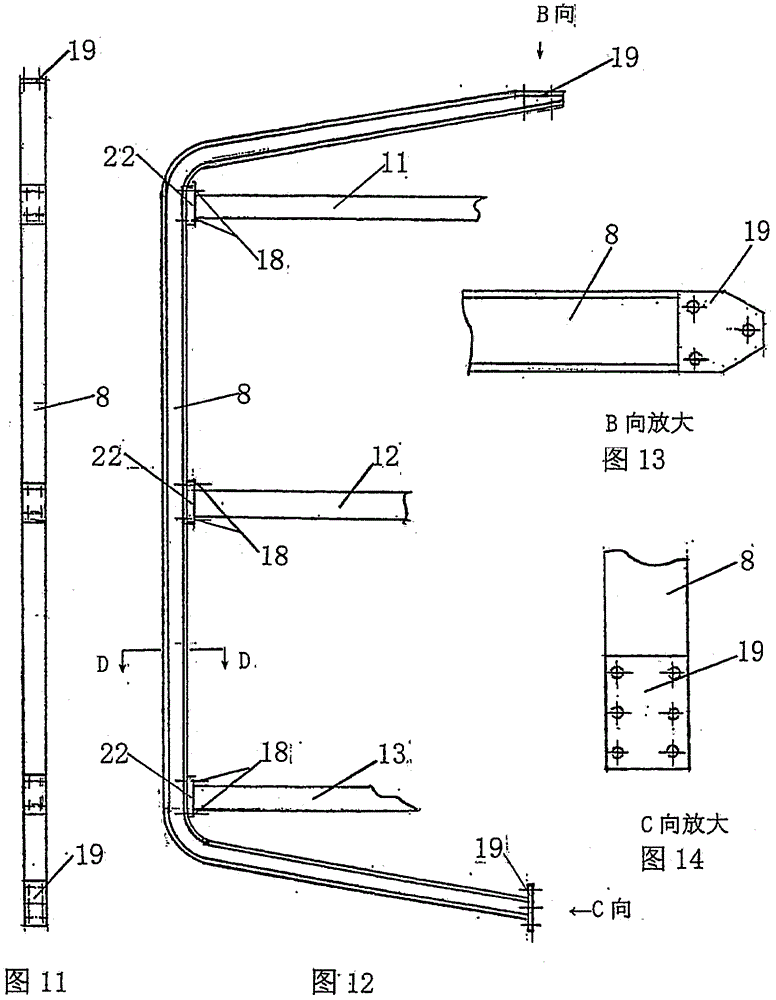

Combined sewage treatment method for oil field

ActiveCN102092886AEfficient captureShort processMultistage water/sewage treatmentCycloneSmall footprint

The invention discloses a combined sewage treatment method for an oil field, which is applied to sewage treatment in a petroleum development gather and delivery process. The method comprises the following steps of: (A) performing a physical separation method: roughly filtering the effluent, regulating the pressure, filtering before metering, and metering the flow to stabilize the pressure; feeding the sewage into a hydraulic cyclone to separate floating oil and dispersible oil; feeding the sewage into a normal pressure buffer tank, and feeding the sewage into the inflating hydraulic cyclone by compression of a screw pump to remove emulsified oil in the sewage; (B) filtering the water flowing out from the inflating hydraulic cyclone into a laminated filter; and (C) feeding the water flowing out from the laminated filter into a magnetic seed mixing tank of a superconducting magnetic separation unit, feeding the nano magnetic seeds into the magnetic seed mixing tank through a magnetic seed feeding tank, pressurizing the water and the magnetic seeds through a mixing pump to enter a pre-sedimentation tank to form lump sediment using the magnetic seeds as cores, feeding the upper clarified liquid and partial water containing the magnetic seed lumps into a superconducting magnetic separation device, and feeding the separated magnetic seeds into the magnetic seed feeding tank. The method has the advantages of no need of chemical agents, short process flow, small floor area and low integral investment and running expenses.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Multi-purpose quickly assembled natural ecological penthouse and manufacturing method thereof

InactiveCN106639364AStructural optimization and specificationIncrease productivityDwelling buildingTerrainEngineering

The invention relates to a multi-purpose quickly assembled natural ecological penthouse with sightseeing property and a manufacturing method of the multi-purpose quickly assembled natural ecological penthouse. A penthouse in the prior art is provided with an assembling type steel-structured house, a house module, a roof module, a staircase module and a flange plate, but cannot be used on terrains under complicated natural environment conditions. The invention aims to develop the multi-purpose quickly assembled natural ecological penthouse and the manufacturing method thereof. According to the structure of the multi-purpose quickly assembled natural ecological penthouse, peripheral columns are connected with steel upright columns 15, floors and a roof 11 by bolts 18 to form a single-steel-structured frame which is connected with walls 16, an air corridor 1, a staircase 3, a support 2 and a door 10 to form the multi-purpose quickly assembled natural ecological penthouse; and a conical top type double-layered single body 6 is used as a center, and is outwards connected with single-layered single bodies which are distributed surrounding the conical top type double-layered single body 6 in a radiation manner, the single-layered single bodies are flat roof type single bodies 5 and conical roof type single bodies 7, and base connecting plates 4 are fixedly welded to lower ends of the steel upright columns 15 of the single bodies and are fixedly connected with foundation bolts. The multi-purpose quickly assembled natural ecological penthouse has the effects that the penthouse facilitates sightseeing, large-scale production standardization of houses and rapid field mounting and use.

Owner:郭山林

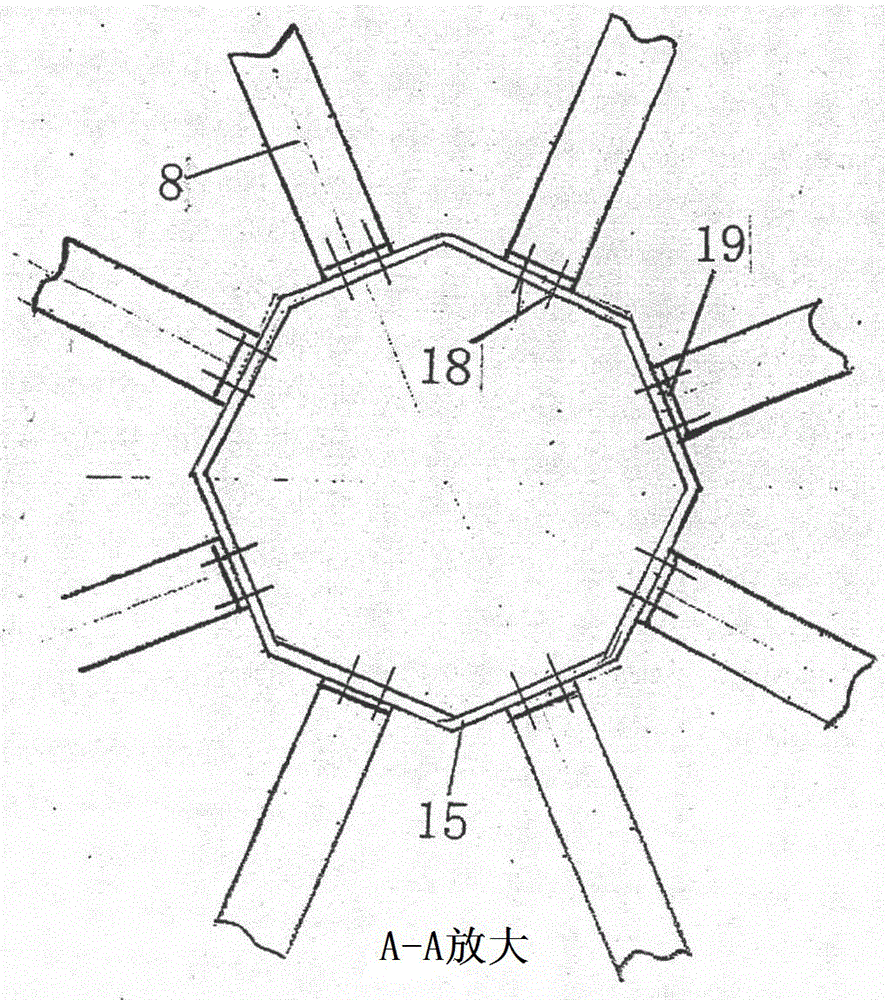

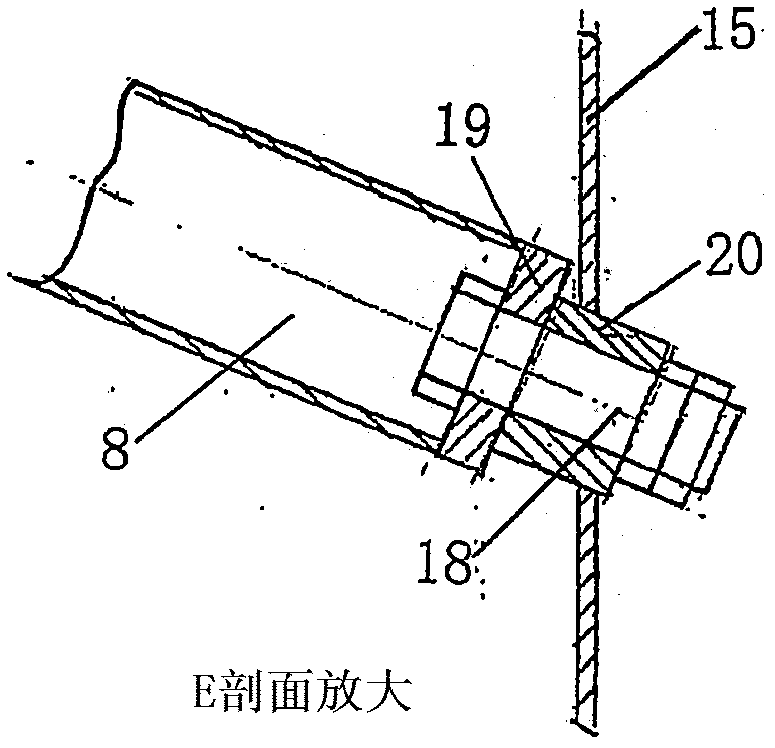

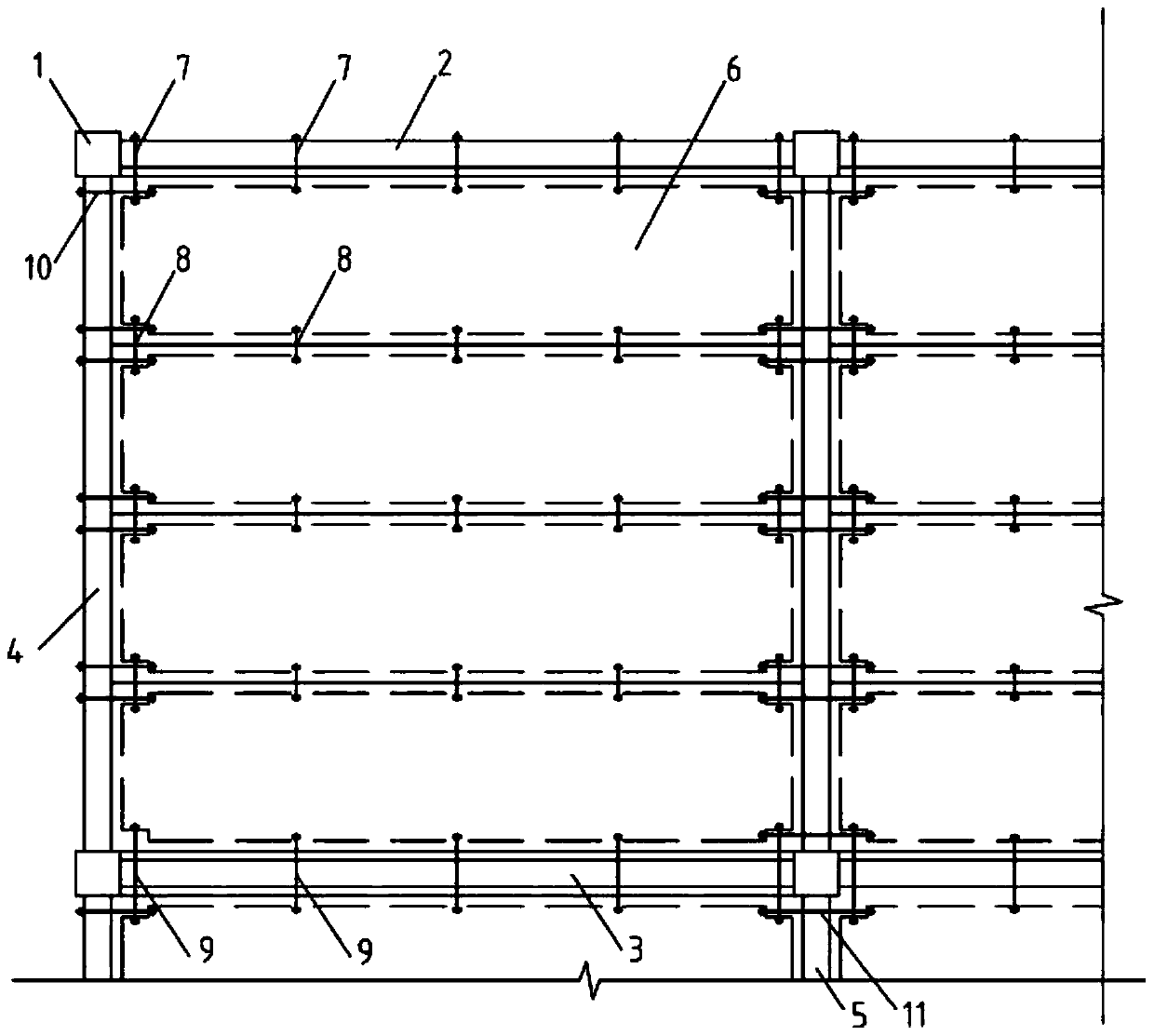

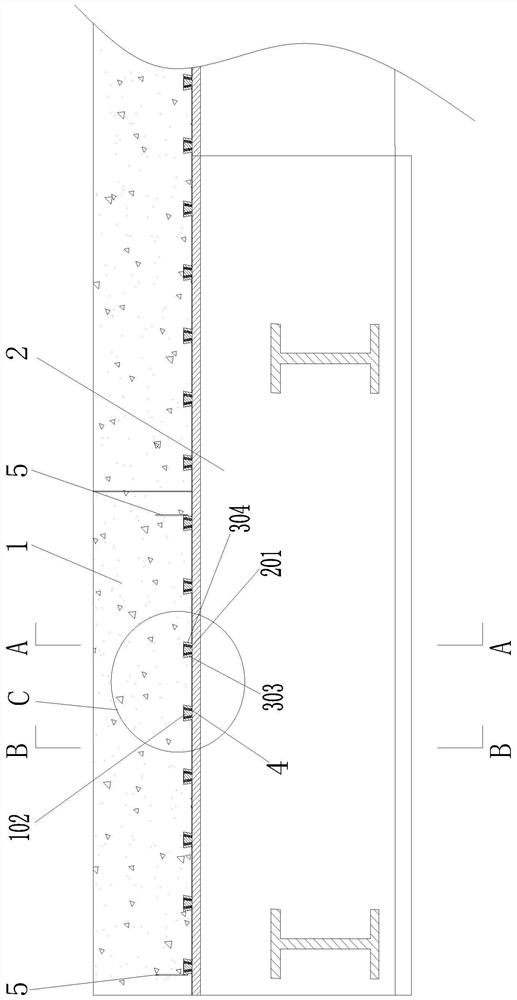

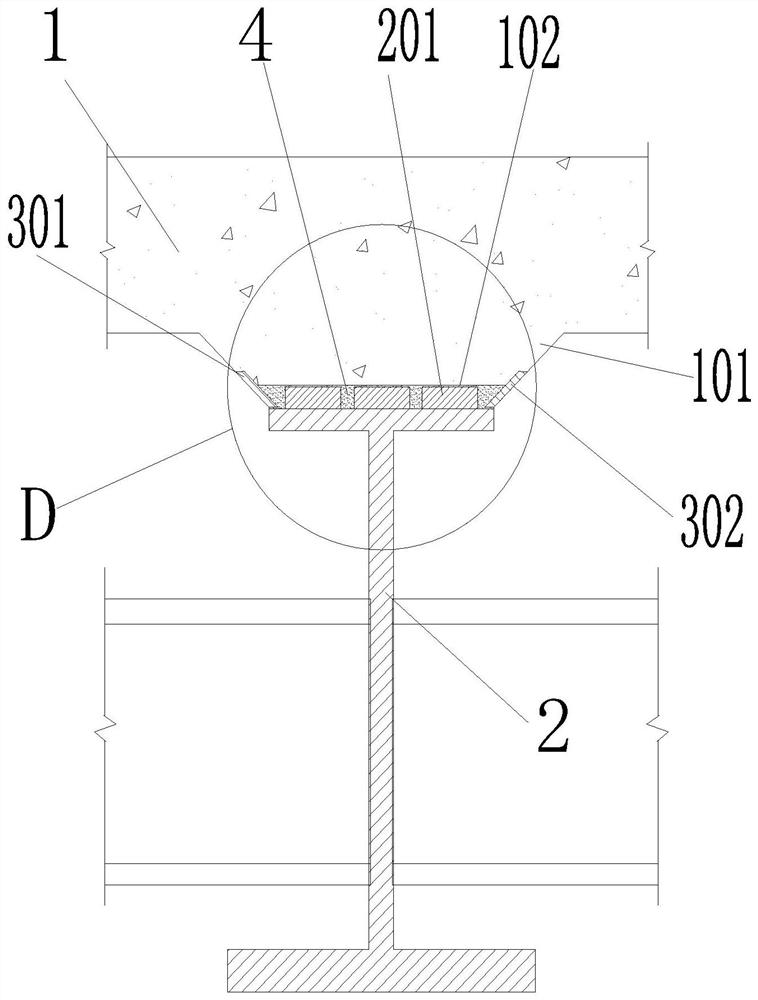

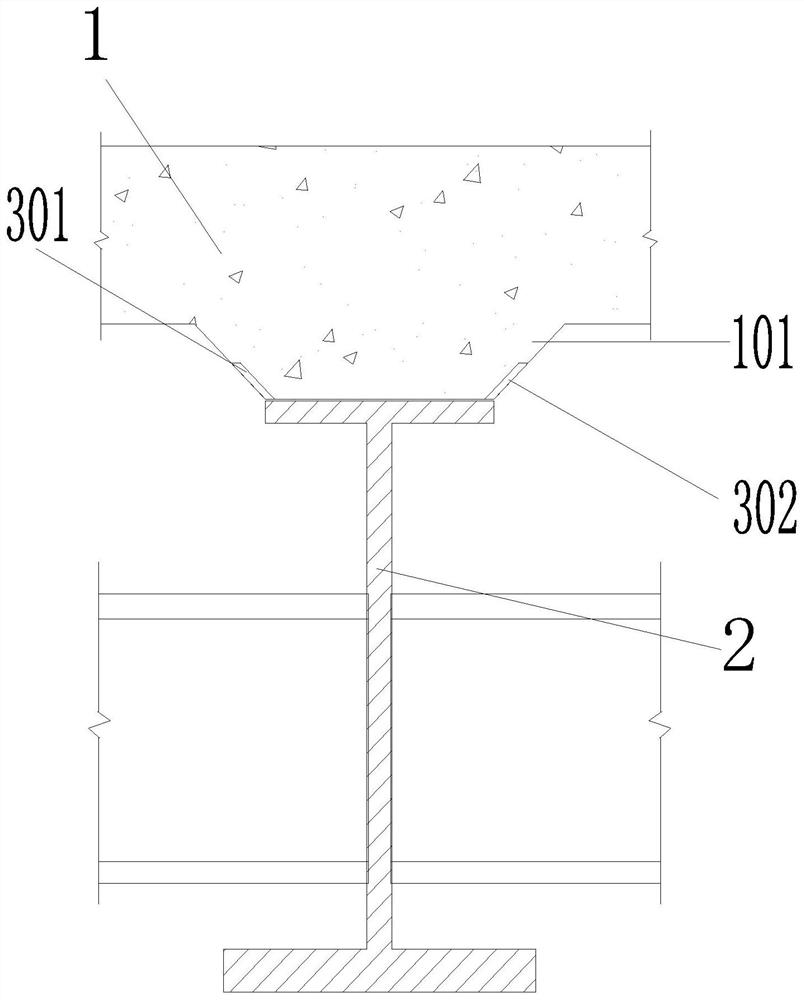

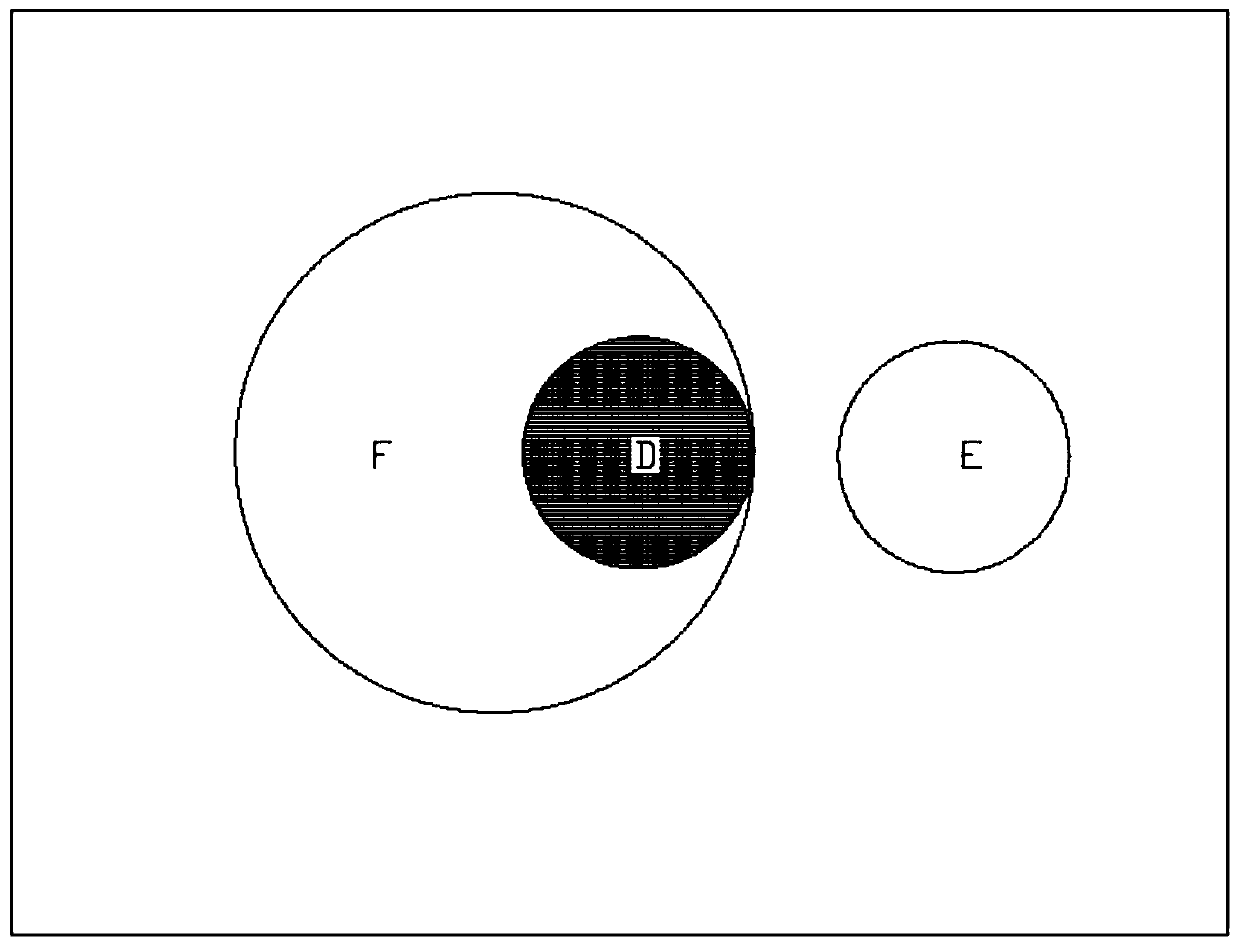

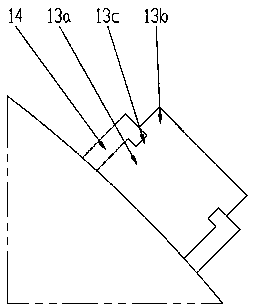

Friction pendulum connected fabricated steel structure system and design method thereof

ActiveCN110409606AImprove bearing capacityImprove reset abilityProtective buildings/sheltersSpecial data processing applicationsSteel frameEngineering

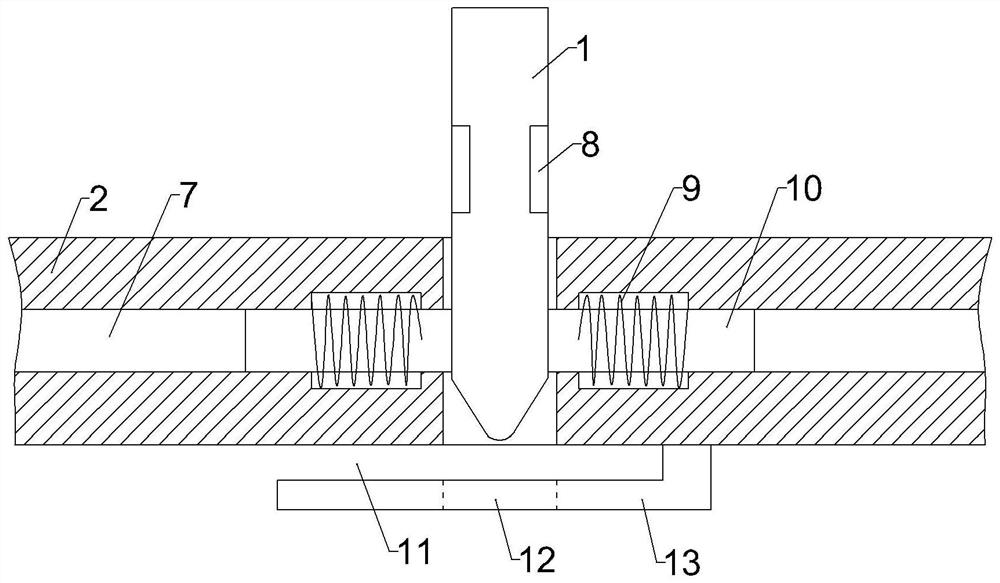

The invention discloses a friction pendulum connected fabricated steel structure system and a design method thereof. The friction pendulum connected fabricated steel structure system comprises at least two layers of steel frame structures and a group of friction pendulum shock isolation devices; steel columns of each layer of steel frame structure are disconnected at the joint with the lower floor; the friction pendulum shock isolation devices are correspondingly arranged between the steel columns of every two layers of steel frame structures; each friction pendulum shock isolation device comprises an upper connection plate and a lower connection plate; the middles of the bottom surfaces of the upper connection plates are connected with plugging blocks; the bottom surfaces of the pluggingblocks are convex curved surfaces which are convex downwards; lugs are arranged on the top surfaces of the lower connection plates; plugging slots are formed in the tops of the lugs; the bottom surfaces of the plugging slots are concave curved surfaces which are concave downwards; the plugging blocks are correspondingly plugged in the plugging slots; the tops of the plugging blocks are higher thanthe tops of the plugging slots; and distances are reserved between the side walls of the plugging blocks and the side walls of the plugging slots. The friction pendulum connected fabricated steel structure system is capable of solving the technical problems that the existing fabricated steel structure buildings are complicated in connection joints, large in field workload and low in constructionefficiency, the joints of the frame structures are rigidly connected and the seismic resistance of the frames is relatively bad are solved.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

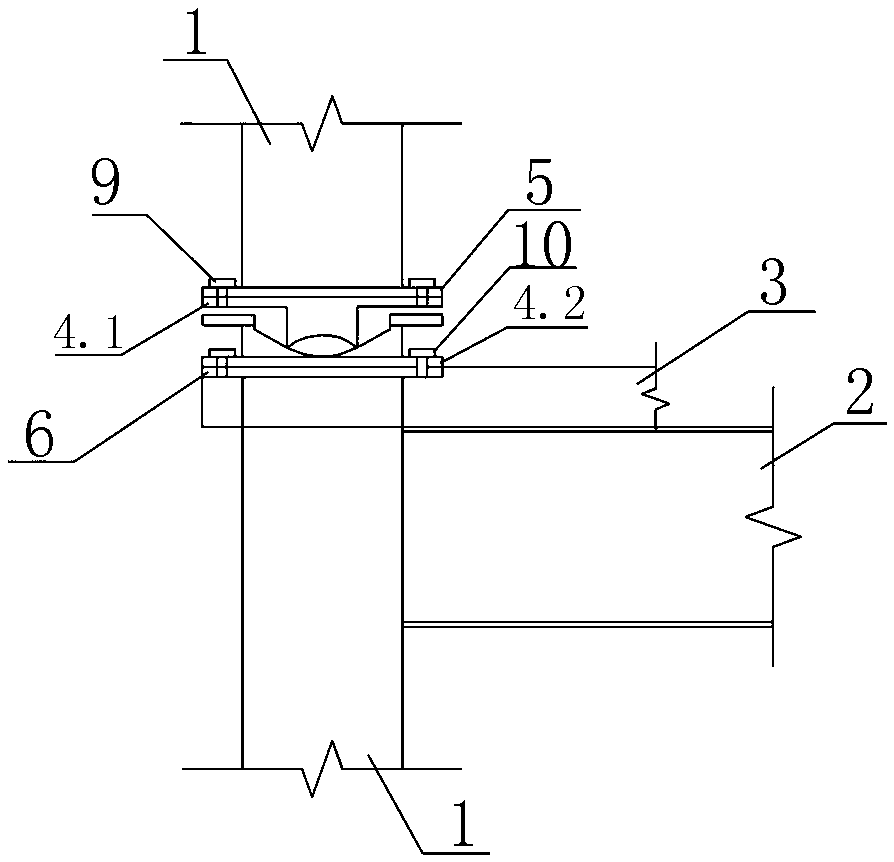

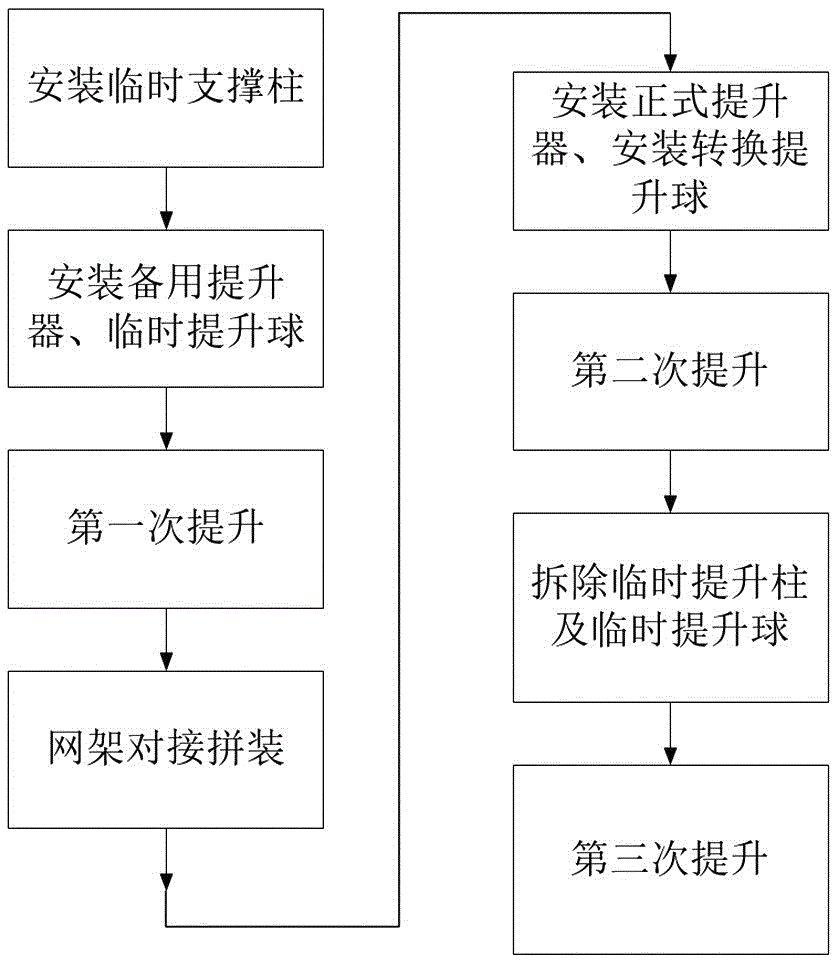

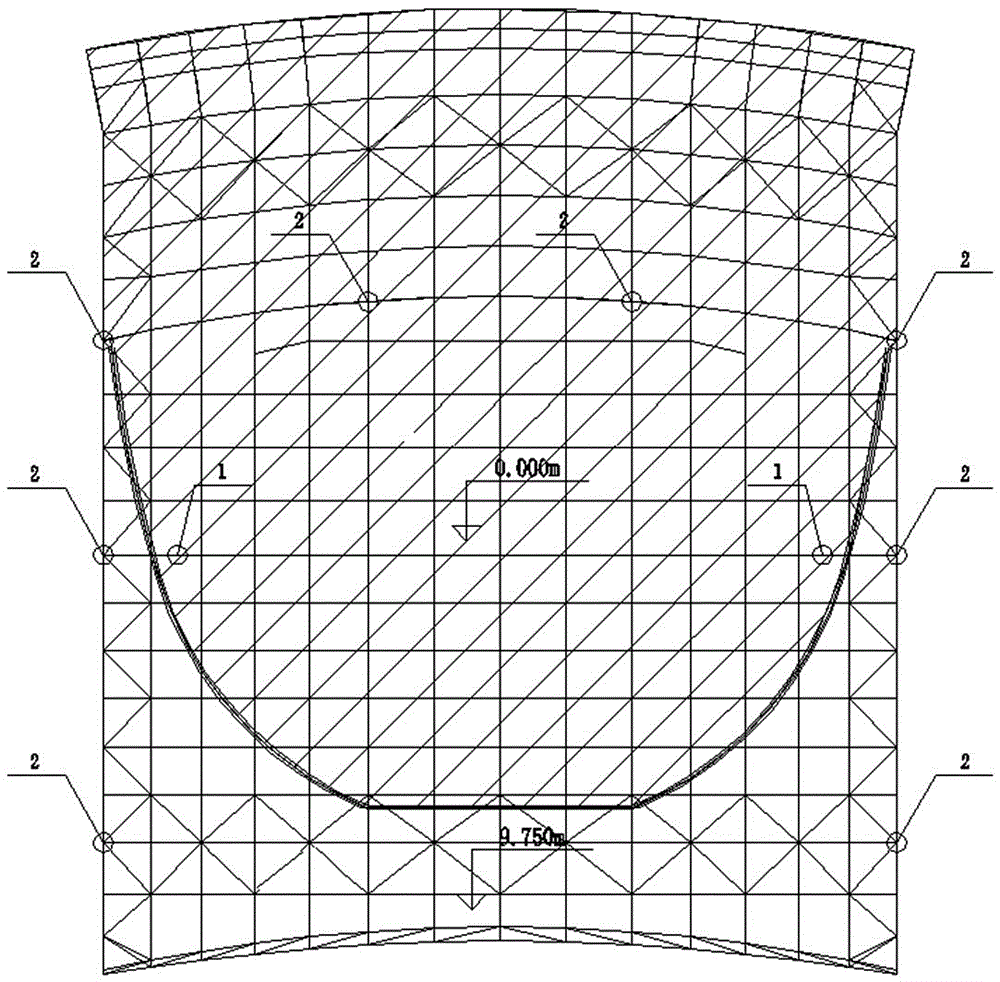

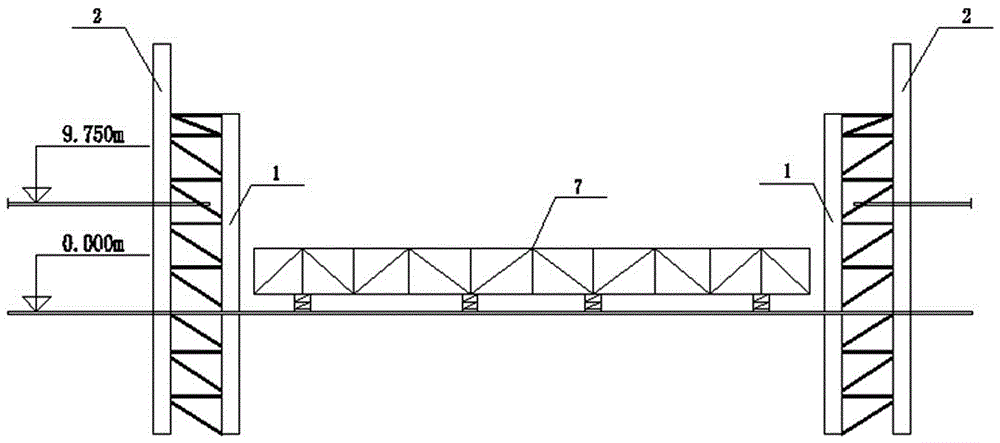

Hoisting construction method of curved truss

InactiveCN105804400AShorten construction period on siteImprove construction efficiencyBuilding material handlingWork periodSupporting system

The invention discloses a hoisting construction method of a curved truss. The method comprises following steps: step 1, installing temporary support columns; step 2, installing spare hoisters and temporary hoisting balls; step 3, performing first hoisting operation; utilizing the temporary support columns, the spare hoisters and the temporary hoisting balls to firstly hoist a truss in the outer periphery to the hoisting height which is the height for changing, hoisting and splicing; step 4, aligning and splicing trusses in order to form an overall hoisting truss; step 5, installing formal hoisters and changing and hoisting balls; step 6, utilizing the formal hoisters and the changing and hoisting balls to secondarily hoist the truss; step 7, dismantling the temporary support columns, the temporary hoisters and the temporary hoisting balls; step 8, performing third hoisting operation and the hoisting the overall hoisting truss to the elevation level. The hoisting construction method of the curved truss is utilized to hoist the truss to the overall splicing height and does not need to set up a splicing platform of a support system for the overall hoisting truss so that constriction efficiency is improved and the working period of site constriction of a steel structure is effectively shortened.

Owner:CHINA CONSTR FIRST DIV STEEL STRUCTUREENG +1

Prefabricated assembled UHPC-corrugated steel web combined box girder bridge and construction method

PendingCN113215949ASimple structural designThe force characteristics are clearBridge erection/assemblyArchitectural engineeringBox girder

The invention belongs to the technical field of civil engineering, and relates to a prefabricated assembled UHPC-corrugated steel web combined box girder bridge and a construction method thereof. The bridge comprises a bridge pier and a UHPC-corrugated steel web combined box girder which is arranged on the bridge pier and connected with the bridge pier. The combined box girder is formed by sequentially splicing a plurality of UHPC-corrugated steel web combined box girder sections; each section comprises a UHPC top plate, a UHPC bottom plate, a corrugated steel web and a UHPC transverse partition plate. The UHPC top plate and the UHPC bottom plate are axially arranged in parallel; the corrugated steel web is arranged at the web position; the UHPC transverse partition plate is vertically arranged between the UHPC top plate and the UHPC bottom plate and makes contact with the corrugated steel web; And the UHPC bottom plate is connected with the bridge pier. The structural design is simple, the dead weight of the box girder bridge is remarkably reduced, and the main span of the bridge is greatly increased; the cracking risk is obviously reduced, and the structural durability is improved; the construction is convenient, and the site construction period is greatly shortened.

Owner:HUNAN UNIV OF SCI & TECH

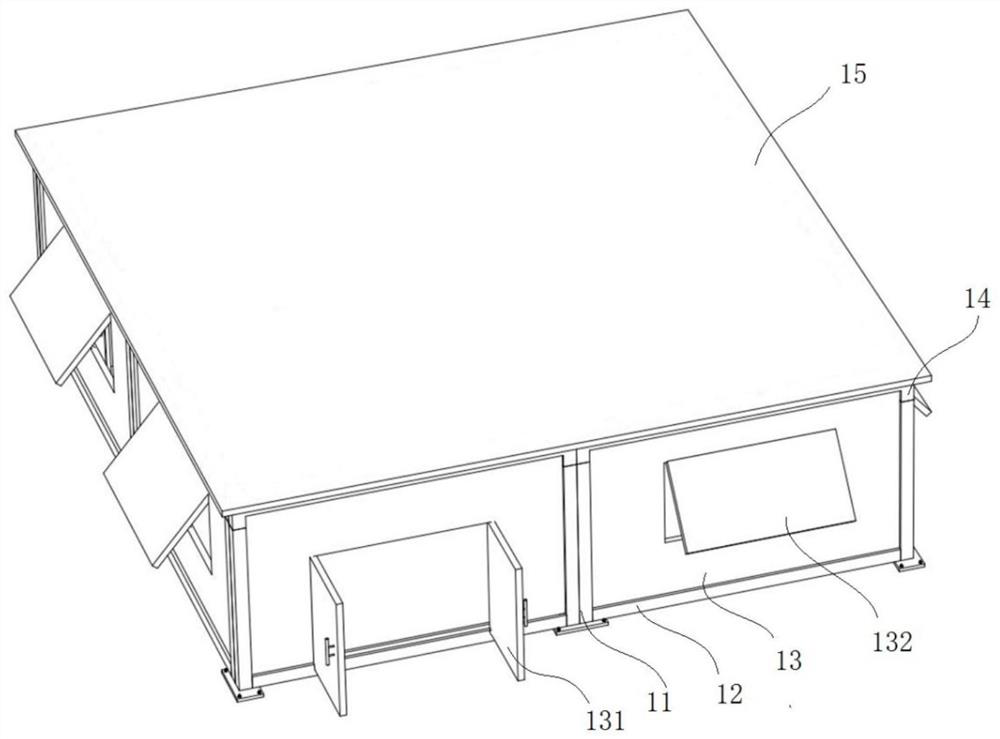

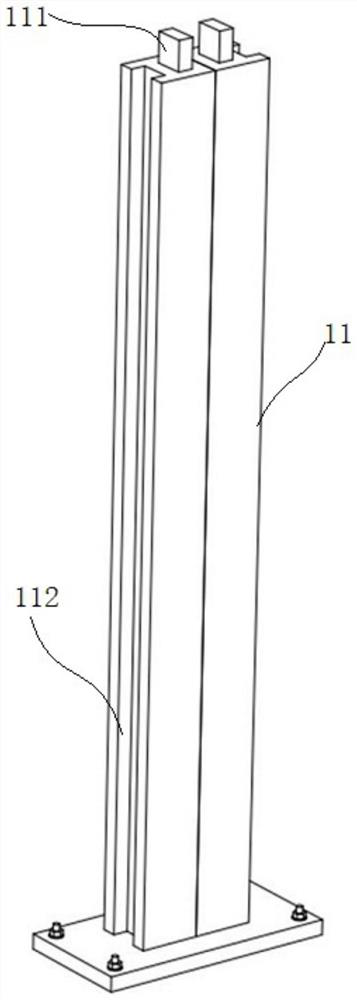

Prefabricated safety learning exploration hall and installation method thereof

PendingCN111794570AShorten construction period on siteAffect on-site disassembly and assembly progressBalustersBalustradesMortise and tenonConstruction engineering

The invention discloses a prefabricated safety learning exploration hall and an installation method thereof, and relates to the technical field of safety. The prefabricated safety learning explorationhall comprises a house building and at least one safety experiment area arranged in the house building, wherein the housing building comprises multiple prefabricated pieces, and the prefabricated pieces are spliced to the house building through mortise and tenon joint structures. The invention furthermore discloses the installation method of the prefabricated safety learning exploration hall. According to the prefabricated safety learning exploration hall and the installation method thereof, the prefabricated pieces are adopted for constructing and splicing the house building through the mortise and tenon joint structures, the process of constructing the house building is simple, and there is no need to additionally use concrete and other building materials; meanwhile, the use of fasteners and other parts is reduced, the construction technology of the house building is simplified, the use of parts and materials in the process of constructing the house building are simplified, the construction period is shortened, the construction cost of the house building is reduced, and convenience is brought to quickly construct, detach, convey and reuse the safety learning exploration hall.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +2

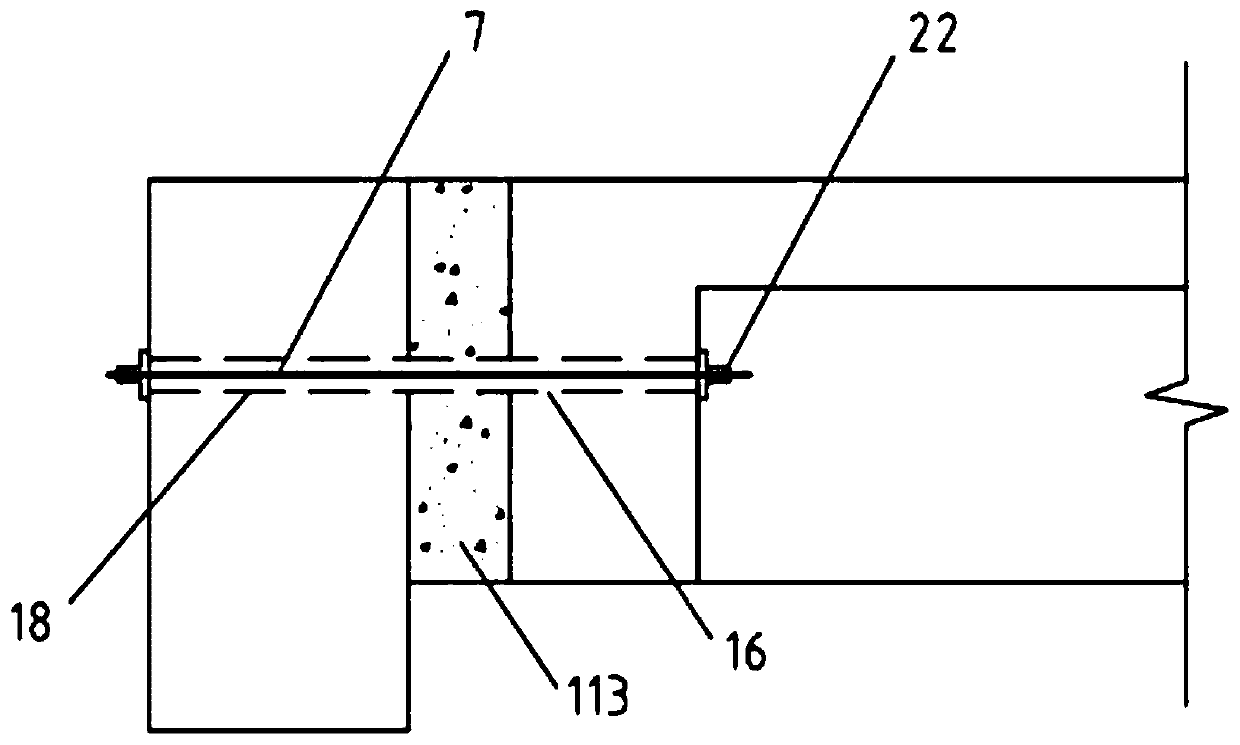

Prefabricated laminated anti-collision wall for urban viaduct and construction method thereof

PendingCN108265623AReduce on-site rebar workShorten construction period on siteBridge structural detailsBridge erection/assemblyBridge deckRebar

The invention relates to the technical field of bridge structures, in particular to a prefabricated laminated anti-collision wall for an urban viaduct and a construction method thereof. The anti-collision wall is formed by connecting inner and outer prefabricated concrete wall panels through a cage-shaped steel skeleton, and a cavity is formed in the middle. At the construction site, vertical connection steel bars are reserved in the surface of a bridge deck, the prefabricated laminated anti-collision wall is hoisted to a predetermined position from top to bottom, during the hoisting process,the reserved vertical connection steel bars protrude into the cavity of the prefabricated laminated anti-collision wall, to be lapped and connected with vertical ribs of the cage-shaped steel skeleton, and the prefabricated laminated anti-collision wall is integrated with the bridge deck by pouring concrete into the cavity. The prefabricated laminated anti-collision wall is prefabricated in factory, the pouring quality of the inner and outer concrete wall panels is guaranteed, the processes of on-site mould erecting and demoulding are eliminated, and most of the on-site bars operation is reduced. Compared with the traditional cast-in-place construction method, the on-site construction speed is greatly improved, the construction period is shortened, and the appearance quality and the personal safety of workers are more easily guaranteed.

Owner:高强

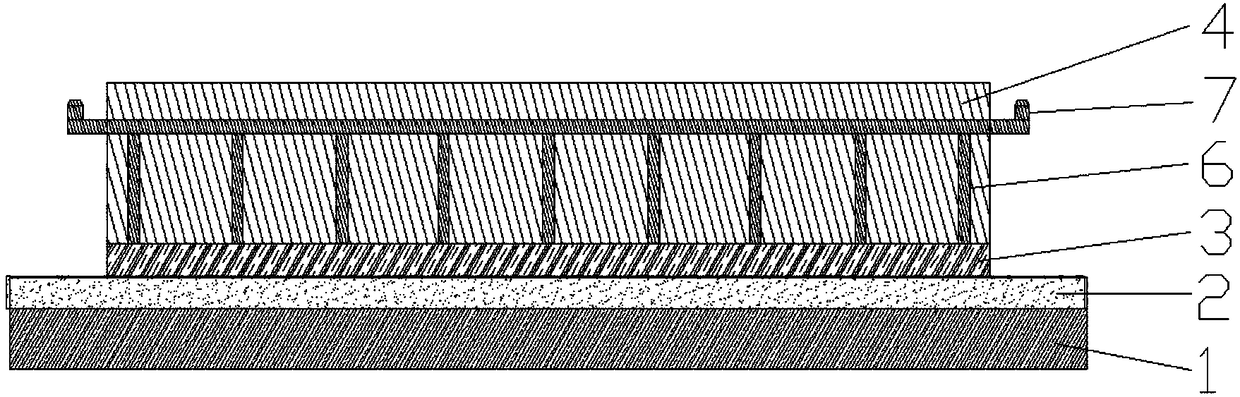

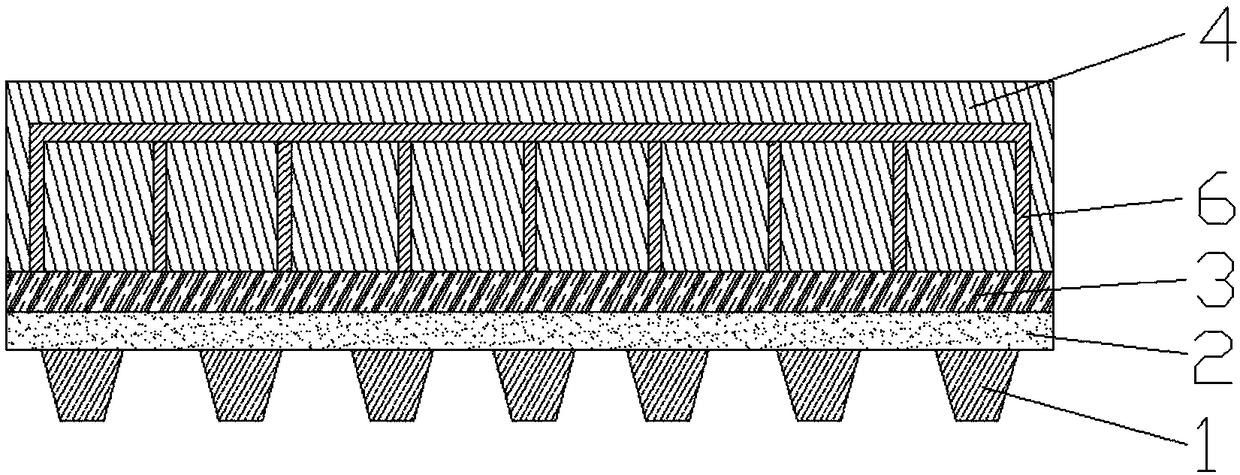

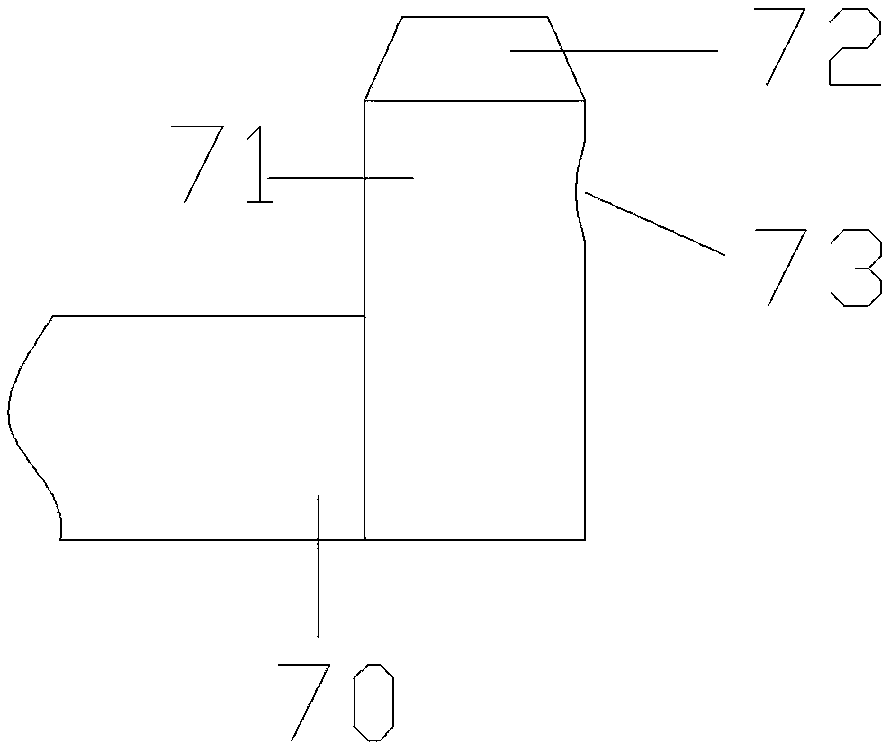

Assembly type steel bridge super-tough durability prefabricated pavement layer structure

PendingCN108589528AShorten construction period on siteUltra-tough durability achievedBridge structural detailsBridge deckResin bonding

The invention discloses an assembly type steel bridge super-tough durability prefabricated pavement layer structure. The structure comprises a steel bridge precast beam section, a steel bridge deck slab, a pavement section bonding layer, a prefabricated pavement layer and a splicing piece used for splicing the pavement layer structure, all of which are sequentially arranged from bottom to top. Theinside of the prefabricated pavement layer is paved with a reinforcing mesh frame, and protruding connecting pieces extending out of the prefabricated pavement layer along the side portions are arranged on the side portions of the reinforcing mesh frame. The two ends of the steel bridge precast beam section extend out of the prefabricated pavement layer to form assembly splicing sections. The splicing piece is arranged between the assembly splicing sections of two adjacent pavement layer structures to form a splicing space. The splicing piece is used for connecting the protruding connecting pieces on the adjacent to-be-spliced pavement layer structures. By the adoption of the assembly type steel bridge super-tough durability prefabricated pavement layer structure, a super-tough resin bonding layer and super-tough resin concrete serve as pavement layer structure materials, and super-tough durability of the pavement layer can be achieved.

Owner:NANJING ROAD KEEPER TECH

Seamless preformed integral polyurethane floor

The invention relates to a seamless preformed integral polyurethane floor. The seamless preformed integral polyurethane floor comprises a structural frame and a polyurethane floor body. The structural frame comprises four primary beams and six secondary beams, wherein the four primary beams and the six secondary beams are connected through metal connecting pieces; and the primary beams and the secondary beams are each made of laminated timber of a heavy-timber structure formed by orthogonally-overlapped and glued battens. Water supplying and draining system pipelines, electric wires and holes for installing devices are embedded in the polyurethane floor body; and in factory modularized production, the structural frame and the embedded metal connecting pieces are added into a mold, then the water supplying and draining system pipelines and the electric wires are fixed into the mold, the hollow holes for installing the devices are reserved, and finally polyurethane materials are poured to form the integral floor which is directly transported to a construction site for direct installation. The seamless preformed integral polyurethane floor has the advantages of good waterproof performance, industrialized production and short construction period, and has good popularization and application prospects.

Owner:HUNAN TIANCHUANG INTEGRATED TECH IND CO LTD

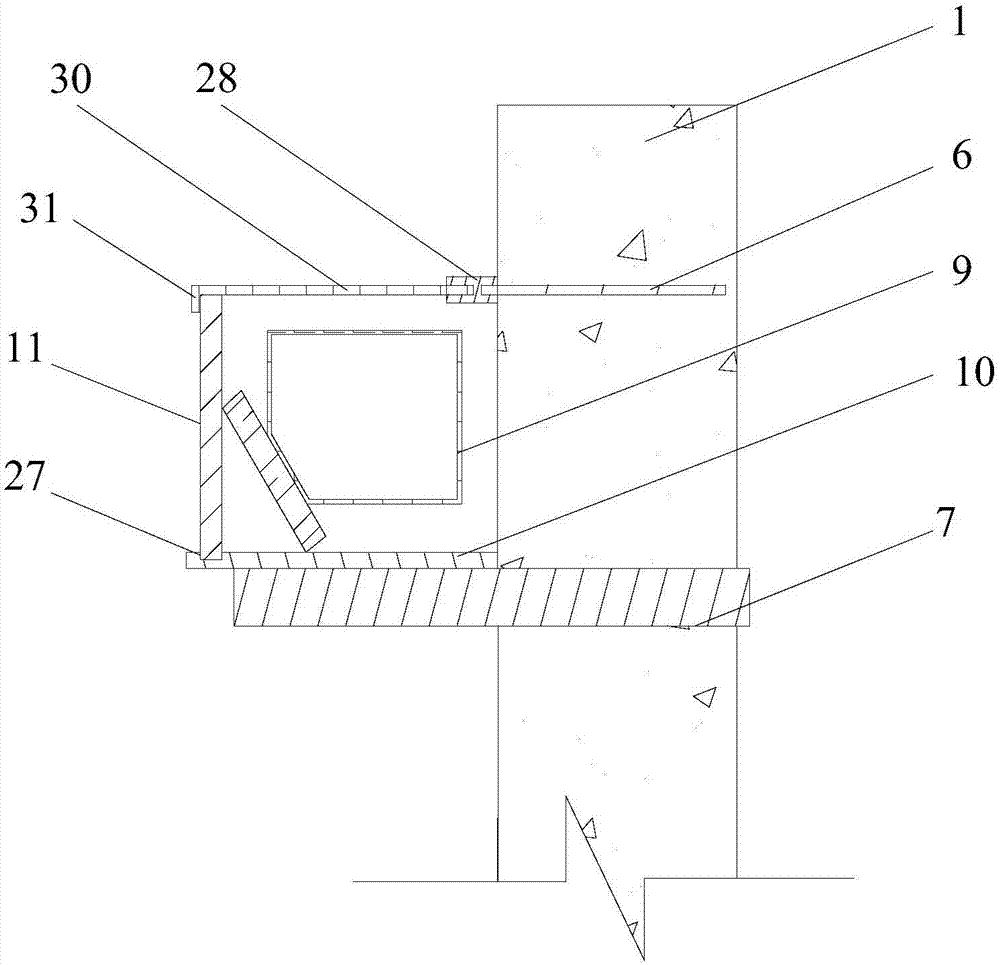

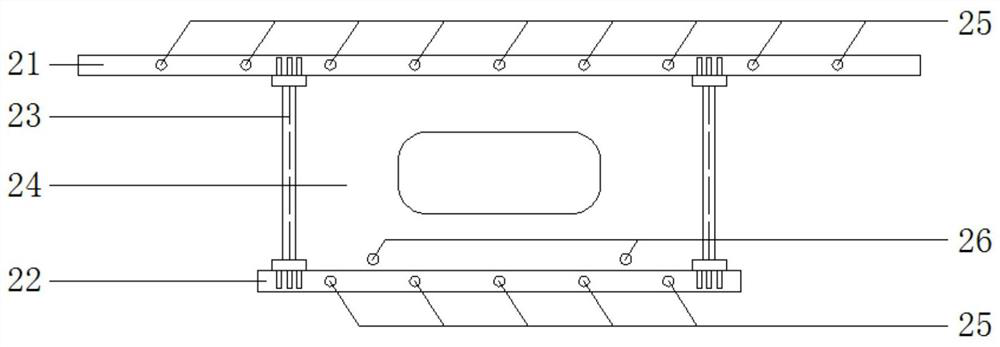

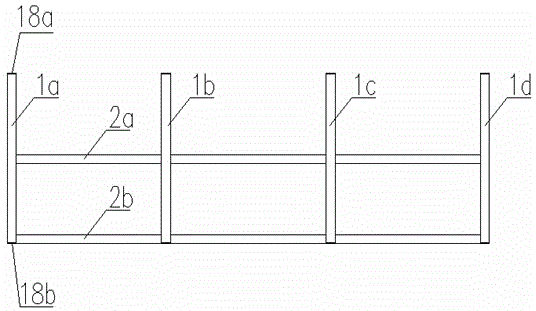

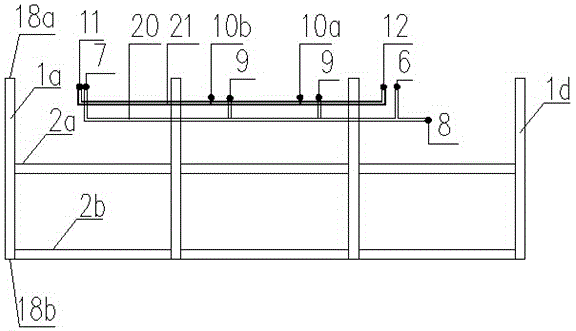

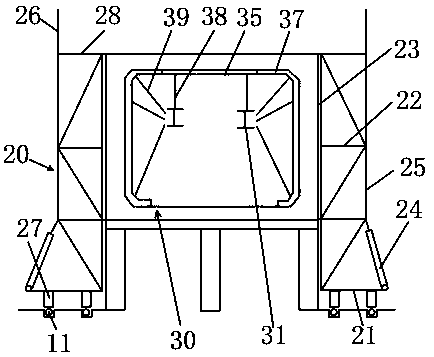

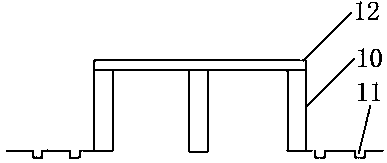

Formwork system of prefabricated comprehensive pipe gallery and construction method thereof

PendingCN110682416AShort exposure timeProcess loss is smallArtificial islandsMouldsArchitectural engineeringStructural engineering

The invention relates to a formwork system of a prefabricated comprehensive pipe gallery and a construction method thereof. The formwork system comprises a prefabricated pedestal, walking rails are arranged on two sides of the prefabricated pedestal in the longitudinal direction correspondingly, the walking rails are provided with outer mold hydraulic systems which are matched with the walking rails and are used for forming a comprehensive pipe gallery outer mold, a bottom plate is arranged on the upper side of the prefabricated pedestal, the bottom plate is provided with an inner mold hydraulic system capable of moving in the longitudinal direction and is used for forming a comprehensive pipe gallery inner mold, and the bottom plate is further provided with an end formwork of the comprehensive pipe gallery. The formwork system of the prefabricated comprehensive pipe gallery is beneficial to improving the engineering construction quality and improving the working efficiency.

Owner:HUNAN NO 6 ENG CO LTD

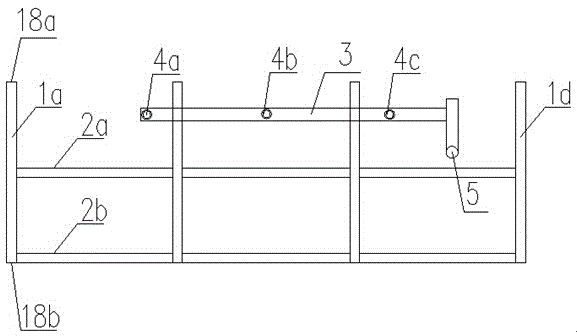

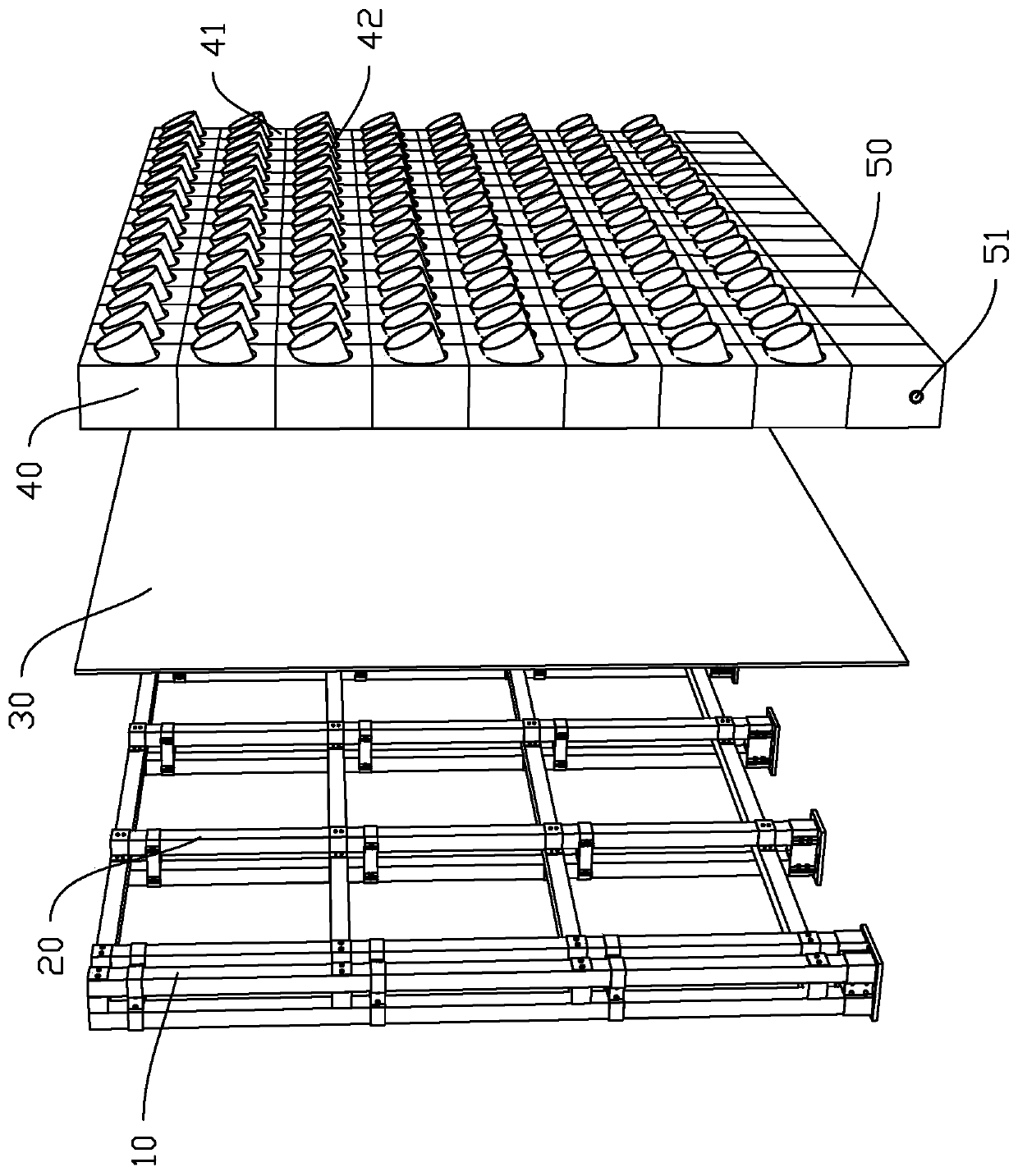

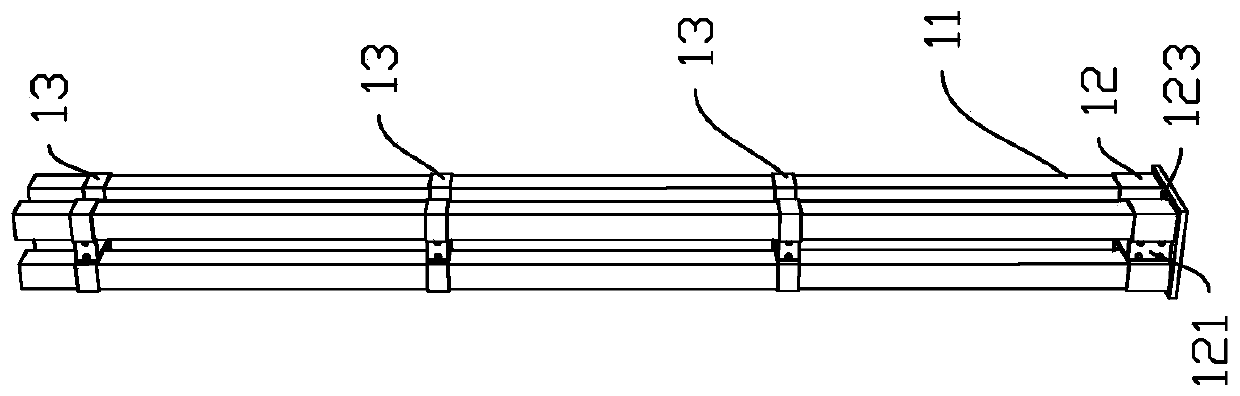

Whole span pre-prefabricated prestressed groove-type rib plate, floor cover structure and assembly method thereof

ActiveCN109853802AIncrease productivitySimplify the side moldFloorsBuilding material handlingPre stressInterconnection

The invention discloses a whole span pre-prefabricated prestressed groove-type rib plate, a floor cover structure and an assembly method thereof. The floor cover structure is composed of framework beams and prefabricated prestressed groove-type rib plates inside beam grillages. The whole span pre-prefabricated prestressed groove-type rib plate is used as a basic assembly unit for a floor cover, suitably wide gaps are formed between longitudinal ribs of laterally adjacent prefabricated groove-type rib plates and between the longitudinal ribs of groove-type rib plates and the adjacent frameworkbeams, and the gaps are filled with sealing materials; and interconnection is achieved by precompression of high-strength bolts vertically passing through the longitudinal ribs and the longitudinal ribs, and the longitudinal ribs and the adjacent framework beams. Transverse ribs of the rib plates are in pre-compressed connection with side faces of the adjacent framework beams by employing curved unbonded steel strands on the, and a gap of a certain width is left between the two, and the gap is filled with high-strength mortar. The whole span pre-prefabricated prestressed groove-type rib plate,the floor cover structure and the assembly method thereof solve the problem that connection joints are excessive, a prefabricated component side mold is complicated, the production efficiency is low,connection integrity is poor, and the like brought by a too small prefabricated component unit of an existing prefabricated floor cover structure, extension of ribs surrounding a prefabricated plate,superimposed pouring, non-prestressed connection, and the like,.

Owner:CHINA UNIV OF MINING & TECH

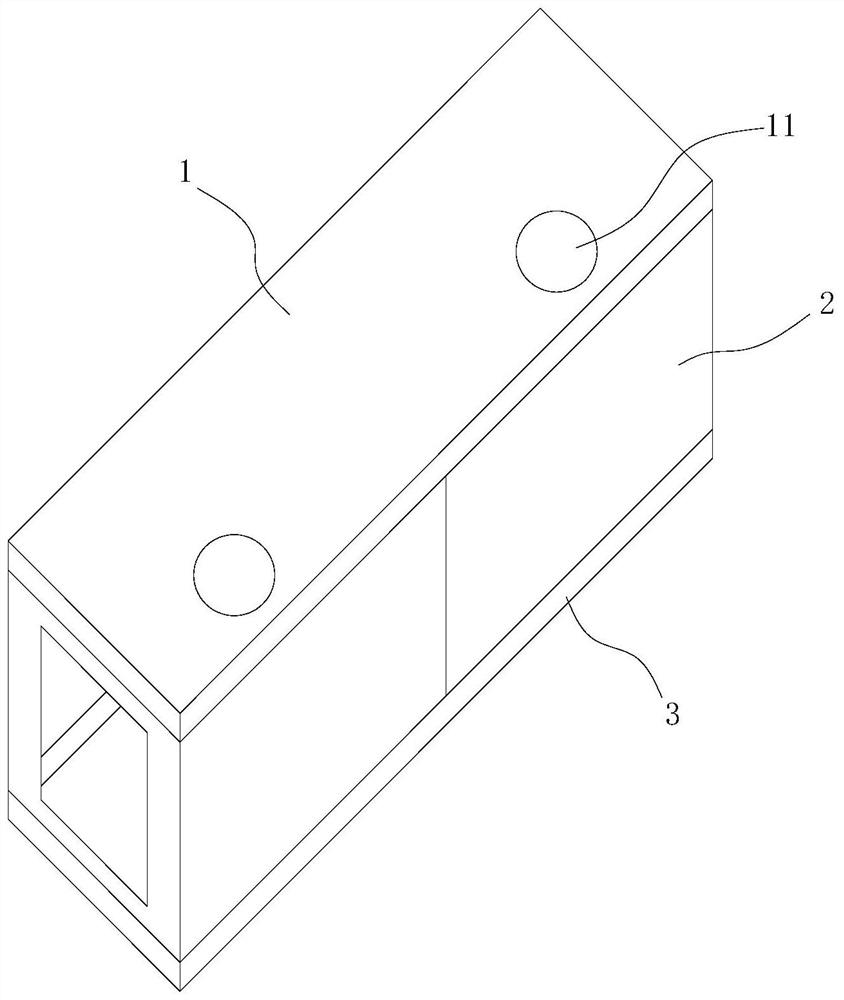

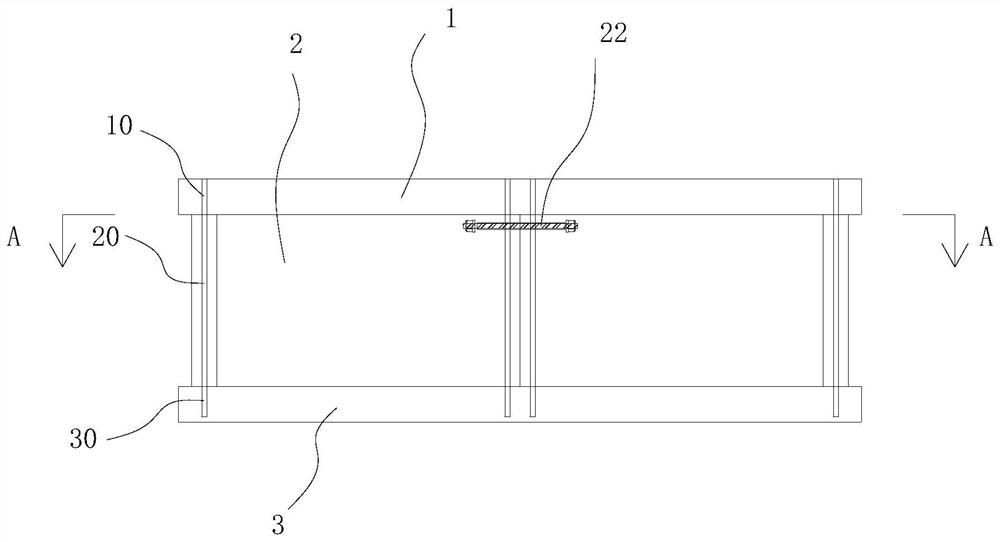

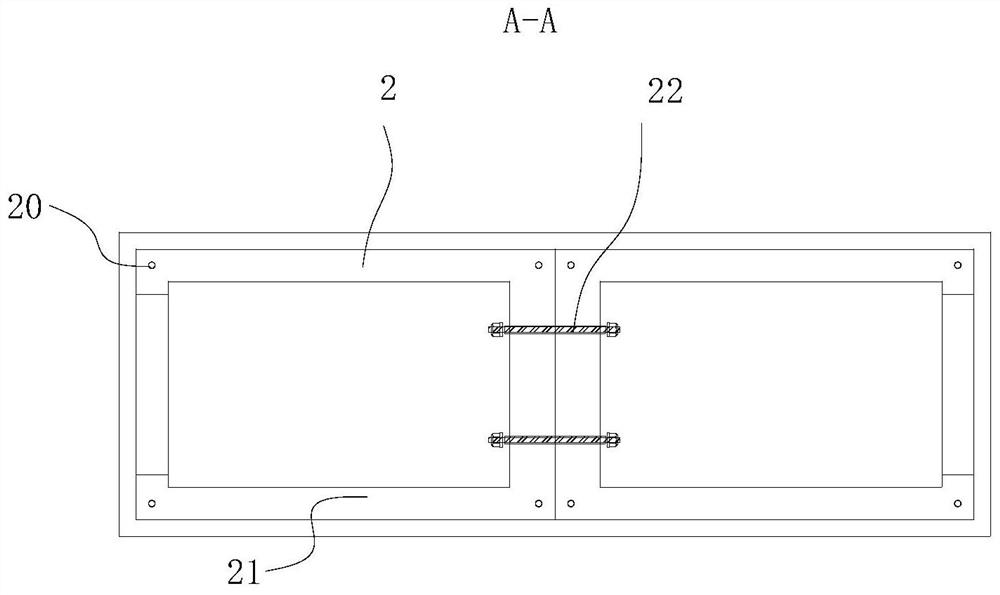

Assembly type cable well

PendingCN111910685ASmall construction impactEasy constructionArtificial islandsElectrical apparatusPublic placeArchitectural engineering

The invention discloses an assembly type cable well. The invention relates to the field of cable assembly equipment, in particular to an assembly type prefabricated multidirectional cable well. The assembly type cable well is provided, prefabricated parts are adopted for assembly operation on site, and therefore the construction period is greatly shortened. The manner that an original cable well is built on site is changed, and the manner is improved into the manner of fragmentation prefabrication, on-site excavation, assembly and landfill. The advantages of rear personnel and machinery are brought into full play, the influence of external climatic environment is avoided, and the construction influence of public places and roads is reduced to the maximum extent. Prefabricated processing iscarried out in a prefabrication factory, sufficient maintenance is carried out, the prefabricated parts are conveyed to a construction site to be hoisted, joint treatment is carried out in the splicing process, and it is guaranteed that the integrity is good and the anti-seismic property is improved by inserting reinforcing steel bars into reserved holes which are through up and down and pouringcement paste into the reserved holes. Therefore, the on-site construction period is greatly shortened, and the effects of reliable strength and convenient construction are achieved.

Owner:扬州浩辰电力设计有限公司

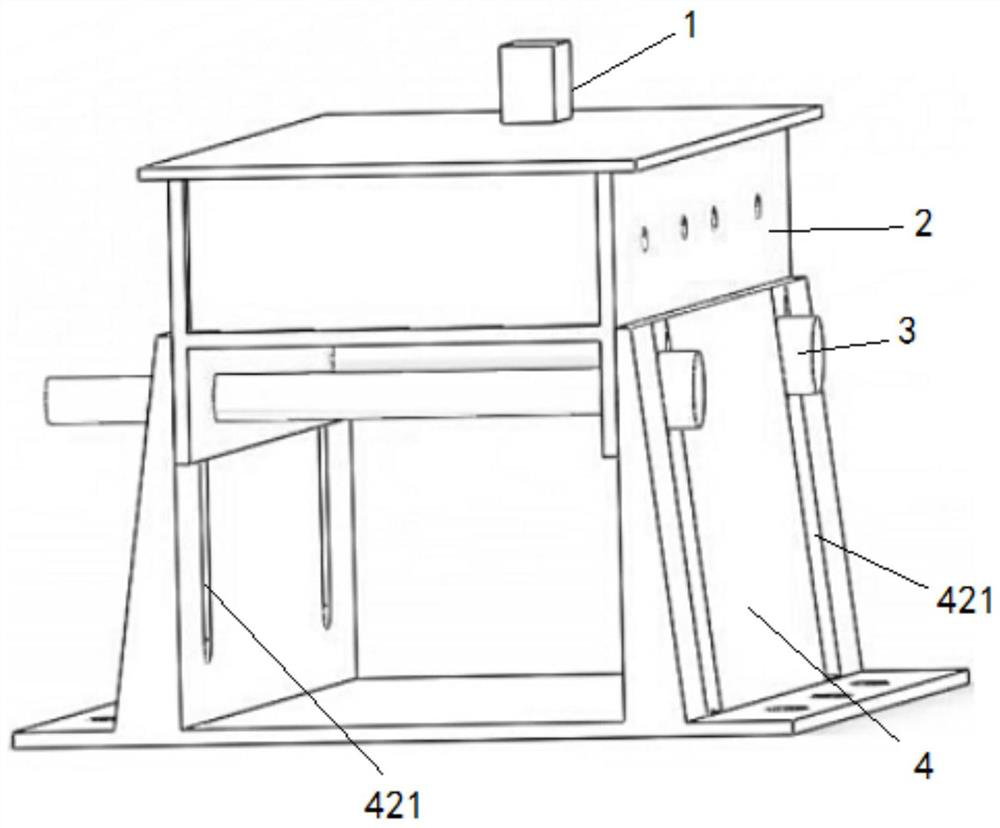

Floor spring assembly type adjustable support and mounting method thereof

PendingCN111962816AMeet the needs of different installation occasionsStable structureBuilding material handlingFalse floorsScrew threadThreaded fastener

The invention relates to a floor spring assembly type adjustable support and an installation method thereof. The support comprises a floor spring fixing piece used for installing a floor spring and afixing support body, and the floor spring fixing piece can move up and down relative to the fixing support body in a vertical direction and can be fastened to the fixing support body through a threaded fastener. The height of the floor spring is adjusted through the height-adjustable support, so that the requirements of different installation occasions are met.

Owner:CHINA CONSTR DONGFANG DECORATION CO LTD

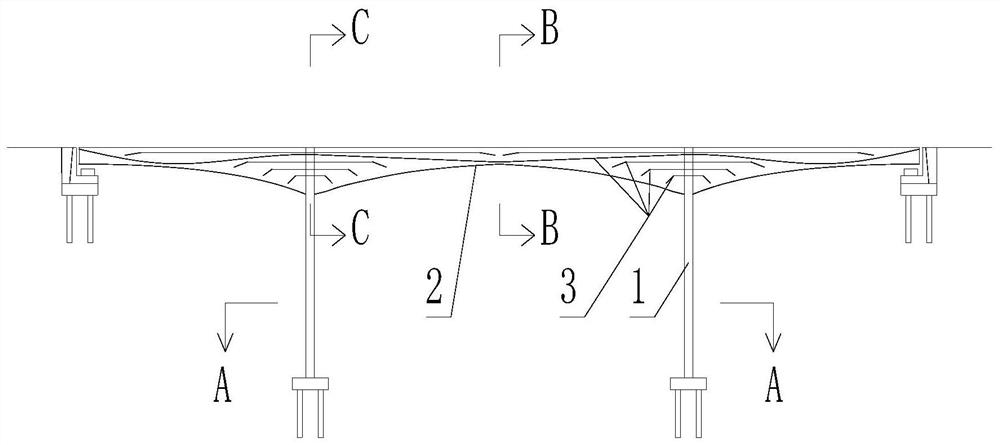

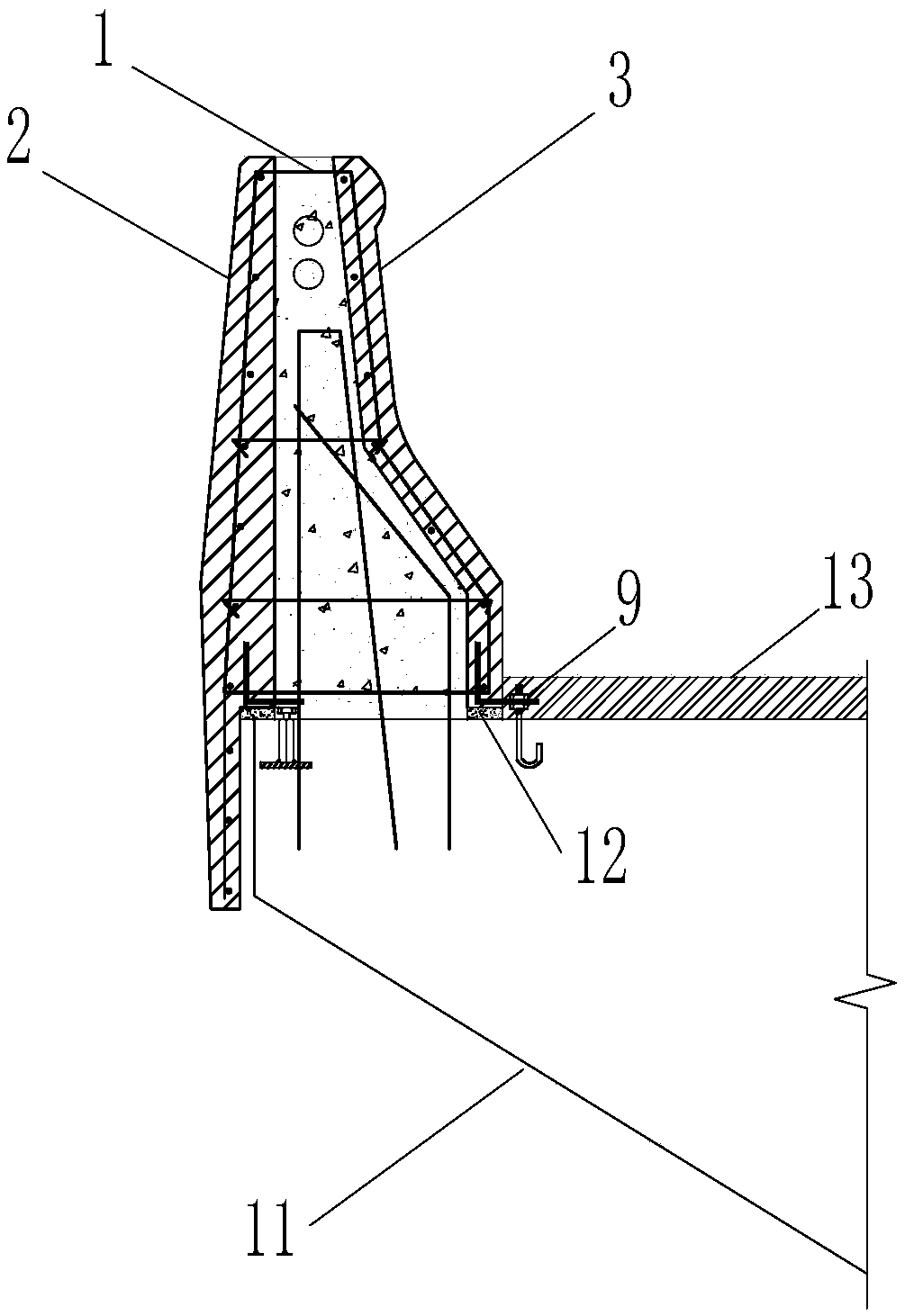

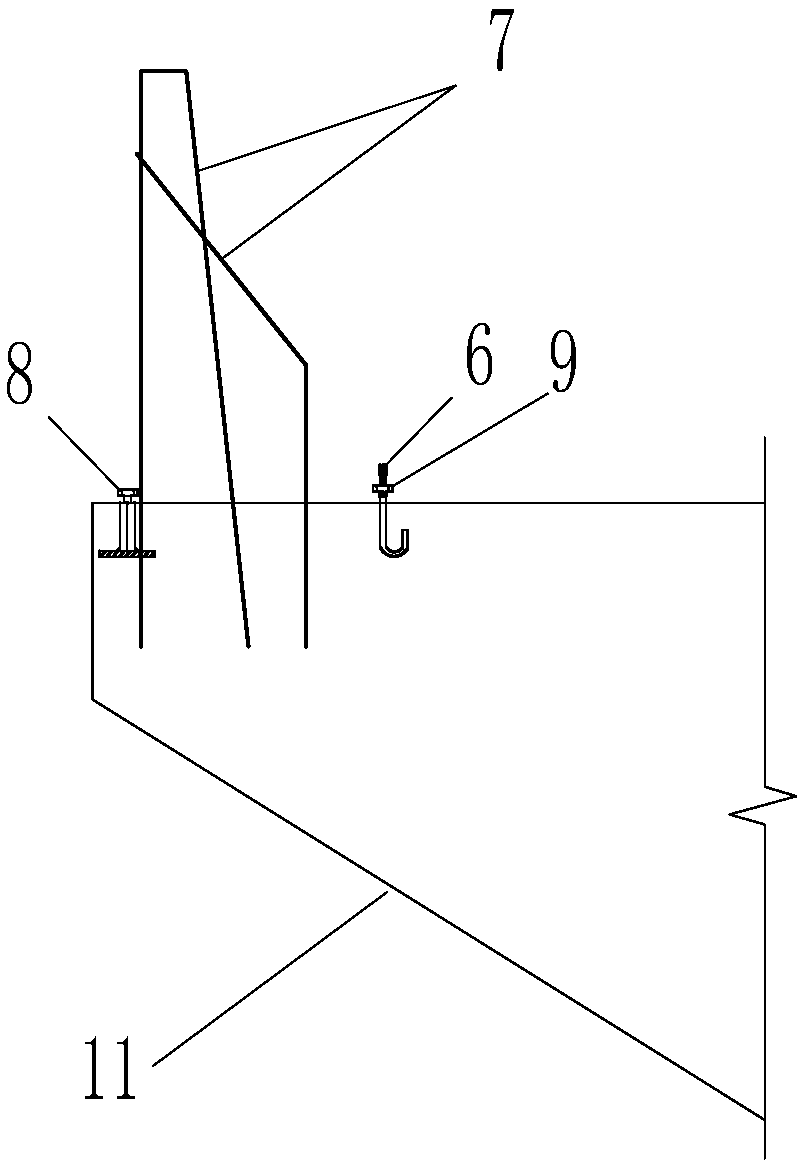

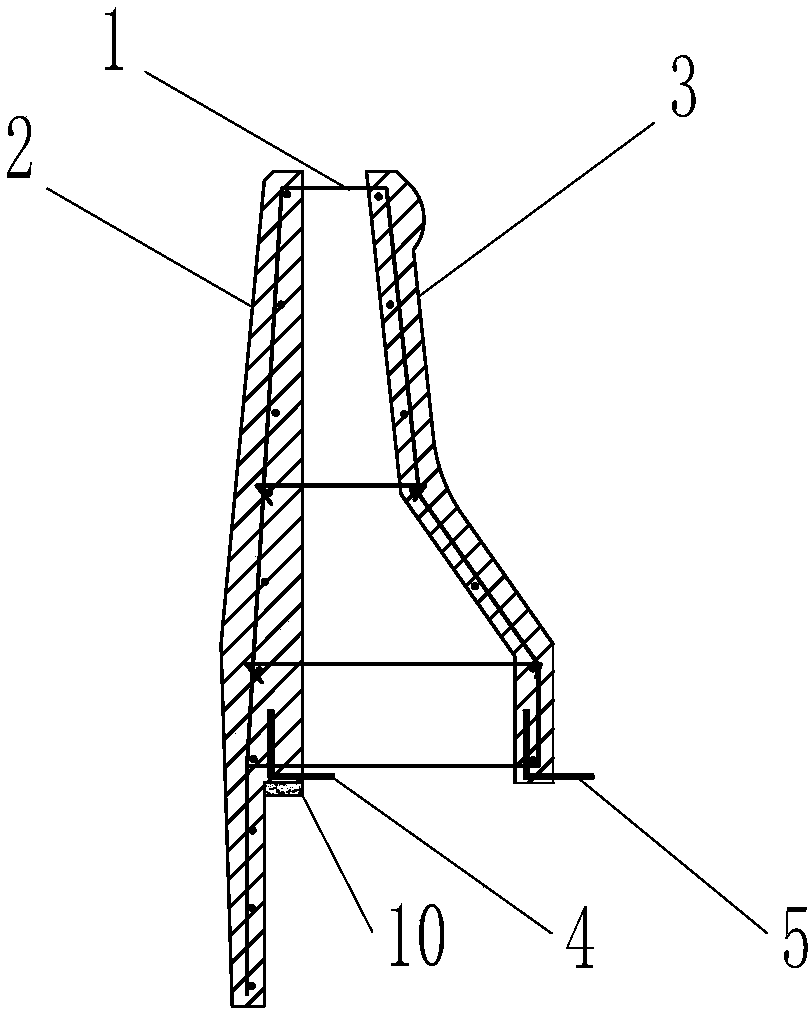

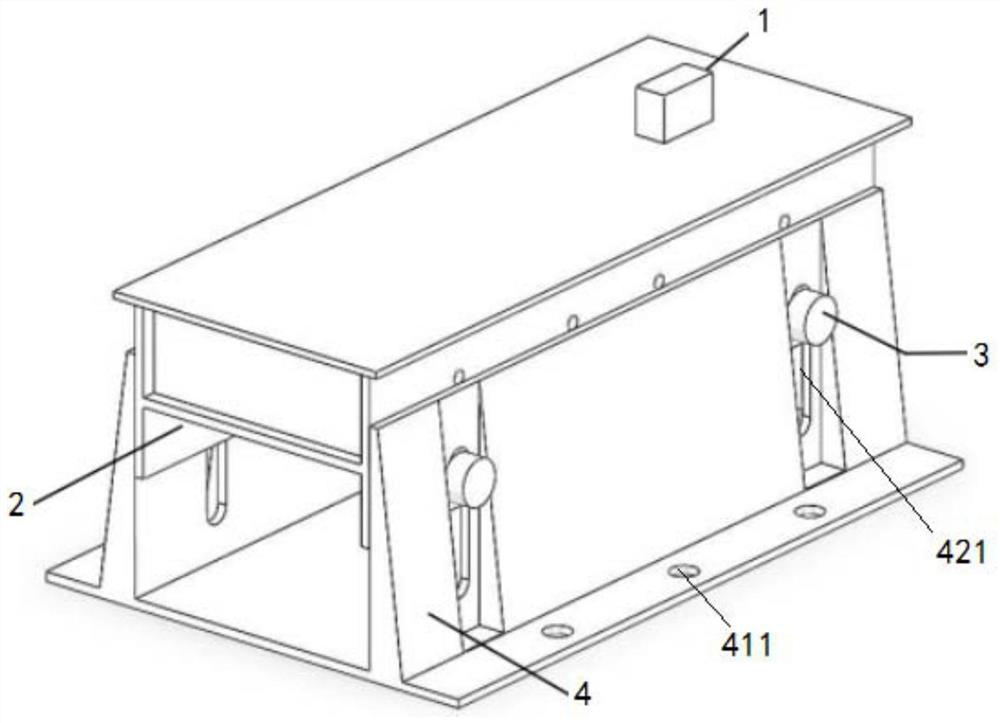

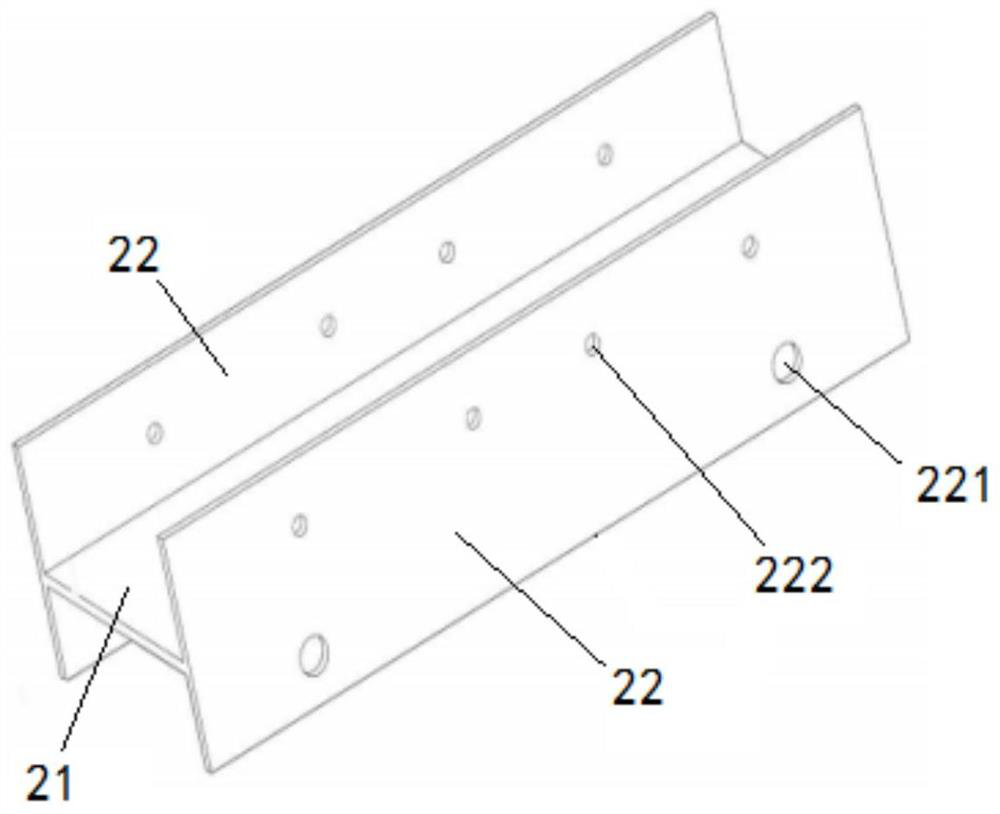

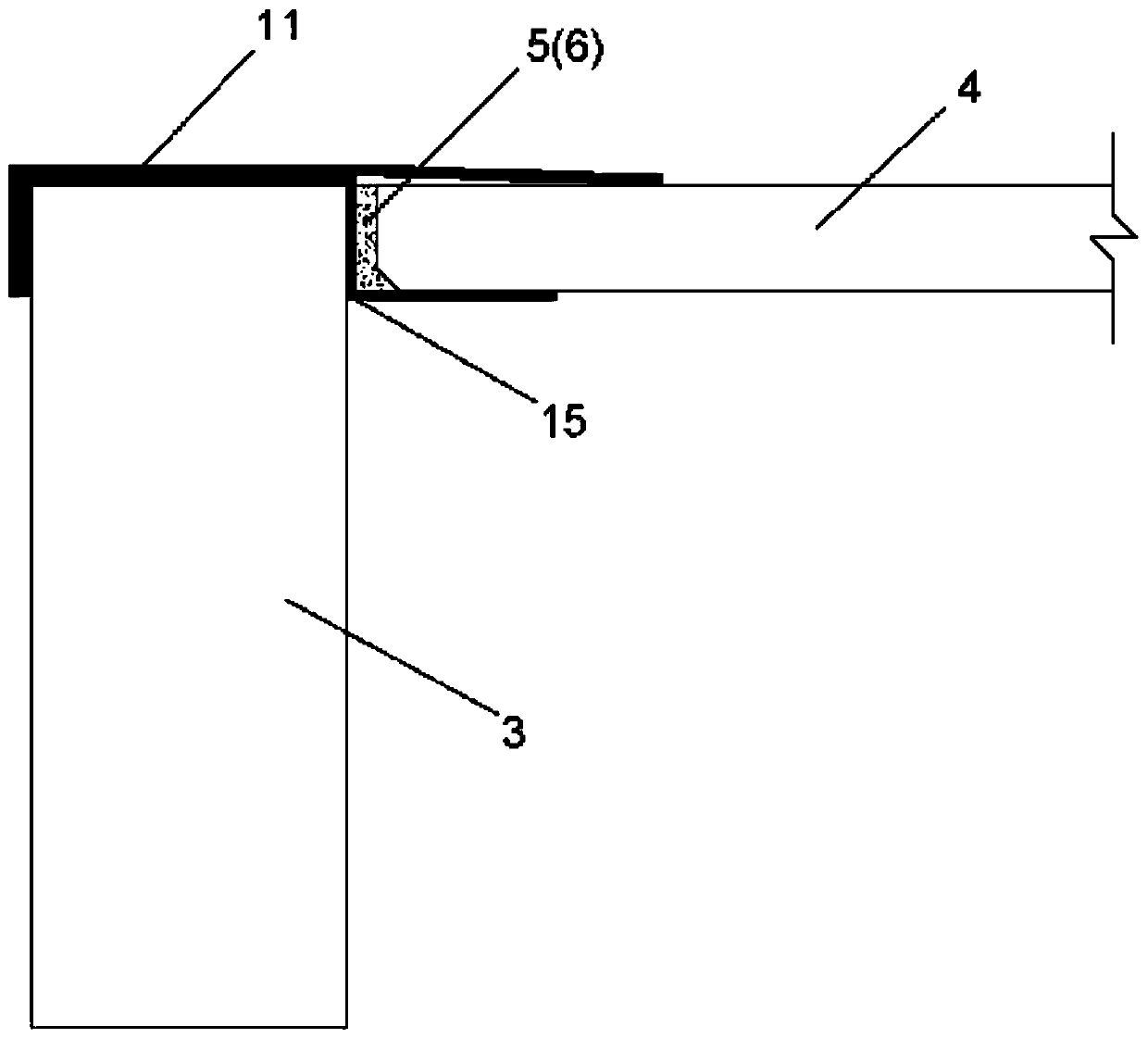

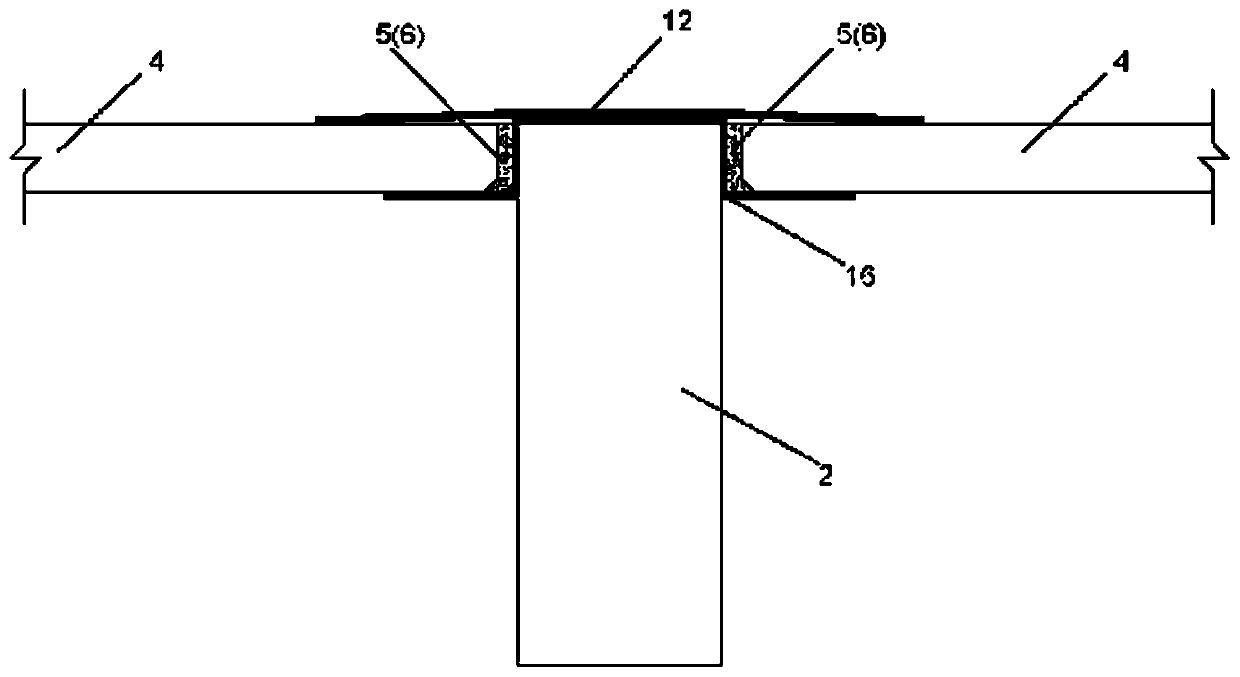

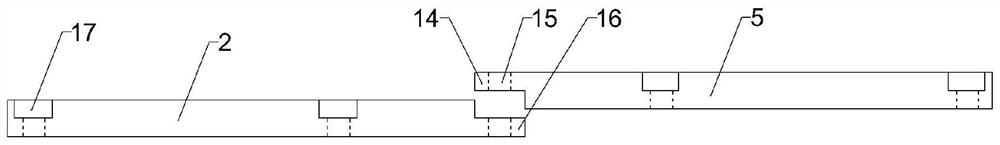

Prefabricated swing pier structure system with additional energy dissipation support or self-resetting energy dissipation support

InactiveCN113481833ASignificant vibration isolationSignificant self-resetting effectBridge structural detailsBridge engineeringArchitectural engineering

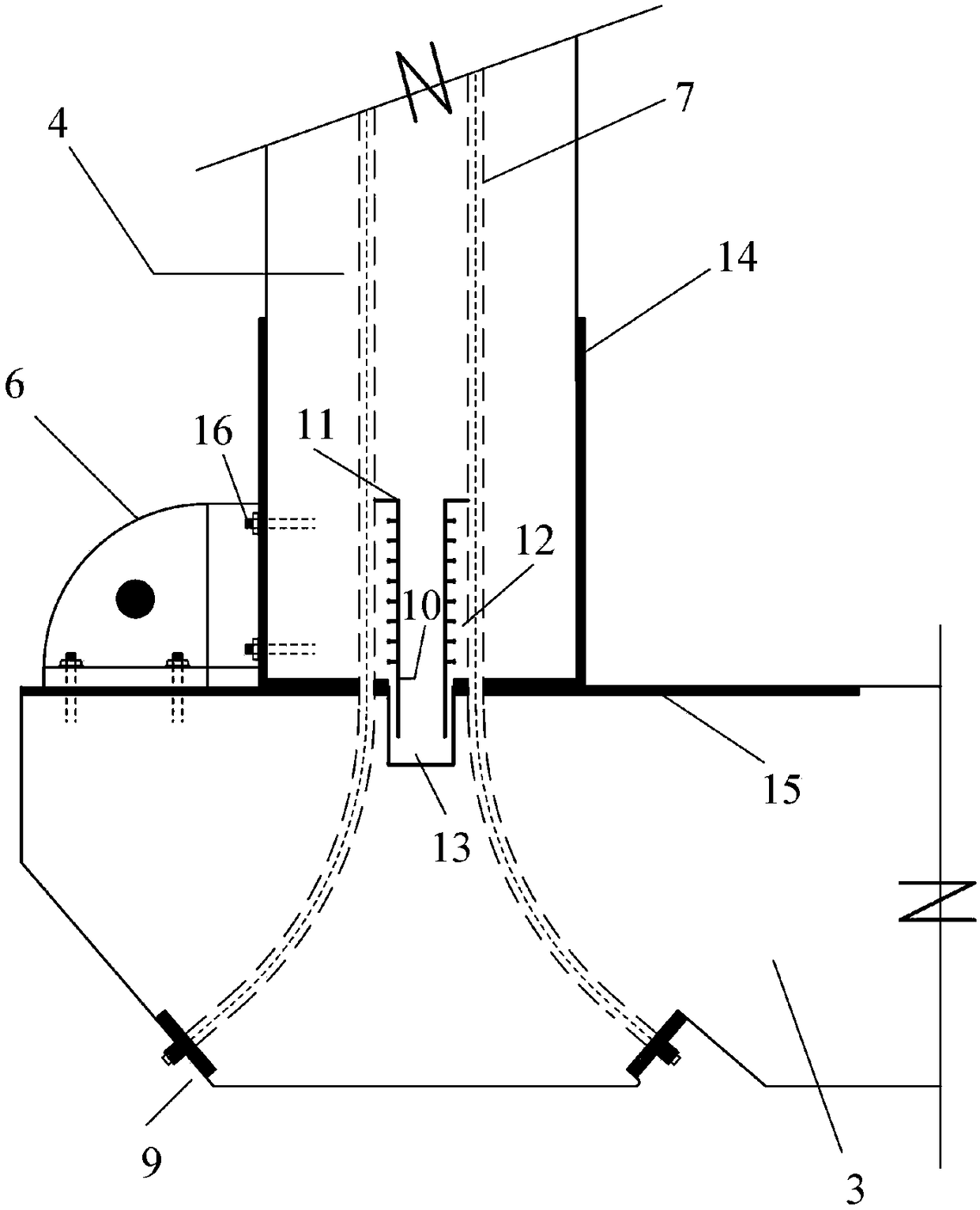

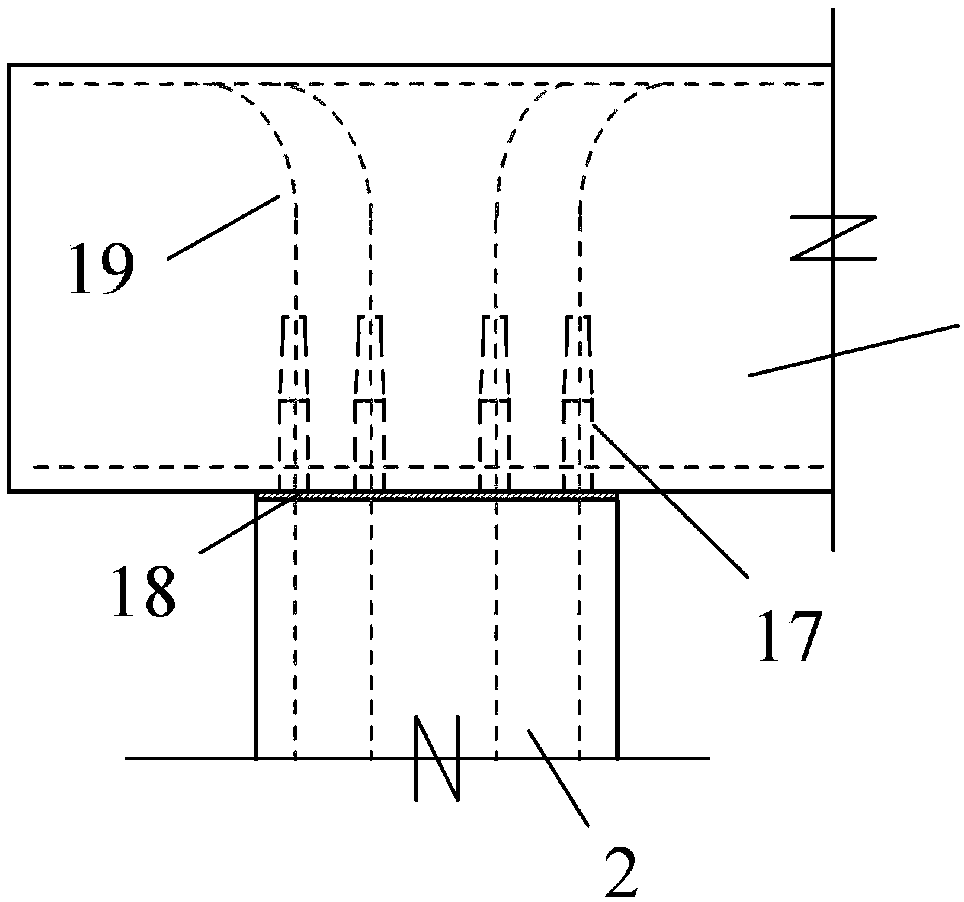

A prefabricated assembly type swing pier structure system with an additional energy dissipation support or a self-resetting energy dissipation support belongs to the technical field of seismic mitigation and isolation of bridge engineering, and mainly comprises a prefabricated bearing platform, a prefabricated pier column, a prefabricated cover beam, a prefabricated support and a resetting rib, two bearing platform sleeves are arranged on the prefabricated bearing platform and are used for connecting the two lower lug plates; column sleeves are arranged at the upper part and the lower part of the prefabricated pier column; a cover beam sleeve is arranged in the middle of the prefabricated cover beam and used for being connected with an upper lug plate. The prefabricated support is arranged between the lower lug plates and the upper lug plate and is hinged through a pin; the reset rib penetrates through holes reserved in the prefabricated bearing platform, the prefabricated pier column and the prefabricated cover beam, and are fixedly connected to the lower end of a platform body of the prefabricated bearing platform and the upper end of a beam body of the prefabricated cover beam through a high-strength bolt and a groove-shaped steel gasket. In the earthquake process, the whole system swings, the bending moment of the top and the bottom of the pier column is released, and plastic hinges at joints are avoided.

Owner:BEIJING UNIV OF TECH

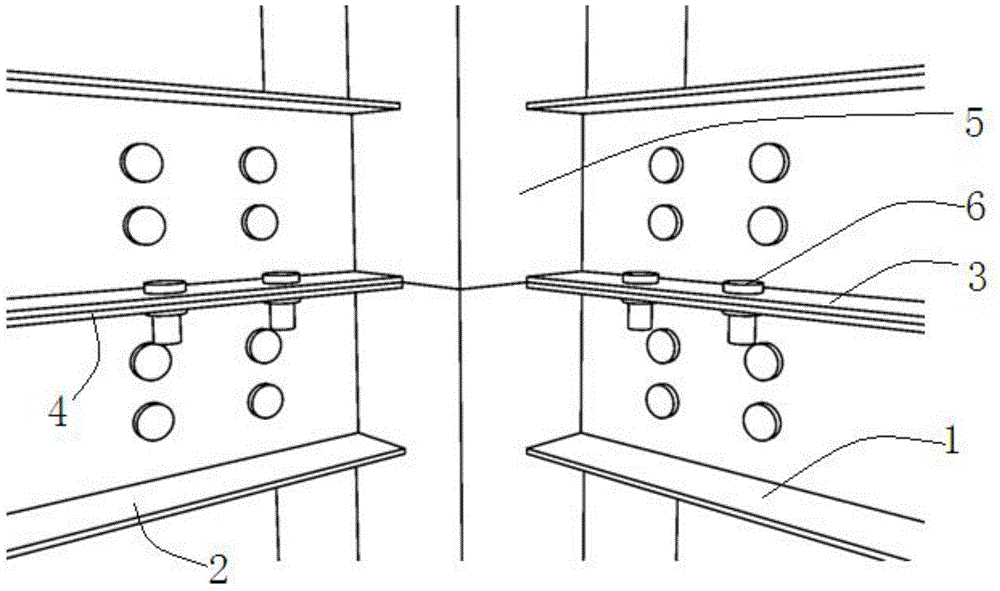

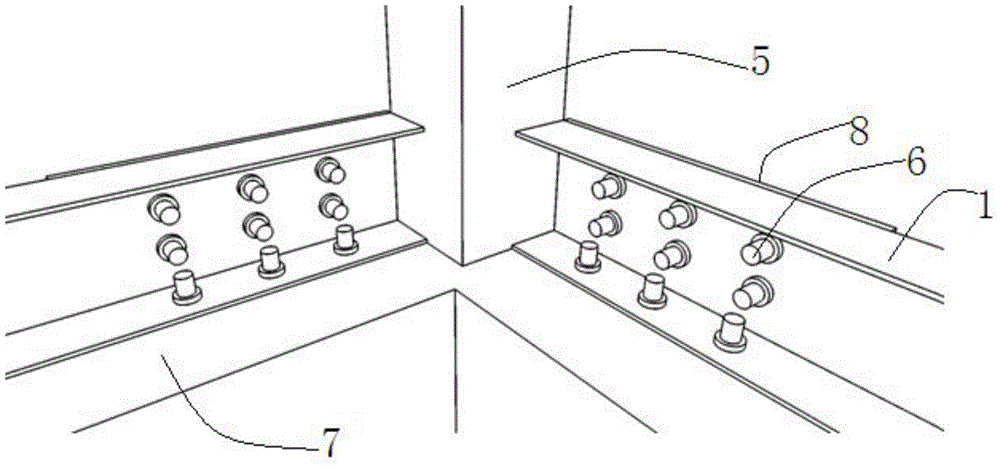

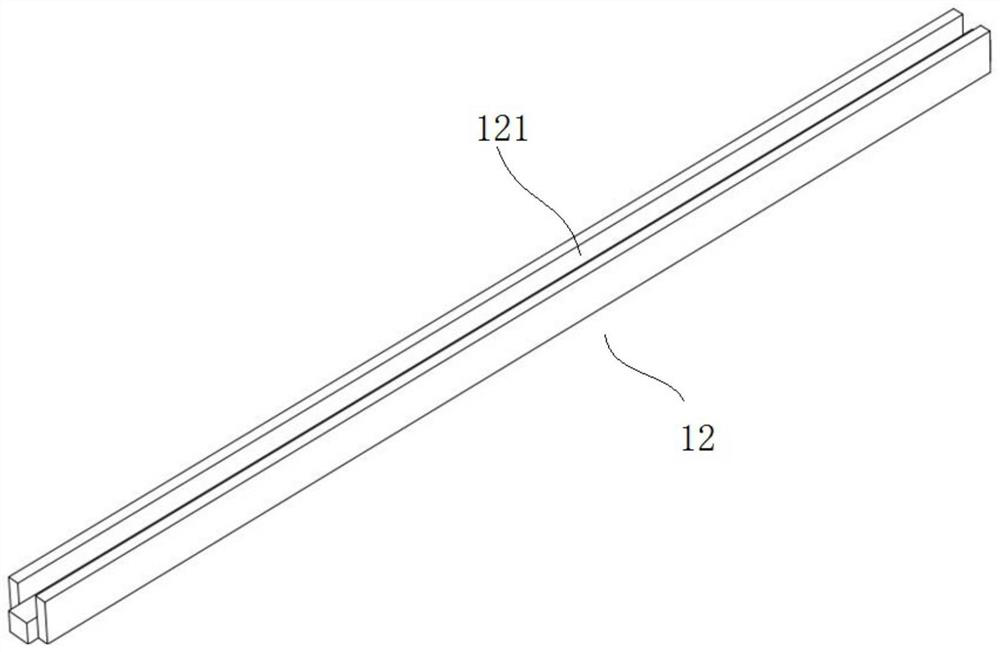

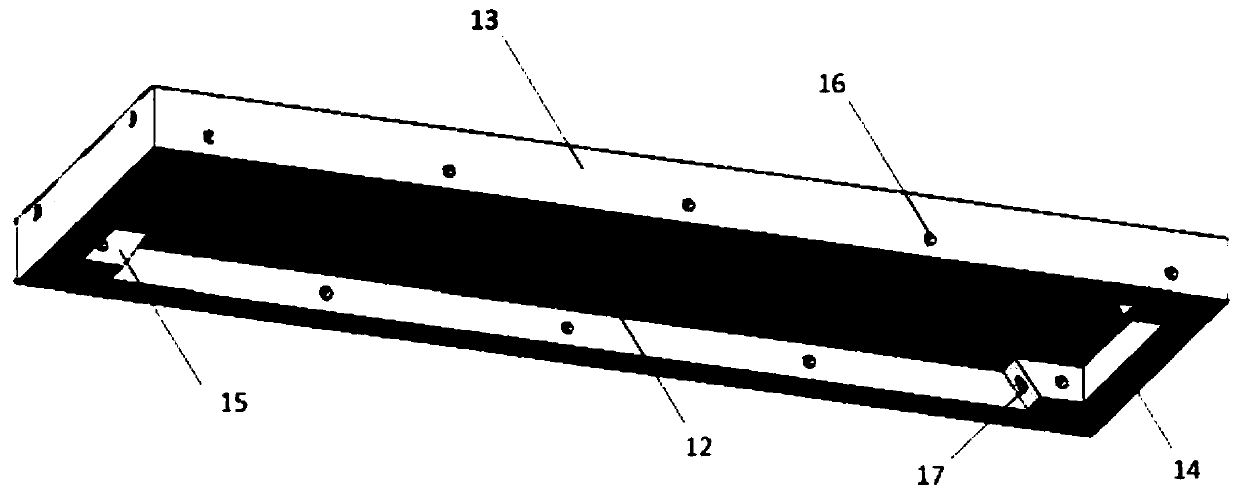

Full-assembly type SBSG shear connection steel-concrete composite beam

PendingCN114059440AReliable shear resistanceReliable pullout abilityBridge structural detailsBridge erection/assemblyConstruction engineeringBridge deck

Disclosed is a full-assembly type SBSG shear connection steel-concrete composite beam that comprises a steel beam and a prefabricated concrete bridge deck, a plurality of steel bolts are fixedly distributed on the top of the steel beam, at least one vertical section of each steel bolt is of a big-end-up structure which is gradually transited, matching grooves with openings in the lower portions are distributed in the lower portion of the prefabricated concrete bridge deck. Each matching groove matches the steel bolt in shape on the vertical section; the invention has reliable shear resistance and pulling resistance, and reliable connection of the bridge deck and the steel beam is achieved without cast-in-place combined concrete; the steel bolts on the top of the steel beam and the matching grooves can adopt steel structures, the requirement for the embedded installation precision of the bridge deck and the top of the steel beam on a bridge site is easily met, a special anti-pulling connecting structure is avoided, the structure is obviously simplified, the embedded installation of the steel bolts and the matching grooves allows a large gap (filling a combination material), and the requirement for the installation precision is obviously reduced; the field workload is obviously reduced, and the reliability of the combined structure is correspondingly improved.

Owner:SHENZHEN UNIV

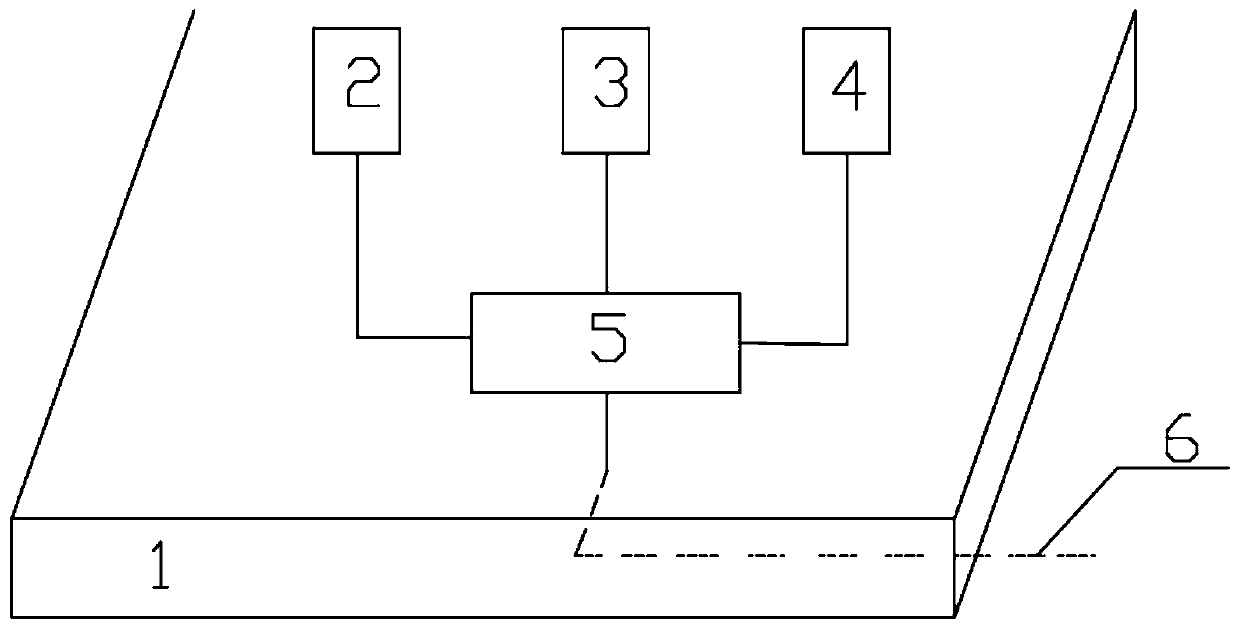

Modular device of cathodic protection system

The invention discloses a modular device of a cathodic protection system. The modular device of the cathodic protection system comprises a steel structure saddle as well as a cathodic protection equipment module, a test equipment module, an equipment and insulation facility protection module, a wiring equipment module and a cathodic protection cable which are connected and installed on the steel structure saddle by a detachable bolt; The cathodic protection equipment module, the test equipment module, the equipment and the insulation facility protection module are respectively connected with the wiring equipment module through a cable. The modular device provided by invention arranges each device in a single module by the modular design; and by optimizing the arrangement of each device inthe module, the modularization of the cathodic protection system device is simpler; the single module is fixed on the base by bolts or plugging, so the module is easy to disassembly, quick to reassemble, convenient to transport, easy to reuse, and the traditional construction mode is improved; each module is simple and clear, easy to internal control, can avoid on-site wiring errors, effectively control the construction quality, and shorten the on-site construction period.

Owner:CHINA PETROLEUM ENG & CONSTR +1

FRP sheet connecting structure of prefabricated concrete beam and slab system and method

The invention provides an FRP sheet connecting structure of a prefabricated concrete beam and slab system and a method. Peripheral side surfaces of full-thickness prefabricated slabs are adjacent to side surfaces of floor beams; an about 20 mm wide adjusting seam is formed between each prefabricated slab and each floor beam and between the prefabricated slabs and is filled with high-strength micro-expansion mortar; planar FRP sheets for anti-bending connection are attached to the top surfaces of joints of the prefabricated slabs and the floor beams and the top surfaces and the bottom surfacesof joints of the prefabricated slabs; folding surface type FRP sheets for anti-shear connection are also attached to the joints of the prefabricated slabs and the floor beams and the joints of the prefabricated slabs; and the fiber direction of the FRP sheets is perpendicular to the longitudinal direction of the joints. The problems that side forms of prefabricated parts are complicated due to thefact that ribs extend out of the periphery of existing platy prefabricated parts, the production efficiency is low, transportation and hoisting operation are difficult and the like are solved; and the problem that substantial wet operation on the scene due to stacking pouring of existing prefabricated slabs and the problem of too large thickness of the slabs are solved.

Owner:CHINA UNIV OF MINING & TECH

Hoisting construction method for square butt joint and inserting connection between bridge steel box girder sections

The invention relates to bridge construction and provides a hoisting construction method for square butt joint and inserting connection between bridge steel box girder sections. The method comprises the following steps that the box bridge sections with webs on the two sides of the mid-span of a bridge steel box girder are hoisted to an adjusting section of a jig frame firstly; a shackle is arranged between two strands of hoisting steel wire ropes and lifting lugs outside the after-installed bridge section of the box with the weds only on one side correspondingly, two strands of hoisting steel wire ropes inside the after-installed bridge section of the box with the weds only on one side are each provided with two serial shackles, and chain blocks are arranged on the steel wire ropes outside the after-installed bridge section of the box with the weds only on one side in an auxiliary mode for tightening; lifting hook is subjected to translation, when diaphragm plates of the after-installed bridge section make contact with top plates of the firstly-installed bridge section, tightening is conducted through traction of horizontal chain falls, and loosening and hook dropping are conducted through cooperation of hoisting chain falls; the diaphragm plates of the after-installed bridge section are completely stuffed in place, and then the lifting hooks completely continue to be subjected to hook dropping till complete loosening is achieved; the after-installed bridge section is measured, the scale height is adjusted by means of the method that base plates are assembled or disassembled at the tops of small vertical pillars of the adjusting section till design requirements are met; and the horizontal chain falls are loosened, the hoisting shackles are disassembled, and thus the after-installed bridge section is completed. According to the hoisting construction method for square butt joint and inserting connection between the bridge steel box girder sections, damage cannot be caused to the diaphragm plates.

Owner:SHANGHAI BAOYE GRP CORP

Prefabricated structure for supporting slope

InactiveCN113174974AImprove fixation stabilityEasy to fixCoastlines protectionExcavationsClassical mechanicsStringer

Owner:CHONGQING VOCATIONAL INST OF ENG

Fabricated open caisson structure and mounting method thereof

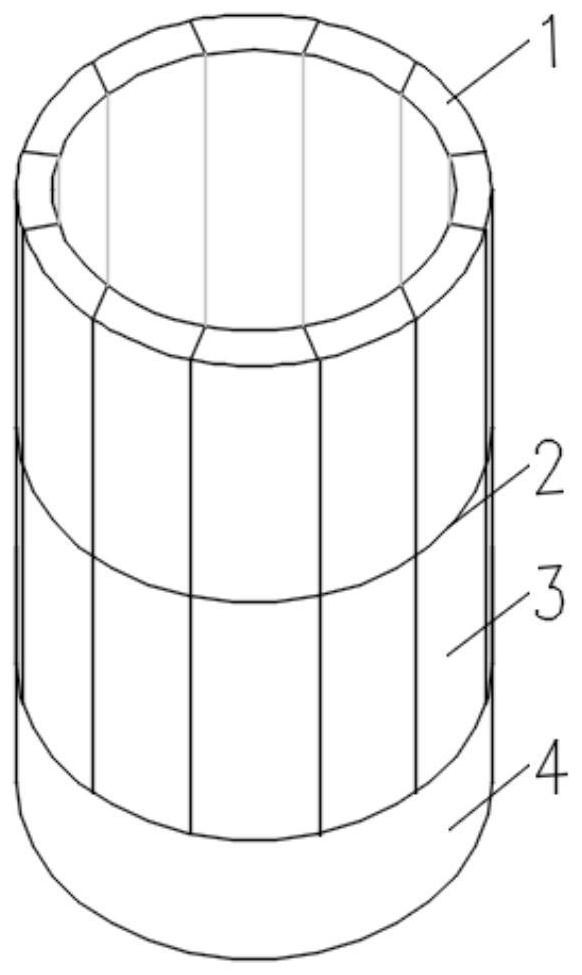

ActiveCN113389213AImprove the level of prefabrication and assemblyRealize fixed positioningArtificial islandsUnderwater structuresArchitectural engineeringMesh reinforcement

The invention provides a fabricated open caisson structure, which is applied to the technical field of building construction. The invention further relates to a mounting method of the fabricated open caisson structure. Reinforcing meshes (9) are arranged in concrete (10) of open caisson blocks (1) of the fabricated open caisson structure, end sealing plates (7) are arranged on the upper and lower ends of the concrete (10) correspondingly, one side of a metal plate pile (5) extends to the side surface of one side of the concrete (10), the other side of the metal plate pile (5) extends to the side surface of the other side of the concrete (10), a bent reserved grouting groove (6) is formed in one side of the metal plate pile (5), and a bent reserved grouting groove (6) is also formed in the other side of the metal plate pile (5). The fabricated open caisson structure has the characteristics of the simple structure, low cost, convenience in processing and installation, convenience and labor saving in site construction and good structural overall stability and water stopping performance and has a high application and popularization value, the site construction period is shortened, and the prefabricated level of open caisson construction is greatly increased.

Owner:中交(广州)建设有限公司 +1

Method and structure of wall body or dam body assembled by stone and brick members

InactiveCN101660329AReduce the impactImprove fire performanceWallsEarth-fill damsBrickEnvironment effect

The invention discloses a method and a structure of a wall body or a dam body assembled by stone and brick members, which is characterized in that stone is used for making a T-shaped member, two sidesof a middle stone plate of the T-shaped member are provided with a male tenon and a female tenon, and stone plates at both ends of the T-shaped member are provided with a male tenon and a female tenon; the male tenon and the female tenon at two sides of the middle stone plate of the T-shaped member are connected with the male tenon and the female tenon in the stone plates at both ends of the T-shaped member, and alternate and continuous assembly is carried out so as to form the wall body or the dam body. The T-shaped member and a straight member of the invention can be processed and shaped ina factory and then assembled in the field of construction, and thus, the invention reduces construction process and has less influence on field environment. The stone members are connected with eachother by glue via the male and female tenons, have simple, stable and firm structure, save materials, reduce self weight, decrease fabrication cost and shorten field construction period.

Owner:王泽飞

Nodular cast iron prefabricated assembly type drainage inspection well

The invention discloses a nodular cast iron prefabricated assembly type drainage inspection well which comprises an inspection well body, and the inspection well body comprises a well body section located on the lower portion and a well shaft section located on the upper portion. At least one water inlet section is arranged between the well body section and the well shaft section, and an adjustingsection used for adjusting the elevation is arranged between every two adjacent water inlet sections and / or between the well body section and the water inlet section located at a lowest position and / or between the well shaft section and the water inlet section located at an uppermost position; the well body section is provided with a water outlet used for being connected with a water outlet pipe,and the water inlet section is provided with a water inlet used for being connected with a water inlet pipe. A bell and spigot assembly structure is adopted between every two adjacent sections of theinspection well body. A limiting and stabilizing mechanism used for preventing the water inlet section and the adjusting section from moving in the radial direction and enabling the water inlet section and the adjusting section to rotate in the circumferential direction is arranged between the well body section and the well shaft section at intervals. The nodular cast iron prefabricated assemblytype drainage inspection well has the advantages that the elevation of the water inlet pipe can be adjusted, and the stability of an assembly structure is good.

Owner:CHONGQING UNIV

Assembled plant wall structure and mounting method

InactiveCN110541494AWide range of application scenariosShorten construction period on siteWallsSelf-acting watering devicesEngineeringComputer module

The invention discloses an assembled plant wall structure and a mounting method. The assembled plant well structure comprises at least two connecting column modules fixed on the ground, wherein a wallframe module is arranged between the two connecting column modules; a detachable planting module is mounted on the wall frame module; the planting module comprises a plurality of module box bodies for planting, and the two adjacent module box bodies are fixed in a buckling mode or a bolt connection mode. The connecting column modules can be directly fixed on the ground without being attached to the wall body for constructing; the splicing is flexible based on the actual space size; and the applicable scope is wide. The connecting column modules, the wall body module and the planting module are standard module parts and are prefabricated in a factory; the field splitting greatly decreases the field construction period of the planting wall. The connecting column modules, the wall body module and the planting module can be dismounted and recovered for recycling.

Owner:GUANGDONG DONGLEE ENVIRONMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com