Combined sewage treatment method for oil field

A sewage treatment method and combined technology, applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of difficult to realize the combined structure and quick installation of sewage treatment equipment, Increase the effect and speed of sedimentation and flocculation of suspended solids, high investment, infrastructure and operation and maintenance costs, and achieve the effects of shortening the construction period, less conversion and connection of pipe networks, and less overall investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

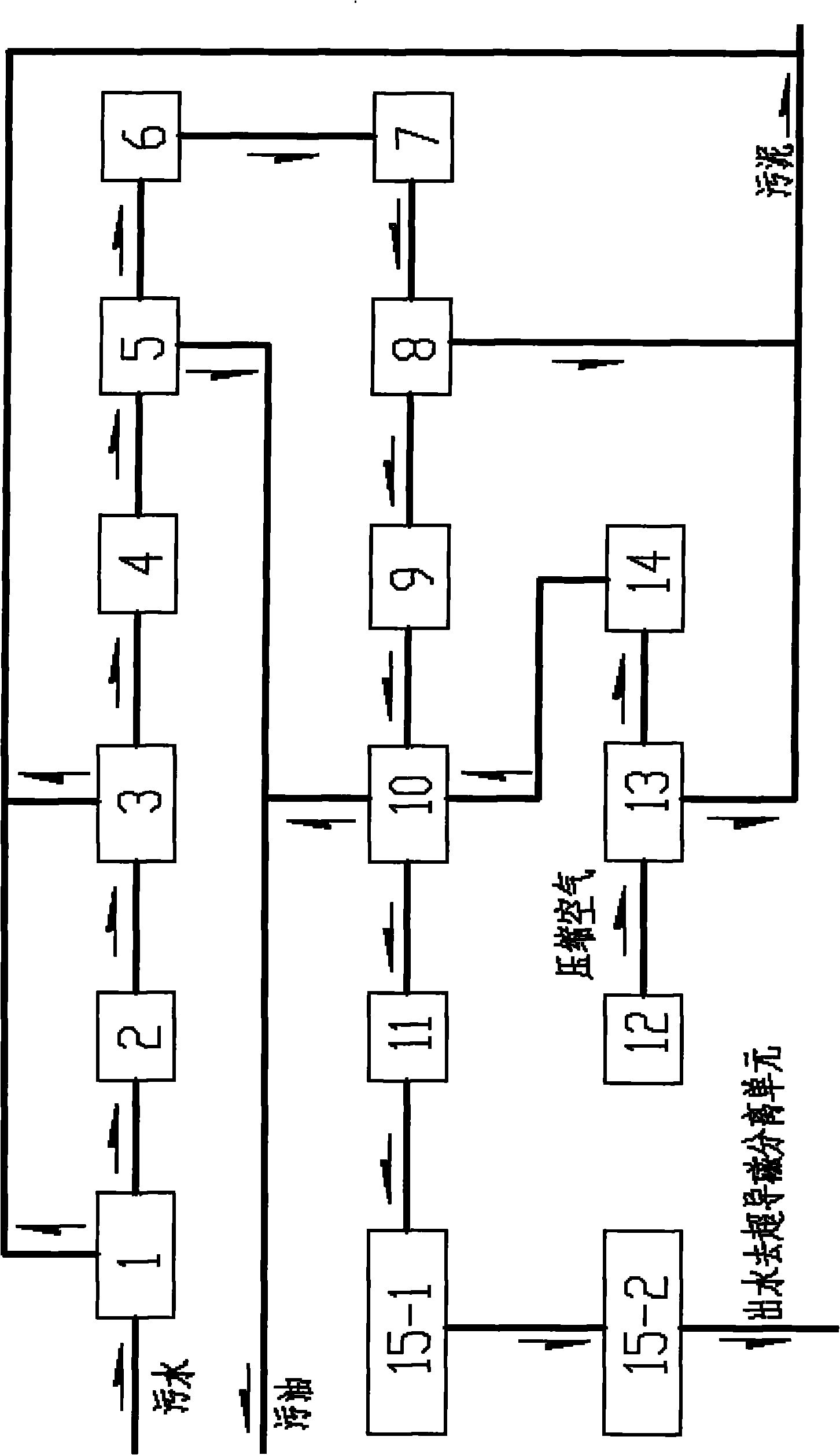

[0037] Embodiment 1: The following is a detailed description of the steps of the combined oilfield sewage treatment method of the present invention in conjunction with the accompanying drawings.

[0038] refer to figure 1 . The "swirl flow pretreatment oil removal unit" of the present invention is the separation method of oil removal and coarse suspended solids removal:

[0039] The produced water to be treated first enters the coarse filter 1, and the coarse filter 1 removes part of the sludge; the produced water discharged from the coarse filter 1 enters the pressure regulating device 2 for pressure regulation, and the water pressure condition is greater than 0.4MPa. If the pressure is too high, decompress in two stages to stabilize the pressure in the range of 0.4-0.6MPa. The pressure is stable, and it is sent to the pre-metering filter 3 for filtration. The pre-metering filter 3 filters out part of the sludge, and the water filtered by the pre-metering filter 3 enters th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com