Formwork system of prefabricated comprehensive pipe gallery and construction method thereof

A technology that integrates pipe gallery and formwork, which is used in the manufacture of tools, molds, artificial islands, etc. It can solve the creep stress loss of the gallery body behind the long bridge, the long exposure time of the foundation pit of the pipe gallery, and the short maintenance time of the pipe gallery segment. problems, to achieve the effect of improving construction quality, long maintenance time and reducing construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

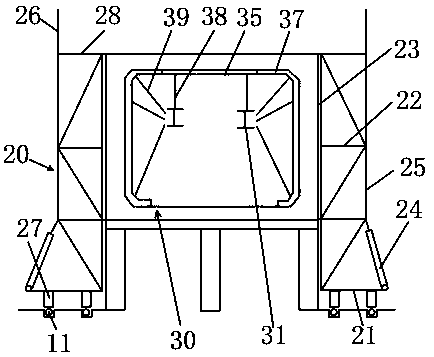

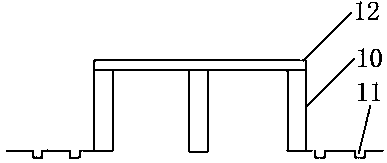

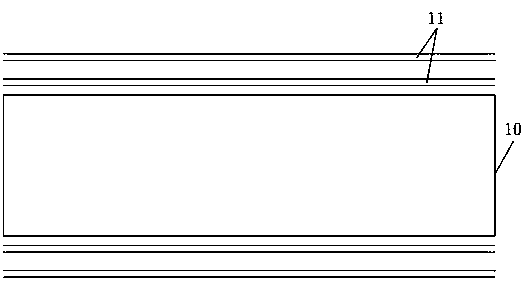

[0034] refer to Figure 1 to Figure 9

[0035] A formwork system for a prefabricated comprehensive pipe gallery, comprising a prefabricated platform 10, the two sides of the prefabricated platform are respectively provided with walking tracks 11 along the longitudinal direction, and the walking tracks are provided with walking tracks 11 that cooperate with it and are used to form a comprehensive pipe gallery. The outer mold hydraulic system 20 of the mold, the upper side of the prefabricated pedestal is provided with a bottom plate 12 made of steel film, the bottom plate is provided with an inner mold hydraulic system 30 that can move in the longitudinal direction and is used to form the inner mold of the integr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com