Full-assembly type SBSG shear connection steel-concrete composite beam

A fully assembled and composite beam technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge materials, etc., can solve the problems of complex local structures of prefabricated bridge slabs and steel beams, high requirements for installation accuracy, and difficult quality control, etc., to achieve reliable Effect of shear performance, reliable shear and pullout resistance, simplified structural construction and field connection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

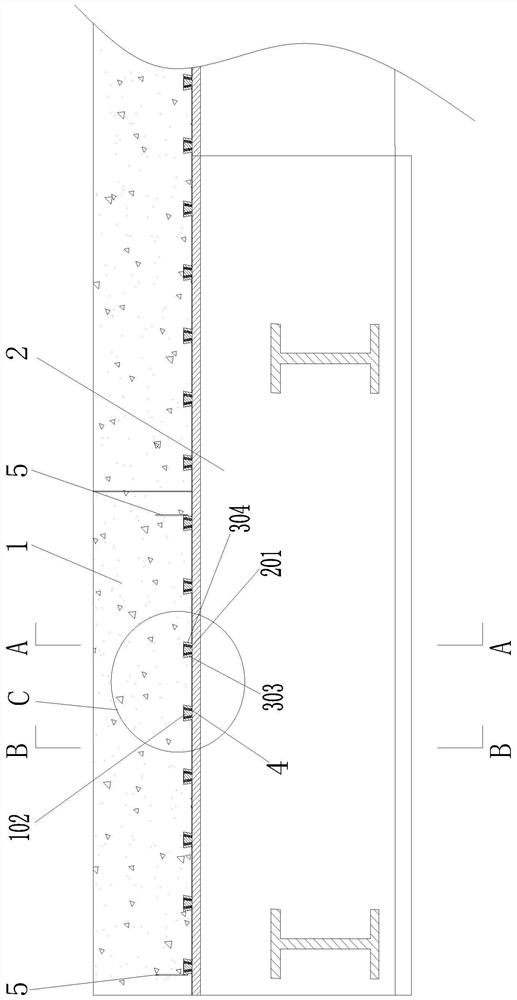

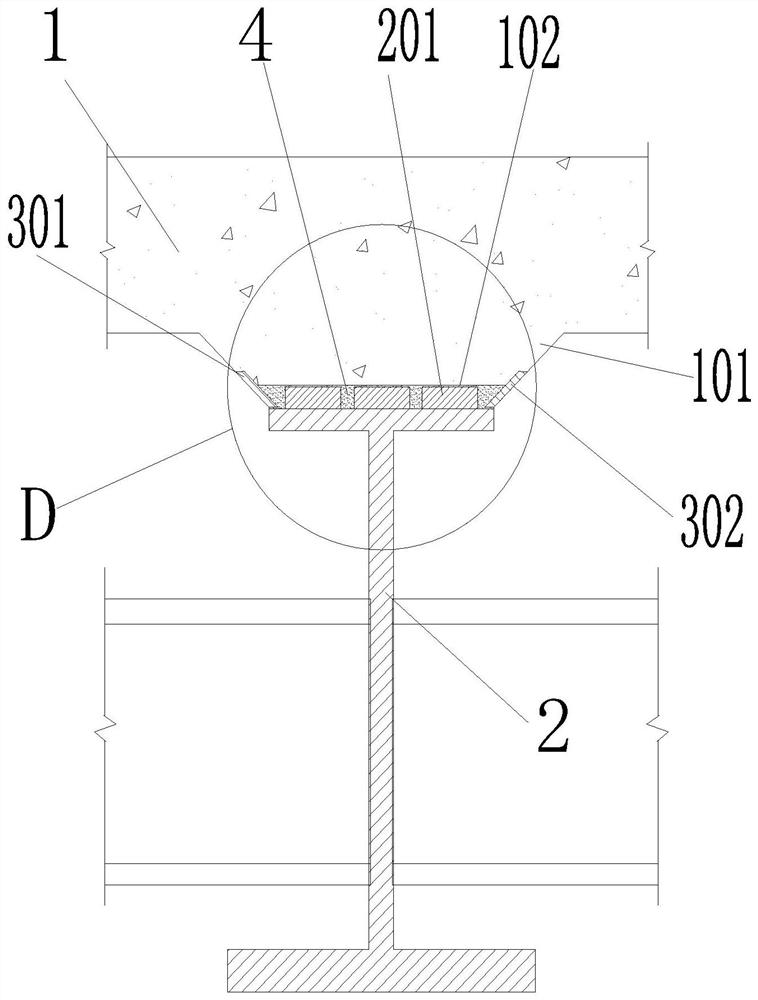

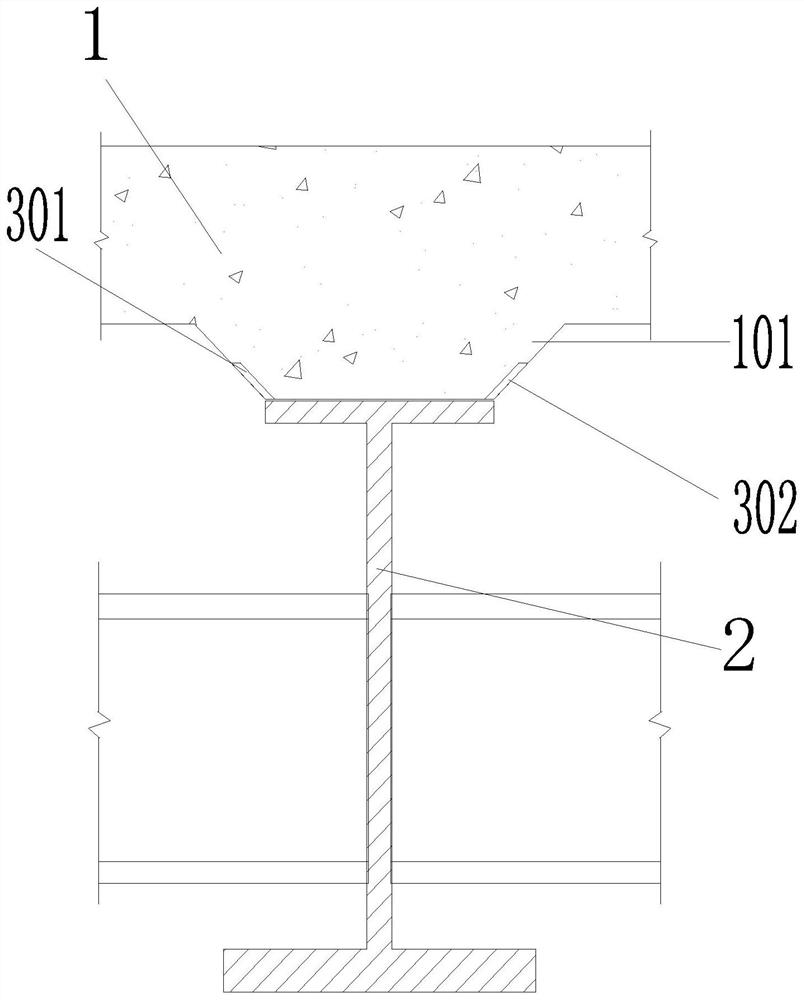

[0038] Such as Figure 1 to Figure 7As shown: the fully assembled SBSG shear connection steel-concrete composite beam of this embodiment includes a steel beam 2 and a prefabricated concrete bridge slab 1, and the top fixed part of the steel beam 1 has a plurality of steel bolts 201, which can be Welding can also be used for other mechanical fixing methods, which will not be repeated here; the steel bolt 201 is at least in a vertical section with a gradually transitional upper and lower structure, and the lower part of the prefabricated concrete bridge slab 1 is distributed There is a fitting groove 102 with a lower opening, and the fitting groove 102 conforms to the steel bolt 201 on the vertical section, and the size of the lower opening of the fitting groove 102 is such that the prefabricated concrete bridge slab is assembled to the steel girder The steel bolt 201 can be inserted at the top, and generally requires a moderate error gap to facilitate assembly, so I won’t repea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com