Patents

Literature

61results about How to "With emission reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electronic invoice generating system for electronic commerce website

InactiveCN102855587AGuarantee authenticityGuaranteed legalityPayment architectureBilling/invoicingDigital signatureInvoice

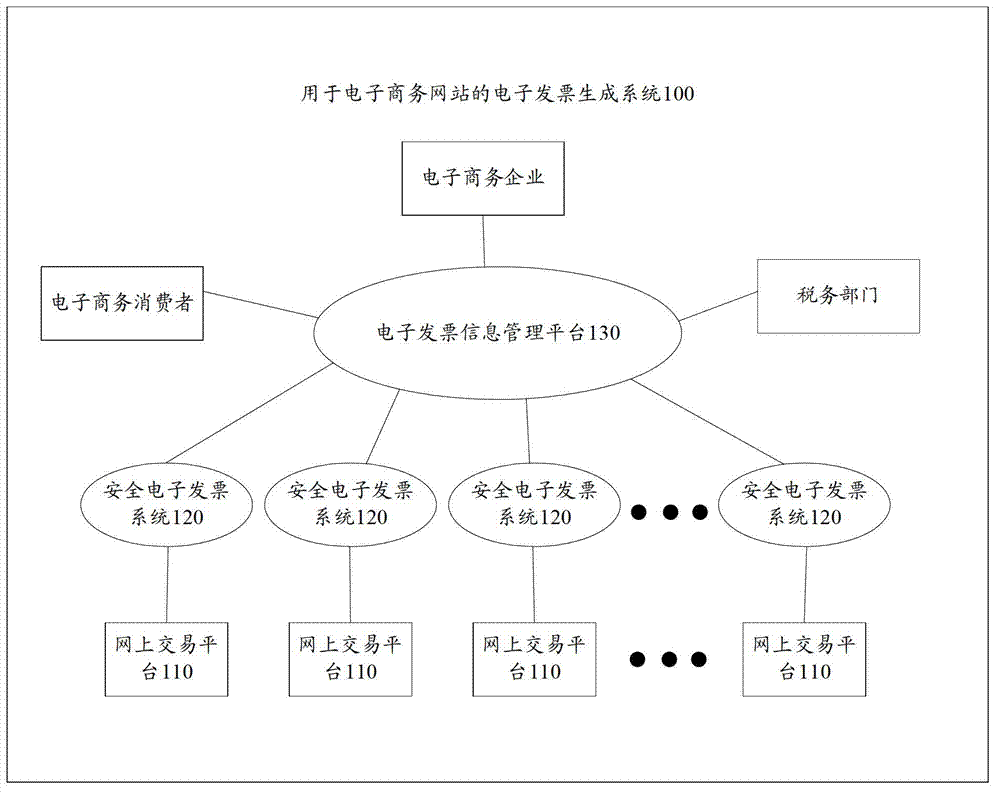

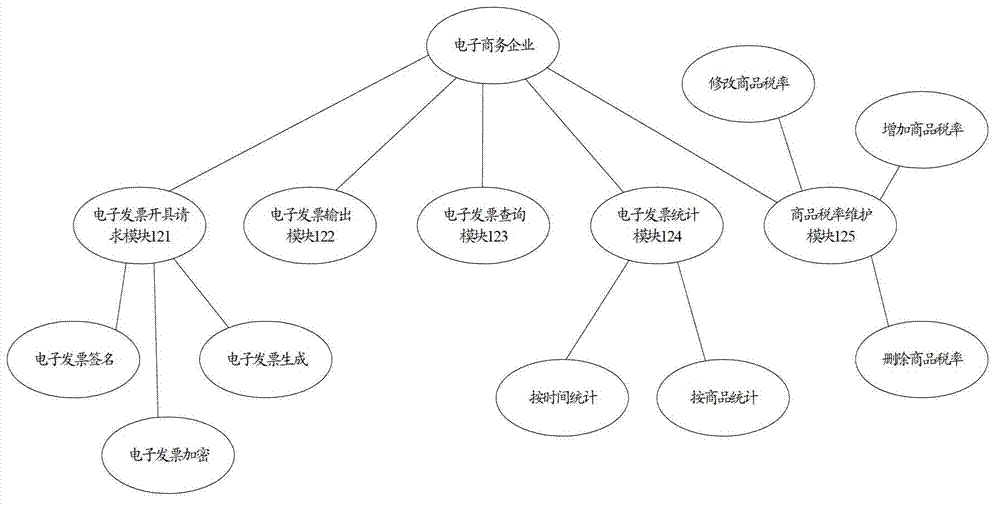

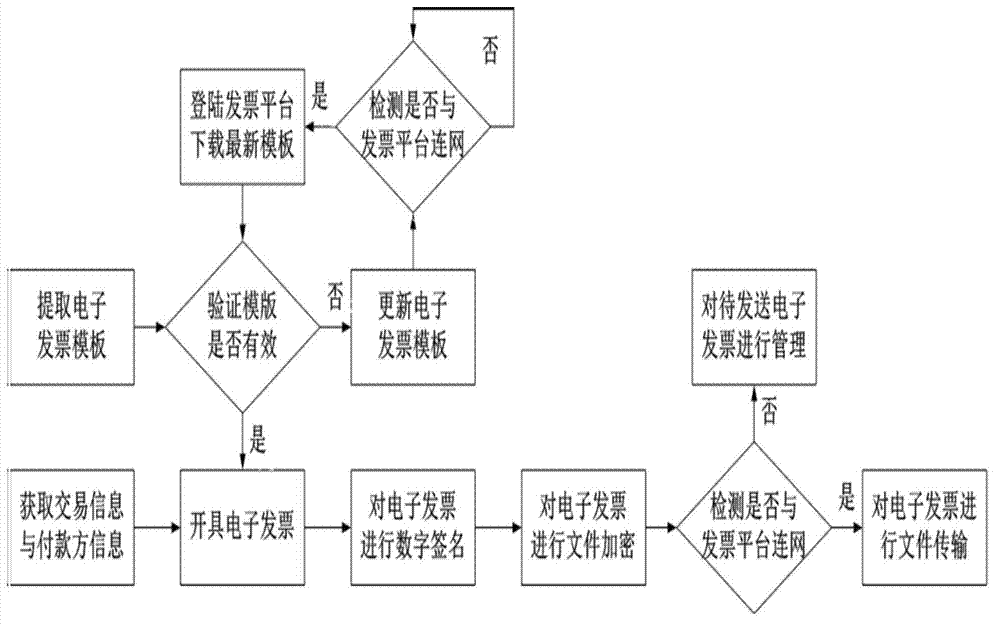

The invention provides an electronic invoice generating system for an electronic commerce website. The electronic invoice generating system comprises an online transaction platform, a safety electronic invoice system and an electronic invoice information management platform, wherein the safety electronic invoice system is pre-stored with a goods and service code table, an electronic invoice template and digital certificates of electronic commerce enterprises and is used for receiving the payer information and transaction information from the online transaction platform, adding the payer information and transaction information into the electronic invoice template to generate a corresponding electronic invoice according to the goods and service code table and performing digital signature on the electronic invoice through the digital certificates of electronic commerce enterprises; and the electronic invoice information management platform comprises an access interface and is used for acquiring the electronic invoice from the safety electronic invoice system so as to put on records of the electronic invoice and providing the record information to a preset user through the access interface. According to the embodiment, the problems of fake invoice, no invoice and virtual invoice are effectively solved, the tax erosion is reduced, the whole process is paper-free, and the system has the advantages of high speed and energy conservation.

Owner:TSINGHUA UNIV

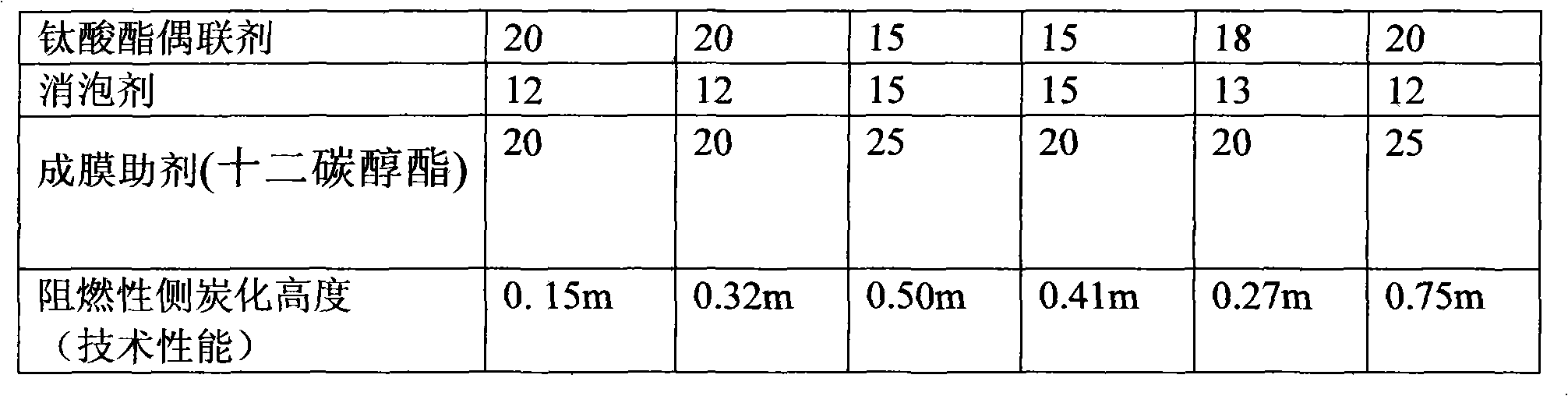

High weather resistance environment-friendly cable fire-refractory coating and preparation process thereof

InactiveCN101597454AGood film forming effectGood water resistanceFireproof paintsSolventAmmonium polyphosphate

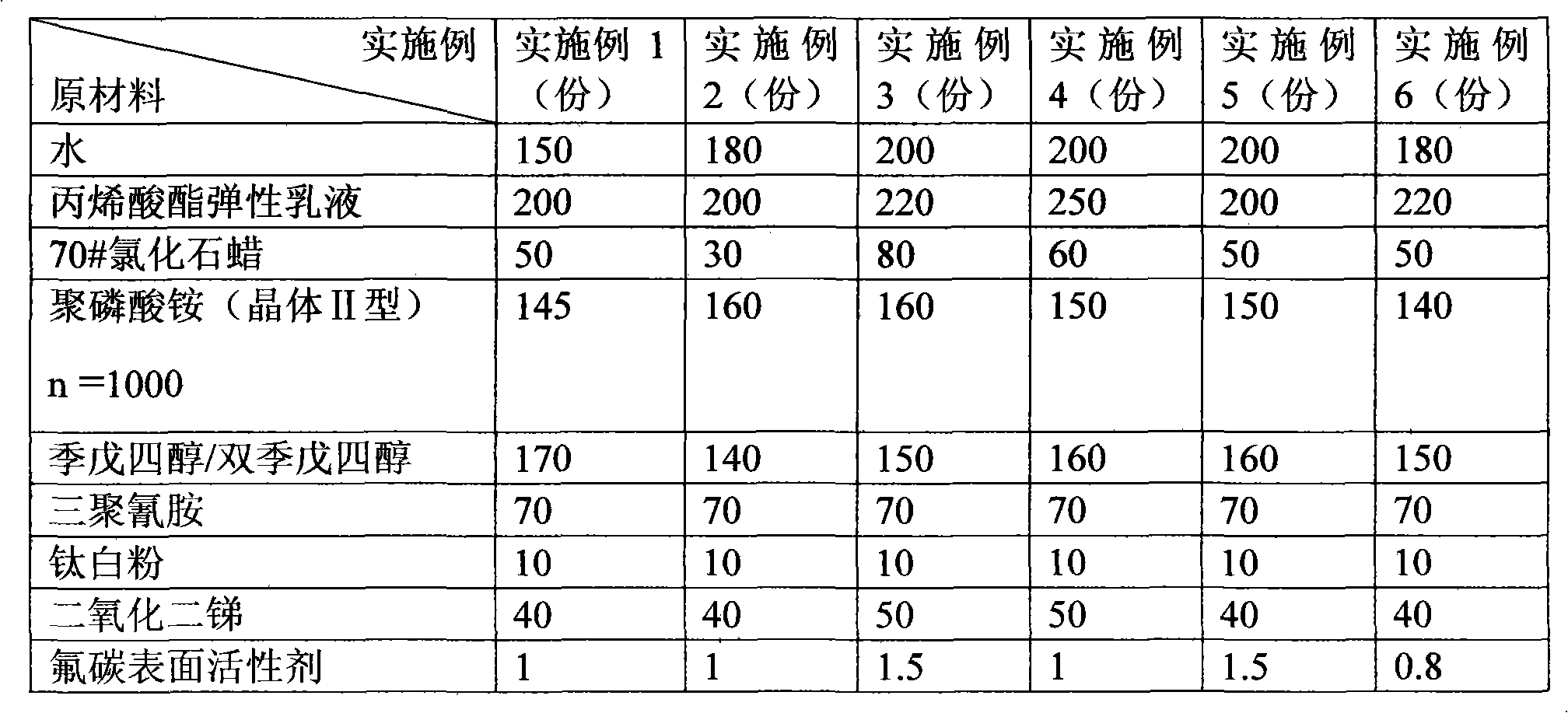

The invention discloses high weather resistance environment-friendly cable fire-refractory coating and a preparation process thereof, belonging to the technical field of coating. The process adopts a base material, namely acrylic ester elastic emulsion, as a main film-forming substance, dopes high polymerization degree ammonium polyphosphate into the base material, has good film-forming effect and water resistance. The method particularly selects Number 70 chlorcosane and diantimony trioxide as synergistic flame-retardant to greatly improve the fire retardant performance, has low proportion of pigment and the base material, optimizes compatibility of a fire retardant system; the coating has weather resistance and has oil resistance for selecting fluorocarbon surfactant. The process improves water resistance and weather resistance of the coating, and adopts titanate coupling agent to improve the combining firmness of the pigment, the base material and cable base materials, and the weather resistance of the coating is further improved. Green and environment-friendly water is used as solvent to reduce cost, and as the solvent is removed in preparation or construction, the coating does not pollute the environment and not hurt the health of operators.

Owner:ZHEJIANG TIANHUA FIREPROOF MATERIAL

Blueing treatment process for semi-processed electrical steel rotor or stator

InactiveCN103060822AReduce iron lossIncrease magnetic inductionSolid state diffusion coatingElectrical steelHigh energy

The invention relates to a blueing treatment process for a semi-processed electrical steel rotor or stator, which is mainly used for solving the technical problems of high energy consumption, great pollution, high cost and the like of the prior art. The key points of the technical scheme are as follows: semi-processed electric steel is adopted for preparing a rotor or stator punched sheet, then oil firing, decarbonization, distressing and annealing are performed on the rotor or stator punched sheet, and blueing treatment is finally performed to prepare a finished product. The blueing treatment process is mainly used in production processes of rotor or stator iron cores of motors.

Owner:HUNAN XUEBAO ELECTRIC APPLIANCE

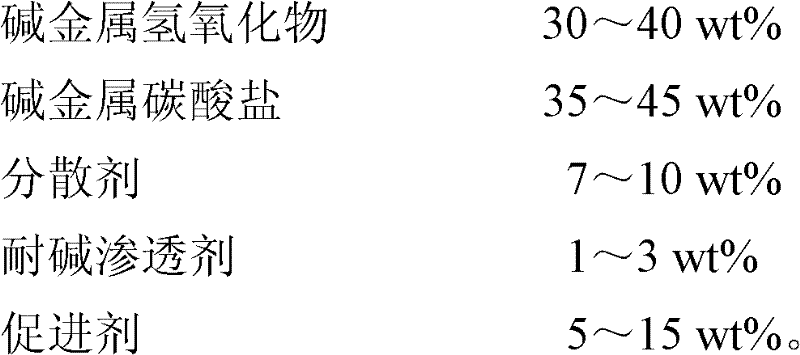

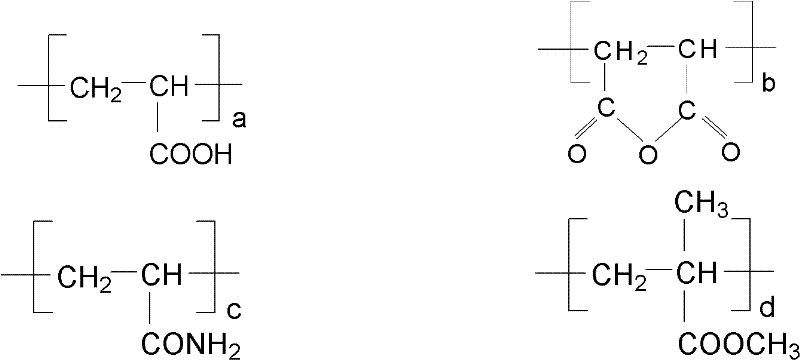

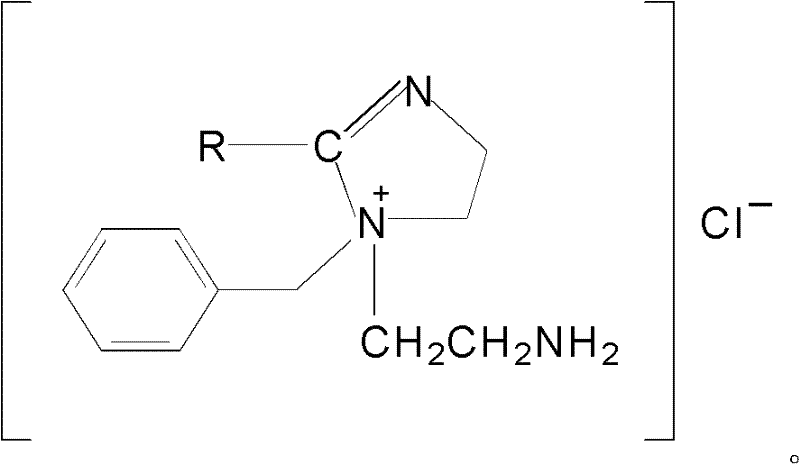

Color fixing substitution alkali for low-salt dyeing by using reactive dye pad steaming process

The invention relates to color fixing substitution alkali for low-salt dyeing by using a reactive dye pad steaming process, and the color fixing substitution alkali can be applied to low-salt color-fixing treatment on a cotton fabric dyed with a reactive dye. The color fixing substitution alkali is an organic / inorganic composite buffer system consisting of alkali metal hydroxide, alkali carbonate, a dispersing agent, an alkali-resistant penetrating agent and an accelerating agent. The traditional color-fixing alkali agent for the reactive dye is replaced and low-salt dyeing is realized under the condition of not changing the traditional technological equipment and flow. The color-fixing substitution alkali agent has the characteristics of low consumption, favorable stability, convenience for operation, and the like, meanwhile, is beneficial to reduction of production cost and environment pollution, has little influence on the equipment and meets the requirements on energy saving, emission reduction and efficiency increase.

Owner:FUJIAN QINGYUAN TECH

Method for producing sponge iron by smelting refractory iron ore (slag) with reduction rotary kiln

InactiveCN102268502ASimple methodReduce manufacturing costFluidised-bed furnacesEnvironmental resistanceRotary kiln

The invention provides a method that various refractory iron ores (slag), reduction coal and lime are placed in a rotary kiln for reduction, so as to prepare industrial spongy iron (TFe>=70-93%, metallization rate>=90-95%) and a baking-free brick raw material, and recover nonferrous metals. A process flow comprises steps of raw material preparation, reduction in the rotary kiln, cooling in a cooling kiln, concentration processing, and briquetting and balling. A granularity of the ore (slag) is no more than 20mm; a coal granularity is less than 15mm; and a lime granularity is no more than 0-2mm. A primary air and a secondary air are employed to combust the coal. A reduction roasting time is 3-10h; a combustion temperature in the kiln is controlled at 1000-1200 DEG C; and water and wind are used for cooling in the cooling kiln. The materials are cooled to a normal temperature under 40 DEG C, and treated with the concentration processing, briquetting and balling, so as to prepare the industrial spongy iron and recover the nonferrous metals. The method of the invention has advantages of simpleness, energy saving, emission reduction, waste reutilization, low production costs, good product quality, green and environmental protection, large market and strong competitiveness; besides the method has good economic benefits as well as good social benefits, and solves a domestic technical problem of refractory iron ore and an environmental protection problem of changing waste into valuables.

Owner:李维成 +2

Hot water supply system device with solar energy metal honeycomb collection, instantaneous water heating of superconducting pipe

InactiveCN101672493AReduce weightSimple structureSolar heat devicesStorage heatersCollector deviceEngineering

The invention relates to a hot water supply system device with solar energy metal honeycomb collection, instantaneous water heating of a superconducting pipe, which consists of a solar energy metal high-efficiency honeycomb heat collector matrix and a straw instantaneous water heater and a superconducting warmer which are heated by a superconducting heat pipe. The hot water supply system device adopts the technology of series heat collection and heating, namely output water in a small section of outputted water pipe is only heated. Compared with the prior boiler, the technology saves over 60 percent of fuels. The hot water supply system device adopts a series heating mode of 'a honeycomb metal heat collector' and 'an instantaneous water heater of the superconducting heat pipe', realizes quick water temperature rise and instantaneous heating, eliminates the conventional boiler system, does not use non-renewable fuels, can save over 80 percent of electricity, is particularly suitable forno-electric areas, and saves electricity or does not consume no electricity. The hot water supply system device is characterized in that: the efficiency of the heat collection and heat conduction ofthe honeycomb metal heat collector is higher than that of a glass pipe; and the honeycomb metal heat collector has light weight, simple structure, uniform temperature distribution, large quantity of heat transfer, long distance of the heat transfer, electricity conservation, reliability and low cost, is convenient for popularization and application, has the social and economic benefits of energy conservation and emission reduction, is the inevitable trend of current and future development, and has great significance.

Owner:陈绍勇 +1

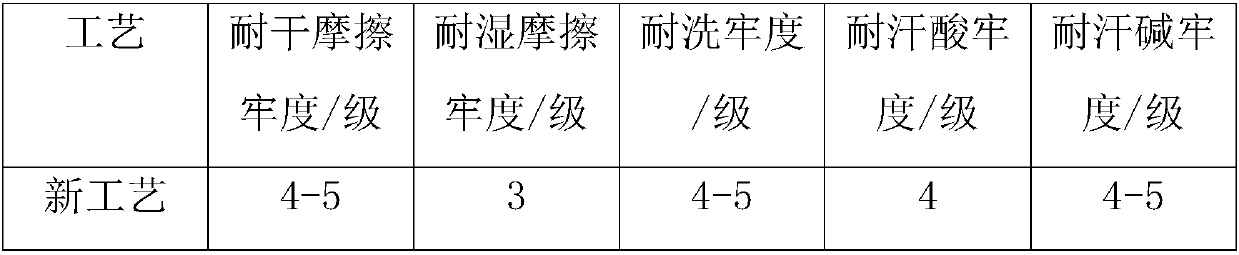

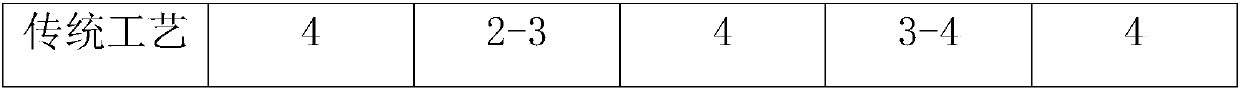

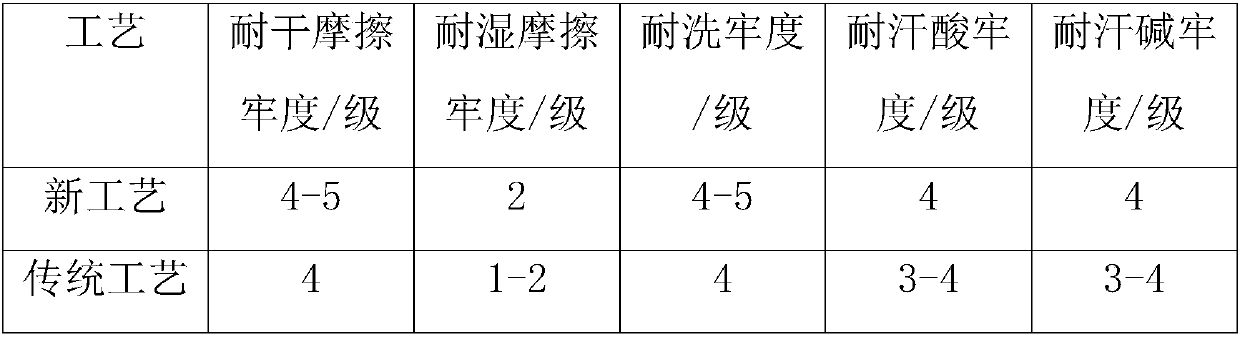

Process method for improving woven dark cloth wet rubbing fastness

ActiveCN107916518AImprove wet rubbing fastnessTightly bondedTextile storage in superimposed formLiquid/gas/vapor open-width material treatmentSurface finishProduct inspection

The invention discloses a process method, and particularly relates to a process method for improving woven dark cloth wet rubbing fastness. The process method includes the steps: (1) cloth distribution; singeing, cooling reaction and desizing; scouring and bleaching; mercerizing; pad dyeing or jig dyeing; wet rubbing fastness improver and auxiliary selection and preparation; wet rubbing fastness improver finishing; over-soft sizing; pre-shrinking; finished product inspection. According to the process method for improving the woven dark cloth wet rubbing fastness, production processes of all procedures are controlled, the capillary effect of a fabric is effectively improved, the surface finish degree of the fabric is improved, friction resistance is reduced, surface dyeing is decreased by strengthening soaping and washing after dyeing, wet rubbing fastness improvers of waterborne polyurethane complexes (Jiangxi Luxi County Xianghua Fine Chemical Co., Ltd., similarly hereinafter) are added after dyeing, under the assistant effects of assistant stabilizers 203 and cracking agents 109, the process method effectively solves the problem that oil floating points are generated in continuous production for 2000 meters or more when single wet rubbing fastness improvers are added in the past, the wet rubbing fastness of dark dyed cloth is improved by one level or more, corresponding washing fastness is improved, pH (potential of hydrogen) values meet requirements, continuous production and product quality are ensured, and a cloth surface has a certain color-deepening effect and softening effect, so that customer satisfaction is achieved.

Owner:佛山市顺德金纺集团有限公司

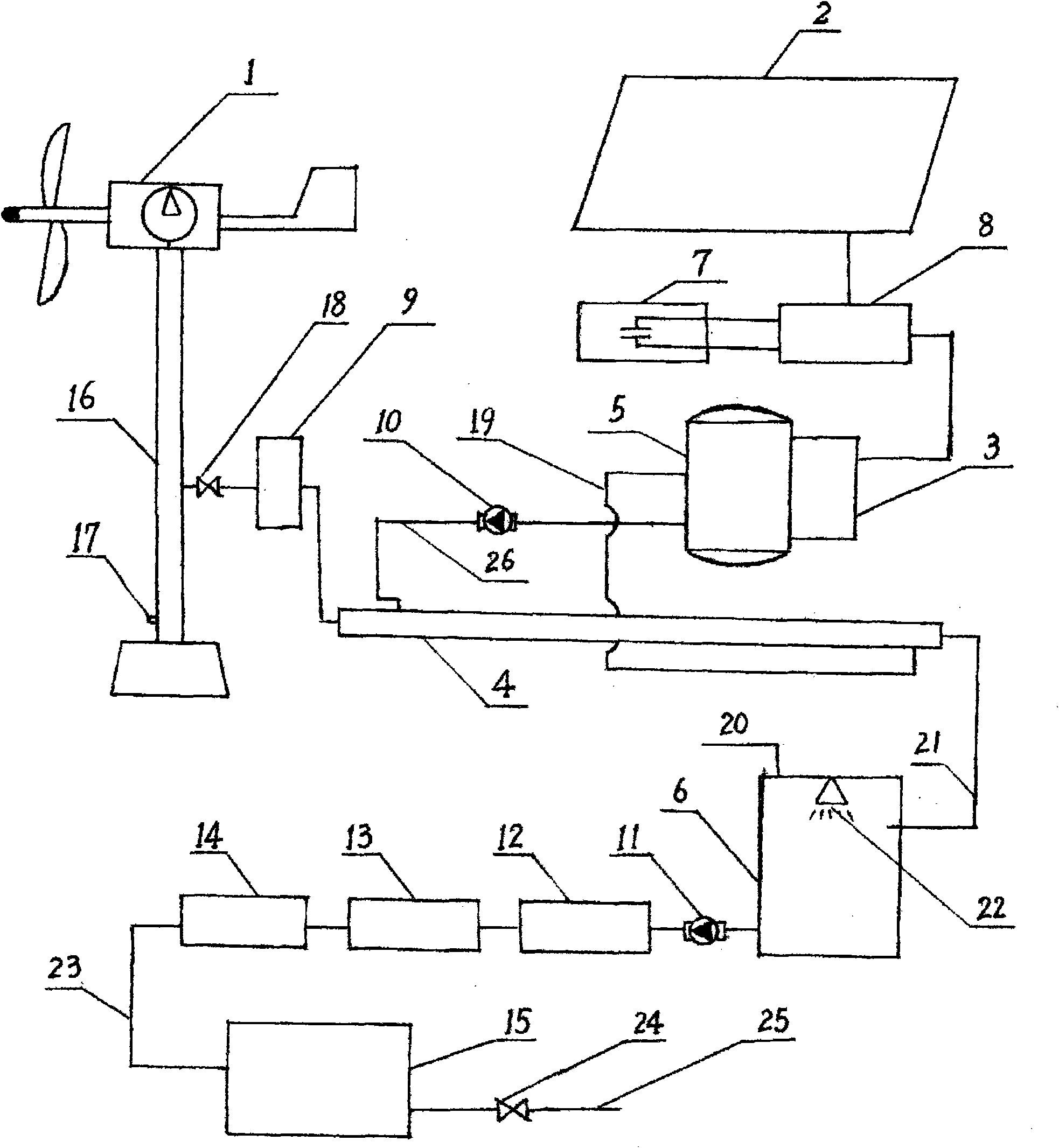

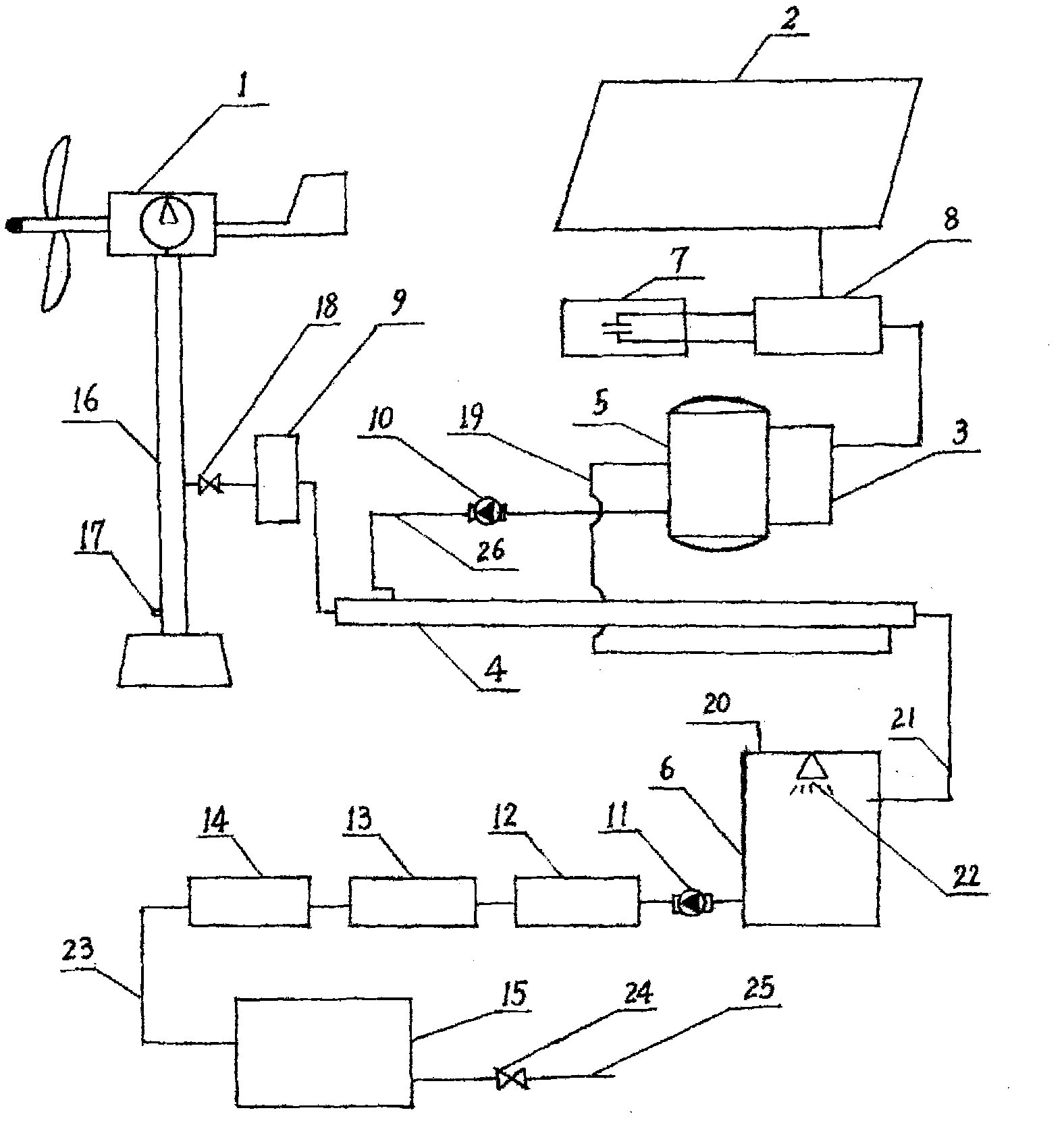

Drinking water produced by air through full natural energy utilization and replacement method thereof

InactiveCN102031804AClean water up to standardNo pollution in the processGeneral water supply conservationDrinking water installationWater storage tankRenewable resource

The invention discloses drinking water produced by air through full natural energy utilization and a replacement method thereof. The replacement method is characterized by comprising the following steps of: generating compressed air by using a wind air compressor; eliminating dust and particles by using an air filter; providing electric power by using solar energy; generating low-temperature circulating water by using a refrigerating compressor for an air condensation pipe; separating water from the compressed air to form dried air and crystal water; converging the crystal water and performing ultraviolet sterilization by using a sterilization water storage tank; exhausting the dried air from an exhaust pipe on the top of the sterilization water storage tank; and conveying the crystal water in the water storage tank to a multi-media, active carbon and precision membrane tertiary filter by using an electric pump to generate purified water which can be drunk directly. By the method, renewable resources such as solar energy and wind energy are fully utilized, no conventional energy is consumed; and a new way of developing and utilizing water resource is provided.

Owner:刘方旭

Low temperature dehydration process of thick oil

ActiveCN102127465AHas the effect of energy saving and emission reductionSave energyDewatering/demulsification with chemical meansDemulsifierChemical reaction

The invention discloses a low temperature dehydration process of thick oil. Crude thick oil is introduced into a settling tank, a demulsifier is added, and ammonium chloride and sodium nitrite of which the total weight is three thousandths based on the crude oil are added simultaneously; the ammonium chloride and the sodium nitrite are subjected to chemical reaction in the settling tank to generate nitrogen which can allow the thick oil to be spongy so as to be easy to dehydrate, and heat which can allow the thick oil to be thermostatic simultaneously; the spongy thick oil is dehydrated and separated in the settling tank; and the dehydrated crude oil which meets the standard is output from the settling tank, heated and externally output. The low temperature dehydration process has the effects of energy saving and emission reduction.

Owner:LIAONING HUAFU PETROLEUM HIGH TECH

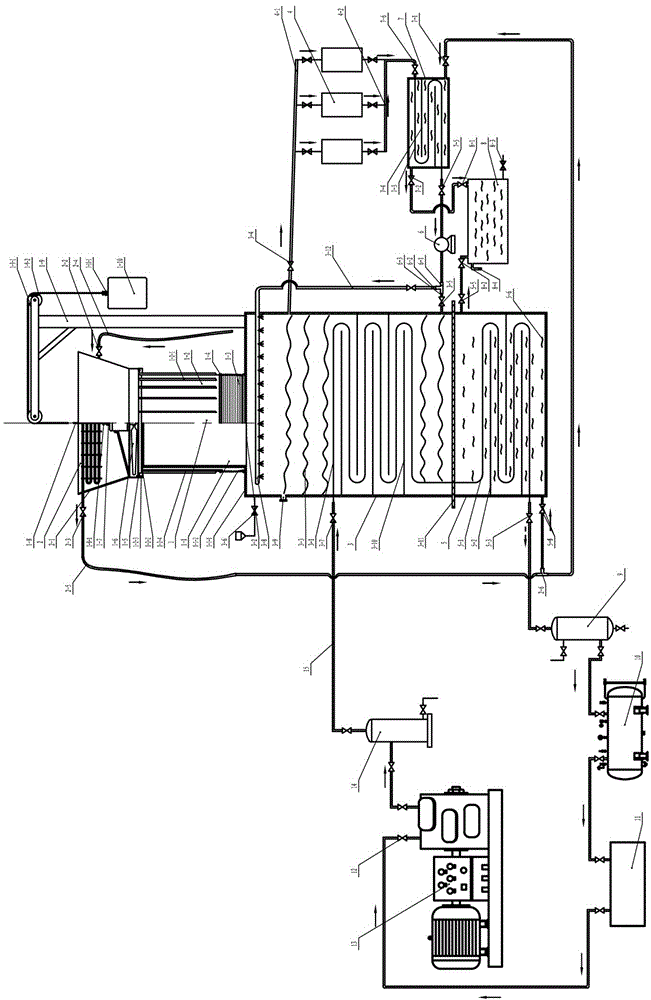

Zero water consumption stainless energy-saving combined condenser

ActiveCN104567120AExtend working lifeNormal pressure work without dangerEvaporators/condensersSteam/vapor condensersHeat sinkRefrigerant

A non-water consuming, scaleless, energy-saving combined condenser for reducing temperature of a refrigerant in a refrigeration system comprises a float vapor condensing respirator (1), an air serial pipe assembly with fins and with compensated temperature reduction using tap water (2), an atmospheric-pressure heat-exchanger box (3), a spray water main pipe and valve (3-12), a heat dissipation piece (4), a box with compensated temperature reduction using tap water for a refrigerant (5), a refrigerant heat-exchange serial lower pipe (5-1), an automated cyclic water pump (6), a box with compensated temperature reduction using tap water for heat exchange water (7), and a warm water tank (8). The advantages of the condenser lie in that: In a process of reducing the temperature of a refrigerant in a refrigeration system, no water is consumed and no scale is generated, and warm water at about 45°C may further be obtained; the work is done at an atmospheric pressure and no danger is involved; air is isolated and an erosive effect of oxygen is reduced, the service life is extended; therefore, energy-saving, consumption reducing, and emission reducing effects are provided.

Owner:山东省金锐制冷设备有限公司

Magnesium-calcium dry material and preparation method thereof

The invention relates to a magnesium-calcium dry material, which comprises the following raw materials in parts by weight: 35-50 parts of active magnesium oxide, 25-35 parts of waste magnesium-calciumbrick aggregate, 3-12 parts of granular magnesium oxide, 10-15 parts of a compound bonding agent, 5-10 parts of an additive, 3-5 parts of zirconate and 0.3-0.5 parts of sol. The product and raw materials in the invention are safe and non-toxic, have no adverse effect on users and the environment, has high density, high heat conductivity, excellent thermal stability, thermal shock resistance, corrosion resistance, normal temperature mechanical property and high temperature mechanical property, and has an extremely wide application prospect in the field of metallurgical steel-making; and as modified resin is used as a bonding agent, no choking smoke or toxic and harmful gas is generated in a decomposition process. The magnesium-calcium dry material provided by the invention has the advantages of energy conservation, emission reduction, environmental protection, low cost and the like; meanwhile, the product solves the problems of poor normal temperature strength and poor high-temperatureslag resistance of dry materials.

Owner:浙江攀盛冶金材料有限公司

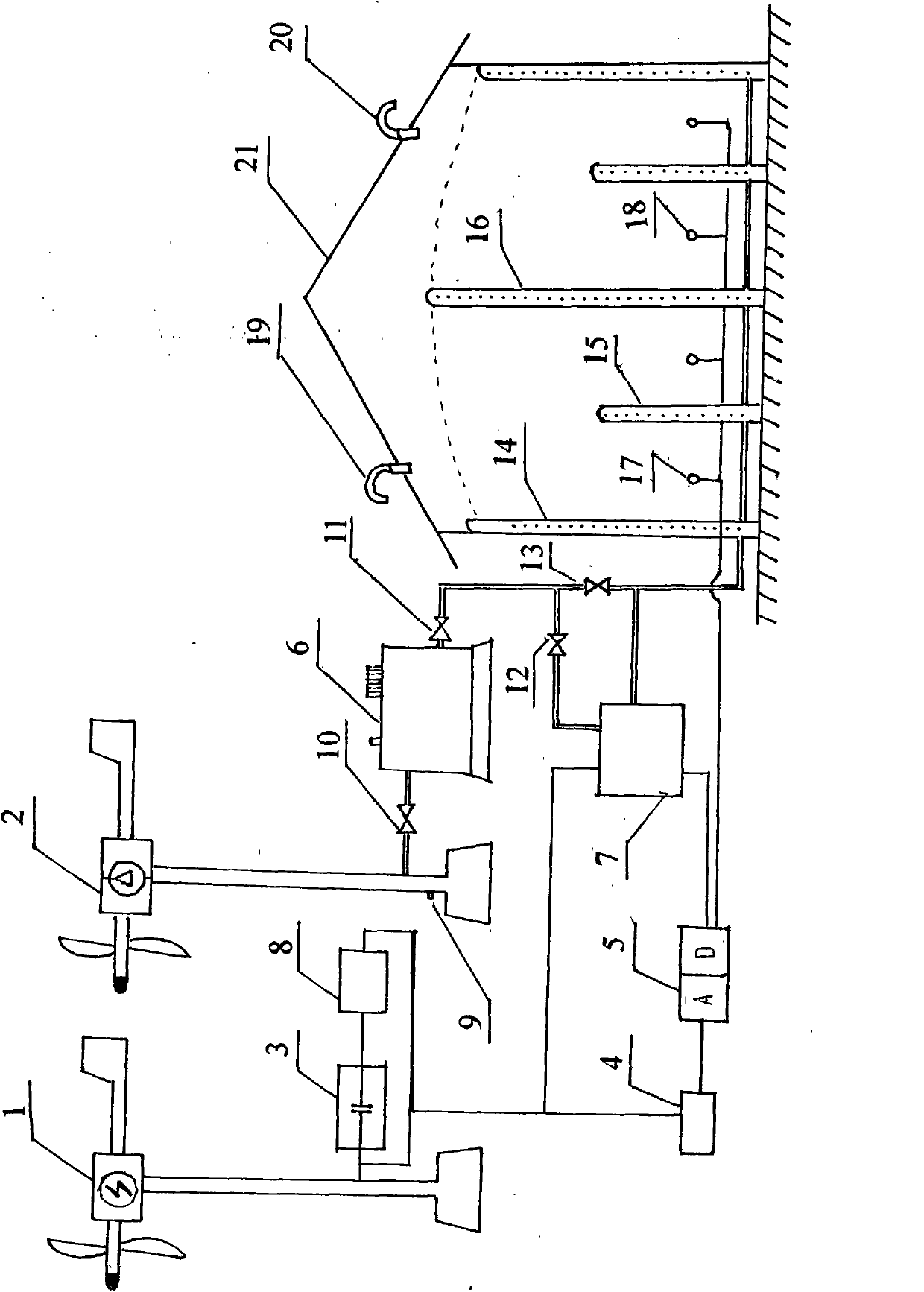

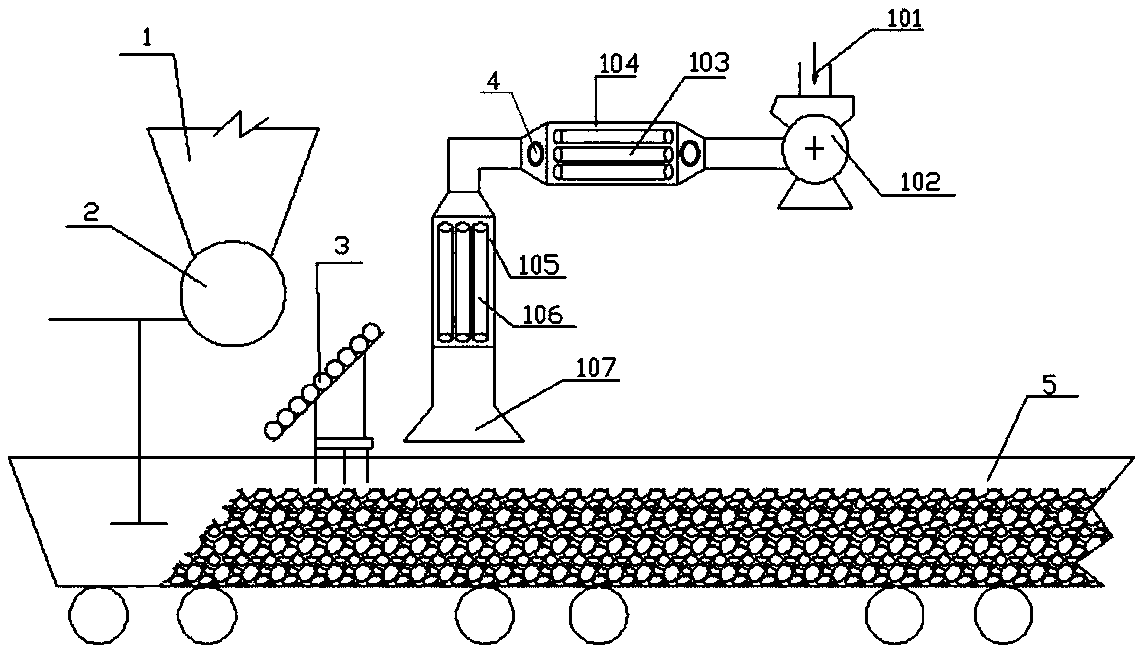

System device for processing granular feed by utilizing wind energy

The invention relates to a device for processing granular feed by utilizing wind energy. The device consists of a wind air compressor, a GBM gas (pneumatic) supercharger, an HK type pneumatic multi-purpose pneumatic crushing machine, an XC pneumatic straw crushing machine, a conical double-helix pneumatic mixing machine and a pneumatic granular feed machine, wherein the wind air compressor is used for producing a compressed gas source; a GBM gas supercharger is used for supercharging; the supercharged high-pressure gas source supercharged is transmitted to the HK type pneumatic multi-purpose pneumatic crushing machine and the XC pneumatic straw crushing machine to serve as power for crushing raw materials; the crushed raw materials are placed into the conical double-helix pneumatic mixing machine to mix in a ratio; and the mixed materials are placed into the pneumatic granular feed machine to be extruded into granular feed. The device uses the wind energy high-pressure gas source as power, does not have consumption of electric energy and the like during production, has small carbon discharge quantity, does not have pollution, and has the characteristics of safety, energy conservation, emission reduction and environment friendliness.

Owner:刘方旭

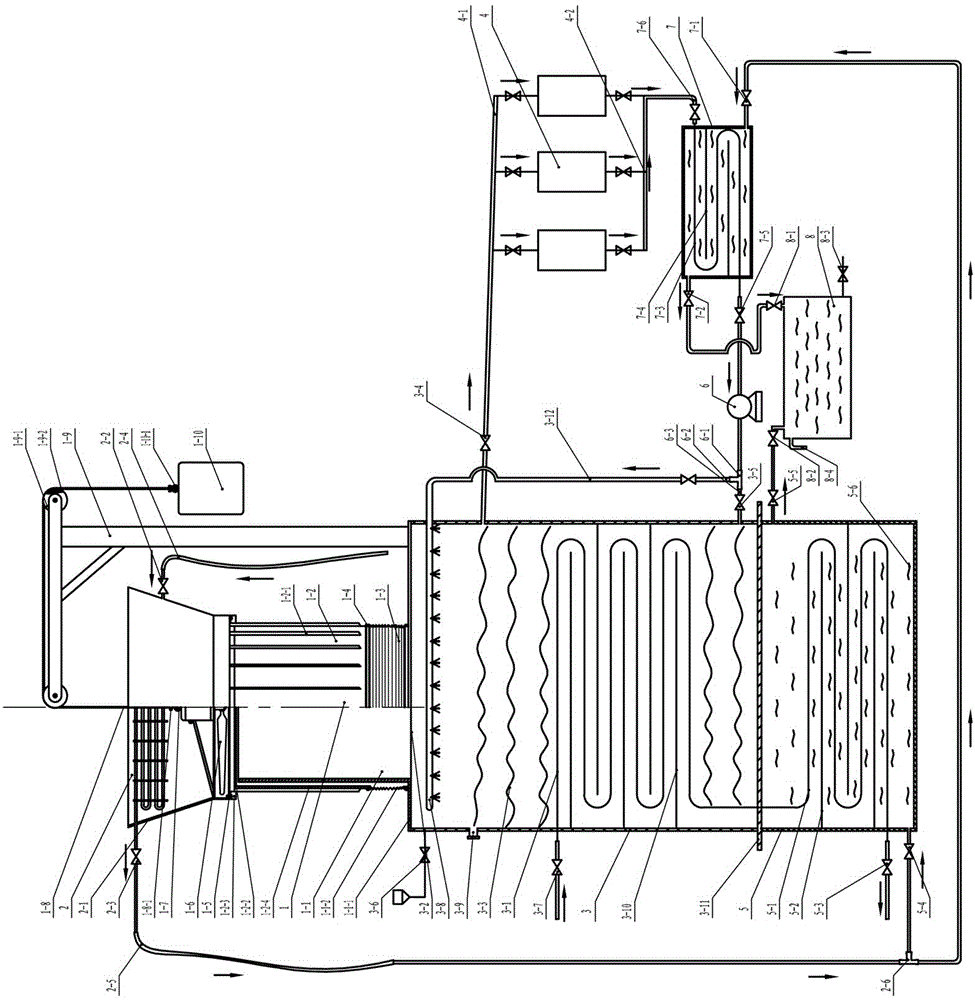

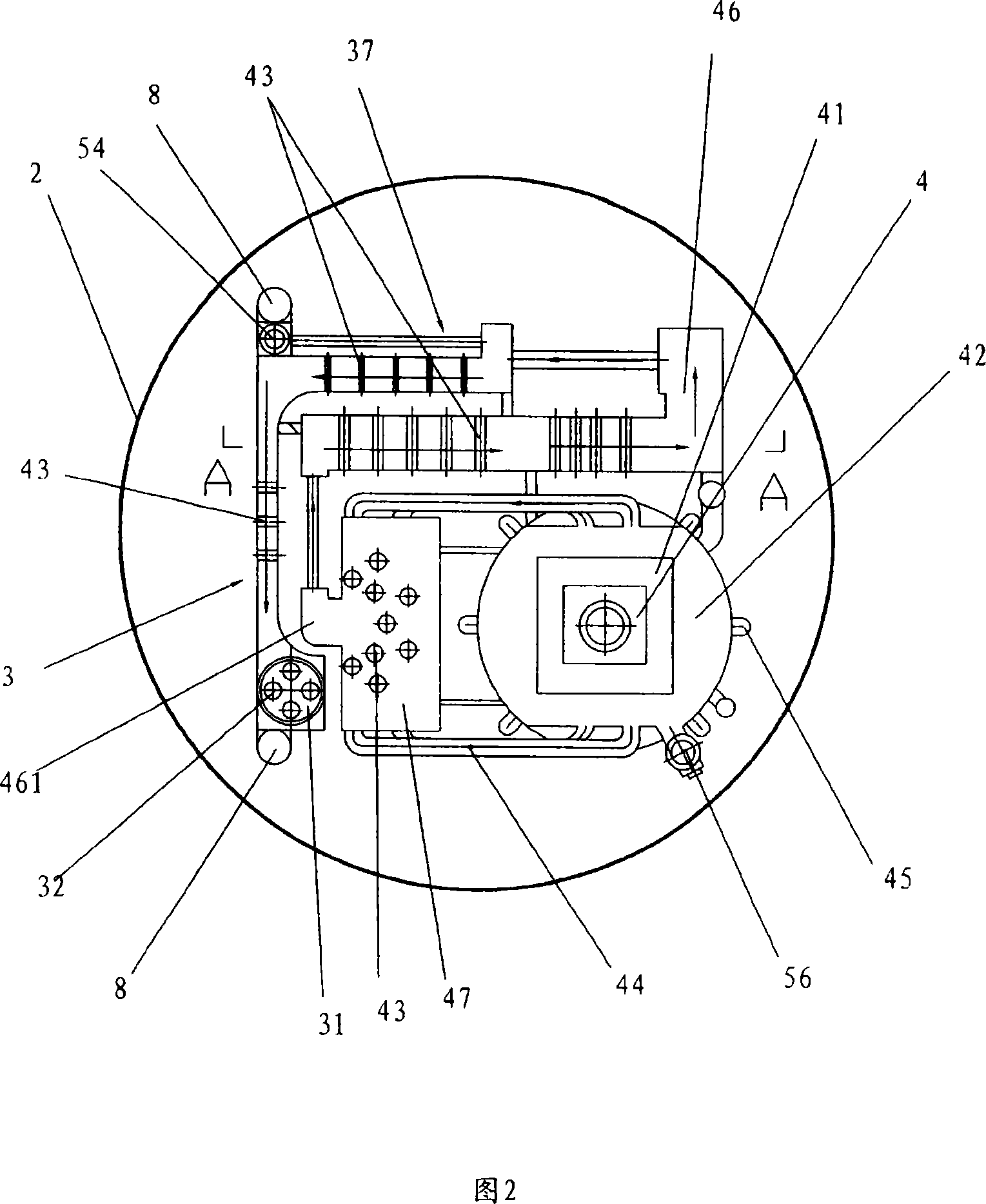

Water heat exchange system and method applying alternately solar, fuel oil and gas thermo power

InactiveCN101201224AFull heat exchangeImprove efficiencySolar heat devicesStationary conduit assembliesGas burnerFuel oil

The invention relates to a water heat exchange system and method applied to the exchange of solar energy and fuel, air heat energy. The system comprises a solar heat absorbing device, a fuel / gas burner, a burning chamber, a water heat exchanger and a water tank; the water heat exchanger and the burning chamber are arranged in the water tank; a water-proof tank is arranged on and communicated with the burning chamber; the burner is installed in the waterproof tank; the water heat exchanger is serially connected between the solar heat absorbing device and the burning chamber. The system pre-heats the water which enters into the water tank by setting a solar waste heat device at the solar energy outlet, so as to make full use of the solar energy; dispose the waste gas by a filter connected to a smoke pipe of a flue gas waste heat exchanger, so as to reduce pollution of the waste gas produced by burning of the burner to the air; and the has the advantages of environmental protection and emission reduction. The air flows from bottom to top in flow channels separated by a plurality of air partition boards which are deranged in the box solar heat absorbing device, so that the solar heat energy can be fully absorbed.

Owner:李明强

Quadric catalysis method of enamel wire drying oven

InactiveCN101357301AReduce contentAvoid pollutionDispersed particle separationIncinerator apparatusWater vaporHazardous substance

The invention discloses a secondary catalysis method of an enameled wire oven. The method comprises the following steps: a secondary catalytic combustion device is additionally arranged in an exhaust gas discharge channel of the enameled wire oven, secondary catalytic combustion is carried out on the exhaust gas for which primary catalytic combustion is carried out before being discharged by an exhaust fan by virtue of the secondary catalytic combustion device, therefore, the residual organic solvent and diluent in the exhaust gas after the primary catalytic combustion are completely oxidized into carbon dioxide and water vapor after the secondary catalytic combustion. The secondary catalysis method can completely decompose the organic solvent and the diluent with benzene volatilized by the enameled wire oven after baking varnish, thus minimizing the contents of hazardous substances discharged into the atmosphere, and effectively preventing pollution and damage to the atmospheric environment; the secondary catalysis method has significant social and economic benefits in solving pollution problems of enameled wire production enterprises, energy saving and environmental protection.

Owner:浙江郎立电工器材有限公司

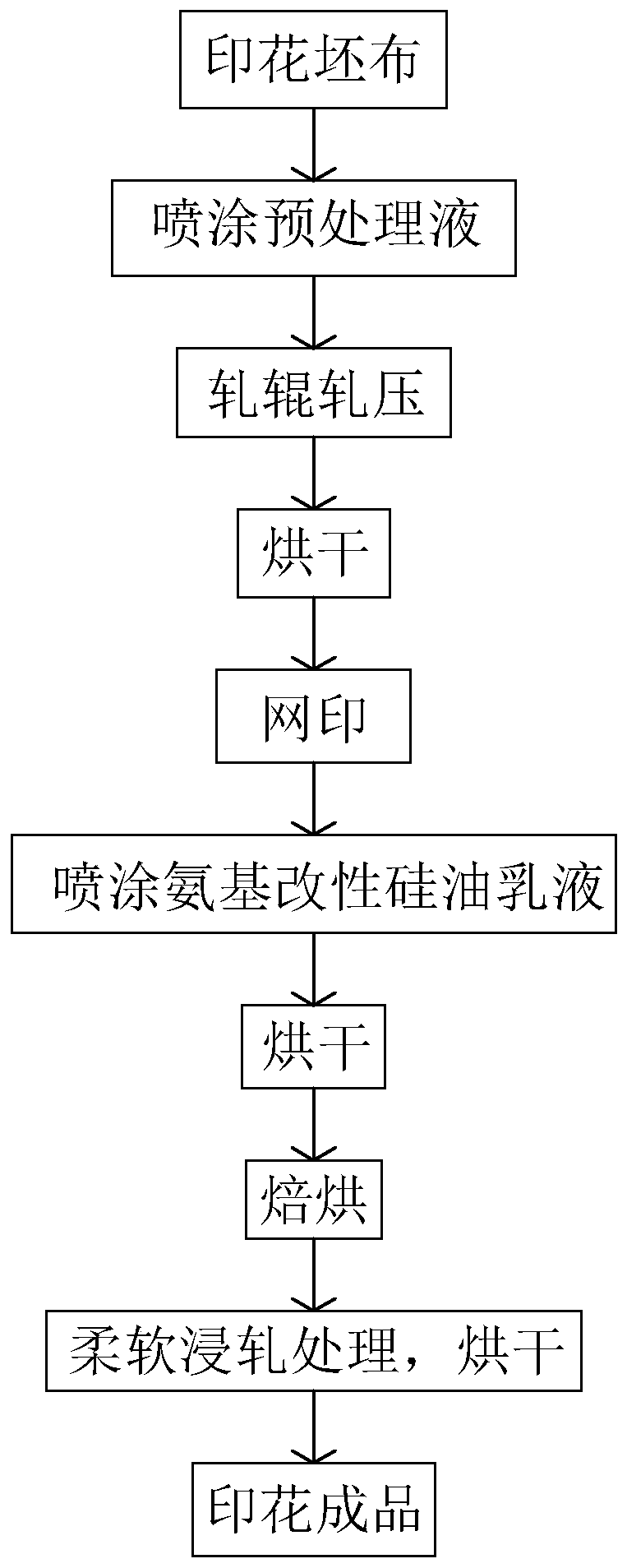

Ageing-free washing-free printing technique of diverse dyes

ActiveCN110438822AImprove wrinkle resistanceOmit steamingGrip property fibresDyeing processDisperse dyeScreen printing

The invention discloses an ageing-free washing-free printing technique of diverse dyes and relates to the technical field of printing of textile products. The ageing-free washing-free printing technique of diverse dyes according to the technical scheme is characterized by comprising the steps of pretreating, to be specific, spraying a pre-prepared pretreatment liquid to the surface of a printing grey cloth prior to drying; printing, to be specific, printing the printing grey cloth with ageing-free washing-free printing color paste with a circular screen printer or a flat screen printer or by amanual printing technique, wherein the ageing-free washing-free printing color paste, per 160 parts, comprises, by weight, 5-8 parts of diverse dyes, 60-70 parts of thickeners, 1-2 parts of dyeing accelerants, 0.1-0.5 part of pH regulators, and the balance of deionized water; drying, to be specific, drying at 100-120 DEG C for 2-4 min before discharging from the screen printing machine; and baking, to be specific, baking at 180-200 DEG C for 1-3 min to cause color development. The ageing and washing steps of the conventional printing techniques are omitted herein; the technique of the invention has the advantages of low water consumption, low energy consumption and low emission; the finished product printed via the technique is equivalent to products printed via the conventional printingtechniques in terms of color fastness and color uniformity.

Owner:CHANGSHU FUYI PRINTING & DYEING

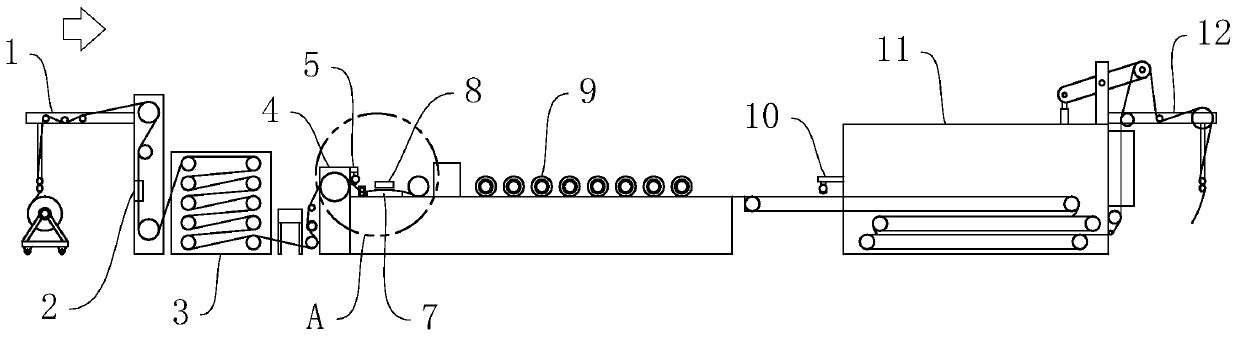

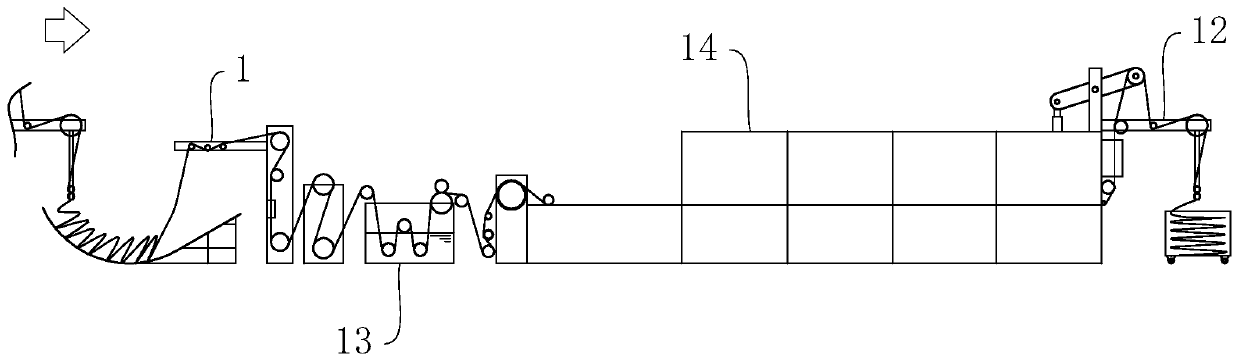

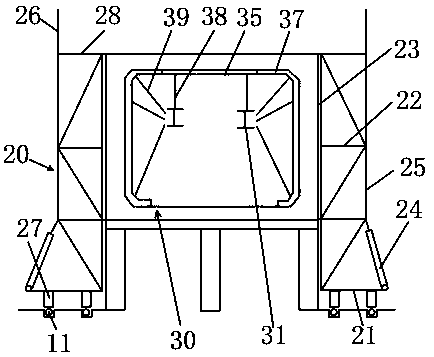

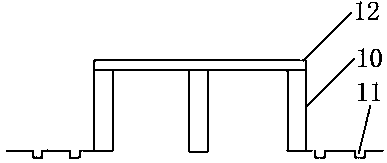

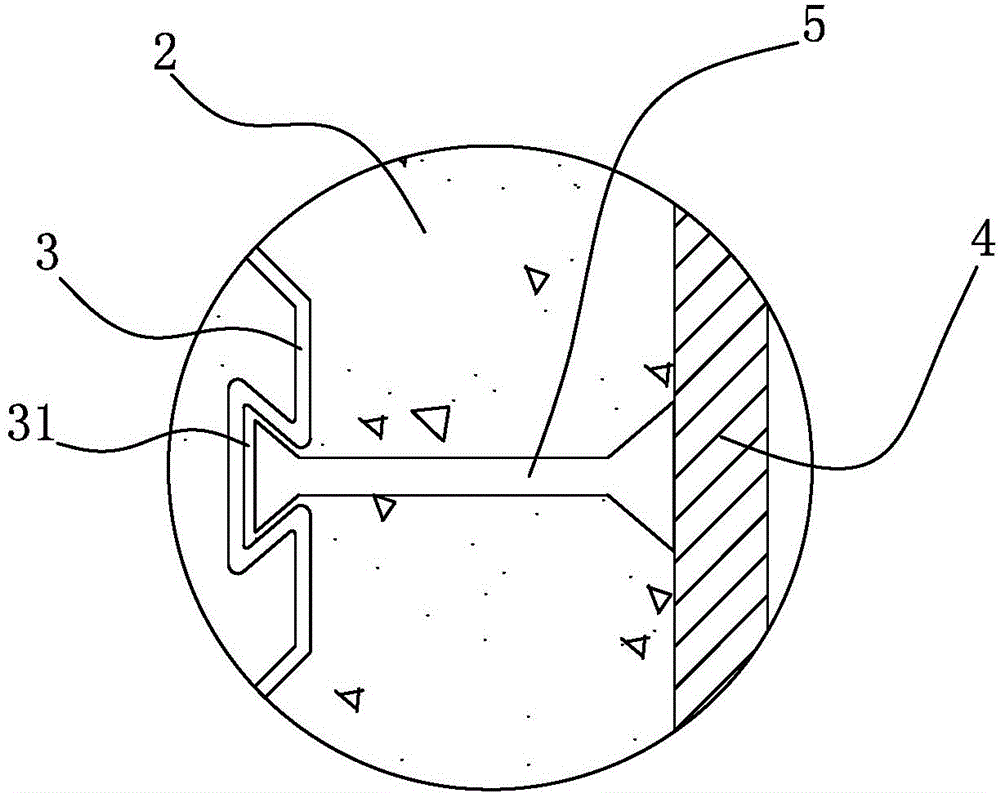

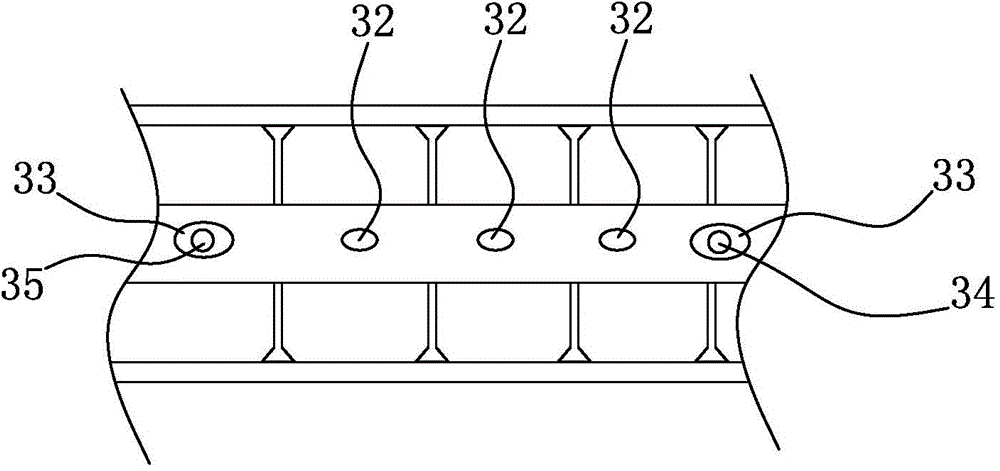

Formwork system of prefabricated comprehensive pipe gallery and construction method thereof

PendingCN110682416AShort exposure timeProcess loss is smallArtificial islandsMouldsArchitectural engineeringStructural engineering

The invention relates to a formwork system of a prefabricated comprehensive pipe gallery and a construction method thereof. The formwork system comprises a prefabricated pedestal, walking rails are arranged on two sides of the prefabricated pedestal in the longitudinal direction correspondingly, the walking rails are provided with outer mold hydraulic systems which are matched with the walking rails and are used for forming a comprehensive pipe gallery outer mold, a bottom plate is arranged on the upper side of the prefabricated pedestal, the bottom plate is provided with an inner mold hydraulic system capable of moving in the longitudinal direction and is used for forming a comprehensive pipe gallery inner mold, and the bottom plate is further provided with an end formwork of the comprehensive pipe gallery. The formwork system of the prefabricated comprehensive pipe gallery is beneficial to improving the engineering construction quality and improving the working efficiency.

Owner:HUNAN NO 6 ENG CO LTD

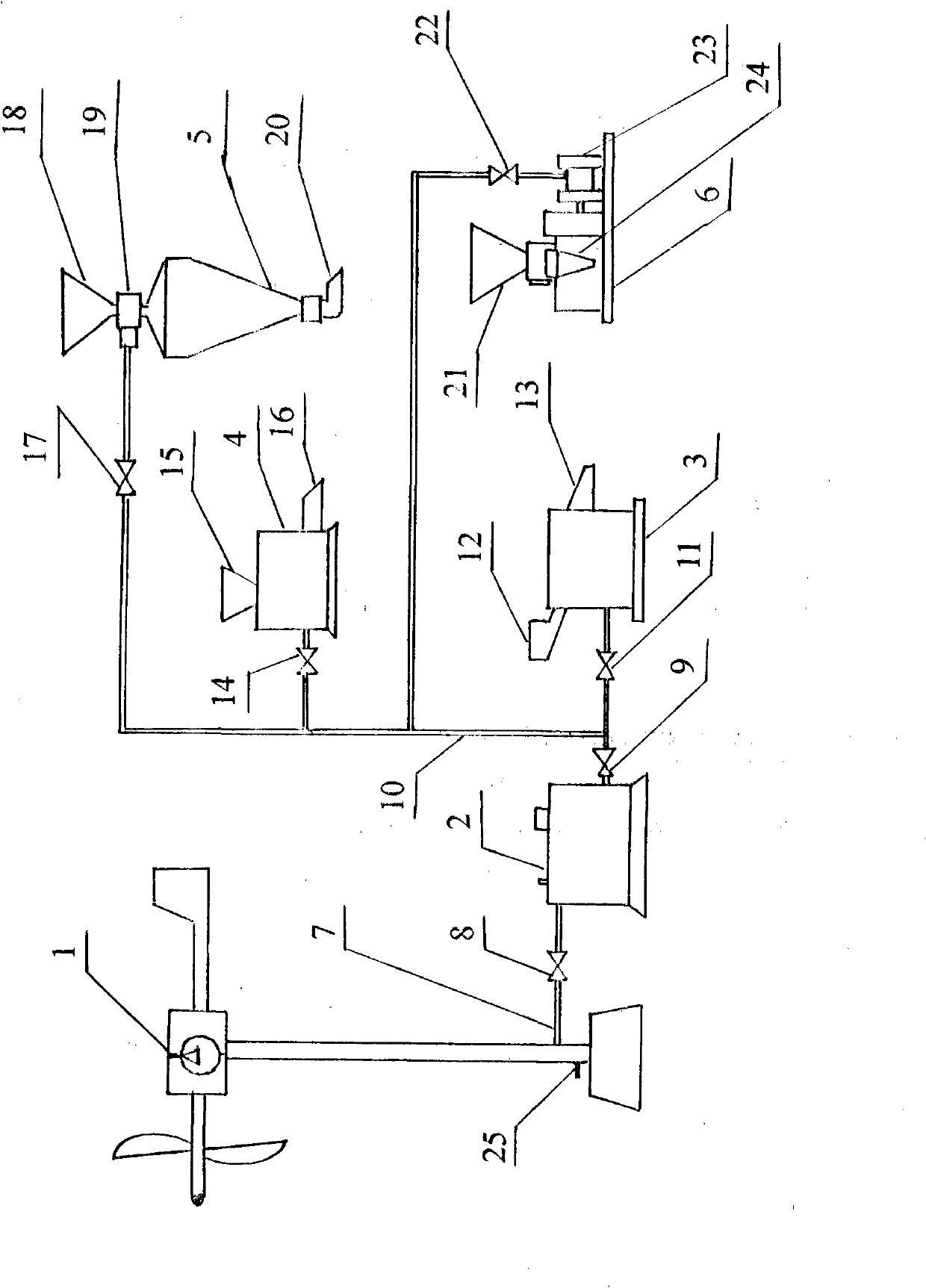

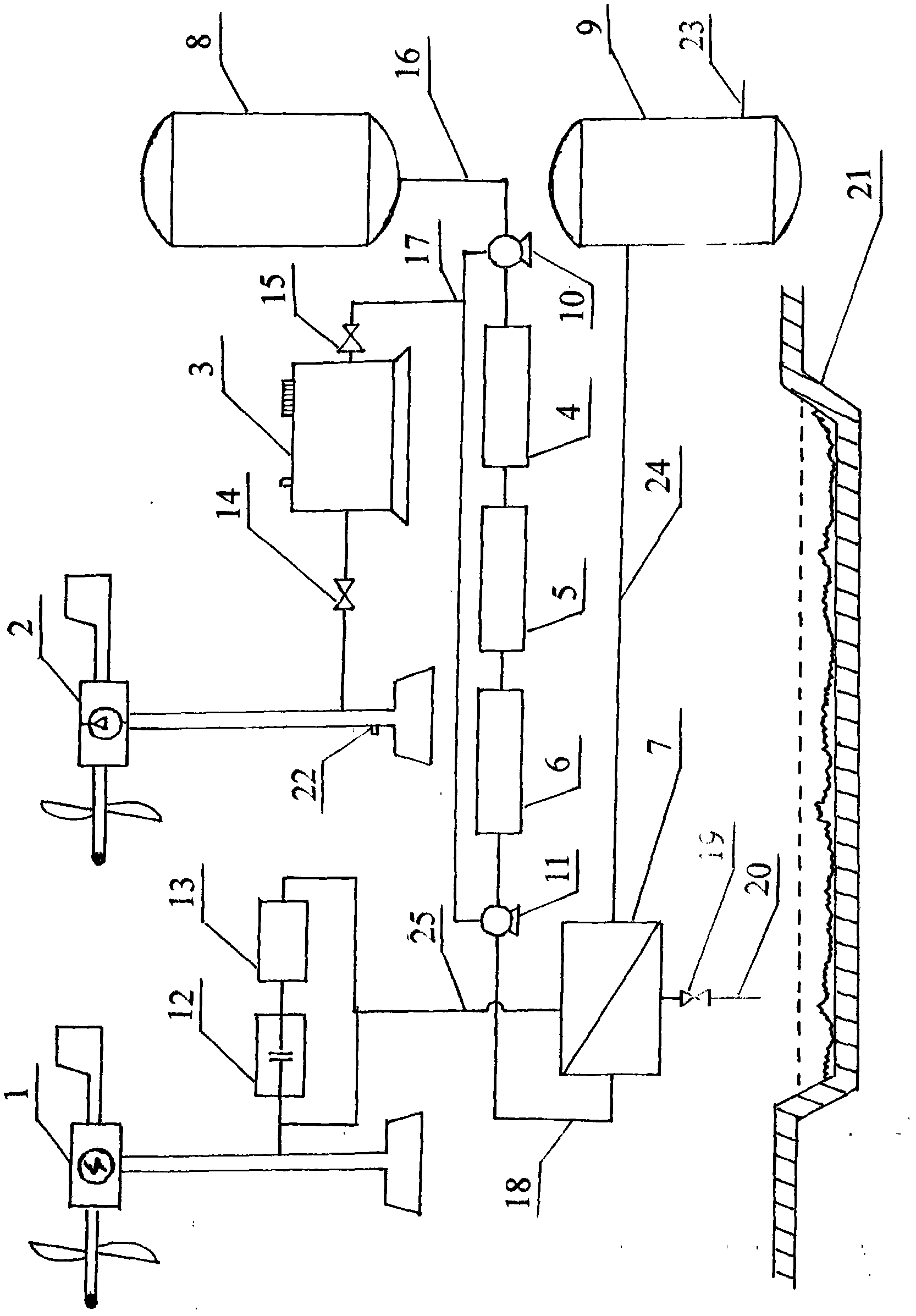

Method for desalinizing seawater and producing sea salt by using full natural energy

InactiveCN102381792AAvoid the inconvenience of installing a wired power supplySave resourcesGeneral water supply conservationSeawater treatmentWind drivenHigh concentration

The invention discloses a method for desalinizing seawater and producing sea salt by using full natural energy. In the method, electric energy is provided by a wind-driven generator, a storage battery pack and an inverter; seawater is fed into a seawater tank by using an air source of a wind air compressor as power of a pneumatic pump; the seawater is injected into a multi-medium filter, an active absorption tower and a precise filter by the pneumatic pump; then the sweater is injected into a reverse osmosis sweater desalinizing host machine by a pneumatic high-pressure pump; the desalinized seawater is introduced into a fresh water tank for storing; and high-salinity concentrated seawater is introduced into a salt field crystallizing pond through a discharge pipe and is further sub-cured to produce the sea salt, and thereby wind energy power generation, seawater desalinization and high-concentration seawater salt sun-curing integrated operation is formed. According to the method disclosed by the invention, wind power is adopted for generating power and the wind air source is used as a power source, so that electric energy can be greatly saved, the expense generated by mounting cables is avoided and a large amount of resources are saved; meanwhile, a production period of the sea salt is shortened and the production efficiency of the sea salt is improved; and the method has remarkable advantages and market competitiveness in the structure, functions, cost, the reliability and other aspects.

Owner:刘方旭

Energy-saving efficiency increasing primer-topcoat anti-corrosion coating and preparation method thereof

InactiveCN107652834AImprove anti-corrosion performanceSimple construction processAnti-corrosive paintsEpoxy resin coatingsSolventChemistry

The invention discloses an energy-saving efficiency increasing primer-topcoat anti-corrosion coating and a preparation method thereof. The anti-corrosion coating comprises epoxy resin, waterborne polyurethane resin, glass flakes, environment friendly pigments and fillers, silane coupling agents, thixotropic agents, activated diluents, curing agents, auxiliaries and solvents. The preparation methodincludes the steps: (1) glass flake pretreatment; (2) raw material mixing. By a reasonable formula design and the preparation method, the prepared anti-corrosion coating has excellent anti-corrosioneffects and long anti-corrosion effects, the anti-corrosion performance of the coating is effectively enhanced, the primer-topcoat coating can be directly sprayed and cured at low temperature, has rust removal functions and has the advantages of energy conservation, emission reduction, safety and environmental protection, the construction process is effectively simplified, industrial three industrial wastes are decreased, and the market prospect is wide.

Owner:CHANGSHU FANGTA COATING CHEM

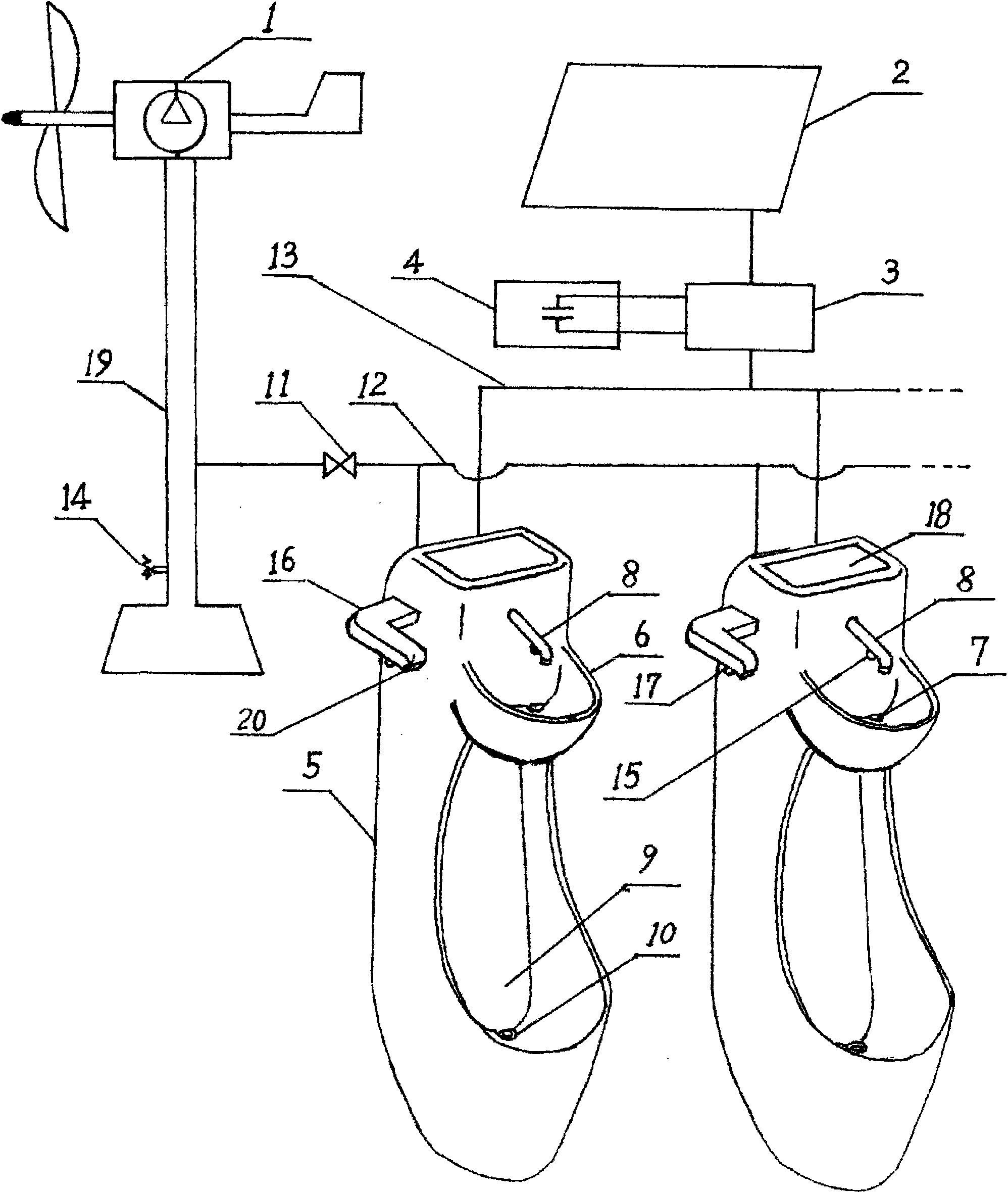

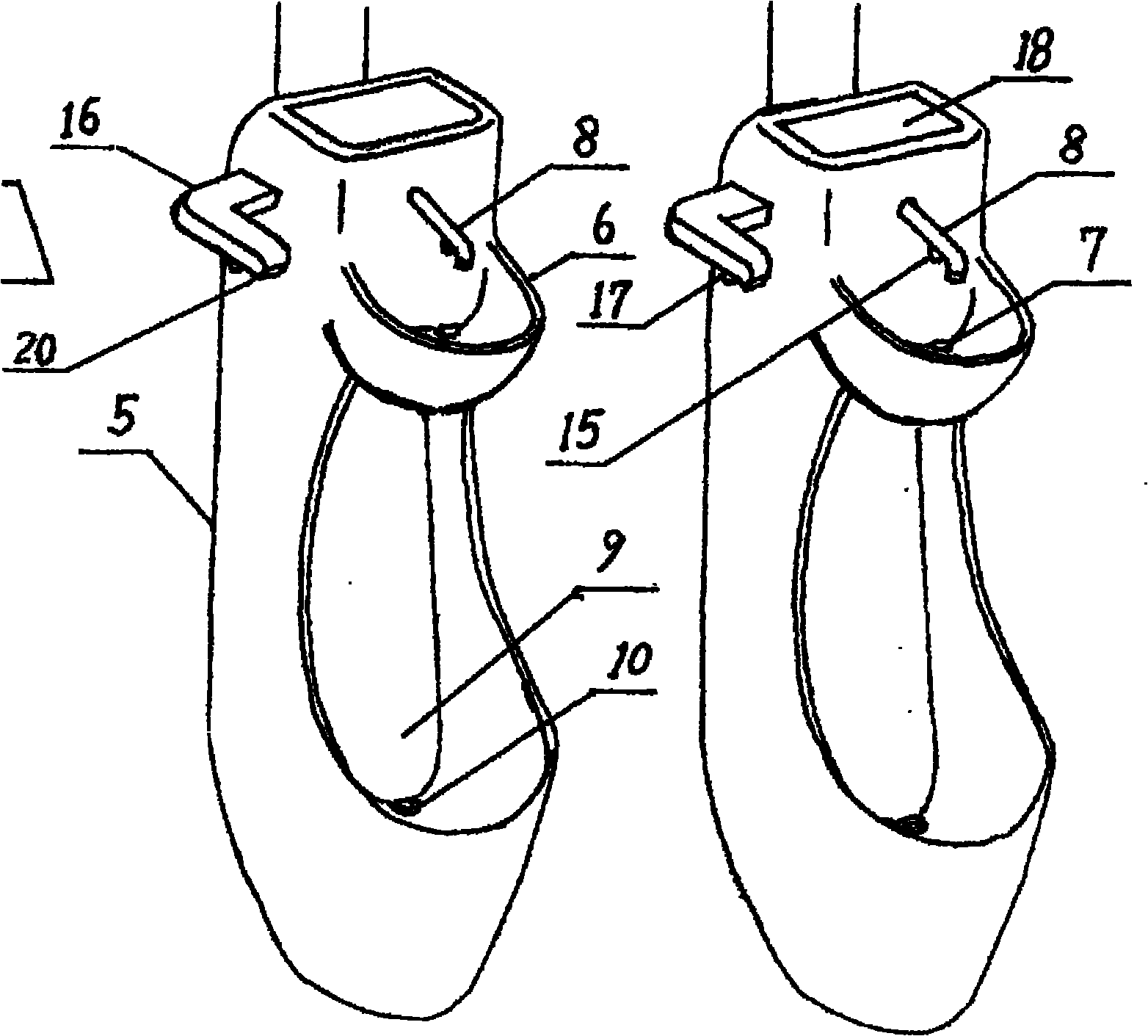

Control system of full natural energy water-saving vertical urinal

InactiveCN102146701ASave conventional electricityHigh air qualityUrinalsBatteries circuit arrangementsWashing handsWind force

The invention relates to a control system of a full natural energy water-saving vertical urinal. The control system is characterized in that: a solar photovoltaic power generation column group provides electrical energy, a wind power air compressor generates wind energy, the function of a hand basin is increased on the basis of an inductive water nozzle of the vertical urinal, the water for washing hands can be directly used for flushing the urinal, meanwhile, a wind hand drier is increased, and the water on the hands is dried by using the natural wind generated by the wind power air compressor and by heating of a spiral heating wire supplied with power by solar energy. Power is supplied by using solar energy, air is supplied by using the wind power air compressor, and an infrared induction switch controls an electromagnetic valve, so that the water for washing the hands in a hand sink after defecating can be saved, and the control system has significance of saving 50 percent of toilet water on the aspects of saving water and reducing consumption.

Owner:刘方旭

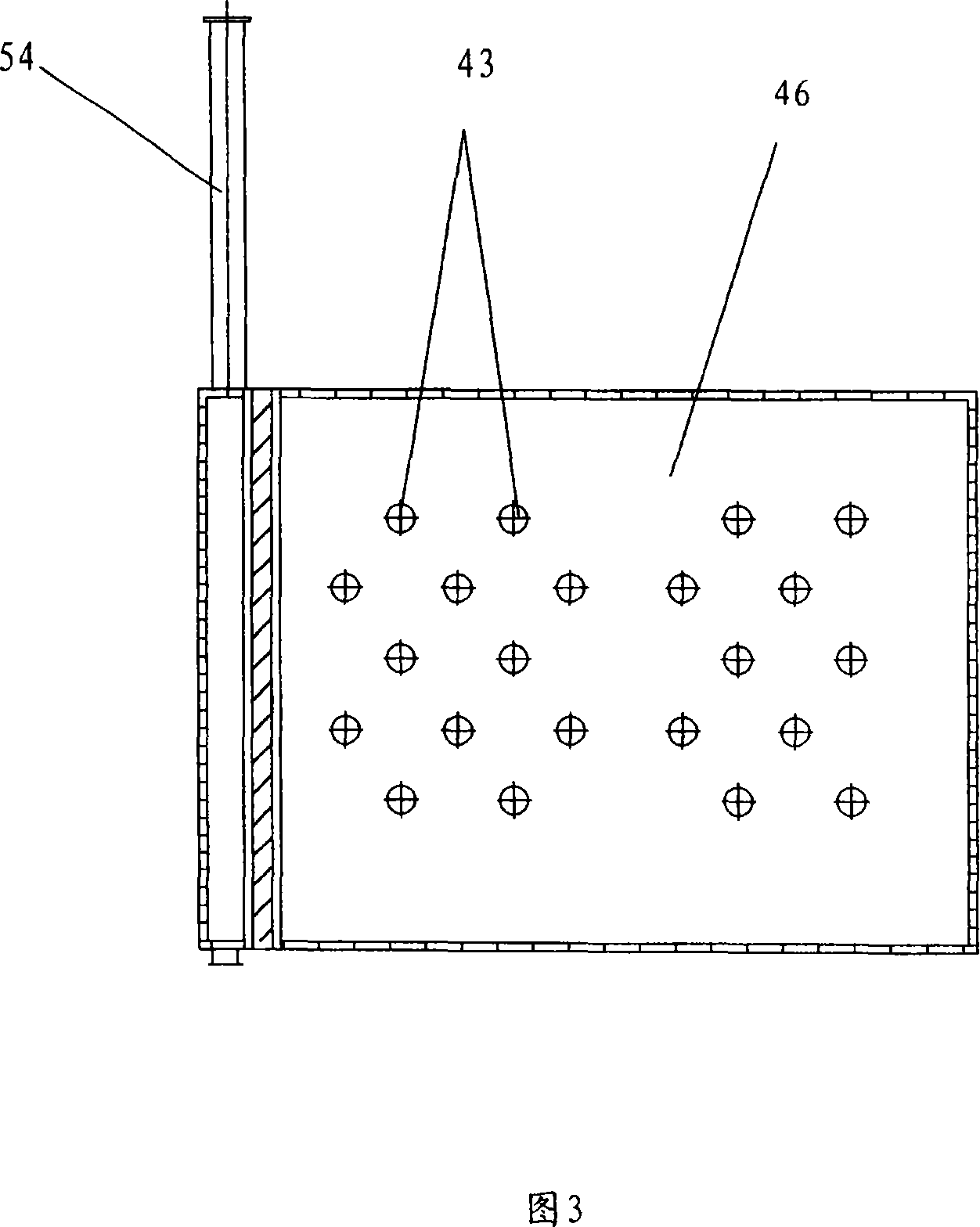

Full-natural automatic-control granary ventilation and drying device

InactiveCN102379195AImprove air qualityNo pollution in the processAgriculture tools and machinesClimate change adaptationMicrocontrollerAutomatic control

The invention relates to a full-natural automatic-control granary ventilation and drying device, which is characterized in that electric energy is provided by a wind-driven power generator, a storage battery pack and an inverter, a wind-driven air compressor generates compressed air and the compressed air is further boosted through a GBM gas booster and is used as high-pressure air for granary ventilation; an auxiliary heat source is arranged in a ventilation pipeline to increase the temperature of the high-pressure air in the ventilation pipeline; a single-chip microcomputer instructs a pneumatic valve to open or close the ventilation pipeline according to the upper limit value and the lower limit value of data transmitted by a plurality of temperature-sensitive and humidity-sensitive probes arranged in a granary; and fine holes on air outlet columns which are connected with each other and are arranged in the granary evenly exhaust the high-pressure air to achieve the goal of ventilating and drying grains in the granary. The full-natural automatic-control granary ventilation and drying device has the advantages that the stored rice can be dewatered gently and evenly, no dead zone exists, the operation is intelligently conducted, the labor is saved, the conventional energy is saved, the drying and the storage are environmental-friendly and pollution-free and the requirements on environmental protection are satisfied.

Owner:刘方旭

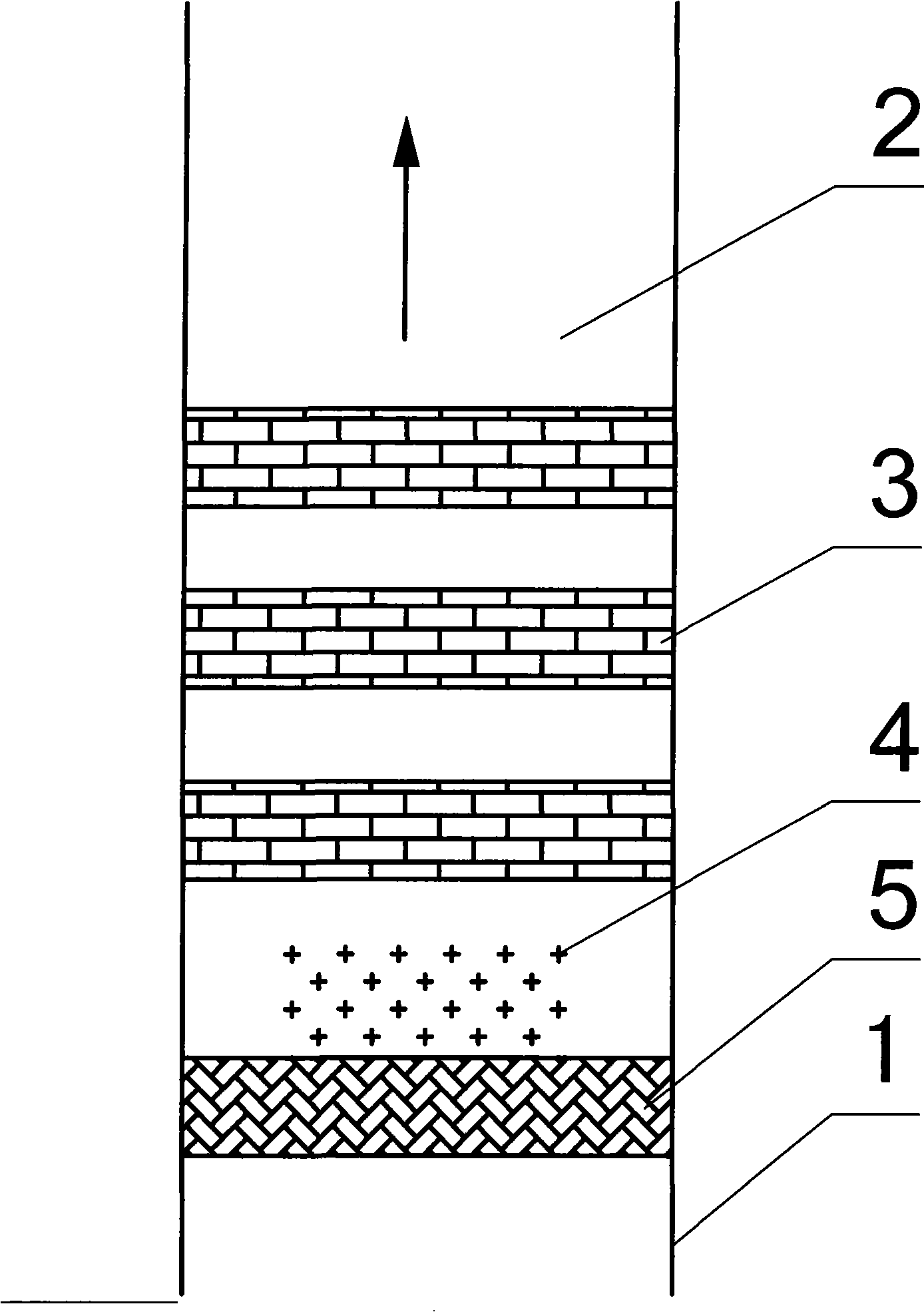

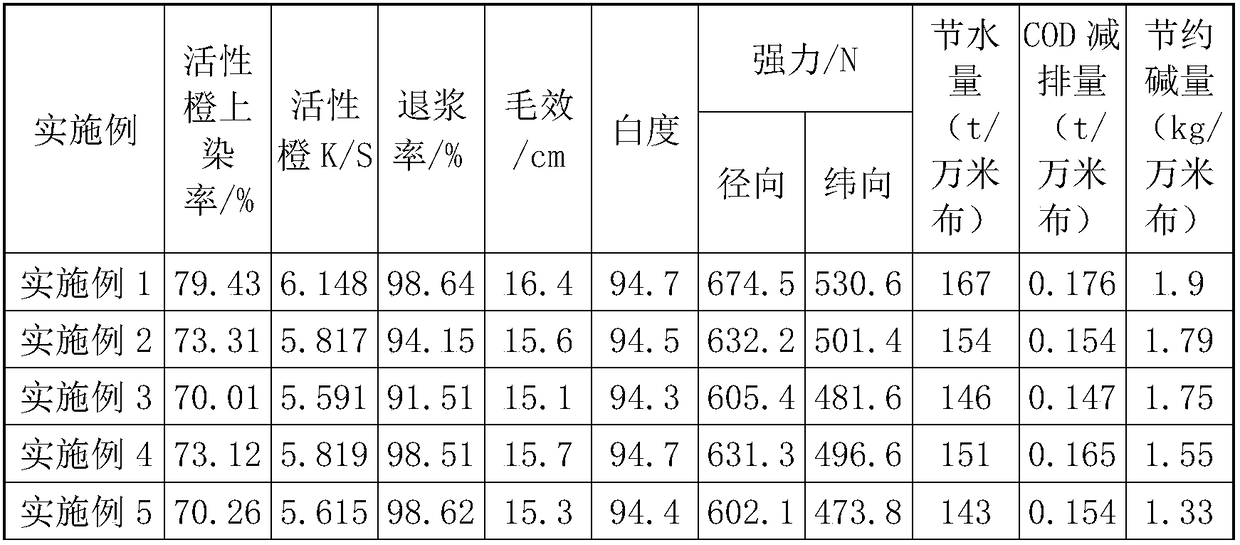

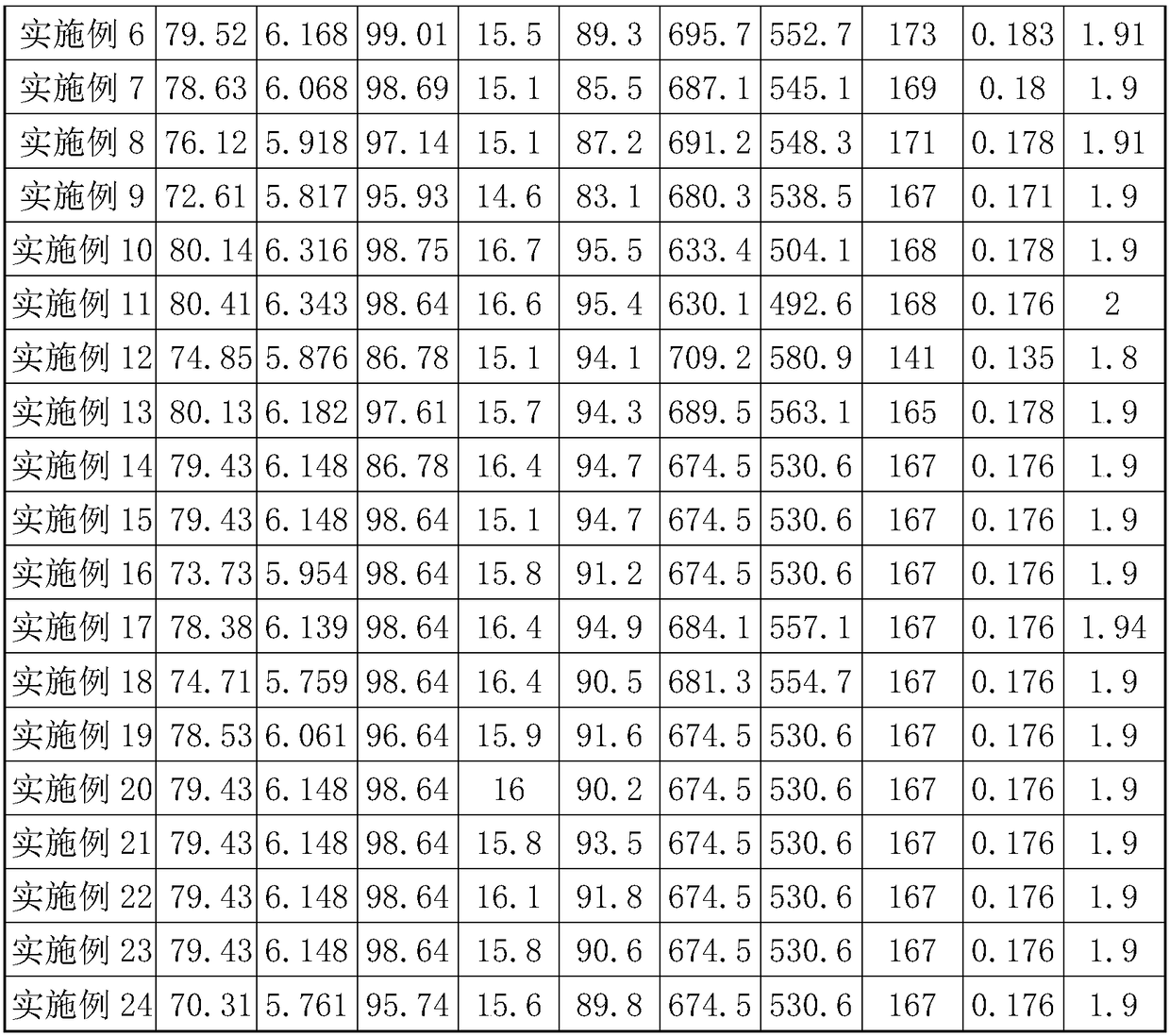

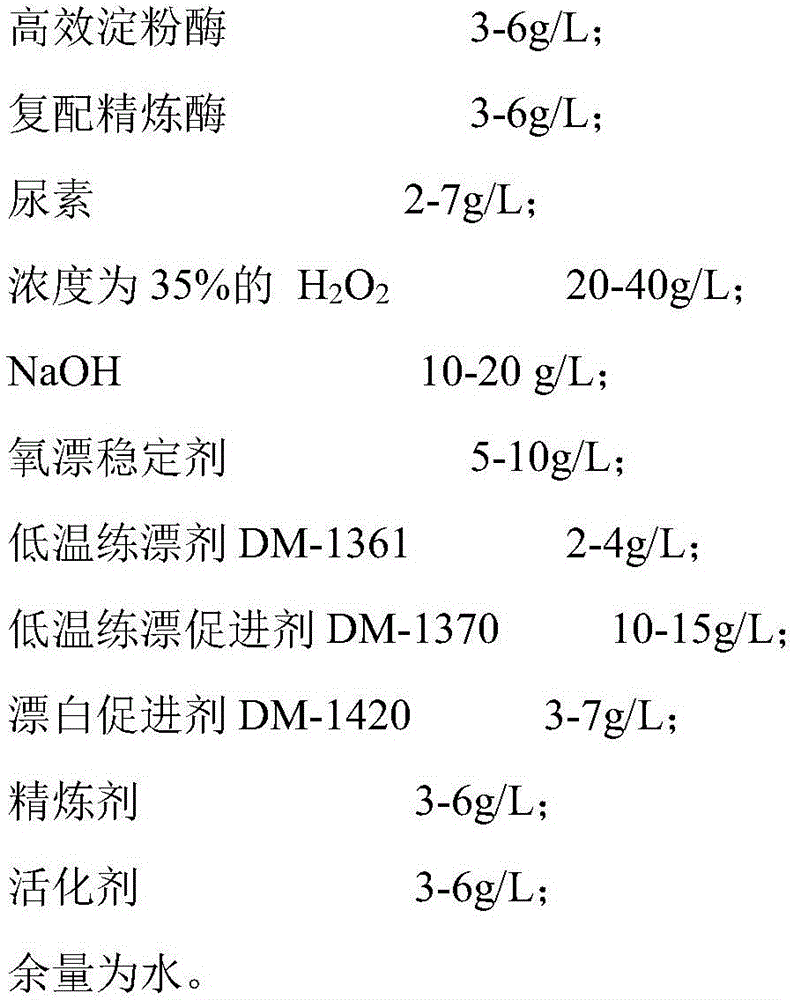

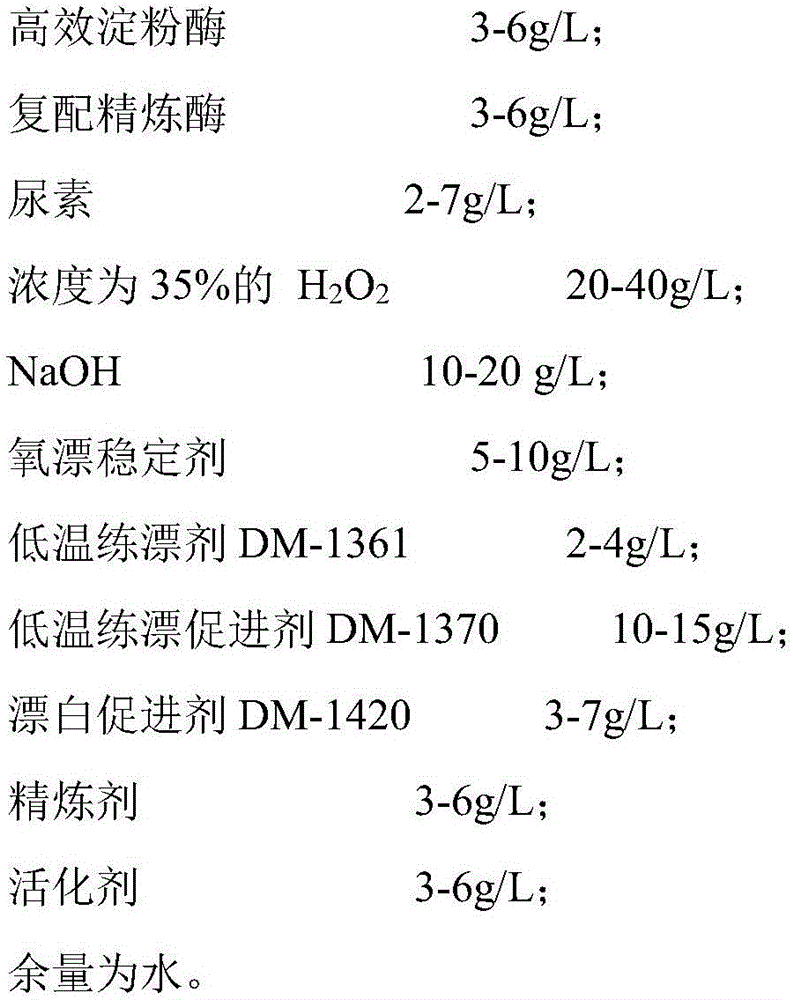

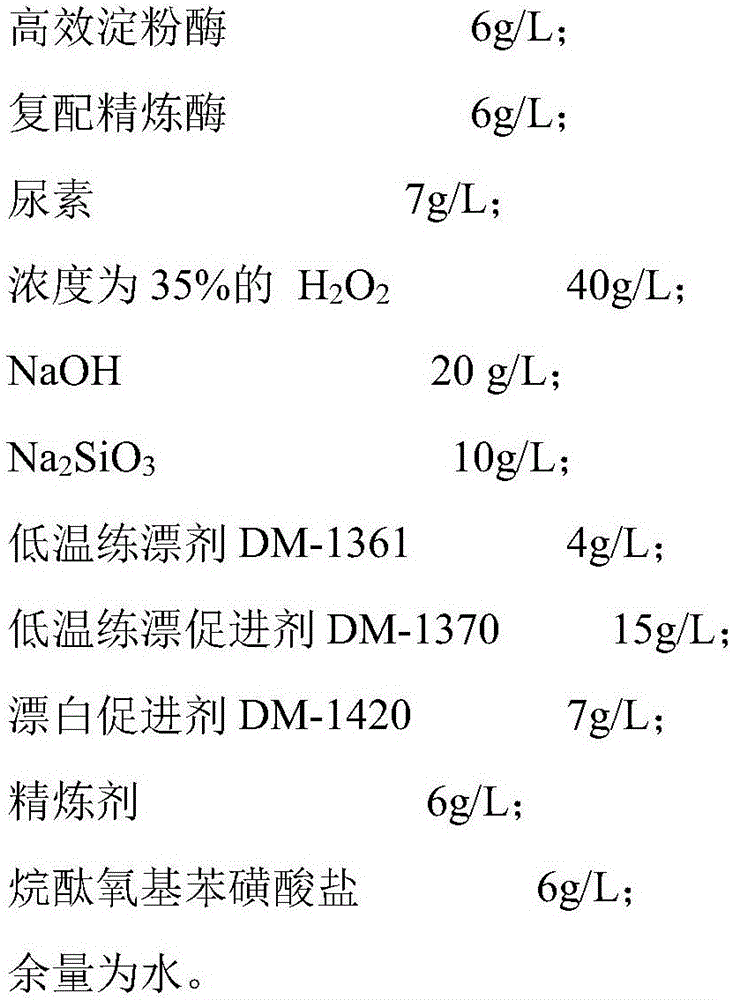

The pre-treatment process of cotton woven fabrics and the formula of desizing working solution

ActiveCN106367941BWater-savingWith emission reductionPhysical treatmentBiochemical fibre treatmentHigh concentrationEngineering

The invention discloses a dyeing and printing pretreatment process for a cotton woven fabric and a desizing working solution formula. The dyeing and printing pretreatment process for the cotton woven fabric comprises the following three processes: singeing, desizing and alkali peeling, wherein the desizing step comprises the following sub-steps: performing 2-6-level rinsing by working solution of which the concentration is decreased progressively sequentially, and sequentially rinsing the singed grey cloth by high-concentration working solution and low-concentration working solution sequentially; the alkali peeling comprises multi-level alkaline liquor in which NaOH concentration is decreased progressively sequentially, and the grey cloth in the step S2 is sequentially subjected to alkali peeling; trough inverting is performed when the processes of desizing and alkali peeling reach the upper limit; the trough inverting step comprises the sub-steps: discharging the working solution or alkaline liquor with the highest concentration for recycling, and pouring the low-concentration working solution or alkaline liquor into working solution or alkaline liquor with higher level concentration. Clean water is supplemented into the original potcher with the lowest concentration, and the concentration of the working solution in each potcher is blended. The process has the advantages of water conservation and emission reduction.

Owner:HANGZHOU DADI PRINTING & DYEING CO LTD

High solid content anticorrosive paint used on steel structure surfaces, and spraying method thereof

InactiveCN107674473ALow solvent contentLow volatilityPretreated surfacesAnti-corrosive paintsSolventCorrosion inhibitor

The invention discloses a high solid content anticorrosive paint used on steel structure surfaces, and a spraying method thereof. The high solid content anticorrosive paint used on steel structure surfaces comprises epoxy resin, a pigment filler, aluminum-zinc alloy powder, a silane coupling agent, an active diluent, a corrosion inhibitor, an auxiliary agent, a curing agent, and acrylic acid. Thespraying method comprises following steps: 1, steel structure surface treatment; 2, primary spraying; 3, low temperature roasting; 4, secondary spraying; 5, low temperature roasting; and 6, drying curing molding. The formula design of the high solid content anticorrosive paint is scientific and reasonable; no toxic or harmful ingredient is used; solvent content is low; volatility is low; the highsolid content anticorrosive paint is safe, and is friendly to the environment; no pollutant such as waste water or smoke is generated in spraying process, three wastes discharge is reduced; layered low temperature roasting pre-curing is adopted, so that curing temperature is reduced effectively, and energy consumption is reduced effectively. The high solid content anticorrosive paint and the spraying method are safe, are friendly to the environment, are capable of saving energy and reducing discharge, and are promising in market prospect.

Owner:CHANGSHU FANGTA COATING CHEM

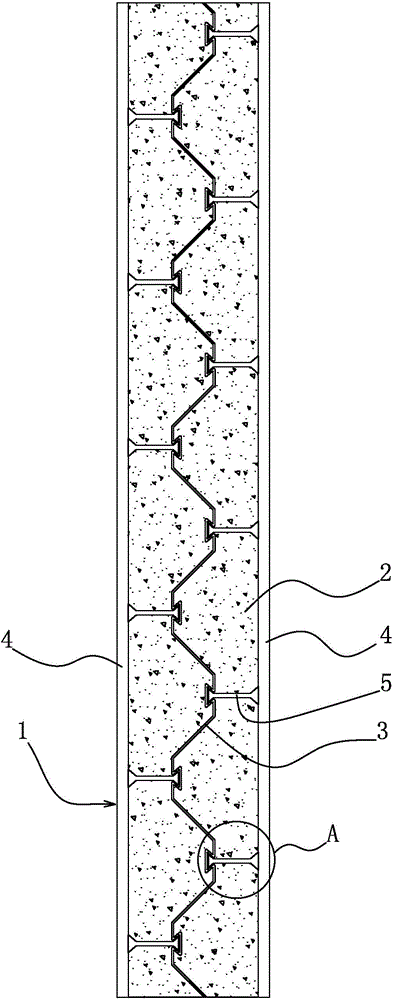

Corrugated loading high-strength wallboard

ActiveCN105822010AReduce weightRealize large-scale productionBuilding componentsMetal layered productsKeelMetallic materials

The invention relates to a corrugated loading high-strength wallboard. The corrugated loading high-strength wallboard comprises a high-strength keel produced by a metal material and a loading material, and is characterized in that the keel comprises a corrugated plate, panels positioned at two sides of the corrugated plate, a thickness adjusting connecting piece for connecting the corrugated plate and the panel, and the loading material is placed in a cavity formed by the corrugated plate, the panels and the connecting piece. The wallboard has the advantages of light weight, flexible installation, fire resistance and insulation, and low cost.

Owner:黄通

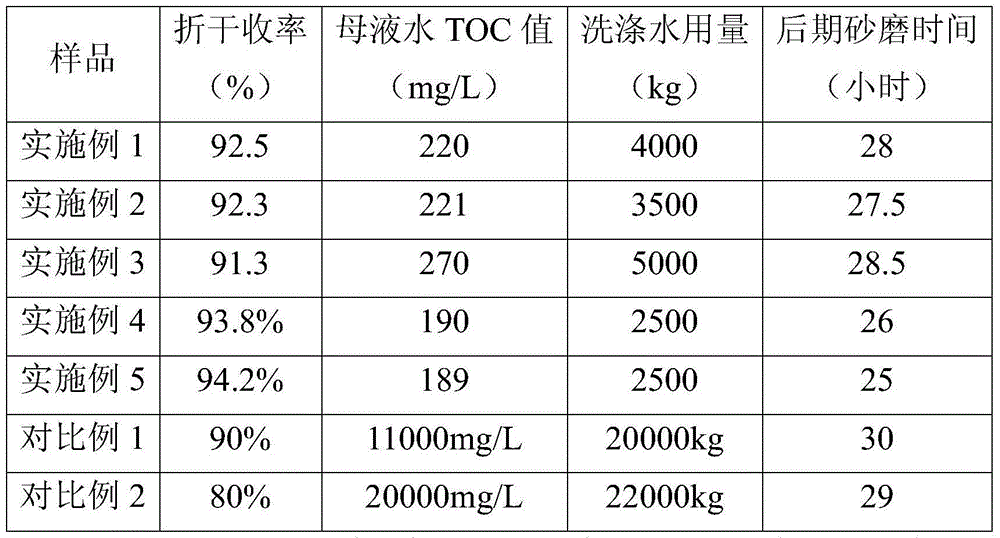

Preparation method of energy-efficient and environmentally-friendly disperse dye

ActiveCN105440737AReduce the amount of dissolutionPromote resource utilizationMonoazo dyesDisperse dyeSodium sulfate

The invention discloses a preparation method of an energy-efficient and environmentally-friendly disperse dye. The method comprises the following steps: carrying out a coupling reaction on a diazo salt and a coupling component to obtain a corresponding azo compound, adding an alkali to to adjust the pH value of the obtained system to 2-7.5, carrying out heating crystal transformation to obtain a stable crystal form, press-filtering obtained crystals, and washing the press-filtered crystals with water to obtain a dye filter cake. The method mainly has the following advantages: 1, the pH value of the system is improved, so obtaining of the stable crystal form through dye crystal transformation is facilitated, and electricity and time are saved in the sand milling process; 2, parts of the disperse dye dissolved in a mother liquor can be recovered, so the content of organic matters in the mother liquor is greatly reduced, and the wastewater treatment difficulty is reduced; 3, the filter cake mother liquor is rich in ammonium sulfate (or sodium sulfate), and can be used to prepare ammonium sulfate (or sodium sulfate), so wastewater recycling is realized; and 4, the amount of water for washing is greatly reduced, so the wastewater discharge is greatly reduced.

Owner:ZHEJIANG DIBANG CHEM

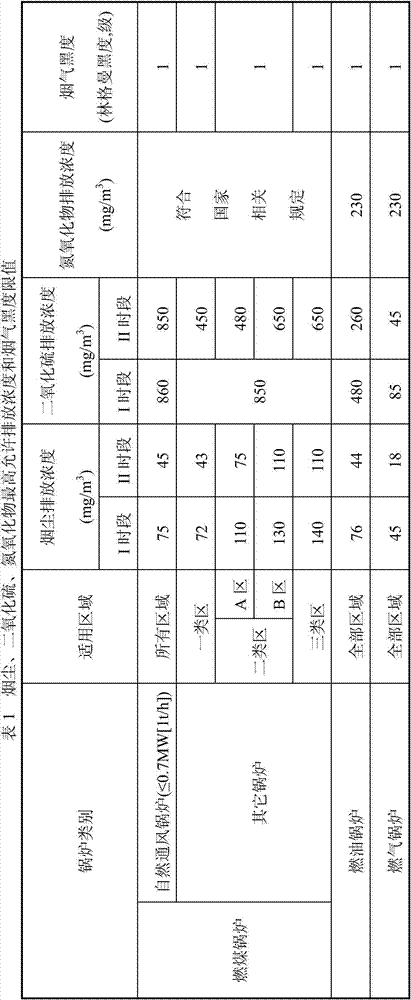

Combustion improver for boiler as well as preparation method and application of combustion improver

The invention provides a combustion improver for a boiler. The combustion improver is prepared from the following ingredients in parts by weight: 4 parts of manganese dioxide, 4 parts of molybdenum oxide, 4 parts of ferric oxide, 4 parts of zinc oxide, 4 parts of copper oxide, 4 parts of calcium oxide, 4 parts of magnesium oxide, 4 parts of potassium oxide, 4 parts of sodium oxide, 4 parts of aluminum oxide, 16 parts of selenium dioxide, 16 parts of strontium oxide, 16 parts of oxygen difluoride, 16 parts of No.97 gasoline, 16 parts of No.20 diesel, 16 parts of ethyl alcohol, 16 parts of kerosene, 10 parts of paraffin, 10 parts of normal octane, 10 parts of nonane, 10 parts of decane, 10 parts of undecane, 10 parts of dodecane, 10 parts of eicosane, 10 parts of triacontane and 10 parts of tetracontane. The combustion improver provided by the invention has the advantages that the pollution can be reduced, the combustion efficiency is improved, and the service life of the boiler is prolonged. The invention also provides a preparation method and application of the combustion improver.

Owner:上海悦和科技有限公司

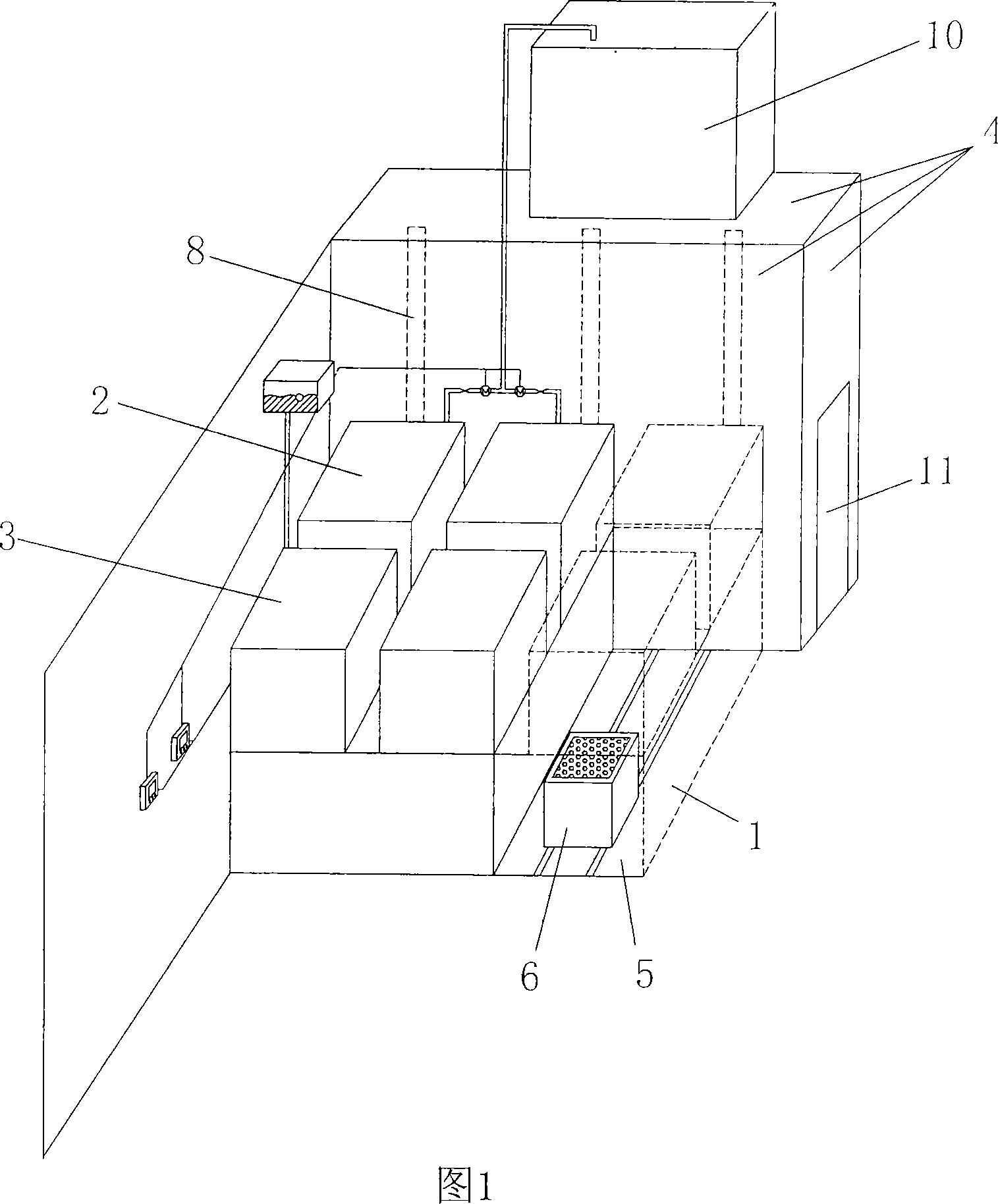

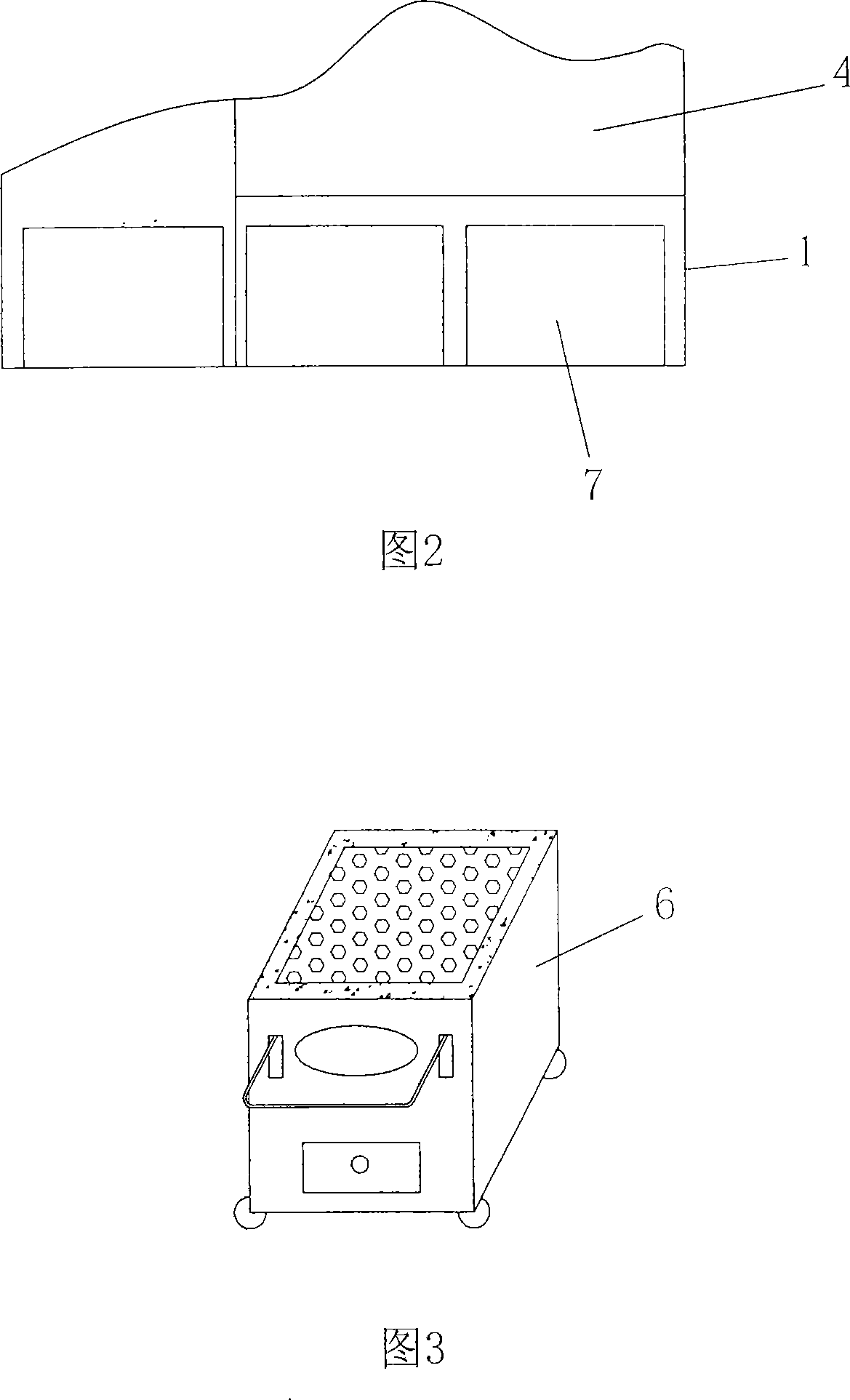

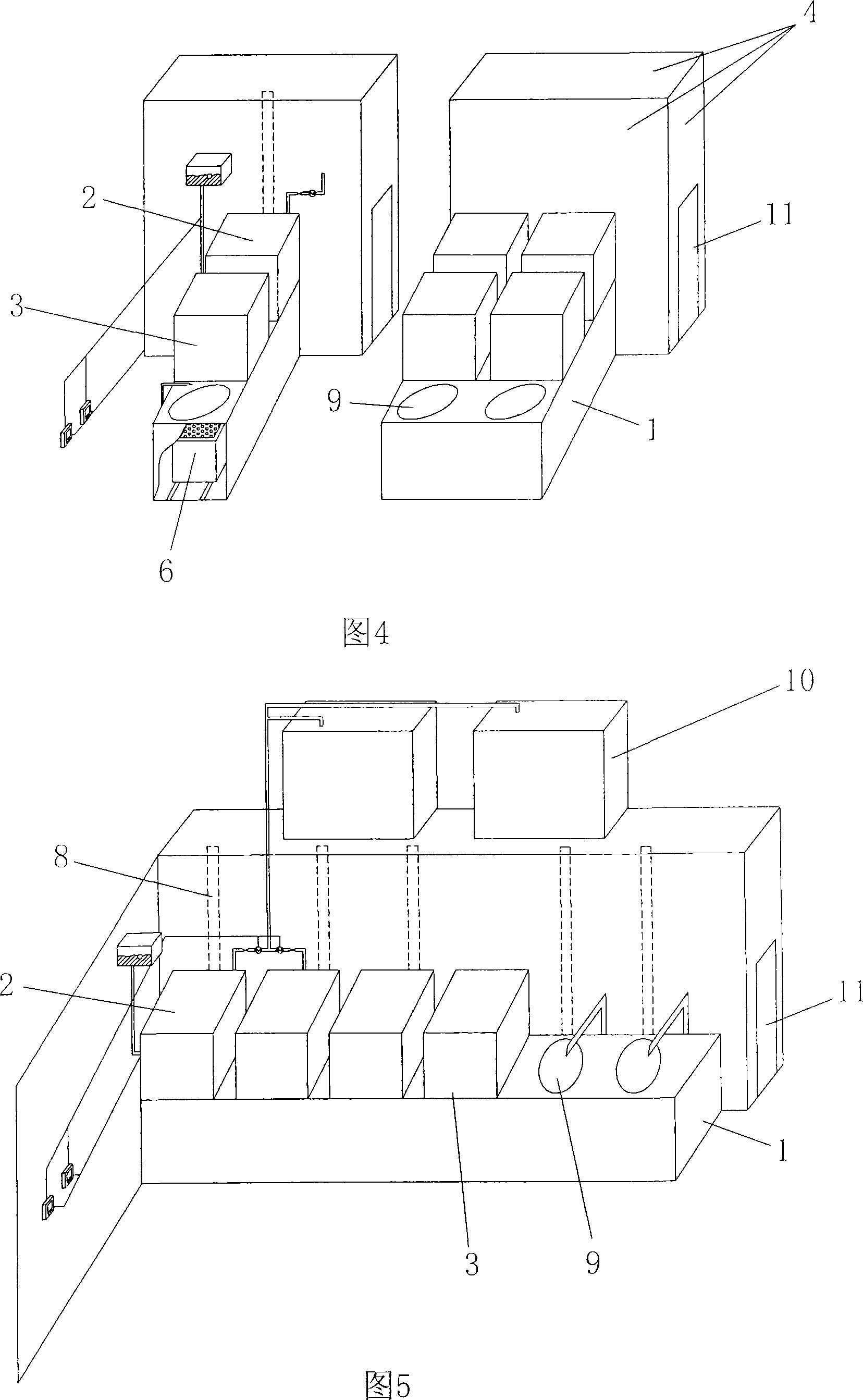

Large energy-saving, discharge reducing and anti-pollution stove

InactiveCN101089480AReduce exposureImprove hygiene qualityDomestic stoves or rangesLighting and heating apparatusOperation roomPollution

The present invention relates to a multifunctional stove and cooking utensils integrated large energy-saving discharge-reducing and contamination-isolating machine unit. It includes the following several portions: stove body, several cooking utensils, contamination-isolating wall or contamination-isolating plate, stove operation room and looking operation room. Said invention can be substituted for domestic boiler and cooking range.

Owner:张正军

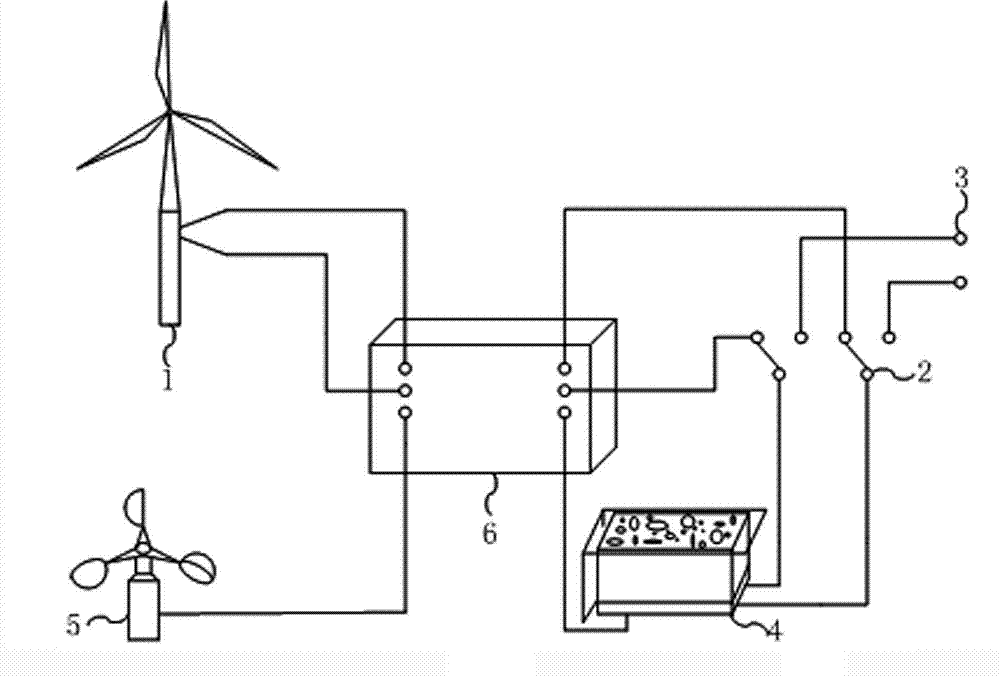

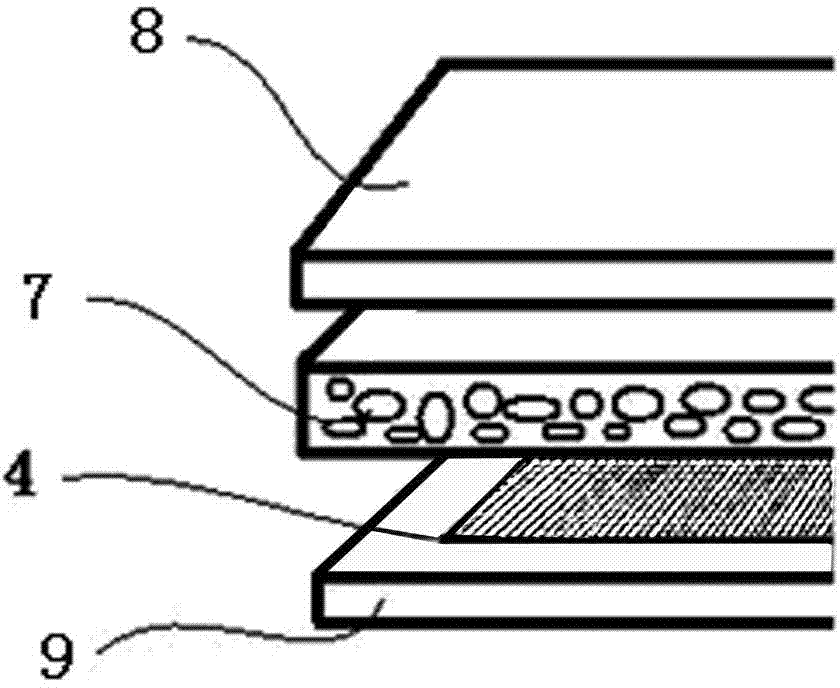

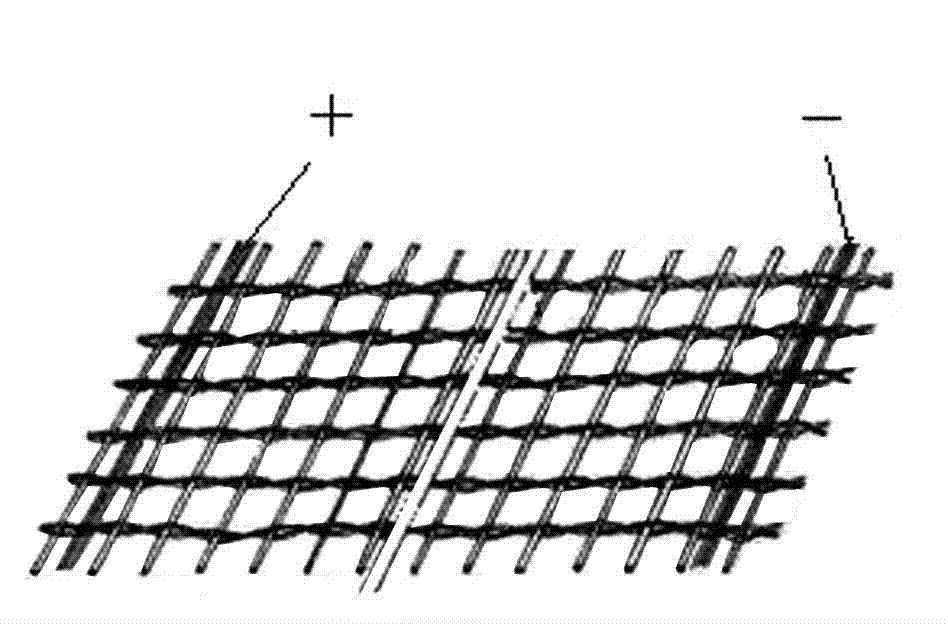

Adaptive-with-wind load power type off-grid wind power heat storage and heating system for rural residences

InactiveCN103925630ASimple structureLow running costWind motor controlLighting and heating apparatusWind drivenHeating system

The invention belongs to the field of heat energy and utilization thereof, and discloses an adaptive-with-wind load power type off-grid wind power heat storage and heating system for rural residences. The adaptive-with-wind load power type off-grid wind power heat storage and heating system for rural residences is structurally characterized in that output ends of a wind driven generator (1) and a wind speed sensor (5) are connected with an input end of a wind-following type load power regulating device (6), an output end of the wind-following type load power regulating device (6) is connected with a heating element (4) of an indoor heat storage and heating conversion device, and a switch controller (2) is connected with a 220V domestic power source (3). The adaptive-with-wind load power type off-grid wind power heat storage and heating system is a distributive wind power heat storage and heating system provided for northern rural residents and is free of pollution, low in cost and wide in application range. Further, the system is capable of making full use of wind power which is a non-pollution renewable resource, and has the remarkable advantages of convenience, energy saving, environment friendliness and emission reduction.

Owner:SHENYANG AGRI UNIV

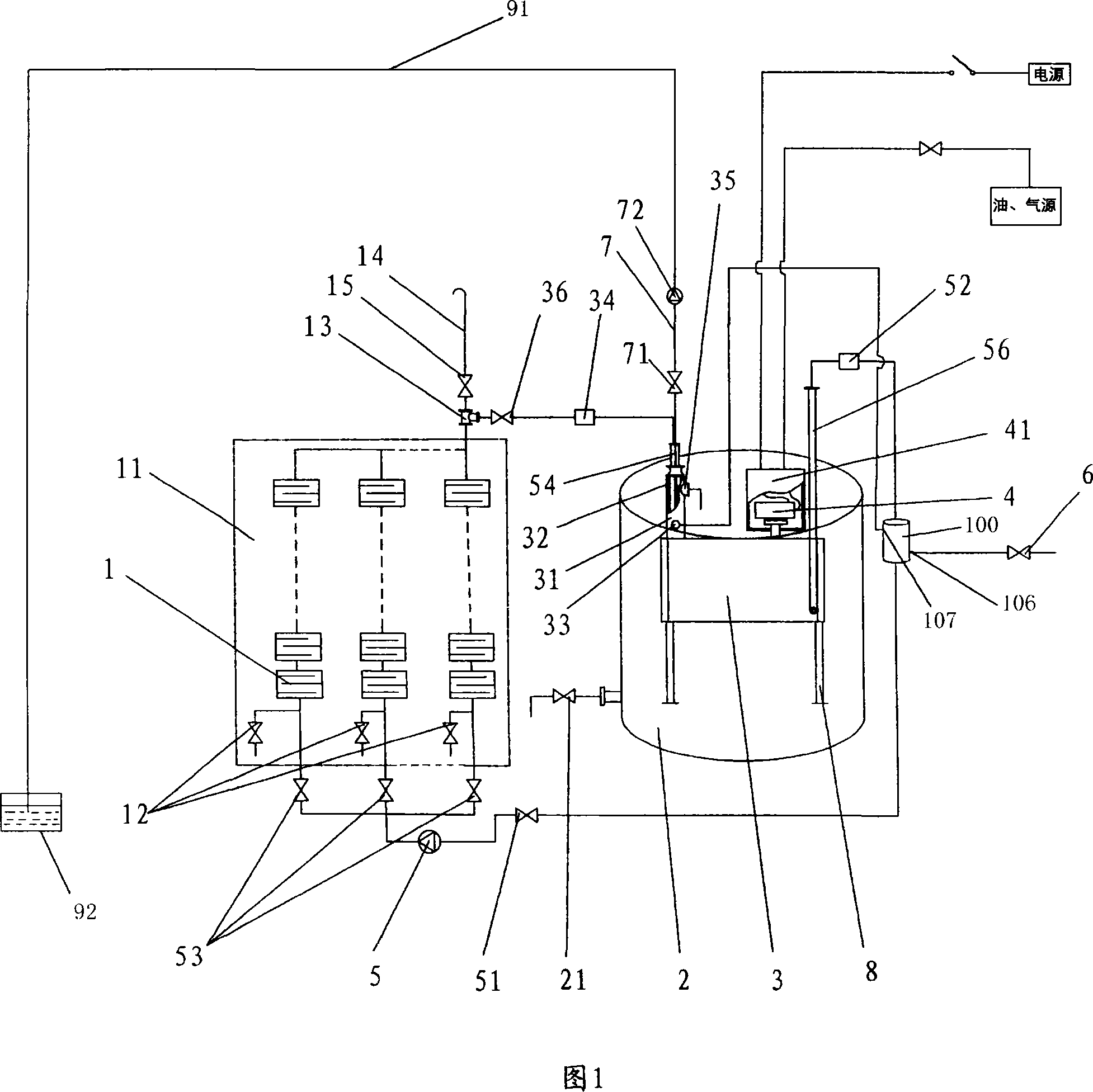

Step-heat-supplying oxygen-enrichment microwave ignition device

InactiveCN108085483AEmission reductionTo achieve the purpose of oxygen-enriched ignitionMicrowaveEngineering

The invention discloses a step-heat-supplying oxygen-enrichment microwave ignition device. The step-heat-supplying oxygen-enrichment microwave ignition device comprises a microwave heating area and anelectrical heating area, wherein the microwave heating area comprises a microwave generator and a ceramic tube capable of converting microwaves into heat energy under microwave radiation, the ceramictube is connected with a draught fan, and auxiliary airflow passes through the draught fan and can form primary oxygen-enrichment hot air through the ceramic tube; the primary oxygen-enrichment hot air is further heated through the electrical heating area, and secondary oxygen-enrichment hot air reaching the temperature required by sintering ignition is generated. According to the step-heat-supplying oxygen-enrichment microwave ignition device, the ignition mode is changed, a heat storage medium is heated in a step-heat-supplying mode through clean load energy such as microwaves or infrared or resistance, then air or hot waste gas is blown in and used for heat exchanging, high-temperature oxygen enrichment hot gas flow is formed, and therefore the oxygen-enrichment ignition aim is achieved; the ignition effect is improved, waste-gas discharging is reduced, the safer and more reliable effects are achieved, and the step-heat-supplying oxygen-enrichment microwave ignition device has theadvantages of being capable of saving energy, reducing emission, improving the quality and increasing the yield.

Owner:湖南景远微波科技有限公司

Dyeing and printing pretreatment process for cotton woven fabric and desizing working solution formula

ActiveCN106367941AAvoid damageAchieve reusePhysical treatmentBiochemical fibre treatmentHigh concentrationEngineering

The invention discloses a dyeing and printing pretreatment process for a cotton woven fabric and a desizing working solution formula. The dyeing and printing pretreatment process for the cotton woven fabric comprises the following three processes: singeing, desizing and alkali peeling, wherein the desizing step comprises the following sub-steps: performing 2-6-level rinsing by working solution of which the concentration is decreased progressively sequentially, and sequentially rinsing the singed grey cloth by high-concentration working solution and low-concentration working solution sequentially; the alkali peeling comprises multi-level alkaline liquor in which NaOH concentration is decreased progressively sequentially, and the grey cloth in the step S2 is sequentially subjected to alkali peeling; trough inverting is performed when the processes of desizing and alkali peeling reach the upper limit; the trough inverting step comprises the sub-steps: discharging the working solution or alkaline liquor with the highest concentration for recycling, and pouring the low-concentration working solution or alkaline liquor into working solution or alkaline liquor with higher level concentration. Clean water is supplemented into the original potcher with the lowest concentration, and the concentration of the working solution in each potcher is blended. The process has the advantages of water conservation and emission reduction.

Owner:HANGZHOU DADI PRINTING & DYEING CO LTD

Automobile chassis part composite coating

InactiveCN110295003AImprove anti-corrosion performanceGood weather resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsDefoaming AgentsPolyurea

The invention discloses an automobile chassis part composite coating and belongs to the technical field of automobile coating. The composite coating consists of two coating layers, wherein the first layer is an electrophoretic coating layer or a powder coating layer or a primer coating layer, and the second layer is a polyurea coating layer. The polyurea coating layer consists of a component A anda component B, wherein the component A comprises, by mass percentage, 28-30% of polyaspartic acid ester resin, 19-20% of environment-friendly zinc phosphate, 24-25% of precipitated barium sulfate, 4-5% of strontium yellow, 2% of a polyurethane dispersant, 0.5% of an organic silicon defoaming agent, 0.5% of a polyurethane leveling agent, 3% of polyethylene wax, 4% of bentonite and 10-15% of a diluent; the component B comprises, by mass percentage, 60-75% of isocyanate and 35-40% of a diluent. Polyurea bottom surface integrated paint is sprayed onto the original primer coating layer, and the automobile chassis part composite coating has the advantages that the coating can be dried quickly at the low temperature, energy is saved, and the production efficiency is improved; the construction solid content is as high as 65% or above, the VOC content is low, and the automobile chassis part composite coating has the advantages of saving energy and reducing emission and accords with the development trend of environmentally friendly and high-quality automobile coating.

Owner:CHINA FIRST AUTOMOBILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com