T-shaped plate girder segment prefabricating unit based on steel truss and combined bridge deck slab

A technology for composite bridges and steel trusses, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of a large number of shear nails to be welded, large local stress on the bridge deck, and low connection efficiency, so as to save formwork machine support Process, high bearing capacity, and improved construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

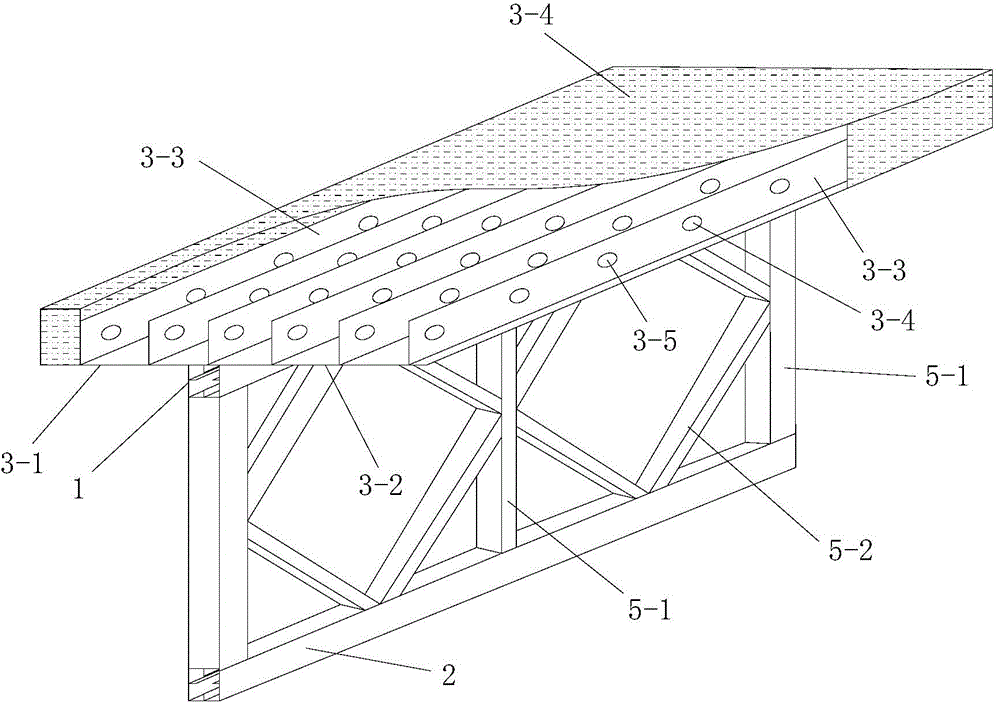

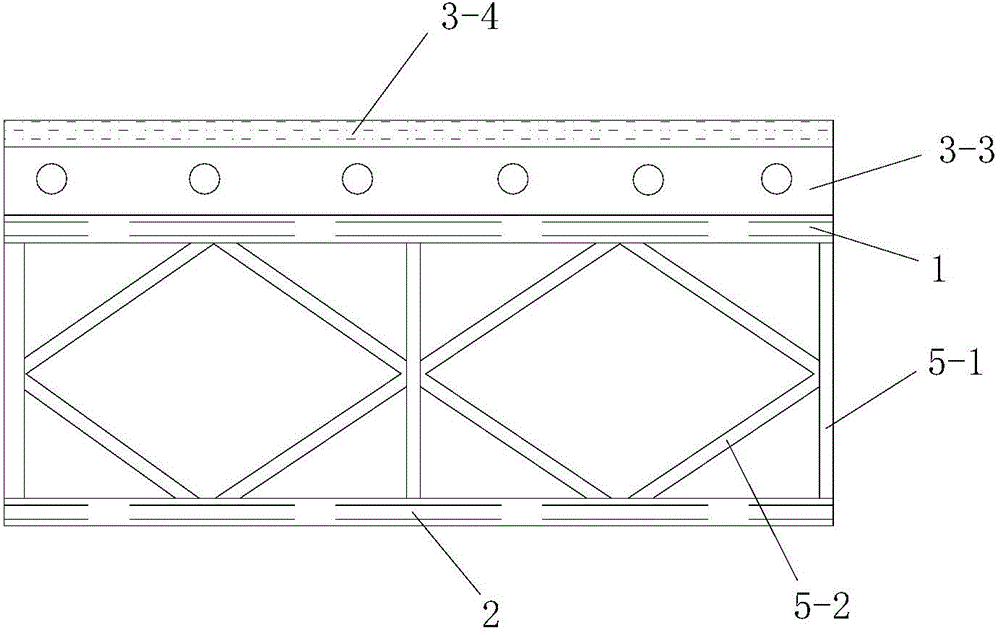

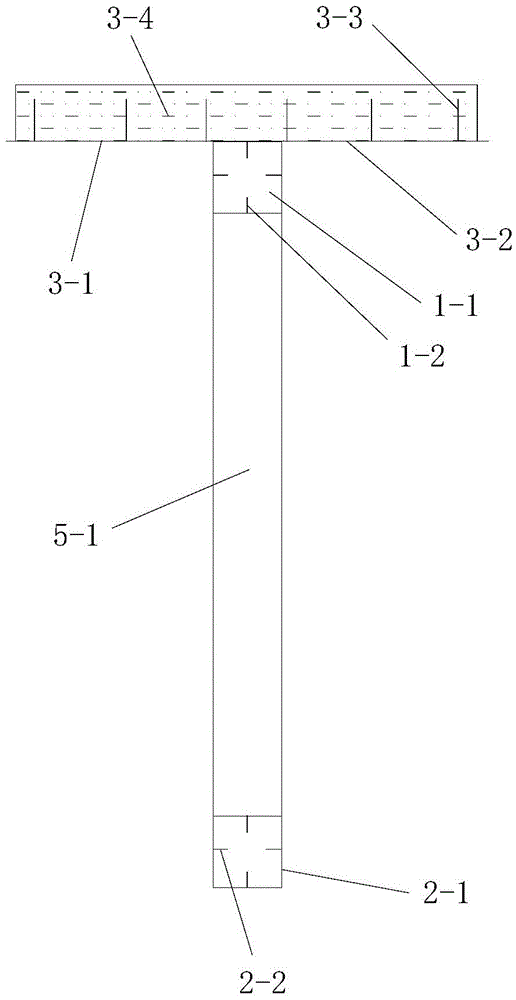

[0038] Such as figure 1 , figure 2 and image 3The shown T-shaped plate truss segment prefabricated unit based on steel truss and composite bridge deck includes a lower load-bearing structure and a composite bridge deck arranged on the lower load-bearing structure, and the composite bridge deck is located on the Directly above the lower load-bearing structure and the two are vertically arranged, the composite bridge deck and the lower load-bearing structure are arranged along the longitudinal bridge direction of the bridge being constructed.

[0039] The lower load-bearing structure is a planar truss composed of an upper chord 1, a lower chord 2 and multiple webs connected between the upper chord 1 and the lower chord 2. The lower chord 2 is located at the front of the upper chord 1 below and the two are arranged in parallel. The upper chord 1 includes a first rectangular steel pipe 1-1, and first longitudinal stiffeners 1-2 are evenly distributed on the four inner walls o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com