Prefabricated laminated anti-collision wall for urban viaduct and construction method thereof

A technology of anti-collision walls and viaducts, which is applied in the direction of erecting/assembling bridges, bridges, and bridge parts, etc., which can solve the problems of poor quality of pouring, low construction efficiency, and long construction period, so as to improve quality and construction efficiency and reduce on-site reinforcement operation and shorten the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

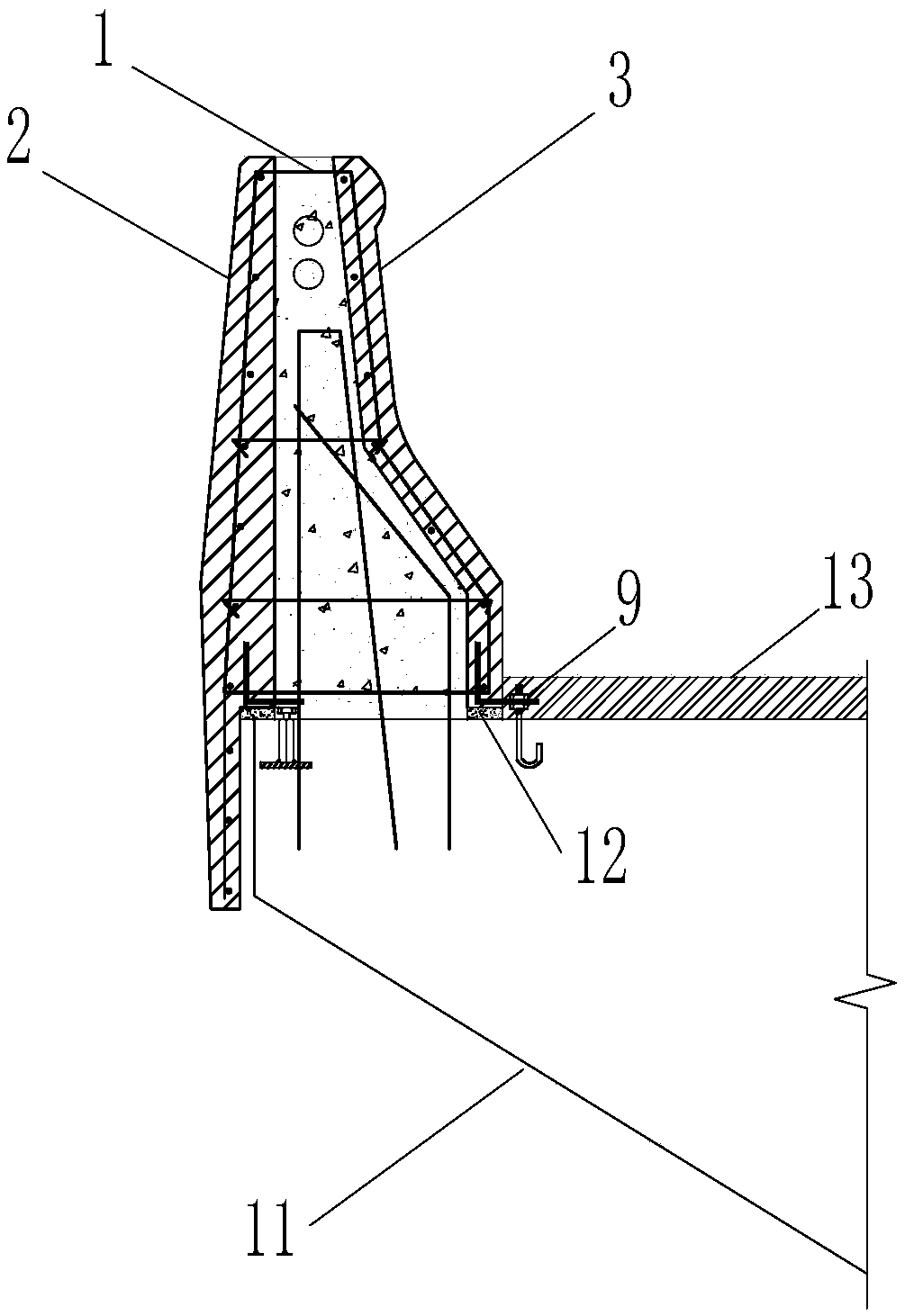

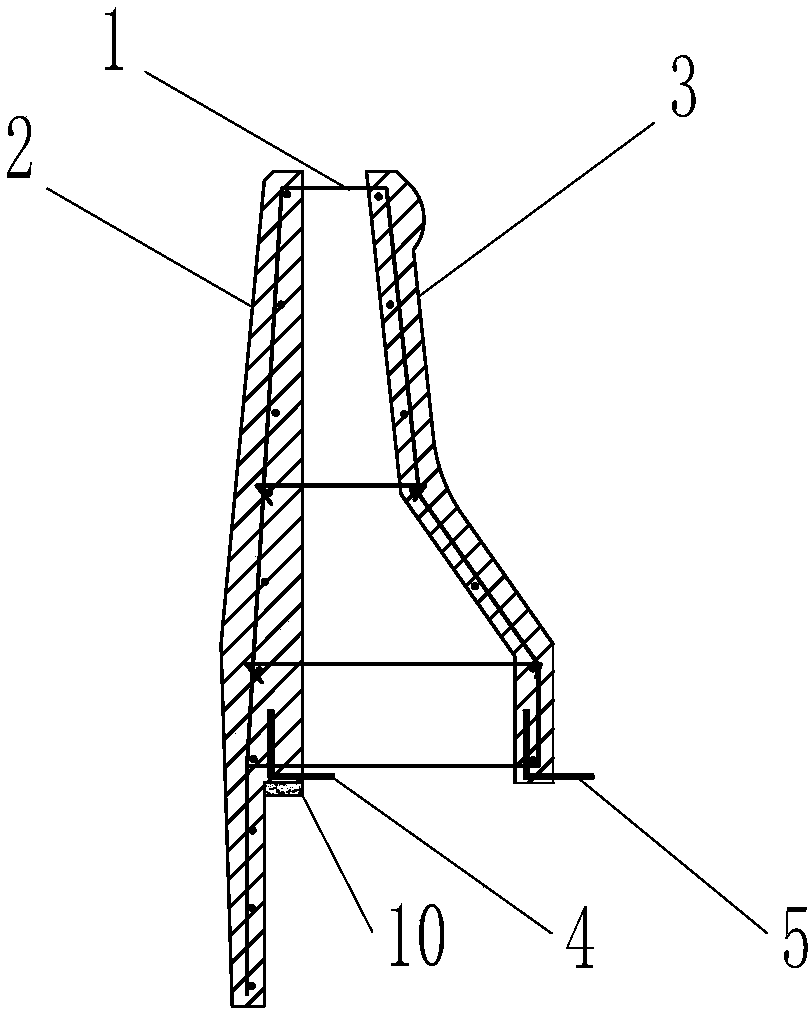

[0032] Such as Figure 1 ~ Figure 4 As shown, the prefabricated laminated anti-collision wall for urban viaducts of the present invention is composed of a cage-shaped steel skeleton 1 connected to an outer precast concrete wall panel 2 and an inner precast concrete wall panel 3, and a cavity is formed in the middle.

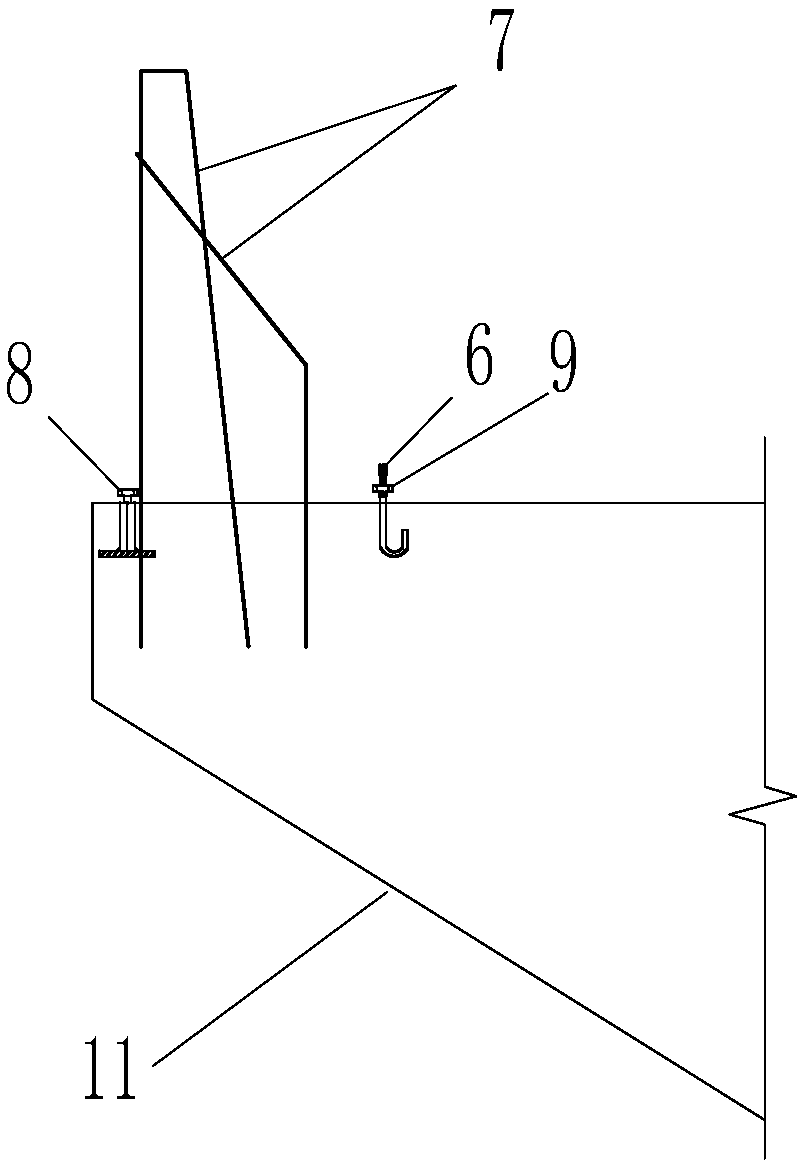

[0033] The intersections of the horizontal bars and the vertical bars of the cage-like reinforcement frame 1 can be welded firmly by spot welding to make the reinforcement cage more stable. It is not only the structural stress reinforcement of the anti-collision wall, but also plays the role of connecting the precast concrete wall panels on both sides of the inside and outside. At the same time, it should also meet the integrity requirements of the components during demoulding, turning, transportation and hoisting. At the construction site, the vertical connecting steel bar 7 is reserved on the surface of the bridge deck 11, and the prefabricated composite anti-c...

Embodiment 2

[0044] Such as Figure 5 As shown, the difference from Example 1 is that the lower part of the outer precast concrete wall panel 2 does not have a lower hanging plate, and the anti-collision wall falls on the top of the bridge deck 11 as a whole, and the gap between the bottom of the outer precast concrete wall panel 2 and the bridge deck 11 is also used. Dry hard cement mortar 12 plugging, all the other are with embodiment 1.

Embodiment 3

[0046] Such as Figure 6 As shown, the difference from Example 1 is that the anti-collision wall is located in the middle of the bridge and acts as a separation strip, and the prefabricated concrete wall panels on both sides of the cage-like steel skeleton 1 (outer precast concrete wall panels 2 and inner precast concrete wall panels 3) at the bottom, L-shaped corbels 5 with holes are pre-embedded, vertical screws 6 are pre-embedded on the top of bridge deck 11, and holes corresponding to pre-embedded vertical screws 6 are opened on the bottom plate of L-shaped corbels 5 with holes. A nut 9 is pre-installed to the screw rod 6 top, and the bottom plate of the L-shaped corbel 5 with holes is inserted into the vertical screw rod 6 during hoisting, and falls on the nut 9 pre-installed below. The gap between the bottom of the precast concrete wall panel and the bridge deck 11 is also sealed with dry hard cement mortar 12, the surface layer 13 of the bridge deck 11 covers the expose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com